Patents

Literature

113results about How to "Improve UV aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

Polyurethane caulking material for expansion joints of ballastless track of high speed railway

ActiveCN103992633AImprove displacement abilityModerate mechanical strengthLow temperature curingBond properties

A polyurethane caulking material for expansion joints of a ballastless track of a high speed railway is disclosed. The caulking material is prepared from two parts A and B. the part A is composed of the following raw materials, by weight, 100 parts of isocyanate and its prepolymer, 10-150 parts of a plasticizer, 5-150 parts of a solid filler, 1-20 parts of a diluents, 1-5 parts of an adhesion promoter, 0-10 parts of a thixotropic agent and 1-3 parts of a water-removal agent. The part B is composed of the following raw materials, by weight, 10-20 parts of modified polyhydric alcohol, 1-5 parts of a diluent, 2-30 parts of a plasticizer, 5-30 parts of a solid filler, 0-5 parts of a thixotropic agent, 0.5-2 parts of an antifoaming agent, 0.1-1 part of an anti-aging agent and 0-0.01 part of a catalyst. The mass ratio of the part A to the part B is 4:1-10:1. The polyurethane caulking material has advantages of good low-temperature curing performance, high displacement capability, low tensile modulus, good bond property and excellent endurance quality and fatigue resistance, and is suitable for expansion joints of a ballastless track of a high speed railway as well as expansion joints of roads and airfield runways.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Magnesium-aluminum-base laminar dihydroxide anti-aging elastomer modified asphalt coating material and preparation method thereof

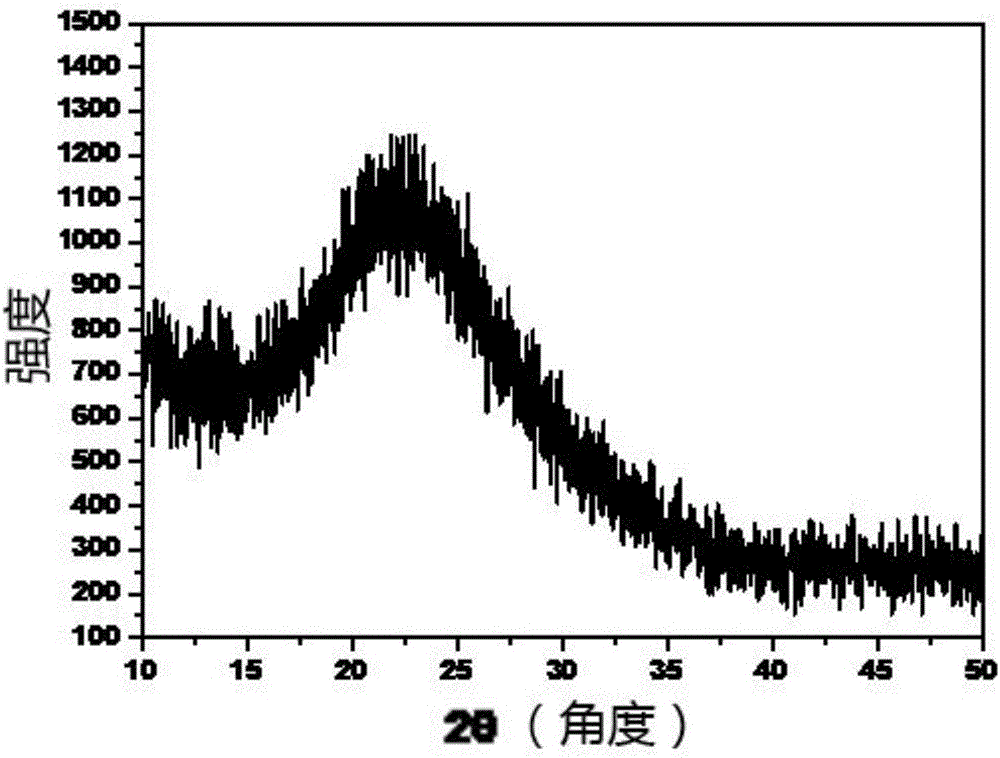

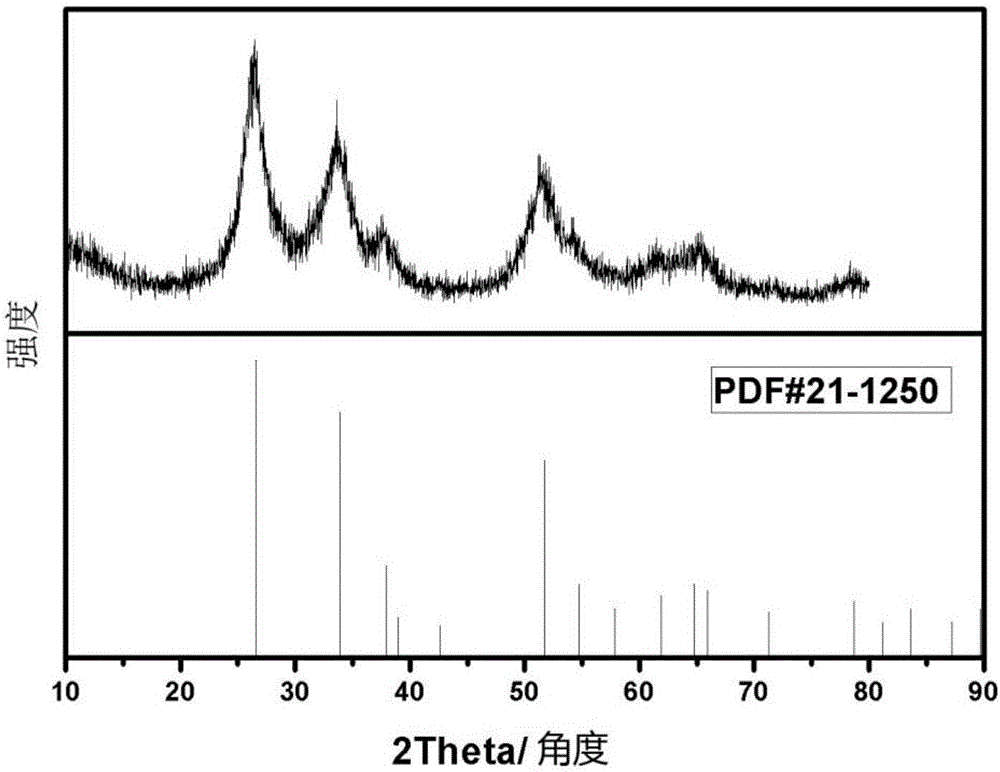

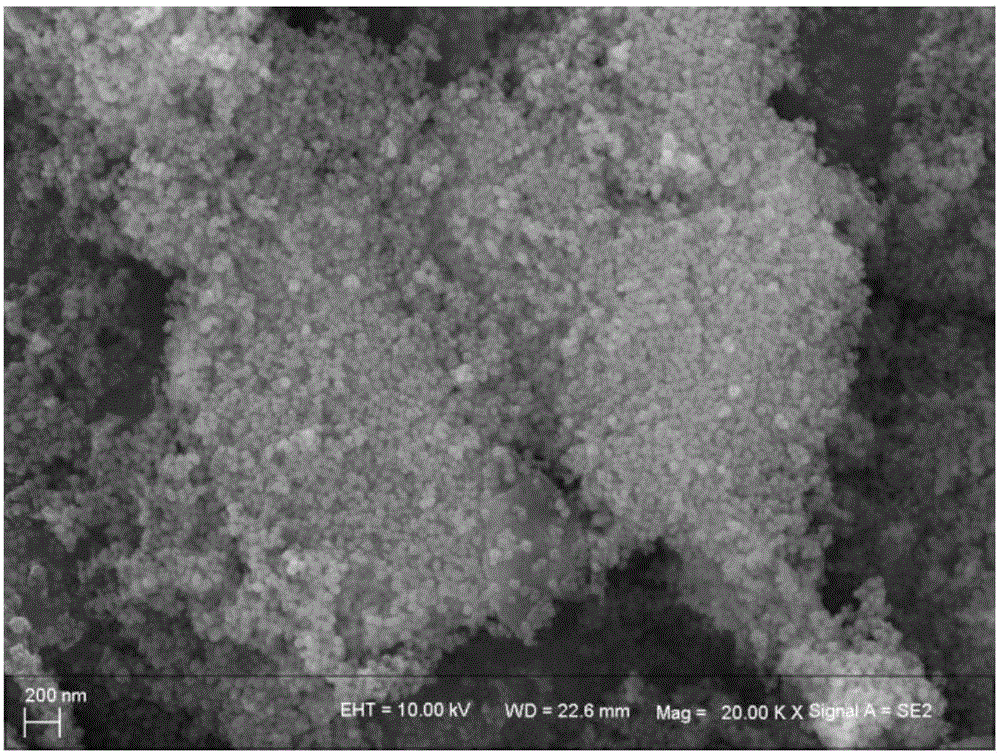

InactiveCN102190957AImproves UV resistanceImprove UV aging resistanceBituminous coatingsElastomerUltraviolet

The invention relates to an anti-aging elastomer modified asphalt coating material for a waterproof coiled material and a preparation method thereof. The magnesium-aluminum-base laminar dihydroxide anti-aging elastomer modified asphalt coating material is characterized by comprising the following raw materials in percentage by mass: 50.5-67.9% of asphalt, 6-8% of SBS (styrene-butadiene-styrene) modifier, 1-6% of magnesium-aluminum-base laminar dihydroxide, 0.1-0.5% of stabilizer and 25-35% of filler. Since the magnesium-aluminum-base laminar dihydroxide is added into the asphalt, the ultraviolet resistance of the elastomer modified asphalt is improved by the physical shielding and chemical absorption actions on the ultraviolet, thereby obviously enhancing the ultraviolet aging resistance of the waterproof coiled material.

Owner:WUHAN UNIV OF TECH

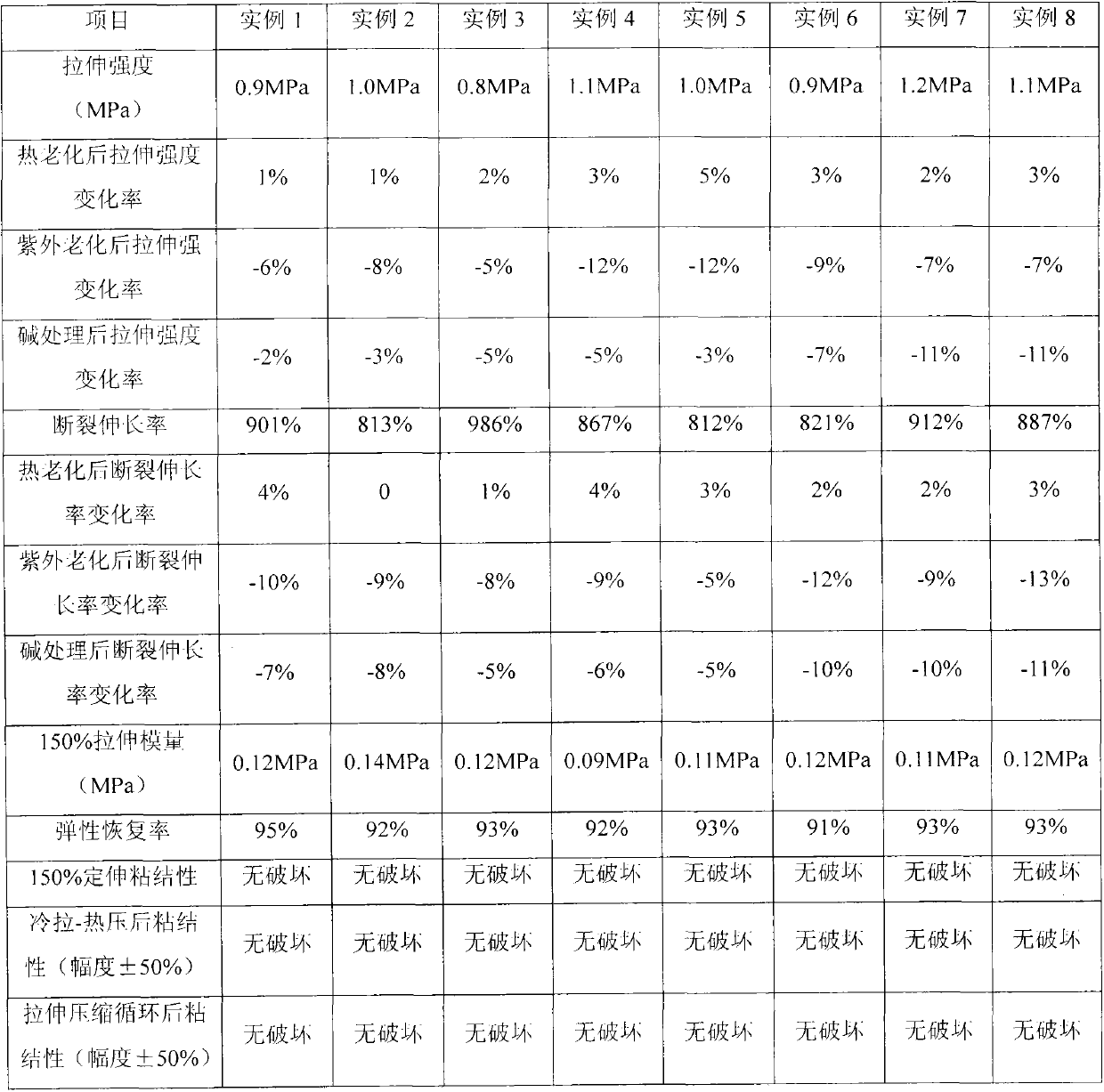

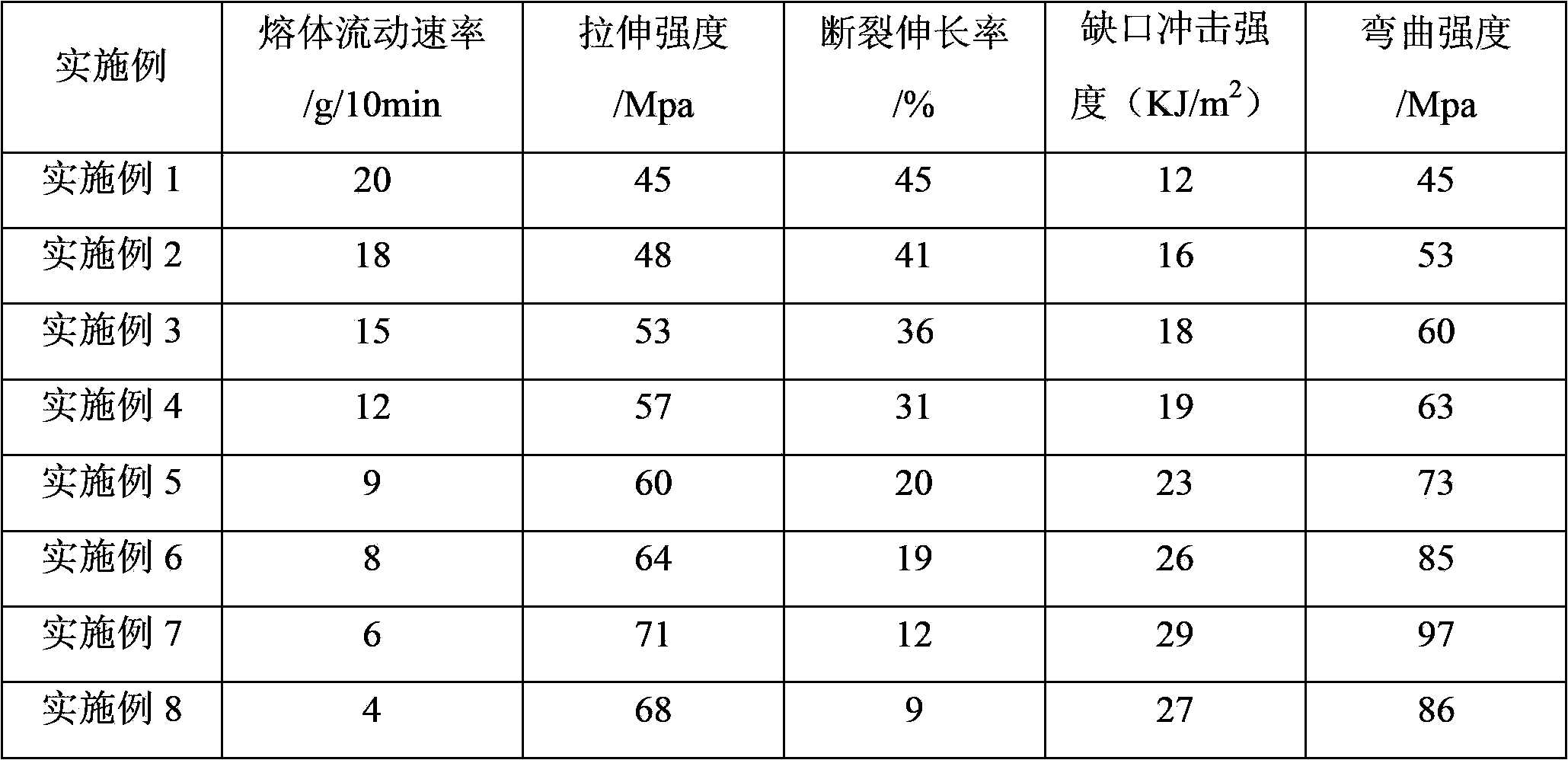

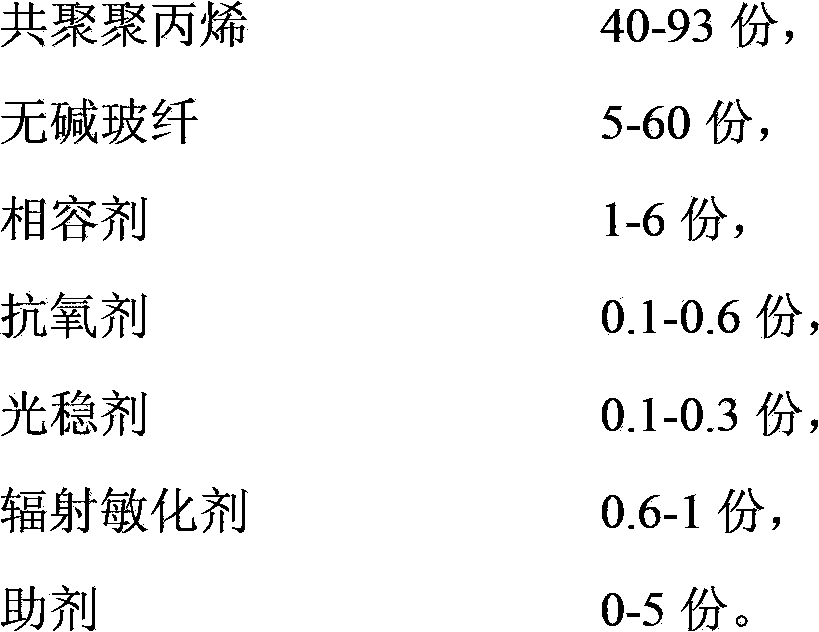

Weather resistant polypropylene composite material and its preparation method and uses

InactiveCN103509247AAvoid damageAvoid breakingForming/stuttering elementsGlass fiberPolypropylene composites

The invention belongs to the technical field of polymer composite materials, and relates to a polypropylene composite material and its preparing method and uses. The polypropylene composite material comprises the following components by weight: 40-93 parts of co-polypropylene, 5-60 parts of alkali free glass fiber, 1-6 parts of a compatible agent, 0.1-0.6 part of an antioxidant, 0.1-0.3 part of a light stabilizer, 0.6-1 part of a radiation sensitizing agent and 0-5 parts of an additive. Through cooperation of the functional additives, the high-strength, high-toughness and weather resistant composite material for building templates can be prepared, and the polypropylene composite material can be used for the preparation of various building templates and other outdoor equipment due to its excellent comprehensive properties.

Owner:HEFEI GENIUS NEW MATERIALS

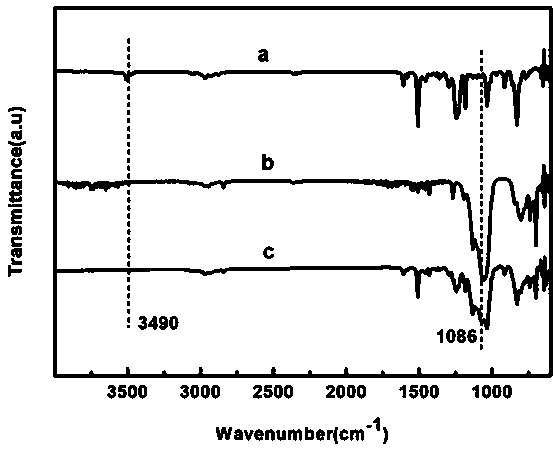

Polysiloxane modified epoxy resin and preparation method thereof

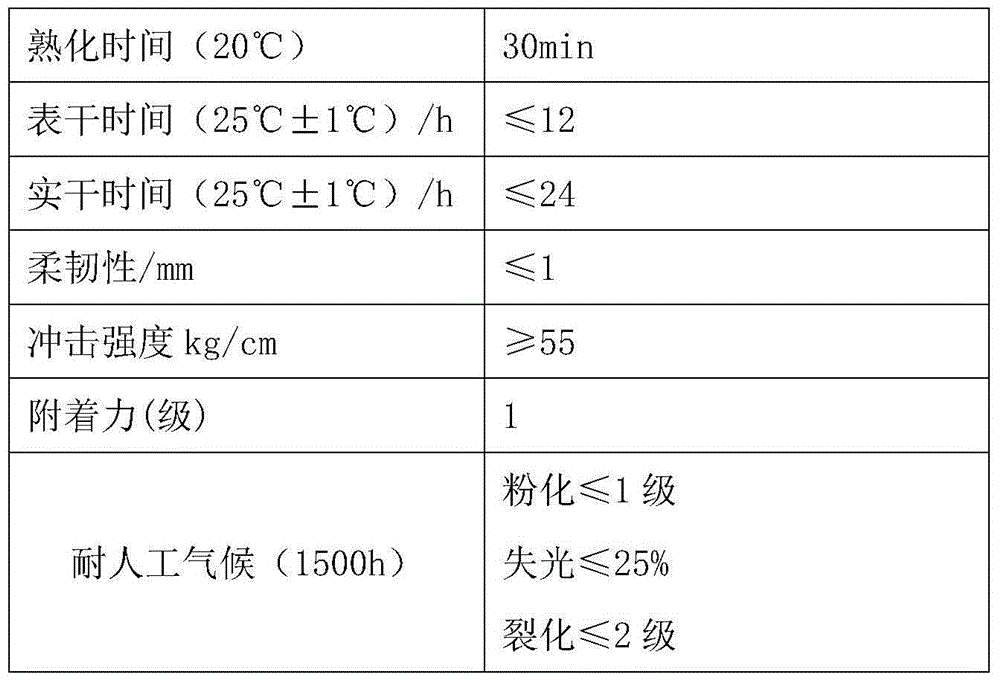

The invention discloses polysiloxane modified epoxy resin and a preparation method thereof. The preparation method comprises the following steps: firstly mixing and dissolving epoxy resin and polysiloxane in an organic solvent, dropwise adding a catalyst at a temperature of 60-100 DEG C in a nitrogen environment, then carrying out stirring for reacting to obtain polysiloxane modified epoxy resin,removing unreacted polysiloxane after the reaction is finished, and carrying out reduced-pressure distillation to remove the organic solvent to obtain the pure modified resin. The polysiloxane modified epoxy resin prepared by the invention can be cured into a film at room temperature, the obtained coating has good flexibility and impact resistance, the ultraviolet aging resistance is remarkably improved, and the service life is greatly prolonged. In addition, the process is simple, and energy consumption is low.

Owner:FUZHOU UNIV

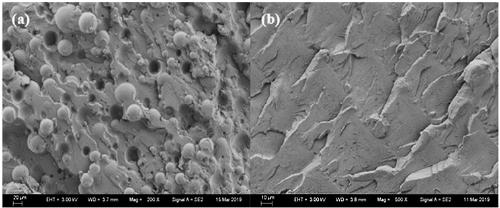

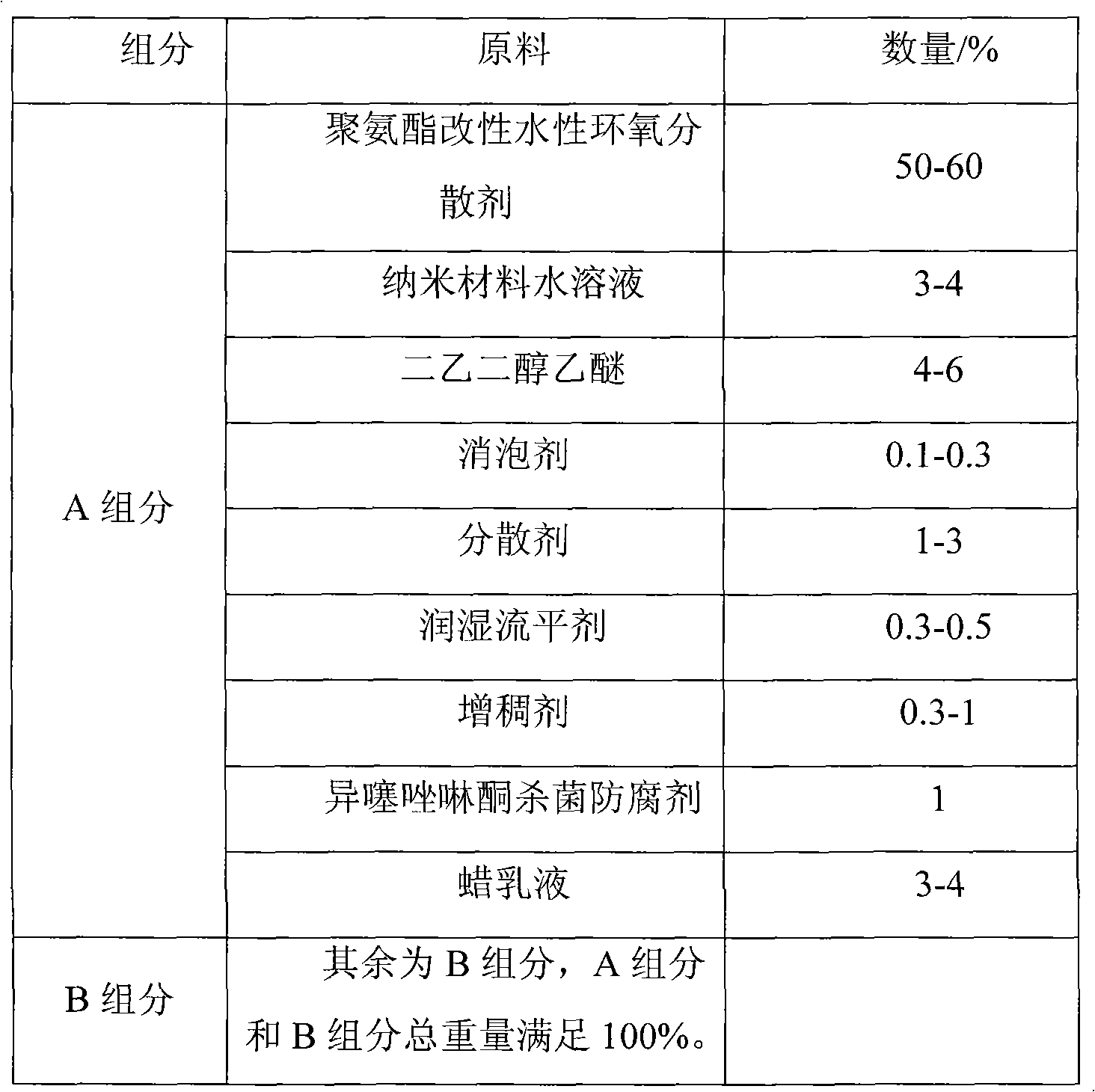

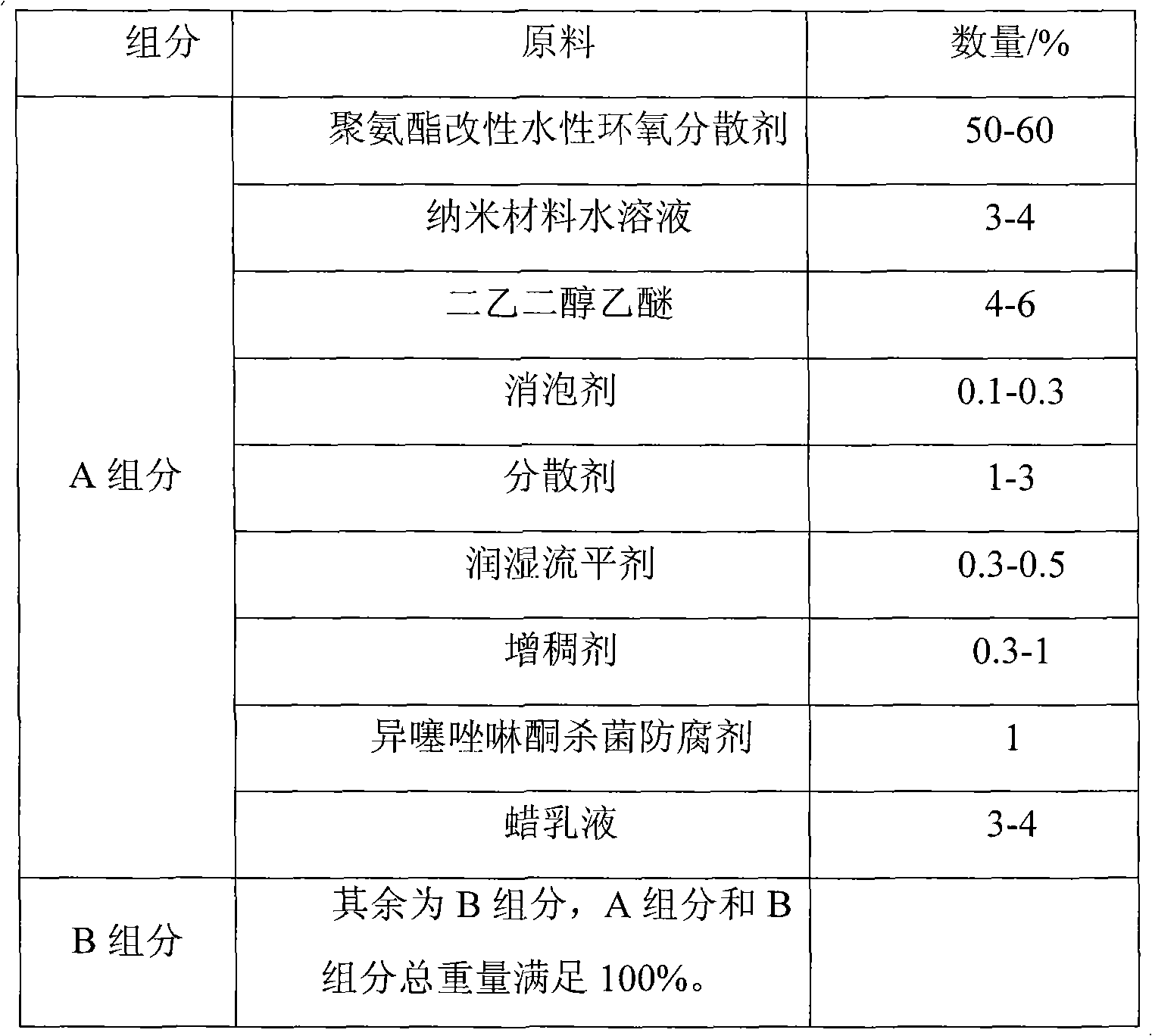

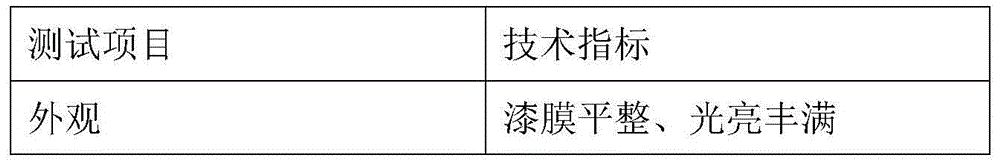

Preparation method of high abrasion water-borne wood coating

The invention belongs to the technical field of coating synthesis, in particular to a preparation method of a high abrasion water-borne wood coating, which comprises the following steps: firstly, using epoxy resin and polyamine to prepare a self-emulsifying water-borne epoxy resin curing agent; and then adding related additive and nano material water solution in polyurethane modified epoxy emulsion, and dispersing at high speed; and finally, blending the prepared curing agent and uniformly dispersed mixture to prepare the product. The invention fully utilizes and combines the advantages of epoxy resin, polyurethane, wax emulsion and inorganic nano-materials, and the obtained product achieves the standard through performance measurement; and the cost is substantially reduced in the experiment process, and the coating has no pollution to the environment, saves energy, and has greater application prospect in the filed of wood coatings.

Owner:TONGJI UNIV

Weather-proof and water-proof cable sheathing material

InactiveCN105255076AGood weather resistanceImprove pollutionPlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chloridePolymethyl methacrylate

The invention discloses a weather-proof and water-proof cable sheathing material. The weather-proof and water-proof cable sheathing material comprises raw materials as follows: polyvinylidene fluoride, polymethyl methacrylate, polyvinyl chloride, acrylonitrile-styrene-butyl acrylate copolymer, nitrile rubber, nano titanium dioxide, nano silica, carbon nano tubes, mica powder, zinc stearate, calcium stearate, zinc oxide, stearic acid, dibutyl phthalate, acetyl trihexyl citrate, triethyl citrate, coumarone resin, an anti-ageing agent, polyvinyl butyral and a silane coupling agent. The weather-proof and water-proof cable sheathing material has high strength, good water resistance and weather resistance and excellent processing performance.

Owner:ANHUI LAND GRP

Ultraviolet-aging-resistant antirust epoxy finish paint and preparation method thereof

InactiveCN104356862AImprove UV aging resistanceUniform and stable performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyUltraviolet

The invention relates to an antirust paint, particularly an ultraviolet-aging-resistant antirust epoxy finish paint and a preparation method thereof. The paint is prepared from the following raw materials in parts by weight: 40-50 parts of epoxy resin, 22-28 parts of polyamide resin, 3-4 parts of ferrocene, 1-3 parts of castor oil polyethenoxy ether, 2-3 parts of polyoxy alkylidene diamine, 1-2 parts of dihydroxy methylbutyric acid, 8-10 parts of nano titanium dioxide, 4-6 parts of hydrogenated rosin, 20-25 parts of butyl acetate, 12-15 parts of n-butanol, 18-25 parts of antirust pigment and 2-3 parts of assistant. The paint raw materials contain the modified ferrocene and nano titanium dioxide powder, so that the combining capacity with the resin slurry can be enhanced, and the ultraviolet aging resistance of the epoxy resin is greatly improved. The raw materials of the epoxy finish paint are combined more sufficiently; the epoxy finish paint has excellent mechanical properties after being completely cured; and the epoxy finish paint has higher outdoor service performance and higher durability, and is suitable to be used as a matched finish paint for various high-performance special-type antirust primers, epoxy zinc-rich paints and epoxy micaceous iron antirust paints.

Owner:合肥宏图彩印有限公司

Preparation method of nanocomposite epoxy polysiloxane coating cured at room temperature and coating thereof

ActiveCN102277083ASimple manufacturing processLow costLiquid surface applicatorsEpoxy resin coatingsEpoxyManufacturing technology

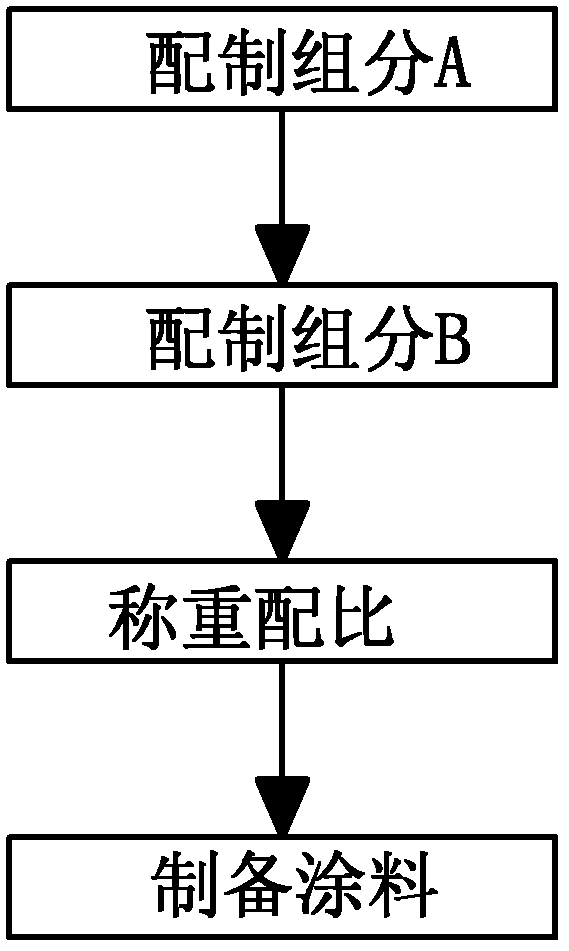

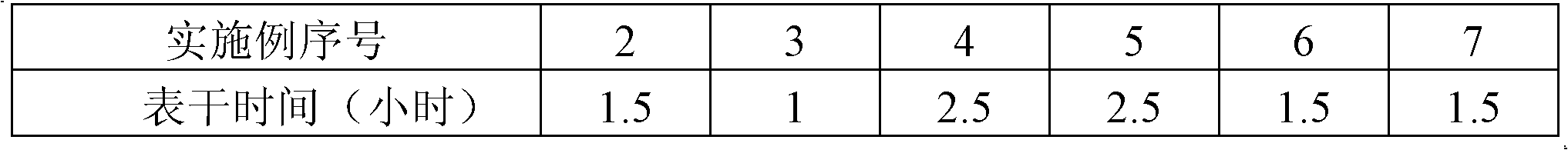

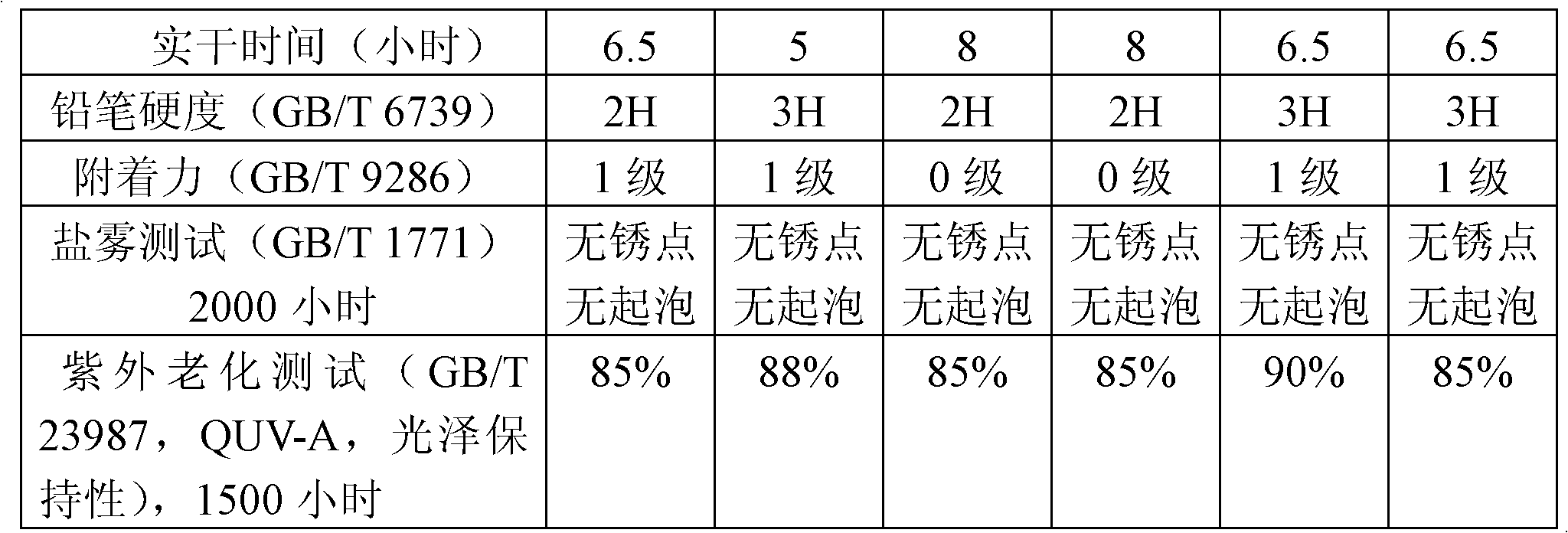

The invention discloses a preparation method of a nanometer composite epoxy polysiloxane coating solidified at room temperature, and the method comprises the following steps: (1) preparing a component A; (2) preparing a component B; (3) weighing and proportioning; and (4) preparing the coating: mixing the component A and the component B in a certain proportion to obtain the coating. The inventionalso discloses a coating which is obtained by implementing the preparation method of the nanometer composite epoxy polysiloxane coating solidified at room temperature. The method provided by the invention has the advantages of simple manufacture technology, low cost and high efficiency. The coating provided by the invention can be cured into a film at constant temperature and is convenient to use, no heat sources are needed, the energy consumption is lowered, and the coating has better corrosion resistance and ultraviolet ray aging resistance; the service life is greatly prolonged; and the coating is especially suitable for the anticorrosion requirements of large industrial steel structures, such as offshore oil platforms, oil tanks, ship superstructures, bridges and the like.

Owner:上海华晖新材料科技宿迁有限公司

Transparent heat insulation film and preparation method thereof

ActiveCN104231910AImproves UV resistanceImprove performancePolyurea/polyurethane coatingsPolyester coatingsPolyesterCarbon nanotube

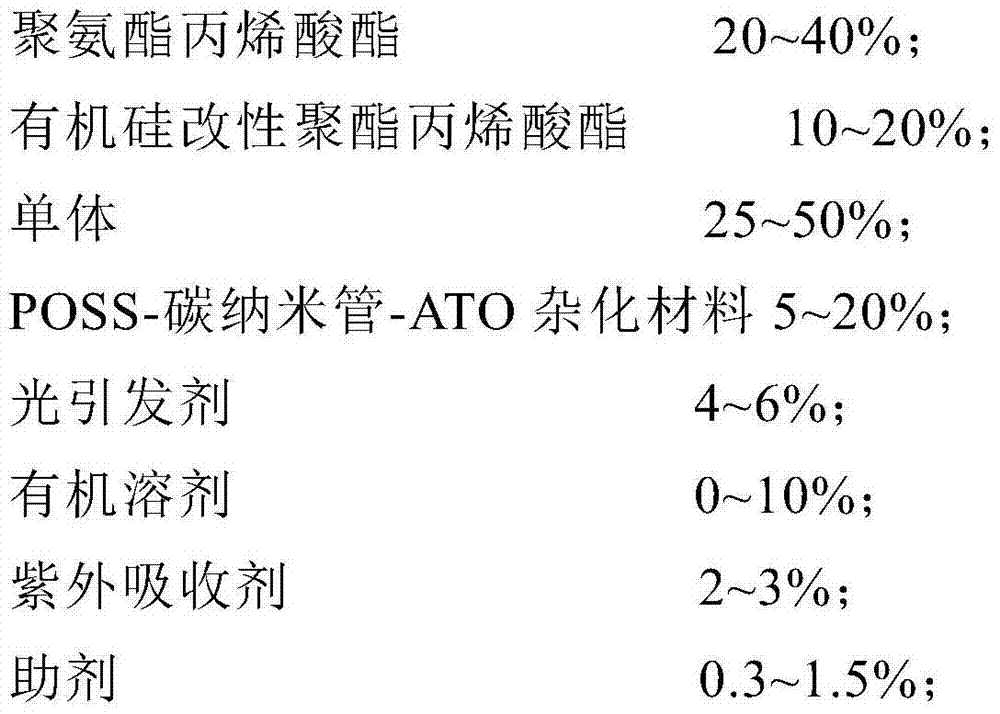

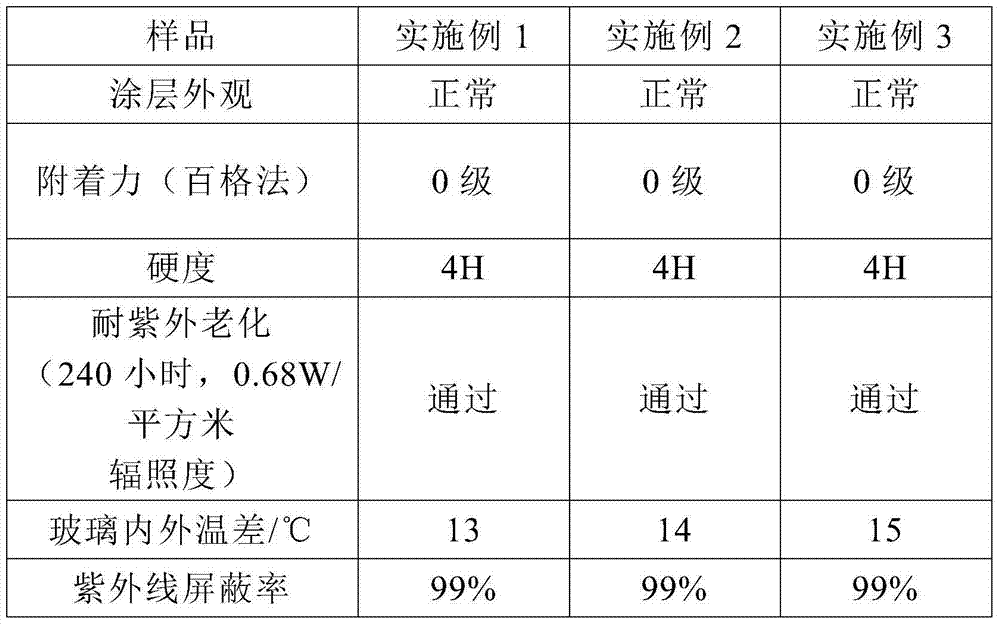

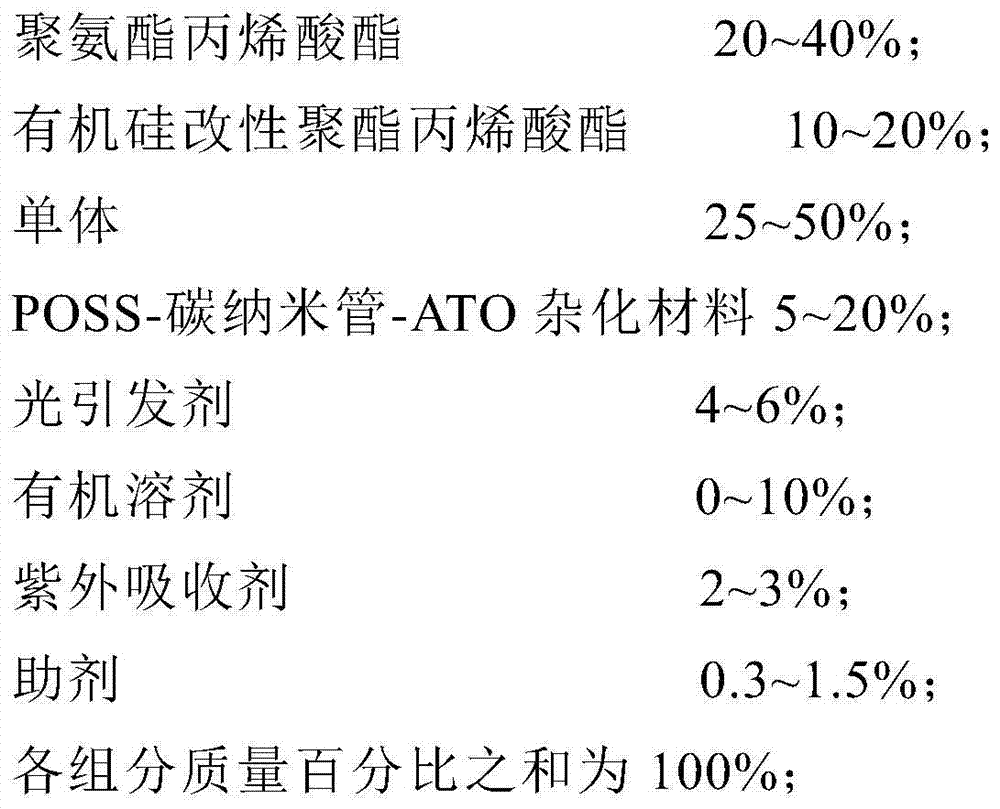

The invention discloses a transparent heat insulation film which is characterized by comprising a transparent film substrate and a heat insulation coating; the heat insulation coating comprises the following components in mass percent: 20%-40% of polyurethane acrylate, 10%-20% of organosilicon modified polyester acrylate, 25%-50% of monomer, 5%-20% of POSS-carbon-nano-tube-ATO hybrid material, 4%-6% of photoinitiator, 0-10% of organic solvent, 2%-3% of ultraviolet absorber, and 0.3%-1.5% of additive; the sum of the mass percent of all the components is 100%, wherein through the use of the POSS-carbon-nano-tube-ATO hybrid material, not only is the heat insulation effect enhanced, but also the ultraviolet ageing resistance and the wear resisting property of the coating can be improved. The invention further provides a preparation method of the transparent heat insulation film; the prepared transparent heat insulation film is good in transparency, heat insulation effect and anti-ultraviolet effect, is simple in technology and low in cost.

Owner:JIANGHAN UNIVERSITY

Nano-titanium dioxide automobile topcoat coating

The invention discloses a nano-titanium dioxide automobile topcoat coating. The nano-titanium dioxide automobile topcoat coating is characterized by being prepared from the following raw materials in parts by weight: 55-70 parts of titanium dioxide slurry, 8.5-21.4 parts of nano-titanium dioxide slurry, 6-8 parts of polar resin, 0.2-0.4 part of a flatting agent and 15-20 parts of a dispersing agent, wherein the nano-titanium dioxide slurry comprises the following components in percentage by mass: 88 percent of hydroxy acrylic resin, 7 percent of nano-titanium dioxide, 2 percent of dimethylbenzene, 2.6 percent of butyl alcohol and 0.4 percent of butyl acetate; the particle diameter of the nano-titanium dioxide is 65-130 nanometers; the dispersing agent is the combination of butyl alcohol, butyl acetate and dimethylbenzene. By adopting the coating, the agglomeration, flocculation and dispersion of titanium dioxide are avoided, and stable ultraviolet resistance, high hardness and high compactness are realized.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Anti-aging plastomer modified asphalt coating material with magnalium-based layed double hydroxide and preparation method thereof

InactiveCN102199359AImprove UV aging resistanceExtended service lifeBuilding insulationsPlastomerAsphalt

The invention relates to an anti-aging plastomer modified asphalt coating material used for a waterproof coiled material and a preparation method thereof. The anti-aging plastomer modified asphalt coating material with magnalium-based layered double hydroxide is characterized by being prepared from the following raw materials in percent by mass of 47% to 64% of asphalt, 10% to 15% of plastomer modifier, 1 to 8% of magnalium-based layered double hydroxide and25% to 30% of stuffing. In the invention, by using the magnalium-based layered double hydroxide, ultraviolet aging resistant performance of the plastomer modified asphalt coating material can be prominently enhanced, the service life of the plastomer modified asphalt coating material is prolonged, and broad application prospects are wide.

Owner:WUHAN UNIV OF TECH

Ultrahigh cut-off EVA packaging adhesive film

InactiveCN105885709AImprove UV aging resistanceReduce dosageMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCross-linkUltraviolet lights

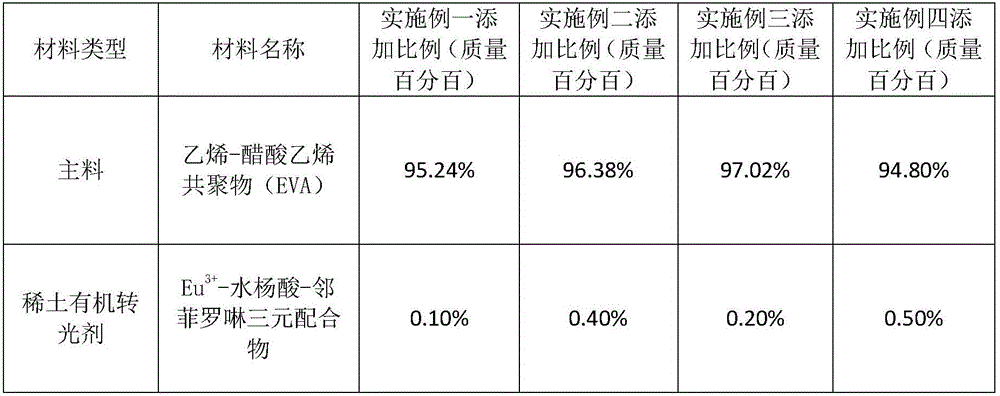

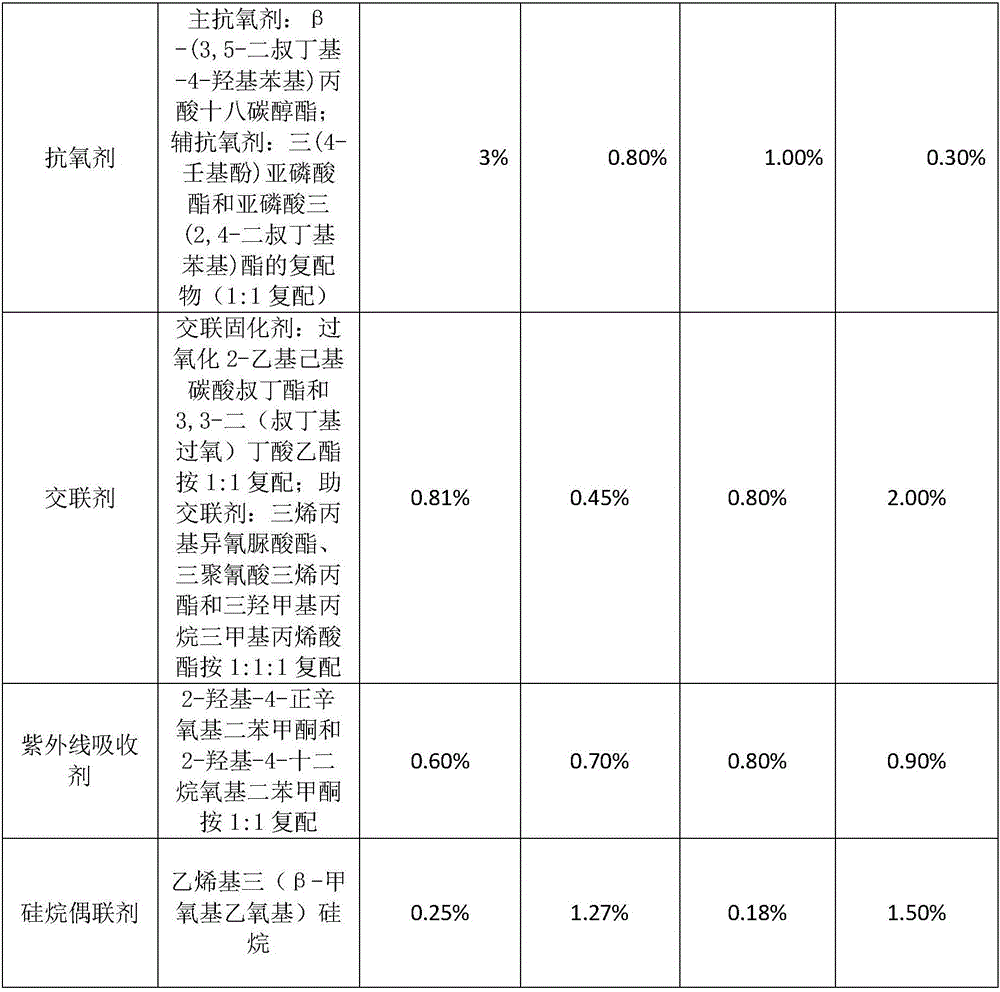

The invention relates to the technical field of packaging adhesive films, in particular to an ultrahigh cut-off EVA packaging adhesive film. The ultrahigh cut-off EVA packaging adhesive film is prepared from the following raw materials in percentage by mass: 94.8%-97.02% of ethylene-vinyl acetate copolymer resin, 0.1%-0.5% of a rare-earth organic light conversion agent, 0.3%-3% of an antioxidant, 0.6%-0.9% of an ultraviolet light absorber, 0.45%-0.2% of a cross-linking agent and 0.18%-1.5% of a silane coupling agent. The transparency and the ultraviolet aging resistance of the EVA adhesive film prepared by a manufacturing method are greatly improved, so that the ultraviolet aging resistance of the adhesive film is improved; the service lifetime of a solar cell assembly is prolonged; and the ultrahigh cut-off EVA packaging adhesive film plays a good protecting role for a backing material of the assembly.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Production process for ultrahigh cut-off EVA (ethylene-vinyl acetate) packaging glue film

InactiveCN105925205AImprove UV aging resistanceReduce dosageMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCross-linkRare earth

The invention relates to the technical field of packaging glue films, in particular to a production process for an ultrahigh cut-off EVA (ethylene-vinyl acetate) packaging glue film. The production process comprises the following steps that EVA copolymer resin is fully mixed with a rare earth organic light conversion agent, antioxygen, an ultraviolet light absorbing agent, a cross-linking agent and a silane coupling agent in proportion, then, extruding, curtain coating, thickness measuring, knurling, sizing, edge cutting, rolling and packaging are carried out in sequence, and the ultrahigh cut-off EVA packaging glue film is produced. The transparence and ultraviolet aging resistance of the EVA glue film manufactured through the manufacturing method are greatly improved, and therefore the ultraviolet aging resistance of the glue film is improved, the service life of a solar cell assembly is prolonged, and the EVA glue film plays a very good role in protecting the back material of the assembly.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Transparent heat-insulating glass glaze material and preparation method thereof

The invention discloses a transparent heat-insulating glass glaze material and a preparation method thereof. The method specifically comprises the following steps: uniformly mixing low-melting-point glass powder, a thermal radiation blocking agent and a thermal conduction blocking agent to obtain a heat-insulating glass glaze material, wherein the ratio of the parts by mass of the low-melting-point glass powder to the thermal radiation blocking agent to the thermal conduction blocking agent is (70-90):(5-15):(5-15), the thermal radiation blocking agent is ITO (indium tin oxide) nano powder, ATO (antimony-doped tin oxide) nano powder, FTO (fluorine-doped zinc oxide) nano powder or ZTO (zinc-doped tin oxide) nano powder, the vitrification transformation temperature of the low-melting-point glass powder is less than or equal to 600 DEG C, and the thermal conduction blocking agent is nano silicon dioxide aerogel. When the above heat-insulating glass glaze material is used for preparing a transparent heat-insulating coating, because organic glass is adopted as a filming medium, the properties of stability, ultraviolet aging resistance, wear resistance and the like of a material can be significantly improved. Therefore, the heat-insulating glass glaze material has a broad application prospect in the field of architectural glass.

Owner:晨合科技(北京)有限公司

Functional bamboo or wood veneer processing method

ActiveCN111421632ADoes not affect bonding propertiesImprove flame retardant performanceWood treatment detailsPretreatment apparatusWood veneerMegasonic cleaning

The invention discloses a functional bamboo or wood veneer processing method. The processing method comprises the following steps: step a, respectively preparing zirconium phosphate suspension, a polyethyleneimine solution and an ammonium polyphosphate solution; b, performing ultrasonic cleaning on the bamboo or wood veneer through ethyl alcohol and deionized water, and then placing the bamboo orwood veneer in an electric heating vacuum drying box to be dried; c, taking out the dried bamboo or wood veneer, and immersing the bamboo or wood veneer into a polyethyleneimine solution; d, immersingthe bamboo or wood veneer into the zirconium phosphate suspension; e, immersing the bamboo or wood veneer into a polyethyleneimine solution; and f, immersing the bamboo or wood veneer into the ammonium polyphosphate solution. According to the functional bamboo or wood veneer processing method provided by the invention, the flame retardant property and the light discoloration resistance of the bamboo veneer can be improved under the condition of ensuring that the gluing property and the original appearance of the bamboo veneer are not obviously changed.

Owner:NANJING FORESTRY UNIV

PBT environment-friendly packaging bag and production process thereof

The invention discloses an environment-friendly PBT packaging bag, and is characterized in that the environment-friendly PBT packaging bag is prepared from the following raw materials in parts by weight: 65 to 75 parts of PBT resin, 10 to 20 parts of chloromethyl azosiltriane ionization modified polybenzophenone-4,4'-dicarboxylic acid N,N'-bis(2-hydroxyethyl)-N,N'-bis(trimethoxysilyl propyl)ethylenediamine ester, 3 to 5 parts of alginic acid, 4 to 8 parts of attapulgite clay powder, 0.3 to 0.5 part of an antioxidant and 0.2 to 0.4 part of a lubricant. The invention further discloses a production process of the environment-friendly PBT packaging bag. The environment-friendly PBT packaging bag disclosed by the invention is good in environmental protection property, good in waterproof property and weather resistance, good in mechanical property and heat resistance, high in impact strength, excellent in comprehensive performance and long in service life.

Owner:苏州市新广益电子股份有限公司

High-shading type double-color TPU (thermoplastic polyurethane) film and production process thereof

The invention belongs to the technical field of TPU films, and particularly relates to a high-shading type double-color TPU film and a production technology thereof.The two faces of the high-shading type double-color TPU film are a black film and a white film respectively, and the black film is prepared from, by weight, 100 parts of TPU masterbatch and 30-50 parts of silane coupling agent modified carbon black. According to the high-shading type double-color TPU film, the black film and the white film are arranged on the two faces of the high-shading type double-color TPU film respectively, the white film outwards contributes to reflecting light rays and heat and has a good heat insulation effect, the black film can play a shading role, and the black film outwards can effectively absorb heat and contributes to increasing the internal temperature; the double-color TPU film can be applied to scenes with different requirements; besides, the carbon black added in the black film is silane coupling agent modified carbon black, so that the dispersion effect of the carbon black in TPU can be effectively improved, the dispersion uniformity is improved, agglomeration is avoided, the influence on the mechanical property of the film is reduced, and meanwhile, a better shading effect is achieved.

Owner:昆山红苹果塑胶新材料有限公司

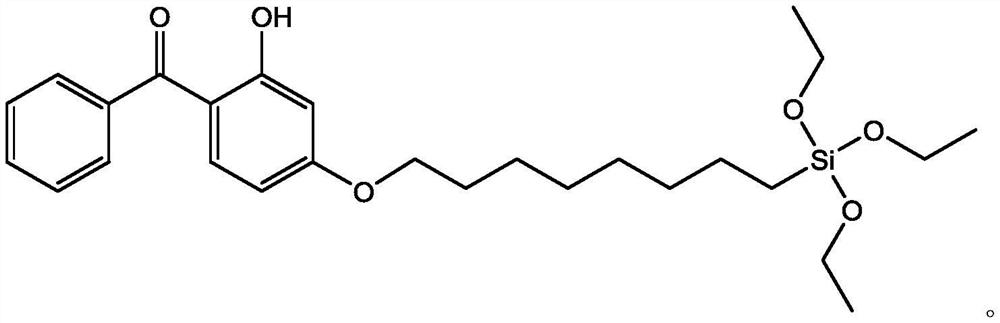

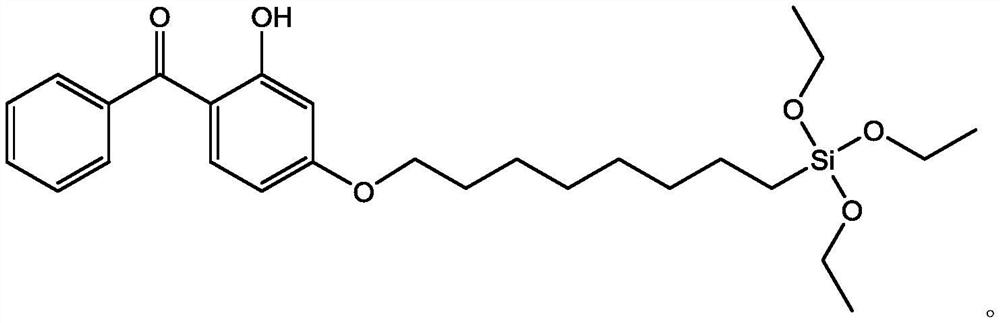

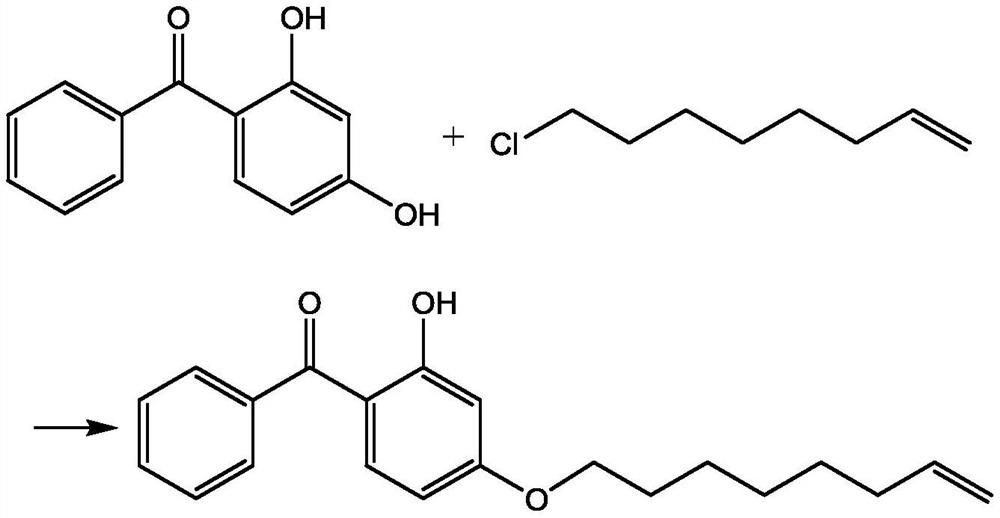

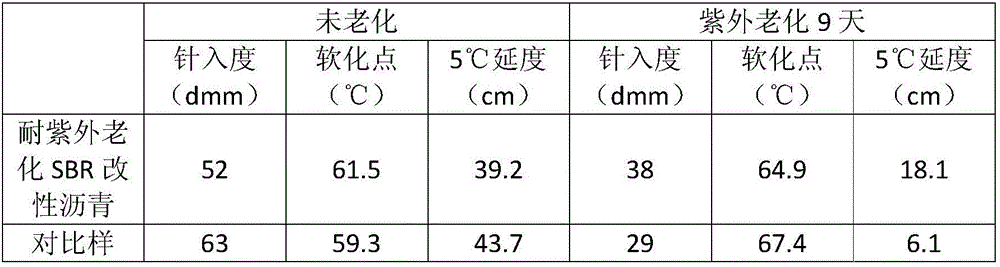

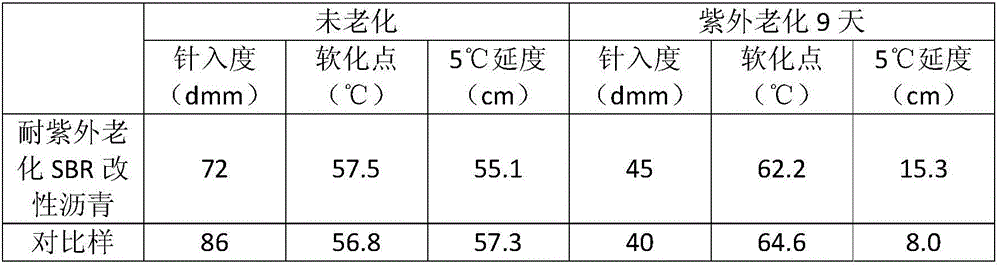

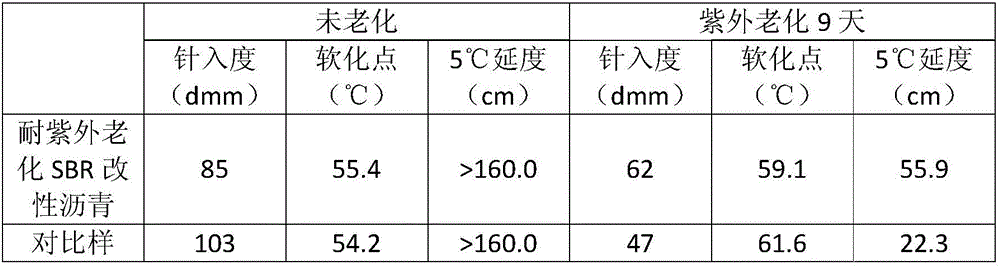

Sodium lignosulfonate grafted magnesium-aluminum-based LDH (layered double hydroxide) modifier, ultraviolet-aging-resistant SBR (styrene-butadiene rubber) modified asphalt and preparation method of ultraviolet-aging-resistant SBR modified asphalt

InactiveCN106832973AExcellent UV reflective abilityGood anti-ultraviolet aging performanceBuilding insulationsPolymer scienceSodium lignosulfonate

The invention relates to a modifier, SBR (styrene-butadiene rubber) modified asphalt and a preparation method of the SBR modified asphalt. A sodium lignosulfonate grafted magnesium-aluminum-based LDH (layered double hydroxide) modifier is characterized by being prepared from lignin and magnesium-aluminum-based LDHs by grafting. Ultraviolet-aging-resistant SBR modified asphalt is characterized by being prepared from raw materials in percentage by mass as follows: 90%-99% of the SBR modified asphalt and 1%-10% of the sodium lignosulfonate grafted magnesium-aluminum-based LDH modifier. The ultraviolet-aging resistance of the SBR modified asphalt can be improved remarkably by adding sodium lignosulfonate grafted magnesium-aluminum-based LDHs to the SBR modified asphalt, magnesium-aluminum-based LDHs can be dispersed in the SBR modified asphalt stably for a long time, and the prepared SBR modified asphalt has excellent ultraviolet-aging resistance.

Owner:WUHAN UNIV OF TECH

Anti-aging and anti-cracking sheath material for mineral insulated cable and preparation method thereof

PendingCN111154171AGood weather resistanceImprove mechanical propertiesPlastic/resin/waxes insulatorsCrack resistanceEngineering

The invention discloses an anti-aging and anti-cracking sheath material for a mineral insulated cable and a preparation method thereof. The sheath material comprises the following raw materials in parts by weight: 40-60 parts of EVA resin, 10-20 parts of high-density polyethylene, 2-4 parts of maleic anhydride grafted high-density polyethylene, 1-2 parts of maleic anhydride grafted ethylene-1-octene copolymer, 40-60 parts of modified magnesium hydroxide, 10-20 parts of modified mica powder, 5-10 parts of modified potassium titanate whiskers, 1-2 parts of a weather-proof agent, 1-1.5 parts of an antioxidant and 1-2 parts of a lubricant. The sheath material has the advantages of excellent insulating property, ageing resistance, cracking resistance, high mechanical strength, good flame-retardant and smoke-suppressing effects and very high use safety, and can play a very good role in protecting a mineral insulated cable.

Owner:ANHUI MENTOR CABLE GROUP

Anti-counterfeiting waterborne pressure-sensitive adhesive protecting film and preparation method thereof

ActiveCN109575835ALow costImprove uniformityNon-macromolecular adhesive additivesEster polymer adhesivesFunctional monomerEmulsion

The invention discloses an anti-counterfeiting waterborne pressure-sensitive adhesive protecting film and a preparation method thereof. The anti-counterfeiting waterborne pressure-sensitive adhesive protecting film comprises the following components in parts by mass: 70-95 parts of soft monomers, 5-20 parts of hard monomers, 2-15 parts of functional monomers, 0.2-2.0 parts of an emulsifier, 0.2-1.5 parts of an initiator, 0.02-1.2 parts of a PH buffer, 0.1-5 parts of luminous aid and 35-140 parts of deionized water. The preparation method comprises the following steps: S1, preparation of the luminous aid; S2, preparation of emulsion; and S3, preparation of an anti-counterfeiting protecting film. In the provided formula, the water is used as a solvent, and the cost is reduced while environmental protection is achieved; and the uniformity and luminous efficiency of the protecting film are good, the anti-counterfeiting protecting film only can show bright visible light color under the illumination of ultraviolet light, anti-counterfeiting checked operation is simple, the cost is low, repeatability and reliability are achieved, a concealed anti-counterfeiting purpose is achieved, and furthermore, the ultraviolet aging resistance of the protecting film can be greatly improved.

Owner:XIANGYANG SUNVALOR AEROSPACE FILMS CO LTD

Anti-aging plastomer modified asphalt coating material with magnalium-based layed double hydroxide and preparation method thereof

InactiveCN102199359BImprove UV aging resistanceExtended service lifeBuilding insulationsAnti ageingAsphalt

The invention relates to an anti-aging plastomer modified asphalt coating material used for a waterproof coiled material and a preparation method thereof. The anti-aging plastomer modified asphalt coating material with magnalium-based layered double hydroxide is characterized by being prepared from the following raw materials in percent by mass of 47% to 64% of asphalt, 10% to 15% of plastomer modifier, 1 to 8% of magnalium-based layered double hydroxide and25% to 30% of stuffing. In the invention, by using the magnalium-based layered double hydroxide, ultraviolet aging resistant performance of the plastomer modified asphalt coating material can be prominently enhanced, the service life of the plastomer modified asphalt coating material is prolonged, and broad application prospects are wide.

Owner:WUHAN UNIV OF TECH

Alicyclic epoxy resin insulating material

The invention provides an alicyclic epoxy resin insulating material, which comprises the following components in percentage by weight: 20%-30% of epoxy resin, 18%-25% of anhydride curing agent, 0.2%-0.3% of amine accelerant, 28%-35% of silica powder, 18%-25% of aluminum hydroxide and 1%-8% of nano composite material; wherein the nano composite material is prepared from coupling agent modified nanoaluminum oxide and coupling agent modified nano silicon oxide, and the weight ratio of the coupling agent modified nano aluminum oxide to the coupling agent modified nano silicon oxide is (1-4) : (1-4). According to the alicyclic epoxy resin insulating material disclosed by the invention, the epoxy resin, the anhydride curing agent and the amine accelerant are matched, and the coupling agent modified nano aluminum oxide and the coupling agent modified nano silicon oxide are combined as a nano composite material, so that the damp-heat resistance and the ultraviolet aging resistance of the alicyclic epoxy resin insulating material are remarkably improved, the service life of the alicyclic epoxy resin insulating material is prolonged, and the safety performance is improved when the alicyclicepoxy resin insulating material is used as an outdoor insulator material.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

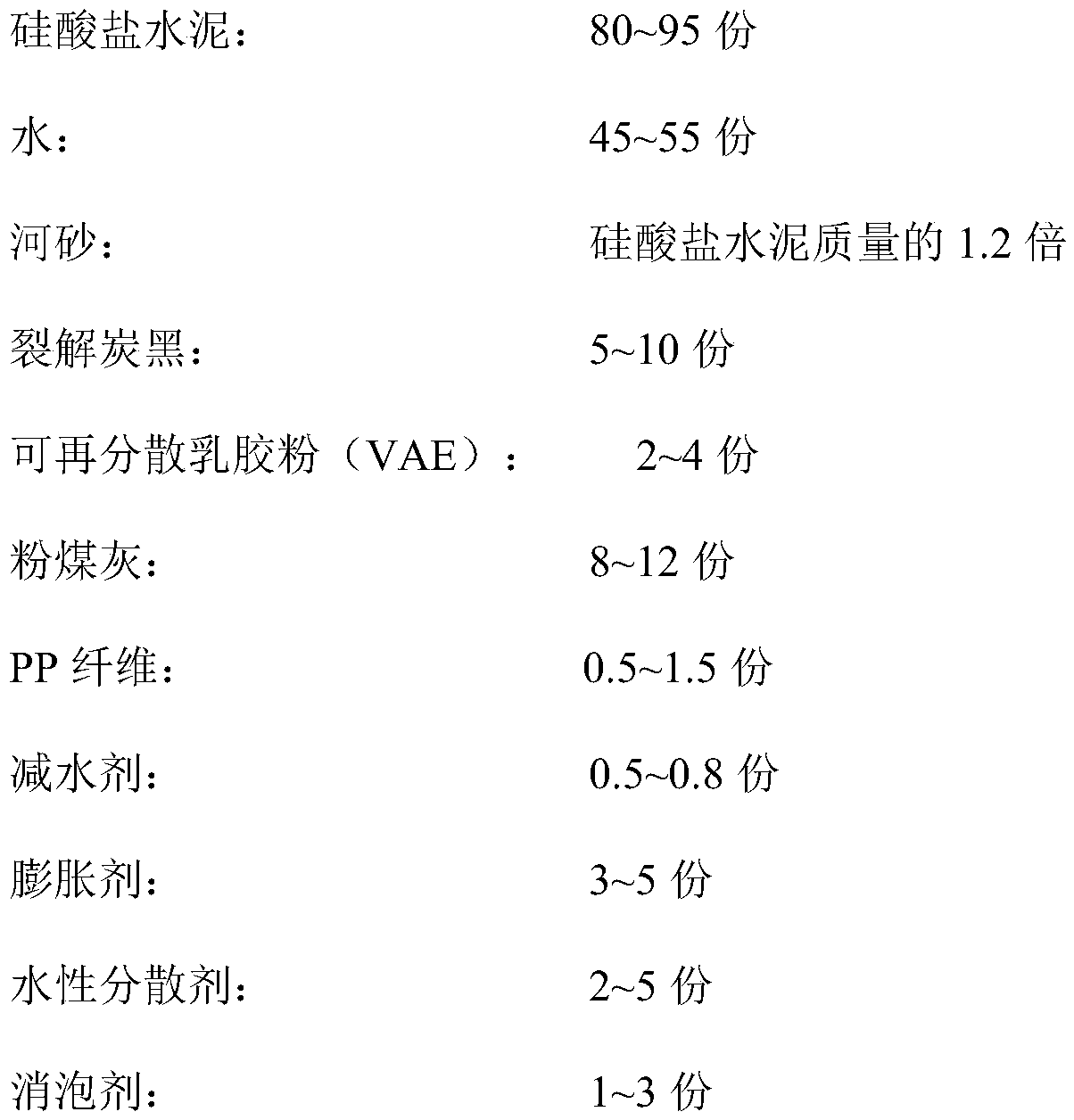

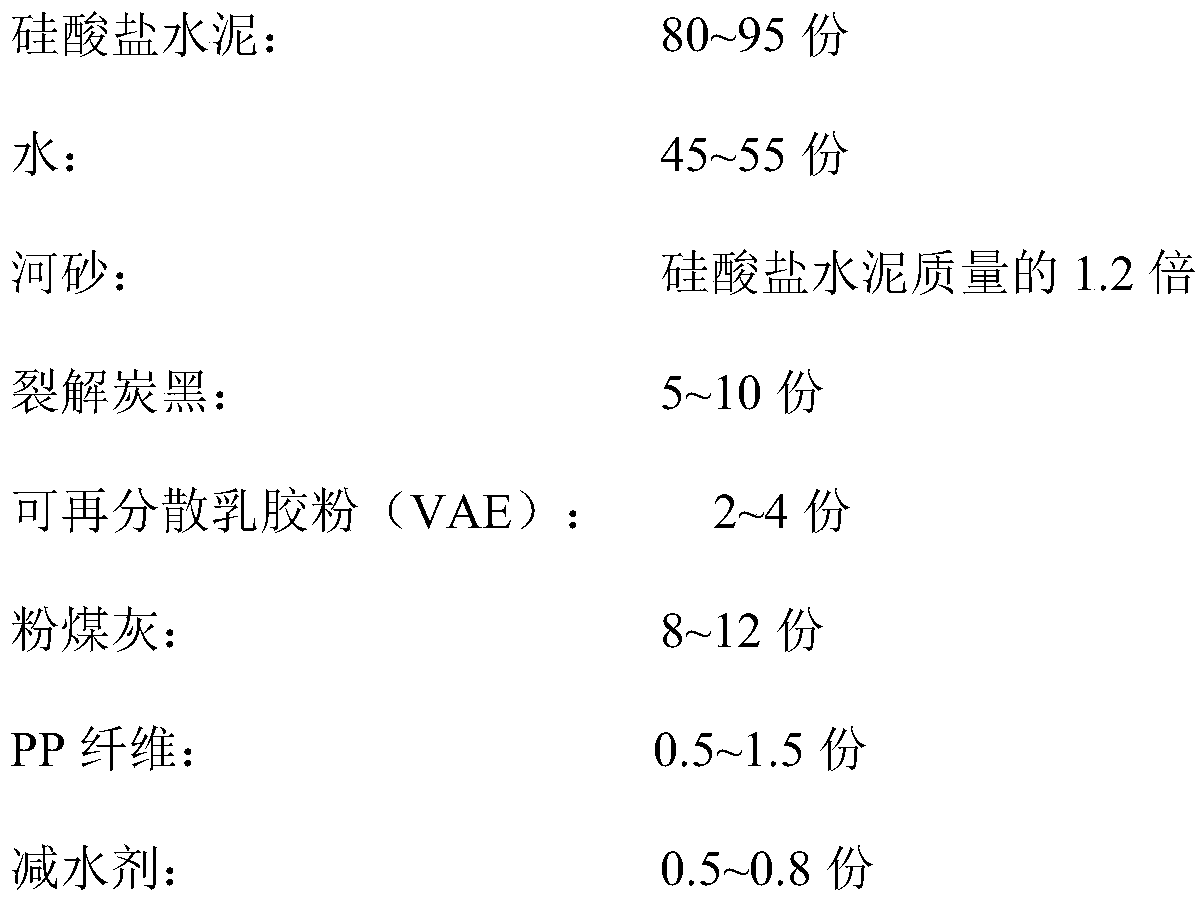

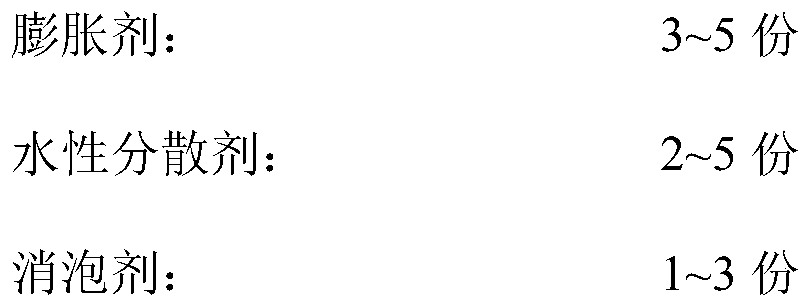

Pyrolysis carbon black modified cement mortar and preparation method thereof

InactiveCN110467398AImprove UV aging resistanceWide variety of sourcesConstruction industryCarbon black

The invention relates to a pyrolysis carbon black modified cement mortar and a preparation method thereof. According to the invention, pyrolysis carbon black is added into a cement raw material, and the ultraviolet aging resistance of cement is improved by utilizing the light stability and ultraviolet aging resistance of the pyrolysis carbon black; redispersible latex powder is added into the mortar, so the mortar can be effectively improved inbonding capacity and cohesion, has enhanced bending resistance, tensile resistance and freeze-thaw stability, and is effectively prevented from cracking; the cement disclosed by the invention contains PP fibers, so the tensile strength, the toughness and the dry crack resistance of the cement can be enhanced, and microcracks caused by shrinkage, dryshrinkage and temperature changes can be effectively controlled; and meanwhile, the cement disclosed by the invention has good compatibility with a concrete structure, and has wide research and application prospects in the civil construction industry and the like.

Owner:QINGDAO UNIV OF SCI & TECH

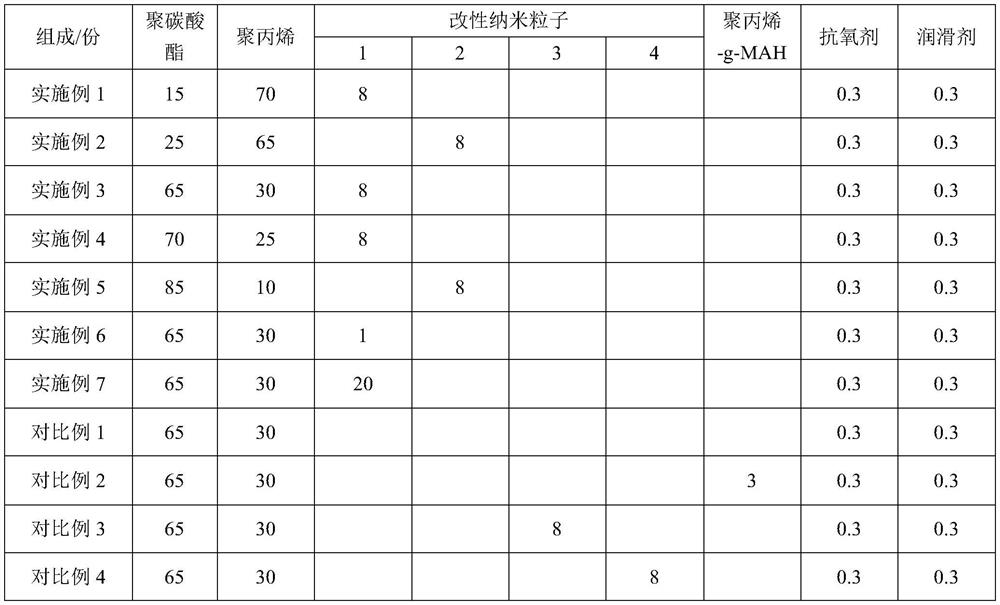

Polycarbonate/polypropylene alloy material and preparation method thereof

The invention relates to a compatibilized anti-aging polycarbonate / polypropylene alloy material and a preparation method thereof. The material comprises polycarbonate; polypropylene; graphene oxide compatibilization nanoparticles by quaternary ammonium salt modified by quaternary ammonium salt; and optionally, a processing aid. The alloy material disclosed by the invention not only has excellent aging resistance, but also can play a better compatibilization role without reducing the strength, and the flame retardant property can be improved.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

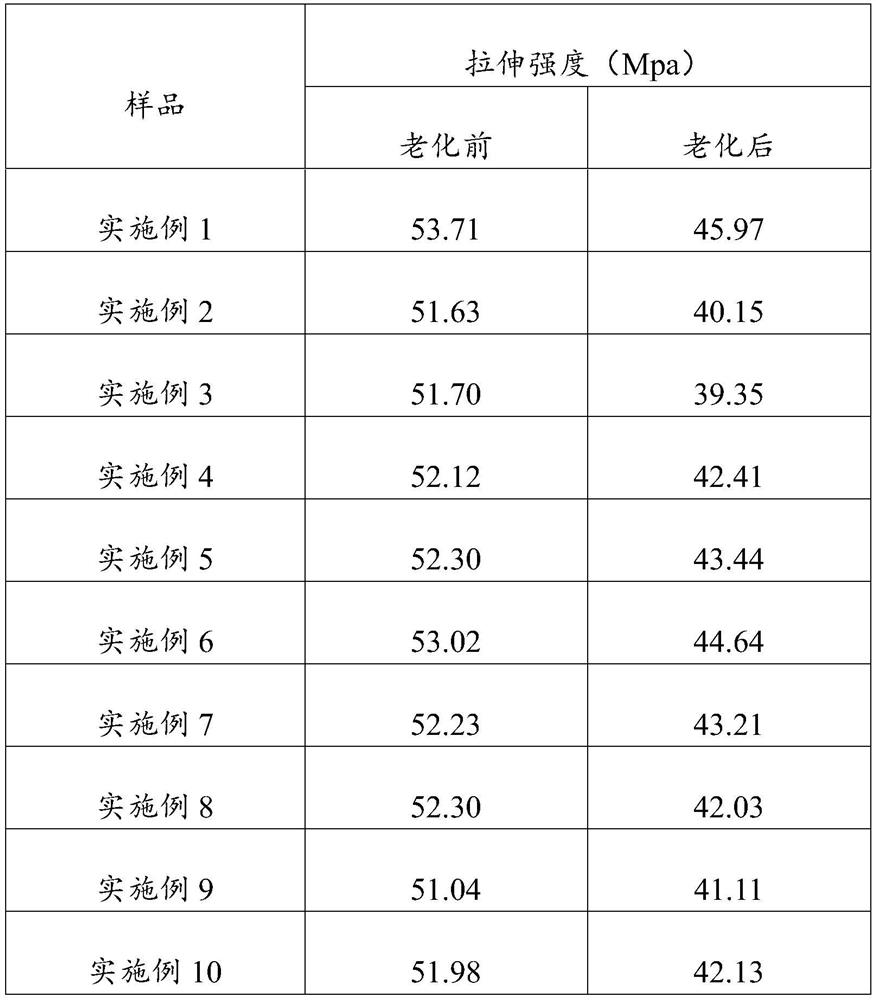

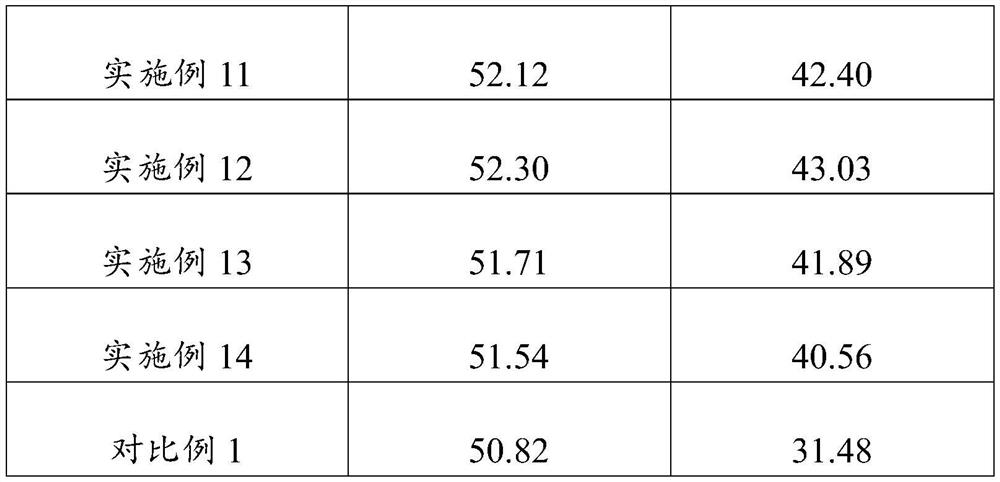

Recycled plastic color master batch for plastic tiles and preparation method thereof

According to the regenerated plastic color master batch for the plastic tiles and the preparation method of the regenerated plastic color master batch, a fluorobenzene structure is introduced by adding poly 3, 5-diamino-1H-pyrazole-4-carboxylic acid allyl ester 2, 3, 5, 6-tetrafluoroterephthalic acid amide, so that the weather resistance and the corrosion resistance of the material are stronger, and a pyrazole structure is introduced; the ultraviolet aging resistance and flame retardancy of the material are further improved, the tensile strength of the prepared regenerated plastic color masterbatch for the plastic tiles is 54.7-55.3 MPa according to GB / T1040-2006 measurement, extrusion cooling equipment cools the color master batch before and after cutting, primary cooling is conducted through heat exchange of a cooling pipe, and secondary cooling is conducted through cooling water discharged by the cooling pipe for cooling, so that the cooling effect is more excellent.

Owner:ANHUI HUANJIA TIANYI RENEWABLE RESOURCES

Super-long weather-resistant surface photovoltaic platform system and installation method thereof

PendingCN109250044ABuoyancy is not affectedBuoyancy effectFloating buildingsPhotovoltaic energy generationPower stationMarine engineering

The invention discloses a super-long weather-resistant surface photovoltaic platform system and an installation method thereof. The system includes a connecting floating body, a support floating bodyand a photovoltaic module which are arranged above that connecting floating body. The lower end of the support floating body is inserted and matched with the hollowed-out part of the connecting floating body, and the upper and lower ends of the photovoltaic module are respectively fixedly connected with the support floating body and the connecting floating body through an upper connector and a lower connector; the connecting floating bodies are arranged in rows and columns, and the connecting floating bodies between adjacent rows and columns are connected with the walkway floating body. According to the invention, the middle part of the connecting floating body is subjected to a hollowing out process, under the premise of satisfying the support of the photovoltaic module and the running buoyancy of the power station, the connecting floating body provided by the invention enlarges the area of the water body contacting the air, improves the light transmittance of the whole floating bodyplatform system, ensures the normal growth of aquatic organisms, and is favorable for the popularization of the surface photovoltaic power generation system. The hollowed-out treatment of the connected floating body also improves the hydrophilicity of the photovoltaic module, which can effectively ventilate and cool the module, thereby improving the power generation efficiency.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Anti-aging texture stone-like paint

InactiveCN107603288AImprove impact resistanceHigh hardnessAntifouling/underwater paintsPaints with biocidesCrack resistanceHeat stability

The invention discloses an anti-aging texture stone-like paint. The stone-like paint comprises the following raw materials in parts by weight: 30 to 40 parts of quartz sand, 18 to 25 parts of coloredsand, 7 to 12 parts of modified styrene-acrylic emulsion, 6 to 10 parts of SiO2 aerogel powder, 4 to 6 parts of a thickening agent, 1 to 2 parts of butyl cellosolve, 0.2 to 0.3 part of methyl alcohol,1 to 2 parts of a wetting agent, 1 to 2 parts of a defoaming agent, 0.5 to 1 part of chitin and 0.1 to 0.2 part of a water repellent. The stone-like paint disclosed by the invention has preferable anti-aging performance, and simultaneously is high in cracking resistance, heat stability, heat insulation and mechanical property.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Sun-proof anti-aging polyethylene pipe

InactiveCN103737991AImprove photoagingExtended service lifeElongated constructional elementsSynthetic resin layered productsEthylene-propylene-diene-monomerEngineering

The invention relates to a sun-proof anti-aging polyethylene pipe comprising two layers of an inner layer and an outer layer, the inner layer is a pipe main body, and the outer layer is a sun-proof anti-aging protective layer. The outer layer thickness is 10%-15% of the overall pipe wall thickness, but is not less than 1mm. The outer layer material comprises the following components: by weight, 50-70 parts of mLLDPE (metallocene polyethylene), 50-30 parts of EPDM (ethylene-propylene-diene monomer), 0.3-4 parts of a chain extender, 0.2-0.5 part of a catalyst, 5-10 parts of carbon black, 1-2 parts of titanium dioxide, 0.5-1.5 parts of an antioxidant and 1-2 parts of a dispersant; the inner layer material is a HDPE (high-density polyethylene) composite material with the carbon black content being more than 2% and the carbon black grade being less than grade 3. The polyethylene pipe is prepared by high-speed mixing and mixed plasticizing of the outer layer material then use of a composite die for extrusion molding of the outer layer material and the inner layer material, compared with ordinary polyethylene pipes, the anti-aging performance is improved, the pipe service life is prolonged, the sun-proof anti-aging polyethylene pipe can be exposed on the earth surface for use, and the application scope of the polyethylene pipe can be expanded.

Owner:浙江经纬集团环保工程有限公司

Cold-resistant rubber for outdoor cable sheath

InactiveCN103183877AImprove low temperature resistanceImproved resistance to twistingInsulated cablesInsulated conductorsUltraviolet lightsEngineering

The invention relates to a rubber sheath material, particularly relates to a cold-resistant rubber for an outdoor cable sheath, and belongs to the technical field of rubbers. The cold-resistant rubber comprises a rubber base material, a sulfurization agent, a stabilizing agent, a cold-resistant softening agent, an anti-aging agent, a fire retarding agent, a reinforcement filling agent and a flow dispersing agent, a chlorinated polyethylene and an ethylene-propylene rubber are adopted as main base materials, a vulcanizing agent, the stabilizing agent, the softening agent and the anti-aging agent are elaborately screened so as to be used as components for preparing a cable sheath material, the properties, proof low temperature, proof torsion, oil proof, proof ozone, proof ultraviolet light aging and proof sea water corrosion of a cable are improved, and the cable can carry out normal operation under minus 40 DEG C environment. The cold-resistant rubber provided by the invention has the advantages that the production process is simple, the required equipment is less, the material application range is wide, and an operating worker can operate in a practised manner; and the cold-resistant rubber provided by the invention uses a scientific method of an orthogonal design, the component identity is reasonable through repeatedly testing for many times, the selected material price is moderate, the cost is lower, and the cold-resistant rubber is suitable for a large scale of production.

Owner:WUXI CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com