Preparation method of high-strength high-toughness graphene/metal composite material

A metal composite material, high-strength and high-toughness technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor bonding between graphene and metal interfaces, easy agglomeration, uneven dispersion of graphene, etc., and achieve a compact structure , good combination, satisfying the effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

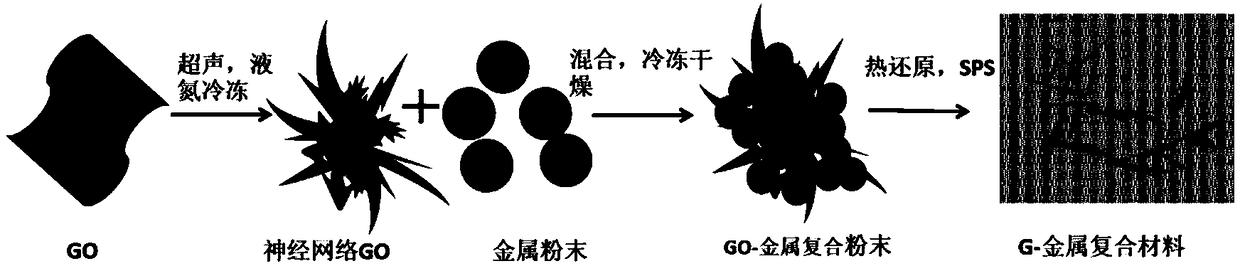

Method used

Image

Examples

Embodiment 1

[0028] Graphene oxide (with a sheet diameter of 20 μm and a thickness of 2 nm) was dispersed in an aqueous solution and ultrasonically dispersed for 1 h to prepare a graphene oxide solution with a concentration of 2 mg / mL. Then heated in a water bath at 80 °C for 20 min and quickly poured into liquid nitrogen. Melt the frozen graphene oxide and mix it with 10 μm flake copper powder (graphene oxide volume fraction is 1%) in water / alcohol solution (v:v=1:9) at high shear speed. is 10000 rpm, and the mixing time is 1 h to obtain a graphene-copper mixed dispersion. The mixed dispersion was quickly placed in liquid nitrogen to freeze to form a solid, and then freeze-dried for 48 h to obtain graphene / copper composite powder. The graphene / copper powder was transferred to a tube furnace and reduced at 300 °C for 60 min in an argon / hydrogen (9:1 v / v) atmosphere. The thermally reduced composite powder was subjected to spark plasma sintering at a sintering temperature of 700 °C, a sint...

Embodiment 2

[0030] Graphene oxide (with a sheet diameter of 20 μm and a thickness of 2 nm) was dispersed in an aqueous solution and ultrasonically dispersed for 1 h to prepare a graphene oxide solution with a concentration of 1 mg / mL. Then heated at 80 °C water area temperature for 20 min and quickly poured into liquid nitrogen. The frozen graphene oxide was melted and mixed with 5 μm spherical copper powder (graphene oxide volume fraction 1%) in water / alcohol solution (v:v=1:9) at high shear speed. 10000 rpm, the mixing time is 2 h, and the graphene-copper mixed dispersion is obtained. The mixed dispersion was quickly poured into liquid nitrogen to freeze to form a solid, and then freeze-dried for 48 h to obtain graphene / copper composite powder. The graphene-copper powder was transferred to a tube furnace and reduced at 400 °C for 60 min in an argon / hydrogen (9:1 v / v) atmosphere. The thermally reduced composite powder was subjected to spark plasma sintering at a sintering temperature o...

Embodiment 3

[0032]Graphene oxide (with a sheet diameter of 10 μm and a thickness of 2 nm) was dispersed in an aqueous solution and ultrasonically dispersed for 1 h to prepare a graphene oxide solution with a concentration of 1 mg / mL. Then heated in a water bath at 60 °C for 20 min and then quickly poured into liquid nitrogen. Melt the frozen graphene oxide and mix it with 2 μm aluminum powder (graphene oxide volume fraction is 1%) in water / alcohol solution (v:v=1:9) at high shear speed at 10000 rpm, and the mixing time was 1 h to obtain a graphene-aluminum mixed dispersion. The mixed dispersion was quickly placed in liquid nitrogen to freeze to form a solid, and then freeze-dried for 48 h to obtain graphene / aluminum composite powder. The graphene-aluminum composite powders were transferred to a tube furnace and reduced at 300 °C for 60 min in an argon / hydrogen (9:1 v / v) atmosphere. The thermally reduced composite powder was subjected to spark plasma sintering at a sintering temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com