Seamless conveying belt and manufacture method thereof

A manufacturing method and conveyor belt technology, applied to conveyors, chemical instruments and methods, transportation and packaging, etc., can solve the problems of poor coating uniformity, difficult control of thickness, complicated process, etc., and achieve uniformity and stress Uniform, overall seamless and flat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

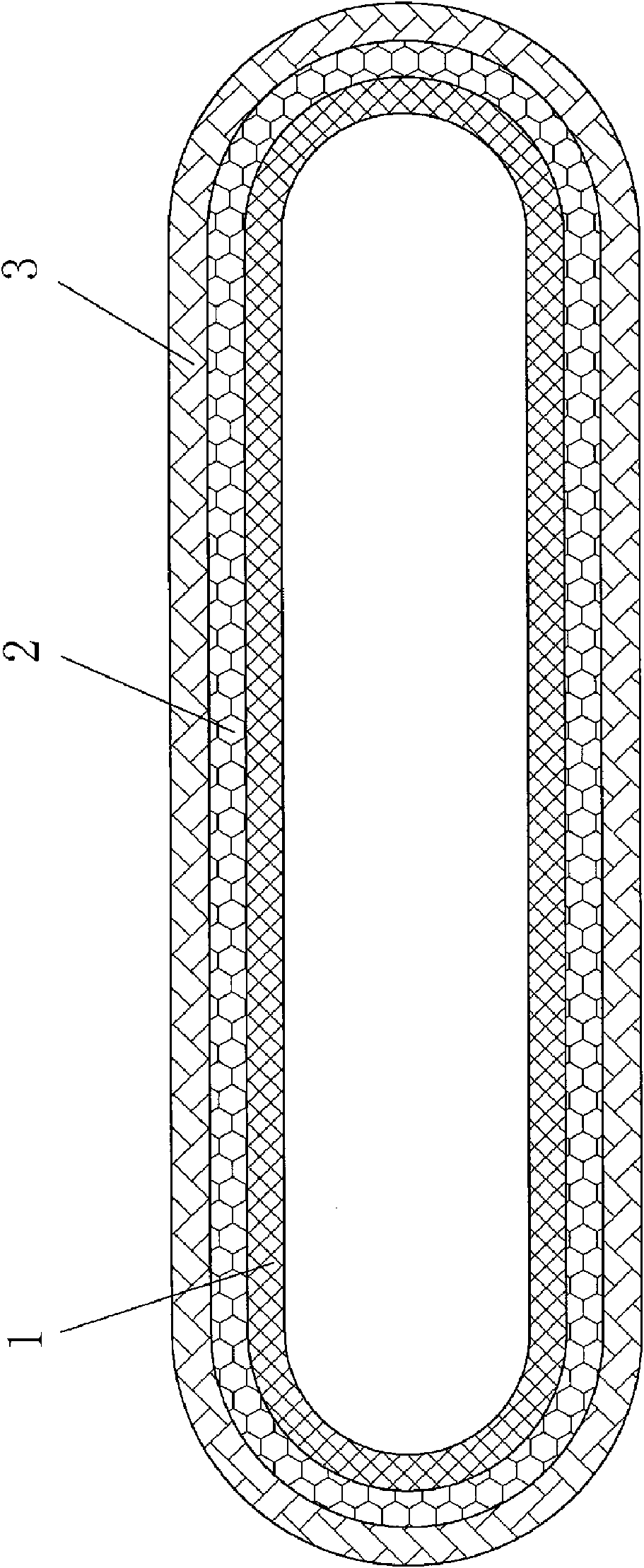

[0021] see figure 1 , a kind of seamless conveyer belt described in the present embodiment, comprises a closed base belt, and this seamless conveyer belt is formed a closed mixed layer 1 by the closed base belt without joint and rubber, and an outer rubber is designed on the outer surface of closed mixed layer 1 Layer 2, an outer silica gel layer 3 is designed on the outer surface of the outer rubber layer 2. The closed mixed layer 1 and the outer rubber layer 2 can be integrally formed by pouring and scraping liquid rubber on the closed base belt without joints. The outer silica gel layer 3 and The outer rubber layer 2 can be tightly connected together by spraying liquid silicone on the outer rubber layer 2 .

[0022] The material selected for manufacturing the jointless closed base belt may be woven fabric, and the woven fabric may be a blanket.

[0023] A method for manufacturing a seamless conveyor belt, the method for manufacturing the seamless conveyor belt comprises th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com