Hot-pressing preparation method for aluminum-coated TPU (thermoplastic polyurethane) film resistance reduction microgrooves for airship skin

A technology of micro-groove and thermal embossing, which is applied in the field of airship skin material preparation, can solve problems such as poor weather resistance, poor heat insulation, and high resistance, and achieve good coating adhesion, good shape retention, and elastic recovery The effect of small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

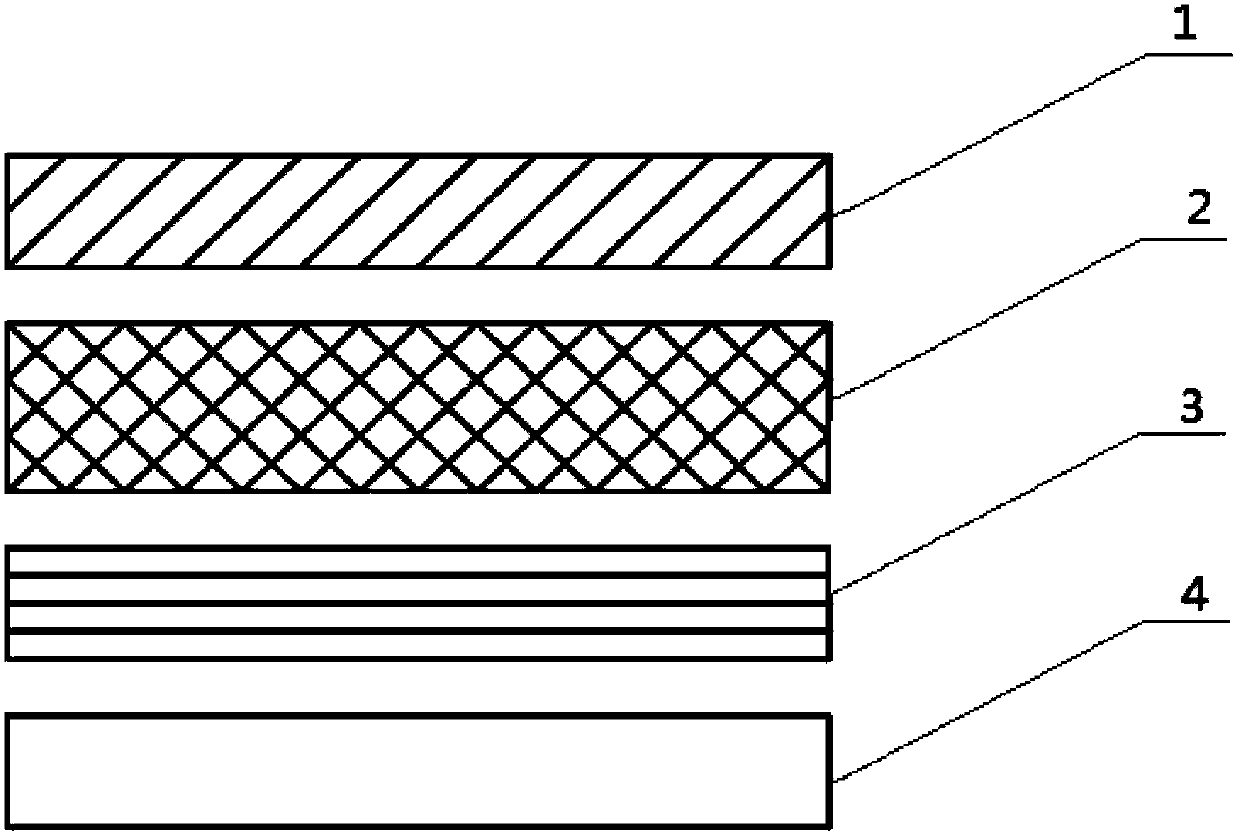

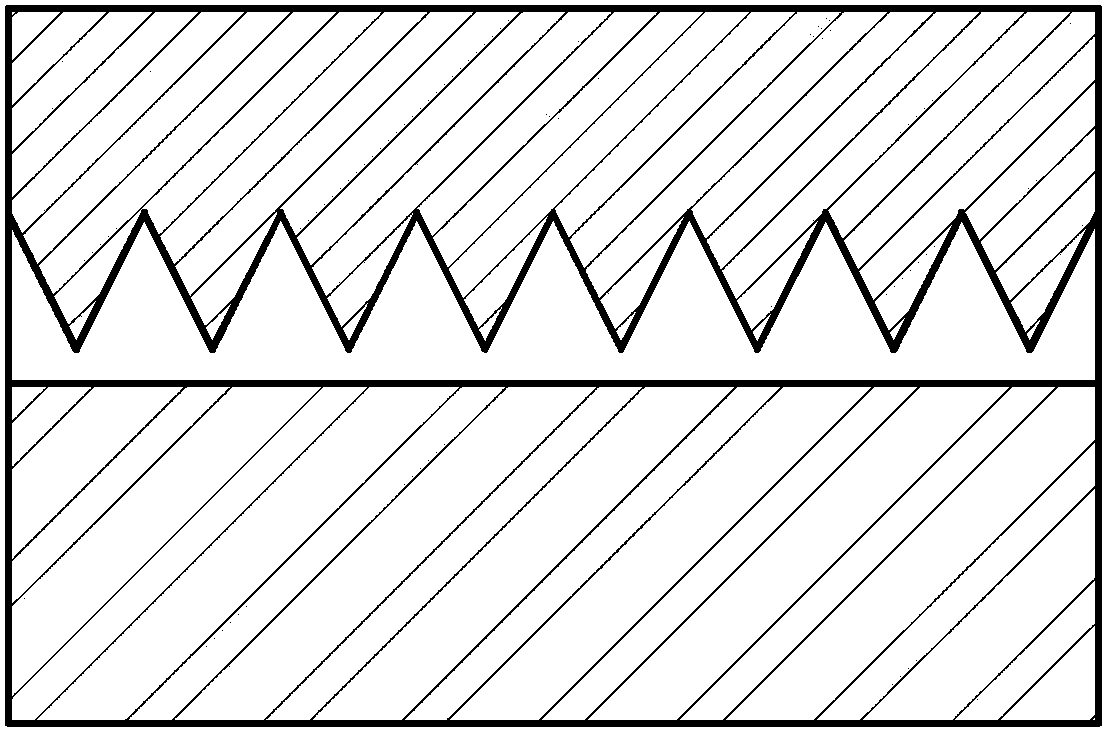

[0051] Specific Embodiment 1: In this embodiment, the hot embossing preparation method of Al-plated TPU film drag-reducing micro-grooves for airship skin is carried out according to the following steps:

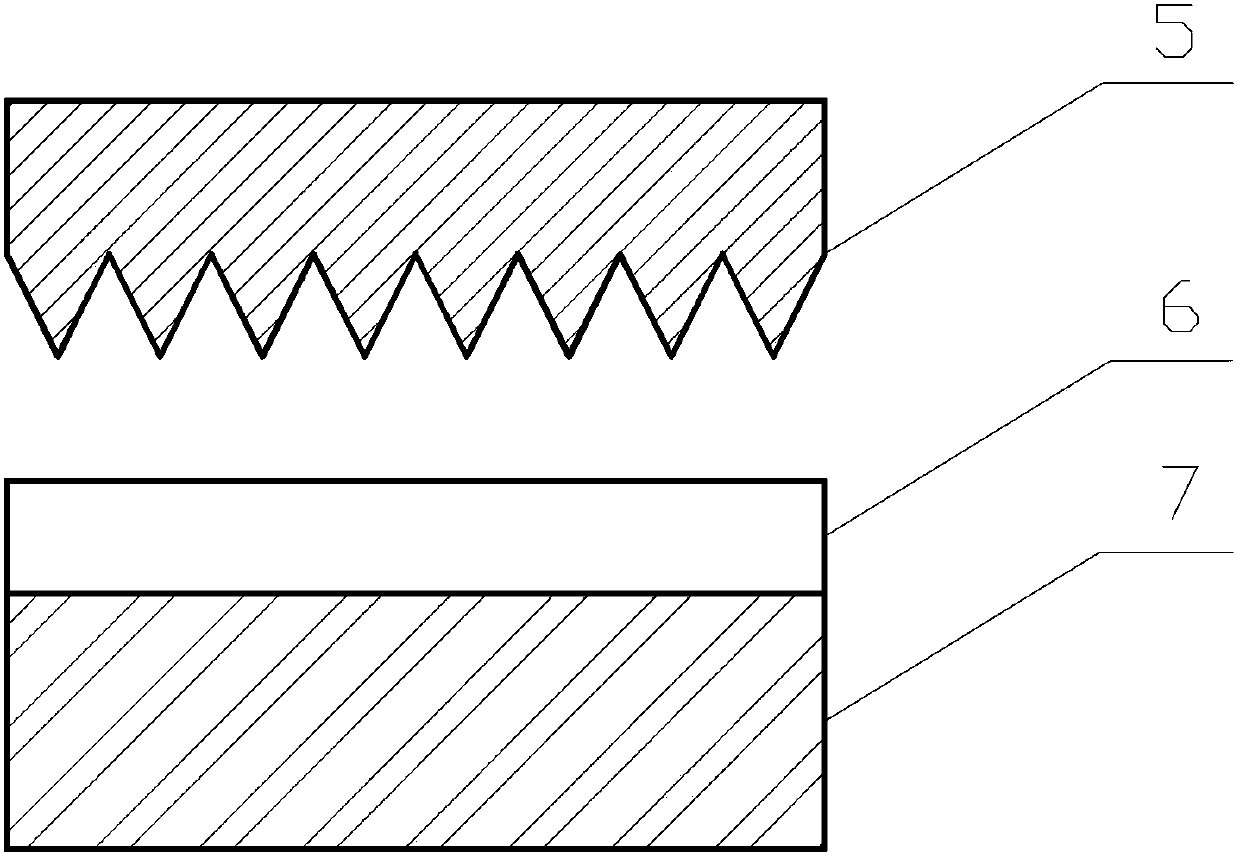

[0052] 1. Use the ultra-precision micromachining machine tool system to process the Al template with a "V" groove structure on the surface. The "V" groove forms alternate transparent grooves on the surface of the Al template. Each groove The width s is 90-110 μm, and the depth h is 90-110 μm;

[0053] 2. Ultrasonic clean the Al template prepared in step 1 with acetone for 15-20 minutes, and after drying, apply three layers of film cleaning agent, then three layers of sealing agent, and finally three layers of water-based mold release agent , the coating time interval of each layer is 15-20min;

[0054] 3. Using vacuum evaporation technology, an aluminum film with a thickness of 90-110 μm is evaporated on the surface of the TPU film to be imprinted to obtain an Al-coated TPU ...

specific Embodiment approach 2

[0058] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the length of the template made of Al is 50-52 mm, the width is 50-52 mm, and the thickness is 5-8 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0059] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, the width s of each groove is 95-105 μm, and the depth h is 95-105 μm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com