Anti-mould PE (polyethylene) alloy with high hardness and friction resistance and preparation method of anti-mould PE alloy

A friction-resistant, high-hardness technology, which is applied in the field of high-hardness, friction-resistant and antibacterial PE alloys and its preparation, can solve the problems of low insulation of high-density polyethylene, high price of high-density polyethylene, and no improvement in insulation performance and antibacterial performance. problem, to achieve the effect of improving antibacterial performance, improving compatibility, and improving abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

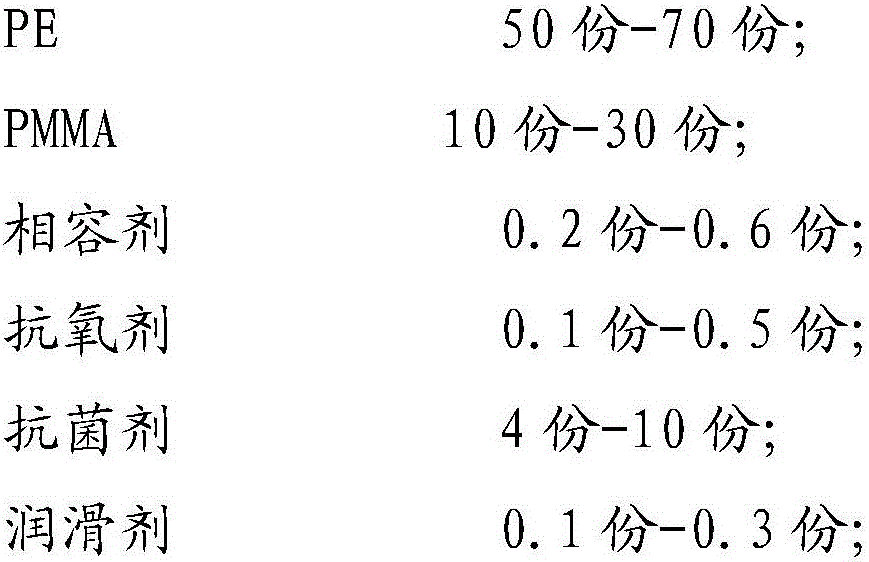

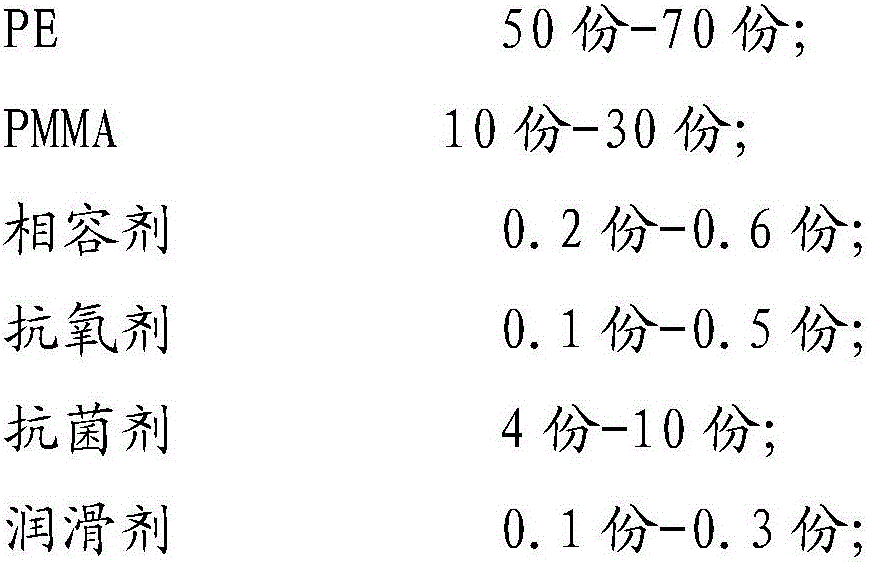

Method used

Image

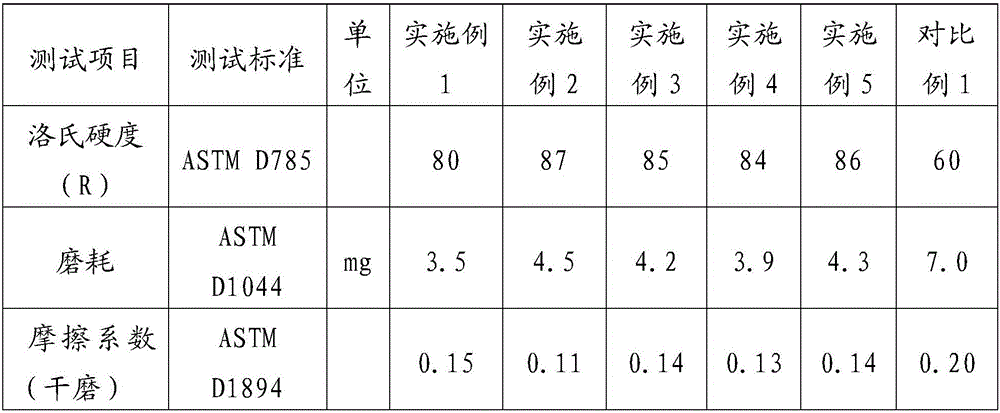

Examples

Embodiment 1

[0033] Weigh 50 parts of PE, 10 parts of PMMA, 0.2 part of PE-g-MAH, 0.05 part of Irganox1010, 0.05 part of Irganox168, 4 parts of cuprous bromide and 0.1 part of ethylene bisstearamide.

[0034] The weighed above-mentioned materials were stirred by a high-speed mixer for 10 minutes to form a mixed material.

[0035] The mixed material is put into the hopper of the twin-screw extruder, melted and reacted, then extruded and granulated.

[0036] Among them, the temperature of the high-speed mixer is 70° C., and the rotation speed is 120 r / min. The twin-screw extruder consists of six zones, in which the temperature and screw speed of each zone are: the temperature of the first zone is 150°C, the temperature of the second zone is 170°C, the temperature of the third zone is 170°C, the temperature of the fourth zone is 170°C, and the temperature of the fifth zone is 170°C. The temperature is 170°C, the temperature in the sixth zone is 170°C, the head temperature is 170°C; the screw...

Embodiment 2

[0038] Weigh 70 parts of PE, 30 parts of PMMA, 0.6 parts of PE-g-MAH, 0.25 parts of Irganox1010, 0.25 parts of Irganox168, 10 parts of silver chloride and 0.3 parts of simethicone.

[0039] The weighed above-mentioned materials were stirred by a high-speed mixer for 12 minutes to form a mixed material.

[0040] The mixed material is put into the hopper of the twin-screw extruder, melted and reacted, then extruded and granulated.

[0041] Among them, the temperature of the high-speed mixer is 120° C., and the rotation speed is 240 r / min. The twin-screw extruder consists of six zones, in which the temperature and screw speed of each zone are: the temperature of the first zone is 180°C, the temperature of the second zone is 200°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 200°C, and the temperature of the fifth zone is 200°C. The temperature is 200°C, the temperature in the sixth zone is 200°C, the head temperature is 200°C; the screw spee...

Embodiment 3

[0043] Weigh 60 parts of PE, 20 parts of PMMA, 0.4 parts of PE-g-MAH, 0.15 parts of Irganox1010, 0.15 parts of Irganox168, 7 parts of silver chloride and 0.2 parts of simethicone.

[0044] The weighed above-mentioned materials were stirred by a high-speed mixer for 11 minutes to form a mixed material.

[0045] The mixed material is put into the hopper of the twin-screw extruder, melted and reacted, then extruded and granulated.

[0046] Wherein the temperature of the high-speed mixer is 95° C., and the rotation speed is 180 r / min. The twin-screw extruder consists of six zones, in which the temperature and screw speed of each zone are: the temperature of the first zone is 165°C, the temperature of the second zone is 185°C, the temperature of the third zone is 185°C, the temperature of the fourth zone is 185°C, and the temperature of the fifth zone is 185°C. The temperature is 185°C, the temperature in the sixth zone is 185°C, the head temperature is 185°C; the screw speed is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com