Patents

Literature

31results about How to "Improve photoaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

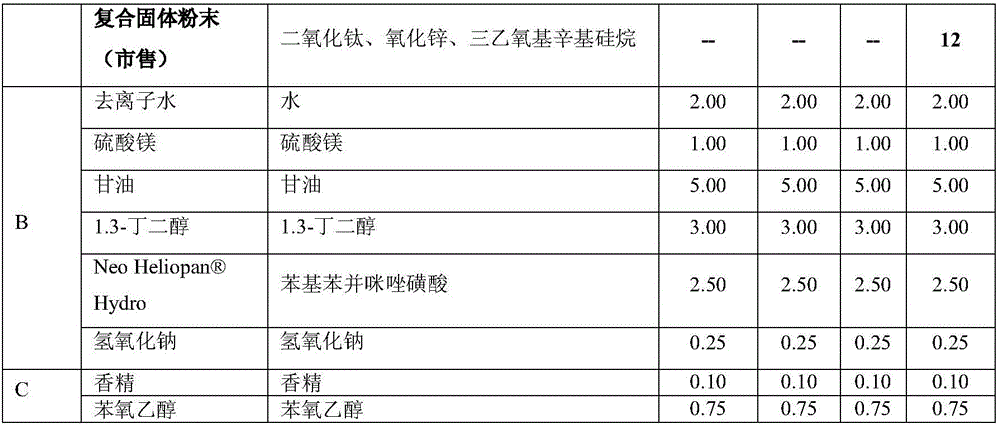

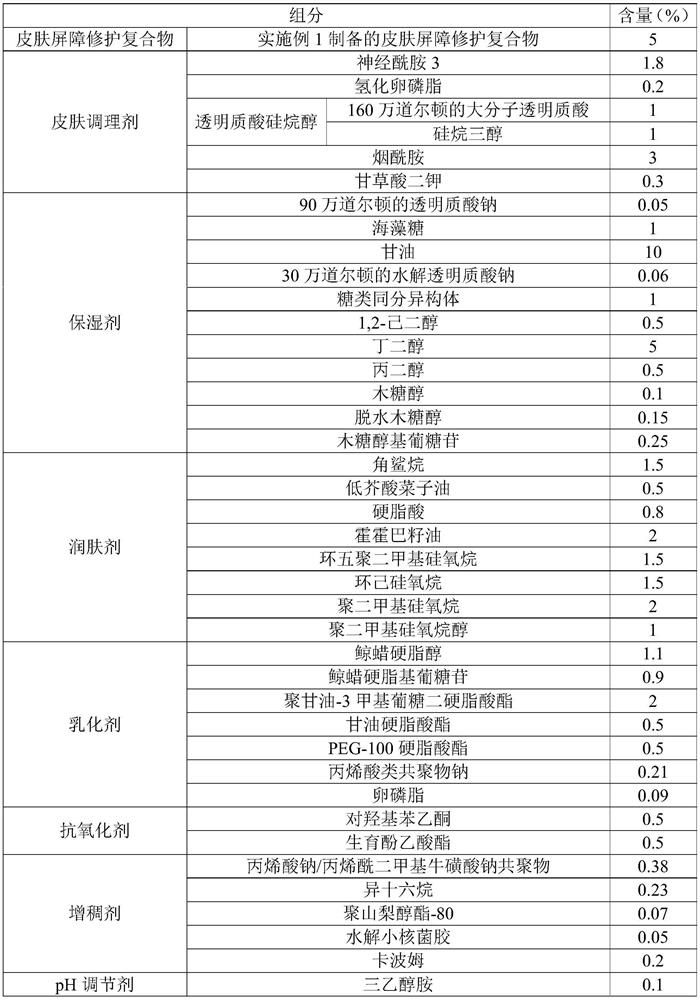

Skin barrier repairing complex, facial cream and preparation method therefor

ActiveCN111407719AImprove water retentionRepair cuticle barrierCosmetic preparationsToilet preparationsGlycyrrhiza inflata root extractPhotoaging

The invention provides a skin barrier repairing complex, facial cream and a preparation method therefor. The skin barrier repairing complex comprises a composition for repairing skin barrier, hydroxylasiaticoside, deacidified carnosine, a glycyrrhiza inflata root extract, a radix scutellariae extract and a hamamelis extract, wherein the composition for repairing skin barrier comprises sea fennelcallus culture filtrate, Ectoin and a hydrolyzed red alga extract. The skin barrier repairing complex can achieve triple effects of simultaneously repairing cutin barrier, repairing immunologic barrier and strengthening microbiologic barrier; and the facial cream prepared from the skin barrier repairing complex is obvious in repairing effect and can be used for effectively improving hydrature of skin, increasing the content of hyaluronic acid in the skin, improving photoaging, helping cell saccharification reversing and reducing fine grain area.

Owner:广州一一生物技术有限公司

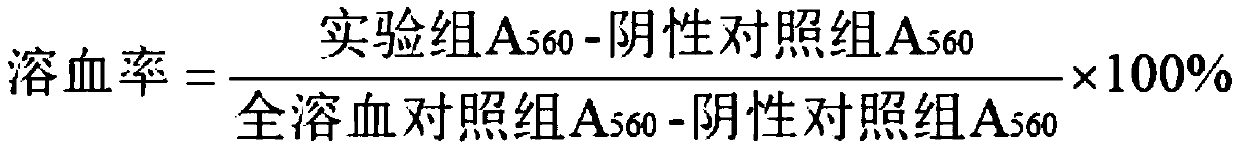

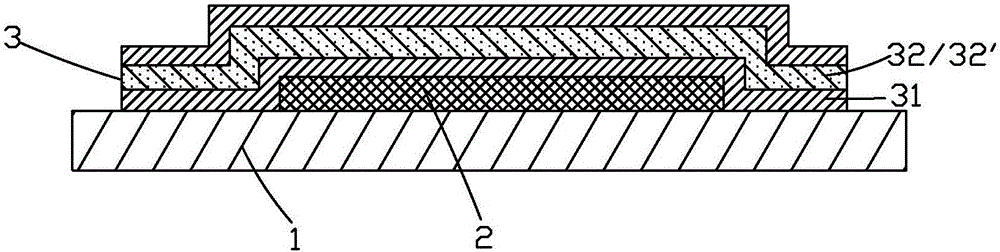

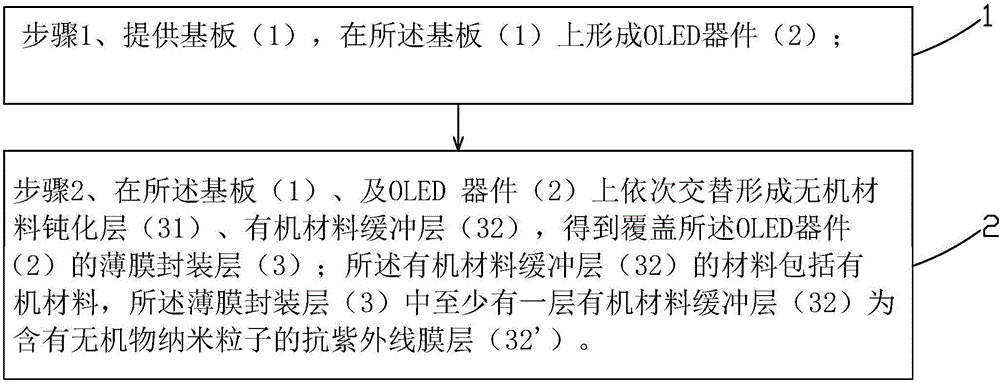

OLED displayer and manufacturing method thereof

InactiveCN106450026AImproves UV resistanceImprove photoagingMaterial nanotechnologySolid-state devicesOptoelectronicsInorganic materials

The invention provides an OLED displayer and a manufacturing method thereof. The OLED displayer comprises a substrate, an OLED device which is arranged on the substrate and a thin-film packaging layer which is arranged on the substrate and the OLED device and covers the OLED device. The thin-film packaging layer comprises at least two inorganic material passivation layers and at least one organic material buffer layer. The inorganic material passivation layers and the organic material buffer layers in the thin-film packaging layer are alternately arranged in a laminated way, and at least one organic material buffer layer in the thin-film packaging layer is an ultraviolet-resistant film layer containing inorganic nanoparticles so as to have the effect of resisting ultraviolet radiation and enhancing the mechanical property of the organic material buffer layer, and thus the ultraviolet-resistant and photoaging-resistant performance of the OLED displayer can be enhanced and the service life can be prolonged.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Composition of yeast fermentation extract and application of composition in cosmetics

InactiveCN108096081AHigh activityIncrease elasticityCosmetic preparationsToilet preparationsSaccharomycesWrinkle

The invention discloses a composition of yeast fermentation extract. The composition is prepared from 75-95% of bifid yeast fermentation product lysate and the balance of multi-yeast complex, whereinthe multi-yeast complex is prepared from lactobacillus fermentation product filtrate and saccharomycete fermentation product filtrate. The invention also discloses application of the composition of the yeast fermentation extract in cosmetics. By combining the effects of anti-ultraviolet damage, purification, regeneration, oxidation resistance and wrinkle prevention of the bifid yeast fermentationproduct lysate and the multi-yeast complex as well as the synergistic effect of the multiple yeast for caring skin, the composition disclosed by the invention realizes multiple care effects on skin and realizes safe and durable effective care.

Owner:上海晶妆生物科技有限公司

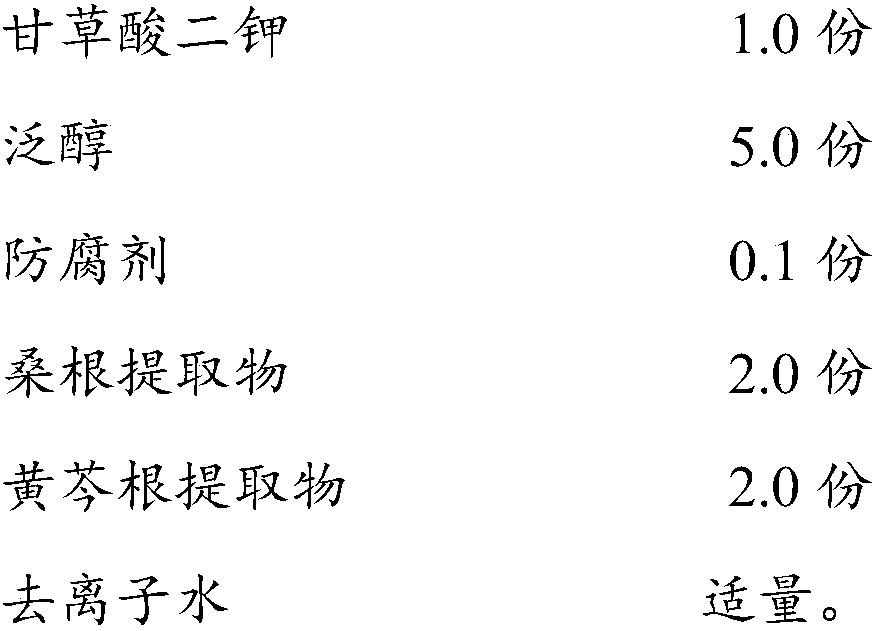

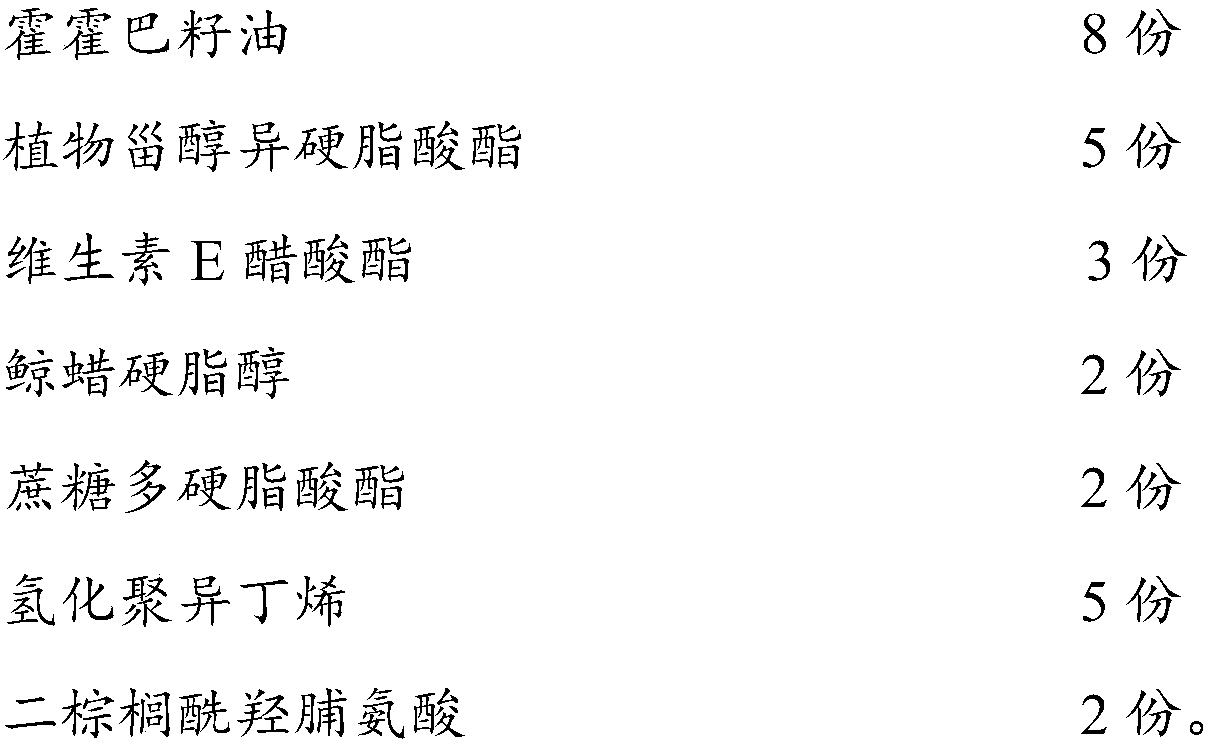

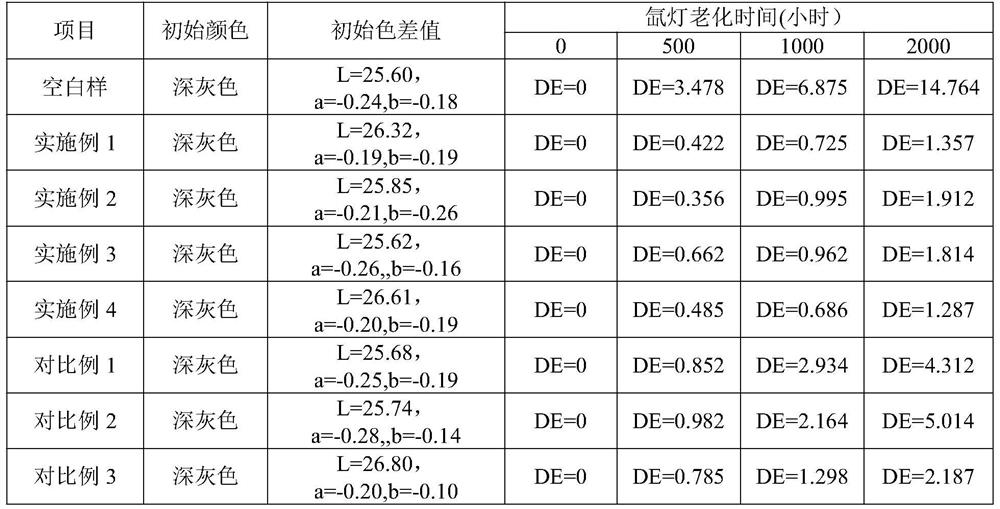

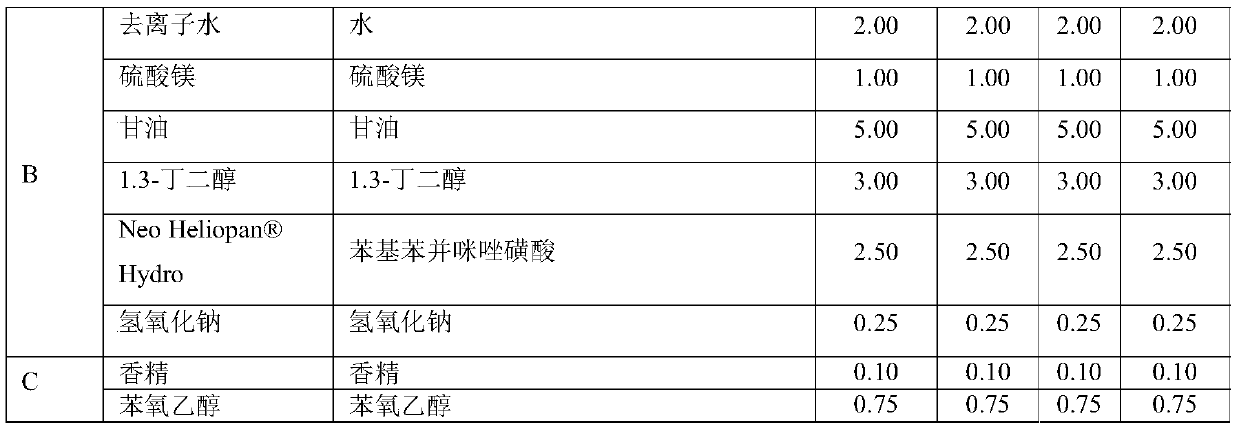

Sustained antioxidant cosmetic composition

PendingCN109939055AImprove process saccharification and photoaging problemsSkin for a long timeCosmetic preparationsToilet preparationsChemistryPanthenol

The invention relates to the technical field of cosmetics, in particular to a sustained antioxidant cosmetic composition. The sustained antioxidant cosmetic composition comprises the following components: water, butanediol, beta-dextran, ascorbic acid, betaine, trehalose, yeast fermentation product filtrate, nicotinamide, Saviae Miltiorrhizae Radix extract, panthenol, hexanediol, octanoylhydroxamic acid, phloretin, sodium hyaluronate, glutathione, gamma-sodium polyglutamate, mannitol, squalane, hydrogenated lecithin, bisabolol, ginger root extract, tocopherol and ferulic acid. According to thesustained antioxidant cosmetic composition, the high-activity components are wrapped through the pharmaceutical principle of slow-release permeation of micro-molecular organisms, the high-activity components quickly reach a target position of skin when in use, the antioxidant activity is slowly released, the problems of saccharification and photo-aging in the process are simultaneously improved,the function of protecting the skin for a long time is achieved, the skin is not dark all day, and the problems of skin allergy, acne and color spots are effectively solved.

Owner:上海科颜生物科技有限公司

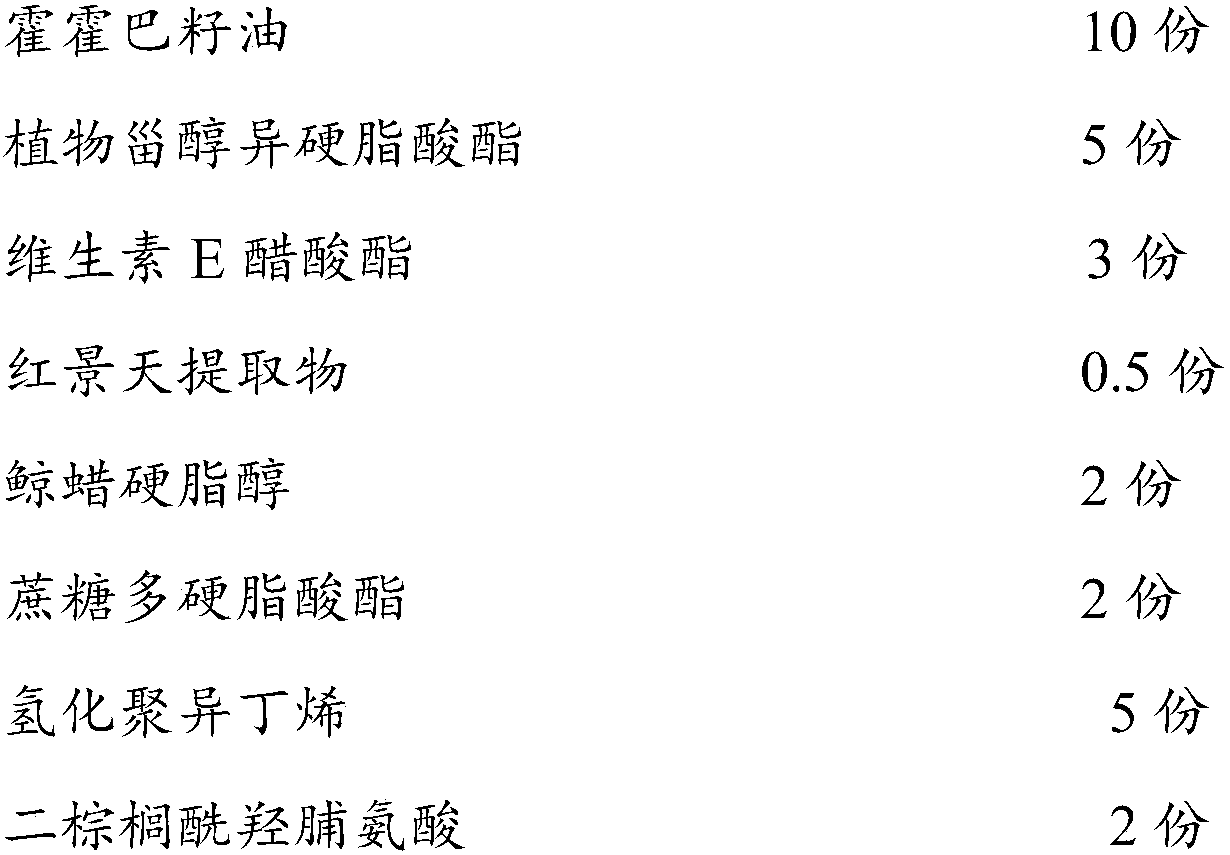

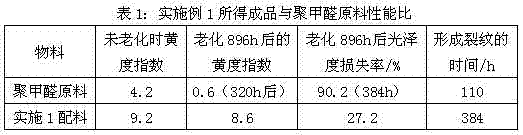

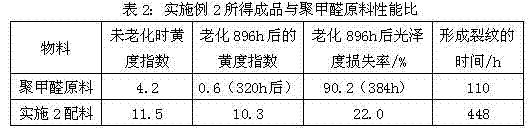

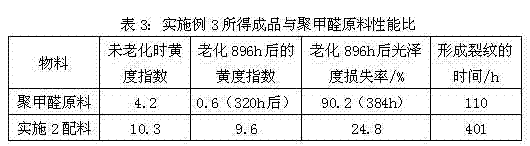

Polyformaldehyde composition with light stability

InactiveCN102516705AImprove photoagingExtended service lifeHindered amine light stabilizersChemistry

The invention discloses a polyformaldehyde composition with light stability. The composition is prepared from the following raw materials in part by weight: 100 parts of polyformaldehyde, 0.3 to 0.5 part of heat stabilizer, 0.1 to 0.8 part of ultraviolet absorbent and 0.1 to 0.8 part of hindered amine light stabilizer. According to the composition, by improving the light aging formula of the polyformaldehyde, the light aging degree of a polyformaldehyde product is improved, and the service life of the polyformaldehyde product is prolonged. The composition has abrasion resistance, self-lubricating property, oil resistance and peroxide resistance; and the aging speed of the composition is obviously reduced, the yellowness index is delayed, the luster loss rate is reduced, and surface cracking and pulverization are delayed.

Owner:TANGSHAN ZHONGHAO CHEM

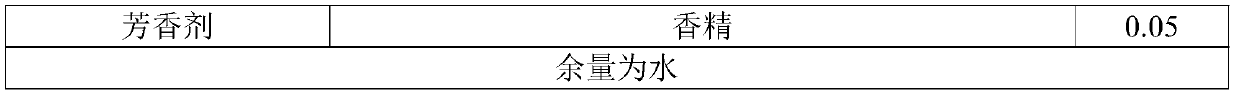

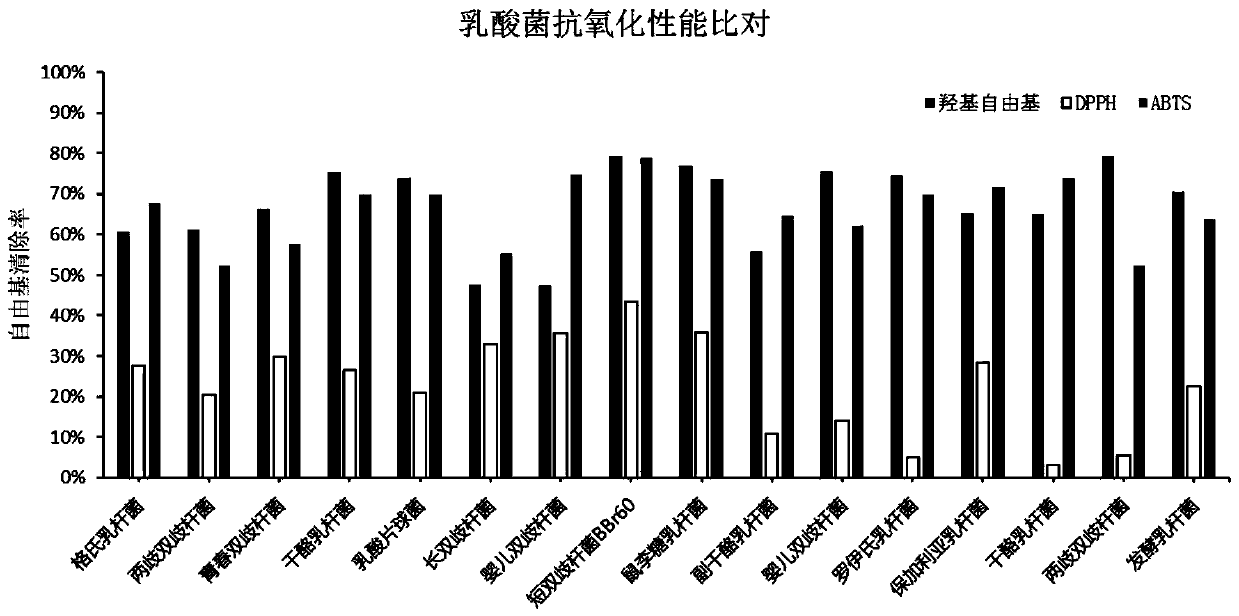

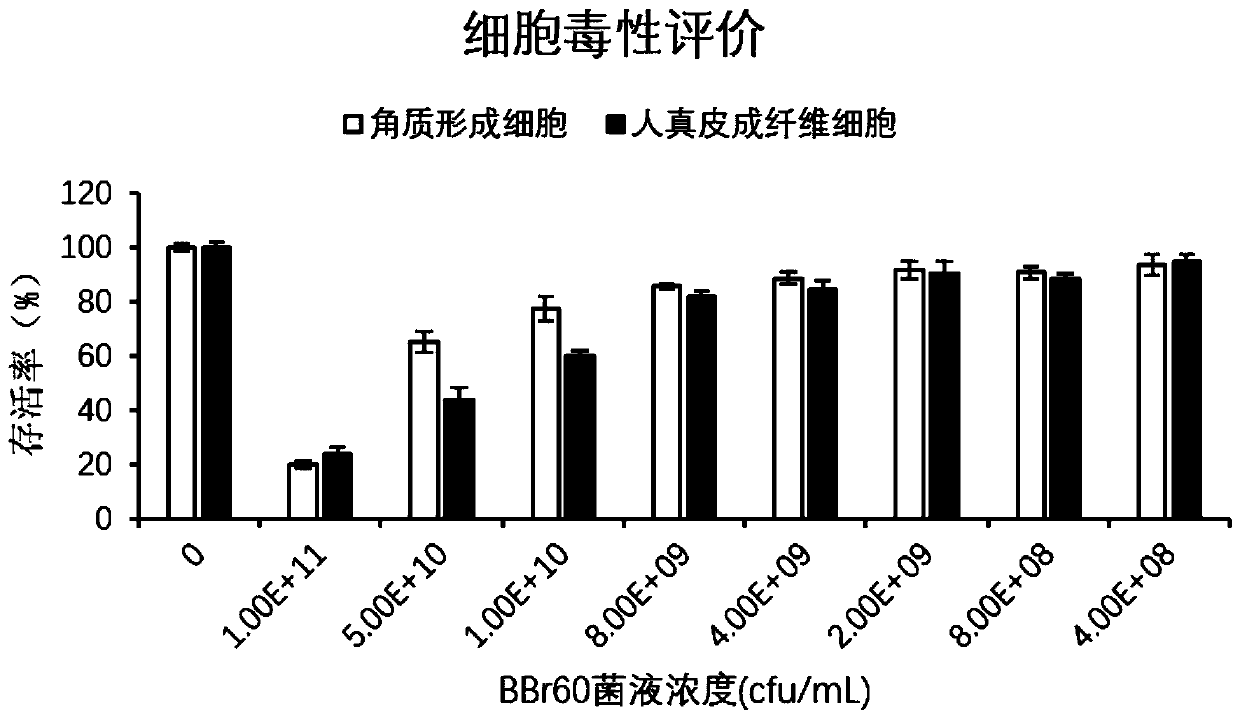

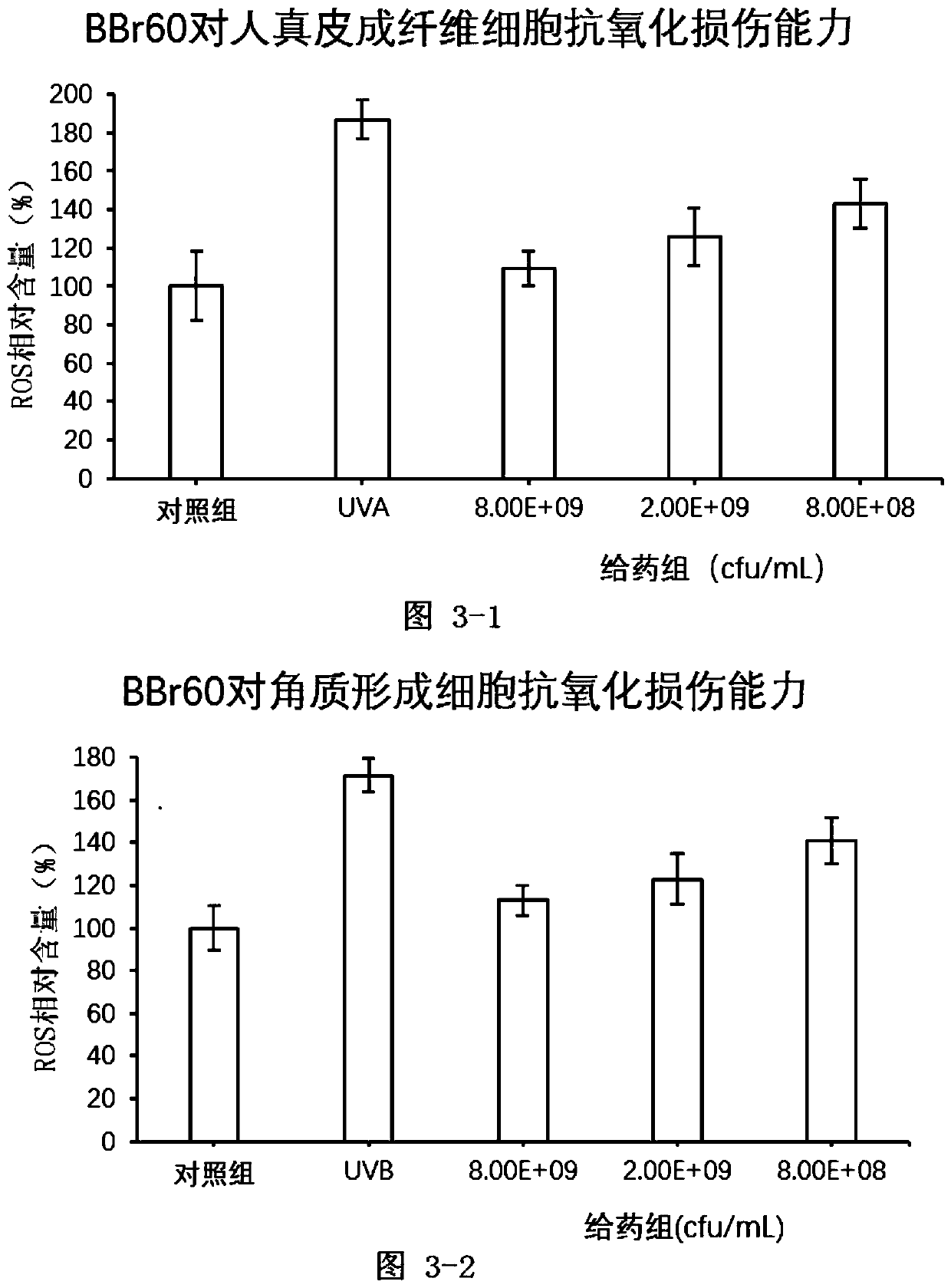

Bifidobacterium breve with effects of repairing ultraviolet injury, relieving inflammation and preventing skin light aging, and preparation method and application thereof

ActiveCN111235058ARepair damageRepair inflammationCosmetic preparationsBacteriaBiotechnologyMicroorganism

The invention discloses bifidobacterium breve with effects of repairing ultraviolet injury, relieving inflammation and preventing skin light aging, and a preparation method and application thereof, and relates to the technical field of microorganisms. The bifidobacterium breve with the effects of repairing ultraviolet injury, relieving inflammation and preventing skin light aging provided by the invention is characterized in that the bifidobacterium breve is named as bifidobacterium breve, and has a preservation number of CGMCC No.12915. Test results show that the bifidobacterium breve provided by the invention has the effects of repairing skin injury and inflammation caused by ultraviolet rays, and can relieve a skin light aging phenomenon caused by long-time repeated irradiation by the ultraviolet rays.

Owner:JIANGSU WECARE BIOTECHNOLOGY CO LTD

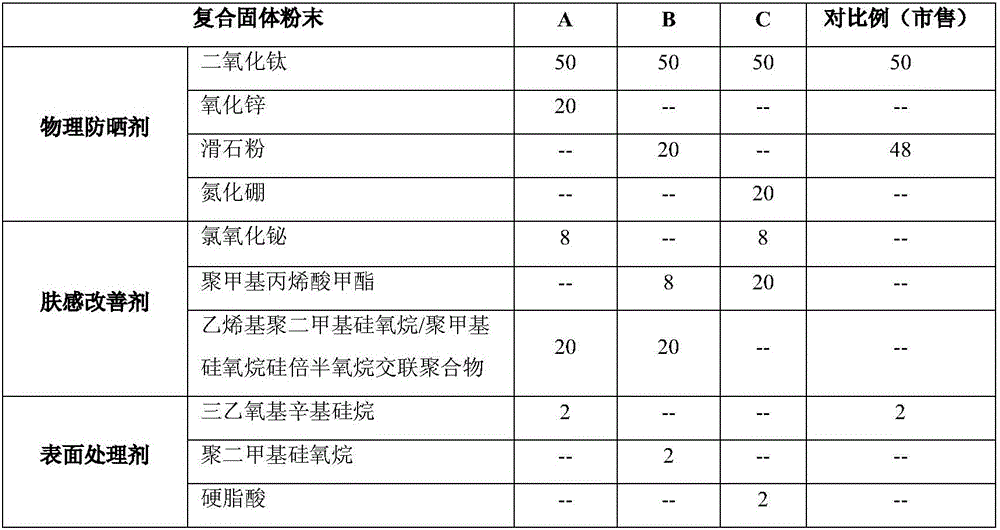

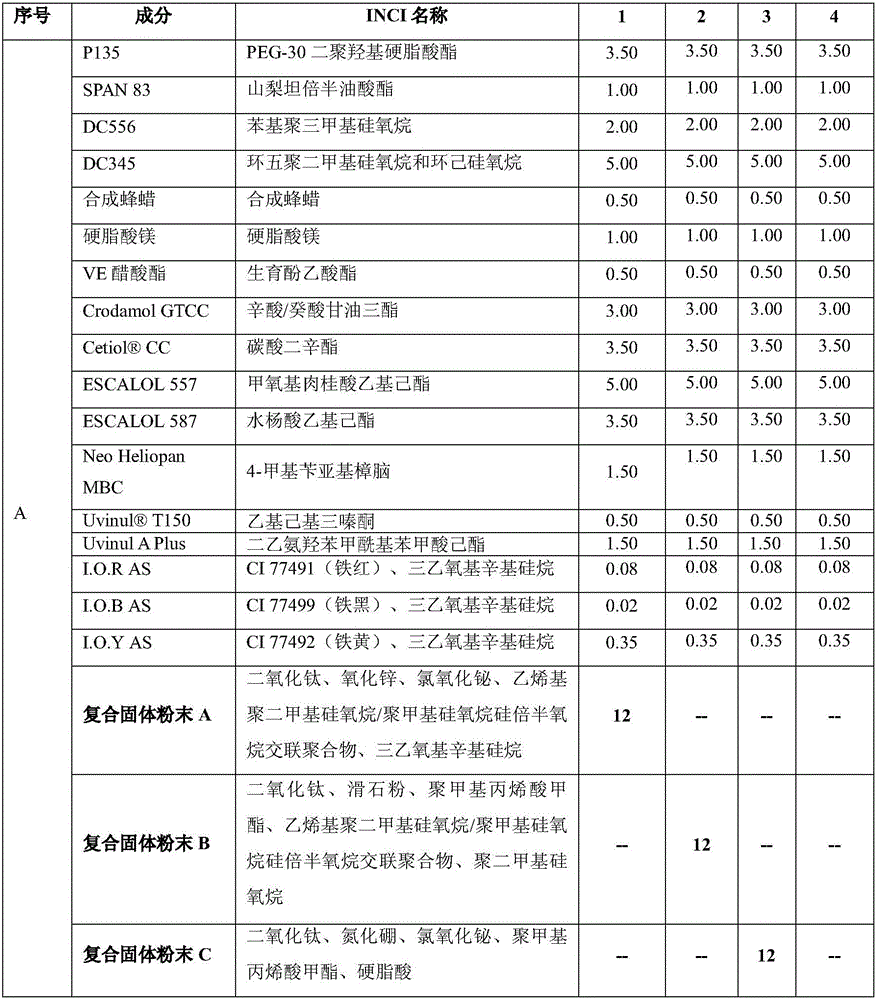

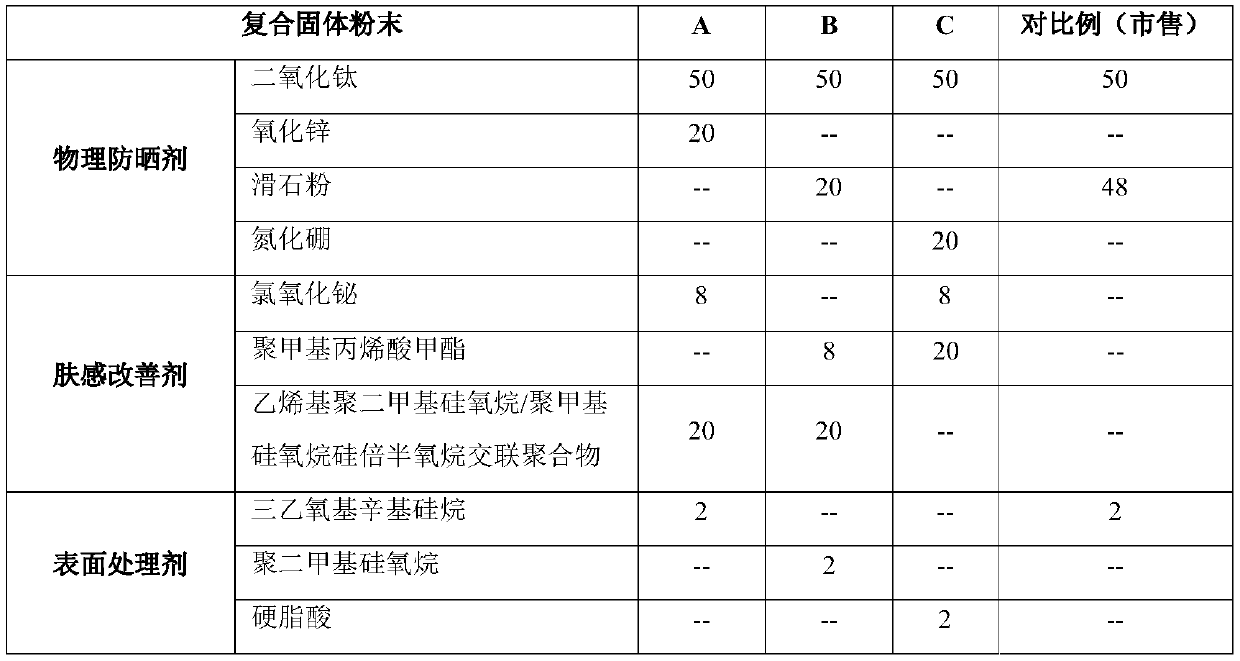

Sunscreen composition containing composite solid powder and polymer film-forming agent

ActiveCN106619194ASmooth and soft to the touchCover tightlyCosmetic preparationsToilet preparationsSkin surfaceSkin texture

The invention belongs to the field of cosmetics and relates to composite solid powder and sunscreen composition containing the same and a polymer film-forming agent. The composite solid powder contains a physical sunscreen, a skin texture improver and a surface treating agent. The smoothness of the cosmetics can be improved remarkably by adding the skin texture improver, and light skin texture is realized. The sunscreen composition contains the composite solid powder and the polymer film-forming agent such as a C30-38 olefin / isopropyl maleate / MA copolymer and the like, cosmetics containing the composition can be applied to skin surface naturally and smoothly to endow skin with smooth and soft texture and durable makeup holding capacity, and more importantly, the SPF (sun protection factor) of the sunscreen can be increased remarkably.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

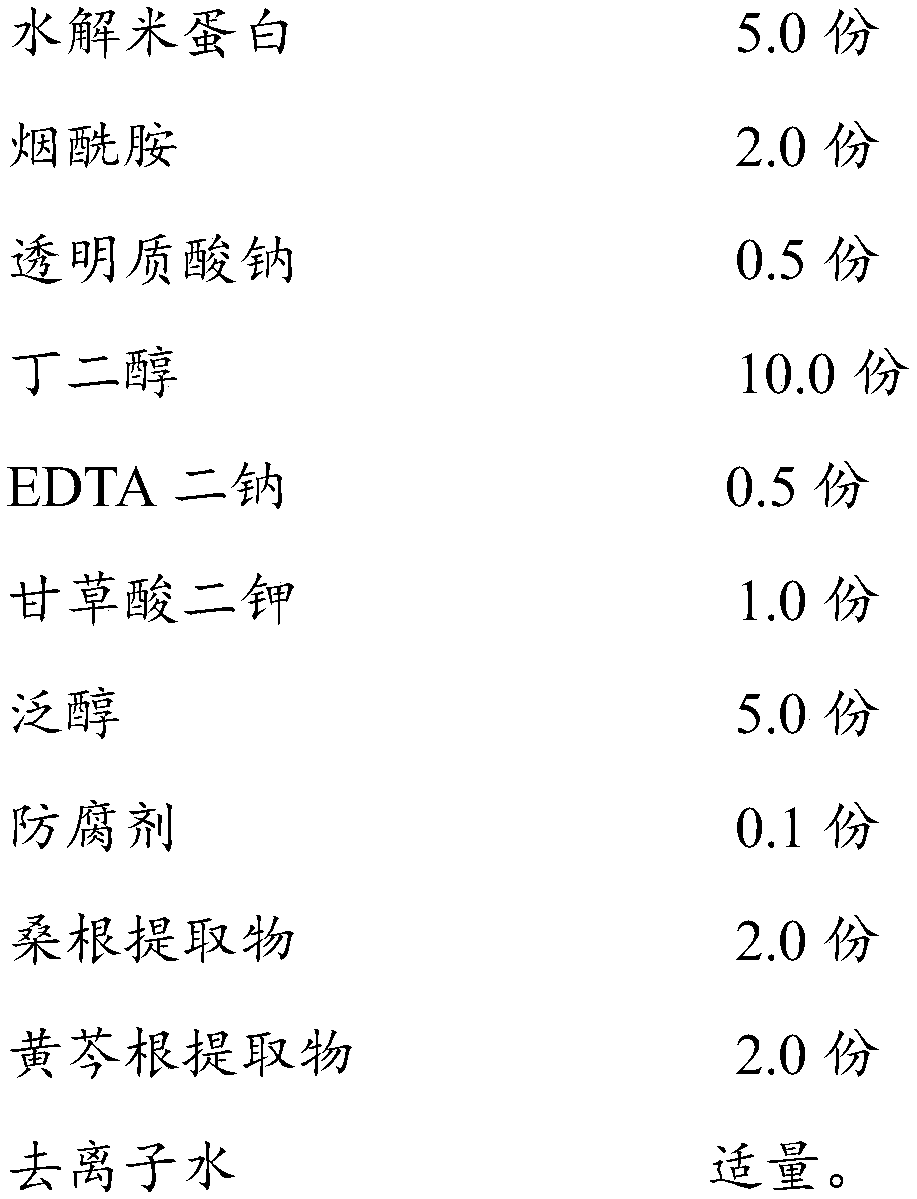

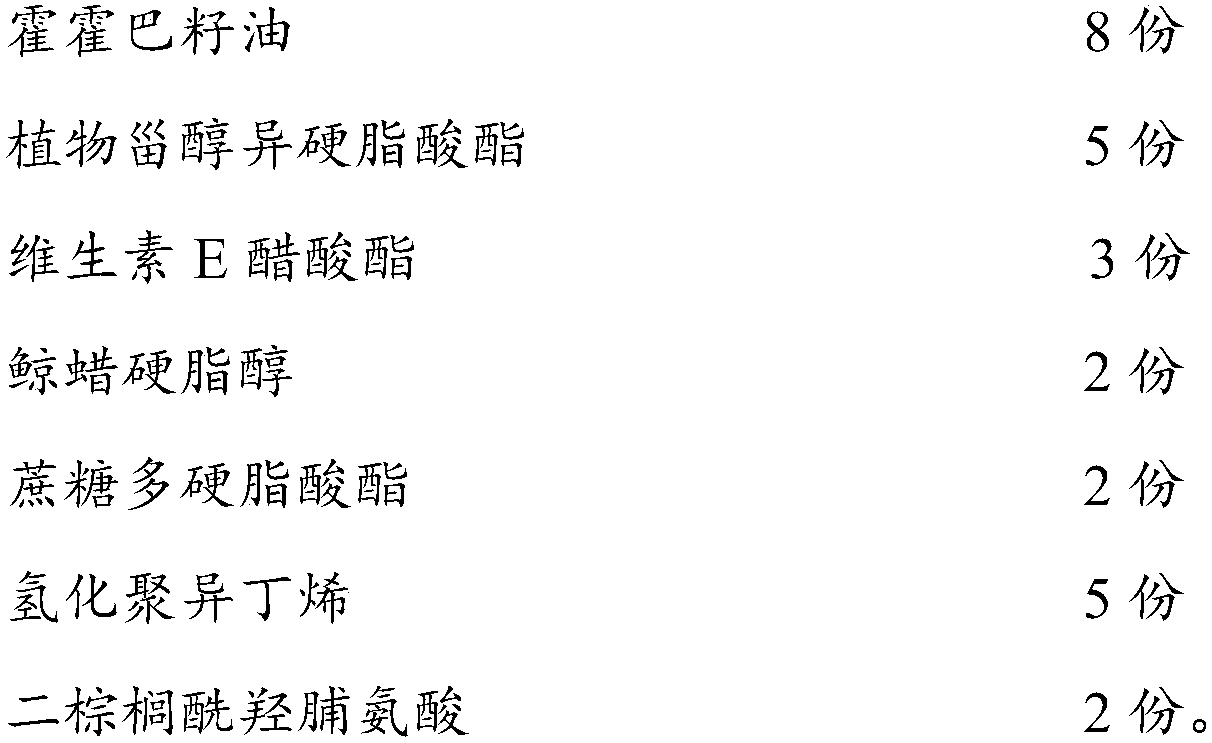

Skin barrier repairing compound, skin care lotion and preparation method thereof

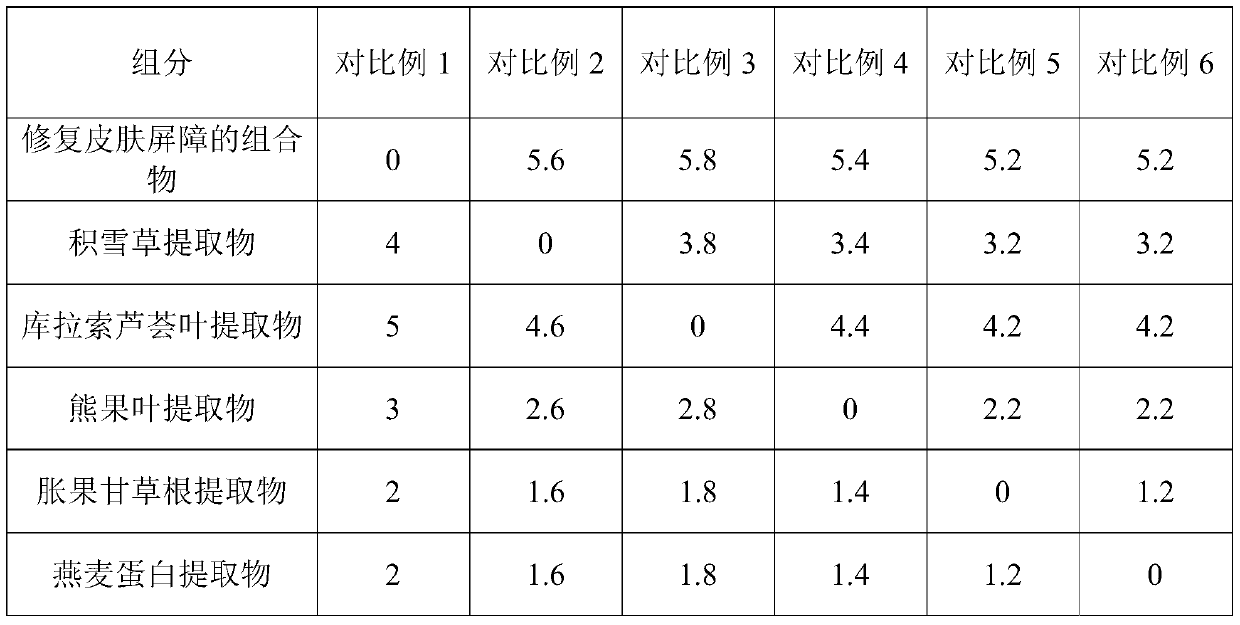

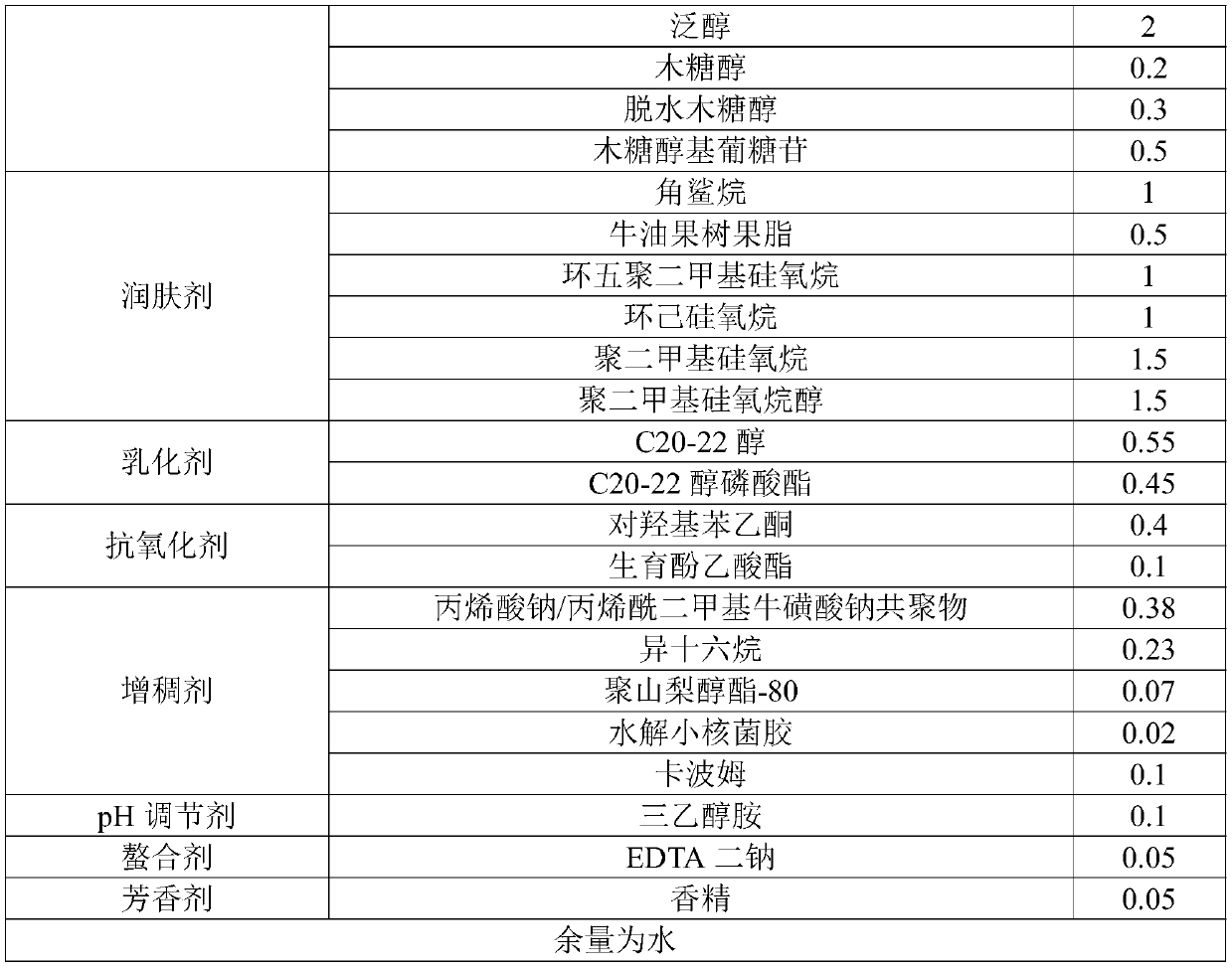

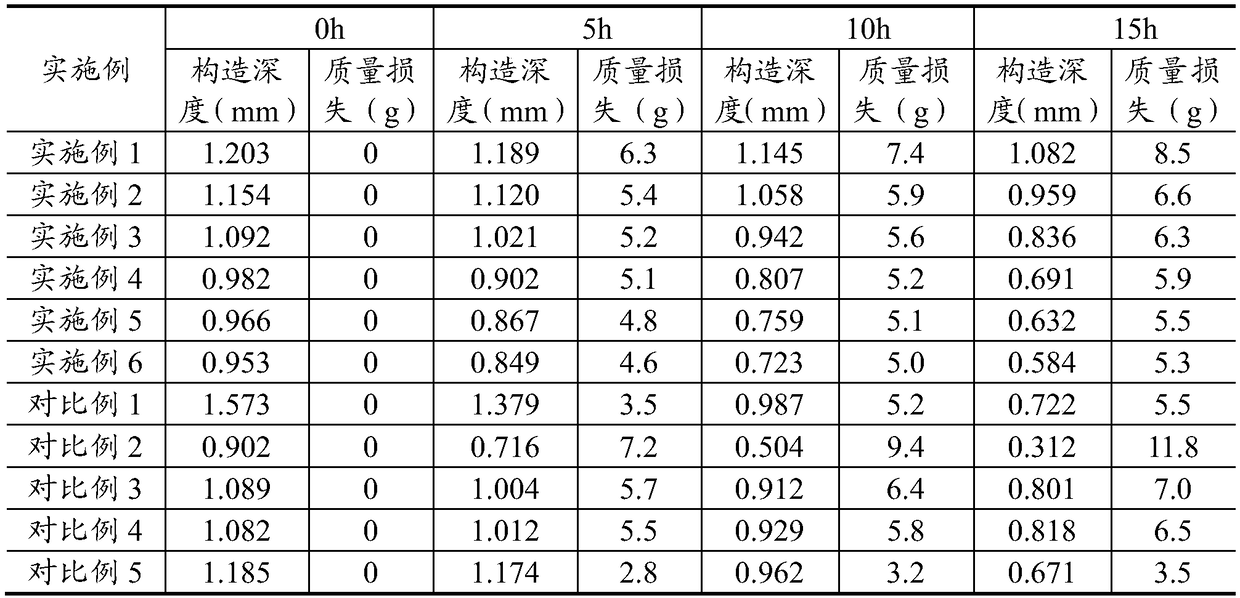

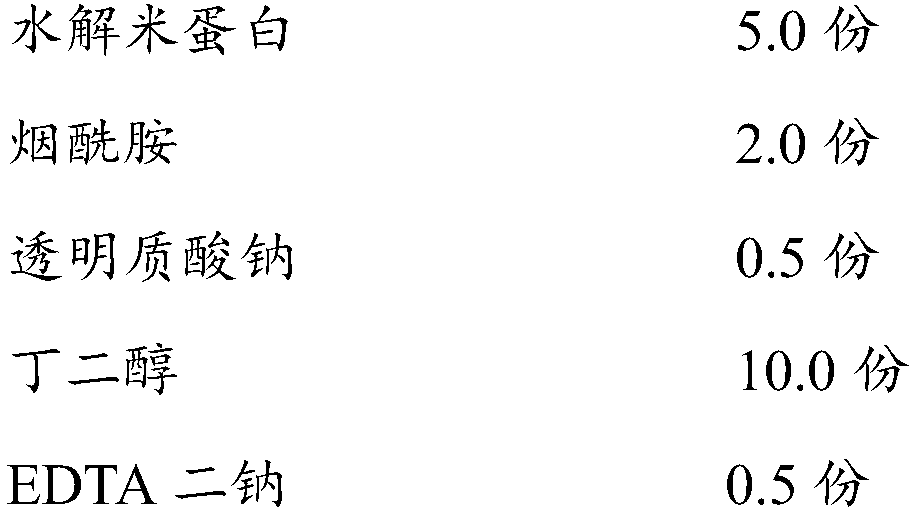

ActiveCN111317701AImprove antioxidant capacityTo promote metabolismCosmetic preparationsToilet preparationsCentella asiatica extractGlycyrrhiza inflata root extract

The invention provides a skin barrier repairing compound, a skin care lotion and a preparation method thereof. The skin barrier repairing compound comprises a composition for repairing a skin barrier,a centella extract, an aloe vera leaf extract, a bearberry leaf extract, a glycyrrhiza inflata root extract and an oat protein extract, wherein the composition for repairing the skin barrier comprises a hypecoum maritimum callus culture filtrate, ectoine and a hydrolyzed red algae extract. The skin barrier repairing compound has the effect of repairing the skin barrier, and can also resist excessive free radicals, improve the antioxidant capacity of the skin, inhibit melanin pigmentation and promote metabolism of the skin. The skin care lotion prepared from the skin barrier repairing compoundhas obvious whitening and repairing effects, can effectively improve skin photoaging, help cell saccharification and reversion and promote skin collagen, and has the effects of slowing down skin aging, improving color spots, whitening and brightening the skin and reducing wrinkles.

Owner:广州一一生物技术有限公司

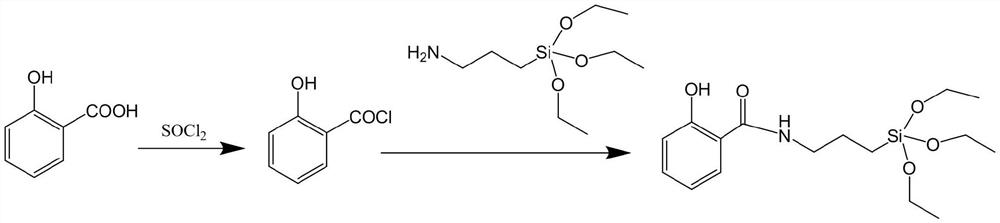

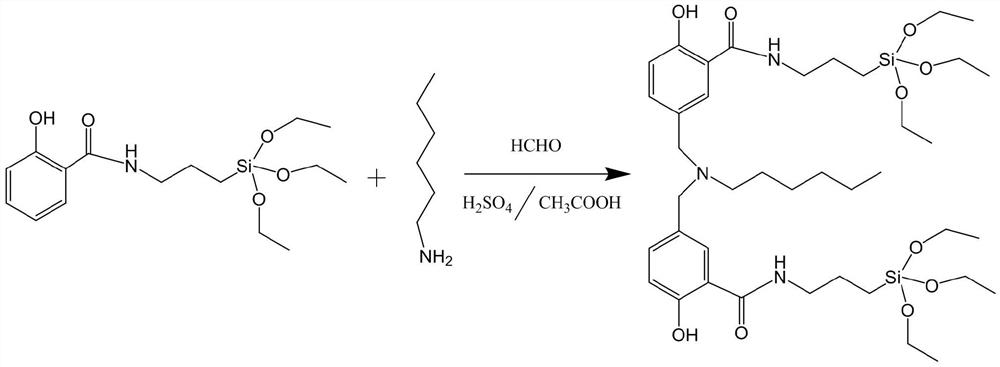

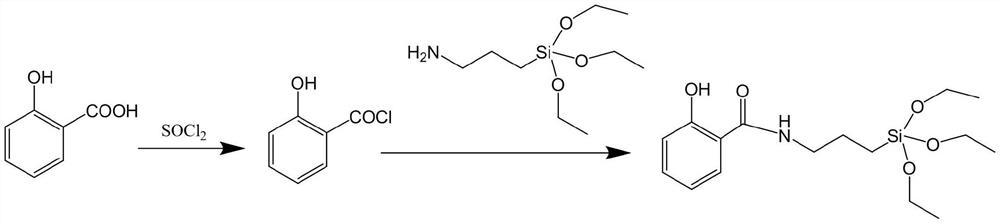

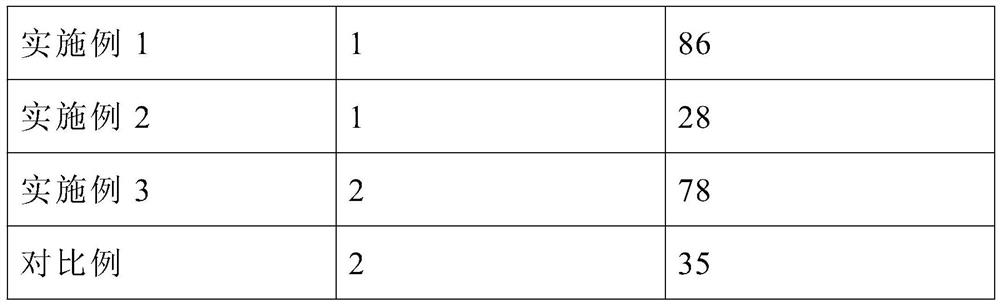

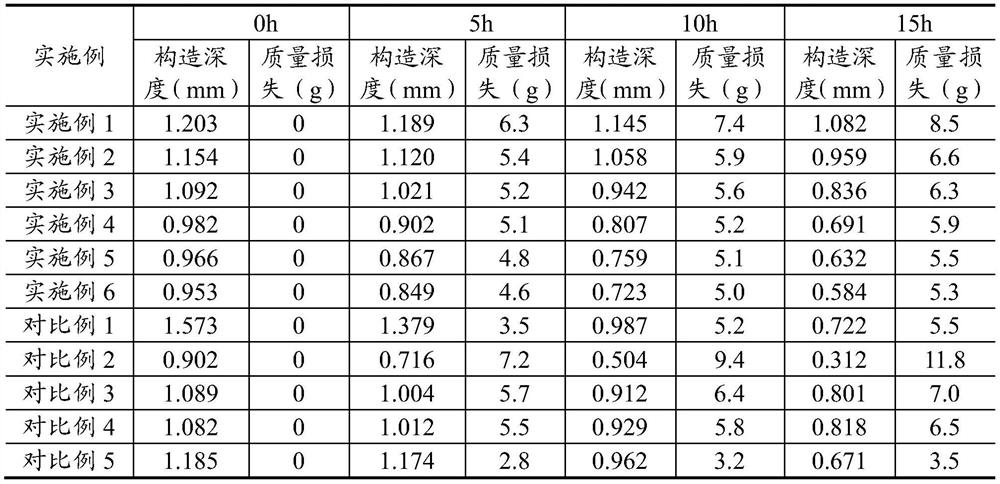

Modified carbon fiber reinforcement asphalt pavement antiskid material and method for preparing same

The invention provides a modified carbon fiber reinforcement asphalt pavement antiskid material and a method for preparing the same. The modified carbon fiber reinforcement asphalt pavement antiskid material comprises surface-modified carbon fibers, SBS (styrene-butadiene-styrene) modified asphalt epoxy cementing materials, ultrafine organic montmorillonite, non-antiskid aggregate and antiskid aggregate. The SBS modified asphalt epoxy cementing materials comprise SBS modified asphalt, epoxy resin and curing agents. The modified carbon fiber reinforcement asphalt pavement antiskid material andthe method have the advantages that the modified carbon fiber reinforcement asphalt pavement antiskid material is good in abrasion resistance and antiskid performance, and accordingly the technical difficult problems of fast antiskid performance decay of asphalt pavements, poor durability of surface treatment layers and the like can be effectively solved; the method is simple, the modified carbonfiber reinforcement asphalt pavement antiskid material comprises the surface-modified carbon fibers, accordingly, functional group bonding of the surfaces of carbon fibers and asphalt and epoxy resincomponents can be promoted, the interfacial properties between the carbon fibers and asphalt-base materials can be reinforced, and the abrasion resistance and the durability of asphalt pavement antiskid surface treatment layer materials can be improved.

Owner:CHANGAN UNIV

Composition of yeast fermentation extracts and application of composition in cosmetics

InactiveCN107898754AHigh activityIncrease elasticityCosmetic preparationsToilet preparationsYeast cell extractYeast extract

The invention discloses a composition of yeast fermentation extracts. The composition is prepared from 75 to 95 percent of a bifida yeast fermentation product cell-lysing substance and the balance ofa poly-yeast compound and a perigord truffle yeast extract, wherein the content of the perigord truffle yeast extract is 0.01 to 0.5 percent. The invention also discloses application of the composition of the yeast fermentation extracts in cosmetics. By combining the effects of ultraviolet damage resisting, purifying and repairing, oxidation resisting and crease resisting of the bifida yeast fermentation product cell-lysing substance and the perigord truffle extract and through a synergistic skin care effect with poly-yeast, multiple care effects on skin and safe and long-term effective care can be realized.

Owner:上海晶妆生物科技有限公司

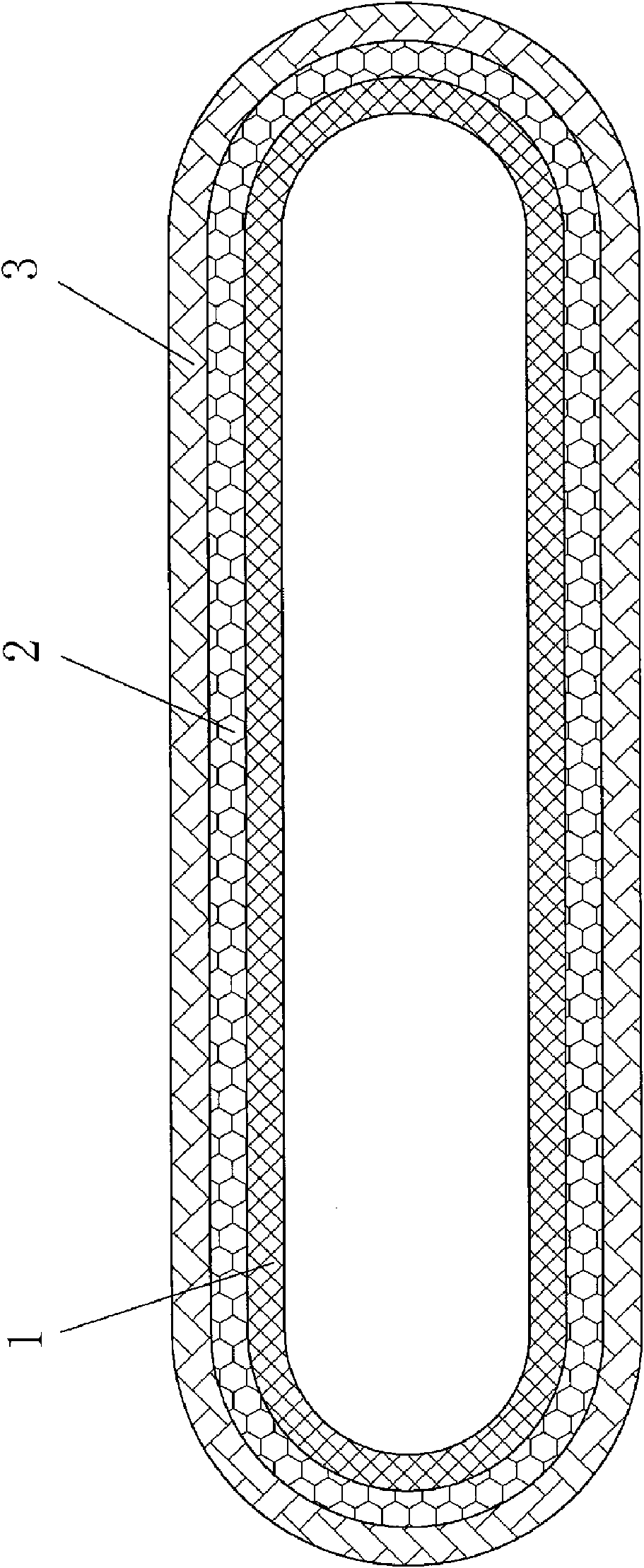

Seamless conveying belt and manufacture method thereof

InactiveCN101638171AImprove photoagingImprove thermal stabilityConveyorsTextiles and paperEngineeringSilica gel

The invention relates to a seamless conveying belt. The conveying belt forms a closed hybrid layer by a joint-free closed base belt and rubber, an outer rubber layer is designed on the outer surface of the closed hybrid layer, and an outer silica gel layer is designed on the outer surface of the outer rubber layer. The manufacture method of the conveying belt comprises the following steps: (1) selecting a plane annular woolen blanket as the joint-free closed base belt; (2) mounting the joint-free closed base belt on a rubber spreading machine; (3) starting the rubber spreading machine, pouringliquid rubber on the joint-free closed base belt and spreading the liquid rubber by a scraper; (4) spraying liquid silica gel on the outer surface of the outer rubber layer; (5) after the outer silica gel layer is solidified, abrading the outer surface of the outer silica gel layer by an abrading machine; (6) taking the product out of the machine and putting into a warehouse. The seamless conveying belt produced by the method has seamless integration and high strength and quality without sticking a conveying object and meets the requirement of a super wide and / or a super long product by a user. The invention has simple manufacture method, high production efficiency and less equipment investment.

Owner:周炳光

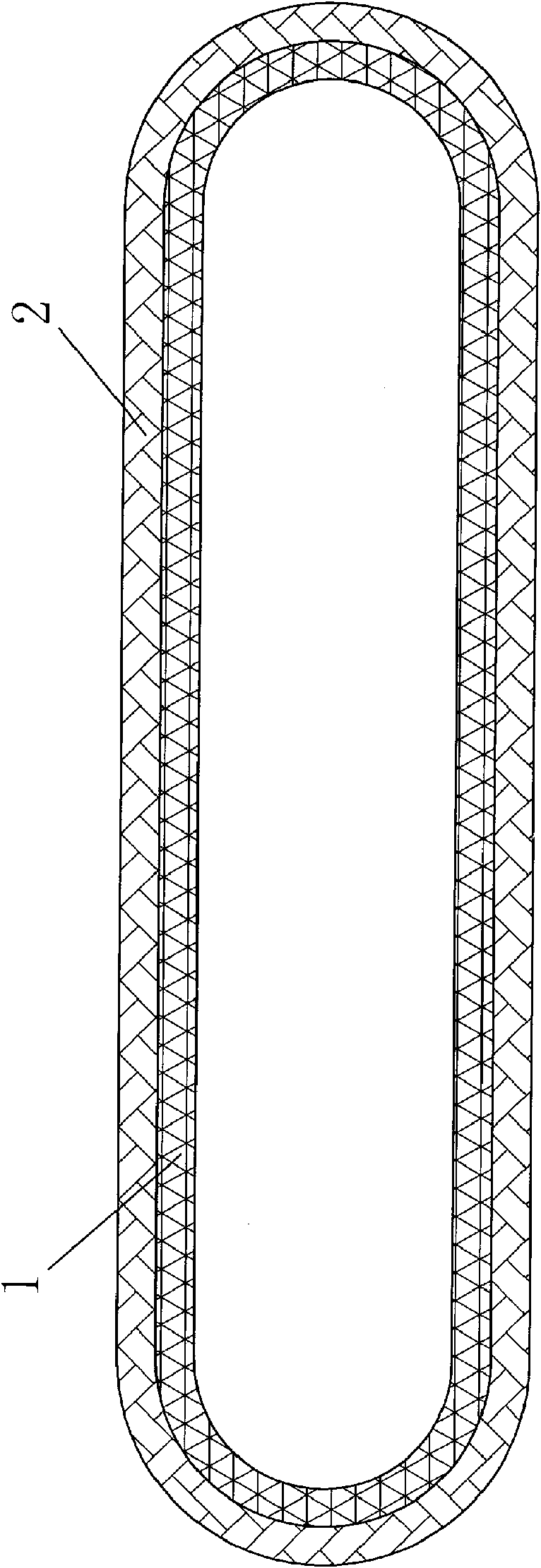

Seamless silica gel conveying belt and manufacture method thereof

InactiveCN101638170AThere will be no phenomenon of sticking to the conveyed objectImprove thermal stabilityConveyorsTextiles and paperLiquid stateEngineering

The invention relates to a seamless silica gel conveying belt. The conveying belt forms a closed hybrid layer by a joint-free closed base belt and silica gel, an outer silica gel layer is designed onthe outer surface of the closed hybrid layer, and the closed hybrid layer and the outer silica gel layer are integrally molded into a whole in such a way that liquid silica gel is poured and spread onthe joint-free closed base belt. The manufacture method of the conveying belt comprises the following steps: (1) connecting the head and the tail of a plane strip base belt to be woven into the joint-free closed base belt; (2) mounting the joint-free closed base belt on a gel spreading machine; (3) starting the gel spreading machine, pouring the liquid silica gel on the joint-free closed base belt and spreading the liquid silica gel by a scraper on the gel spreading machine; (4) after the silica gel is solidified, abrading the outer surface of the outer silica gel layer by an abrading machine; (5) taking the product out of the machine and putting into a warehouse. The seamless silica gel conveying belt produced by the method has seamless integration and high strength and quality without sticking a conveying object and meets the requirement of a super wide and / or a super long product by a user. The manufacture method has simpler working procedures.

Owner:周炳光

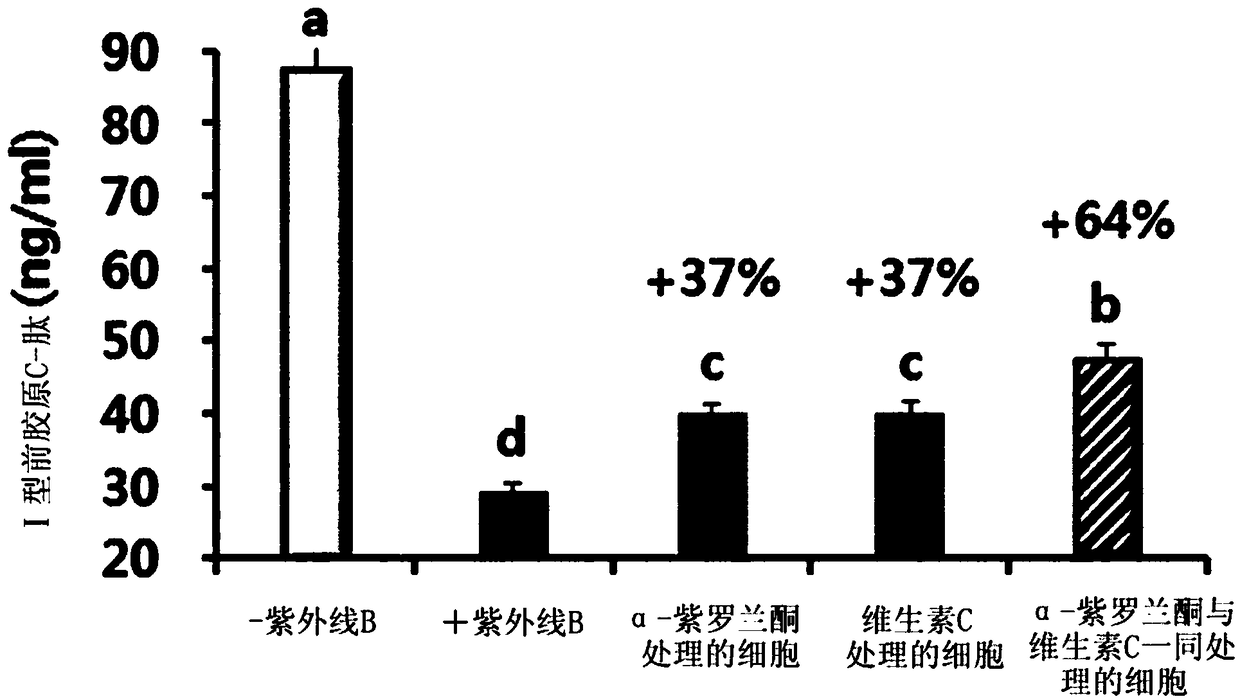

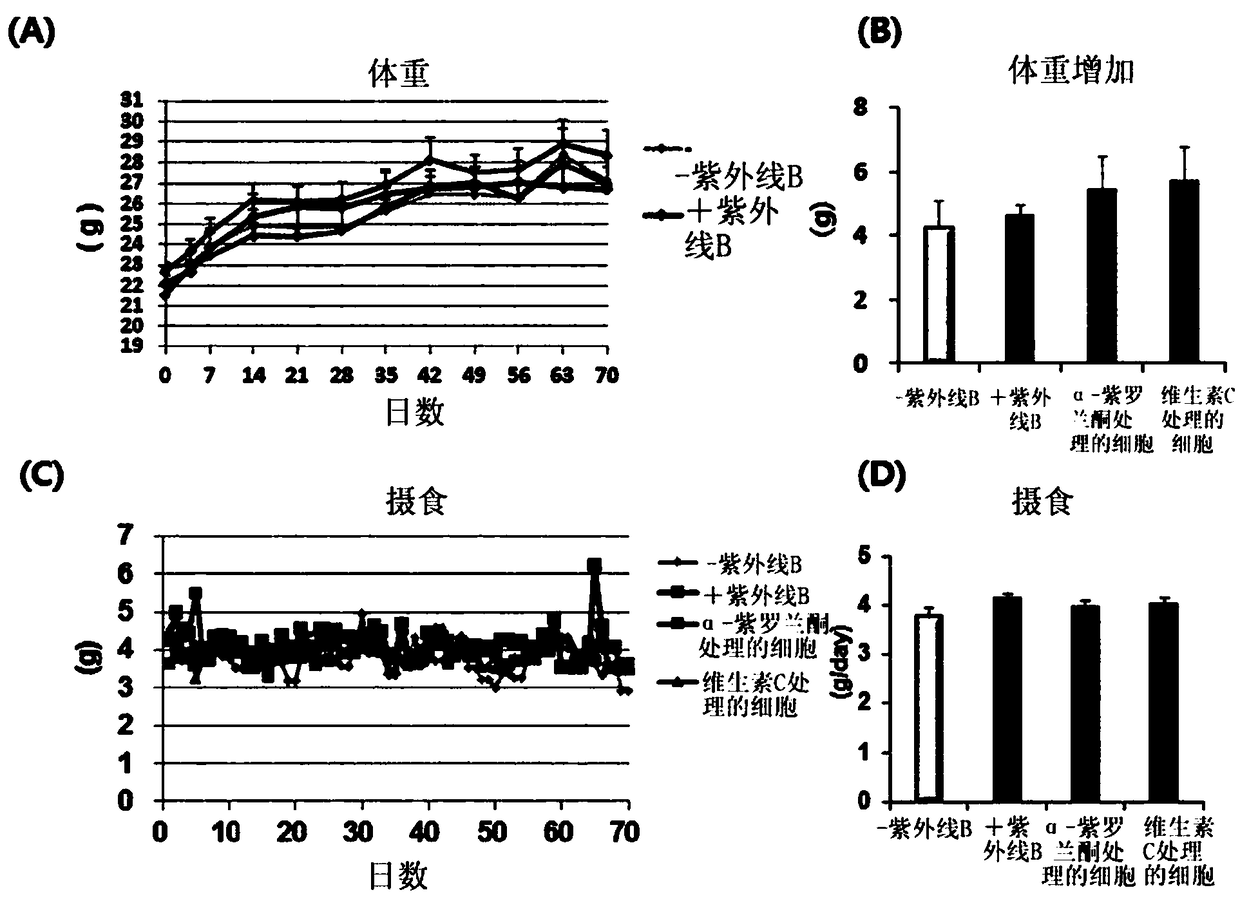

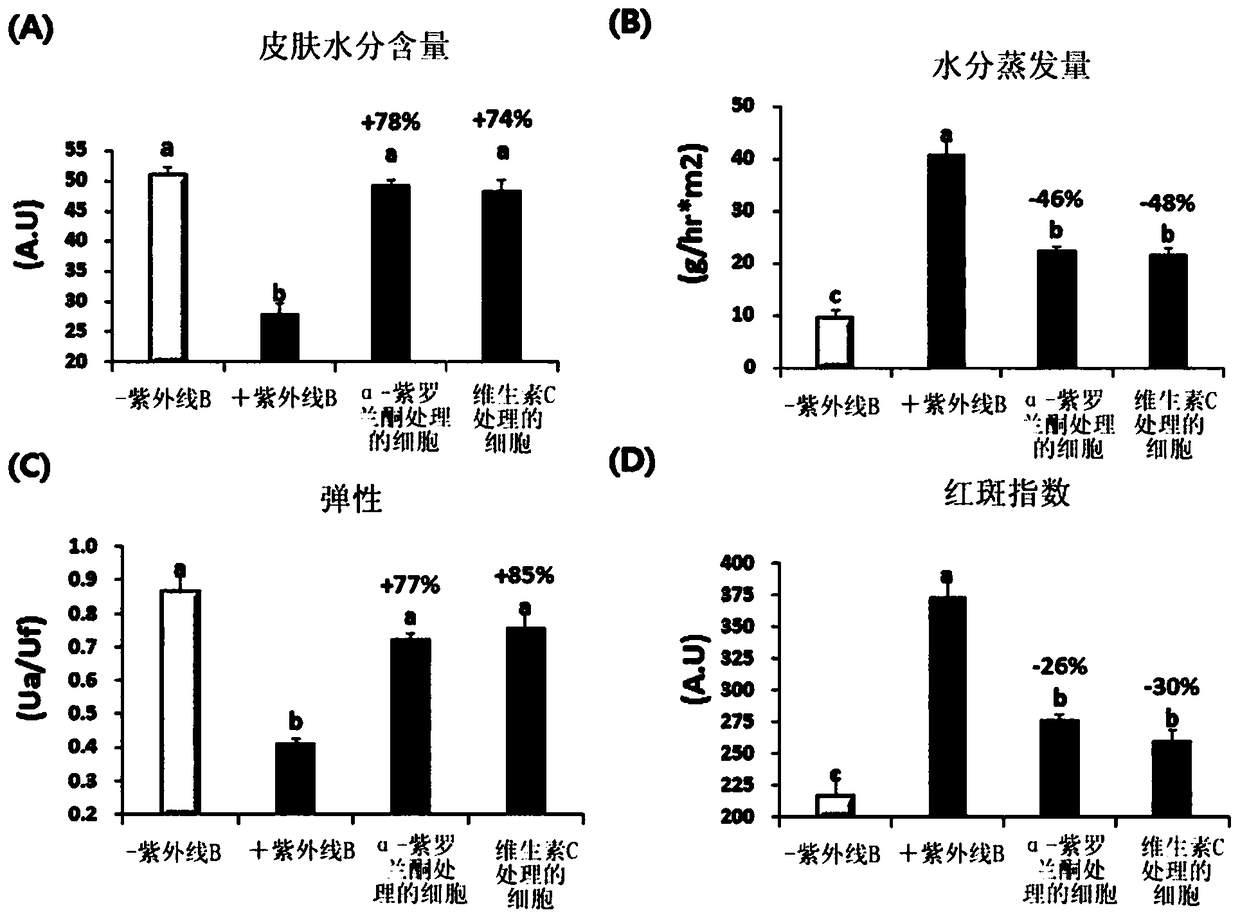

Composition having effect of improving skin moisturization, removing skin keratin, improving skin elasticity, inhibiting erythema, improving skin wrinkles or improving skin photoaging, containing ionone or salt thereof as active ingredient

InactiveCN109348703AIncrease moisture contentIncrease elasticityCosmetic preparationsToilet preparationsWrinkle skinProcollagen type i n-terminal peptide

The present invention relates to a cosmetic composition, a health functional food composition, a pharmaceutical and a quasi-drug composition having an effect of improving skin wrinkles, improving skinmoisturization, removing skin keratin, improving skin elasticity, improving skin wrinkles, inhibiting erythema or improving skin photoaging, the composition containing ionone or a salt thereof as anactive ingredient. Since the ionone or a salt thereof of the present invention exhibits the activities of increasing skin moisture content, decreasing the amount of evaporation from skin, increasing the amount of procollagen secretion, promoting collagen biosynthesis, inhibiting collagen fiber damage, inhibiting collagen fiber decomposition, inhibiting erythema and inhibiting the thickening of a skin epidermal layer, the ionone or a salt thereof of the present invention can be effectively utilized as materials for functional cosmetics, health functional foods, pharmaceuticals and quasi-drugs,etc. that provide an effect of improving skin moisturization, removing skin keratin, improving skin elasticity, improving skin wrinkles, inhibiting erythema, improving skin wrinkles and / or improving skin photoaging.

Owner:PLANT SENSATION CO LTD

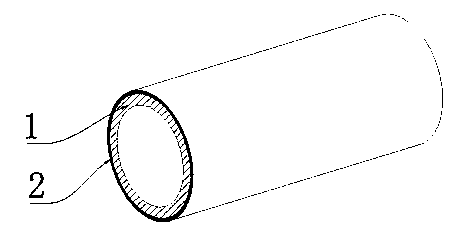

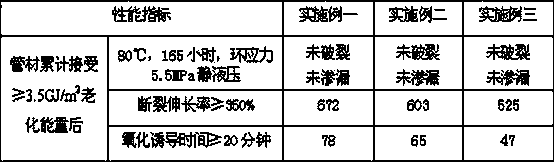

Sun-proof anti-aging polyethylene pipe

InactiveCN103737991AImprove photoagingExtended service lifeElongated constructional elementsSynthetic resin layered productsEthylene-propylene-diene-monomerEngineering

The invention relates to a sun-proof anti-aging polyethylene pipe comprising two layers of an inner layer and an outer layer, the inner layer is a pipe main body, and the outer layer is a sun-proof anti-aging protective layer. The outer layer thickness is 10%-15% of the overall pipe wall thickness, but is not less than 1mm. The outer layer material comprises the following components: by weight, 50-70 parts of mLLDPE (metallocene polyethylene), 50-30 parts of EPDM (ethylene-propylene-diene monomer), 0.3-4 parts of a chain extender, 0.2-0.5 part of a catalyst, 5-10 parts of carbon black, 1-2 parts of titanium dioxide, 0.5-1.5 parts of an antioxidant and 1-2 parts of a dispersant; the inner layer material is a HDPE (high-density polyethylene) composite material with the carbon black content being more than 2% and the carbon black grade being less than grade 3. The polyethylene pipe is prepared by high-speed mixing and mixed plasticizing of the outer layer material then use of a composite die for extrusion molding of the outer layer material and the inner layer material, compared with ordinary polyethylene pipes, the anti-aging performance is improved, the pipe service life is prolonged, the sun-proof anti-aging polyethylene pipe can be exposed on the earth surface for use, and the application scope of the polyethylene pipe can be expanded.

Owner:浙江经纬集团环保工程有限公司

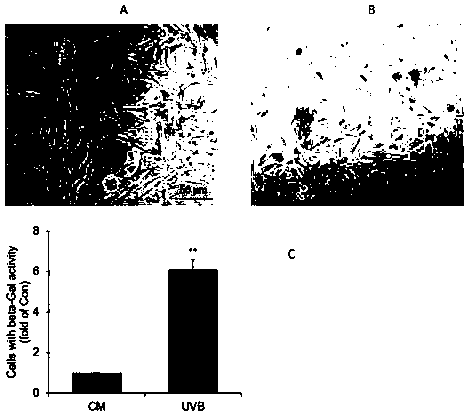

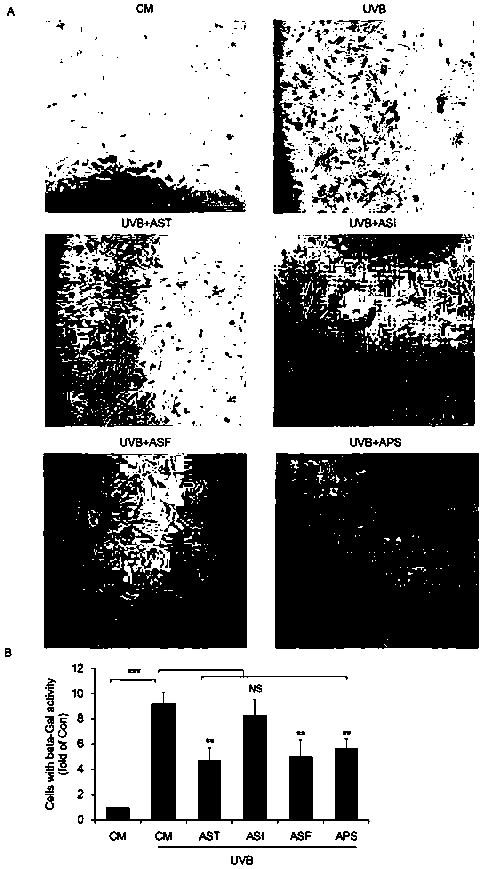

Application of total astragaloside to anti-photoaging and photodamage of skin

InactiveCN108969415APromote accumulationRich sourcesCosmetic preparationsToilet preparationsAstragalosideApoptosis

The invention relates to application of total astragaloside to anti-photoaging and photodamage of skin. The total astragaloside can improve the photoaging caused by long-term repeated irradiation of UVB (Ultraviolet B). As proved by cell level experiments, the total astragaloside has good effects in anti-oxidation, anti-photodamage, anti-photoaging, protection of mitochondria and inhibition of apoptosis induced by the UVB and the like. Meanwhile, the total astragaloside can also reverse the loss process of collagen in skin cells during photoaging, and promote the accumulation of collagen. On the other hand, the autophagy activity of photoaging cells can be up-regulated, and the normal cell homeostasis process is maintained so as to better resist the photoaging process. The total astragaloside is proved to have a good effect in the anti-skin photoaging process, and can be applied in the fields of pharmaceutical, health care products, cosmetics and the like.

Owner:SUN YAT SEN UNIV

Breathable waterproof anti-ultraviolet fabric and preparation method and application thereof

InactiveCN108660580AHigh strengthImprove wear resistanceBiochemical fibre treatmentWoven fabricsPolyesterUltraviolet

The invention relates to the field of outdoor fabrics, in particular to a breathable waterproof anti-ultraviolet fabric, and further relates to a preparation method and application of the breathable waterproof anti-ultraviolet fabric. The fabric is made from an anti-ultraviolet gray fabric with coated nano-silver on the surface, wherein the anti-ultraviolet gray fabric is formed by, by weight, 40-50 parts of ultraviolet modified PVC, 30-40 parts of polypropylene and 10-20 parts of polyester through mixed weaving. The preparation technology is simple and easy to implement, the materials for usage are conventional in the field and cheap, and the made fabric not only has the properties of high strength, abrasion resistance and others, but also has the properties of good water prevention, airbreathing and ultraviolet resistance, and also has the excellent properties of bacterium resistance and bacterium restraining.

Owner:深圳市好美佳智能家居股份有限公司

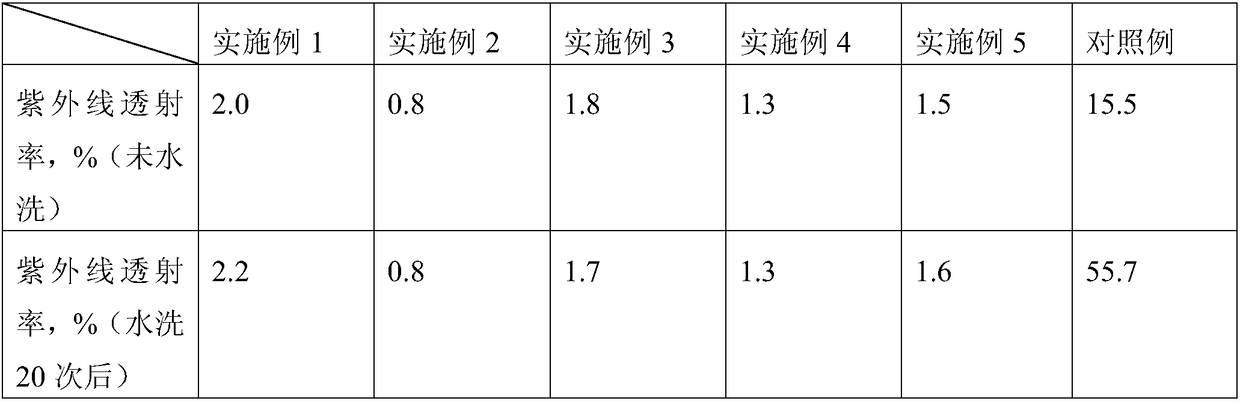

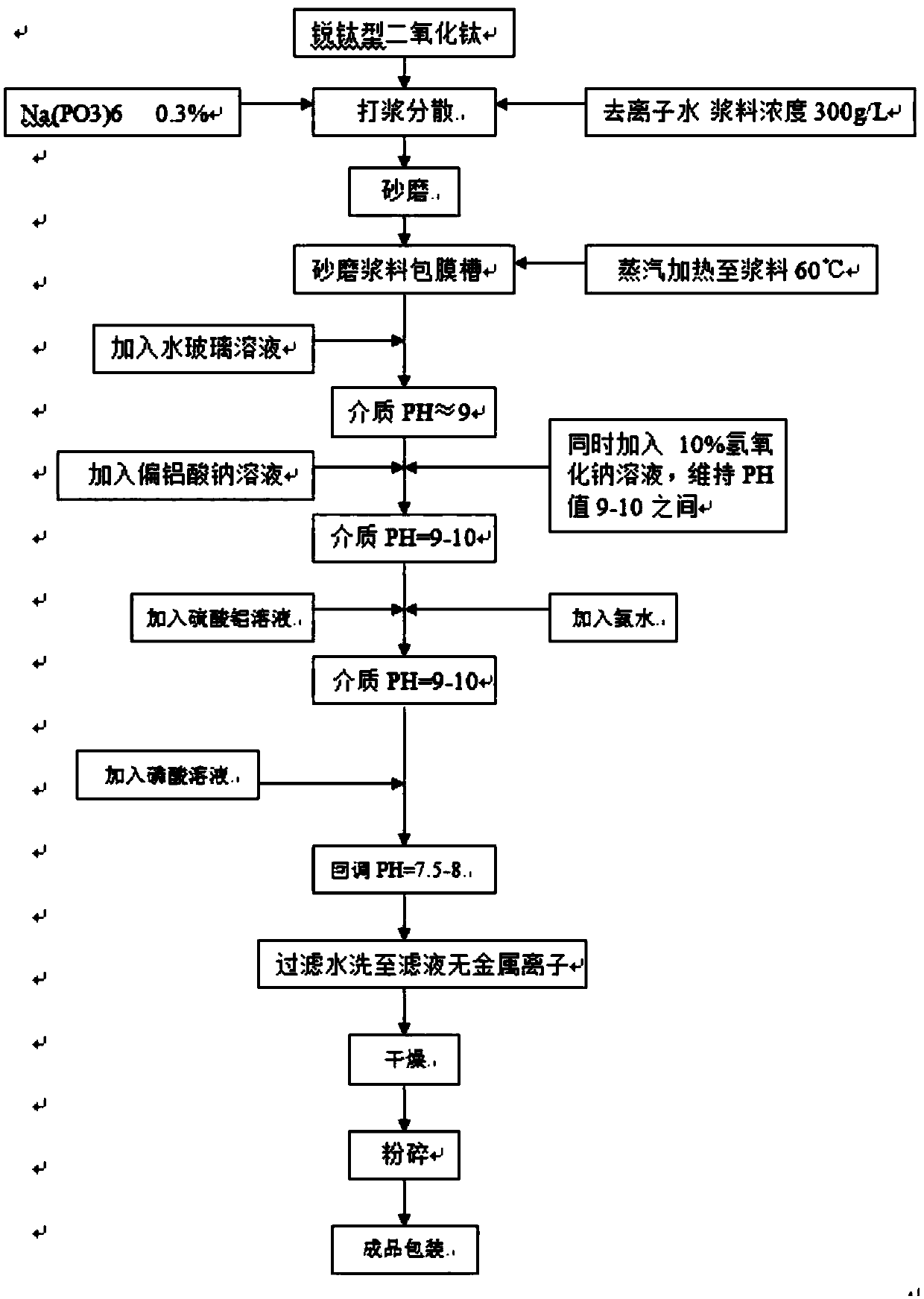

Chinlon chemical fiber titanium dioxide inorganic film-coating treatment process

The invention discloses a chinlon chemical fiber titanium dioxide inorganic film-coating treatment process which comprises the steps: 40-60 parts of polypropylene, 6-8 parts of polyester, 5-7 parts ofviscose fibers, 18-22 parts of polyurethane fiber and 12-15 parts of bamboo fibers are stirred to prepare fiber web base cloth A, cut-off bamboo charcoal fiber suspension slurry is continuously transported o a web curtain, fibers are attached to the web curtain to prepare an addition material B; the base cloth A is subjected to dehydration treatment, then the addition material B is laminated to the upper surface of the base cloth A, the laminated base cloth A and the addition material B are sent to a hot rolling mill and are subjected to bonding treatment, and a composite nonwoven fabric is prepared. According to the chinlon chemical fiber titanium dioxide inorganic film-coating treatment process, the bamboo fibers are woven into a net, then the net is bonded on the surface of the base cloth A through the hot rolling mill, and the falling of the bamboo fibers is avoided; the bamboo fibers have good adsorption performance, can effectively adsorb dust in air, and have antibacterial andbacteriostatic effects and good anti-tearing performance.

Owner:HEBEI HUIERXIN NEW MATERIAL

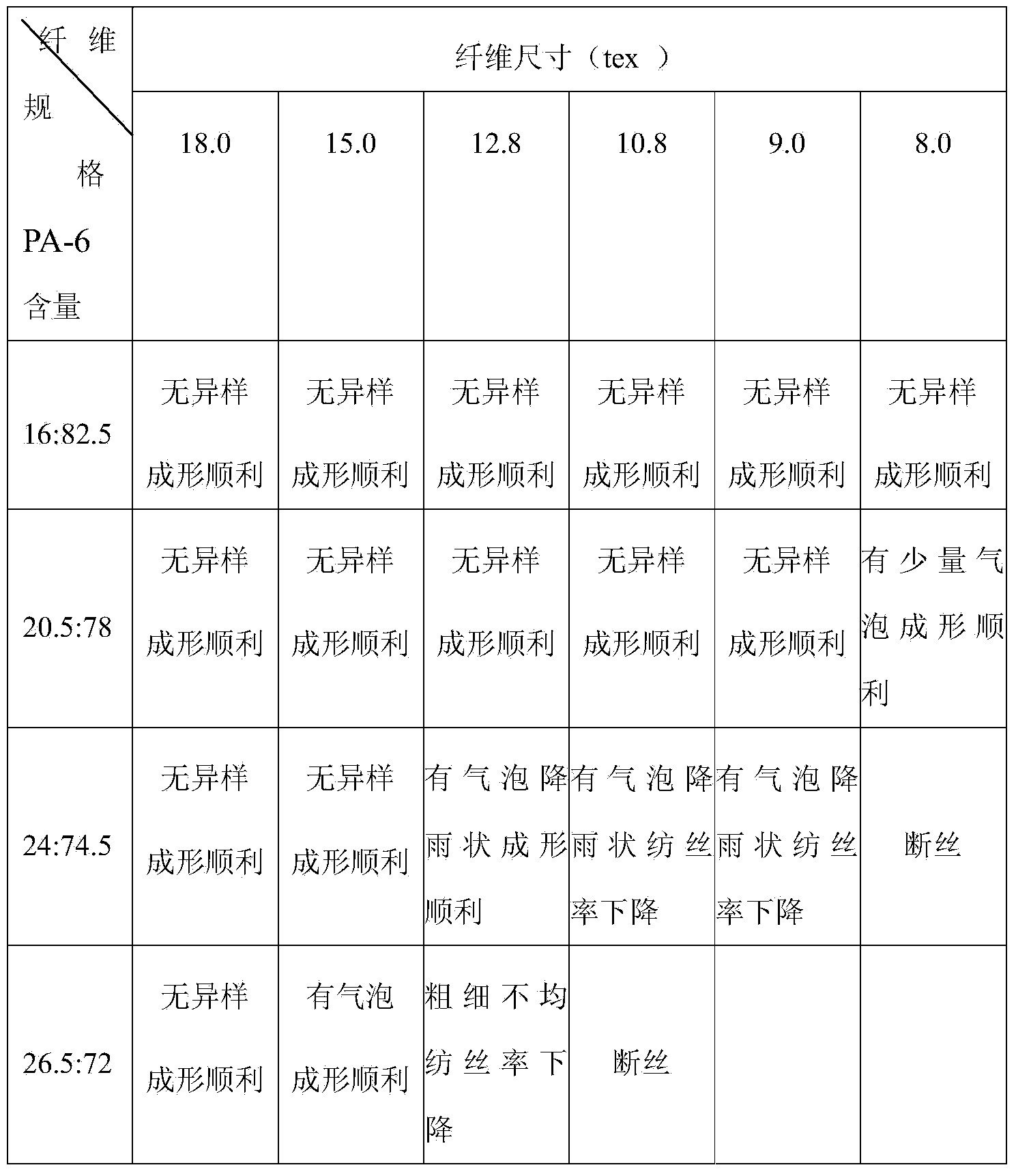

PP-PA6 (polypropylene-polyamide 6) polymer alloy resin for spinning

InactiveCN103333414BMeet the technical requirements of formingImprove low temperature impact resistanceConjugated synthetic polymer artificial filamentsFiberPolymer alloy

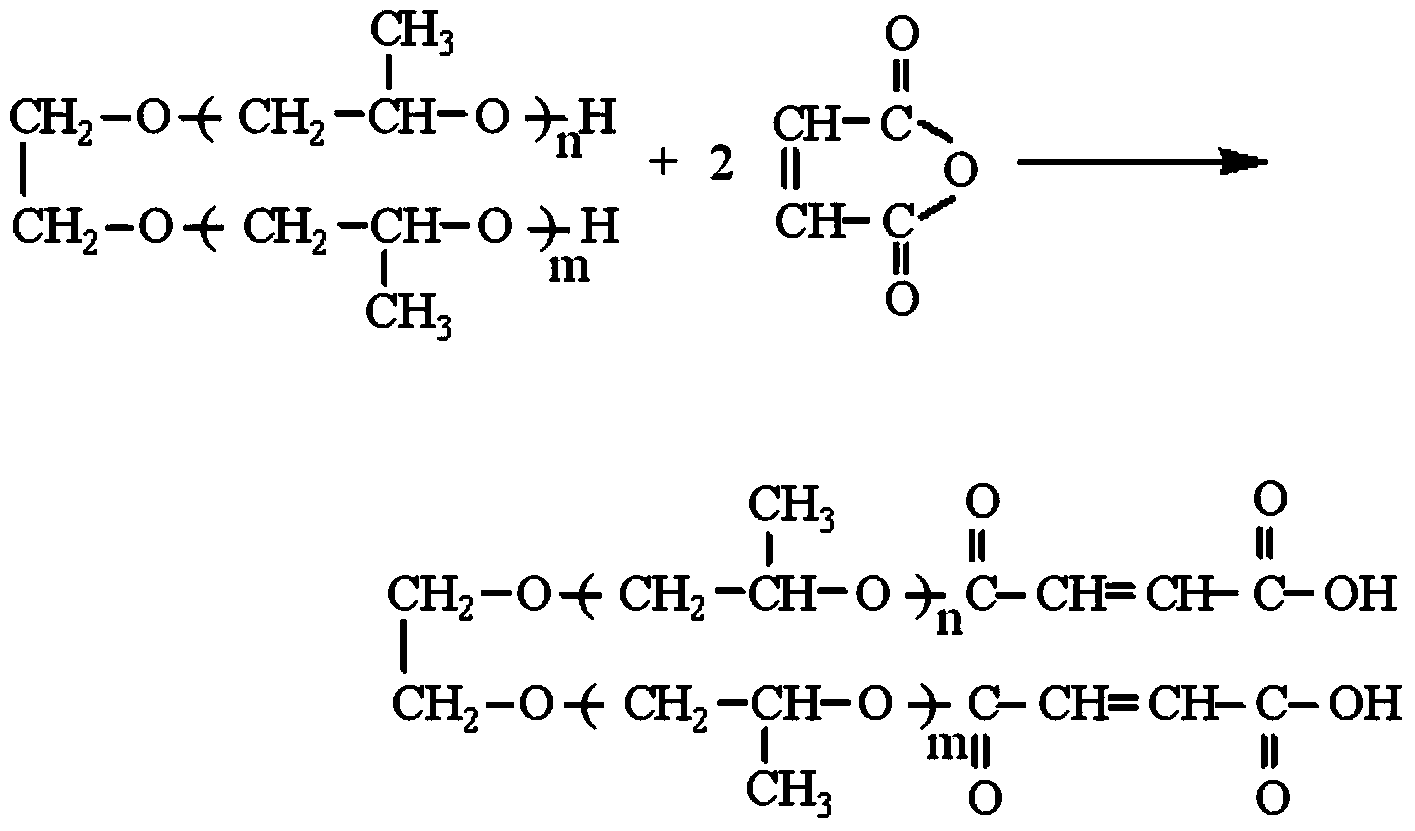

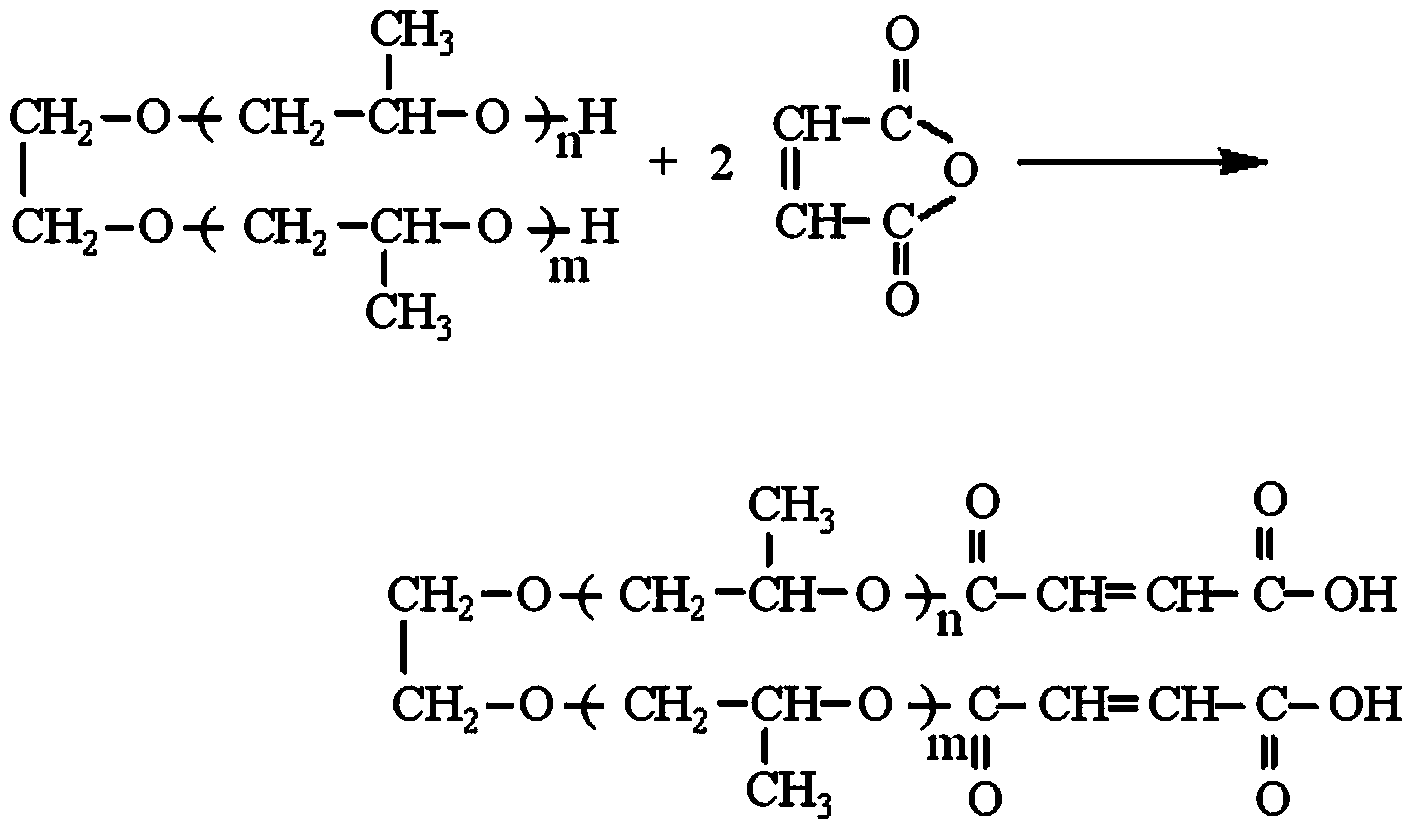

The invention relates to a PP-PA6 (polypropylene-polyamide 6) polymer alloy resin for spinning. A PP molecular chain and maleic anhydride molecular grafting process is adopted. As the maleic anhydride is prepared into a polymer, a solvent does not need to be used a carrier in the grafting reaction. The PP-PA6 polymer alloy resin is prepared from the following raw materials in percentage by weight: 1.2 to 1.8% of PP molecular chain and maleic anhydride molecular grafting polymer, 0.035 to 0.06% of initiator, 73.14 to 78% of PP resin and 20.14 to 25% of PA6 resin. The PP-PA6 polymer alloy resin has the advantages that the produced PP-PP6 polymer fiber is mainly used for earthwork engineering, net cage culturing, building safety nets, industrial filtering cloths, and the like; and meanwhile, along with the raising of the ratio of the PA6, the low-temperature shock-resistant performance, the anti-static performance, the pigmentation degree, the heat aging-resistant performance and the light aging-resistant performance are also improved, and the mechanical strength is improved.

Owner:黑龙江省化工研究院

Anti-aging auxiliary agent bag and preparation method thereof and application of anti-aging auxiliary agent bag in carbon fiber prepreg

PendingCN114058078AImproved resistance to thermo-oxidative and photoagingGood synergyAnoxomerPolymer chemistry

The invention belongs to the technical field of special auxiliary agents, and discloses an anti-aging auxiliary agent bag and a preparation method thereof, and application of the anti-aging auxiliary agent bag in carbon fiber prepreg. The anti-aging auxiliary agent bag is in a uniform transparent liquid state, and comprises the following components in percentage by mass: 45-60% of a liquid ultraviolet absorbent, 20-40% of a liquid HALS light stabilizer and 10-15% of an antioxidant. The preparation method comprises the following steps: stirring and mixing a liquid ultraviolet absorbent and a liquid HALS light stabilizer, then adding solid antioxidant powder, heating and stirring until the antioxidant powder is completely dissolved, filtering, and cooling to room temperature to obtain a clear and transparent anti-aging additive package product. The anti-aging auxiliary agent bag product provided by the invention can effectively solve the problems that the epoxy resin is not resistant to light aging and thermo-oxidative aging in a high-temperature curing process, has the advantages of small influence on the ground color of the epoxy resin and the like, and is very suitable for being applied to epoxy resin curing carbon fiber prepreg cloth.

Owner:江门市严恩化工科技有限公司

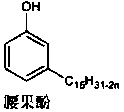

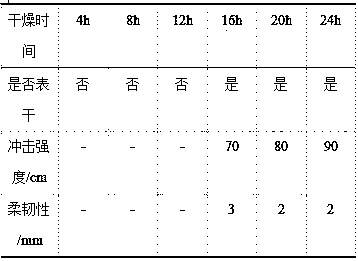

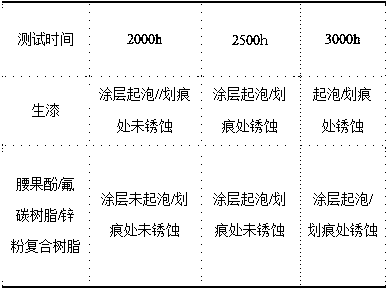

Cardanol/fluorocarbon resin/zinc powder composite marine salt mist-resistant paint and preparation method thereof

InactiveCN110041770AImprove thermo-oxidative stabilityImprove insulation performanceAnti-corrosive paintsAging resistancePreservative

The invention belongs to the technical field of paint materials, and particularly relates to cardanol / fluorocarbon resin / zinc powder composite marine salt mist-resistant paint and a preparation methodthereof. The preparation method thereof comprises the following steps: enabling cardanol to be mixed with fluorocarbon resin and zinc powder, then adding a preservative sodium benzoate, and stirringmechanically at room temperature to mix to obtain cardanol / fluorocarbon resin / zinc powder composite marine antiseptic paint. When the marine salt mist-resistant paint is used, a curing agent hexamethylene diisocyanate trimer, which accounts for 10% of total mass, needs to be added, and coating can be carried out after curing for 15min. Paint can cure to form a film within 24h after curing. The fluorocarbon resin is utilized by a coating to improve the comprehensive use performance, wherein the shock resistance of the coating is improved to 100cm, the flexibility is improved to 2mm, the salt mist resistance reaches 3,000h, the light aging resistance reaches 3,000h, and the discoloration light loss is less than or equal to level 2; and the cardanol / fluorocarbon resin / zinc powder composite marine salt mist-resistant paint can be applied in the marine ship undercoat.

Owner:MINJIANG UNIV

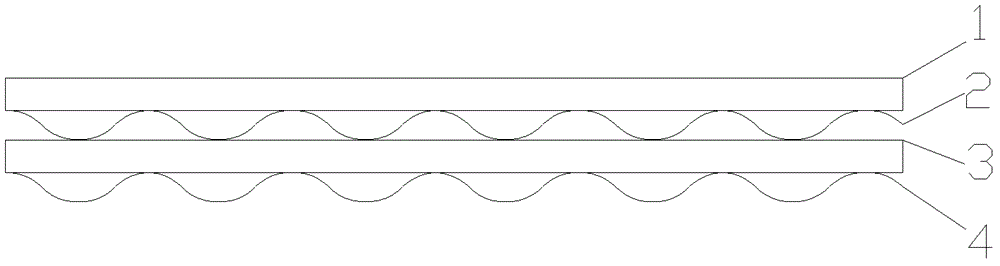

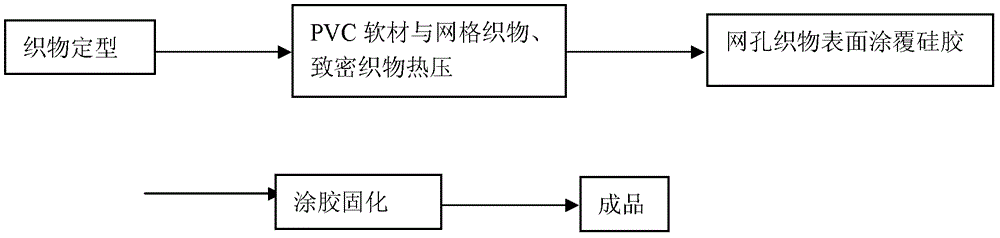

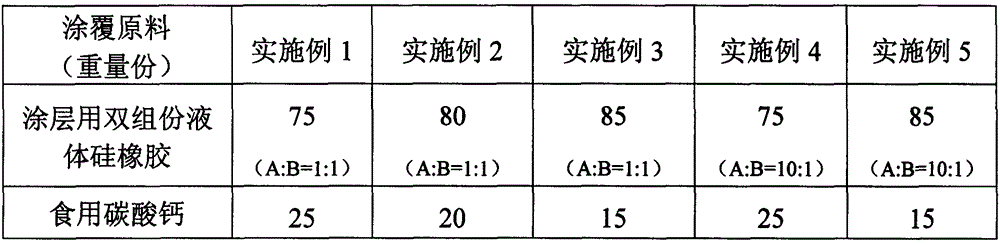

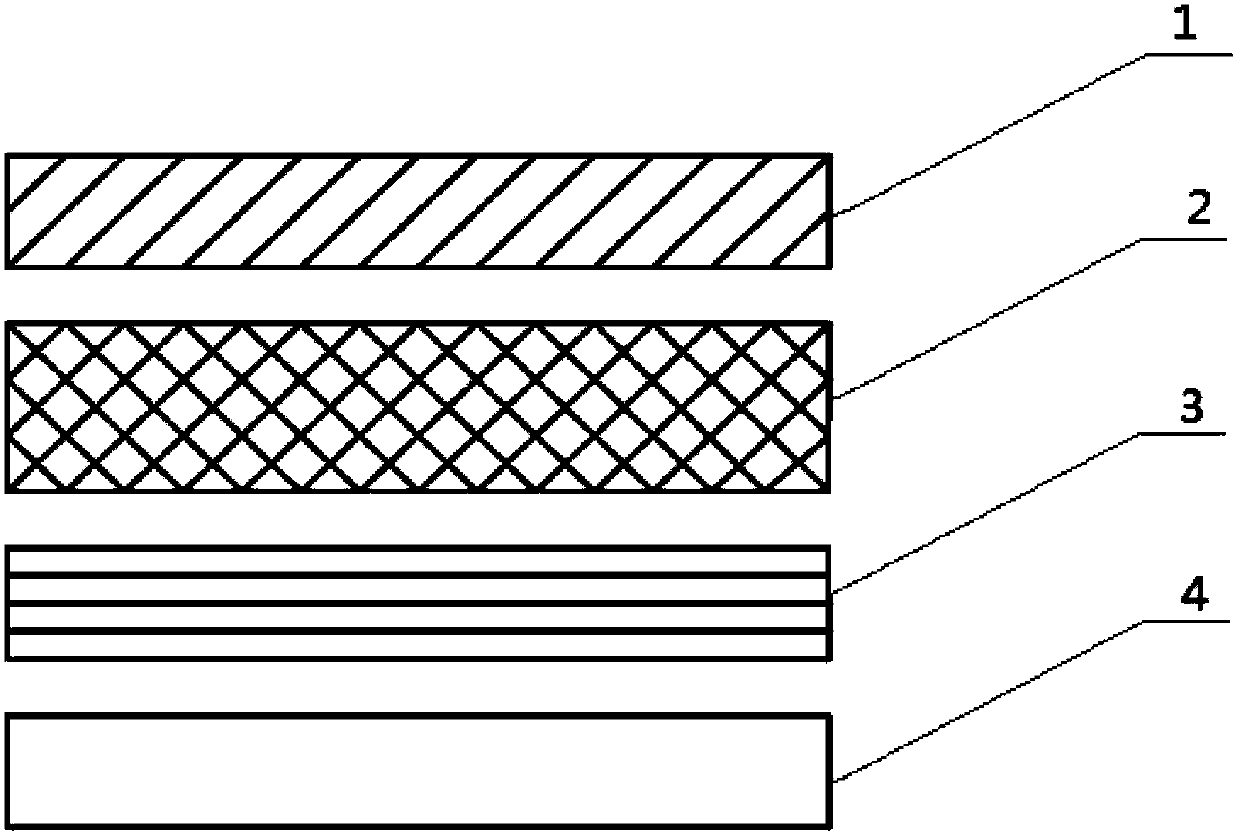

A kind of food and drug conveyor belt and preparation method thereof

ActiveCN103192560BImprove hydrolysis resistanceReduce contentConveyorsSynthetic resin layered productsCompound aFood grade

The invention relates to a food and medicine conveyor belt and a making method thereof. The conveyor belt is a four-layer structure conveyor belt formed by compounding a food grade silica gel coat, a mesh fabric interlayer, a soft PVC layer and a compact fabric substrate which are sequentially arrayed from top to bottom. The food and medicine conveyor belt is made through a hot pressing and coating technology. The preparation method comprises the following steps: setting the mesh fabric and the compact fabric, carrying out hot pressing compounding of the set mesh fabric and compact fabric and PVC, and coating the surface by a food grade silica gel to form a finished product. Compared with conveyor belts in the prior art, the conveyor belt provided by the invention has the advantages of long service life, low cost, reaching of food and medicine contact standards, and suitableness for the food and medicine fields.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

A composite high-strength washing powder packaging bag

ActiveCN111469511BIncrease the degree of cross-linkingHigh strengthLamination ancillary operationsSynthetic resin layered productsPlastic bagPetroleum ether

The invention discloses a composite high-strength washing powder packaging bag. The specific preparation process of the packaging bag is as follows: add petroleum ether, Tween-80 and dodecylbenzenesulfonic acid to the prepared polymer, stir and mix for 20 ‑30min, then the mixture is evenly coated on the surface of the high-strength hydrophobic film, and immediately after the spraying is completed, a layer of high-strength hydrophobic film is compounded on the surface of the coating layer to obtain a three-layer sandwich plastic film. Curing for 2-3 hours to obtain a high-strength drop-resistant plastic film, and then prepare the high-strength drop-resistant plastic film into a packaging bag. The intermediate buffer layer of the packaging bag of the present invention contains a large amount of siloxane bonds, thereby improving the thermal stability of the plastic bag, so that when the packaging bag is aged at high temperature, its breaking strength does not change much, and further improves the thermal stability of the packaging bag. The thermal aging resistance and light aging resistance make the prepared packaging bag resistant to high temperature aging.

Owner:GUANGDONG BAOJIALI COLOR PRINTING IND CO LTD

Skin cream with black eye removing effect and preparation method thereof

InactiveCN111821240AImprove photoagingTo promote metabolismCosmetic preparationsToilet preparationsPhenolic content in teaOphthalmology

The invention discloses skin cream with an effect of removing black eye and a preparation method of the skin cream, and relates to the technical field of cosmetics. The preparation method comprises the following steps: firstly reacting layered nano calcium carbonate with adipic acid, then reacting with a tea polyphenol nano-liposome dispersion liquid and a chitosan solution, filtering and drying to prepare modified calcium carbonate, and finally mixing deionized water with caprylic / capric triglyceride, adding a natural emulsifier, C10-18 triglyceride fatty acid, sucrose laurate, ceramide, squalane, cholesterol, a traditional Chinese medicine extract and modified calcium carbonate to prepare the skin cream with the effect of removing black eye. The prepared skin cream with the dark eye removing effect can cover black eye after being used, the effective components continuously act on the dark eye positions while the skin is protected, and the product has the excellent dark eye removing effect.

Owner:蒋丽菲

A kind of modified carbon fiber reinforced asphalt pavement anti-skid material and preparation method thereof

The present invention provides a modified carbon fiber reinforced asphalt pavement anti-skid material and a preparation method thereof. The modified carbon fiber reinforced asphalt pavement anti-skid material includes the following raw materials: surface modified carbon fiber, SBS modified asphalt epoxy binder, Ultrafine organic montmorillonite, non-slip-resistant aggregate and anti-slip aggregate; wherein, the SBS modified asphalt epoxy binder includes SBS modified asphalt, epoxy resin and curing agent. The modified carbon fiber reinforced asphalt pavement anti-skid material has good wear resistance and anti-skid performance, and can effectively solve technical problems such as fast decay of asphalt pavement anti-skid performance and poor durability of the surface layer. The preparation method is simple, and the surface modification is adopted. Carbon fiber can promote the bonding of functional groups between the carbon fiber surface and asphalt and epoxy resin components, strengthen the interface performance between carbon fiber and asphalt-based materials, and improve the wear resistance and durability of the anti-skid surface layer of asphalt pavement.

Owner:CHANGAN UNIV

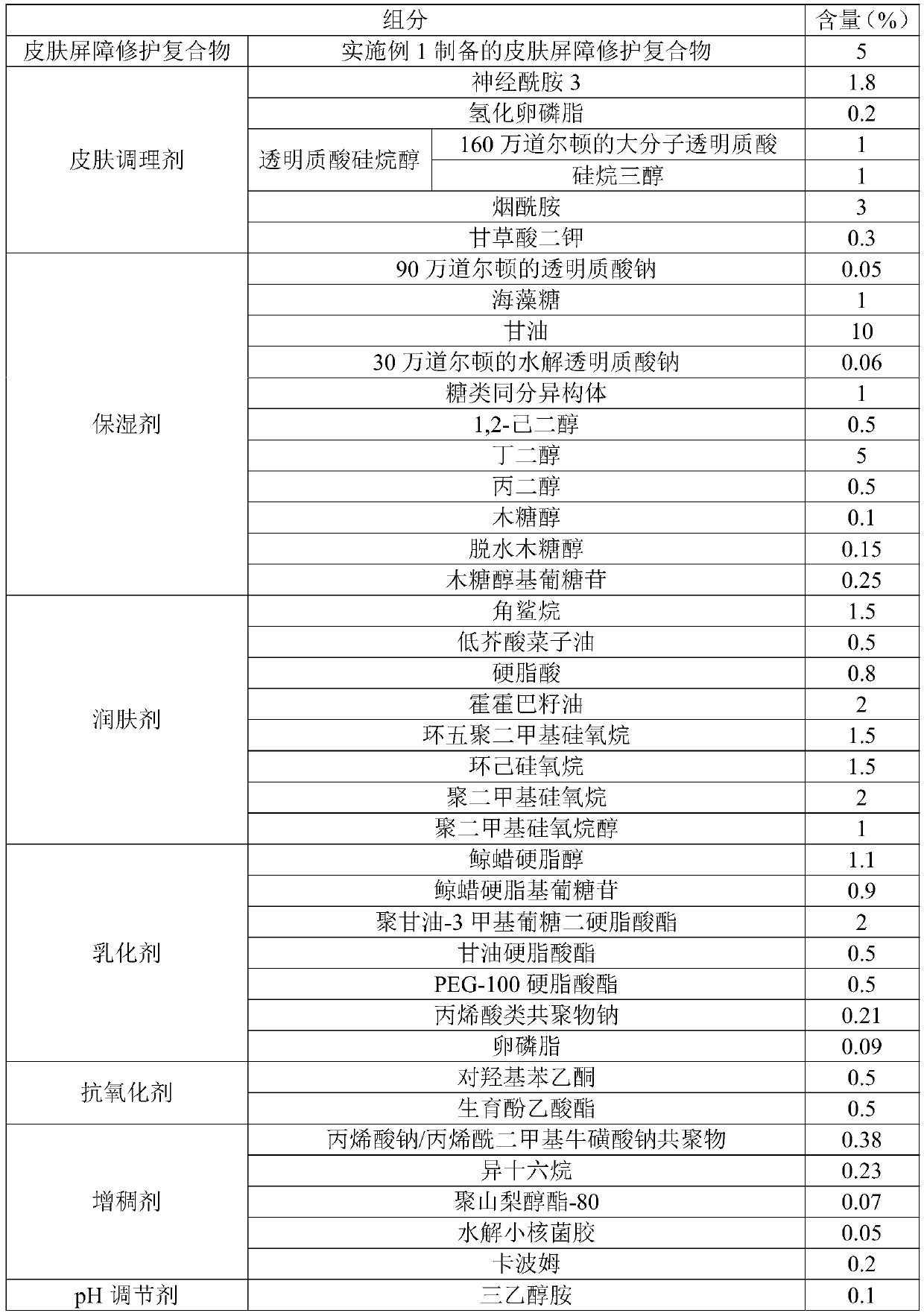

A skin barrier repair compound, face cream and preparation method thereof

ActiveCN111407719BImprove water retentionImprove enduranceCosmetic preparationsToilet preparationsGlycyrrhiza inflata root extractPhotoaging

The invention provides a skin barrier repairing complex, facial cream and a preparation method therefor. The skin barrier repairing complex comprises a composition for repairing skin barrier, hydroxylasiaticoside, deacidified carnosine, a glycyrrhiza inflata root extract, a radix scutellariae extract and a hamamelis extract, wherein the composition for repairing skin barrier comprises sea fennelcallus culture filtrate, Ectoin and a hydrolyzed red alga extract. The skin barrier repairing complex can achieve triple effects of simultaneously repairing cutin barrier, repairing immunologic barrier and strengthening microbiologic barrier; and the facial cream prepared from the skin barrier repairing complex is obvious in repairing effect and can be used for effectively improving hydrature of skin, increasing the content of hyaluronic acid in the skin, improving photoaging, helping cell saccharification reversing and reducing fine grain area.

Owner:广州一一生物技术有限公司

Mixing liquid of Chinese herbal medicine mask powder as well as preparation method and application of mixing liquid

InactiveCN110585084AMaintain moisture contentEasy to keepCosmetic preparationsToilet preparationsLonicera chrysanthaButanediol

The invention provides a mixing liquid of Chinese herbal medicine mask powder. The mixing liquid comprises following components in parts by weight: 40-70 parts of deionized water, 10-20 parts of butanediol, 3-5 parts of polyaminopropyl biguanide stearate, 5-10 parts of chrysanthemum extract, 5-10 parts of lonicera chrysantha flower extract, 2-6 parts of 1,2-hexanediol, 5-9 parts of PEG-40 hydrogenated castor oil and 3-7 parts of borneol. The invention further provides a preparation method of the mixing liquid of the Chinese herbal medicine mask powder. The mixing liquid of the Chinese herbal medicine mask powder can brighten and refresh the skin, can moisten and tighten the skin, has a synergistic inhibition effect on pigment, has a remarkable spot removing effect and high safety and is free of toxic and side effects; and the mixing liquid has an obvious anti-yellowing effect, can tighten pores to enable the skin to be finer and smoother, removes fine wrinkles of face, improves photoaging and brightens the complexion, and therefore, the skin is fresh and bright, the corium layer is directly replenished with rich moisture and the skin is moist and elastic.

Owner:张玉金

Sunscreen cosmetic composition comprising composite solid powder and polymer film-forming agent

ActiveCN106619194BSmooth and soft to the touchCover tightlyCosmetic preparationsToilet preparationsSkin surfaceSkin texture

The invention belongs to the field of cosmetics and relates to composite solid powder and sunscreen composition containing the same and a polymer film-forming agent. The composite solid powder contains a physical sunscreen, a skin texture improver and a surface treating agent. The smoothness of the cosmetics can be improved remarkably by adding the skin texture improver, and light skin texture is realized. The sunscreen composition contains the composite solid powder and the polymer film-forming agent such as a C30-38 olefin / isopropyl maleate / MA copolymer and the like, cosmetics containing the composition can be applied to skin surface naturally and smoothly to endow skin with smooth and soft texture and durable makeup holding capacity, and more importantly, the SPF (sun protection factor) of the sunscreen can be increased remarkably.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

Treatment method for improving water resistance and light aging resistance of wooden products

InactiveCN107627418AImprove water resistanceImprove photoagingWood treatment detailsPressure impregnationChemical reactionAging resistance

The invention relates to the technical field of wooden product processing and manufacturing, and discloses a treatment method for improving the water resistance and the light aging resistance of wooden products. After wood is treated with a prepared metallic nickel organic solution, metallic nickel can permeate into wood cells, and therefore the mechanical property of the wooden products is improved; a hydrophobic agent and hydroxide radicals on the surface of nano-titanium dioxide sol generate a chemical reaction, alkane long chains are successfully grafted on the surface of the wood, and therefore the wood achieves the good hydrophobic property; for second-stage convex-concave structures on the surface of the wood, the convex-concave structures are modified with hydrophobic substances, and therefore the hydrophilcity of the wood surface is changed into hydrophobicity; meanwhile, the light aging resistance of the wood is improved through the good ultraviolet absorption capability of the inorganic nano-material, and then the functional wooden products with the hydrophobicity and the ultraviolet protective property are obtained.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

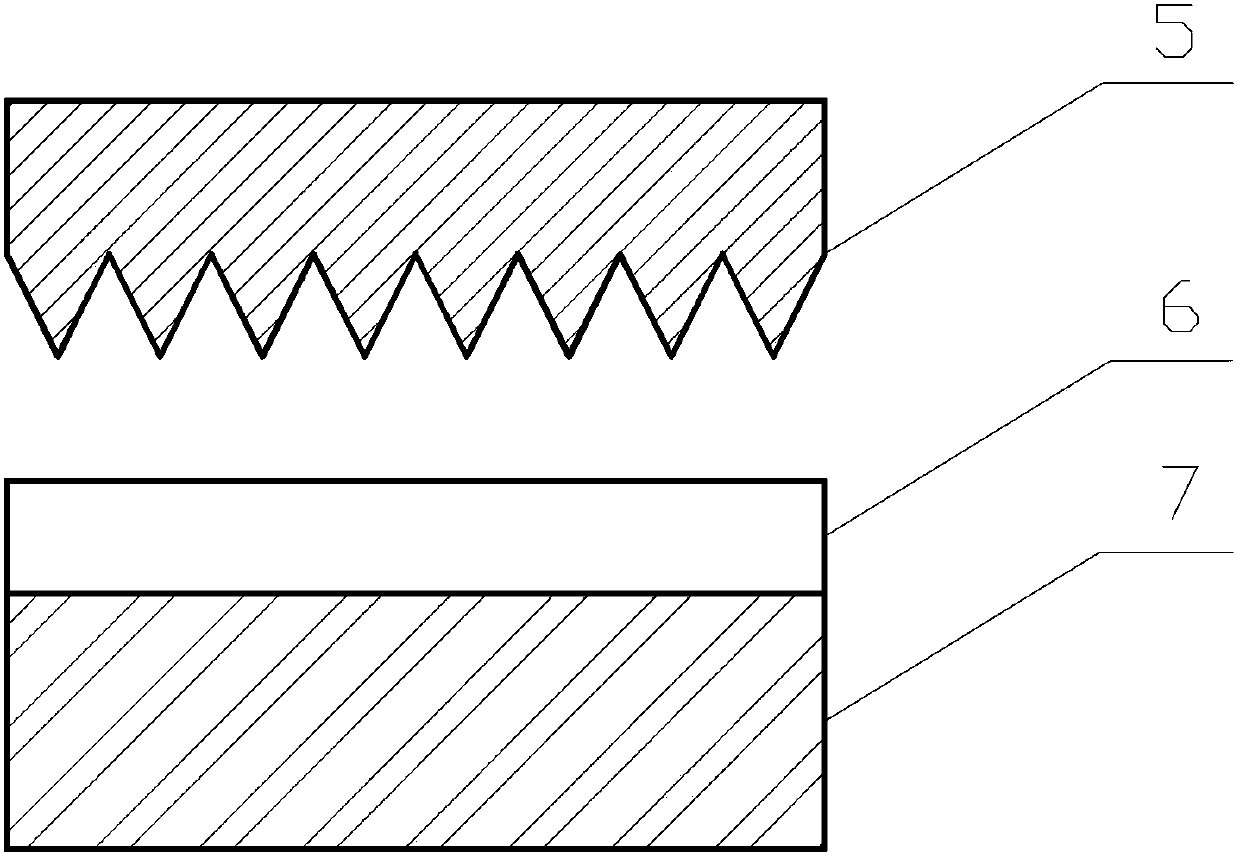

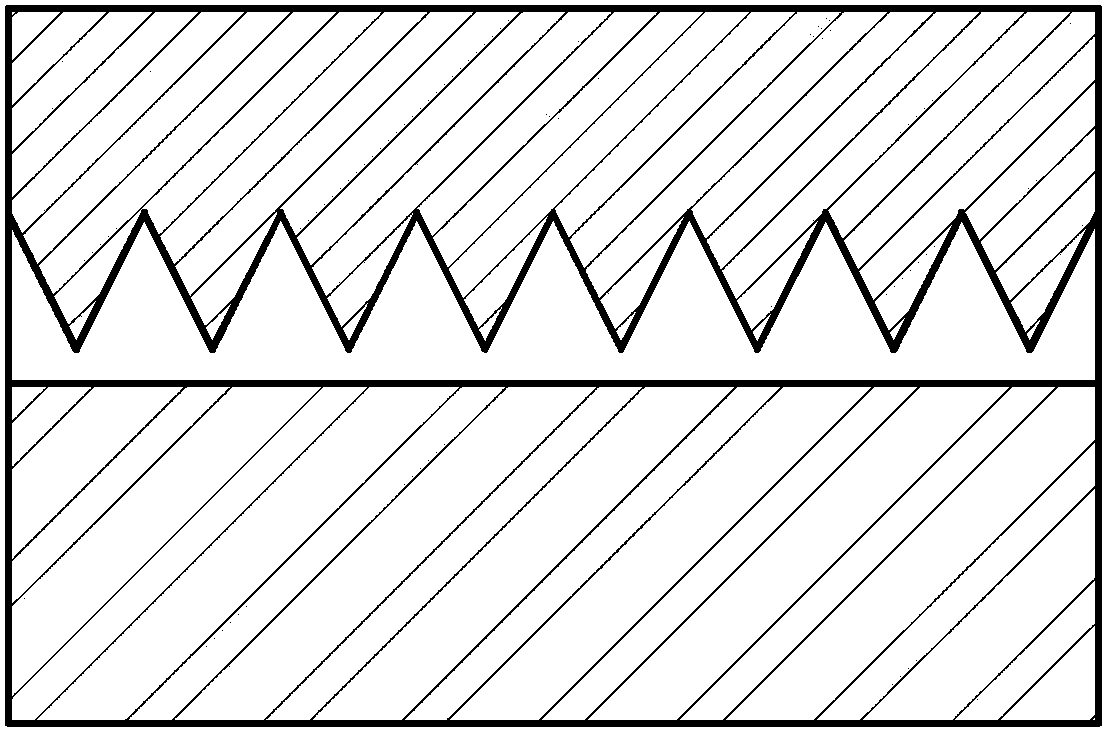

Hot-pressing preparation method for aluminum-coated TPU (thermoplastic polyurethane) film resistance reduction microgrooves for airship skin

InactiveCN102658693BHigh resolutionImprove bindingLamination ancillary operationsLaminationHigh resistanceProcess equipment

The invention relates to preparation methods for airship skin materials, in particular to a hot-pressing preparation method for aluminum-coated TPU (thermoplastic polyurethane) film resistance reduction microgrooves for an airship skin. The hot-pressing preparation method solves the problems of poor weather resistance, high resistance and poor heat insulation of skins. The preparation method includes: firstly, preparing an aluminum mould plate; secondly, cleaning the mould plate and coating release agent; thirdly, evaporating an aluminum film on the surface of a TPU film by the vacuum evaporation technique; and fourthly, pressing for 20-25 minutes under the pressure of 65-75N and at the temperature of 140-145 DEG C to obtain an aluminum-coated TPU film with resistance reduction microgrooves. By the preparation method, microgrooves which are high in resolution and aspect ratio are obtained, the aluminum layer on the surface of the film can reflect solar radiation to improve weather resistance, process equipment is simple, and cost is low. Further, the hot-pressing preparation method is used for preparation of resistance-reducing weather-resistant skin materials for near space airships.

Owner:HARBIN INST OF TECH

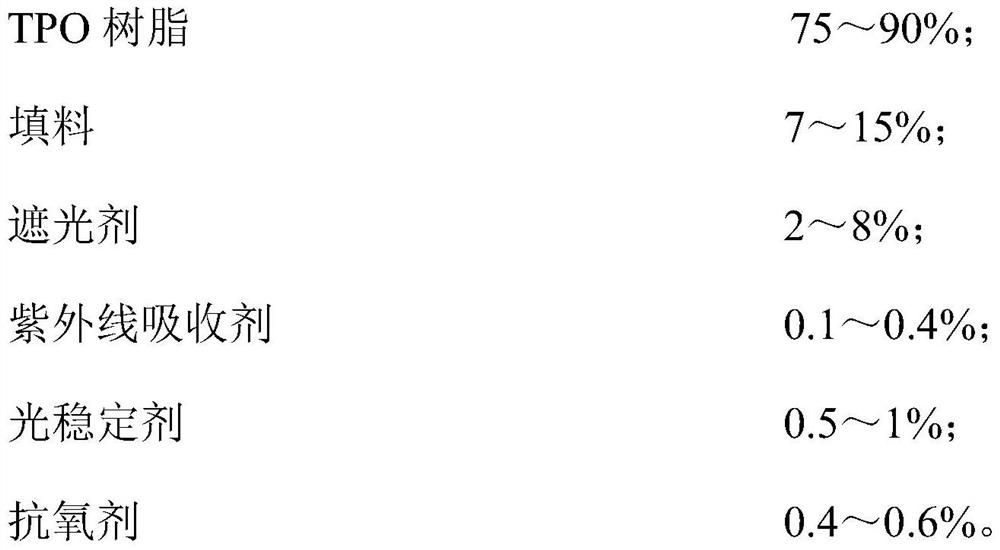

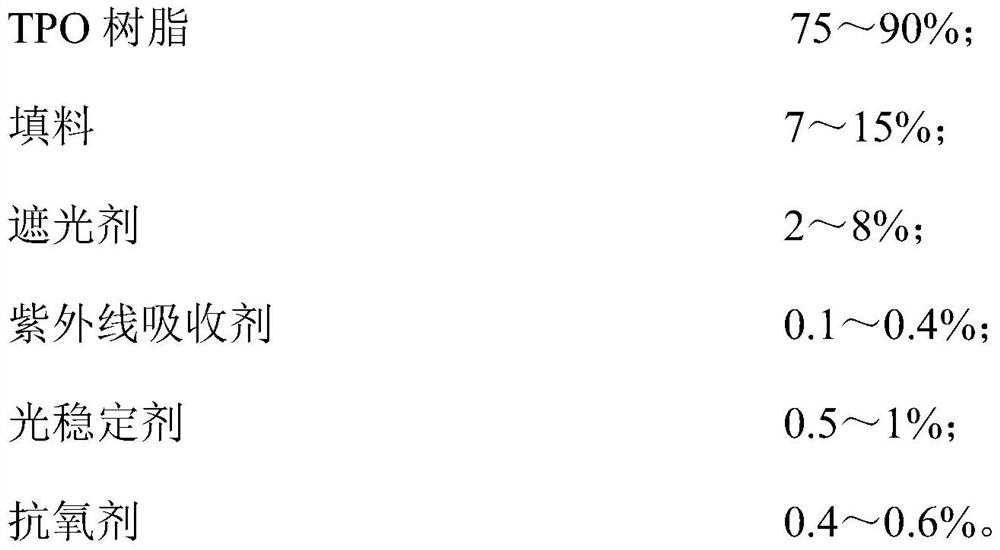

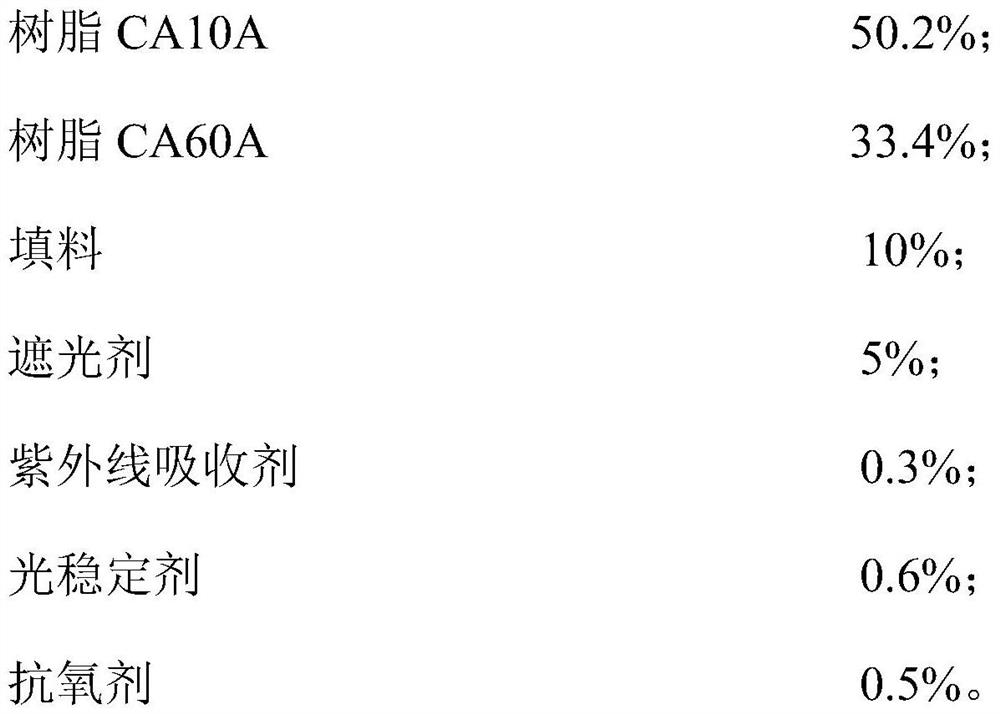

High-weather-resistance TPO waterproof coiled material as well as preparation method and application thereof

PendingCN113637266AHigh photothermal oxygen stabilityHigh photothermal oxygen stability, i.e. high weather resistanceRoof covering using flexible materialsPolymer scienceWeather resistance

The invention provides a high-weather-resistance TPO waterproof coiled material and a preparation method and application thereof. The high-weather-resistance TPO waterproof coiled material is prepared from the following raw materials in percentage by weight: 75-90% of TPO resin; 7-15% of a filler; 2-8% of an opacifying agent; 0.1-0.4% of an ultraviolet light absorber; 0.5-1% of a light stabilizer; and 0.4-0.6% of an antioxidant. According to the invention, multiple defense lines and multiple systems are constructed, so that the TPO waterproof coiled material can keep long-term and efficient weather resistance in the use process.

Owner:SHENZHEN ZHUOBAO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com