Patents

Literature

216results about How to "Act as a bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

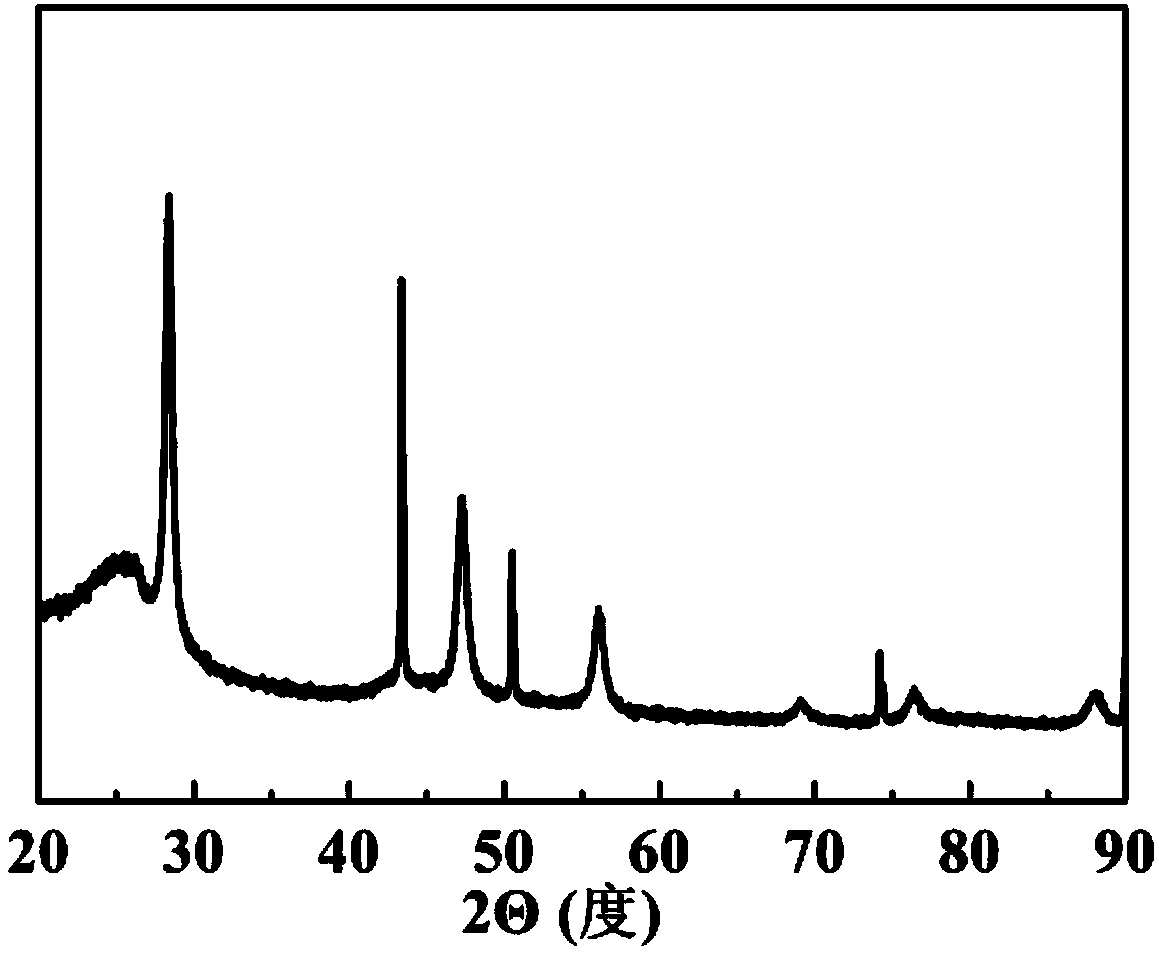

Double-shell-layer structure composite material, preparation method of double-shell-layer structure composite material, and lithium ion battery containing composite material

ActiveCN108511719ASimple processEasy to operateCell electrodesSecondary cellsCarbon coatingCarbonization

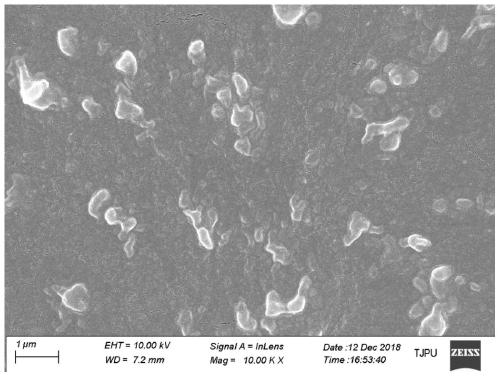

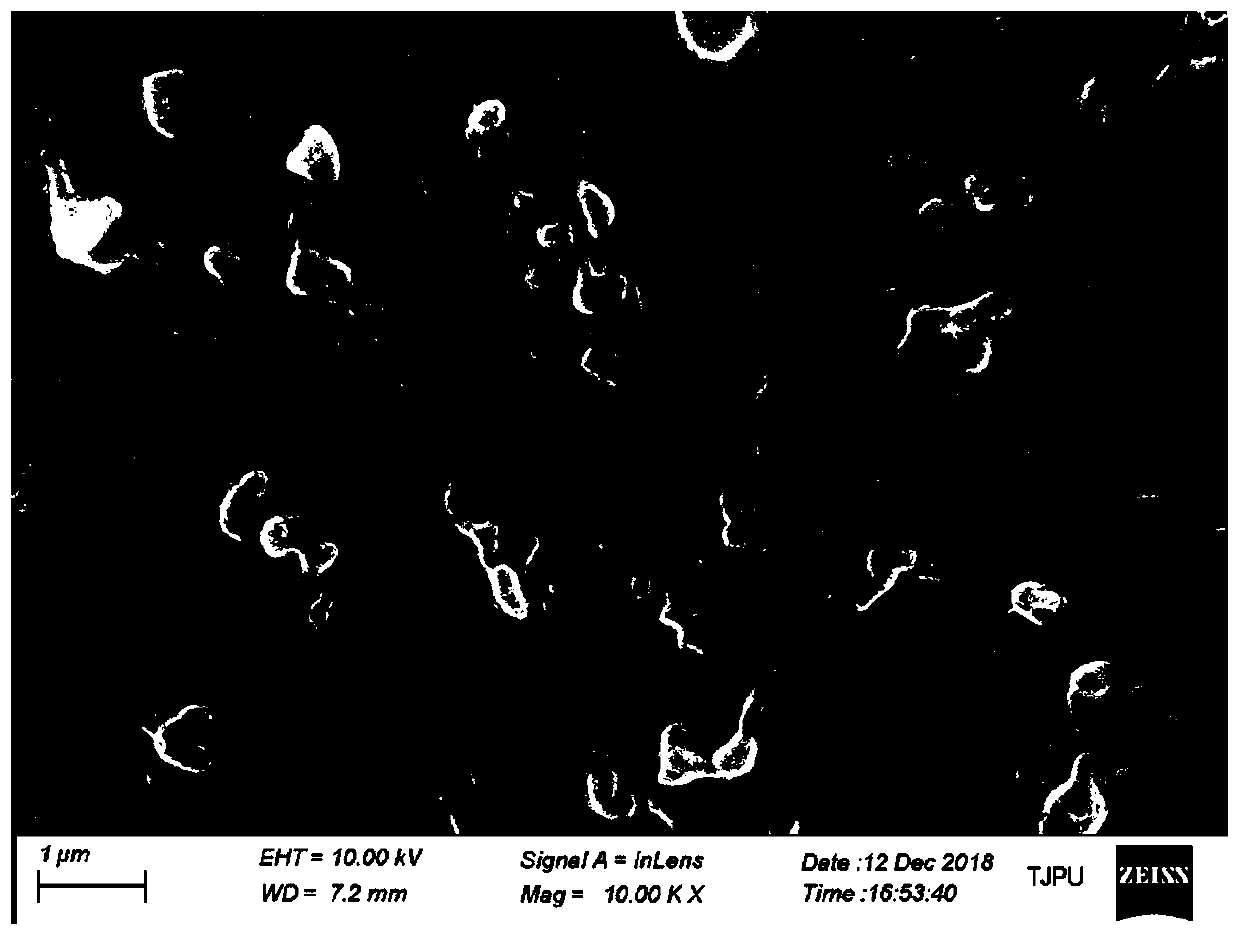

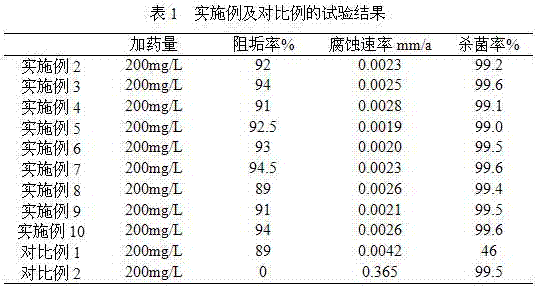

The invention discloses a double-shell-layer structure composite material, a preparation method of the double-shell-layer structure composite material, and a lithium ion battery containing the composite material. The double-shell-layer structure composite material comprises a nanometer silicon inner core, wherein a first coating layer and a second coating layer are sequentially arranged on the surface of the inner core; the first coating layer is nanometer metal particles embedded on the surface of the inner core; pores are formed between the nanometer metal particles; the second coating layeris a carbon coating layer positioned at the outer most layer of the composite material. Firstly, a layer of metal hydroxide covers in situ on the surface of the nanometer silicon particles; then, thesurface is subjected to organic carbon coating; the coating layer organic carbon is subjected to high-temperature carbonization, metal hydroxide of the first coating layer is firstly decomposed intometal oxides and is then reduced into nanometer metal simple substance particles by the carbon coating layer of the second coating layer; a great number of pores are left; the double-shell-layer structure composite material is obtained. The process is simple; when the composite material is used for a negative electrode of the lithium ion battery, the high specific volume and excellent circulationperformance are realized.

Owner:BTR NEW MATERIAL GRP CO LTD

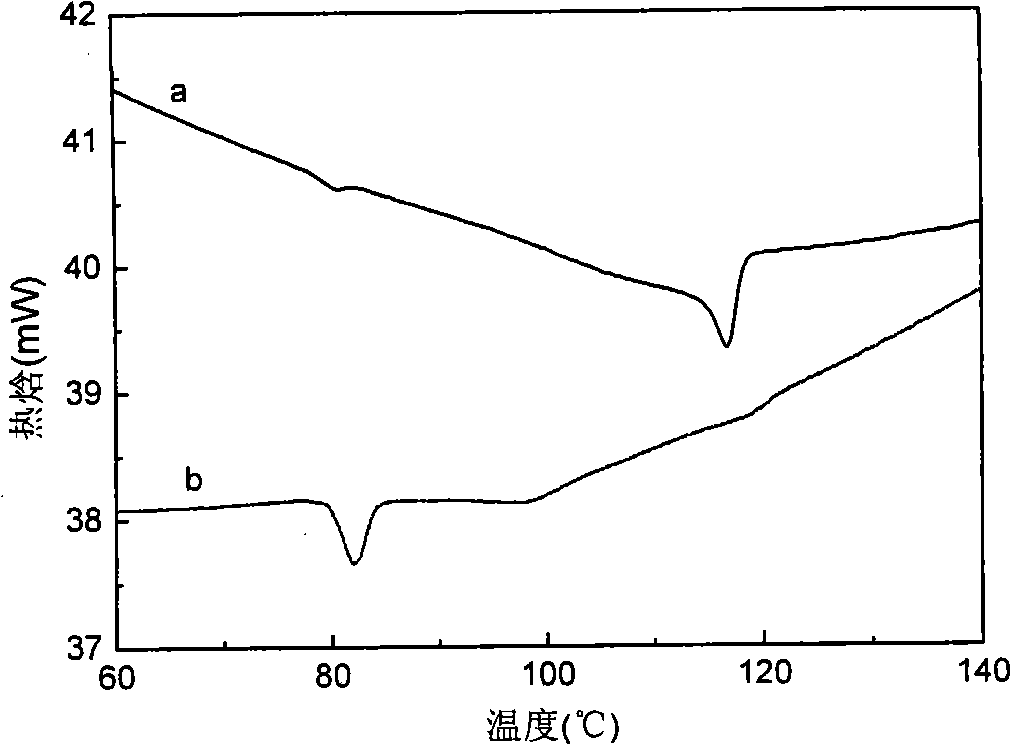

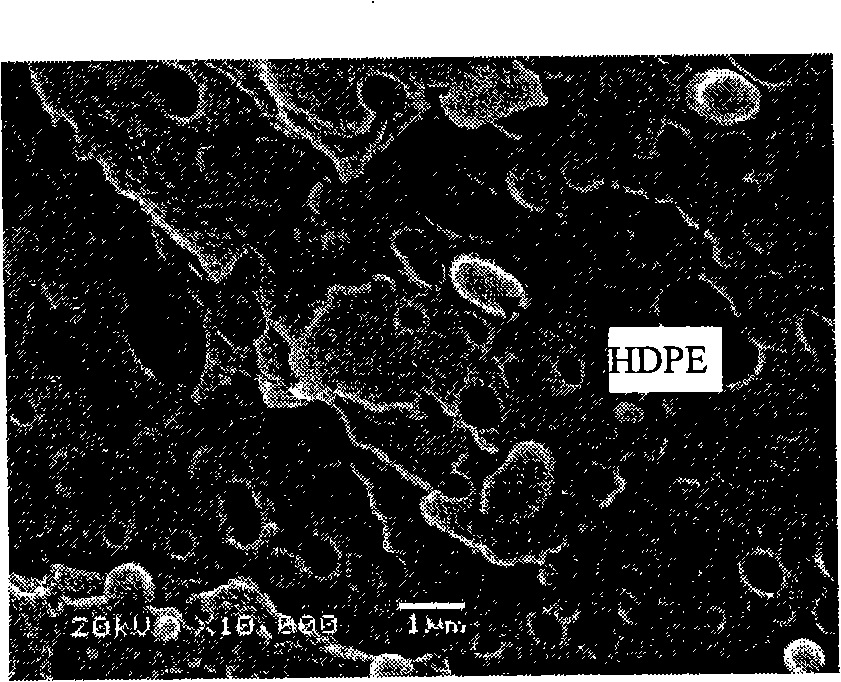

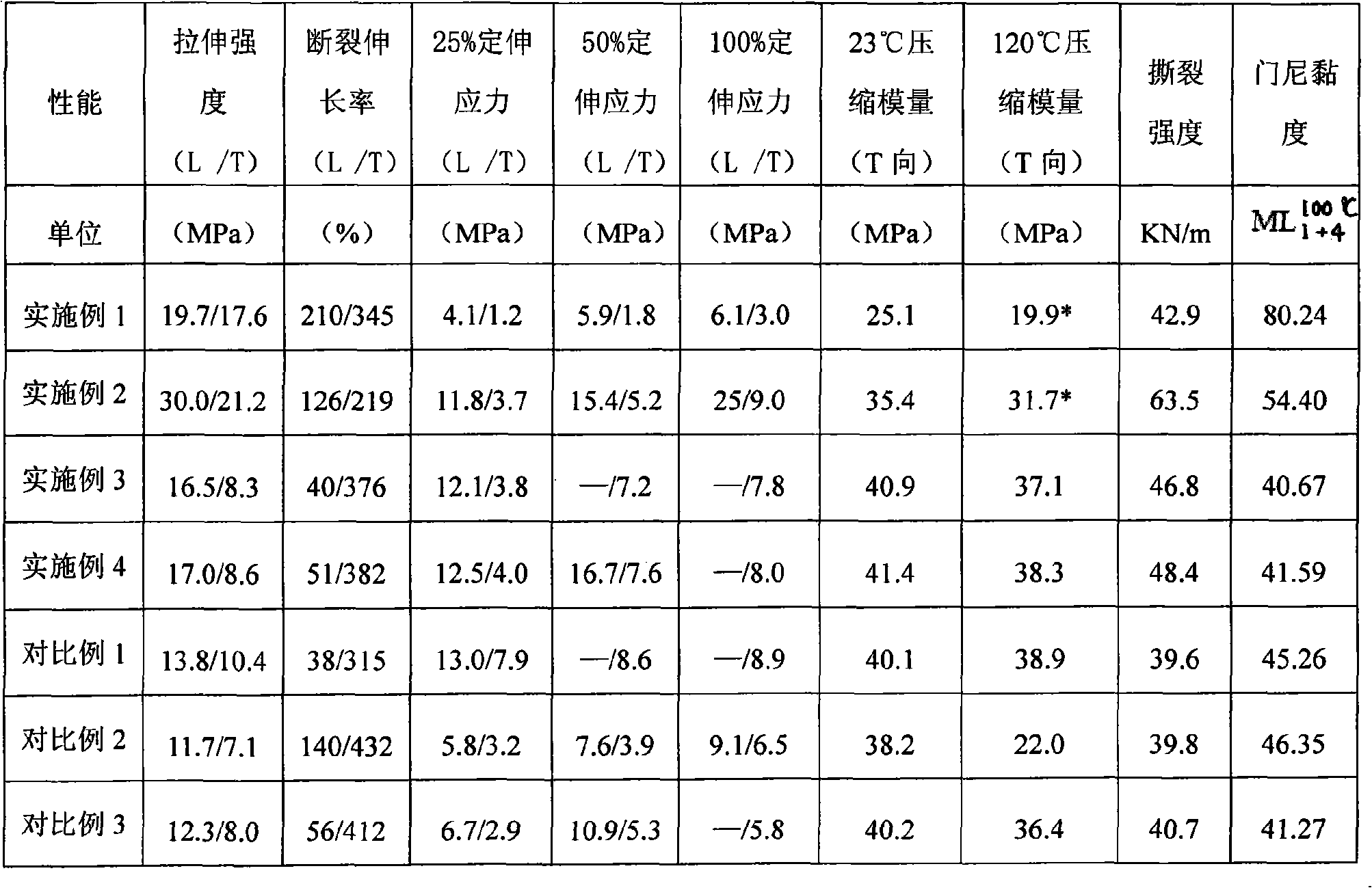

Method for preparing high impact modified material with waste and old polystyrene plastics

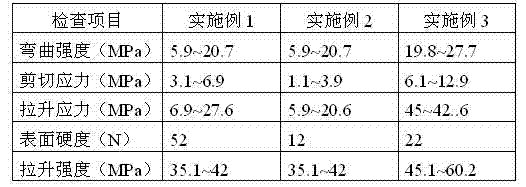

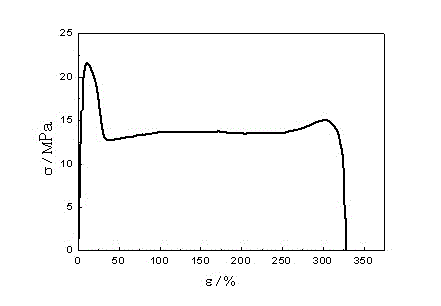

The invention discloses a method for preparing high-impact modified material from waste polystyrene plastic, which comprises the following steps: uniformly mixing 60 to 80 parts of waste polystyrene, 5 to 10 parts of polyethylene, 10 to 30 parts of elastomer, compatibilizer, etc. by stirring, adding to a screw extruder, and melting and blending at 150 to 210 DEG C, wherein the melt index ratio of polyethylene to polystyrene is equal to or less than 0.5. Due to the addition of small amount of polyethylene, the viscosity ratio of polyethylene to polystyrene and the crystallization behavior and the phase size of polyethylene can be controlled by restricting the melt index of waste polystyrene and polyethylene, so that the obtained modified material has a notched impact strength 8 to 10 times as high as that of original waste polystyrene and can maintain or even improve the tensile strength of polystyrene. The prepared modified polystyrene can be used for producing parts of middle- and high-level household appliances such as computer and air conditioner as the substitute of high-impact polystyrene new material, thus achieving remarkable social and economic benefits.

Owner:SICHUAN UNIV

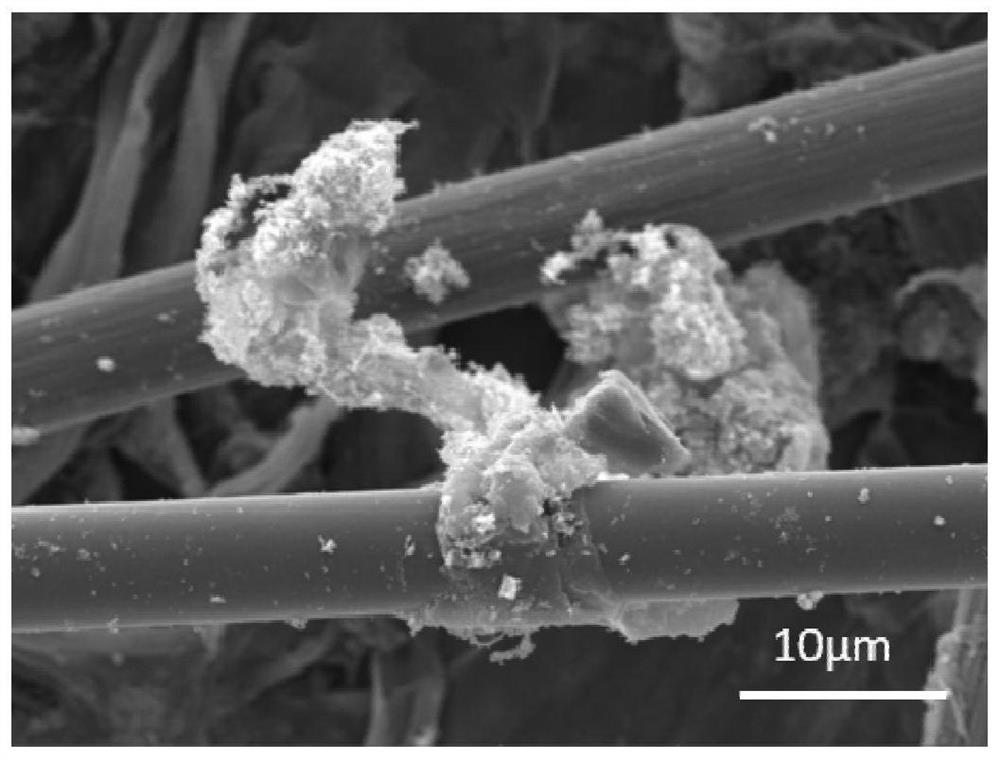

Micron-nano short-fiber rubber composite material for automobile driving belt and method for preparing same

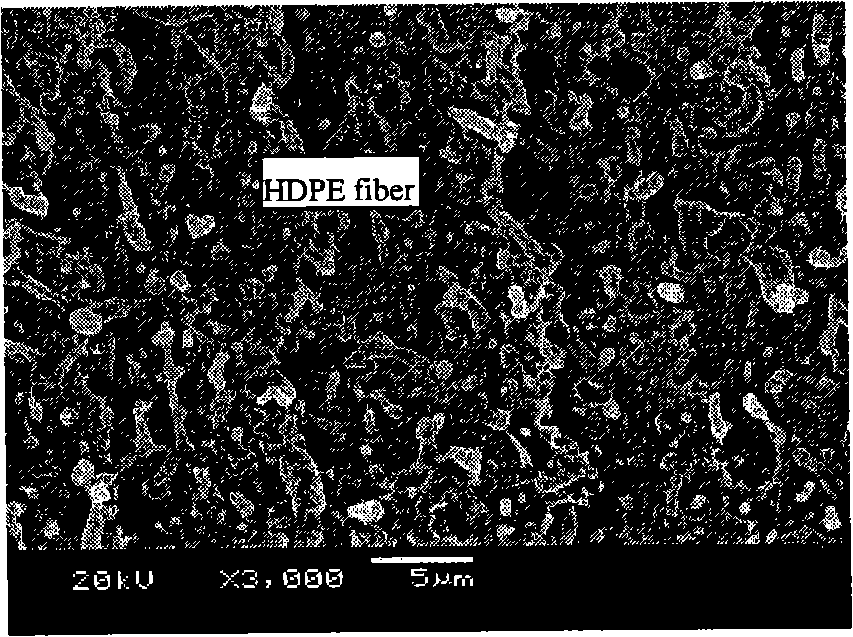

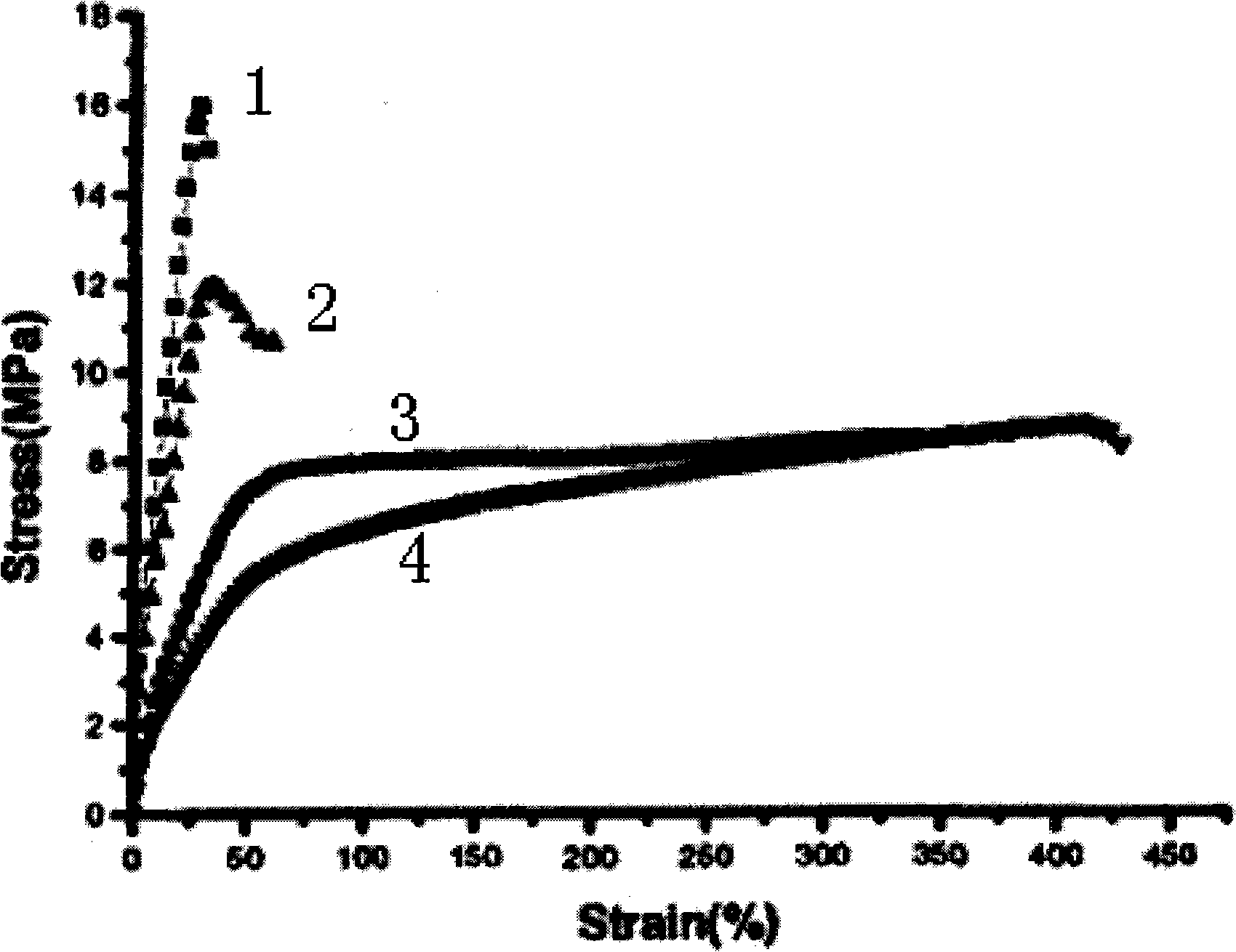

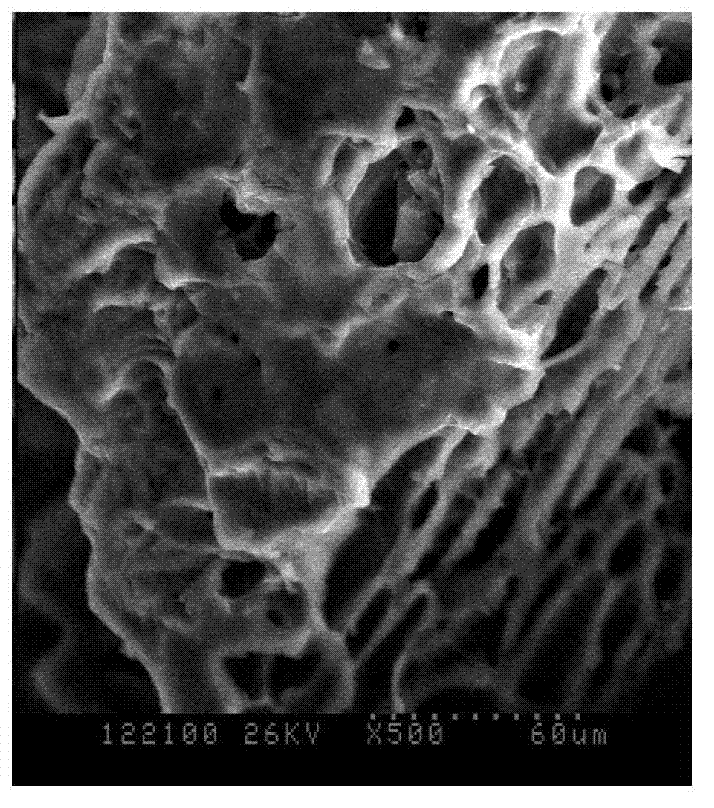

InactiveCN101555335APulling out is not obviousEnhancement effect is goodDriving beltsCross-linkFiber

The invention discloses a micron-nano short-fiber rubber composite material for an automobile driving belt and a method for preparing the same. The method for preparing the micron-nano short-fiber rubber composite comprises the following steps: natural fibrillar silicate and silane coupling agent containing a double-bond functional group are added to a rubber matrix simultaneously and mechanically mixed with the same; after the natural fibrillar silicate is decomposed into nano short-fiber and modified, nano short-fiber is added to the mixture and mixed with the same, and unsaturated carboxylic acid metal salt, anti-aging agent, cross-linking agent, co-crosslinking agent and other auxiliary agents are added in sequence and uniformly mixed; and the new mixture is sheared, orientated and finally sulfurized, thus the micron-nano short-fiber rubber composite material is prepared. The micron-nano short-fiber rubber composite material is used as the base rubber of the automobile driving belt including a poly V-belt, a V-belt, a synchronous belt, and the like, has excellent mechanical property (anisotropic property), machinability and heat resistance, improves the high-temperature resistance of the automobile driving belt and prolongs the service life of the same.

Owner:BEIJING UNIV OF CHEM TECH

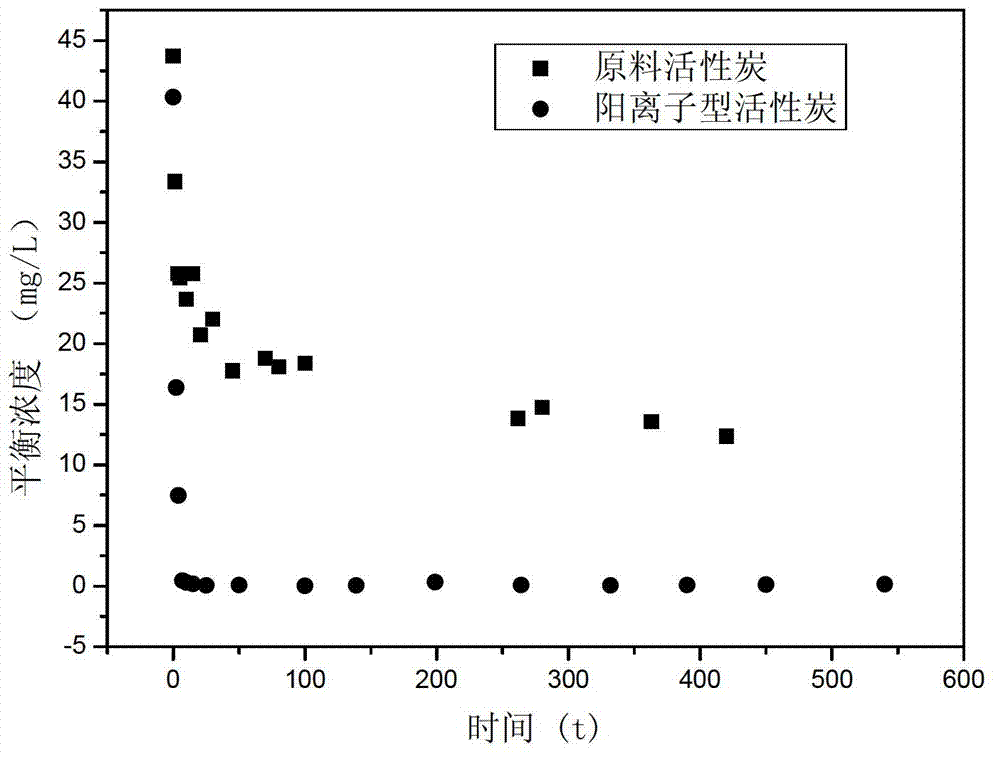

Preparation method for cationic-type activated carbon

ActiveCN102806073ATo overcome the characteristics of poor selectivityRemove fitOther chemical processesWater/sewage treatment by sorptionEpoxyWater baths

The invention relates to a preparation method for cationic-type activated carbon. The preparation method comprises the steps of washing, drying and crushing activated carbon, and oxidizing the activated carbon by concentrated hydrochloric acid or sulfuric acid so that the surface of the activated carbon has hydroxy; heating to the temperature of 80-87 DEG C under the condition of water bath, then adding epoxy chloropropane and N-N dimethylformamide, and stirring and reacting for 0.5-1.5h; and adding ethanediamine to react for 1-1.5h, then continuously dripping triethylamine to react for 0.5-1h, cooling to room temperature, and washing and drying so as to obtain the cationic-type activated carbon. An activated carbon product is the cationic-type activated carbon with positive charges, has a cationic group and a hydroxyl group, further has biodegradability, and is applicable to removing anionic-type pollutants in water.

Owner:SHANDONG UNIV

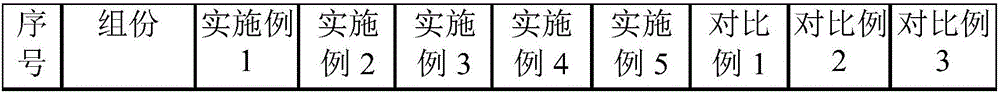

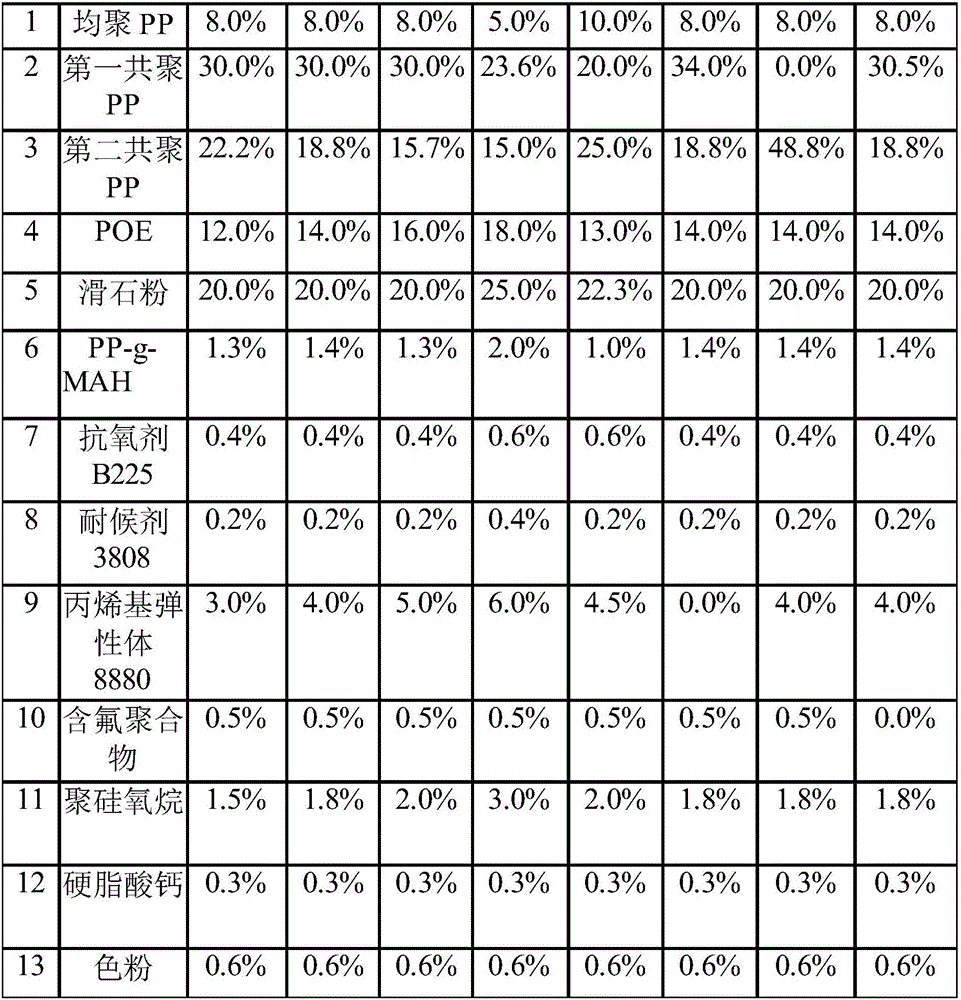

Modified polypropylene material for high-performance thin-wall automobile door panel and preparation method thereof

The invention belongs to the technical field of plastics modification and particularly relates to a modified polypropylene material for a high-performance thin-wall automobile door panel and a preparation method thereof. The material is prepared from, by mass, 5%-10% of homopolymerized PP, 20%-30% of first copolymerized PP, 15%-25% of second copolymerized PP, 12%-18% of toughening agent, 1%-2% of compatilizer, 0.4%-0.6% of antioxidant, 0.2-0.4% of weather resistance agent, 3%-6% of melting index regulator, 20%-25% of mineral enhancer, 1.5-3% of scratch resistant agent and 1-2% of other assistants. The preparation method of the modified polypropylene material comprises the steps of mixing, extrusion and granulation. The material prepared by adopting the preparation method has high liquidity, rigidity and toughness, can well meet the usage requirements of the thin-wall automobile door panel and is low in cost. Compared with the prior art, a high-liquidity allyl elastomer is used as the melting index regulator, the liquidity of the material is remarkably improved, and the thin-wall door panel forming requirements are met. In addition, high-liquidity polypropylene and a low surface energy polymer are used in a mixed mode, and the tiger skin stripe defects on the surface of the thin-wall door panel can be basically eliminated.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

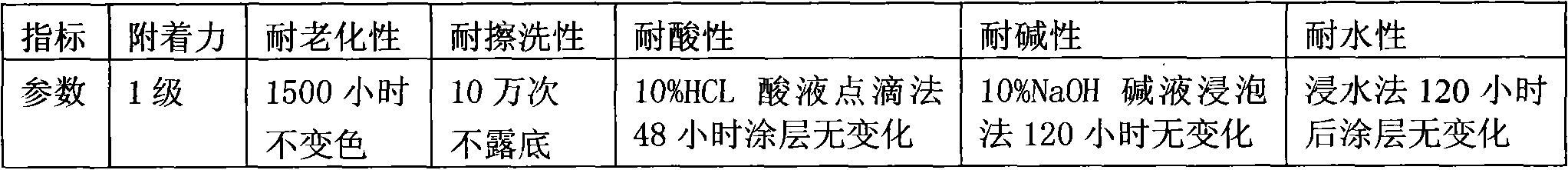

Novel environment-friendly method for refurbishing old ceramic tiles

The invention relates to a method for refurbishing old wall ceramic tiles. Three materials are adopted for overglazing the old ceramic tiles at normal temperature by four steps, and the steps are base layer treatment, coating of a bottom surface material special for ceramic tiles, coating of a middle layer material special for the ceramic tiles, and coating of a glaze material special for the ceramic tiles. The bottom surface material can be well combined with the surfaces of the ceramic tiles and cannot fall off; the middle layer is a bridge, has the property similar to the bottom layer and the surface layer, and can better bear the bottom layer and the glaze layer, so that the whole surface is more plump; and the glaze layer can achieve the glaze effect similar to the surfaces of the ceramic tiles. The method overcomes the defect that the traditional method for refurbishing and transforming the ceramic tiles has high difficulty and high cost, can maintain the decoration effect of the original ceramic tiles simultaneously, and also can change the colors of the surfaces of the ceramic tiles according to customer requirements. The materials are environment-friendly and nontoxic, and the normal office work is not influenced in the construction process.

Owner:王高君

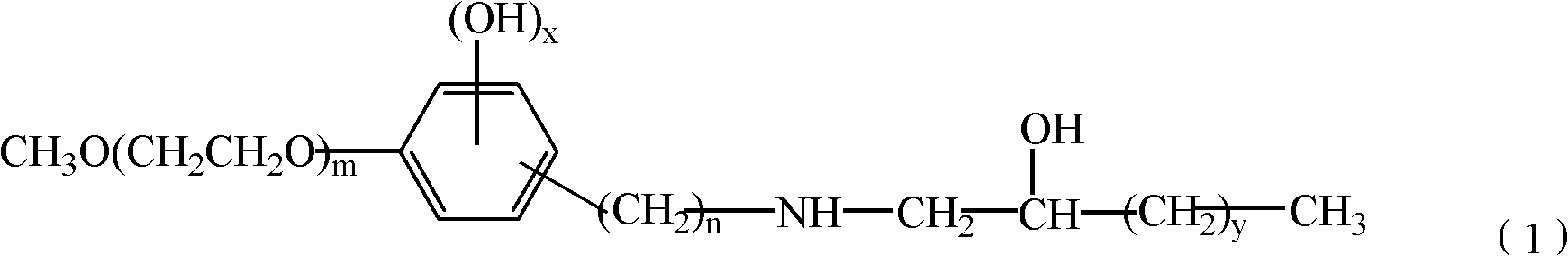

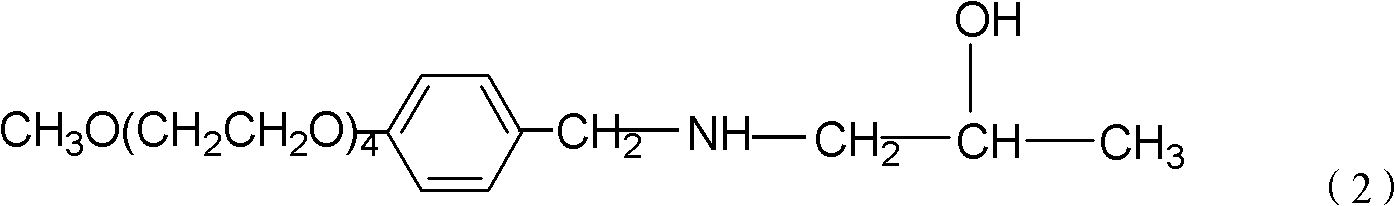

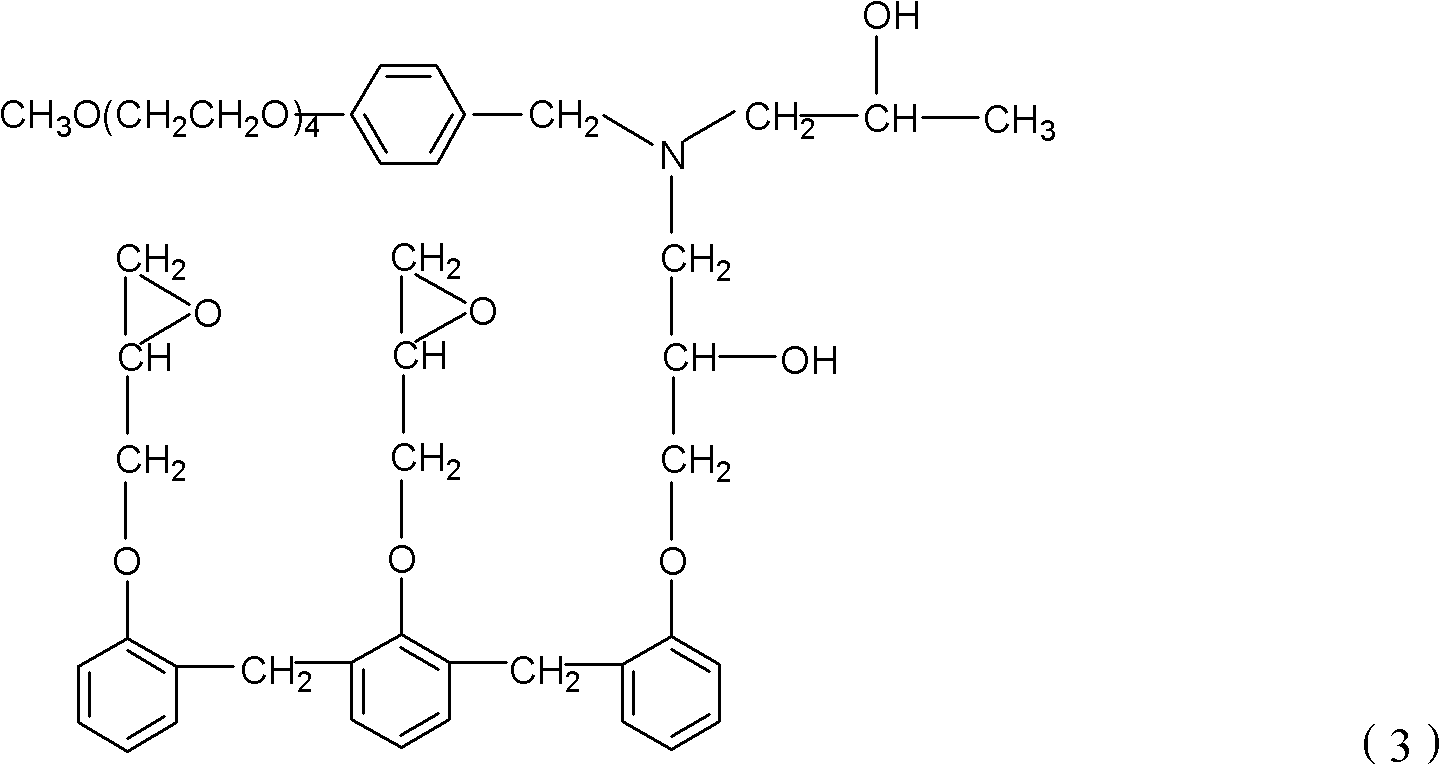

Non-ionic active epoxy emulsifier preparation method and waterborne epoxy resin preparation method

The invention discloses a non-ionic active epoxy emulsifier preparation method and a waterborne epoxy resin preparation method. The non-ionic active epoxy emulsifier preparation method includes: firstly, using a single epoxy group compound to terminate alpha-methoxy-omega-alkyl polyether amine; and then adding novolac epoxy resin and a good amount of solvent in equimolar ratio, stirring the novolac epoxy resin and the solvent to homogeneous-phase solution prior to temperature rise reaction, and removing the solvent by means of reduced pressure distillation after reaction, so that non-ionic active epoxy emulsifier is prepared. The emulsifier and EP (epoxy resin) are added into a dispersing kettle according to different molar ratios to be evenly mixed, and deionized water is dropwise added to prepare epoxy resin aqueous emulsion with the solid content of 40-60% by means of phase inversion. The emulsion is high in storage stability, non-toxic and high in packing ratio of packing and can be cured at the room temperature, and a cured product has the advantages of high adhesive force and flexibility and is high in water proofing and solvent resistance.

Owner:KING STRONG MATERIAL ENG LTD +1

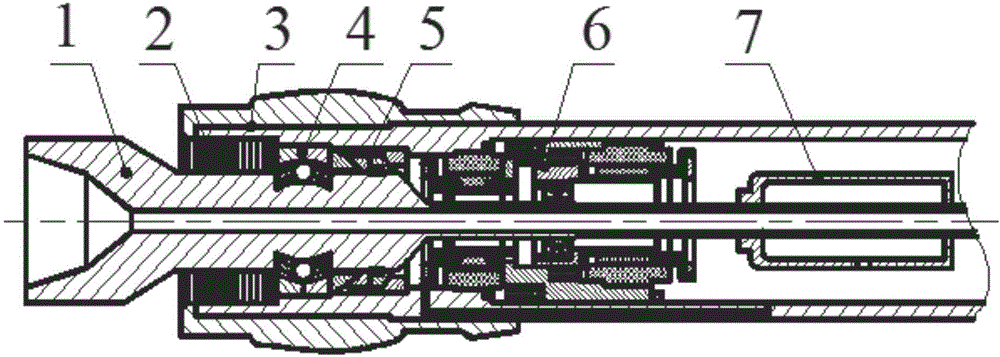

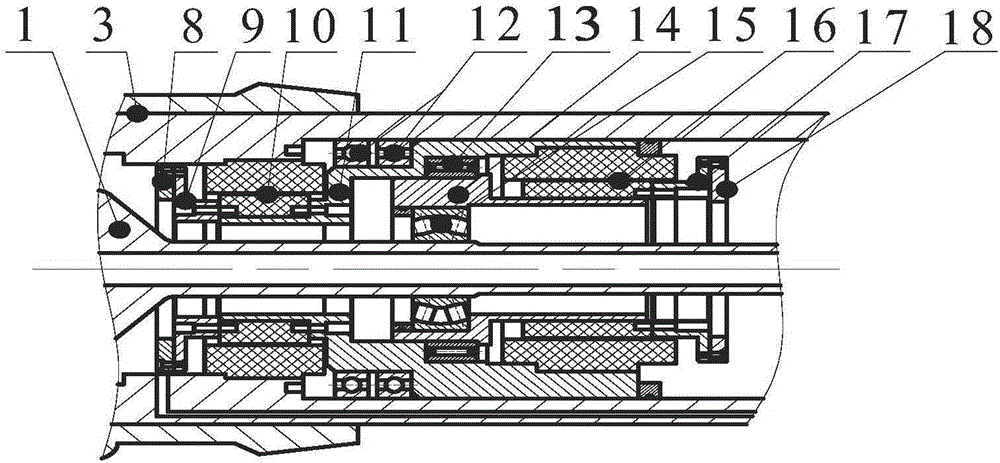

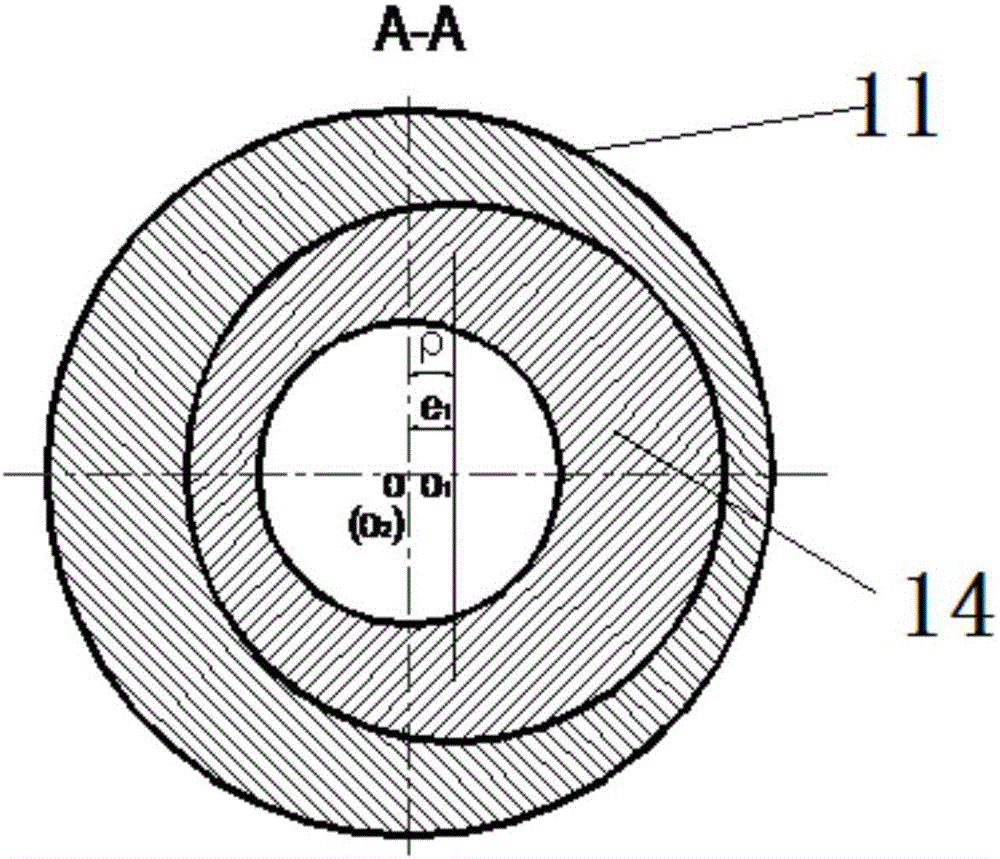

Eccentric mechanism of dynamic pointing type rotary guiding well-drilling tool

ActiveCN106677703AExtended service lifeImprove reliabilityDirectional drillingWell drillingEngineering

The invention discloses an eccentric mechanism of a dynamic pointing type rotary guiding well-drilling tool. An external eccentric ring frameless direct-driving motor encoder is connected with an external eccentric ring flange, the external eccentric ring flange is connected with an external eccentric ring frameless direct-driving motor, and an external eccentric ring frameless direct-driving motor rotor is connected with an external eccentric ring; the outer wall of the external eccentric ring is matched with an external eccentric ring holding bearing, the outer wall of the external eccentric ring holding bearing is matched with the inner wall of a rotary outer sleeve, and the inner wall of the external eccentric ring is matched with the outer walls of an internal eccentric ring fitted bearing and an external eccentric ring fitted bearing; the inner walls of the internal eccentric ring fitted bearing and the external eccentric ring fitted bearing are matched with the outer wall of an internal eccentric ring, and the inner wall of the internal eccentric ring is matched with the outer wall of the internal eccentric ring fitted bearing; and an internal eccentric ring frameless direct-driving motor rotor is connected with an internal eccentric flange, and the internal eccentric flange is connected with an internal eccentric ring frameless direct-driving motor encoder. Control of the eccentric mechanism over the internal eccentric ring and the external eccentric ring is achieved mainly by controlling frameless direct-driving motors, so that tool guiding is achieved, and accurate control of well track is achieved.

Owner:XI'AN PETROLEUM UNIVERSITY

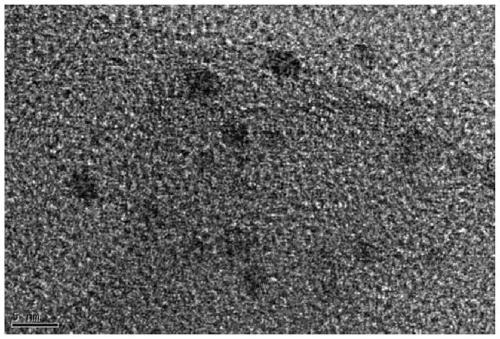

Nitrogen-doped carbon-coated catalyst as well as preparation method and application thereof

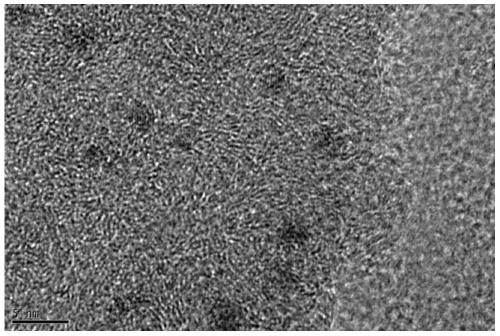

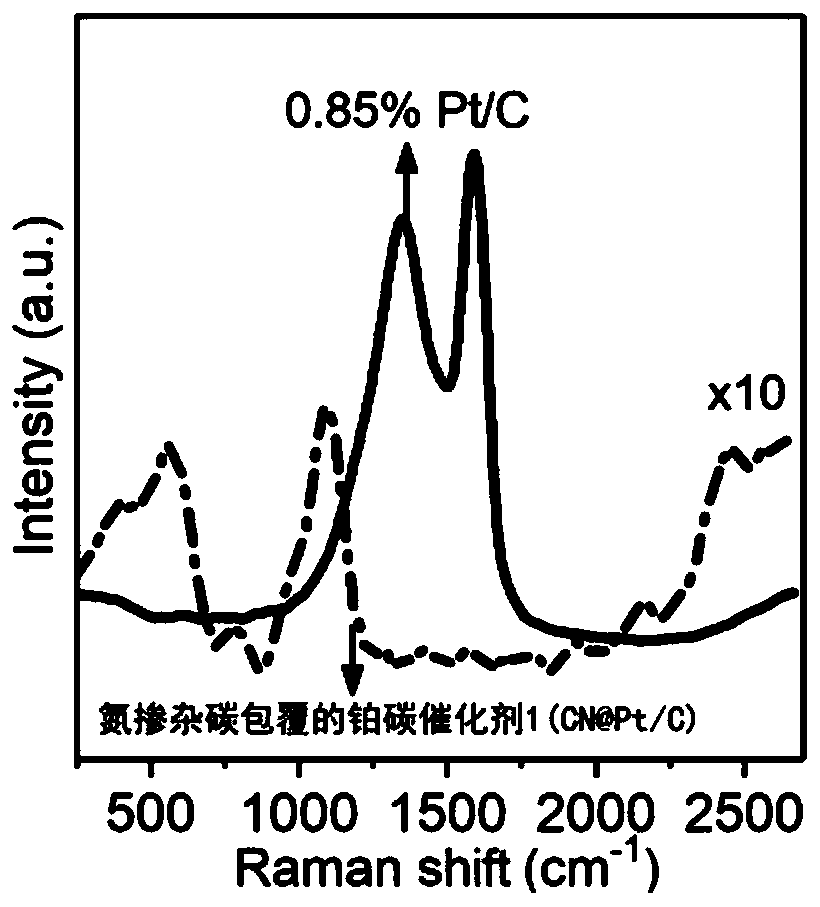

ActiveCN111151284ASimple preparation processStable hydrogenation activityMolecular sieve catalystsOrganic compound preparationCarbon layerPtru catalyst

The invention discloses a nitrogen-doped carbon-coated catalyst as well as a preparation method and application thereof. The invention provides a nitrogen-doped carbon-coated catalyst for preparing halogenated arylamine through catalytic hydrogenation of halogenated nitroaromatic hydrocarbons; the nitrogen-doped carbon-coated catalyst comprises a supported metal catalyst and a coating layer, the supported metal catalyst comprises a carrier and a metal active component, the coating layer is a nitrogen-doped carbon layer, and the thickness of the nitrogen-doped carbon layer is 0.1 nm-10 nm. Themetal active component is G-M, G is one or more of noble metals Pt, Pd, Rh or Ru, and M comprises at least one of metals Fe, Co, Ni, Sn and Mo. The catalyst provided by the invention is applied to preparation of halogenated arylamine through catalytic hydrogenation of halogenated nitroaromatic hydrocarbon; the conversion rate of the halogenated nitrobenzene is as high as 100%, the nitrogen-doped carbon-coated catalyst is quite high in activity and excellent in stability, high-purity halogenated arylamine can be obtained, the selectivity can reach 99.7% or above, dehalogenation is smaller than0.3%, and dehalogenation is effectively inhibited; a dechlorination inhibitor does not need to be added into a reaction system, so that the cost is reduced, the complexity of the reaction system is reduced, and side reactions possibly introduced are reduced.

Owner:XIAMEN UNIV

Method for producing paperboards and paper tubes

InactiveCN102248562AImprove adhesionHigh compressive and flexural strengthWood compressionGrain treatmentsFiberAnimal fiber

The invention relates to a method for producing paperboards and paper tubes, comprising the following steps of: (1) carrying out steam blasting and fluid energy milling on plant waste materials to obtain a raw material A; (2) carrying out the steam blasting on waste and old textiles and animal fibers to obtain a raw material B; (3) preparing a sodium silicate solution with the mass concentration of 12-15% to obtain a raw material C; (4) uniformly mixing the raw material A with the mass percent of 84-86%, the raw material B with the mass percent of 6-9%, the raw material C with the mass percent of 6-8% and thermosetting resin with the mass percent of 0-4%, putting the mixture into a paper pressing machine to prepare the paperboards and the paper tubes; and (5) carrying out air drying and curing on the obtained paperboards and paper tubes or curing by adopting a drying machine or a blast blower. The invention has the advantages that: process is simple, raw materials are available; manpower and energy are saved, production efficiency is improved, production cost is reduced; and the obtained paperboards and the paper tubes have good and stable quality, thus the method is applicable topopularization and application and is environment-friendly for papermaking.

Owner:强光初

Preparation method of modified diatomite/polyethylene composite plastic

The invention belongs to the field of composite materials and particularly relates to a preparation method of modified diatomite / polyethylene composite plastic. The preparation method comprises the steps as follows: drying superfine diatomite and then mixing the dried superfine diatomite and alcohol, conducting ultrasonic dispersion, adding a modifier, mechanically stirring, centrifugally separating, and conducting vacuum drying on a solid product obtained by separation for 1-24h to obtain the modified diatomite; or directly mixing the modifier and the alcohol, uniformly spraying a mixed solution onto the surface of the cooled diatomite to obtain the modified diatomite, adding the modified diatomite and polyethylene to an internal mixer for blending, and then conducting hot pressing with a plate vulcanizing machine to fabricate a diatomite / polyethylene composite plastic plate. The method adopts superfine and surface modification technologies to prepare the novel low-carbon, low-emission and environment-friendly polyethylene plastic which can be used for replacing a calcium carbonate filler in plastics.

Owner:YINGKOU DONGSHENG IND +1

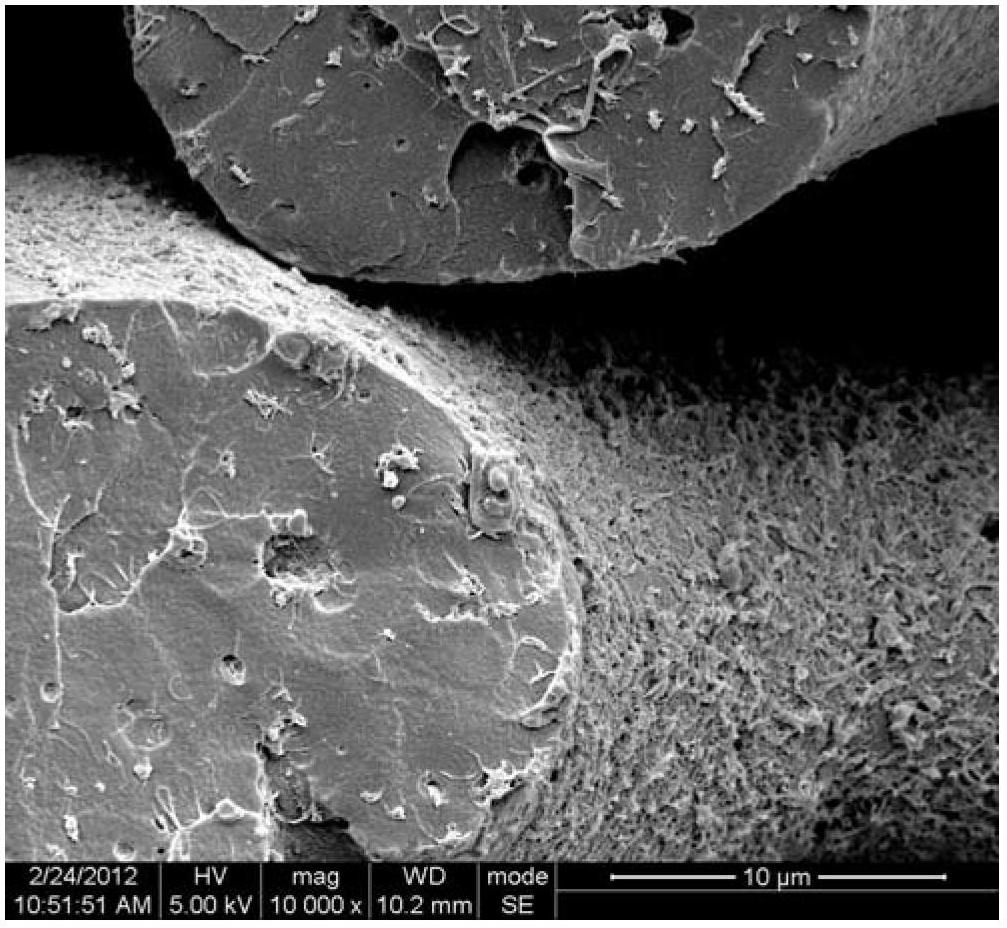

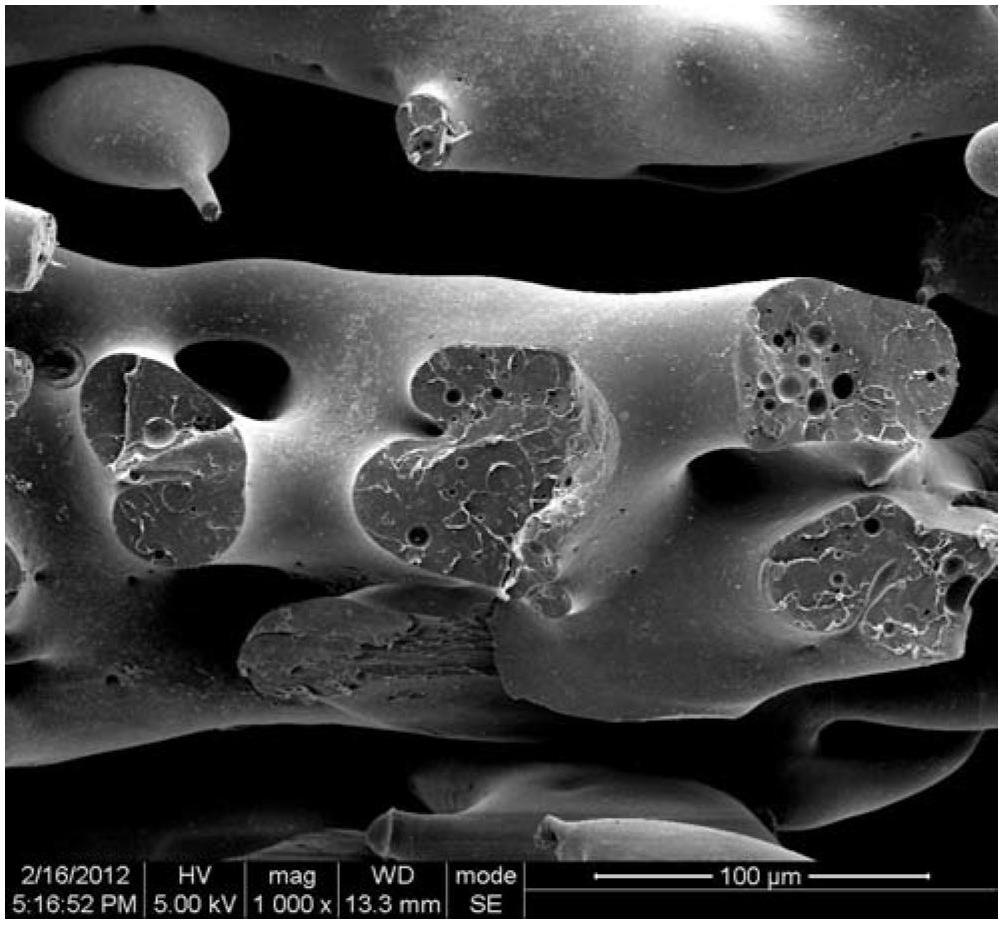

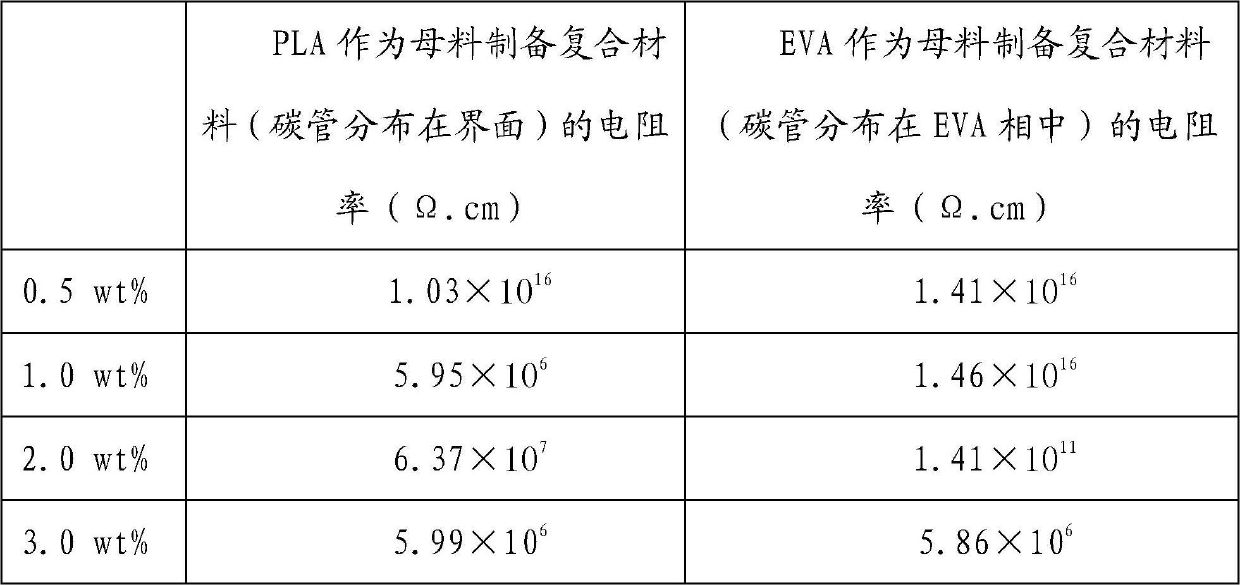

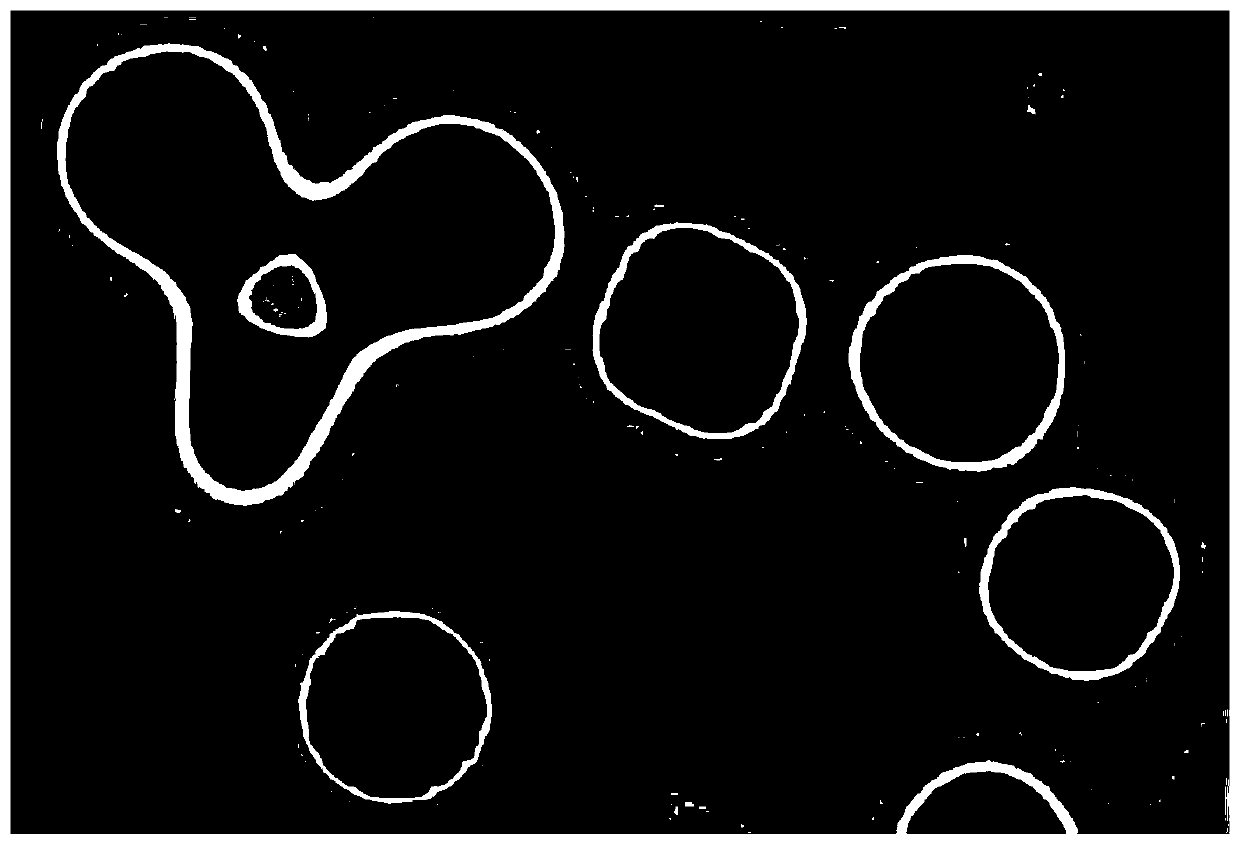

Method for preparing polymer-based conducting composite material by melt blending

ActiveCN102675893AImprove conductivityIncrease profitNon-conductive material with dispersed conductive materialPolymer scienceCarbon nanotube

A method for preparing polymer-based conducting composite material by melt blending comprises the steps of (1) selecting a carbon nano tube or graphite to serve as a conducting filler, or selecting a first polymer or a second polymer, and enabling the viscosity ratio between the first polymer and the second polymer to be not smaller than 100; or enabling the first polymer to be low in affinity with the conducting filler, enabling the second polymer to be high in affinity with the conducting filler, the theoretic infiltration coefficient omega a of a blending system formed by the conducting filler, the first polymer and the second polymer to be larger than 1, enabling gamma to represent interfacial tension between two phases, and enabling the first polymer and the second polymer to be incompatible in chemical property; (2) performing calcination or acidizing treatment to the conducting filler; and (3) enabling the conducting filler to first undergo melt blending with the first polymer, obtaining a master batch, enabling the master batch to undergo melt blending with the second polymer, and obtaining the polymer-based conducting composite material. According to the method, the consumed quantity of the conducting filler is low, and the prepared conducting composite material is good in conducting performance and strong in mechanical property.

Owner:SOUTHWEST JIAOTONG UNIV

Iron-based sodium-ion battery positive electrode material and preparation method thereof

ActiveCN110931784AInhibition formationHigh yieldMaterial nanotechnologyCell electrodesElectrical batterySodium-ion battery

The invention discloses an iron-based sodium-ion battery positive electrode material, comprising Na3Fe2(SO4)3F and a carbon-based material embedded into a Na3Fe2(SO4)3F body structure, wherein in theiron-based sodium-ion battery positive electrode material, the mass fraction of the carbon-based material is 1-10%. The invention also provides a preparation method of the iron-based sodium-ion battery positive electrode material. According to the Na3Fe2 (SO4) 3F positive electrode material disclosed by the invention, the sodium storage specific capacity can be ensured, meanwhile, the cycling stability and the rate capability are greatly improved, and the sodium storage electrochemical performance is obviously superior to that of a pure-phase NaxFey(SO4)z material. Compared with other sodium-containing layered transition metal oxide, polyanionic vanadium-based phosphate and other positive electrode materials, the Na3Fe2(SO4)3F positive electrode material has obvious advantages in working potential and energy density.

Owner:苏州高博储能科技有限公司

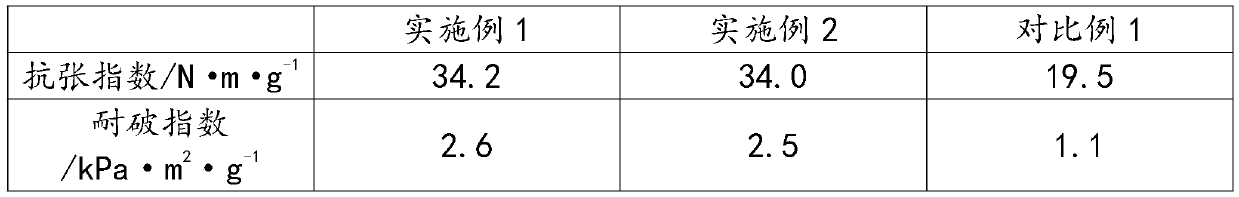

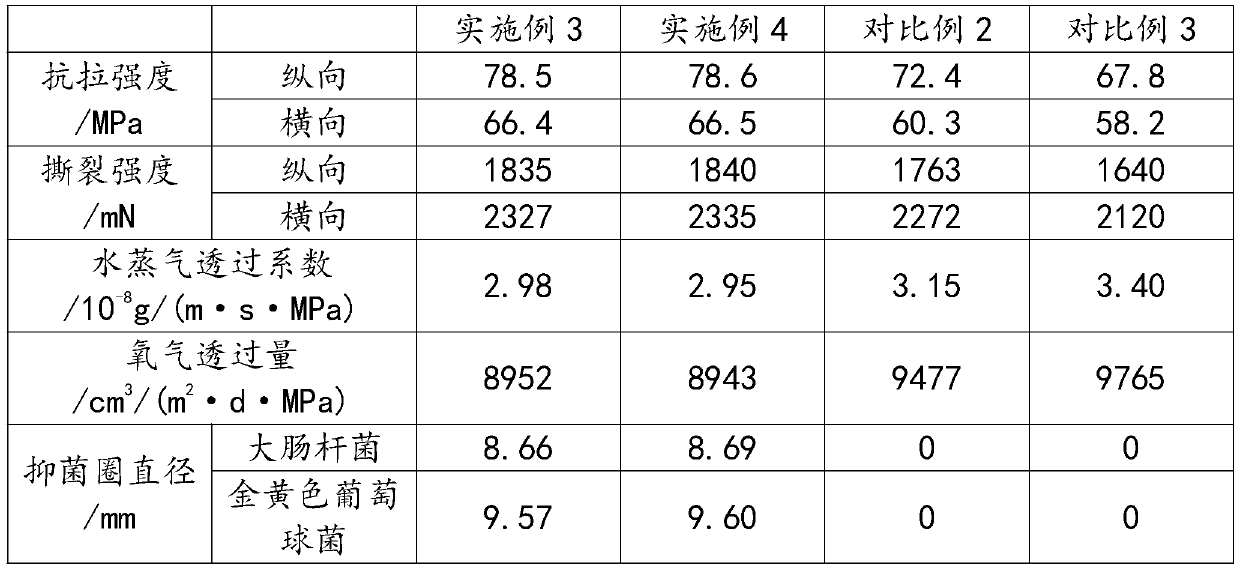

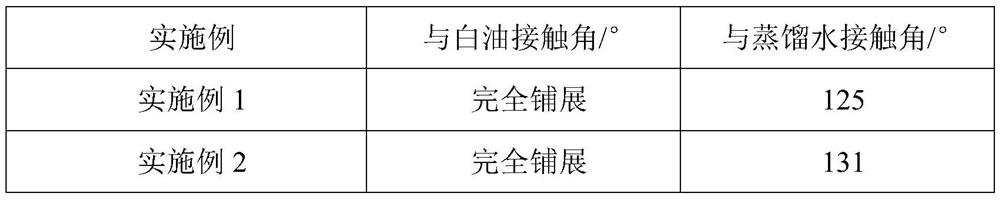

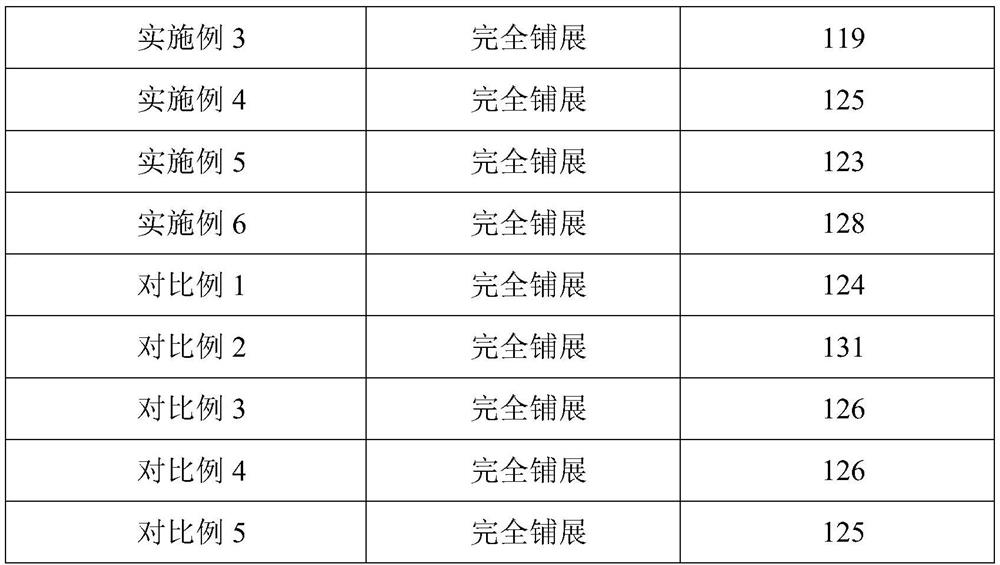

Environment-friendly high-barrier packaging paper and preparation method thereof

PendingCN110284371AImprove physical strengthHigh strengthFlexible coversWrappersFiberPulp and paper industry

The invention discloses environment-friendly high-barrier packaging paper and a preparation method thereof. The packaging paper comprises a base paper body and a coating applied on the surface of the base paper body; coating liquid is uniformly applied on the surface of the base paper body and single-sided coating is adopted; after coating is completed, the coated paper is immediately put into a drying box for drying; finally, the dried coated paper is placed in a constant-temperature and constant-humidity box for rewetting treatment, and the packaging paper is obtained. The base paper body prepared by mixing plant fiber and mucor fiber not only has high physical strength and good hydrophobic performance, but also is free of toxics, environmentally friendly and easy to degrade. By coating the surface of the base paper body with the coating liquid, the coating liquid fills paper fiber gaps, a dense film is formed on the surface of the paper, and the physical strength and barrier performance of the packaging paper are improved. An antibacterial agent in the coating liquid can make the packaging paper endowed with good antibacterial performance, and the packaging paper which is easy to degrade, free of toxics, environmentally friendly, good in antibacterial performance and high in barrier performance is prepared.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

Inorganic/polymer composite plugging agent for ultrahigh-temperature-resistant oil-based drilling fluid, and preparation method and application thereof

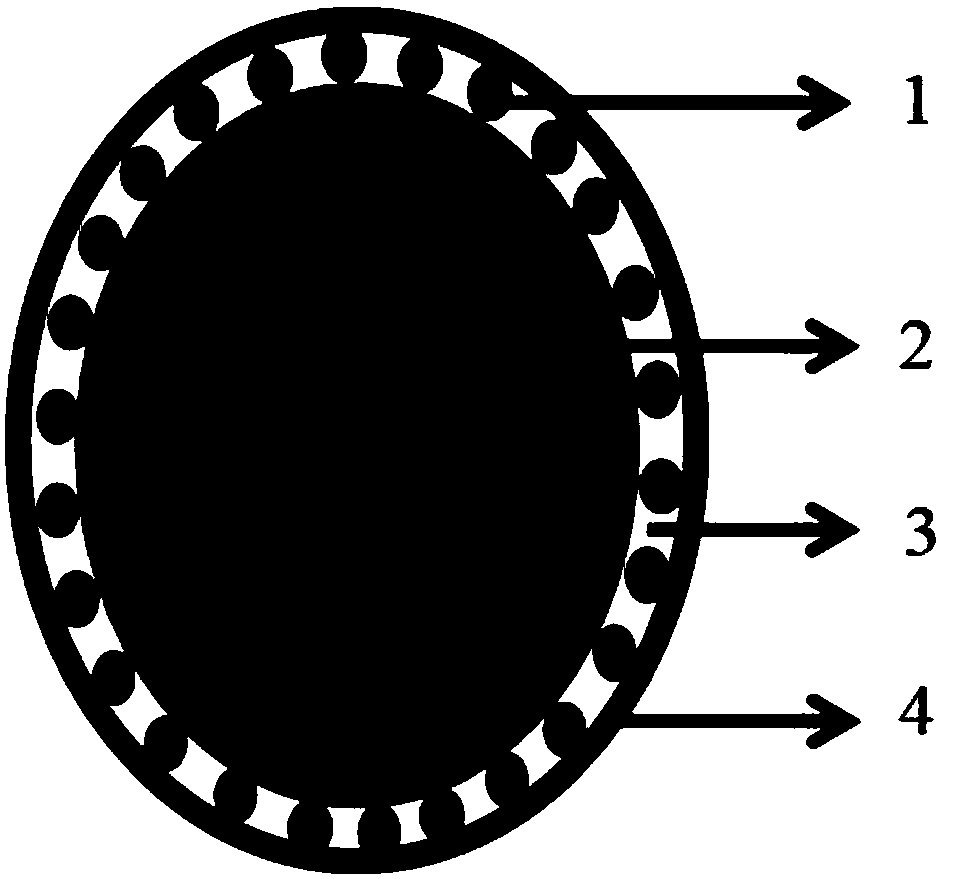

ActiveCN112011315AImprove seal strengthAct as a bridgeDrilling compositionAcrylic resinPolymer composites

The invention provides an inorganic / polymer composite plugging agent for an ultrahigh-temperature-resistant oil-based drilling fluid, and a preparation method and application thereof. The plugging agent has a core-shell structure, the core is silane coupling agent modified quartz powder, and the shell is an acrylic resin material; the acrylic resin material is prepared from styrene, a vinyl-containing organic silicon monomer and a high-temperature-resistant monomer; and the high-temperature-resistant monomer comprises an oil-soluble hard monomer and an oil-soluble soft monomer. The invention also provides a preparation method of the plugging agent. The plugging agent disclosed by the invention is high in lipophilicity and has relatively good dispersity in an oil-based system; and the plugging agent has the advantages of good high-temperature resistance, good adaptability, good adsorption performance and excellent plugging capability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

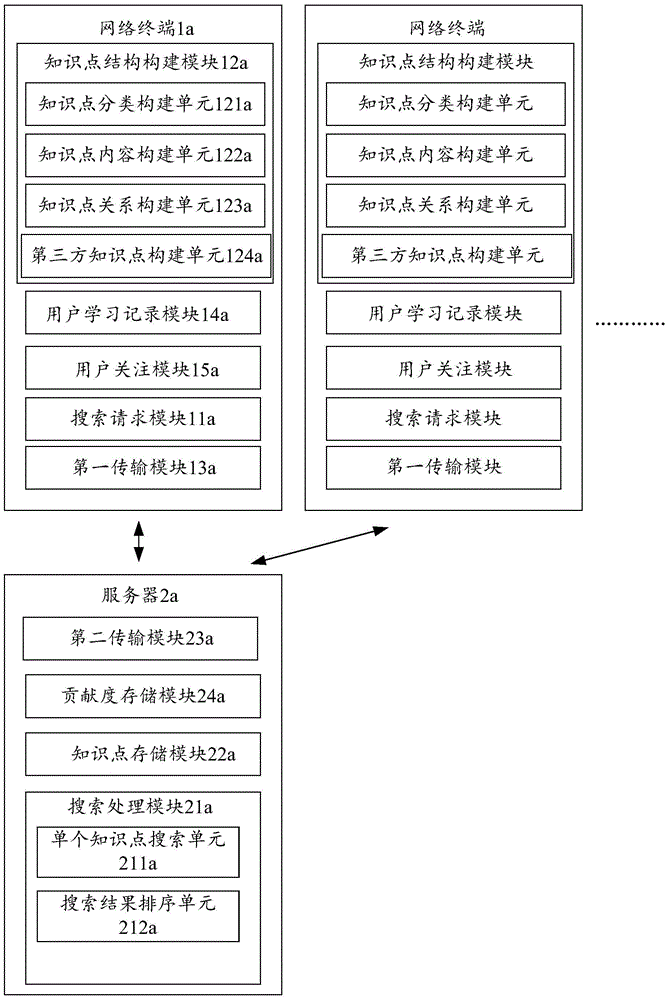

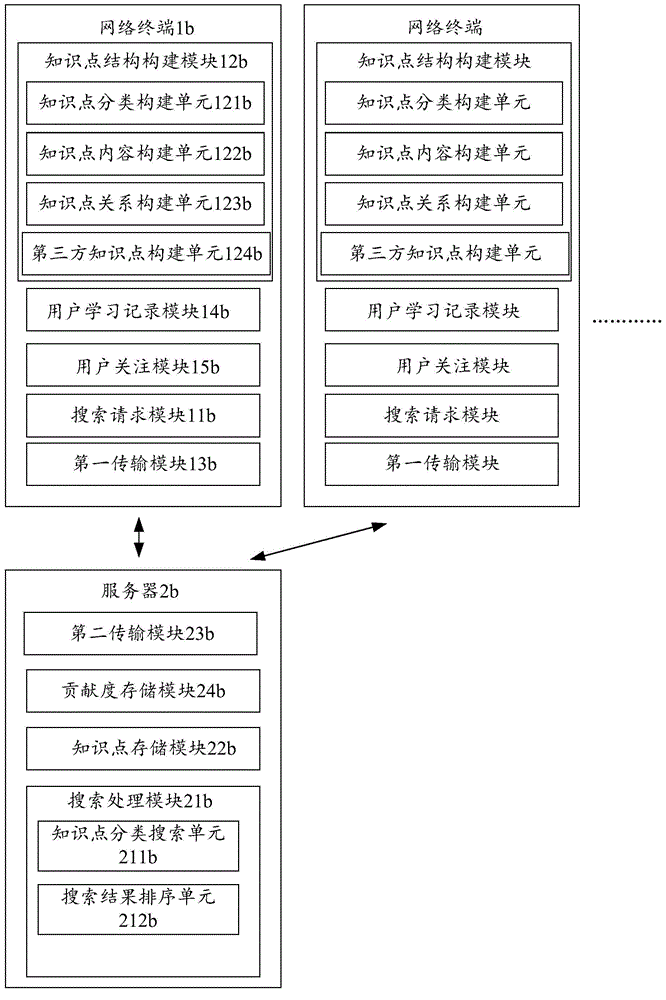

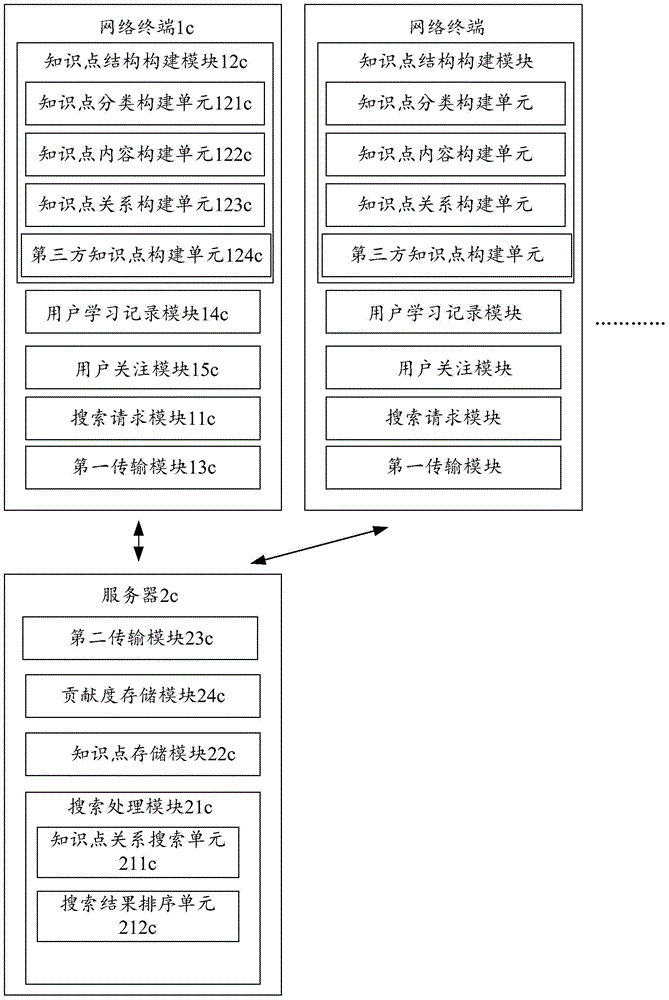

Knowledge point structure based searcher

ActiveCN104951560AGood search resultAct as a bridgeMultimedia data queryingKnowledge representationStructure basedInformation retrieval

The invention discloses a knowledge point structure based searcher. According to the knowledge point structure based searcher, multiple search results are provided and are sequenced based on sharing frequency, and users can interact with each other based on sharing. The technical scheme is that one user builds own knowledge point structure based on own understanding, multiple search results belonging to different users are provided by a server according to a search request submitted by the user, and the search results are sequenced based on the click rate. Generally speaking, the search result with the highest click rate is more accepted by the masses, and accordingly, the user can get the best search result in a time-saving and labor-saving manner. Besides, correlation of following and being followed is established between the user clicking the search result and the user who the search result belongs to, so that the correlated users can perform interaction.

Owner:谭红 +1

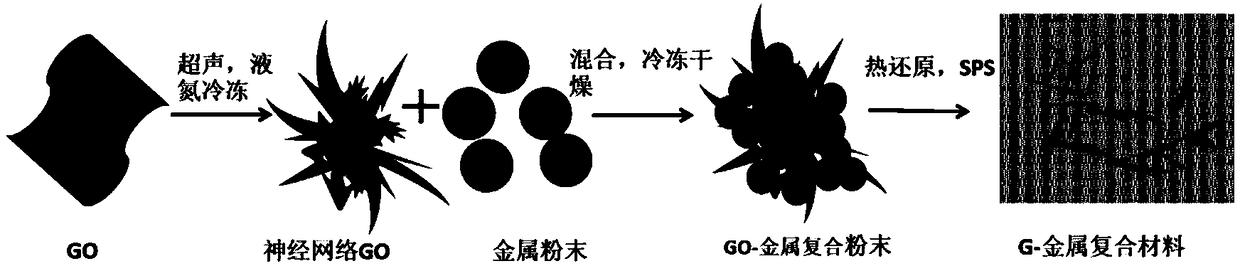

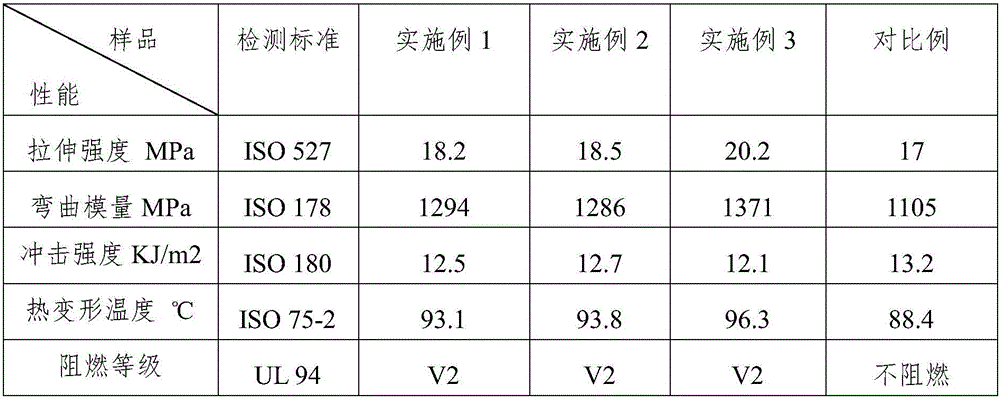

Preparation method of high-strength high-toughness graphene/metal composite material

InactiveCN109277560ADelays/Hinders ExpansionEvenly distributedTransportation and packagingMetal-working apparatusWater bathsGraphite oxide

The invention relates to a preparation method of a graphene / metal composite material, and belongs to the technical field of metal-based composite materials. The method comprises the following steps ofpreparing a graphene oxide solution with certain concentration, and quickly pouring the graphene oxide solution into liquid nitrogen after water-bath heating; melting the frozen solid of the grapheneoxide solution, then carrying out high-speed shearing to uniformly mix the melted graphene oxide solution with metal powder in an ethanol / water solution, and then placing the mixture into the liquidnitrogen again for rapid freezing to obtain graphene oxide / metal composite powder after freezing and drying. After being subjected to thermal reduction, the composite powder becomes the high-density graphene / metal composite material through spark plasma sintering. Due to the fact that the graphene in the prepared graphene / metal composite material is of a neural network structure, the strength of the composite material can be improved while the toughness of a metal base body is maintained, and the performance of the composite material is obviously superior to that of composite materials of thesame type. The process method is simple and feasible, and the steps are easy to operate; and the process method is high in safety and reliability, low in cost and suitable for large-scale production.

Owner:LANZHOU JIAOTONG UNIV

Hydrotalcite-intercalated flame-retarding-enhanced polypropylene material and preparing method thereof

The invention provides a hydrotalcite-intercalated flame-retarding-enhanced polypropylene material and a preparing method thereof, and relates to the technical field of polymeric composite materials. The hydrotalcite-intercalated flame-retarding-enhanced polypropylene material is prepared from polypropylene, a light stabilizer, a lubricating agent, modified hydrotalcite, a compatilizer, an antioxidant and an assistant. The hydrotalcite-intercalated flame-retarding-enhanced polypropylene material has the high strength, the heat stability and the flame-retarding performance.

Owner:ORINKO NEW MATERIAL CO LTD

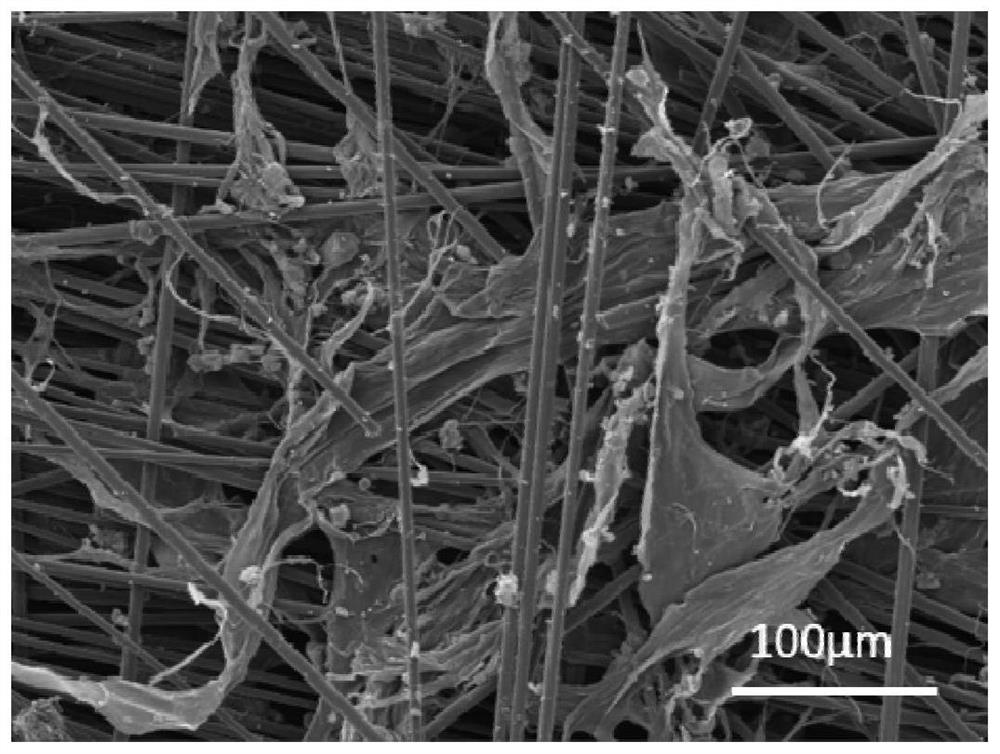

Carbon fiber paper with conductive network enhanced by carbon black and preparation method of carbon fiber paper

InactiveCN114164709AAvoid uneven dispersionMeet the needs of normal workSpecial paperNon-macromolecular organic additionCarbon fibersAramid

The invention provides carbon fiber paper with a conductive network enhanced by carbon black and a preparation method thereof, and the method comprises the following steps: step 1, uniformly dispersing carbon fibers, aramid fibrid and carbon black in a polyoxyethylene aqueous solution according to a ratio of (40-80): (10-50): 10 to obtain a mixed slurry; step 2, molding the mixed pulp to obtain a wet paper web of the carbon fiber paper, and sequentially squeezing and drying the wet paper web of the carbon fiber paper to obtain raw paper of the carbon fiber paper; and step 3, dipping raw paper of the carbon fiber paper in the phenolic resin solution, airing, and hot-pressing at 150-160 DEG C to obtain the carbon fiber paper with the conductive network enhanced by the carbon black. The carbon fiber electric heating paper with high heating rate and good temperature resistance is prepared by introducing aramid fibrid as dispersion forming fiber and carbon black as a three-dimensional network structure bridge.

Owner:SHAANXI UNIV OF SCI & TECH

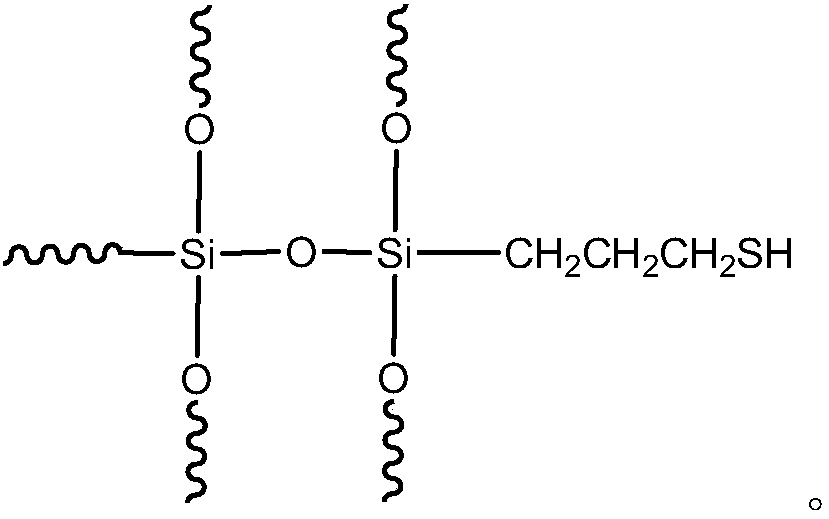

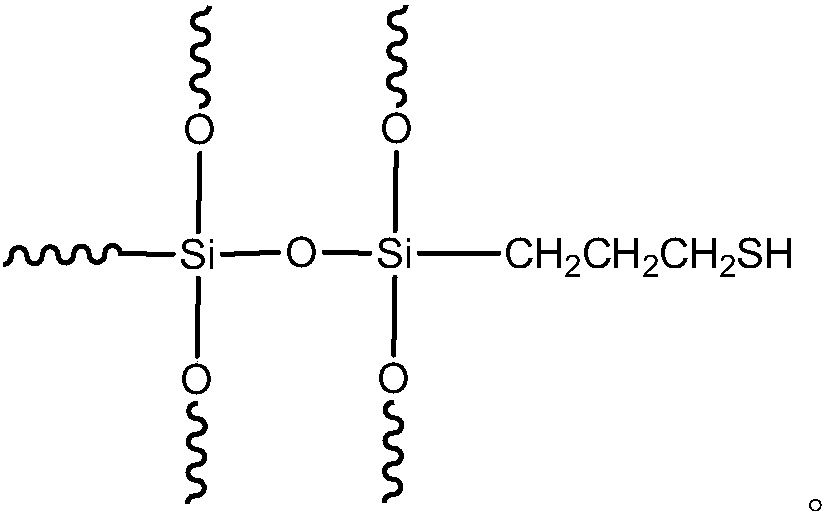

Inorganic-organic silicon hybridized chain transfer agent as well as preparation method thereof, modified (methyl) acrylate polymerization emulsion and preparation method thereof

The invention discloses an inorganic-organic silicon hybridized chain transfer agent as well as a preparation method thereof. The inorganic-organic silicon hybridized chain transfer agent is preparedby modifying silicon dioxide with organic siloxane and by further introducing a sulfydryl silane coupling agent. The invention further discloses a modified (methyl) acrylate polymerization emulsion, and further discloses a preparation method thereof. The preparation method comprises the following steps: in the presence of nitrogen, mixing a (methyl) acrylate monomer, water, an anionic emulsifier,a nonionic emulsifier, an inorganic / organic silicon hybridized chain transfer agent and an initiator, and enabling the components to react for 2-10 hours at 65-90 DEG C, thereby obtaining the modified(methyl) acrylate polymerization emulsion. The modified (methyl) acrylate polymerization emulsion disclosed by the invention is stable in property, very good in high / low temperature resistance, weather resistance and water resistance, and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +2

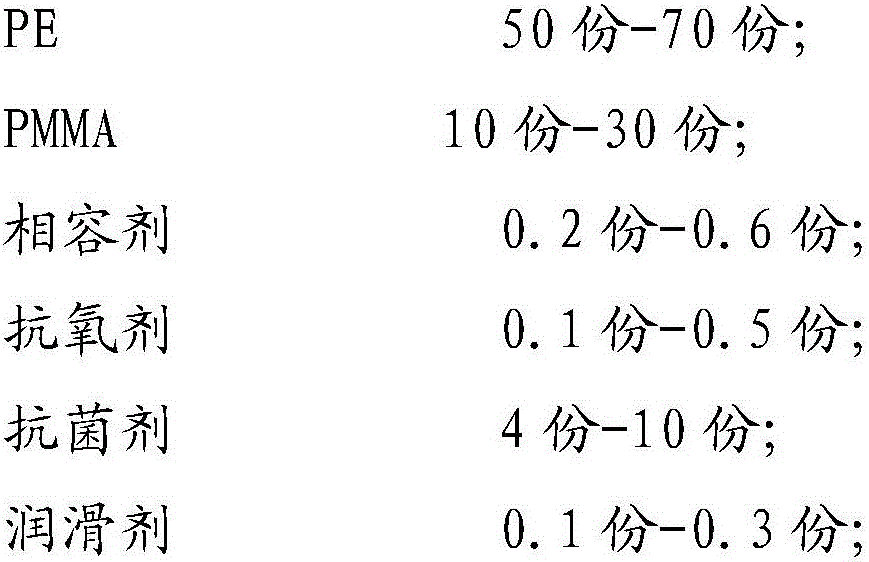

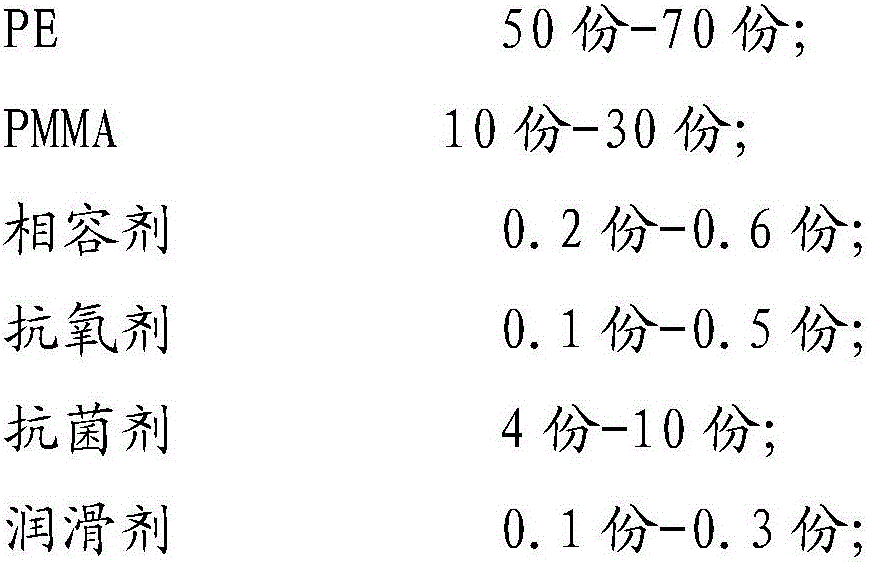

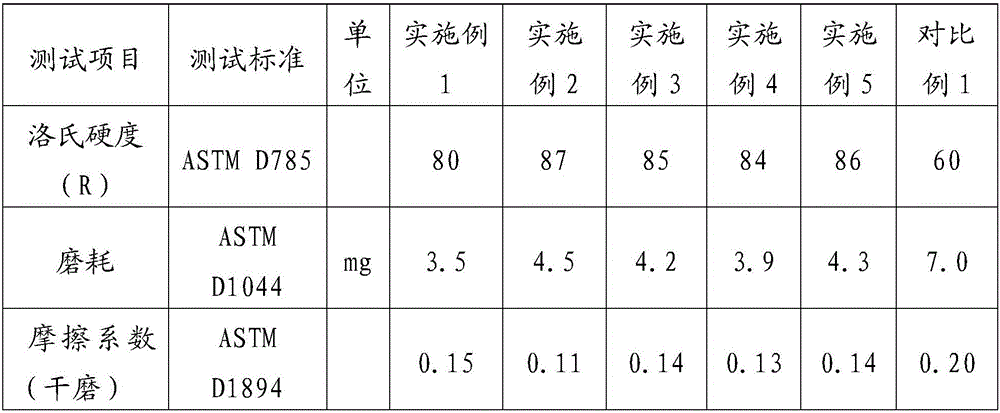

Anti-mould PE (polyethylene) alloy with high hardness and friction resistance and preparation method of anti-mould PE alloy

InactiveCN105949564AImprove the shortcomings of low surface hardnessExcellent abrasion resistanceAntioxidantPolymethyl methacrylate

The invention relates to an anti-mould PE (polyethylene) alloy with high hardness and friction resistance. The anti-mould PE alloy comprises raw materials in parts by weight as follows: 50-70 parts of PE, 10-30 parts of PMMA (polymethyl methacrylate), 0.2-0.6 parts of a compatilizer, 0.1-0.5 parts of an antioxidant, 4-10 parts of an anti-mould agent and 0.1-0.3 parts of a lubricant. With addition of PMMA with high surface hardness, the defect of low surface hardness of the PE material can be overcome, and the friction resistant effect is improved. The anti-mould performance of the material is improved through addition of CuBr or AgCl, Cu<+1> or Ag<+1> is dissolved out when CuBr or AgCl is added to the material, gets free gradually and binds with active proteins in mould when contacted with the mould, and the active proteins are inactivated, so that the mould is killed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Anti-aging plastomer modified asphalt coating material with magnalium-based layed double hydroxide and preparation method thereof

InactiveCN102199359AImprove UV aging resistanceExtended service lifeBuilding insulationsPlastomerAsphalt

The invention relates to an anti-aging plastomer modified asphalt coating material used for a waterproof coiled material and a preparation method thereof. The anti-aging plastomer modified asphalt coating material with magnalium-based layered double hydroxide is characterized by being prepared from the following raw materials in percent by mass of 47% to 64% of asphalt, 10% to 15% of plastomer modifier, 1 to 8% of magnalium-based layered double hydroxide and25% to 30% of stuffing. In the invention, by using the magnalium-based layered double hydroxide, ultraviolet aging resistant performance of the plastomer modified asphalt coating material can be prominently enhanced, the service life of the plastomer modified asphalt coating material is prolonged, and broad application prospects are wide.

Owner:WUHAN UNIV OF TECH

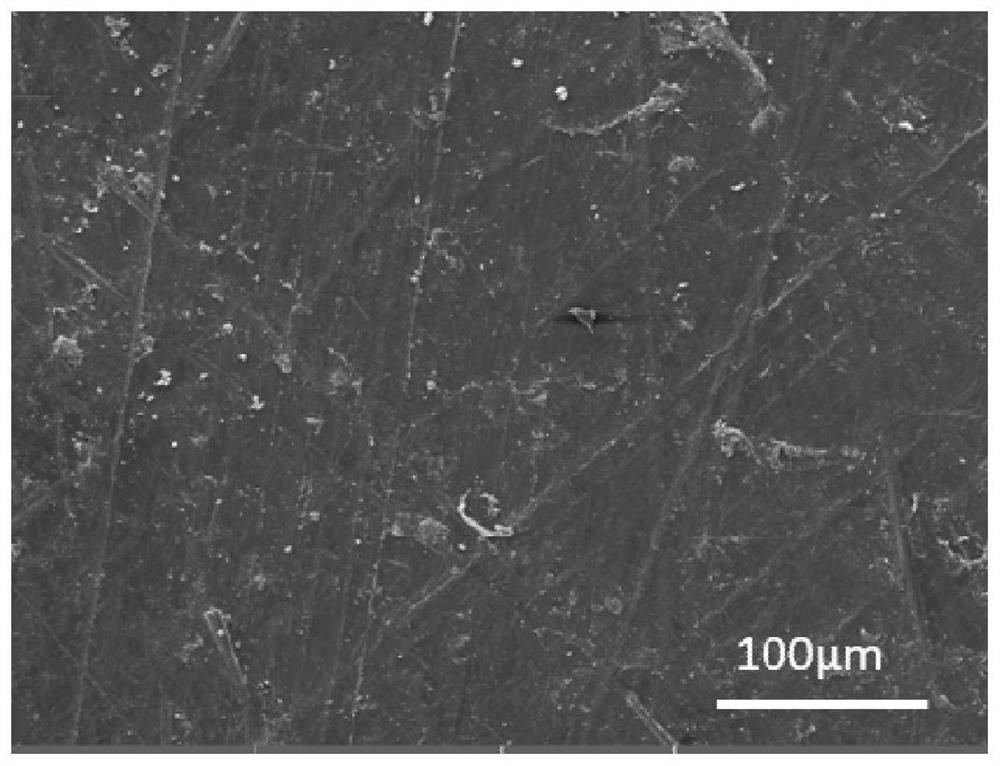

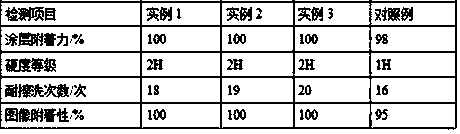

Preparation method for film printing coating

InactiveCN108587367ALow priceSimple coating processPolyurea/polyurethane coatingsChemistryBonding strength

The invention relates to a preparation method for a film printing coating, belonging to the technical field of printing. According to the invention, fumed silica with high purity, good dispersity andstandard spherical particle shape is synthesized through gaseous detonation by using mixed gas of hydrogen and oxygen as a detonating source and silicon tetrachloride as a precursor, and the silicon hydroxyl group on the surface of the fumed silica is activated; a silane coupling agent is hydrolyzed to generate a dehydration reaction with the silicon hydroxyl group on the surface of the fumed silica, so an organism in the silane coupling agent is connected with the surface of the fumed silica; silane coupling agent modified fumed silica is dispersed into an adhesive cross-linked by waterborneacrylic resin and waterborne polyurethane in a cationic coating manner to prepare an ink-absorbing coating; the preparation method provided by the invention adopts the silane coupling agent modified fumed silica as a filling material, so ink-absorbing properties and glossiness of a coating are greatly reinforced; meanwhile, the adhesive cross-linked by the waterborne acrylic resin and the waterborne polyurethane facilitates improvement of bonding strength and wear resistance of the coating.

Owner:杨帮燕

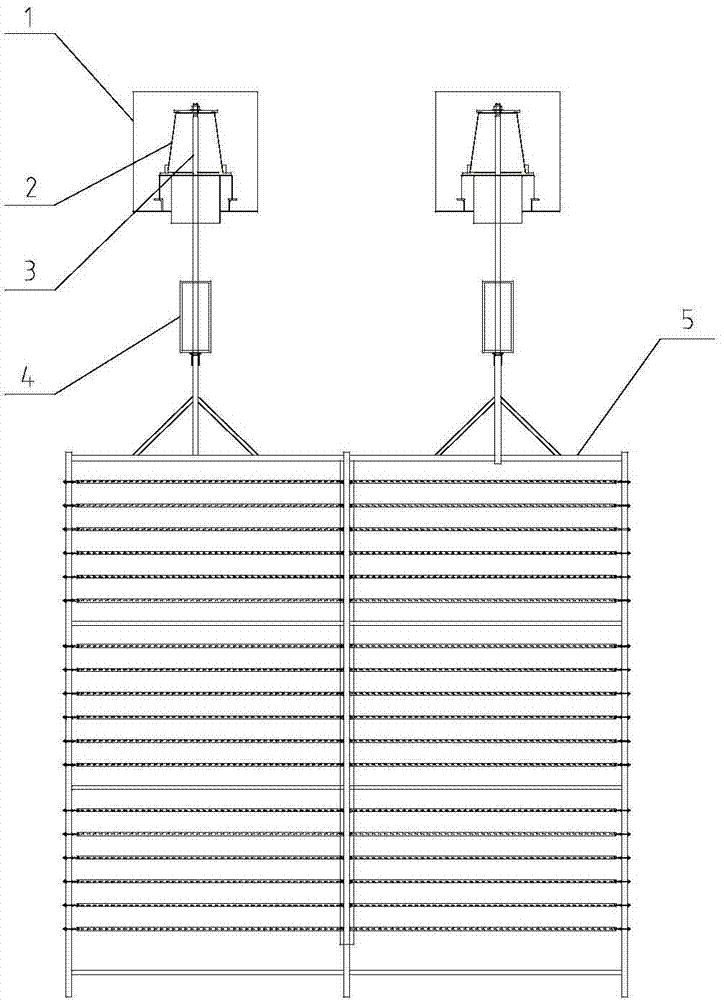

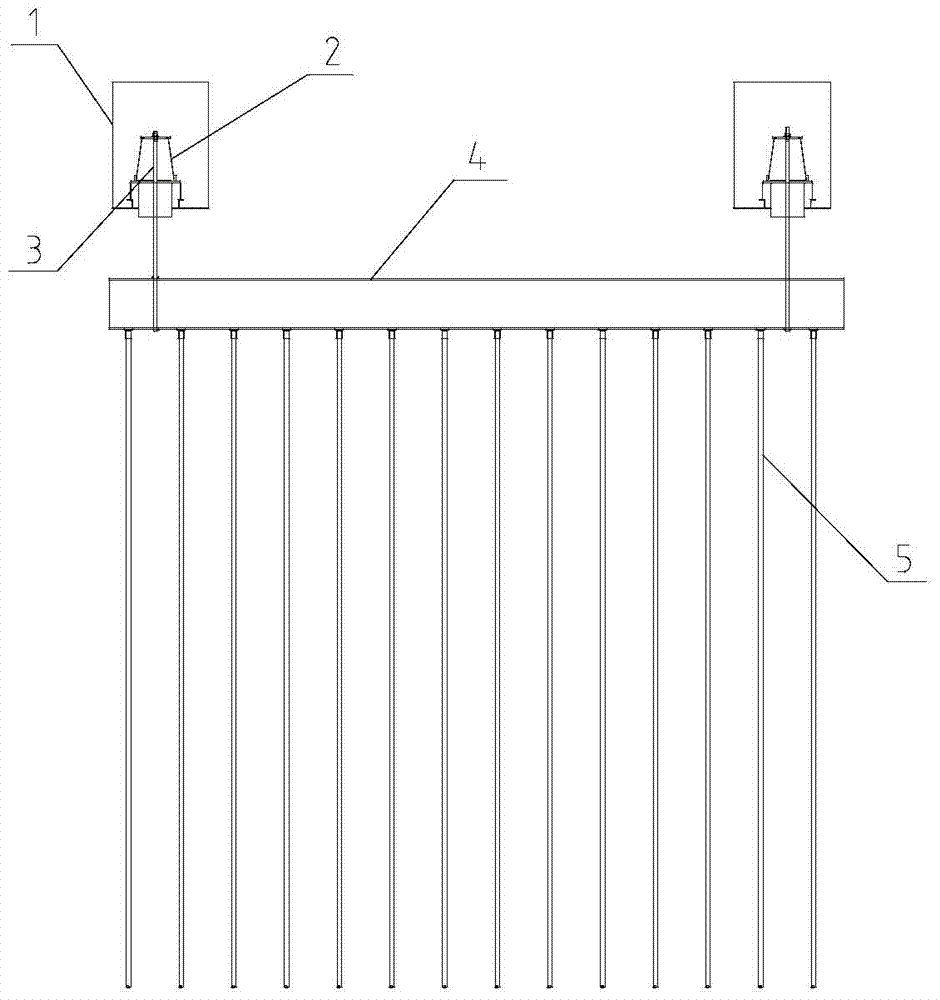

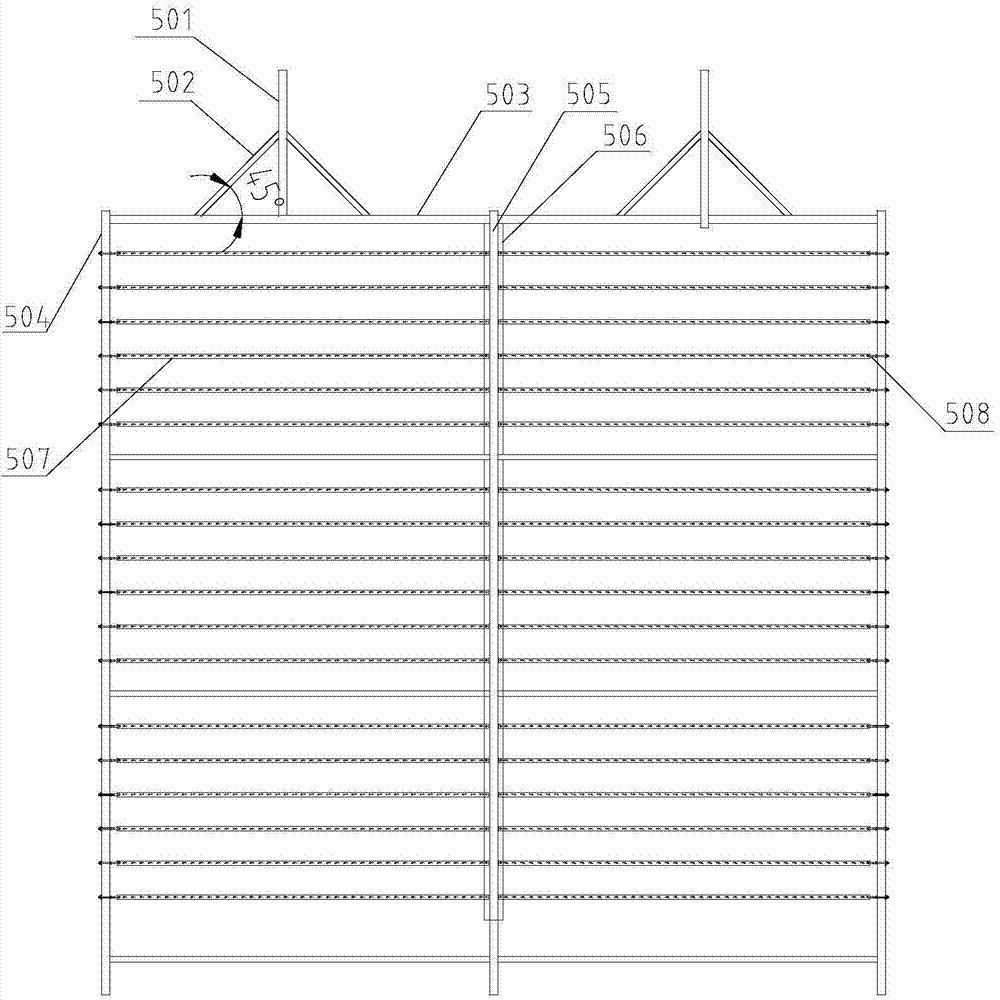

Cathode system and discharging method used for wet-process electrostatic dust collector

ActiveCN104722403AGuaranteed safe operationCompact structureExternal electric electrostatic seperatorElectrode constructionsElectricityEngineering

The invention discloses a cathode system and a discharging method used for a wet-process electrostatic dust collector. The cathode system comprises a cathode hanging rod, a cathode suspension beam and a plurality of rows of cathode frameworks which are arranged in parallel. An insulator sleeve covers the cathode hanging rod and the cathode hanging rod is arranged in a heat insulation box; the cathode suspension beam is a hollow cuboid; each cathode framework comprises a vertical pipe, a transverse pipe, a reinforcement tube, a corona wire and a lug plate. The discharging method comprises the following steps: a high-voltage power supply is used for conveying high-voltage power to a cathode system structure in a shell through the cathode hanging rod; the heat insulation box and the insulator sleeve are used for drying and insulating the cathode hanging rod; the barb tip of each corona wire releases the high-voltage power to form a wet type electric field, so that fine particles are charged. According to the cathode system, the wet-process electrostatic dust collector can be effectively safely and efficiently operated; the layout of the cathode system is scientifically and reasonably optimized; and the uniform and stable discharging is guaranteed, and the removing efficiency of PM2.5 is effectively enhanced.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

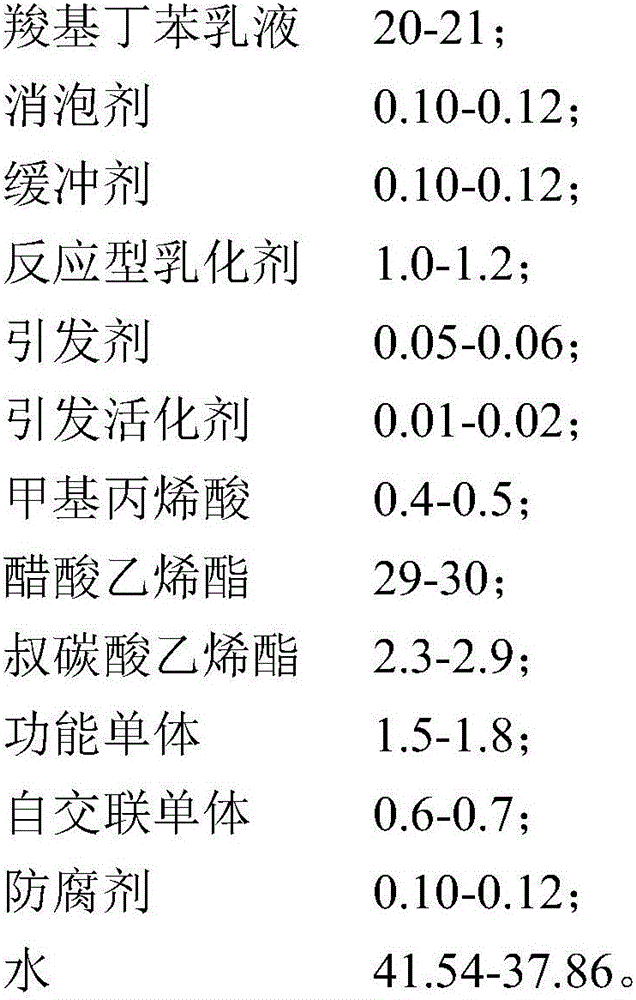

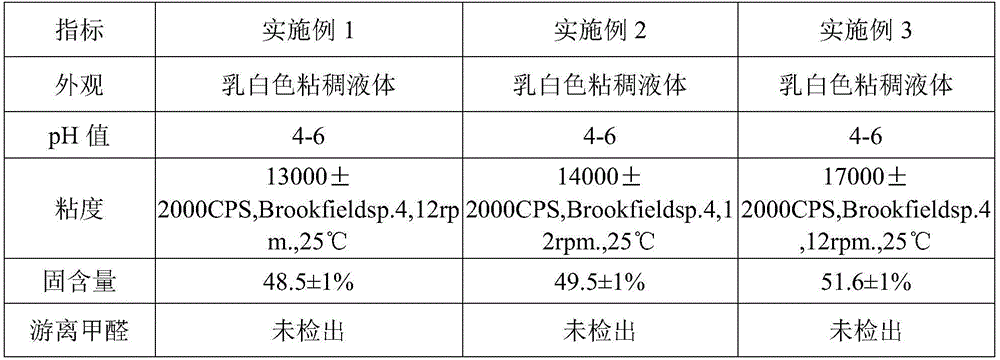

Emulsion for water-based two-component wood splice adhesive and preparation method of emulsion

The invention discloses emulsion which is prepared for a water-based two-component wood splice adhesive by taking carboxylated styrene-butadiene emulsion as a seed. The emulsion is prepared from the styrene-butadiene emulsion, a defoaming agent, a buffering agent, polyvinyl alcohol, a reactive emulsifier, an initiator, methacrylic acid, vinyl acetate, vinyl versatate, a functional monomer, a self-cross linking monomer, a preservative and the like. According to the emulsion for the wood splice adhesive, carboxylated styrene-butadiene is taken as the seed emulsion, flexible chains are introduced into emulsion particles, and therefore the anti-cracking property of the emulsion for the wood splice adhesive is improved; water is taken as a dispersion medium, use is convenient, no pollution is generated to the environment, after compounding is conducted, a polyisocyanate curing agent is added to prepare the two-component wood splice adhesive, and the functional monomer-primary hydroxyl group and the polyisocyanate curing agent in the emulsion achieve bridging, so that the strength and the water resistance are improved.

Owner:顶立新材料科技股份有限公司

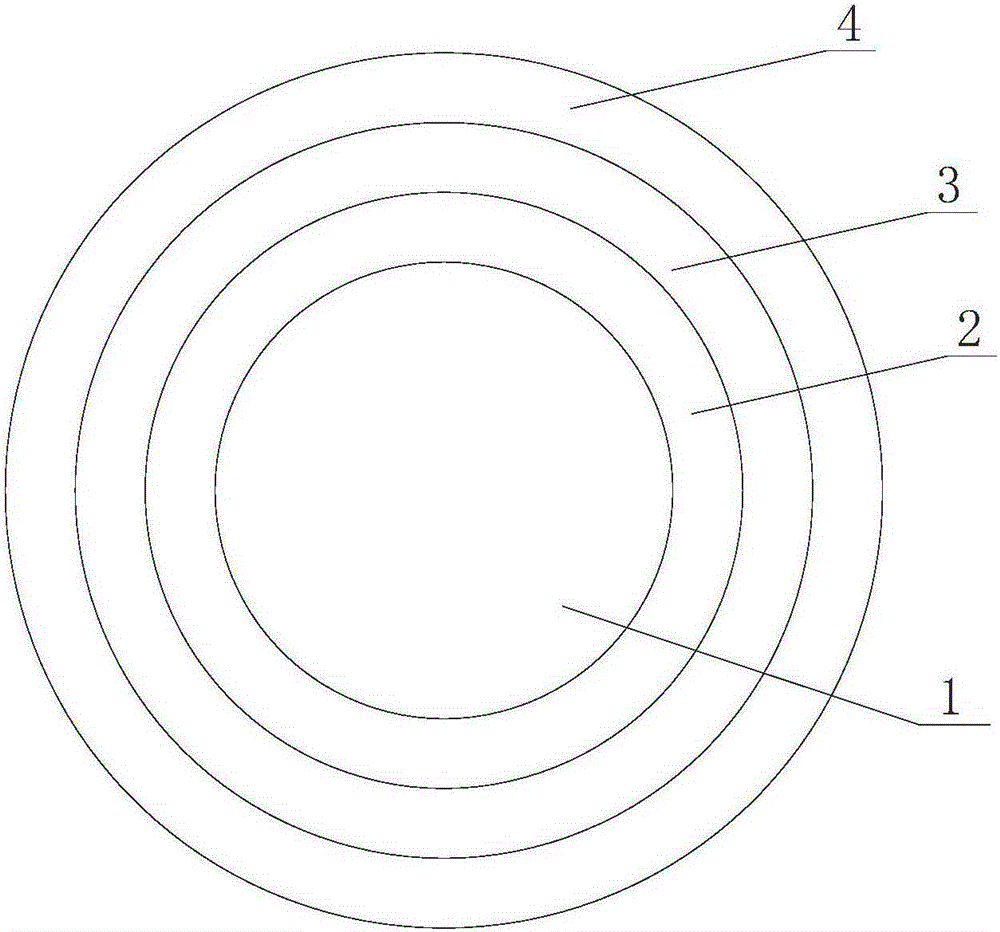

Heat conducting flame-retardant control cable

InactiveCN105199225AFacilitate cross-linkingImprove thermal conductivityInsulated cablesInsulated conductorsFiberAntioxidant

The invention discloses a heat conducting flame-retardant control cable which comprises a core, an insulating layer, a shielding layer and a sheath layer. The insulating layer wraps the core, the shielding layer wraps the insulating layer, and the sheath layer wraps the shielding layer; the insulating layer is made of low-smoke halogen-free polyolefin materials, the low-smoke halogen-free polyolefin materials comprise, by weight, polypropylene, methylvinyl silicone rubber, ethylene-vinyl acetate copolymers, tetra propyl ammonium phenylsulfonyl, isopropyl tri-(iso-stearoyl) titanate, caprolactam, magnesium oxide, 2, 5-dimethyl-2, 5-tert butyl peroxy-3-hexyne, alkylated diphenylamines, 2-mercapto benzimidazole zinc salt, dicyclohexyl phthalate, kaolin, cerium dioxide, polyacrylonitrile fibers, anti-aging agents and antioxidants. The heat conducting flame-retardant control cable has the advantages of good heat conductivity and excellent flame-retardant property.

Owner:ANHUI LAND GRP

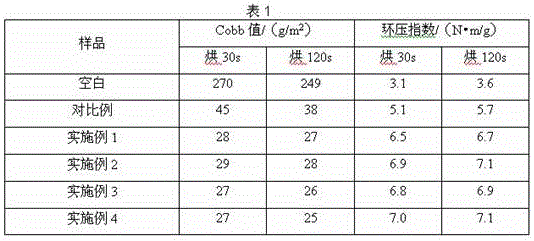

Novel surface sizing agent and preparation method thereof

ActiveCN106368062AIncreased ring compressive strengthReduce the Cobb valueWater-repelling agents additionPaper coatingAcetic acidGram

The invention discloses a novel surface sizing agent and a preparation method thereof. The preparation method comprises the following steps: 1, uniformly mixing methyl styrene, an acrylate monomer, a cationic monomer and an initiator to form a mixed monomer; 2, adding 10-20% of the mixed monomer obtained in the step 1 into a four-necked flask, heating to the temperature of 80-140 DEG C, reacting for 5-20 minutes, and dripping the residual mixed monomer; 3, adding acetic acid, and reacting at the temperature of 80-140 DEG C for 20-60 minutes; 4, adding preheated deionized water at the temperature of 80-140 DEG C, continuously reacting for 0.5-2 hours, adding siloxane for reacting 0.5-3 hours, cooling, and filtering, thereby obtaining the novel surface sizing agent. The novel surface sizing agent disclosed by the invention is capable of greatly reducing a Cobb value, promoting rapid curing, and greatly improving the ring crush compression resistance of corrugated paper and reducing gram weight of paper on the premise of maintaining invariable sizing agent amount.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

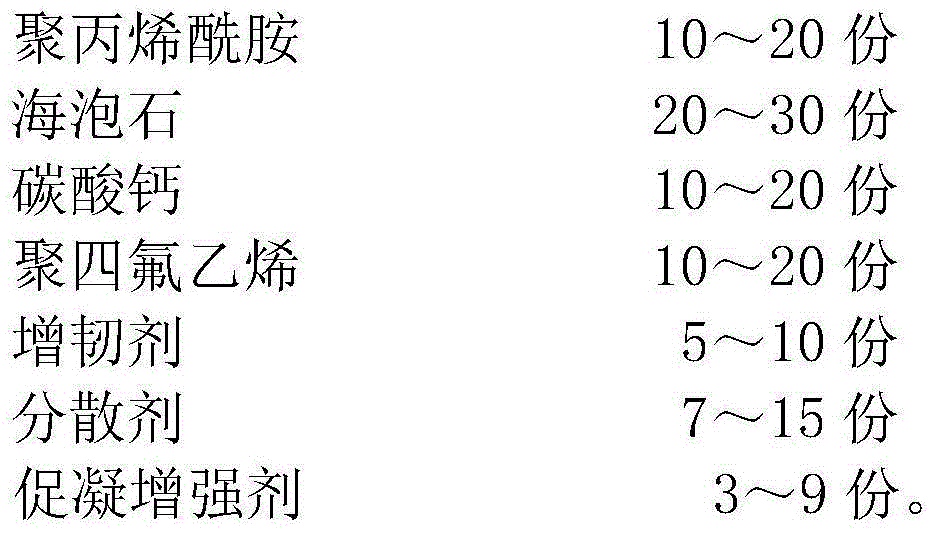

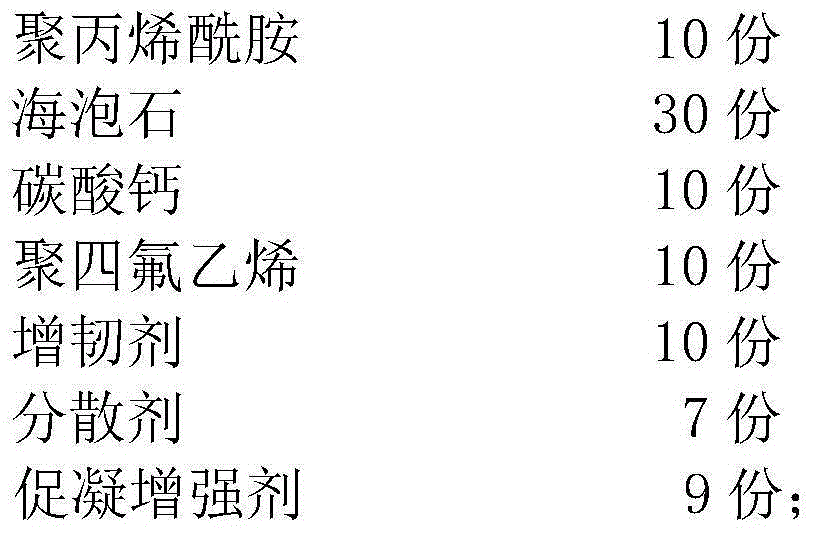

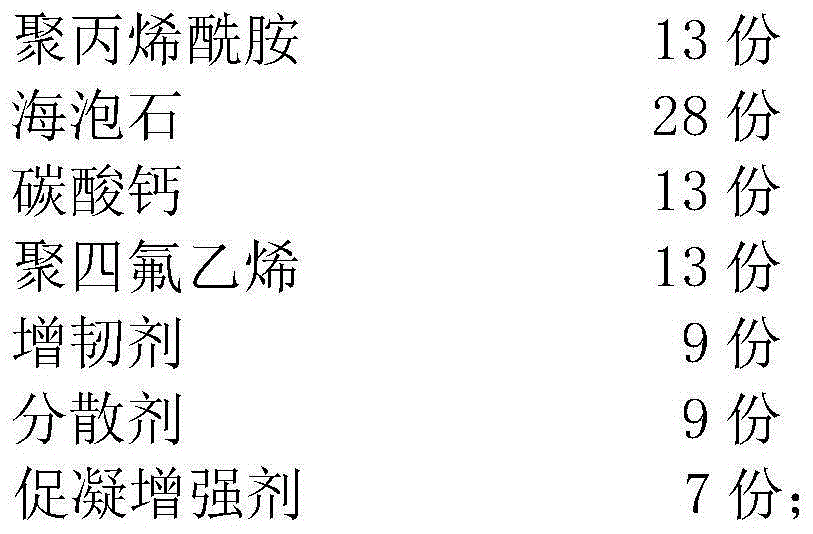

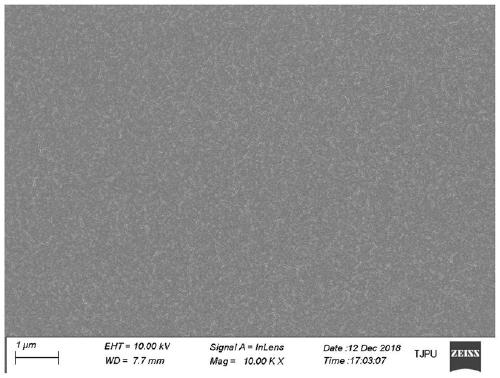

Expansion-controllable plugging agent

The invention relates to the technical field of a plugging agent, especially to an expansion-controllable plugging agent. The expansion-controllable plugging agent is prepared from the following raw materials, by weight, 60-80 parts of polyacrylamide, 10-20 parts of meerschaum, 10-20 parts of teflon, 5-10 parts of a flexibilizer, 7-15 parts of a dispersant and 3-9 parts of a coagulant enhancer. The expansion-controllable plugging agent can control expansion speed, has good deformability and adaptability, can reduce permeability of a plugged zone, enhance strength of the plugged zone and raise pressure-bearing capacity of the plugged zone, is low-cost, is non-toxic, harmless and pollution-free, and is green and environmentally friendly.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Preparation method of surface-heparinized anticoagulation medical device based on ionic bond-covalent bond synergistic action

The invention relates to the field of medical devices, in particular to a preparation method of a surface-heparinized anticoagulation medical device based on ionic bond-covalent bond synergistic action. The method comprises the following steps: firstly, fixing heparin on the surface of a medical device by utilizing a hydrophilic polymer modified by low-molecular-weight hyperbranched polyethyleneimine as a side chain in an ionic bond combination manner; and furthermore, grafting a stable heparin coating through covalent bonds, so as to obtain the anticoagulant biomedical device with high anticoagulant activity and high anticoagulant stability. The device has a wide application value in the field of biomedical treatment. The method is simple in preparation process, high in controllability and low in material price, does not involve toxic reagents in the experiment process, has universality for various medical device structures, and is suitable for industrial production.

Owner:JIANGSU STMED TECH CO LTD

Scale- and corrosion-inhibiting and antibacterial compounded water treatment agent and preparation method of same

The invention discloses a scale- and corrosion-inhibiting and antibacterial compounded water treatment agent which includes, by weight, 2-10% of 2-phosphonobutane-1,2,4-tricarboxylic acid, 2-10% of hydroxyl ethidine diphosphonic acid, 5-15% of hydrolyzed polymaleic anhydride, 3-10% of a sulfonic acid copolymer, 0.1-1% of alkylphenol polyoxyethylene ether, 2-10% of quaternary ammonium salt, 0.2-1% of benzotriazole, and the balanced being water. In the invention, a scale- and corrosion-inhibiting agent is compounded with an antibacterial agent, so that the water treatment agent is multifunctional and can deal with three major problems of scaling, corrosion and microorganisms in air conditioner circulation water. The water treatment agent is added in a continuous manner, so that the water treatment agent can quite stably control the microorganisms; in addition, according to water quality in site, ratio of the scale- and corrosion-inhibiting agent to the antibacterial agent can be adjusted on the basis of specific situations.

Owner:卢永杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com