Preparation method for cationic-type activated carbon

A cationic, activated carbon technology, used in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as cationic activated carbon that have not yet been found, and achieve good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, a kind of preparation method of positively charged cationic activated carbon comprises the following steps:

[0028] (1) Activated carbon pretreatment: wash 2g of activated carbon with water, dry at 80°C-100°C, crush to 100-200 mesh, and oxidize the activated carbon with 10mL of 36% hydrochloric acid for 10h to make more hydroxyl groups appear on the surface;

[0029] (2) Put the three-neck flask into the water bath, heat up to 85°C, add the activated carbon pretreated in step (1), then add 5mL epichlorohydrin, 5mL N-N dimethylformamide, and stir for 1h;

[0030] (3) Add 3mL of ethylenediamine, the reaction is violent during this process, so it is advisable to add slowly drop by drop. React for 1 hour; continue to add 5 mL of triethylamine, and react for 30 minutes.

[0031] (4) After the reaction, cool to room temperature, wash, and dry at 70°C to obtain a cationic activated carbon product.

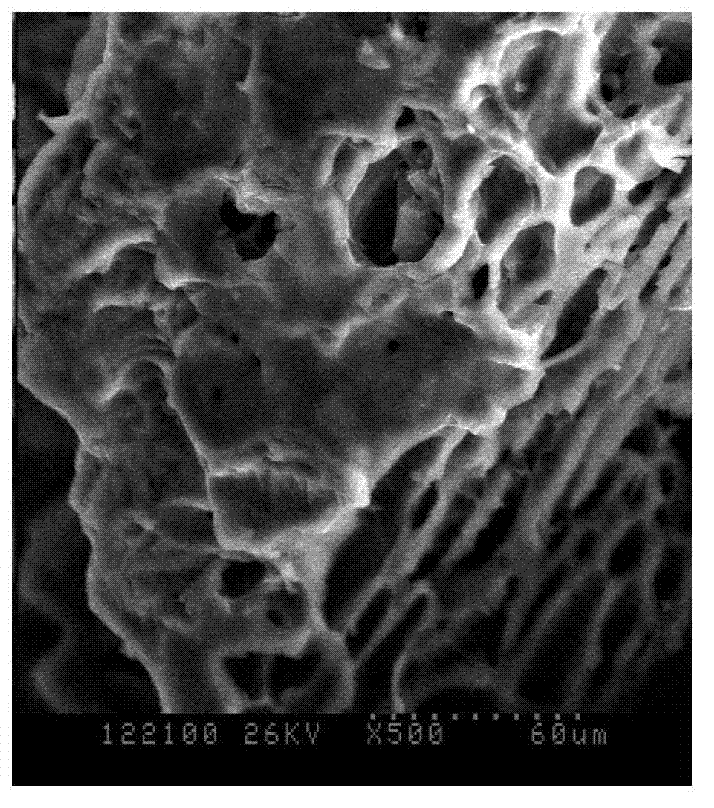

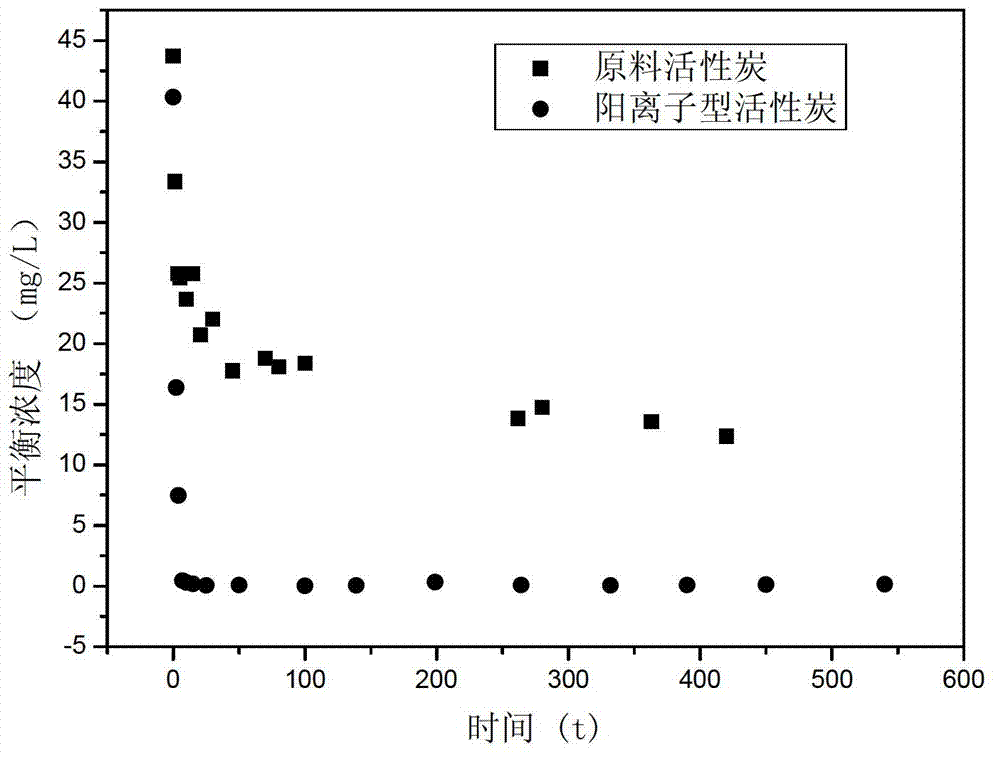

[0032] The scanning electron microscope picture of the cation...

Embodiment 2

[0034] As described in Example 1, the difference is: 40% sulfuric acid was used to oxidize the activated carbon for 10 h during the pretreatment of the activated carbon, so that more hydroxyl groups appeared on the surface.

Embodiment 3

[0035] Embodiment 3, a kind of preparation method of cationic activated carbon comprises the following steps:

[0036] (1) Activated carbon pretreatment

[0037] Wash 6g of activated carbon with water, dry at 80°C-100°C, crush to 100-200 mesh, impregnate with 30mL of 36.5% concentrated hydrochloric acid, and treat for 9h;

[0038] (2) Add the activated carbon pretreated in step (1) into the reaction vessel, raise the temperature to 86°C in a water bath, then add 15mL of epichlorohydrin and 16mL of N-N dimethylformamide, and stir for 1.2h;

[0039] (3) Then add ethylenediamine 10mL dropwise and react for 1.2h; continue to add triethylamine 15mL dropwise and react for 40 minutes.

[0040] (4) After the reaction, cool to room temperature, wash, and dry at 70-75°C to obtain a cationic activated carbon product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com