Method for preparing high impact modified material with waste and old polystyrene plastics

A technology for waste polystyrene and modified materials, which is applied in the field of waste polystyrene recycling and modification, can solve the problems of reducing the rigidity and strength of materials, and achieve the effects of increasing tensile strength, increasing impact strength and improving impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

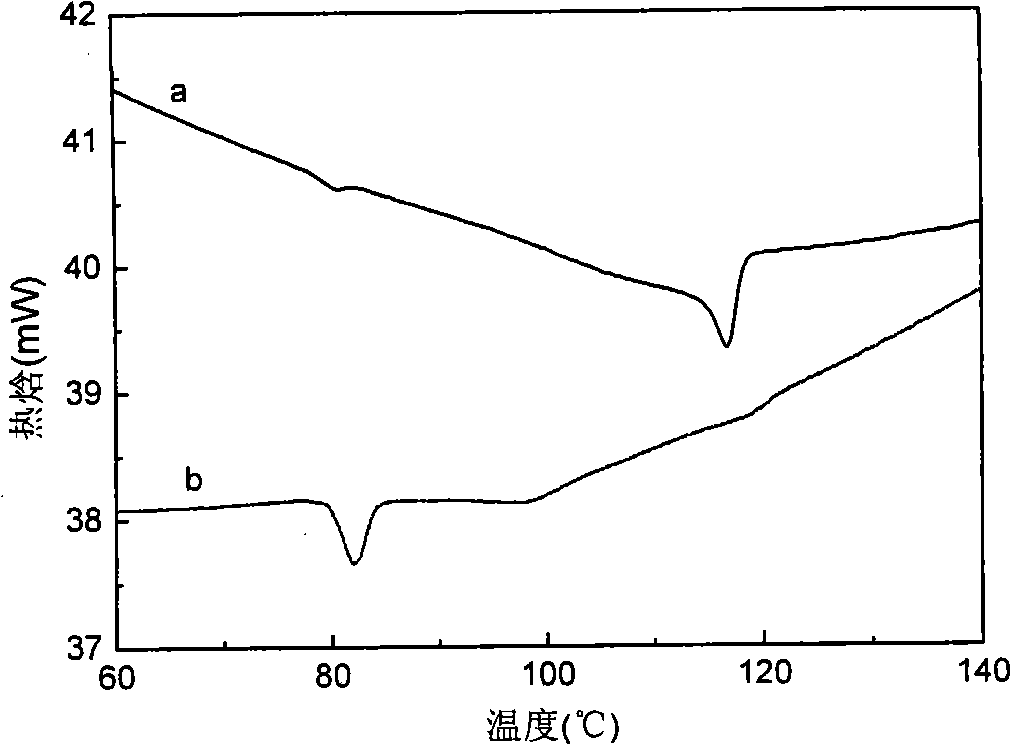

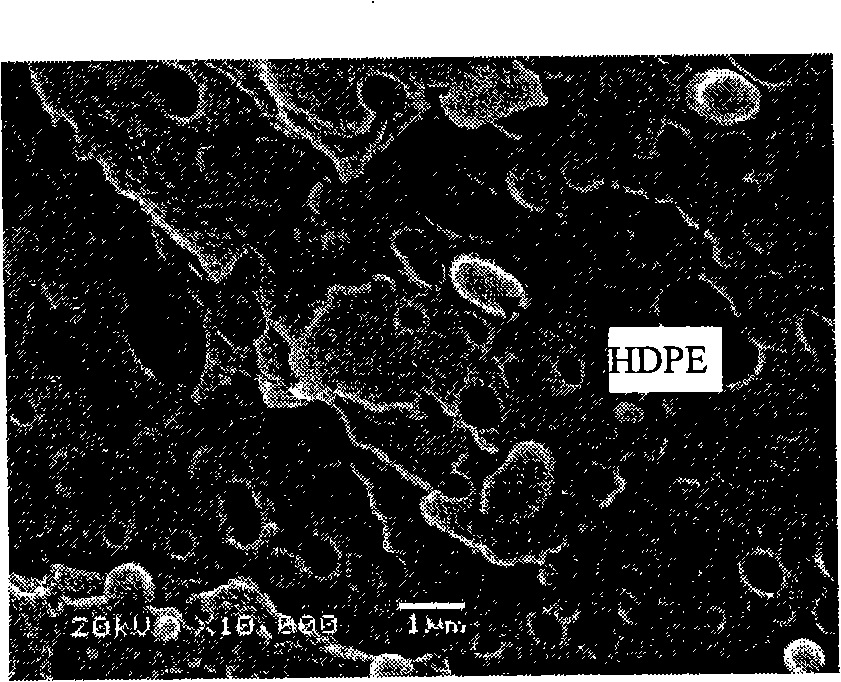

[0036] First, 72 parts of waste polystyrene with a melt index of 20g / 10min, 10 parts of styrene-butadiene rubber, 8 parts of high-density polyethylene with a melt index of 5.5g / 10min, styrene-ethylene-butadiene-styrene copolymer 10 parts and 0.001 parts of antioxidant 1076 were stirred and mixed evenly, then put into a twin-screw extruder, and melted and blended at the temperatures of 150°C, 170°C, 190°C, 210°C, 210°C, and 200°C respectively to obtain increased Toughened modified waste polystyrene material. The notched impact strength measured by the material is 9.27KJ / m 2 , The tensile strength is 24.13MPa.

Embodiment 2

[0038] First, 60 parts of waste polystyrene with a melt index of 23g / 10min, 28 parts of natural rubber, 5 parts of high-density polyethylene with a melt index of 3.0g / 10min, and 7 parts of styrene-isoprene-styrene thermoplastic elastomer 1010 and 0.002 parts of antioxidant 1010 were stirred and mixed evenly, then put into a twin-screw extruder, and melted and blended at the temperatures of 150°C, 170°C, 190°C, 210°C, 210°C, and 200°C to obtain toughening Modified waste polystyrene material. The notched impact strength measured by the material is 10.22KJ / m 2 , The tensile strength is 23.12MPa.

Embodiment 3

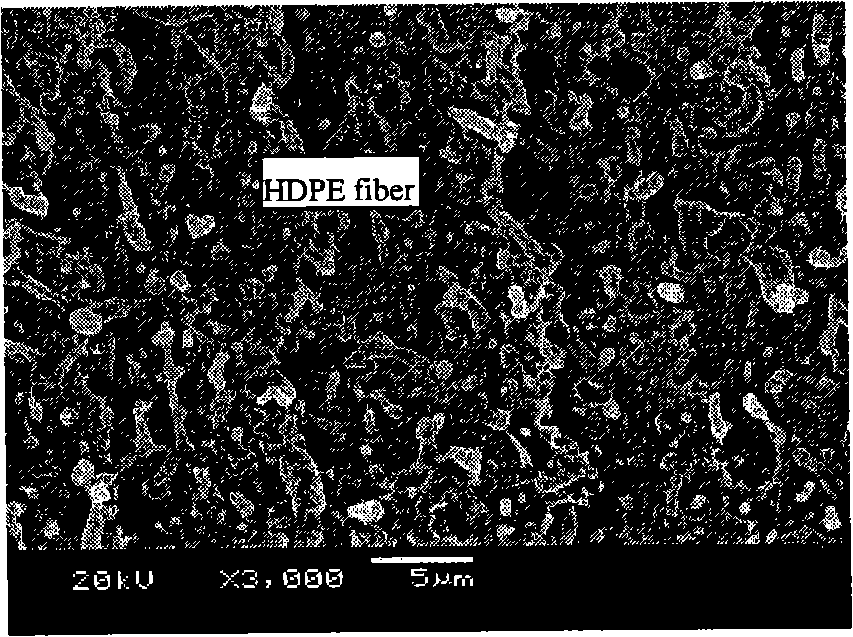

[0040] First, 80 parts of waste polystyrene with a melt index of 12g / 10min, 10 parts of polyolefin elastomer POE, 6 parts of ultra-high molecular weight polyethylene recycled materials with a melt index of 6g / 10min, 4 parts of styrene grafted ethylene copolymer and Stir and mix 0.003 parts of antioxidant 1010 evenly, then put it into a single-screw extruder, melt and blend at the temperatures of 150°C, 170°C, 190°C, 210°C, 210°C, and 200°C in each zone to obtain toughening modification Waste polystyrene material. The notched impact strength measured by the material is 8.12KJ / m 2 , The tensile strength is 25.55MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com