Alicyclic epoxy resin insulating material

A technology of epoxy resin and insulating materials, which is applied in the field of high-voltage transmission insulating materials, can solve the problems of short life, easy aging and aging of insulators, etc., so as to improve the service life, safety performance, moisture resistance and ultraviolet aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

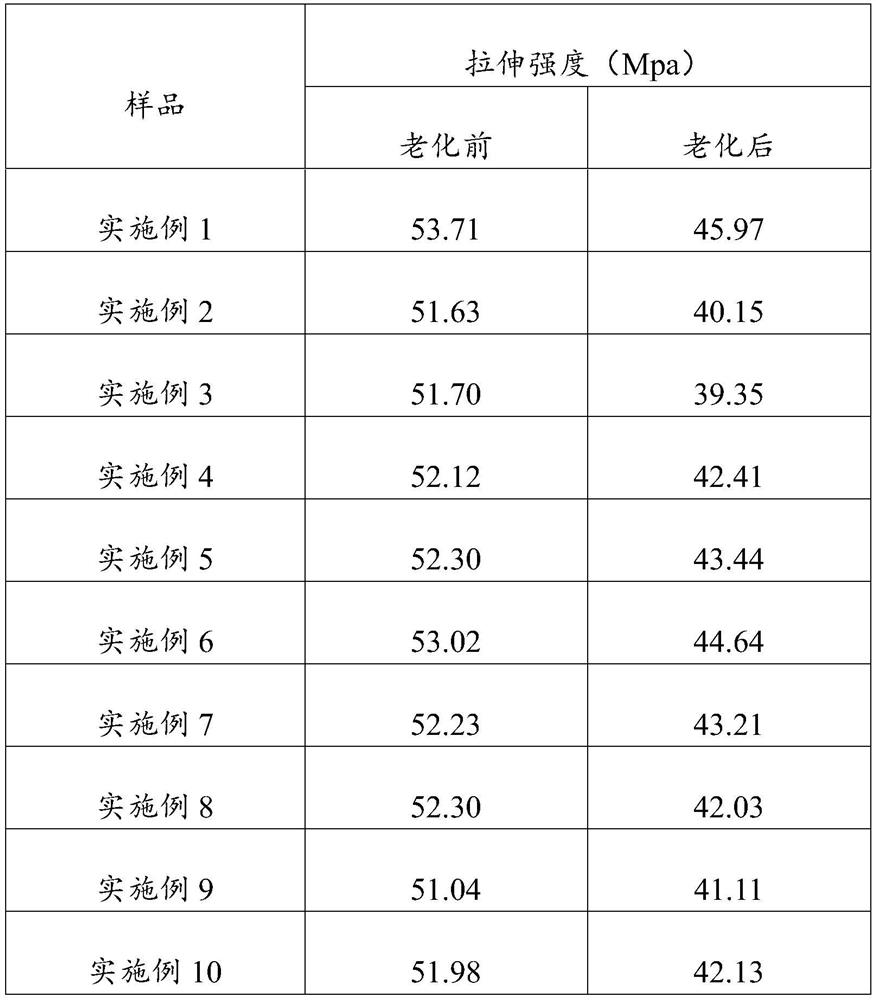

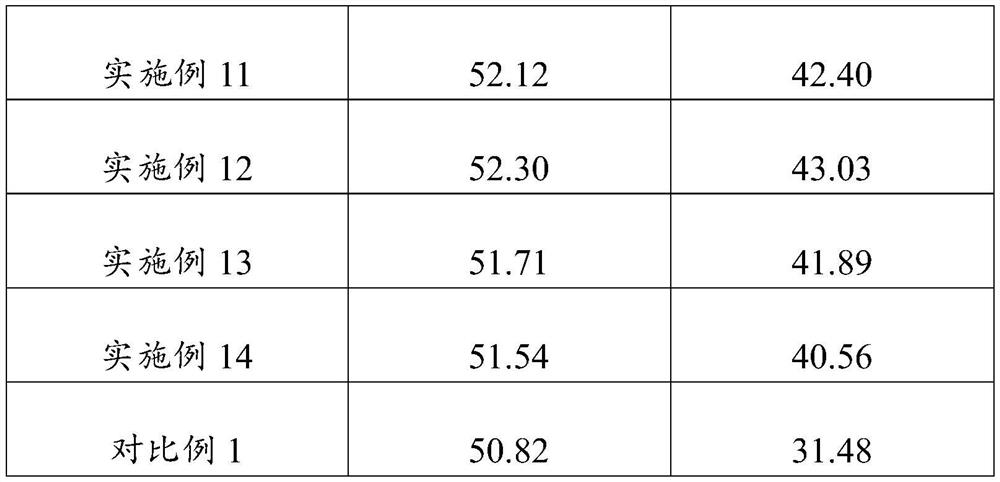

Examples

Embodiment 1

[0022] As a kind of cycloaliphatic epoxy resin insulating material of the embodiment of the present invention, described cycloaliphatic epoxy resin insulating material comprises the following components by weight percentage: 26% epoxy resin, 20.4% curing agent, 0.2% Accelerator, 28% microsilica powder, 20.4% aluminum hydroxide and 5% nanocomposite material, the nanocomposite material is coupling agent modified nano-alumina and coupling agent modified nano-silicon, said The weight ratio of coupling agent-modified nano-alumina and coupling agent-modified nano-silicon is 1:1; the curing agent is an acid anhydride curing agent, and the acid anhydride curing agent is methyl hexahydrophthalic anhydride. The accelerator is an amine accelerator, the amine accelerator is N,N-dimethylbenzylamine, and the epoxy resin is an alicyclic glycidyl type epoxy resin;

[0023] The preparation method of the coupling agent modified nano-alumina and the coupling agent-modified nano-silicon is to mix...

Embodiment 2

[0029] As an alicyclic epoxy resin insulating material according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the nanocomposite material accounts for 1% of the weight of the alicyclic epoxy resin insulating material, The epoxy resin accounts for 30% by weight of the cycloaliphatic epoxy resin insulating material.

Embodiment 3

[0031] As an alicyclic epoxy resin insulating material according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the nanocomposite material accounts for 2% of the weight of the alicyclic epoxy resin insulating material, The epoxy resin accounts for 29% by weight of the cycloaliphatic epoxy resin insulating material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com