Patents

Literature

117results about How to "Stop cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

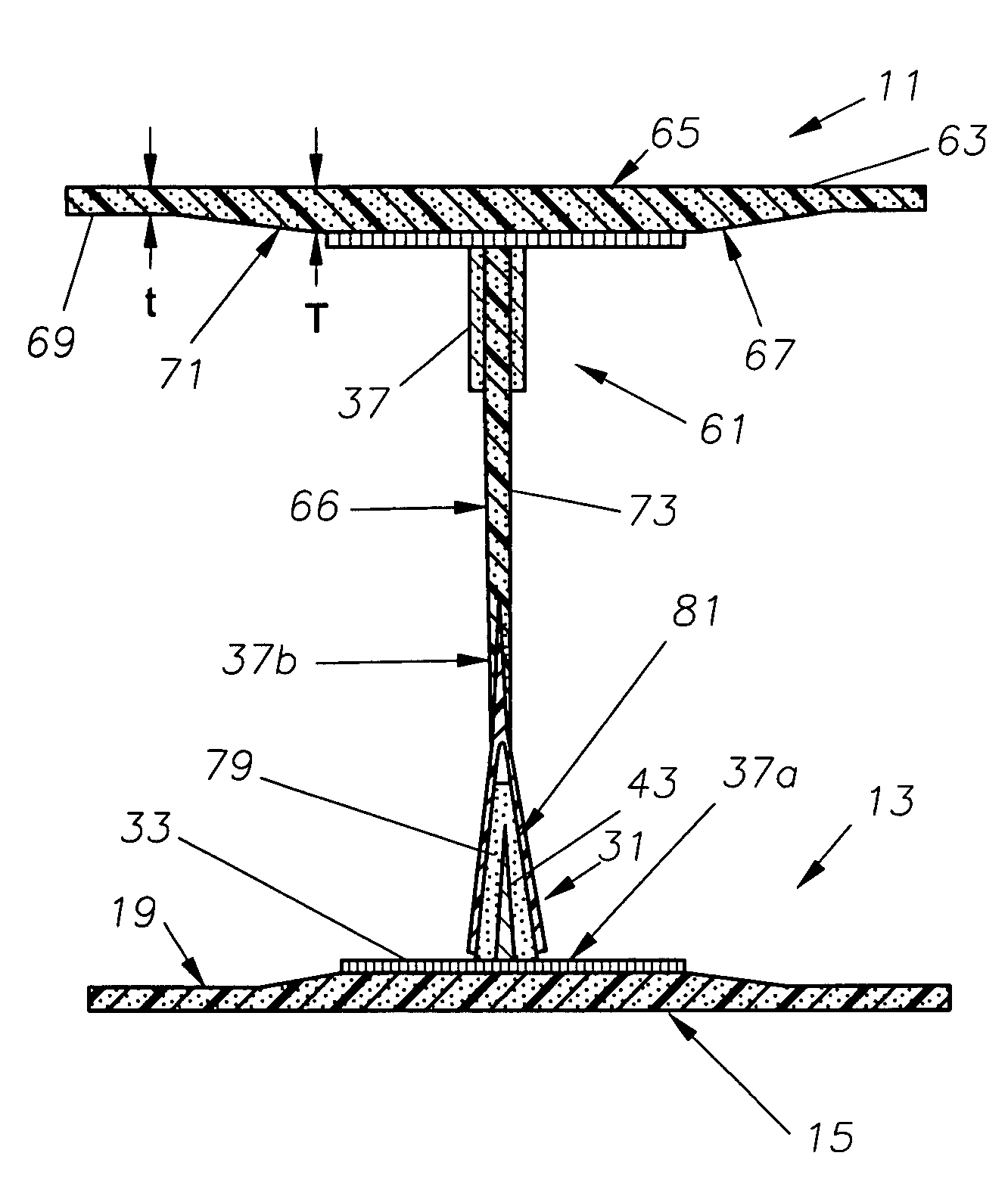

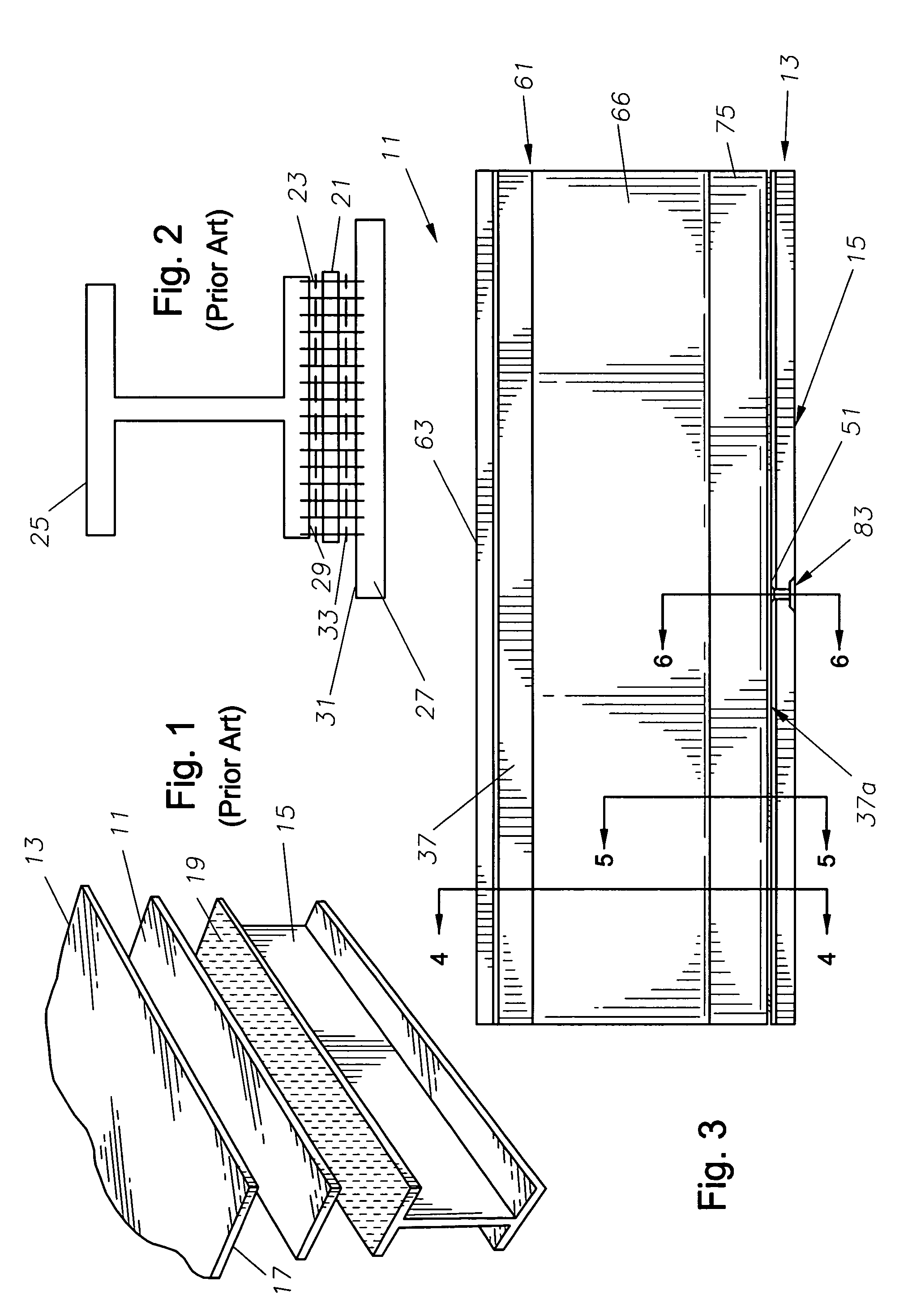

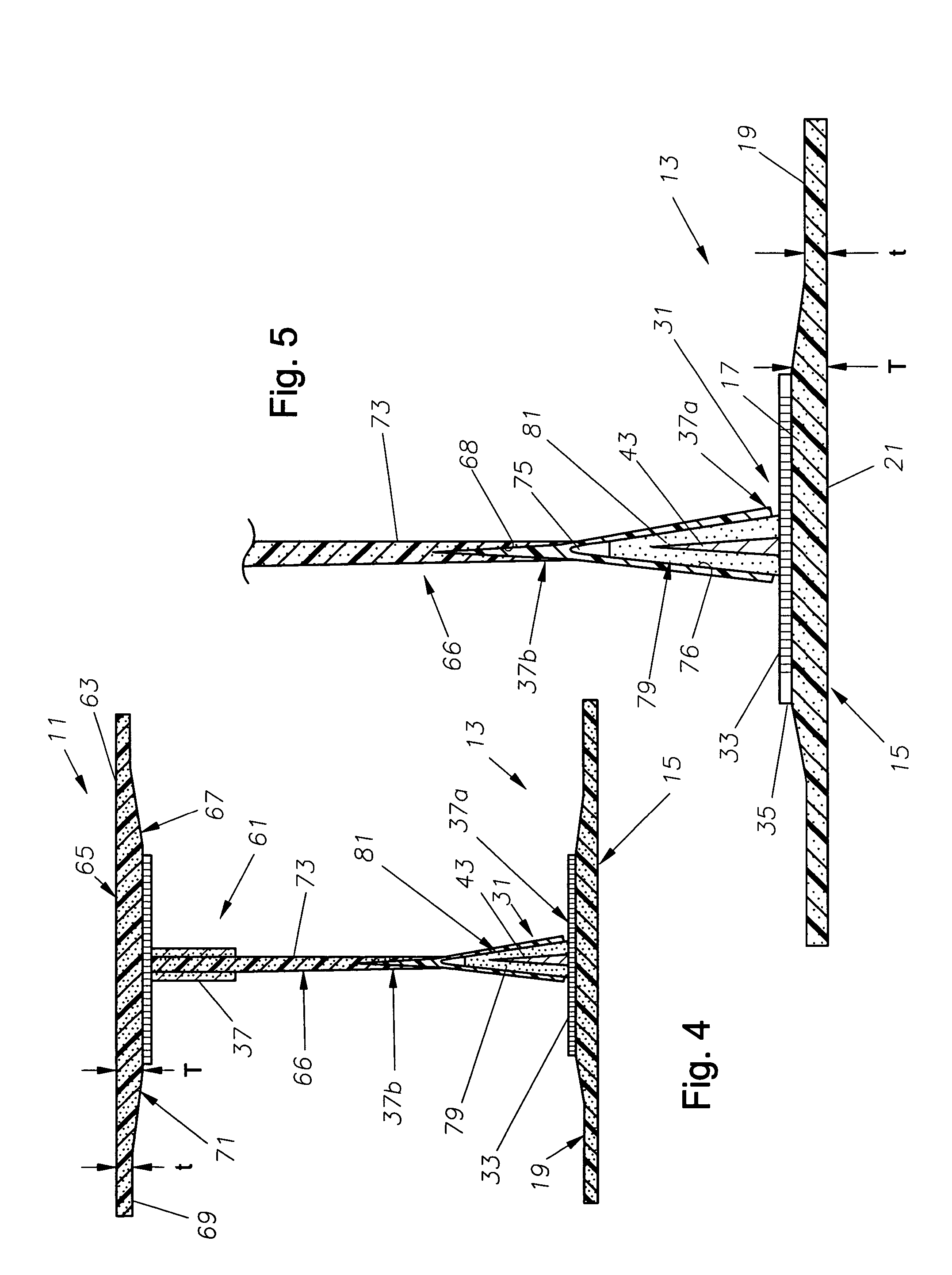

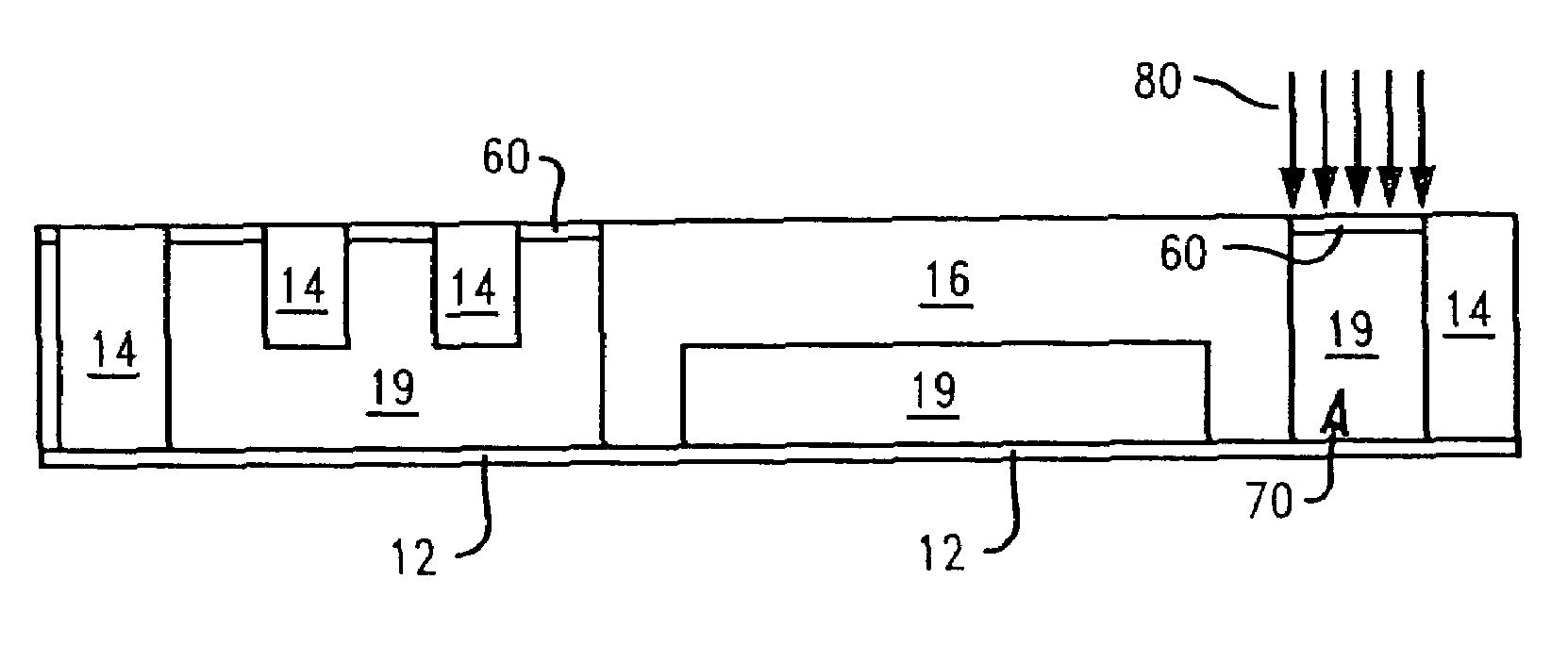

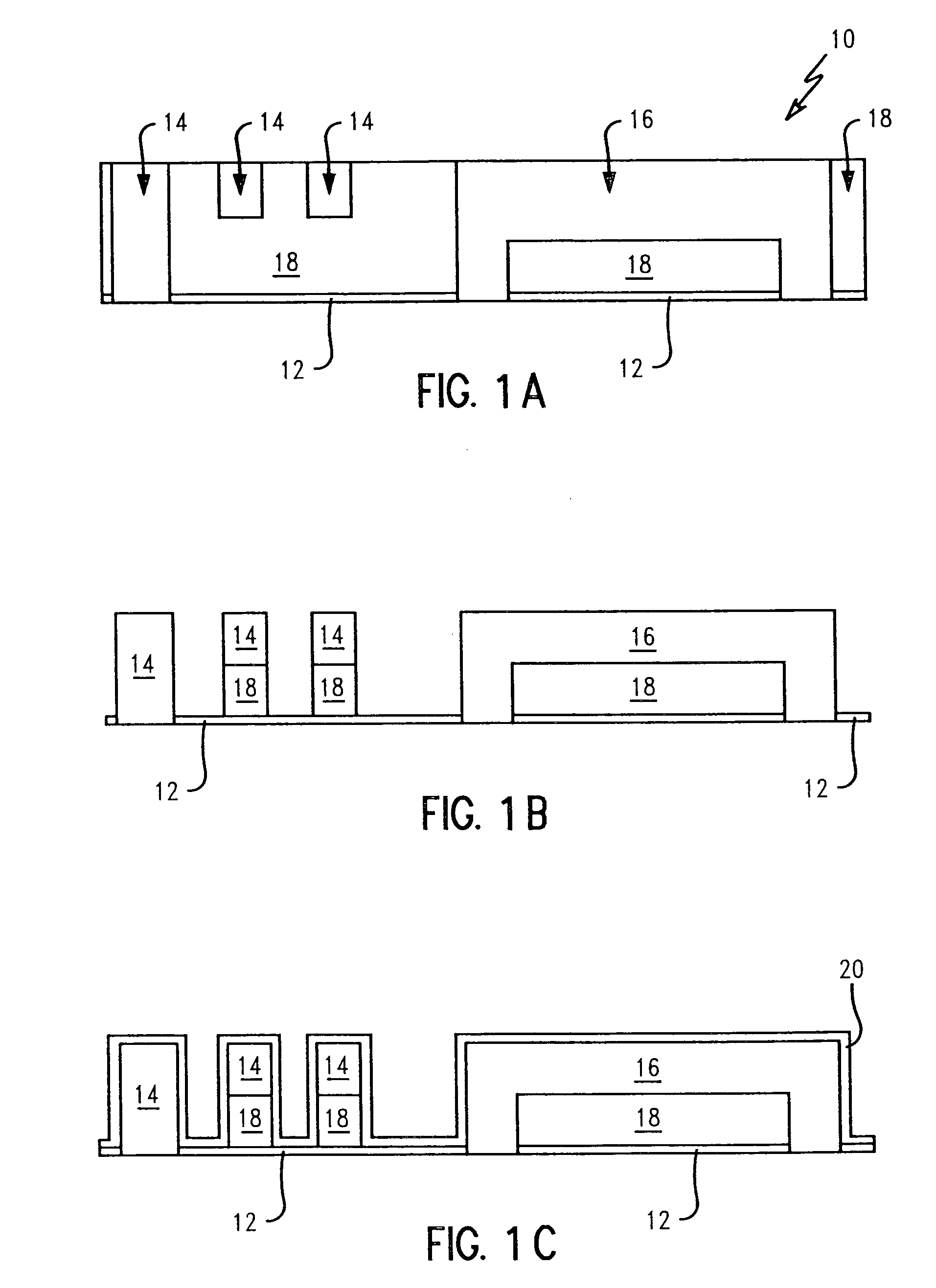

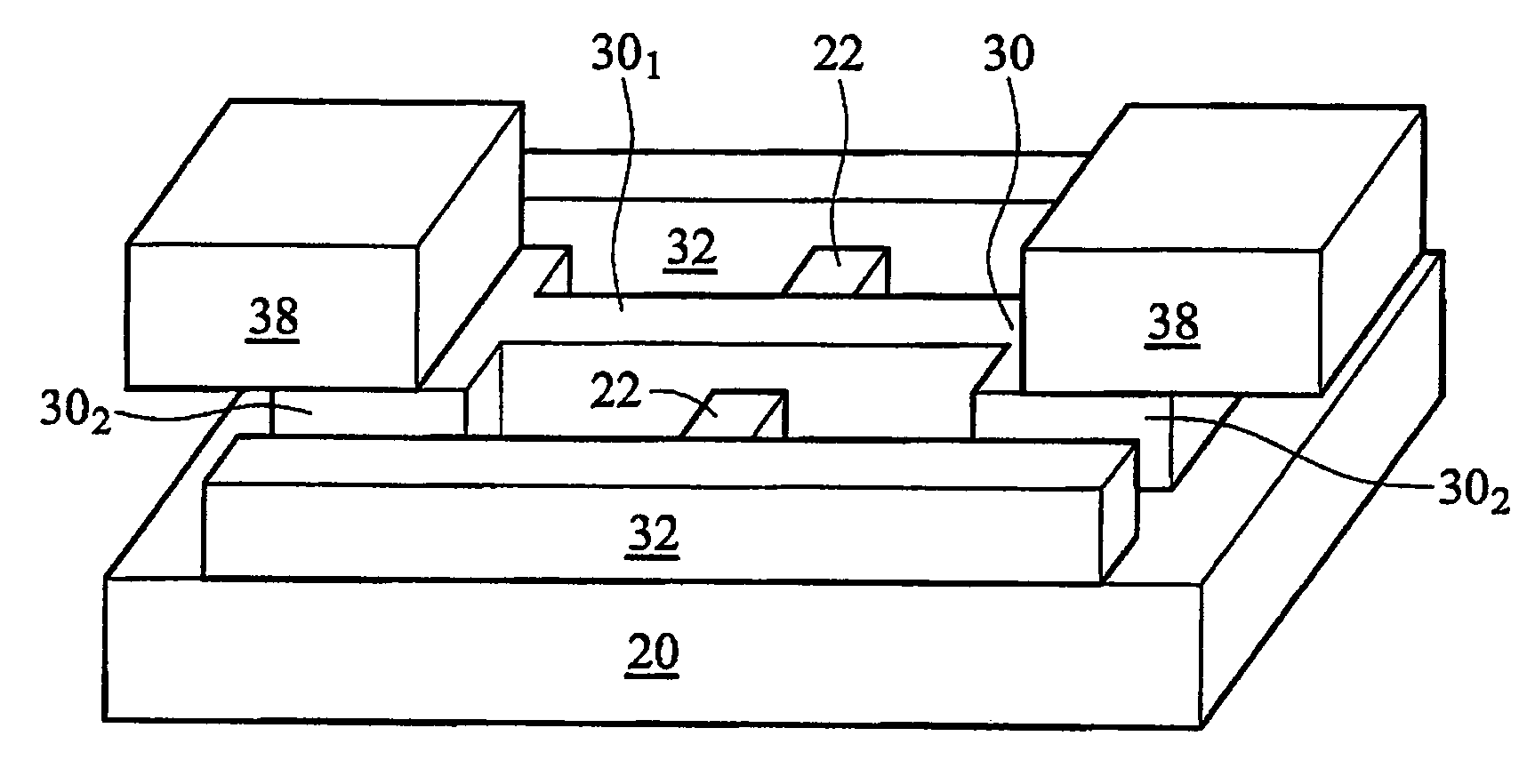

Apparatus, system, and method of joining structural components with a tapered tension bond joint

InactiveUS7244487B2Enhanced ballistics survivabilityStop crackingFuselage framesAircraft stabilisationEngineeringHigh intensity

A system of composite and adhesive materials provides for a high strength, producible closeout joint in the form of tapered tension bond joint for high performance structures. The system includes one skin that is co-bonded to flat panel spars, with the joint being positioned at the opposite side of the spars. The spar includes a female receptacle that receives a male blade from the closeout skin assembly. The blade and receptacle are wedge-shaped woven preforms. The flat panel spars have imbedded nut elements that serve as “internal tooling” to provide a positive stop for locating and clamping the structural members together.

Owner:LOCKHEED MARTIN CORP

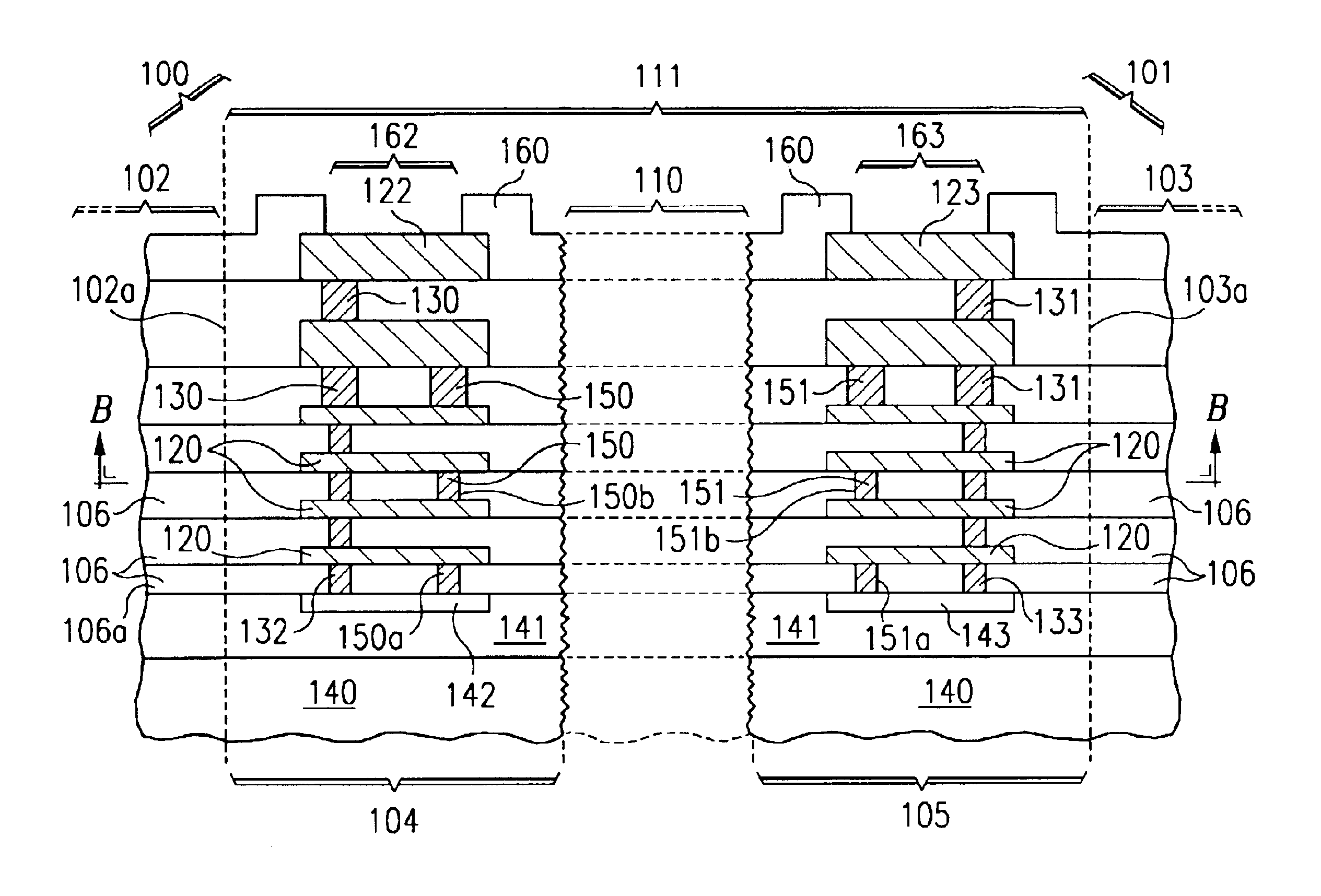

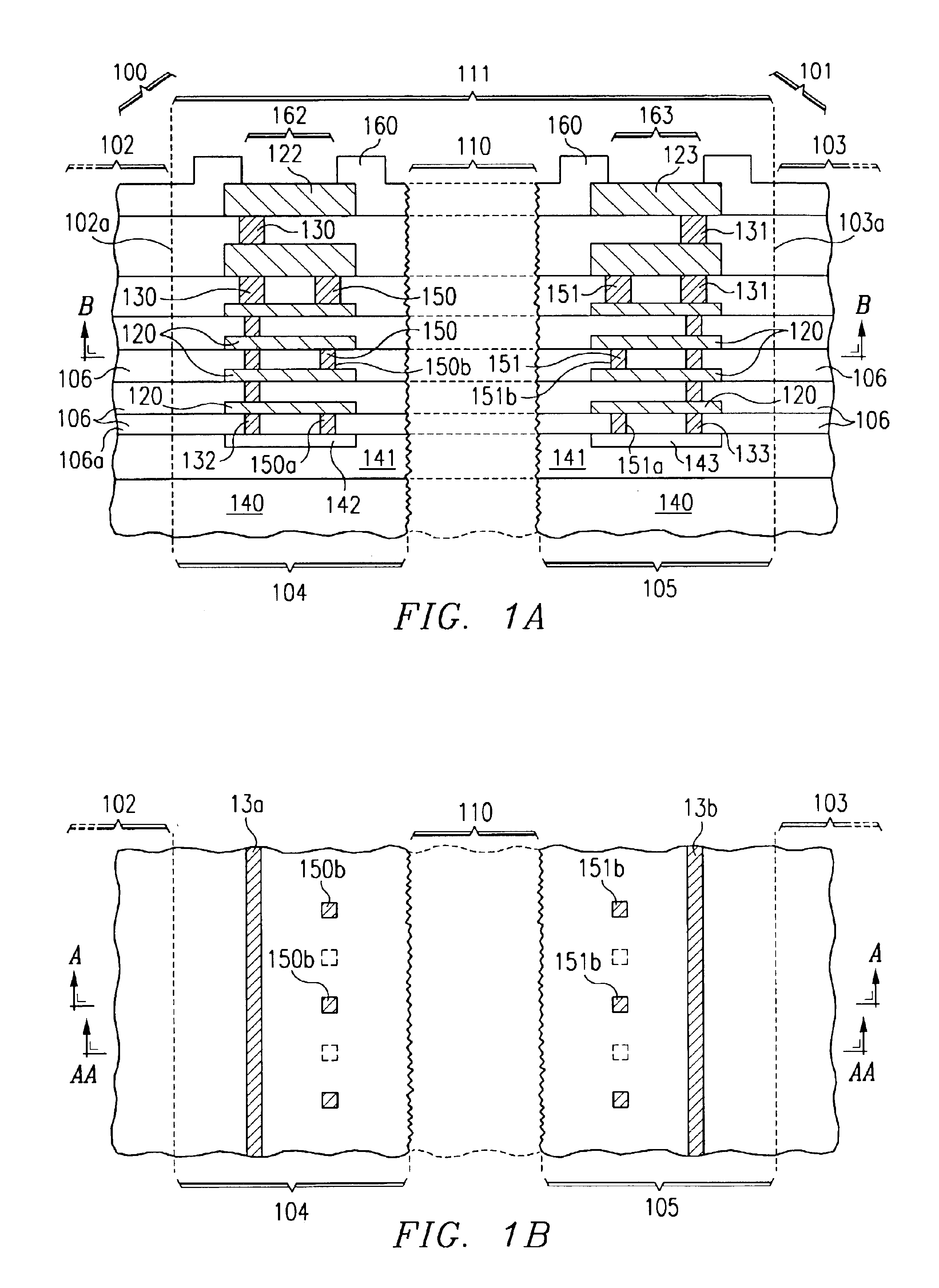

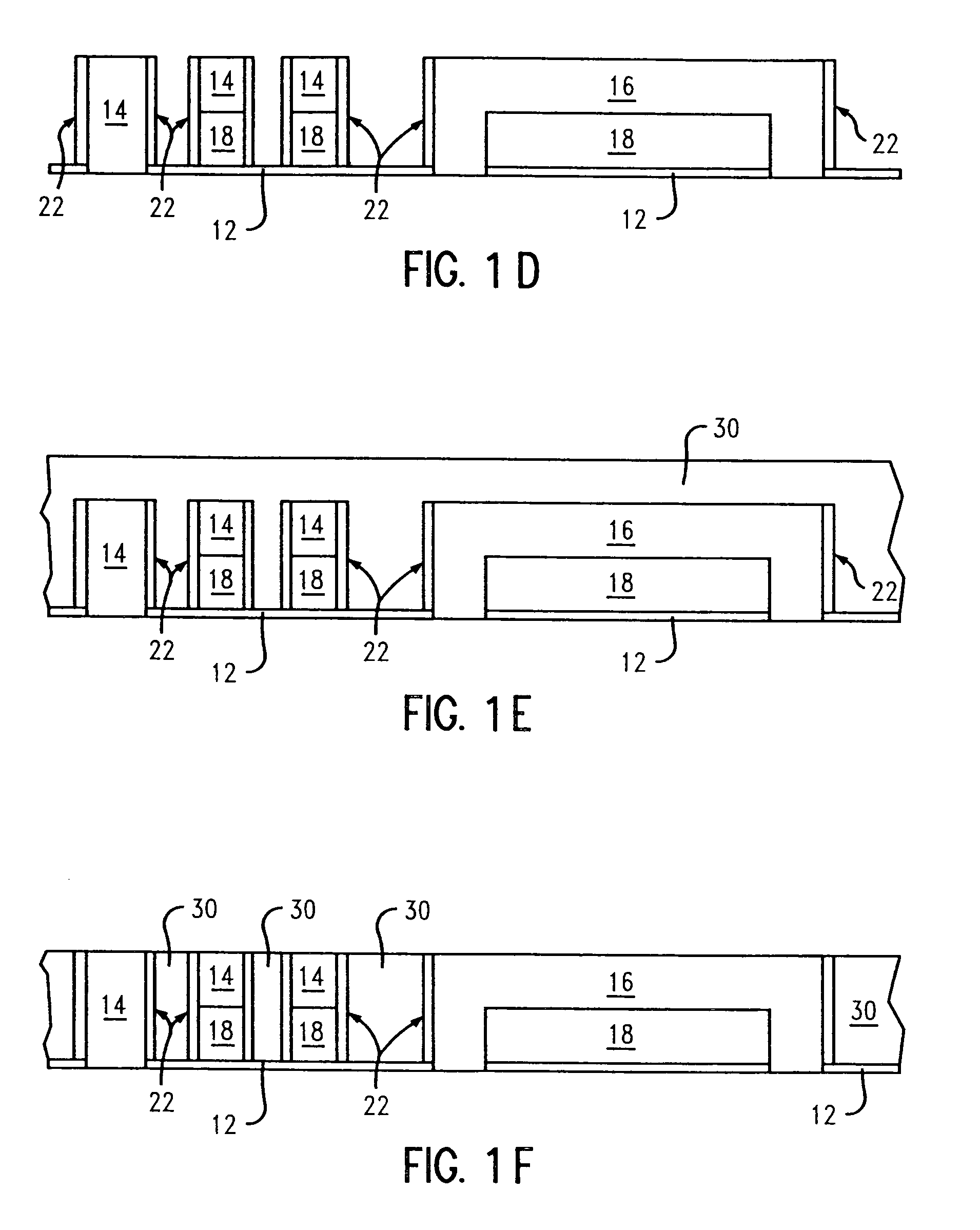

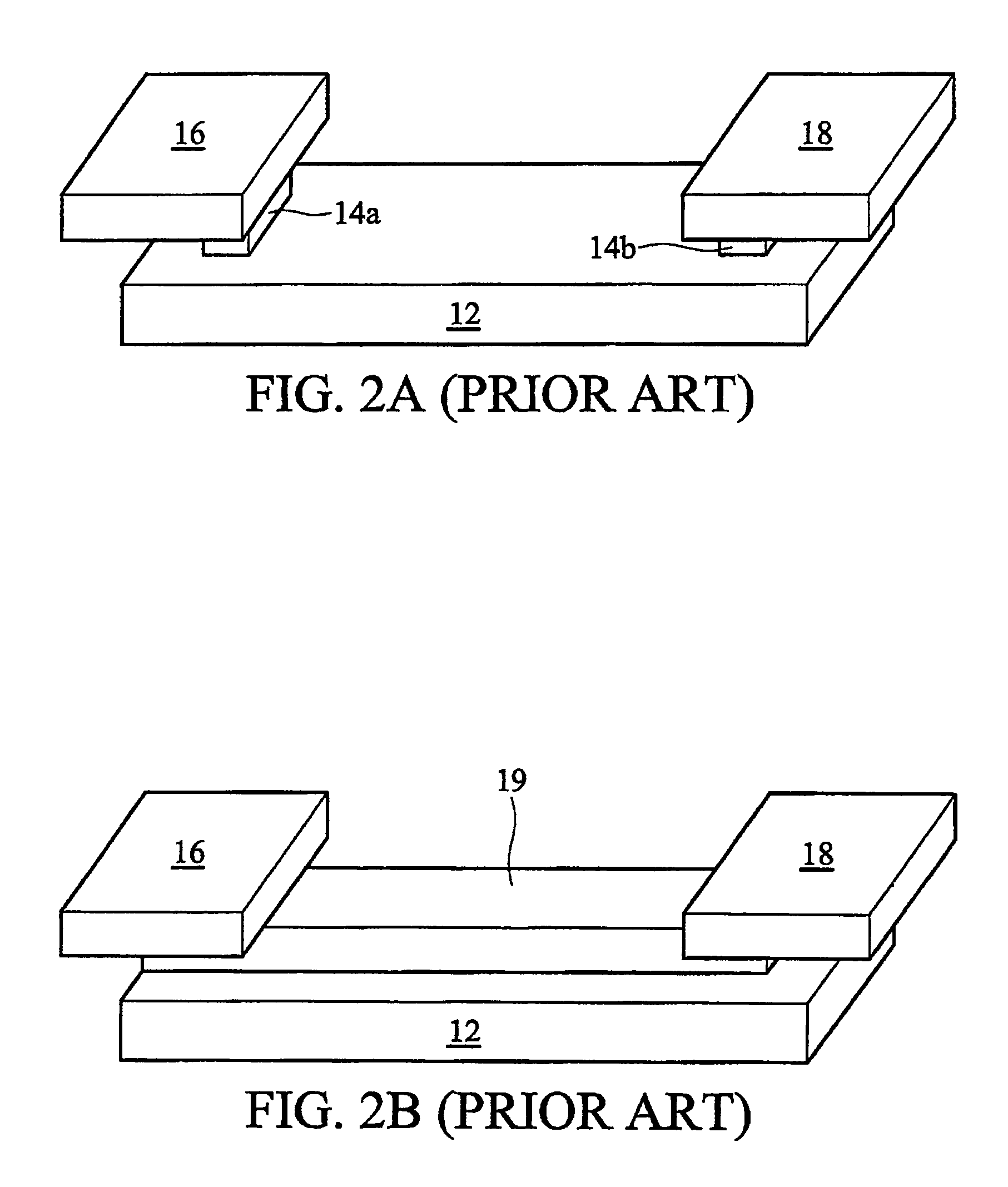

Scribe street seals in semiconductor devices and method of fabrication

InactiveUS6841455B2Improve toughnessImprove energy absorption capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

An integrated circuit wafer, covered by a protective overcoat, comprising an array of integrated circuit chips bordered by seal regions and separated by dicing lines; at least two sets of substantially parallel structures within each of said seal regions, each set extending along the edge of a chip on opposite sides of each said dicing line, respectively; each of said sets comprising at least one continuous barrier wall adjacent each chip, respectively; at least one sacrificial composite structure in combination therewith, between said wall and the center of said dicing line, said composite structure being a discontinuous barrier wall comprising metal rivets interconnecting electrically conductive layers in an alternating manner, whereby said composite structure provides mechanical strength to said sets and simultaneously disperses the energy associated with crack propagation; and at least one slot opened into said protective overcoat, reaching from the surface of said overcoat at least to the surface-nearest electrically conductive layer of said composite structure, whereby cracks propagating in said protective overcoat will be stopped.

Owner:TEXAS INSTR INC

Fruit tree protection glue for preventing fruit tree disease scar and wound generated by pruning from rot

The invention relates to a fruit tree protective agent, particularly a kind of fruit protective glue for preventing fruit tree scar and rotting wound produced by pruning. The invention solves the problems existing in present technology, for instance the traditional technology of treating fruit tree wound and cut is simple, the effect is bad, and so on. The product is composed of the following materials: 60-70 parts by weight of polyvinyl alcohol, 10-20 parts by weight of glycerol, 0.004-0.006 parts by weight of GA, 4-5 parts by weight of asomate, 85-100 parts by weight of water, heating and dissolving and at last forming a jelly solution. The product can prevent rot disease, and occurrence of new diseases, heal the wound and scar gradually, prevent the cracks between the tree bark and the xylem, make the tissue around the scar or wound heal in Jun-Jul in present year, and the efficiency is 95%. The product is applied in apple tree, pear tree, peach tree and other economic crops. The product is easy to use all year round without preparation at the scene.

Owner:郑永昌

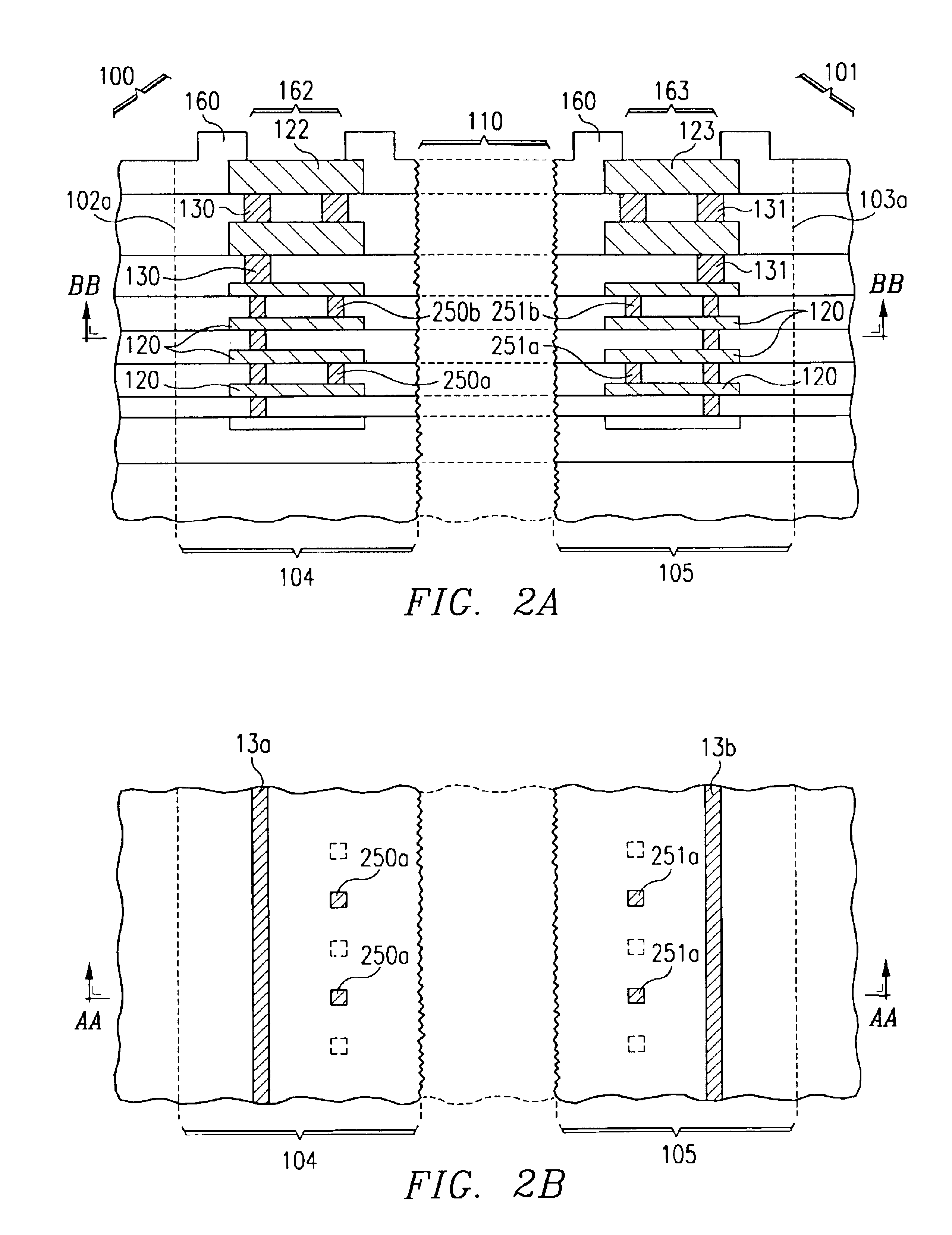

Crackstop with release layer for crack control in semiconductors

InactiveUS7109093B2Avoid crackingReduce crackingLiquid surface applicatorsSemiconductor/solid-state device detailsEngineeringVertical channel

Methods of forming and the integrated circuit device structure formed having vertical interfaces adjacent an existing crack stop around a perimeter of a chip, whereby the vertical interface controls cracks generated during side processing of the device such as dicing, and in service from penetrating the crack stop. The vertical interface is comprised of a material that prevents cracks from damaging the crack stop by deflecting cracks away from penetrating the crack stop, or by absorbing the generated crack energies. Alternatively, the vertical interface may be a material that allows advancing cracks to lose enough energy such that they become incapable of penetrating the crack stop. The present vertical interfaces can be implemented in a number of ways such as, vertical spacers of release material, vertical trenches of release material or vertical channels of the release material.

Owner:GLOBALFOUNDRIES INC

Forsterite-C-contained MgO-SiC-C fire-resistant material and preparation thereof

The invention relates to a forsterite-C-containing MgO-SiC-C material refractory and a method for preparing the same. The technical scheme comprises firstly mixing the 25-40wt% of magnesia particles with a grain size of 3-1mm, 20-35wt% of magnesia particles with a grain size of 1-0mm, 5-40wt% of forsterite-C mixed fine powders and 0-35wt% of magnesia fine powders, adding a 4-10wt% of bonding agent accounting for the weight of the mixed material, stirring or mulling for 10-30 minutes, drying after pressing formation, sintering at a reductive atmosphere with a sintering temperature of 1450-1700 DEG C and a heat preservation time of 4-8 hours, getting the MgO-SiC-C material composite refractory. The MgO-SiC-C material refractory prepared by adding the forsterite and carbon not only can solve the problem of magnesia resource shortage, reduces the production cost, but also the SiC prepared by the reaction of magnesia and carbon at a high temperature can reinforce the conjugation inside the material, and be useful for improving the refractory performance. The invention can also adopt low grade magnesia.

Owner:WUHAN UNIV OF SCI & TECH

Metal electrical fuse structure

InactiveUS7651893B2Stop crackingMeet compatibilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

An electrical fuse and a method for forming the same are provided. The electrical fuse includes a dielectric layer over a shallow trench isolation region and a contact plug extending from a top surface of the dielectric layer to the shallow trench isolation region, wherein the contact plug comprises a middle portion substantially narrower than the two end portions. The contact plug forms a fuse element. The electrical fuse further includes two metal lines in a metallization layer on the dielectric layer, wherein each of the two metal lines is connected to different ones of the end portions of the contact plug.

Owner:TAIWAN SEMICON MFG CO LTD

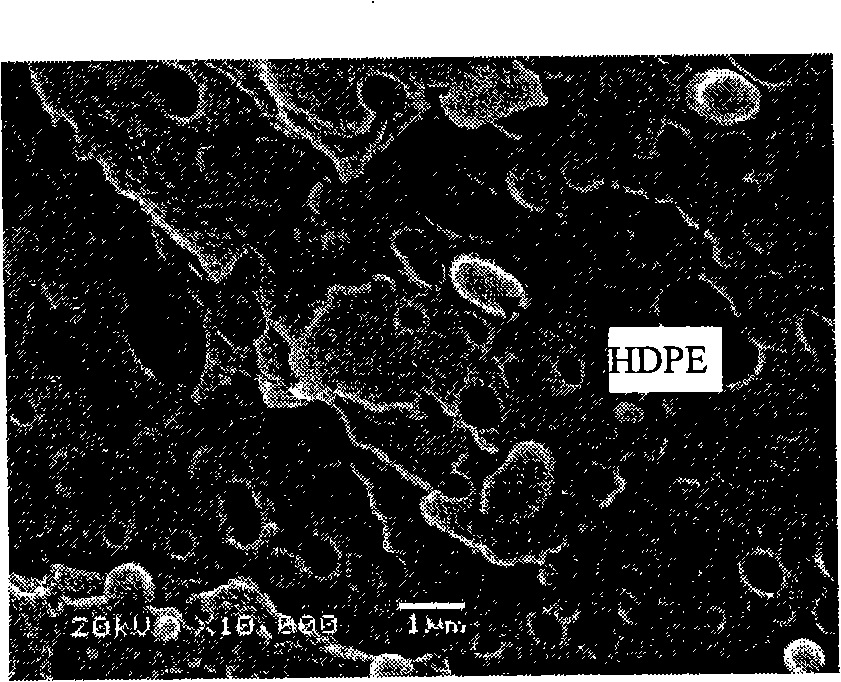

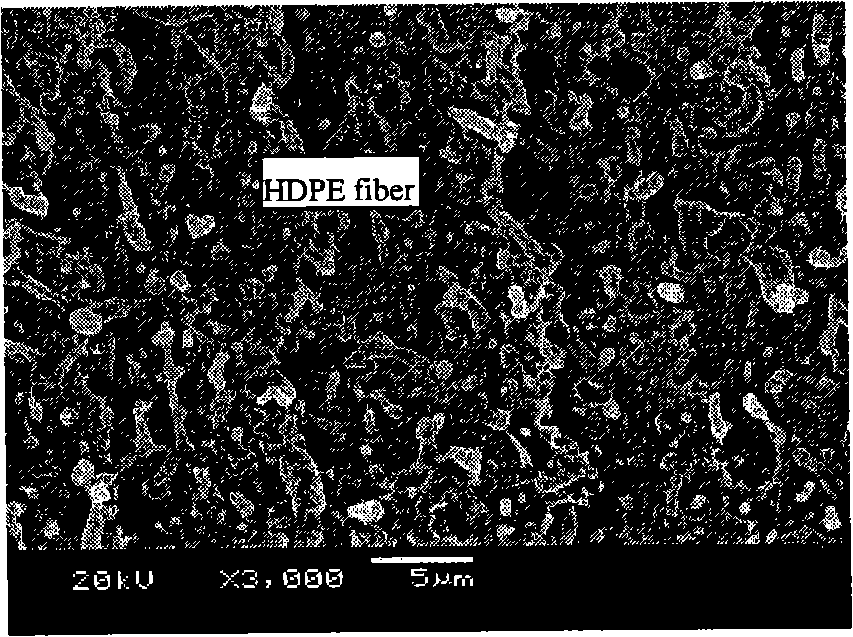

Method for preparing high impact modified material with waste and old polystyrene plastics

The invention discloses a method for preparing high-impact modified material from waste polystyrene plastic, which comprises the following steps: uniformly mixing 60 to 80 parts of waste polystyrene, 5 to 10 parts of polyethylene, 10 to 30 parts of elastomer, compatibilizer, etc. by stirring, adding to a screw extruder, and melting and blending at 150 to 210 DEG C, wherein the melt index ratio of polyethylene to polystyrene is equal to or less than 0.5. Due to the addition of small amount of polyethylene, the viscosity ratio of polyethylene to polystyrene and the crystallization behavior and the phase size of polyethylene can be controlled by restricting the melt index of waste polystyrene and polyethylene, so that the obtained modified material has a notched impact strength 8 to 10 times as high as that of original waste polystyrene and can maintain or even improve the tensile strength of polystyrene. The prepared modified polystyrene can be used for producing parts of middle- and high-level household appliances such as computer and air conditioner as the substitute of high-impact polystyrene new material, thus achieving remarkable social and economic benefits.

Owner:SICHUAN UNIV

MgO-SiC-C refractory material synthesized by forsterite-C and method

The invention relates to MgO-SiC-C refractory material synthesized by forsterite-C and a method. The technical proposal to be adopted is as follows: firstly, forsterite mineral powder and industrial carbon powder are blended according to molar ratio of 1: (1-5); and then the mixture is added with 4 to 10 wt% of bonding agent, stirred or mulled for 10 to 30 minutes, pressed to be formed and dried; and finally under the Ar gas condition, the mixture is sintered in the sintering temperature of 1530 to 1800 DEG C with heat preservation for 2 to 8 hours to obtain MgO-SiC-C refractory material synthesized by forsterite-C. The invention is characterized by comparatively simple processing technique, low producing cost, high producing efficiency, wide raw material source and being capable of reducing energy consumption of high temperature synthesis reaction. The prepared MgO-SiC-C refractory material has the advantages of excellent high temperature performance, anti-corrosion and good durability.

Owner:WUHAN UNIV OF SCI & TECH

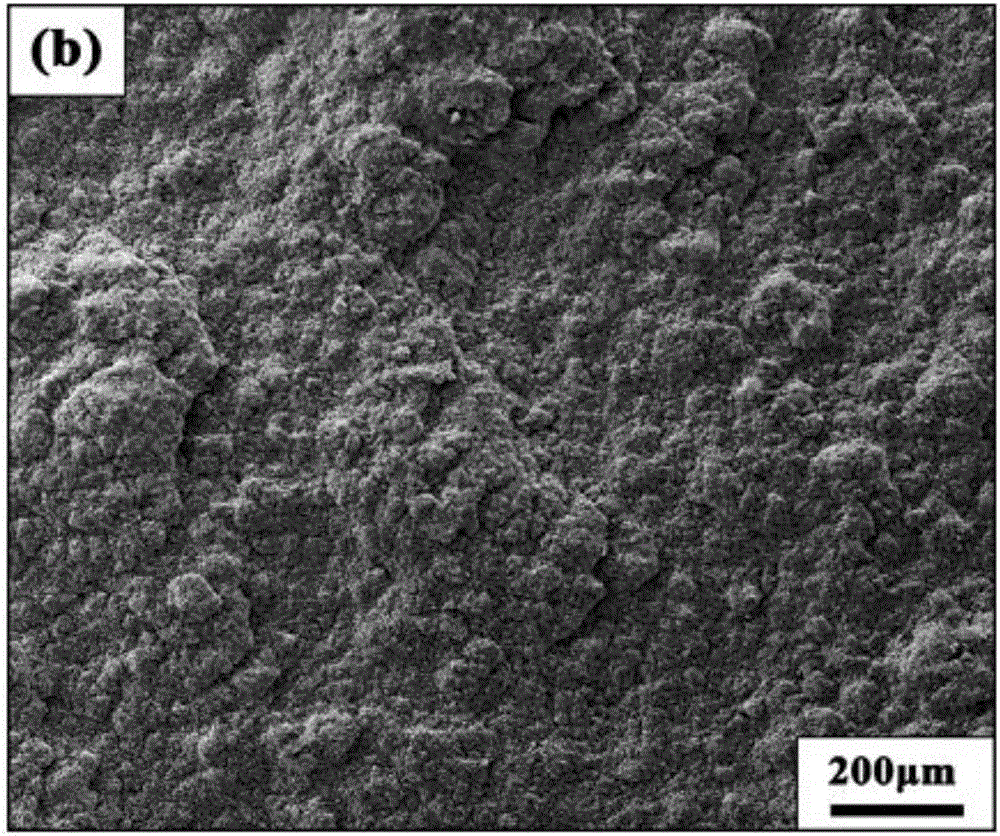

Rare earth oxide modified Si-Mo-O gradient anti-oxidation coating layer and production method thereof

The invention relates to a rare earth oxide modified Si-Mo-O gradient anti-oxidation coating layer and a production method thereof. The production method comprises the following steps: embedding a SiC internal coating layer in the surface of a sample to alleviate heat stress caused by a difference between the thermal expansion coefficients of a matrix and the coating layer, producing a SiC-MoSi2 intermediate transition layer to solve the heat adaption problem between the internal coating layer and an external coating layer, spraying a rare earth oxide modified Si-Mo-O external coating layer, immersing the obtained sample in a silica sol solution, carrying out heat treatment, and sealing holes to improve the compactness of the coating surface. The rare earth oxide modified Si-Mo-O gradient anti-oxidation coating layer produced in the invention has the advantages of few surface defects, low porosity, high compactness, low oxygen permeability, strong bonding force between coating layers, and difficult cracking. LaSiO5, La2Si2O5 and Y2Si2O5 formed by liquid rare earth oxides (La2O3 and Y2O3) can stabilize a SiO2 glass phase in the anti-oxidation process, so the compactness of the coating layer is improved, the endosmosis of oxygen is blocked, and the anti-oxidation performance is substantially improved. The method has the advantages of very large application potential, and substantial economic and social benefits.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

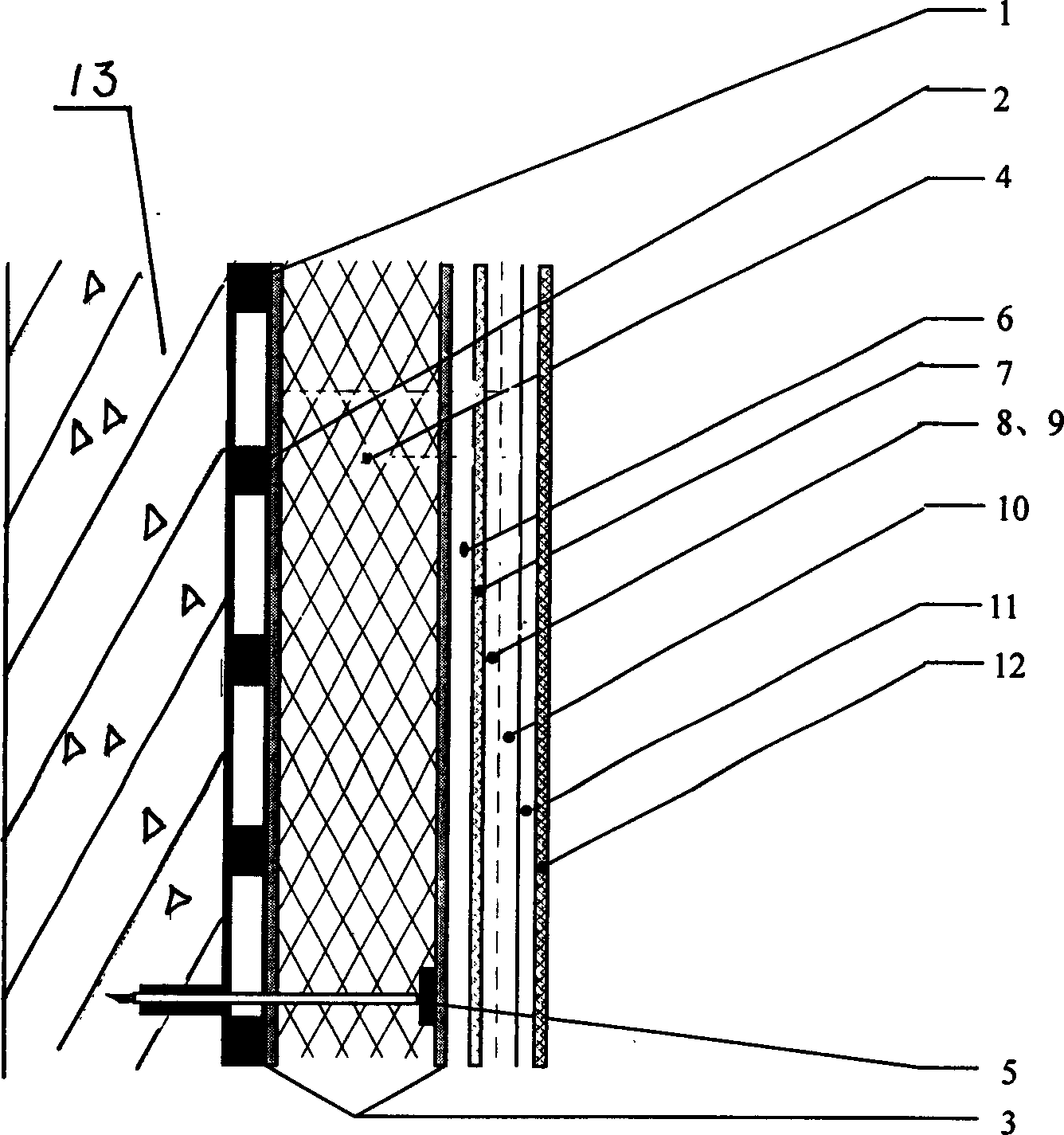

Heat insulating system outside external wall

InactiveCN1811088AAvoid spreadingStop crackingHeat proofingBuilding reinforcementsEngineeringFire retardant

The heat insulating system outside external wall features that there are base layer with alkali resistant strengthening treating agent outer the concrete base wall and connected to the heat insulating board through silicon modified polymer mortar adhesive and plastic anchor part, alkali resistant netted cloth outside the heat insulating board, elastic anticracking silicon modified polymer putty and self-structured waterproof anticracking closing layer between the heat insulating board and the alkali resistant netted cloth, facing silicon modified polymer mortar outside the alkali resistant netted cloth, fire retardant paint around the window and silicon modified acrylate paint in the outmost layer. The present invention has the advantages of simple structure, low cost, easy construction, raised wall surface quality and fire retarding function.

Owner:上海英硕聚合材料股份有限公司

Al4SiC4/SiC composite refractory materials and preparation method thereof

The invention relates to a composite refractory material of Al4SiC4 and SiC and a method for preparing the same. The technical proposal is as follows: firstly, 50 to 65 weight percent of clay and 35 to 50 weight percent of industrial carbon powder are mixed; and the mixture is added with 3 to 10 weight percent of bonding agent to be stirred for 5 to 25 minutes, is pressed to be shaped, and is dried for 12 to 36 hours under the condition of between 60 and 110 DEG C or naturally dried for 24 to 48 hours indoors; and secondly, the mixture is sintered for 2 to 6 hours under argon atmosphere and under the condition of between 1,600 and 1,800 DEG C, and is cooled naturally to obtain the composite material of the Al4SiC4 and the SiC. The composite refractory material has the characteristics of rich raw material resource, low production cost and easy industrialized production. The composite refractory material of the Al4SiC4 and the SiC prepared by the method not only has excellent performance, but also can prolong the service life, is suitable for a novel furnace lining material for nonferrous metal and iron and steel smelting equipment, particularly suitable for producing ladle inside lining and refining furnace lining of clean steel such as low carbon steel, ultra-low carbon steel and so on, and is favorable for improving the quality of steel.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing LaB6/Si-Mo gradient high-temperature anti-oxidation coating

The invention relates to a method for preparing a LaB6 / Si-Mo gradient high-temperature anti-oxidation coating. According to the method, a SiC internal coating is prepared on the surface of a C / C composite material to relieve the problem of concentrated thermal stress caused by thermal expansion coefficient difference between a matrix and the coating; the intermediate layer is a SiC-MoSi2 transition coating and serves as a transition layer of internal and external coatings, cracks, pores and other defects of the external coating generated under a high-temperature condition can be effectively reduced, the excellent high-temperature oxidation resistance of the coating can be achieved, and the resistance adaptability of the C / C composite material under high-temperature aerobic relieving condition is further improved; the LaB6 / Si-Mo coating is prepared by utilizing a plasma spraying method, so that the thickness of the coating can be accurately controlled, and the problem of uneven thickness of the coating is solved. Gradient is sequentially formed among the coatings, so that generation of thermal stress is reduced, and the binding force among the coatings is improved. Advantages of the plasma spraying method and an embedding method are combined, so that the high-temperature oxidation resistance of the coating can be greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

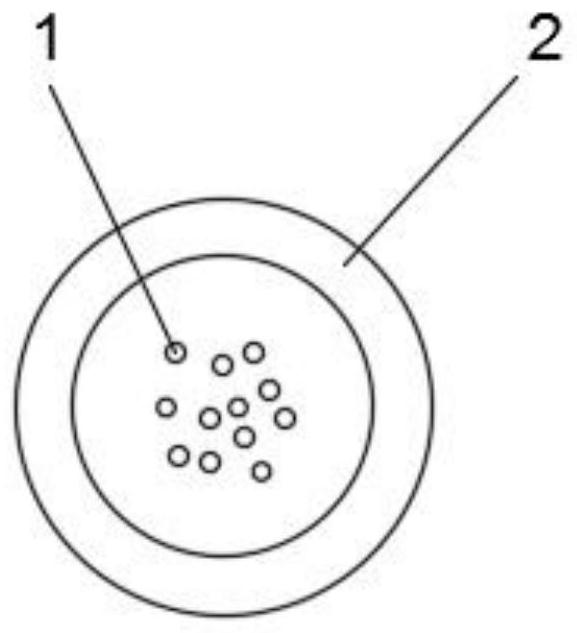

Lead-acid storage battery separator and preparation method thereof

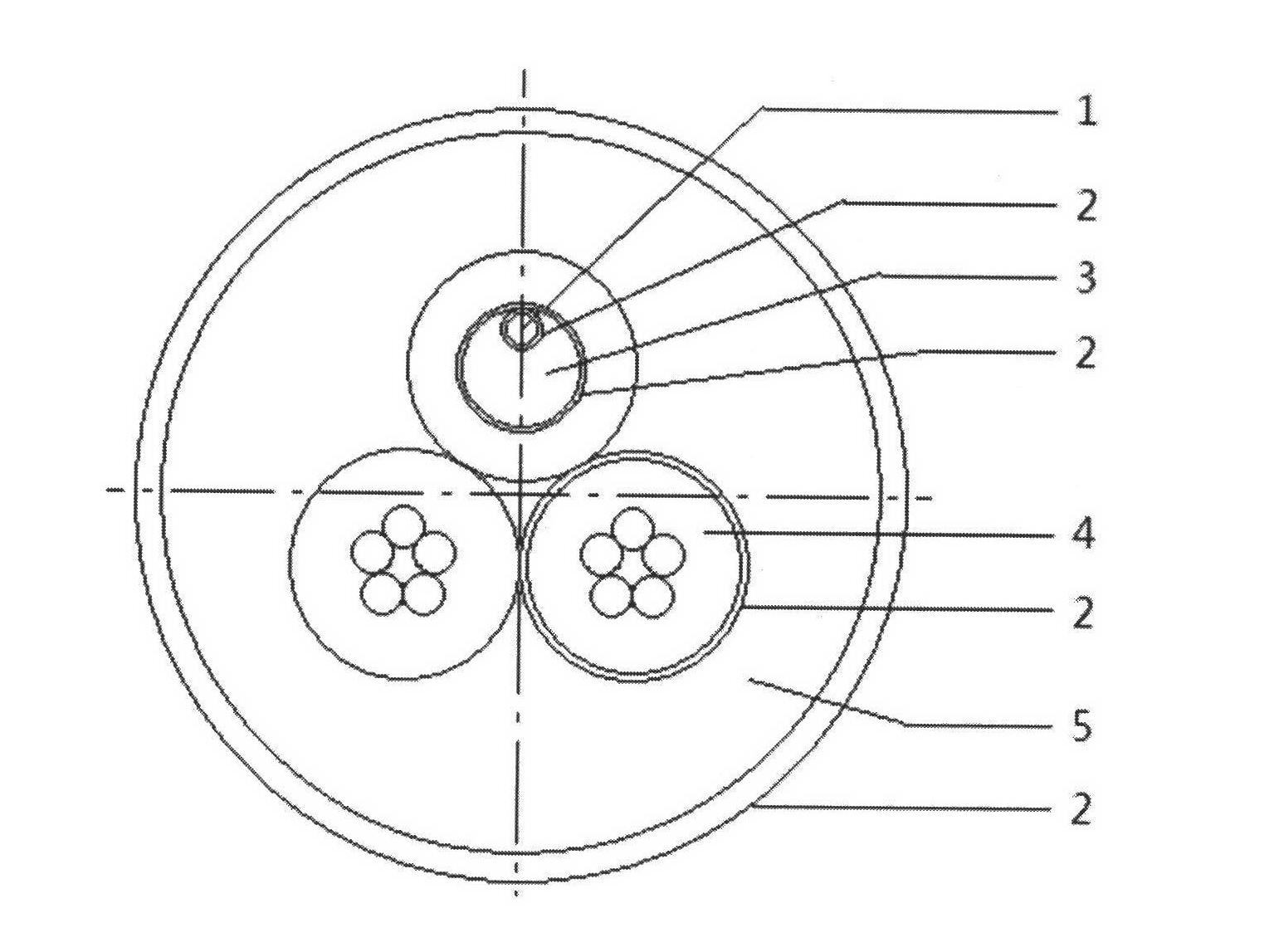

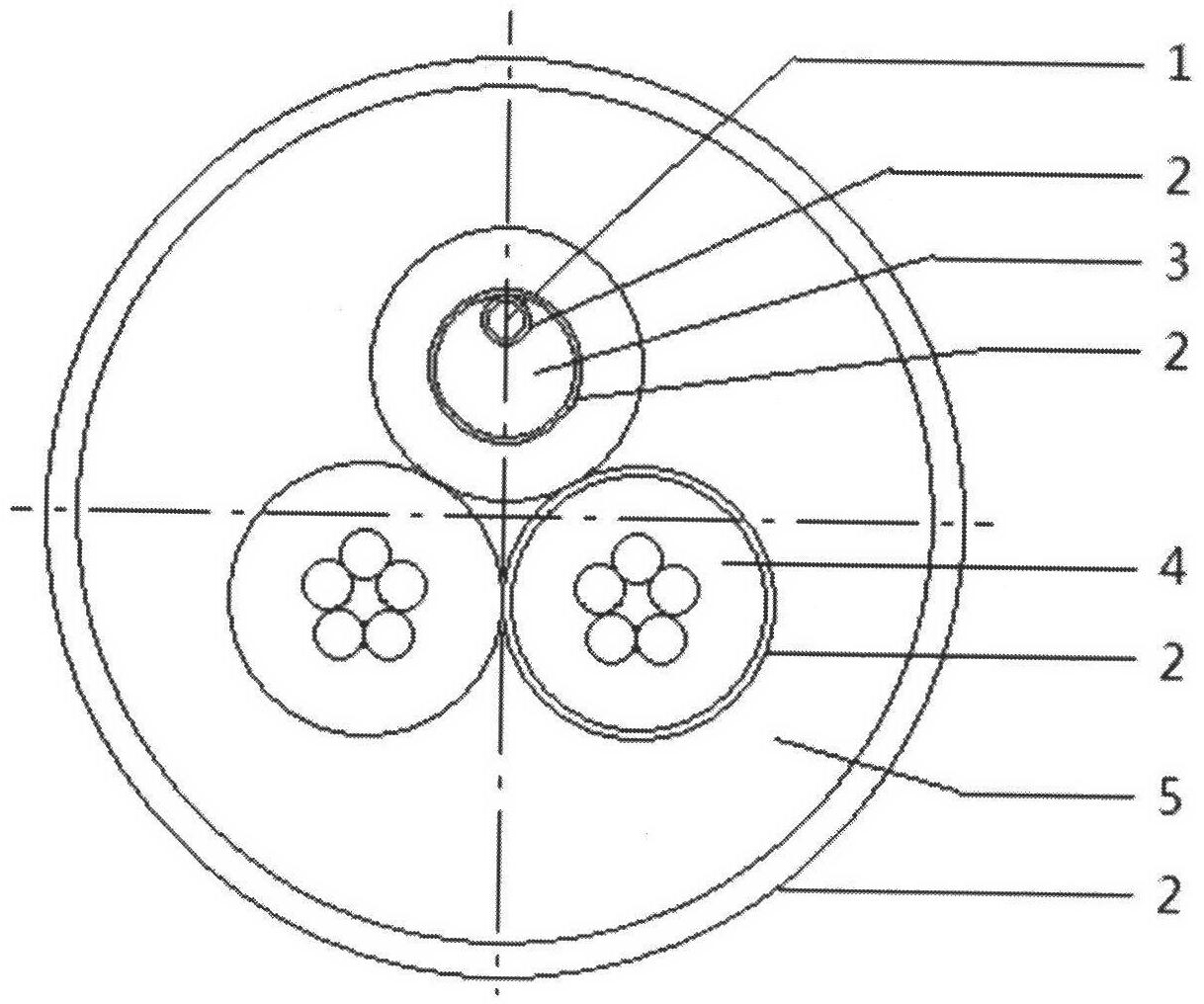

InactiveCN104852002AReasonable structureTightly bondedFinal product manufactureCell component detailsGlass fiberPolyester

The invention discloses a lead-acid storage battery separator which comprises 85-95 percent by weight of superfine glass fibers, 4-10 percent by weight of polyester fibers and 1-5 percent of cellulose acetate fibers. A preparation method comprises the following steps: pulping the superfine glass fibers for 5-10min and then adding the polyester fibers and the cellulose acetate fibers, pulping for 8-12min, forming and beating to enter a drying system at a constant speed, drying at a temperature of 160-2500 DEG C, winding and cutting to obtain the lead-acid storage battery separator. The lead-acid storage battery separator prepared by adopting the preparation method is reasonable in structure; the polyester fibers and the cellulose acetate fibers are added, so that the advantages of insulation, isolation and storage of an acid liquor of an existing AGM separator can be kept, the relatively high mechanical strength, excellent puncture resistance and excellent compression rebound property are obtained, the performance of a storage battery is improved, the service life of the storage battery is prolonged, and the application is relatively wide.

Owner:QIDONG HENGRUI POWER SUPPLY TECH CO LTD

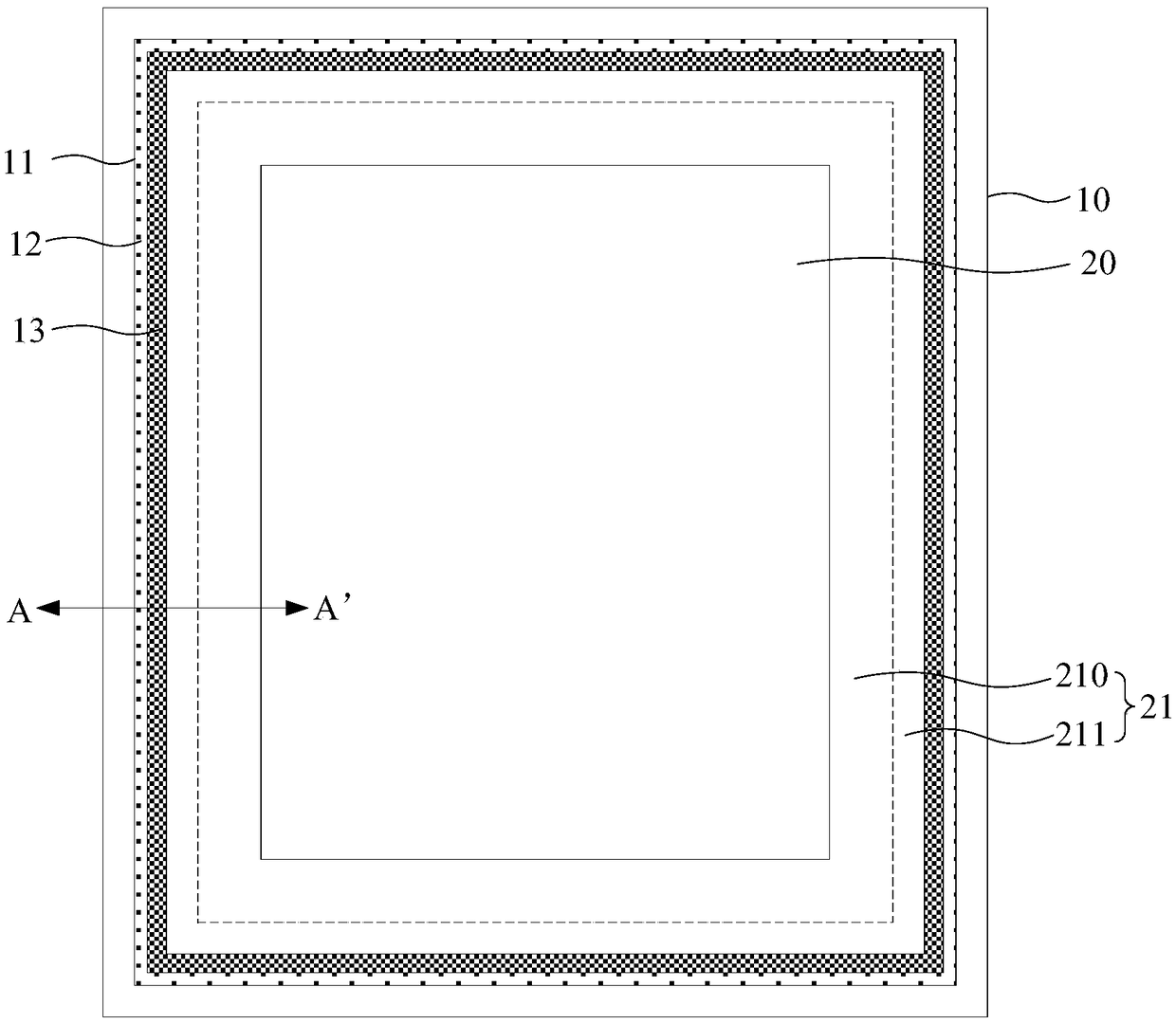

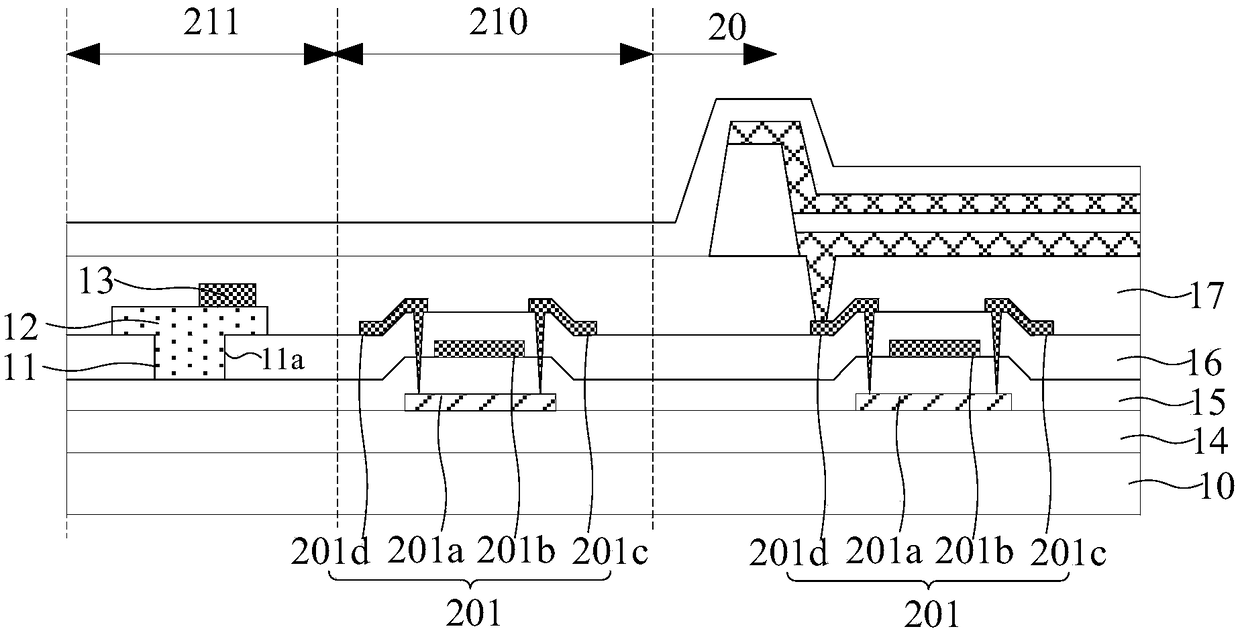

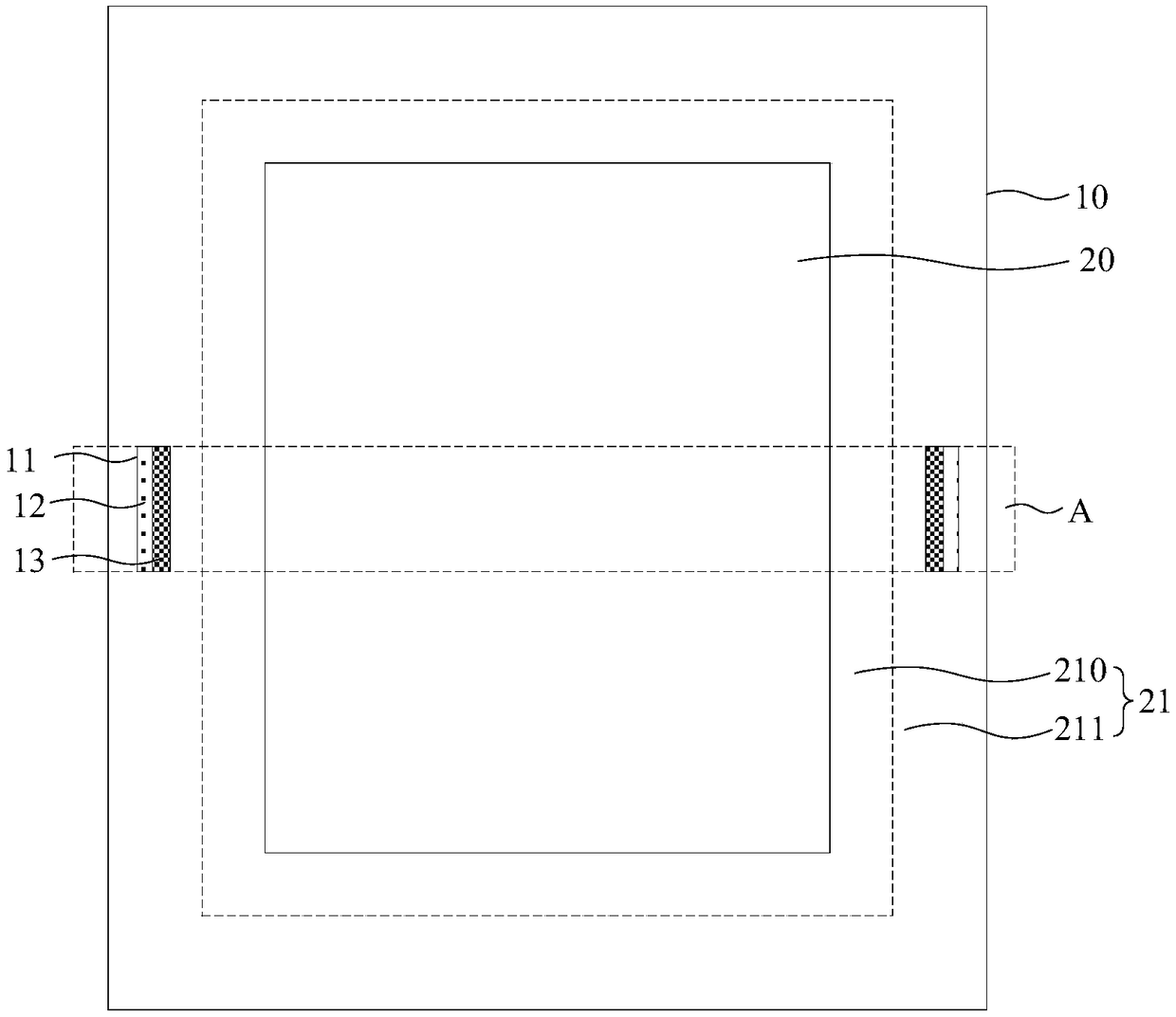

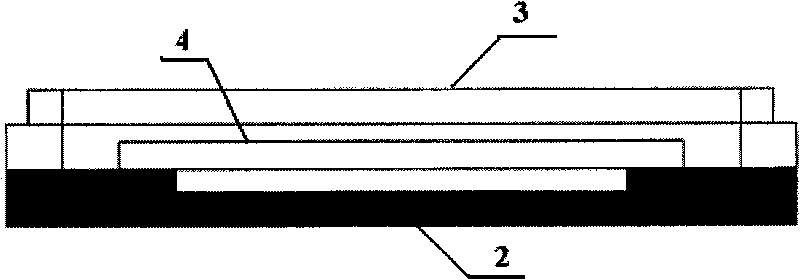

Flexible display panel and flexible display device

ActiveCN108766996AAffect the display effectReduce crackingSolid-state devicesSemiconductor devicesWater vaporOxygen

The invention provides a flexible display panel and a flexible display device. The flexible display panel comprises a flexible substrate and at least one inorganic layer arranged on the flexible substrate, wherein the flexible substrate comprises a display area and a non-display area; the non-display area comprises at least one trench arranged in each inorganic layer, a first organic layer covering the trenches, and a metal layer located on the surface of the first organic layer; and the metal layer at least covers an interface, close to the display area, of each trench and each inorganic layer, so that, based on this, the probability of cracks in the inorganic layers on the edge can be reduced and the cracks in the inorganic layers on the edge can be effectively prevented from further extending towards the inorganic layers in the display area at the inner side and other films, thereby avoiding the condition that water vapor and oxygen enter the display area from the cracks to affect the display effect of the flexible display panel.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Al4SiC4-Al2O3 composite refractory materials and preparation method thereof

The invention relates to a composite refractory material of Al4SiC4 and Al2O3 and a method for preparing the same. The adopted technical proposal is as follows: firstly, 50 to 65 weight percent of bauxite and 35 to 50 weight percent of industrial carbon powder are mixed; and the mixture is added with 3 to 10 weight percent of bonding agent to be stirred for 5 to 25 minutes, is pressed to be shaped, and is dried for 12 to 36 hours under the condition of between 60 and 110 DEG C or naturally dried for 24 to 48 hours indoors; and secondly, the mixture is sintered for 2 to 6 hours under argon atmosphere and under the condition of between 1,600 and 1,800 DEG C, and is cooled naturally to obtain the composite refractory material of the Al4SiC4 and the Al2O3. The composite refractory material has the characteristics of rich raw material resource, low production cost and easy industrialized production. The composite refractory material of the Al4SiC4 and the Al2O3 prepared by the method not only has excellent performance, but also can prolong the service life, is suitable for a furnace lining material for nonferrous metal and iron and steel smelting equipment, and particularly suitable for producing ladle inside lining and refining furnace lining of clean steel such as low carbon steel, ultra-low carbon steel and so on.

Owner:WUHAN UNIV OF SCI & TECH

Light-weight and shock-absorbing combined shoe sole and production method thereof

InactiveCN107400268APrevent vomiting creamCream SuppressionSolesDomestic footwearRubber materialEngineering

The invention relates to a production technology of a shoe sole, in particular to a light-weight and shock-absorbing combined shoe sole and a production method thereof. The combined shoe sole consists of an outsole and a midsole, wherein the outsole is produced from a rubber material by mixing, performing open mixing, vulcanizing and other processes; the midsole is produced from an EVA material by mixing, performing open mixing, granulating, foaming once, and performing oil pressing twice. The raw materials and the processes of the light-weight and shock-absorbing combined shoe sole provided by the invention are optimized, so that various problems of the rubber material and the EVA material in application are effectively solved; a finished product is light in weight, good in resilience and excellent in shock-absorbing effect, and is not prone to aging and frosting problems.

Owner:LILANG CHINA

Refractory material for homogeneous skimming ball for continuous casting ladle and method for making skimming ball

Provided is a refractory material for a homogeneous skimming ball for a continuous casting ladle. The refractory material is prepared from, by weight, 62%-80% of ZrO2, 14%-32% of Al2O3, 2%-6% of SiO2, 2%-4% of SiC, 3.0%-6.5% of silica sol and the balance inevitable impurities. The phenomenon that slag in the ladle enters tundish can be effectively prevented, the heat shock resistance stability is good, erosion or melting is prevented, and cracking or busting is effectively prevented.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

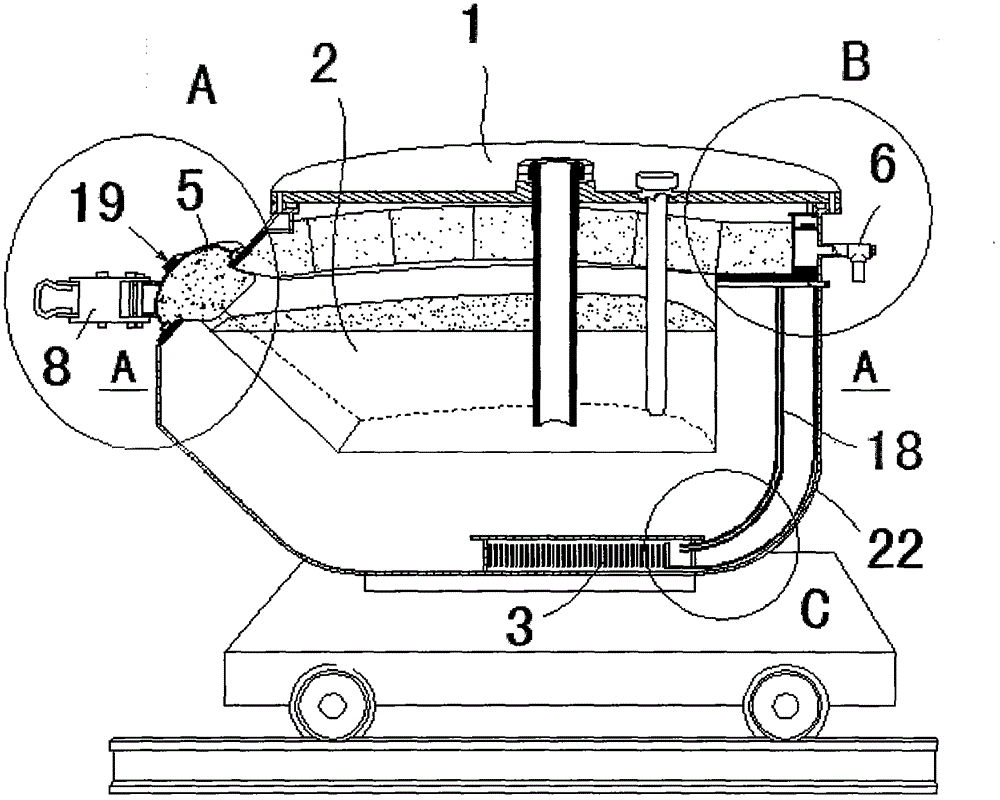

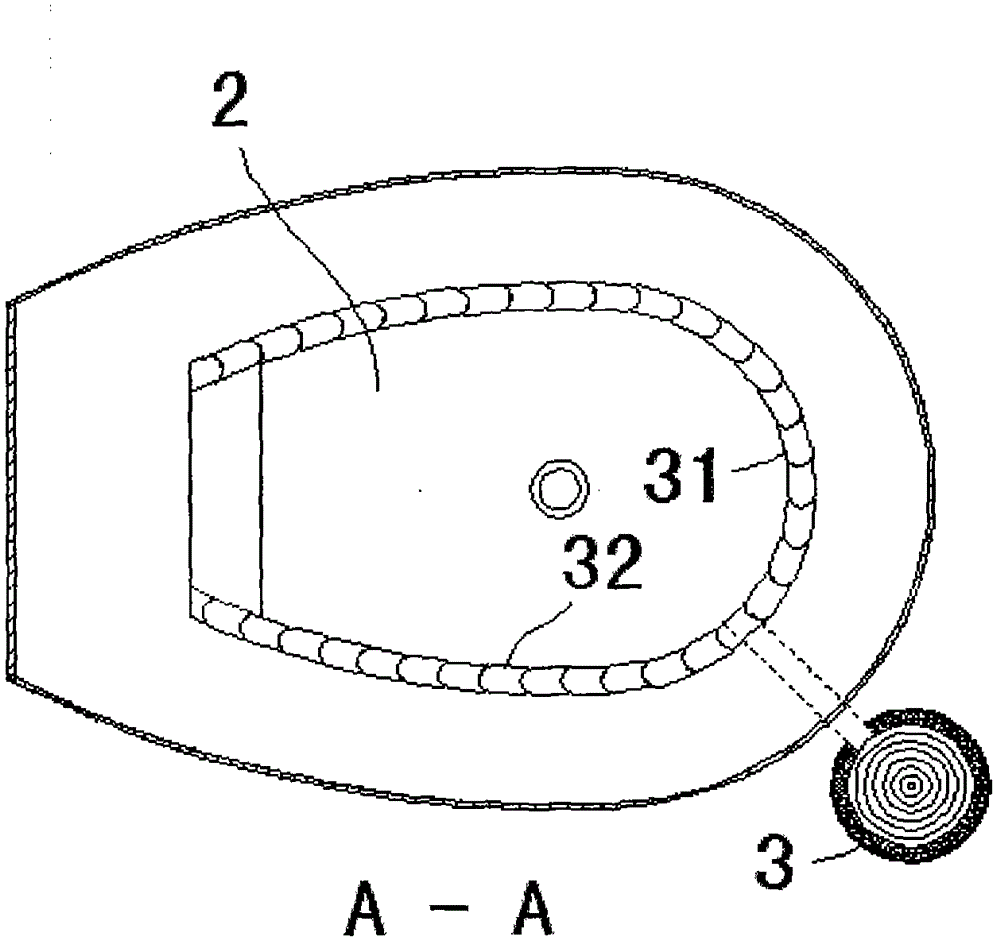

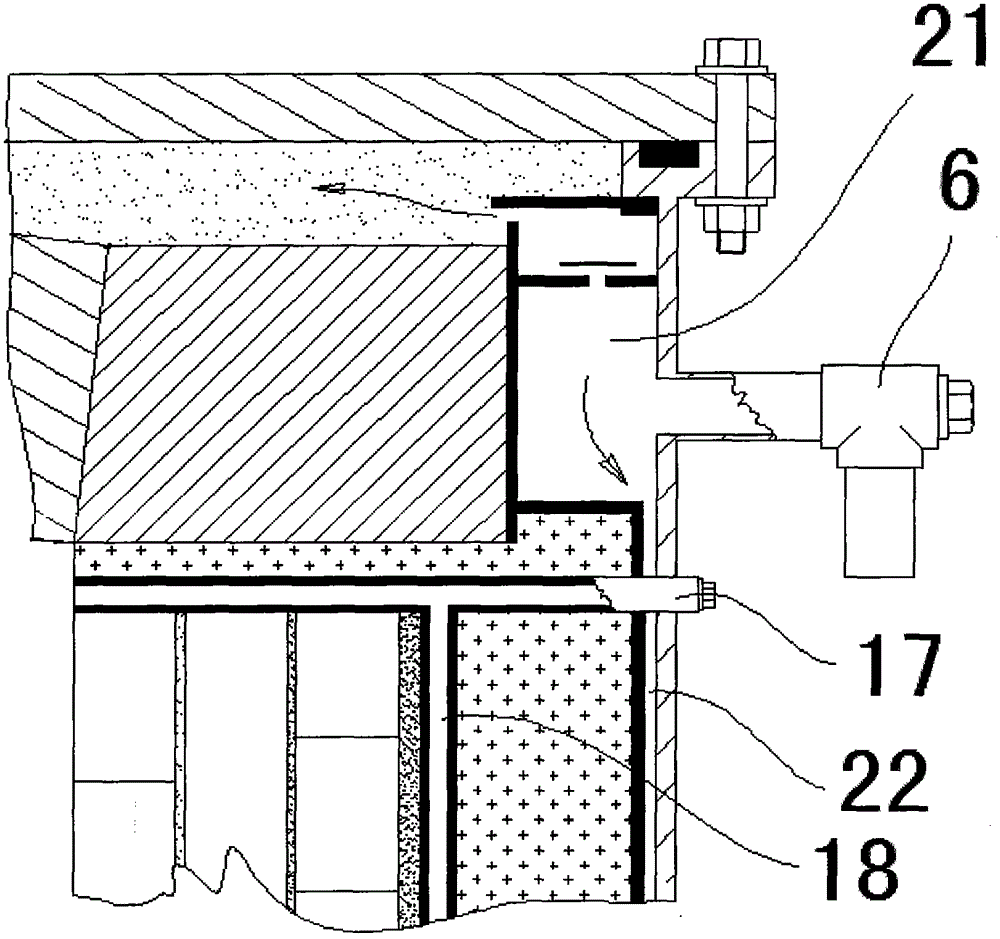

Heat-storage maintaining furnace

InactiveCN104942273AUniform stressReduce consumptionMolten metal conveying equipmentsBrickAluminum foil

The invention discloses a heat-storage maintaining furnace and relates to metallurgy aluminum casting. The heat-storage maintaining furnace comprises a furnace (1), a hearth (2) is shaped in water drop arc, the vertical wall of the hearth (2) of two symmetric large arcs (32) is tangential to the vertical wall of a small arc (31), the wall and the bottom of the hearth (2) are built by more than three layers of bricks, a liner layer is made of ceramic bricks, and the other layers are heat-insulation bricks. An aluminum foil is attached to the surfaces of the heat-insulation bricks, a powder layer (4) is formed between the brick layers, microfine powder (4) is filled in the power layer (4) and is made of ores smaller than 320 meshes, specific gravity is larger than or equal to 2.7 g / cm, and powder smaller than or equal to 320 meshes contains fine powder smaller than or equal to 800 meshes. The hearth (2) is horizontally provided with an air passage (17) in the upper portion, the air passage (17) is communicated with a vertical air guide pipe (18), and the vertical air guide pipe (18) is connected with a heat accumulator (3).

Owner:李宗保

Novel coating having electromagnetic radiation resistance and anti-static function

A novel coating having electromagnetic radiation resistance and an anti-static function is characterized by comprising 85% of environment-friendly coating, 10% of carbon nano-tube, 1.5% of polypeptide molecules and 3.5% of conductive mica powder. Wet method muscovite serves as a substrate for the conductive mica powder, a nanotechnology is adopted, and a conductive oxide layer is formed on the surface of the substrate through surface treatment and semiconductor doping treatment. The long diameter of the carbon nano-tube is not larger than 150 nm. The problem that a coating manufactured according to a conventional preparation process does not have dual effects of static resistance and radiation resistance is solved, so that the construction becomes simple and convenient. The use range of the carbon nano-tube is expanded, the damage to the lung of the human body and the skin caused by the carbon nano-tube is reduced, the coexistence of people and the environment is harmonized while the energy saving and environmental protection are achieved, and the novel coating can well be used for oil tanks, gas stations, factories, homes and intensive radiation region environments near high-tension cables or substations and the like and the environment where the static requirements are high.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Concrete with high toughness

The invention relates to concrete with high toughness, which is used in the technical field of constructional engineering. The concrete comprises the following components in portion by weight: 30 to 50 portions of cement, 30 to 50 portions of quartz sand, 2 to 25 portions of steel fiber, and 10 to 20 portions of water. The concrete has the advantages that the concrete has ultrahigh strength and high elastic modulus, improves breaking energy, has high toughness and high durability, prolongs the service life of a structure, does not need reinforcing bars, lowers construction cost of engineering, and can be used for pouring large-span concrete bridges and high-rise building struts and replace steel to pour large-sized pressure pipelines and the like.

Owner:朱世忠

Anti-sticking coating used for motor and electric appliance connection wire and its coating process

InactiveCN102559046AGood uniformityPrevent contactCoatingsCable/conductor manufactureMethyl siliconeDimethyl benzene

The present invention discloses an anti-sticking coating used for an motor and electric appliance connection wire and its coating process, the anti-sticking coating comprises one or more of 106 silicone rubber, 107 silicone rubber, 239 silicone grease, 239-3 silicone grease and 201-100 methyl silicone oil, and a diluent is 120# industrial gasoline. The present invention is characterized by using industrial gasoline to replace diluents such as toluene, xylene and styrene which are commonly used in industry, and the toxicity to environment and the human body can be greatly reduced. The coating process of the present invention possesses good control of uniformity and thickness of an anti-sticking protective film which possesses effects for preventing the contact of paint liquid, metal filaments and an insulating sleeve contact during the impregnation process, and inhibiting the hardened metal filaments due to bonding, and bonding, swelling, sticky, fracturing, damage phenomena of the insulating sleeve.

Owner:SHANGHAI YUHONG SPECIAL WIRE & CABLE

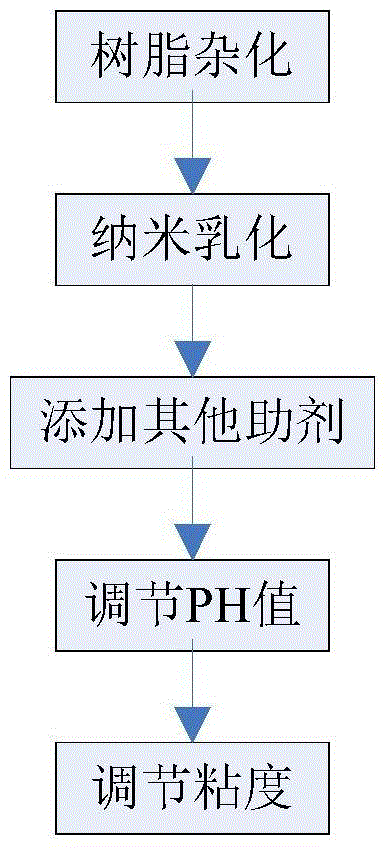

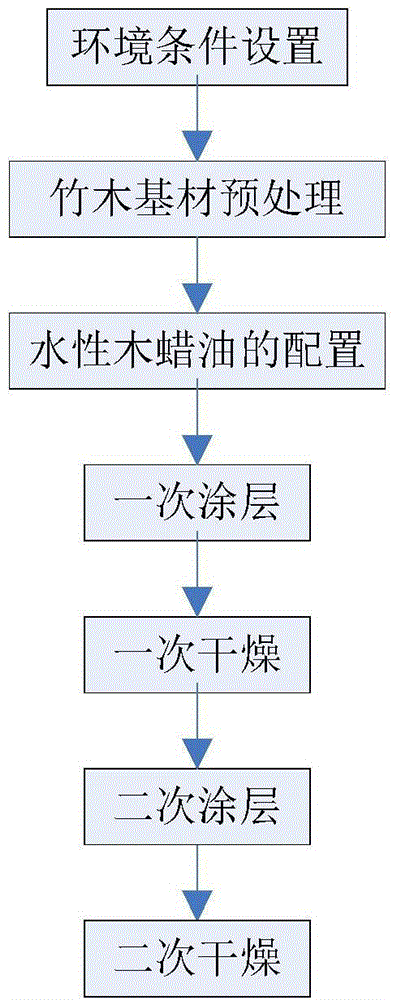

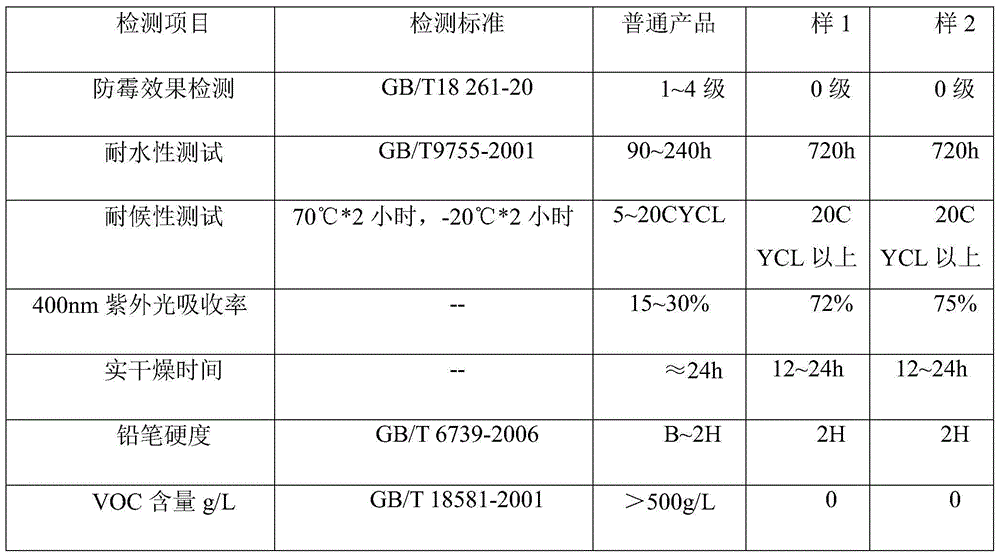

Durable anti-mildew aqueous wood wax oil, preparation method thereof and application technology thereof

InactiveCN105860793ADoes not change natural propertiesBreathe freelyAntifouling/underwater paintsPretreated surfacesWaxFoaming agent

The invention discloses durable anti-mildew aqueous wood wax oil. The wood wax oil comprises the following components: 40-80% of aqueous urethane oil, 0.5-10% of a nano oxide, 0.2-5% of a silane coupling agent, 10-40% of water, 2-4% of a film-forming auxiliary agent, 0.05-5% of a dispersant, 0.05-5% of a levelling agent, 0.05-5% of an anti-foaming agent, 0.05-5% of a wetting agent, and 0.2-0.4% of a pH conditioning agent. The invention also provides a preparation method of the durable anti-mildew aqueous wood wax oil and an application technology thereof. The durable anti-mildew aqueous wood wax oil has good environmental protection performance, has deep and durable protection performance on bamboo and wood base materials, and has excellent moisture-resistance performance and is not easy to go moldy.

Owner:HUNAN BANFERT NEW MATERIALS TECH

Al4SiC4-Al2OC composite refractory materials and preparation method thereof

The invention relates to a composite refractory material of Al4SiC4 and Al2OC and a method for preparing the same. The technical proposal adopted by the invention is as follows: firstly, 30 to 70 weight percent of bauxite, 10 to 45 weight percent of industrial carbon powder, and 20 to 55 weight percent of metallic aluminium powder are mixed; and the mixture is added with 3 to 10 weight percent of bonding agent to be stirred for 5 to 25 minutes, is pressed to be shaped, and is dried for 12 to 36 hours under the condition of between 60 and 110 DEG C or naturally dried for 24 to 48 hours indoors; and secondly, the mixture is sintered for 2 to 6 hours under argon atmosphere and under the condition of between 1,600 and 1,800 DEG C, and is cooled naturally to obtain the composite refractory material of the Al4SiC4 and the Al2OC. The composite refractory material has the characteristics of rich raw material resource, low production cost and easy industrialized production. The composite refractory material of the Al4SiC4 and the Al2OC prepared by the method not only has excellent performance, but also can prolong the service life, is suitable for a novel furnace lining material for nonferrous metal and iron and steel smelting equipment, and particularly suitable for producing ladle inside lining and refining furnace lining of clean steel such as low carbon steel, ultra-low carbon steel and so on.

Owner:WUHAN UNIV OF SCI & TECH

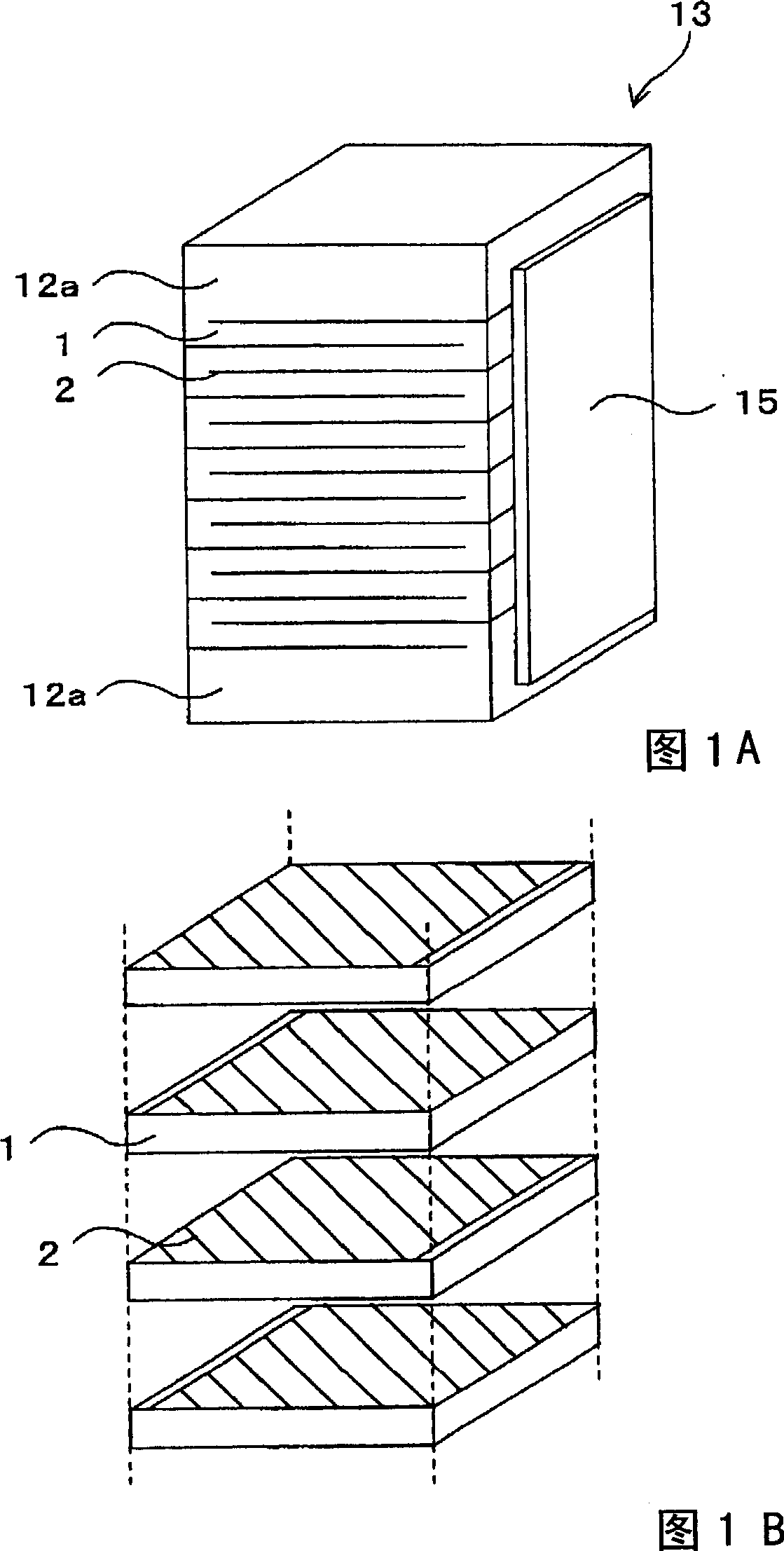

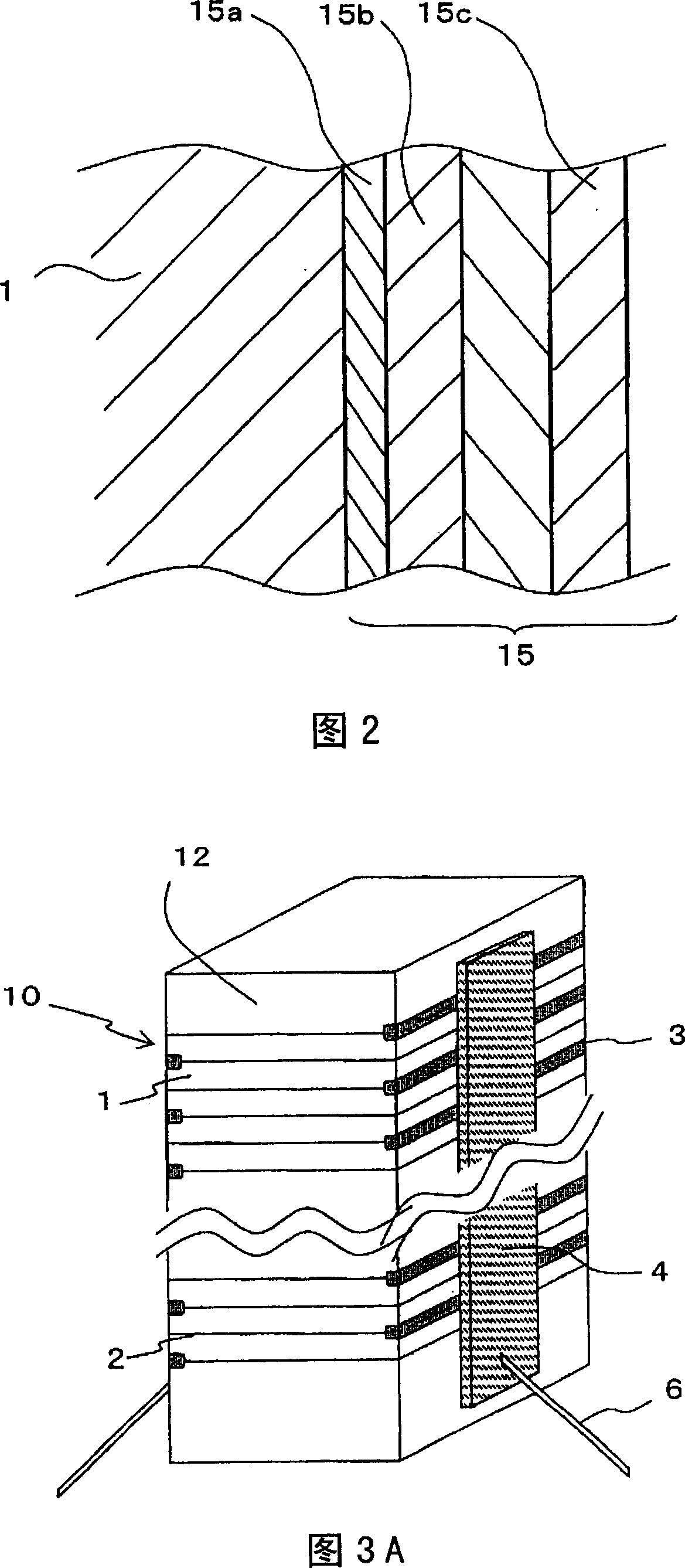

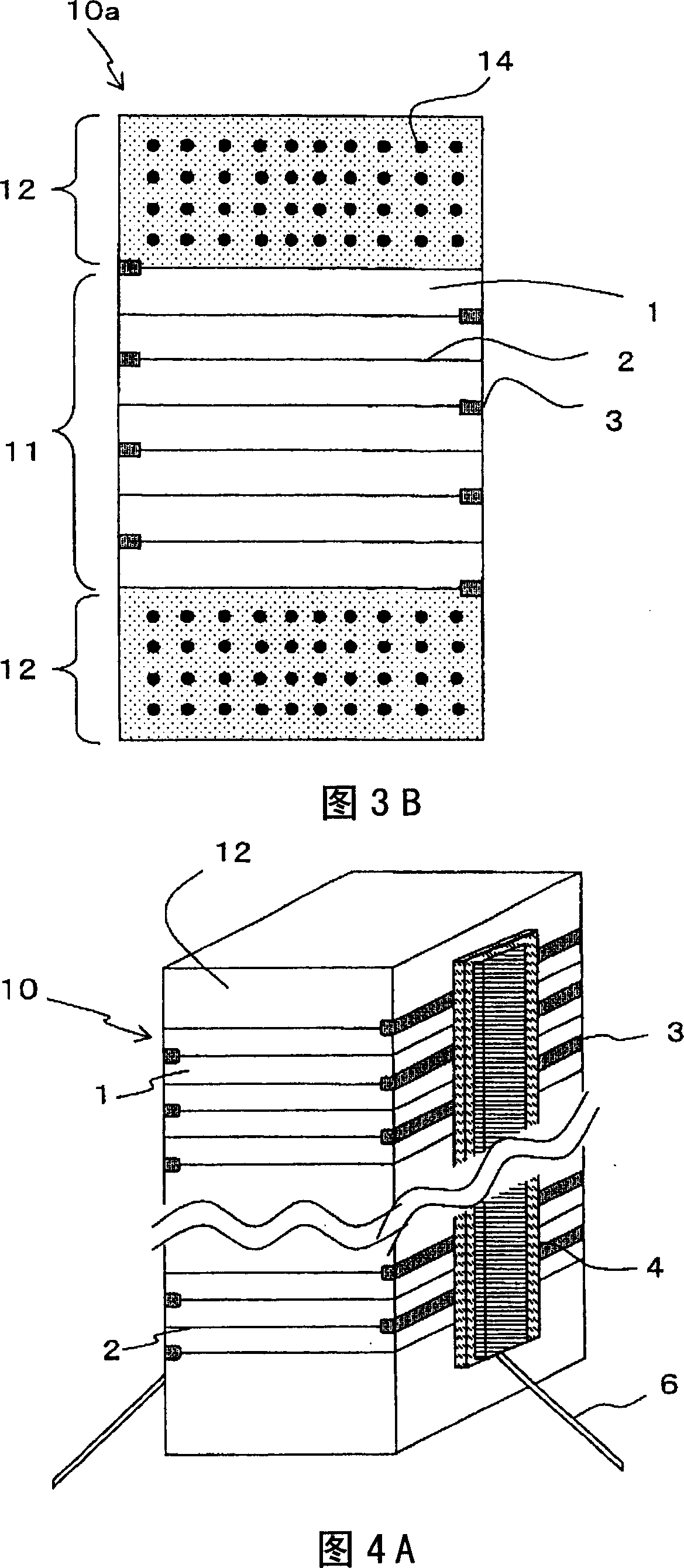

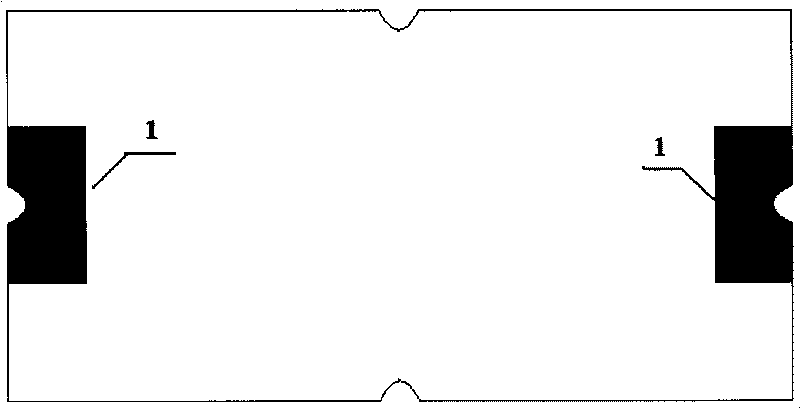

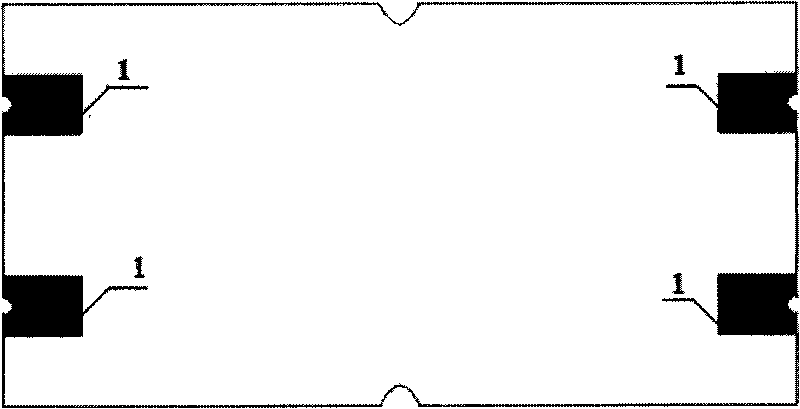

Multilayer piezoelectric element and its manufacturing method

ActiveCN1938873ABlock crackStop crackingPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesVoltageElectrode

A multilayer piezoelectric element excellent in durability comprises a multilayer body and external electrodes. The multilayer body has an active portion which is formed by alternating at least one piezoelectric body and internal electrodes including first and second internal electrodes and expands / contracts depending on the voltage applied between the first and second internal electrodes. The external electrodes are formed on two side surfaces of the multilayer body. One of the external electrodes is connected to the first internal electrode, and the other is connected to the second internal electrode. Each external electrode is composed of three or more layers including a first layer in contact with the side surface of the multilayer body and a second layer formed on the first layer.

Owner:KYOCERA CORP

MgO-SiC-C fire resistant pouring material based on forsterite and method for preparing same

The invention relates to a MgO-SiC-C fireproof casting material based on forsterite-C and a preparation method thereof. In the technical proposal, forsterite and C powder are mixed according to the mol ratio of (1 to 4) to (3 to 6), and a binder of 1 to 10 percent of the mixture by weight is added. After the mixture is beaten, moulded and dried, the mixture is synthesized into MgO-SiC-C material for two to eight hours at the temperature of 1450 to 1700 DEG C under the reducing atmosphere. 10-25 weight percent of 10-5mm granule, 15-25 percent weight of 5-3mm granule, 15-25 weight percent of 3-1mm granule, 10-20 weight percent of 1-0mm granule, 25-35 weight percent of 0.1-0mm fine powder are mixed with 2-8 weight percent of the binder, and are beaten uniformly, thus getting the MgO-SiC-C fireproof casting material. The manufacturing cost of the invention is low; the process is simple; and the fireproof casting material prepared has good performance, and is widely applied.

Owner:WUHAN UNIV OF SCI & TECH

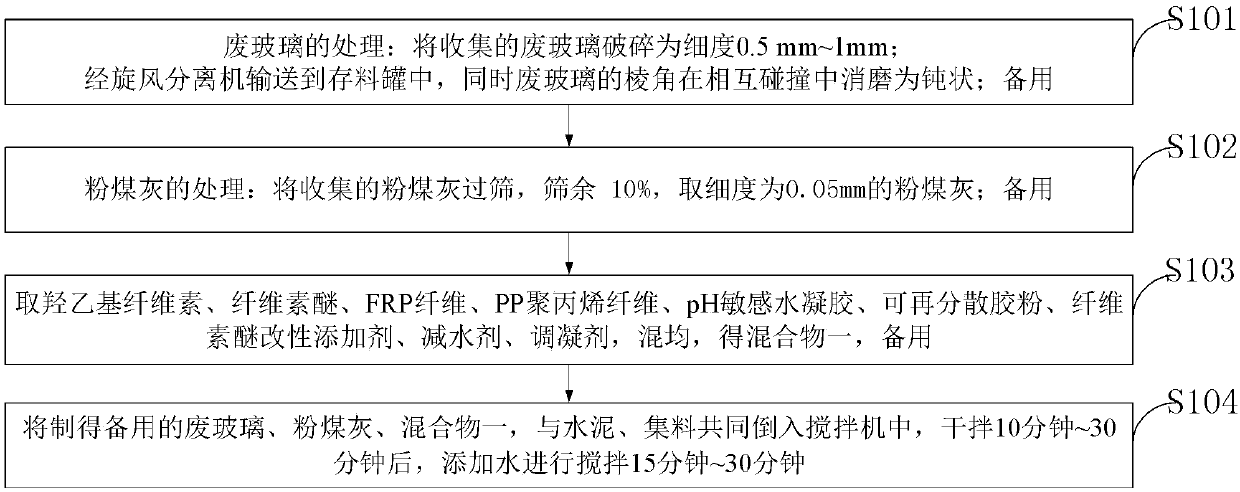

High-toughness anti-cracking cement concrete and preparation method thereof

The invention belongs to the technical field of building materials, and discloses high-toughness anti-cracking cement concrete and a preparation method of the high-toughness anti-cracking cement concrete. The high-toughness anti-cracking cement concrete comprises the following raw materials in a mass ratio: 3% to 8% of hydroxyethyl cellulose, 0.2% to 0.8% of cellulose ether, 4% to 6% of FRP fiber,3% to 5% of PP fiber, 0.2% to 0.8% of pH sensitive hydrogel, 20% to 25% of cement, 45% to 55% of aggregate, 1% to 2% of redispersible rubber powder, 0.5% to 1% of a cellulose ether modified additive,1% to 2% of a water reducer, 0.1% to 0.2% of an adjustable solidification agent, 5% to 10% of waste glass and 10% to 15% of fly ash. According to the invention, the FRP fiber is a high-strength material to improve the strength of cement concrete, and the PP fiber is a high-toughness material to improve the toughness of the cement concrete, and effectively prevent the drying shrinkage and crackingof the concrete.

Owner:NANTONG INST OF TECH

Preparation method of autoclaved lightweight high-strength high-fly-ash-content ceramsite

InactiveCN112250334AEasy accessLow costSolid waste managementCeramic shaping apparatusProcess engineeringFly ash

The invention discloses a preparation method of autoclaved lightweight high-strength high-fly-ash-content ceramsite, which comprises the following steps: preparing raw materials, mixing the raw materials, preparing a wet material, performing balling by a balling disc, performing screening, performing natural curing, carrying out moisturizing curing, carrying out autoclaved curing and the like.According to the method, coal ash is mainly used as a main raw material, and the mixing amount of the coal ash reaches 90% or above; The preparation method is a preparation method of the fly ash ceramsitewith a high mixing amount, fly ash is cheap industrial solid waste, and the higher the using amount is, the lower the cost is, so that the cost of unfired fly ash is reduced to a certain extent, meanwhile, the comprehensive utilization way of fly ash is increased, and the comprehensive utilization rate of fly ash is increased. The maintenance process provided by the invention is relatively simpleand effective, cement is hardened through natural maintenance, the ceramsite has certain initial strength, water required by a silicon-calcium reaction is provided for the ceramsite through moisturizing maintenance, the ceramsite is in a humid state, cracking and autoclaved maintenance in the autoclaved maintenance process are avoided, the ceramsite preparation process is simplified, and the utilization rate of raw materials is increased.

Owner:ANHUI GAODI BUILDING MATERIAL CO LTD +1

Method for packaging SMT crystal resonator/oscillator by epoxy resin mold

The invention discloses a method for packaging an SMT crystal resonator / oscillator by an epoxy resin. The method comprises the following steps of: A10, welding welding-points on a base of a crystal resonator / oscillator with a base plate into a whole body by solders with the thickness less than 40 microns; A20, placing the crystal resonator / oscillator welded with the base plate in a mold, pouring thermosetting epoxy resin with the temperature of 160-180 DEG C in a mold cavity under the pressure of 2-4 Mpa, wherein the thermosetting epoxy resin is doped with spherical silicon granules with the diameter of 13-75 microns; and A30, after passing the curing time of 90 seconds, de-molding to obtain the SMT crystal resonator / oscillator. The invention can efficiently prevent materials of plastic package from flowing into intervals between the base of the crystal resonator / oscillator and the base plate such that the pressure of injection molding does not act on the base of the crystal resonator / oscillator; therefore, the cracking of the base of the crystal resonator / oscillator is prevented, the finished product ratio is improved, and effective guarantee is provided for the batch production of the plastic package of the crystal resonator / oscillator mold.

Owner:WUHAN WINNINGCHINA MICROSYST TECH

Porcelain-like paint and preparation method thereof

InactiveCN106905793AImprove the decorative effectImprove protectionAntifouling/underwater paintsPaints with biocidesCelluloseEmulsion

The invention discloses a porcelain-like paint and a preparation method thereof, which relates to the technical field of the porcelain-like paint. The porcelain-like paint comprises the following raw materials by parts: 60-80 parts of nanoparticles, 50-60 parts of a modified acrylic resin emulsion, 30-40 parts of modified phosphogypsum powder, 20-30 parts of ceramic powder, 20-30 parts of a refractory material, 2-10 parts of an auxiliary agent, 2-8 parts of a color paste, 2-8 parts of cellulose, and 40-80 parts of deionized water. The preparation method comprises the following steps: 1) preparing the auxiliary agent; 2) preparing the modified acrylic resin emulsion; 3) preparing the modified phosphogypsum powder; 4) preparing a glue solution; and 5) preparing the finished product. The coating has the advantages that the coating is flat and bright, the corrosion-resistant and mildew resistant performances are high, waterproofness is good, age proof performance is good, washability frequency is many, the paint has the advantages of safety and no toxic, and high environmental protection performance, and has good decoration and protection effects for inner walls.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

Masonry mortar made from mine tailings

InactiveCN102260066ASolving resource constraintsAchieve scale developmentSolid waste managementRural landSoil science

The invention belongs to the technical field of building materials, in particular to a masonry mortar made from tailings. It is characterized in that the production of masonry mortar made of tailings that meets M2.5-M10 has the following proportions by weight: 100-245 parts of Portland cement, 1270 parts of tailings, 234-56 parts of lime paste, and 1 part of water reducing agent. -1.36 parts, water 277 parts. The present invention uses tailings with a particle size of 0.15-0.3 mm, which is obtained by grading through screening equipment in the gravity separation and magnetic separation processes, and its purpose is to avoid the incorporation of harmful components and the fluidity of the mortar with too fine tailings particle size, which cannot construction. Its production cost is about 20 yuan per cubic meter, about 60 yuan can be saved per cubic meter, and the annual benefit is about 180 million yuan. In addition, the replacement of river sand with tailings can also reduce the discharge of mine tailings, extend the service life of tailings ponds, reduce the damage to natural rivers caused by the mining of river sand, and ultimately achieve the purpose of less rural land occupation and environmental protection.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com