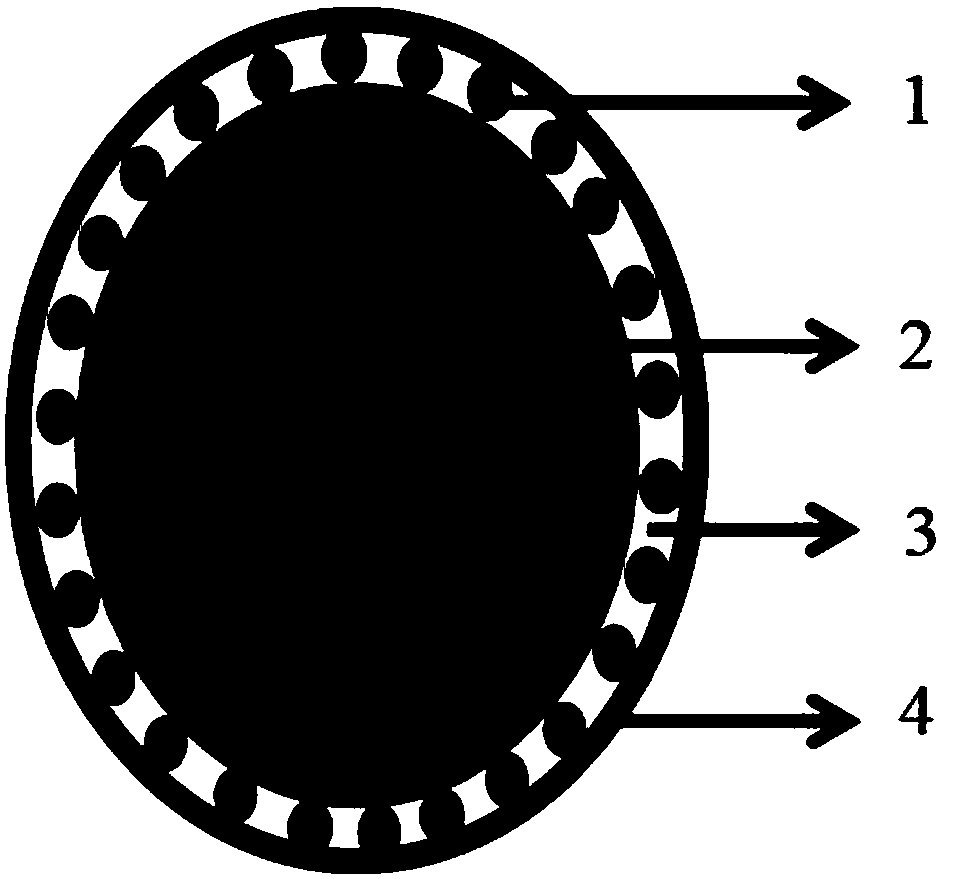

Double-shell-layer structure composite material, preparation method of double-shell-layer structure composite material, and lithium ion battery containing composite material

A composite material, double-shell technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of inability to meet commercial anode materials, large volume expansion, and poor cycle retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

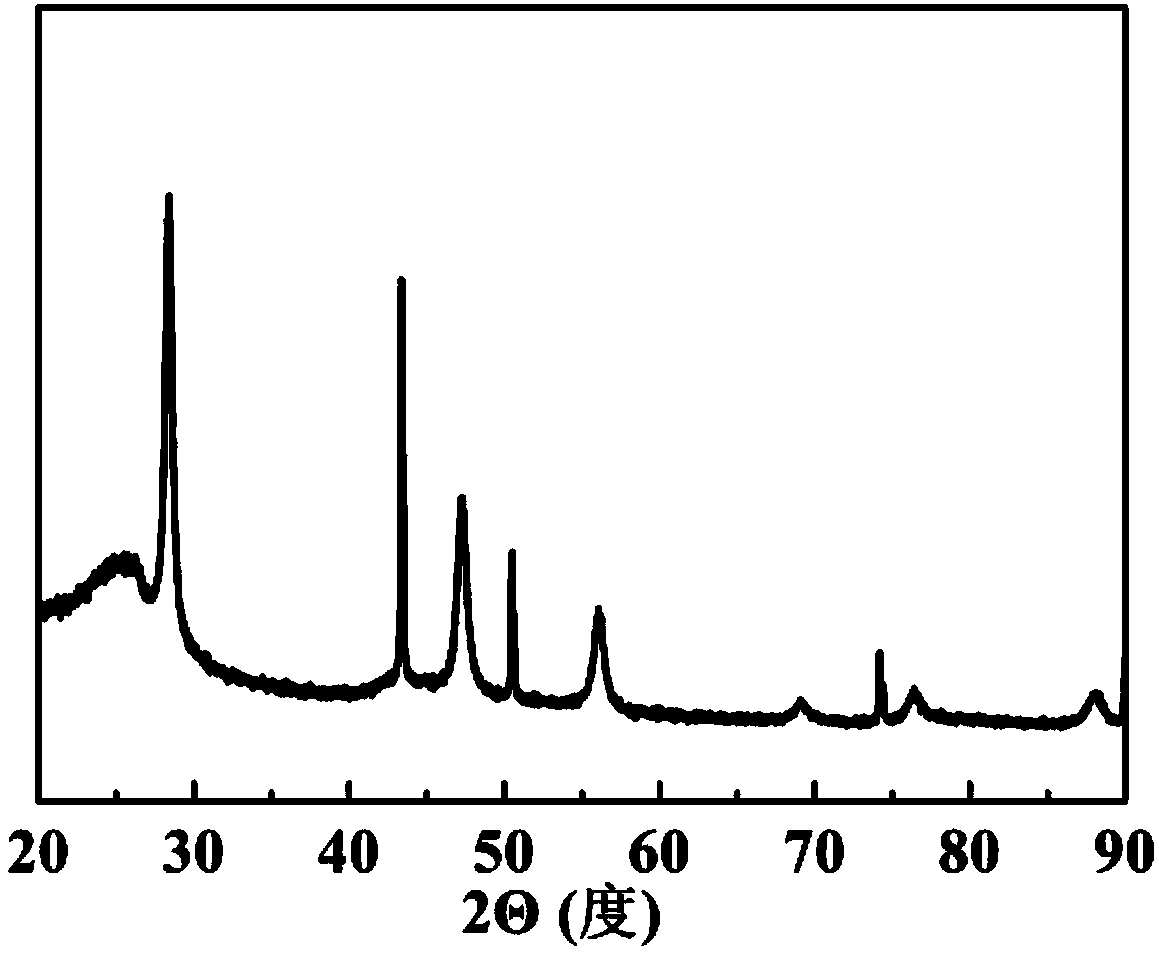

Embodiment 1

[0079] (1) Disperse nano-silicon with a median particle size of 100 nm in a mixed solvent of ethanol and deionized water, the mass ratio of ethanol and deionized water is 8:2, and ultrasonically stir for 1 h to obtain precursor suspension A.

[0080] (2) Add copper sulfate solid with a molar ratio of 10:3 to the precursor suspension A under stirring conditions, then add 0.5mol / L hydrochloric acid solution dropwise to the solution to adjust the pH=3 of the solution, After ultrasonic stirring for 0.5h, continue to slowly add 0.5mol / L sodium hydroxide solution to it, so that the copper particles are transformed into copper hydroxide and evenly coated on the surface of the nano-silicon particles, and the dripping is stopped when the pH of the solution is 7 Add sodium hydroxide solution, continue stirring for 0.5 h, filter, and dry to obtain precursor 1.

[0081] (3) Disperse the precursor 1 obtained in step (2) in deionized water, add glucose with a mass ratio of 1:2 to the precur...

Embodiment 2

[0088] (1) Disperse nano-silicon with a median particle size of 100 nm in a mixed solvent of ethanol and deionized water, the mass ratio of ethanol and deionized water is 8:3, and ultrasonically stir for 1 h to obtain precursor suspension A.

[0089](2) Add copper chloride solid with a nano-silicon molar ratio of 10:3 to the precursor suspension A under stirring conditions, and then add 0.5mol / L hydrochloric acid solution dropwise to the solution to adjust the pH of the solution to 3 After ultrasonic stirring for 0.5h, continue to slowly add 0.5mol / L sodium hydroxide solution to it, so that the copper particles are converted into copper hydroxide and evenly coated on the surface of the nano-silicon particles, and the dripping is stopped when the pH of the solution is 7. Add sodium hydroxide solution, continue stirring for 0.5 h, filter, and dry to obtain precursor 1.

[0090] (3) Disperse the precursor obtained in step (2) in deionized water, add aniline monomer with a mass ra...

Embodiment 3

[0092] (1) Disperse nano-silicon with a median particle size of 100 nm in ethanol / deionized water mixed solvent, the mass ratio of ethanol and deionized water is 1:1, and ultrasonically stir for 1 h to obtain precursor suspension A.

[0093] (2) Add copper chloride solid with a nano-silicon molar ratio of 10:3 to the precursor suspension A under stirring conditions, and then add 0.5mol / L hydrochloric acid solution dropwise to the solution to adjust the pH of the solution to 3 After ultrasonic stirring for 0.5h, continue to slowly add 0.5mol / L sodium hydroxide solution to it, so that the copper particles are converted into copper hydroxide and evenly coated on the surface of the nano-silicon particles, and the dripping is stopped when the pH of the solution is 7. Add sodium hydroxide solution, continue stirring for 0.5 h, filter, and dry to obtain precursor 1.

[0094] (3) Disperse the precursor 1 and asphalt obtained in step (2) in the n-butanol solution at a mass ratio of 55:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com