Preparation method of high abrasion water-borne wood coating

A technology of wood coatings and high wear resistance, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of insufficient flexibility, limitations, and poor anti-powdering performance, and achieve the goal of reducing pollution and improving tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

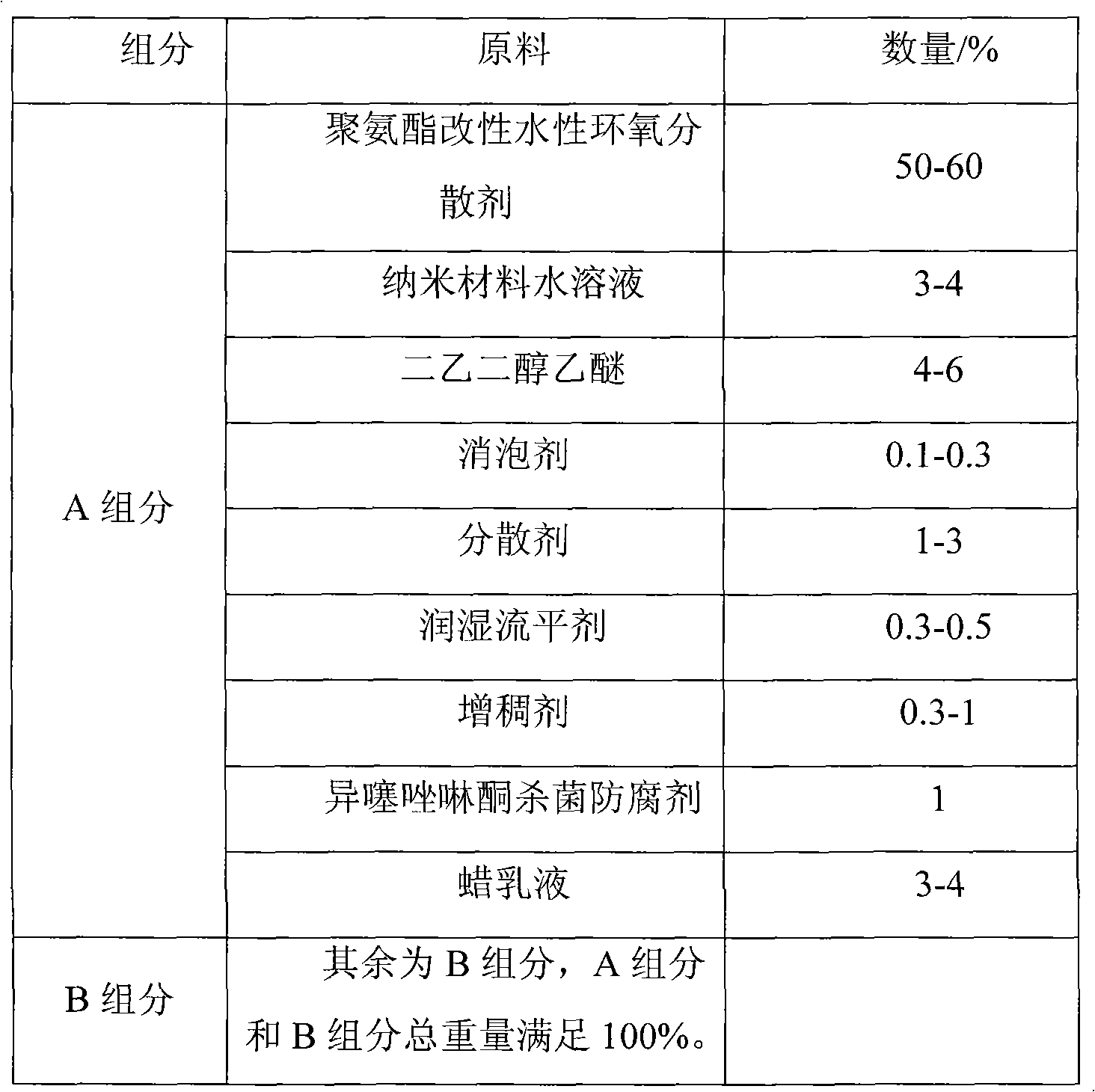

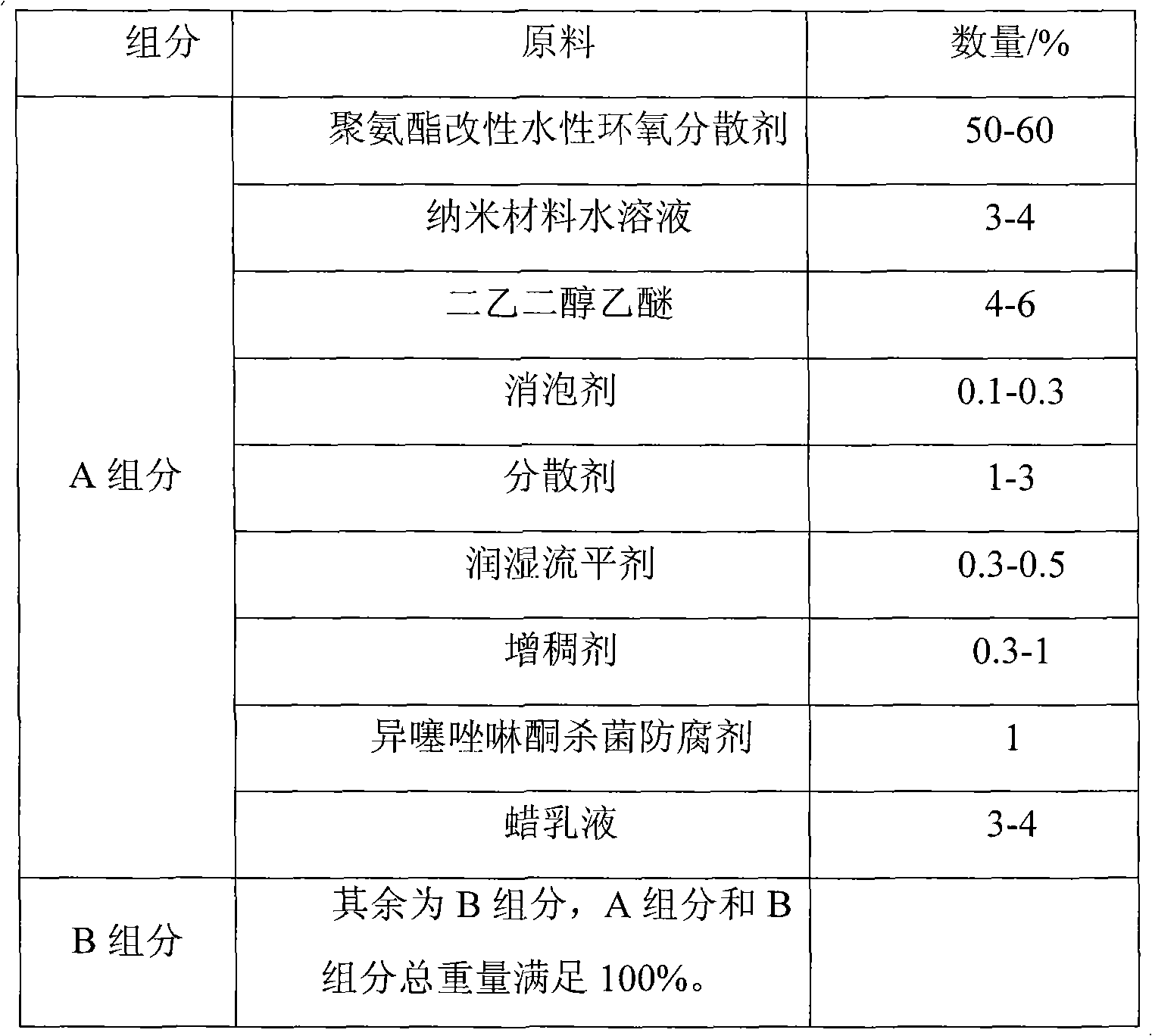

[0030] Weigh the following raw materials by mass:

[0031] Take 18g of epoxy resin, 1.5g of surfactant, mix, heat until completely dissolved, cool down to 75-85°C, add 3g of polyamine, react at 100°C for 1 hour, cool down naturally to 80°C, add 4.5g of Water and the ether solution of the epoxy resin block copolymer of 3g, stir evenly, obtain nonionic water-based epoxy curing agent.

[0032] Take 15g of non-ionic water-based epoxy curing agent as component B of the coating, take 55g of polyurethane modified water-based epoxy dispersant, 3g of nanomaterial aqueous solution, 6g of diethylene glycol ether, and 1g of isothiazolinone for sterilization and anticorrosion 4g of wax emulsion and 10g of water were mixed evenly under the conditions of room temperature and rotating speed of 1000 rpm, adding a pH regulator to adjust the pH of the mixture to about 8.5, dispersing the mixed solution to below 15 mesh, and adding 0.2g of disinfectant Foaming agent, 3g of dispersant, 0.5g of we...

Embodiment 2

[0035] Weigh the following raw materials by mass:

[0036] Take 18g of epoxy resin, 1.5g of surfactant, mix, heat until completely dissolved, cool down to 75-85°C, add 3g of polyamine, react at 100°C for 1 hour, cool down naturally to 80°C, add 4.5g of Water and the ether solution of the epoxy resin block copolymer of 3g, stir evenly, obtain nonionic water-based epoxy curing agent.

[0037] Take 17g of non-ionic water-based epoxy curing agent as component B of the coating, take 60g of polyurethane modified water-based epoxy dispersant, 4g of nanomaterial aqueous solution, 6g of diethylene glycol ether, and 1g of isothiazolinone for sterilization and anticorrosion 4g of wax emulsion and 6g of water were mixed evenly under the conditions of room temperature and rotating speed of 1000 r / min, adding a pH regulator to adjust the pH of the mixture to about 8.5, dispersing the mixed solution to below 15 mesh, and adding 0.2g of disinfectant Foaming agent, 3g of dispersant, 0.5g of w...

Embodiment 3

[0040] Weigh the following raw materials by mass:

[0041] Mix 18g of epoxy resin and 1.5g of surfactant, heat until completely dissolved, cool down to 75-85°C, add 3g of polyamine, react at 100°C for 1 hour, naturally cool down to 80°C, add 4.5g of water And the ether solution of the epoxy resin block copolymer of 3g, stir, obtain nonionic water-based epoxy curing agent.

[0042] Take 20g of non-ionic water-based epoxy curing agent as component B of the coating, take 55g of polyurethane modified water-based epoxy dispersant, 4g of nanomaterial aqueous solution, 6g of diethylene glycol ether, and 1g of isothiazolinone for sterilization and anticorrosion 4g of wax emulsion and 5g of water were mixed evenly under the conditions of room temperature and rotating speed of 1000 rpm, adding a pH regulator to adjust the pH of the mixture to about 8.5, dispersing the mixed solution to below 15 mesh, and adding 0.2g of disinfectant Foaming agent, 3g of dispersant, 0.5g of wetting and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com