Patents

Literature

57results about How to "Small stretch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

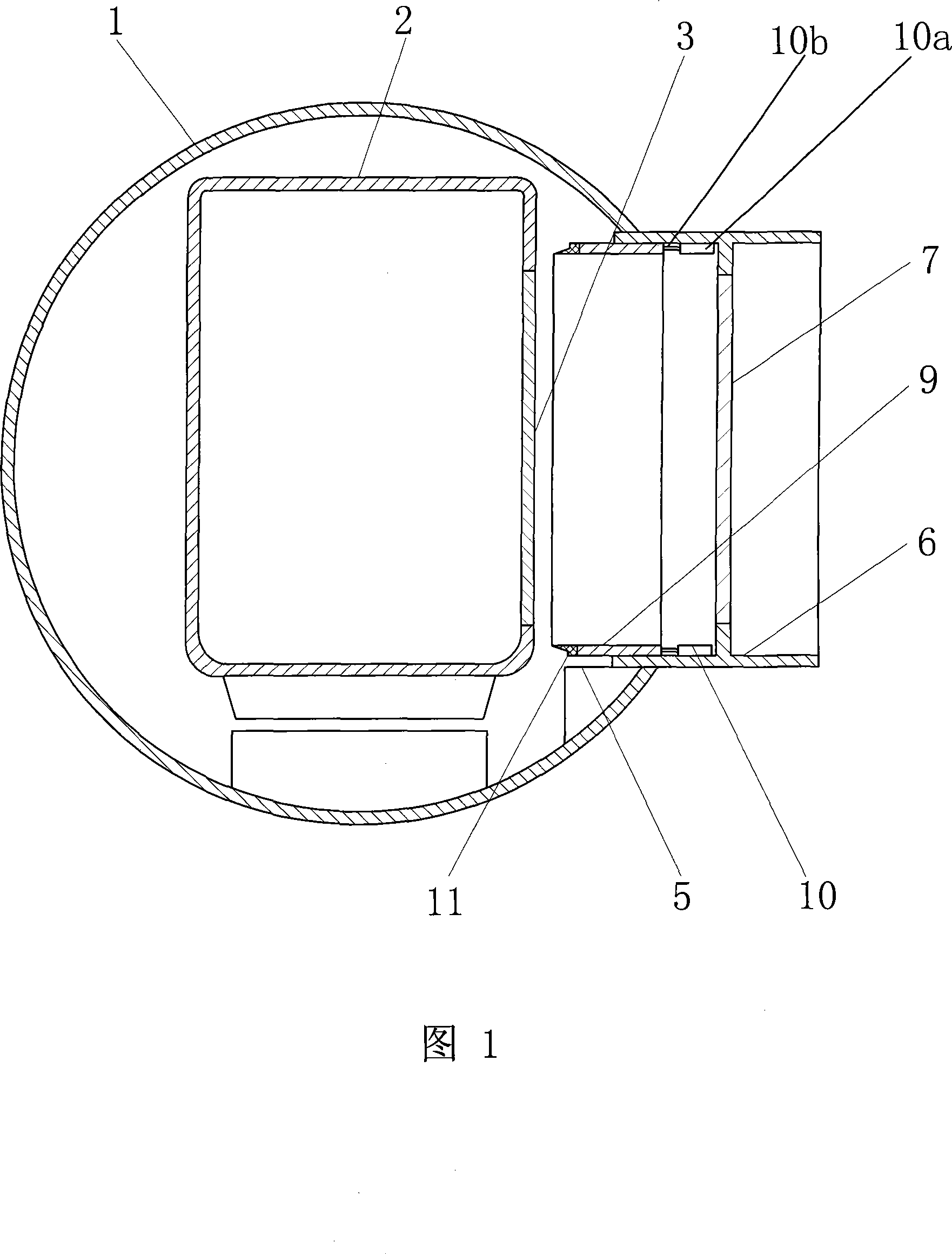

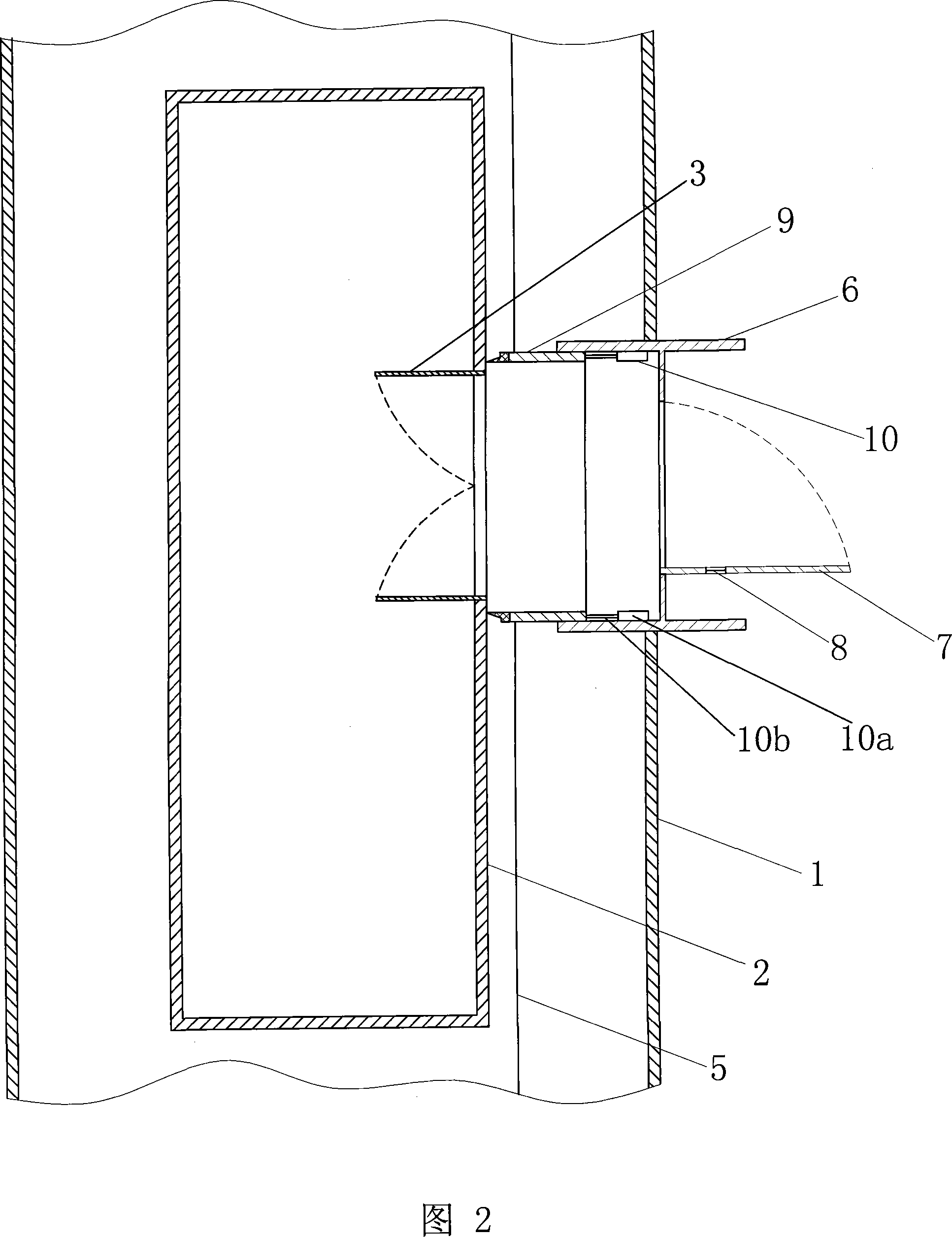

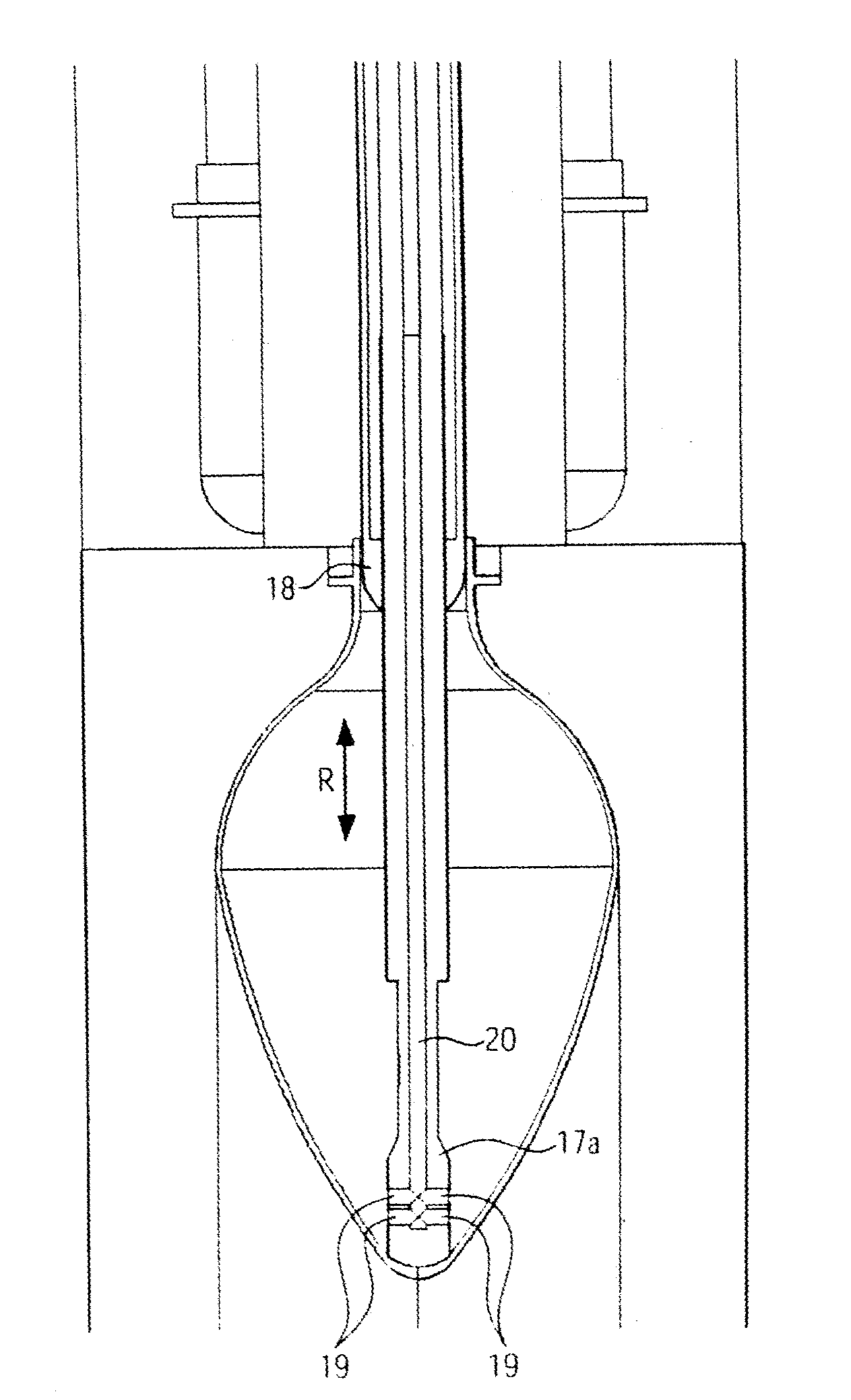

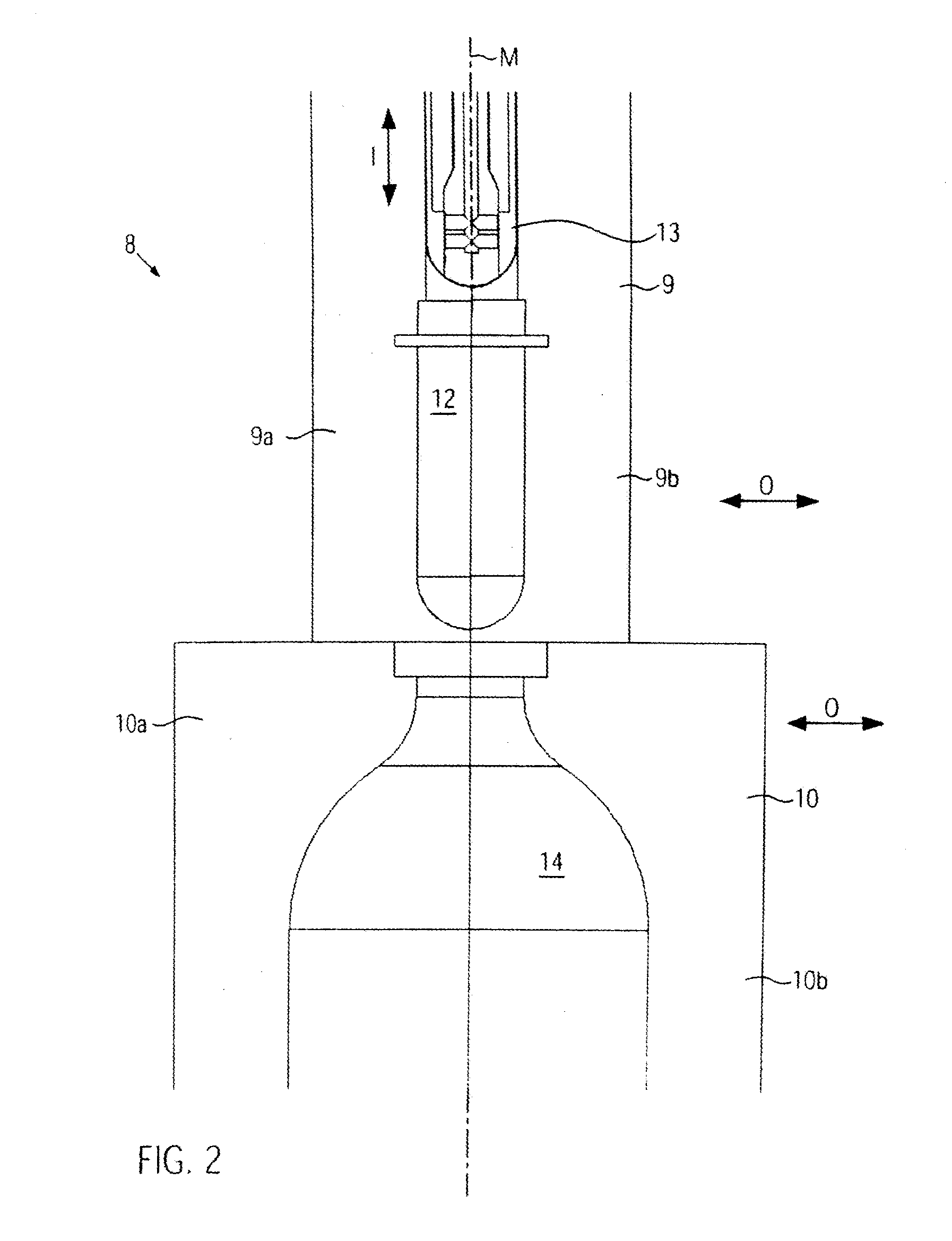

Assembling corridor for vacuum pipe traffic

InactiveCN101054087AReduce volumeImprove operational efficiencyRailway tunnelsRailway componentsCar doorEngineering

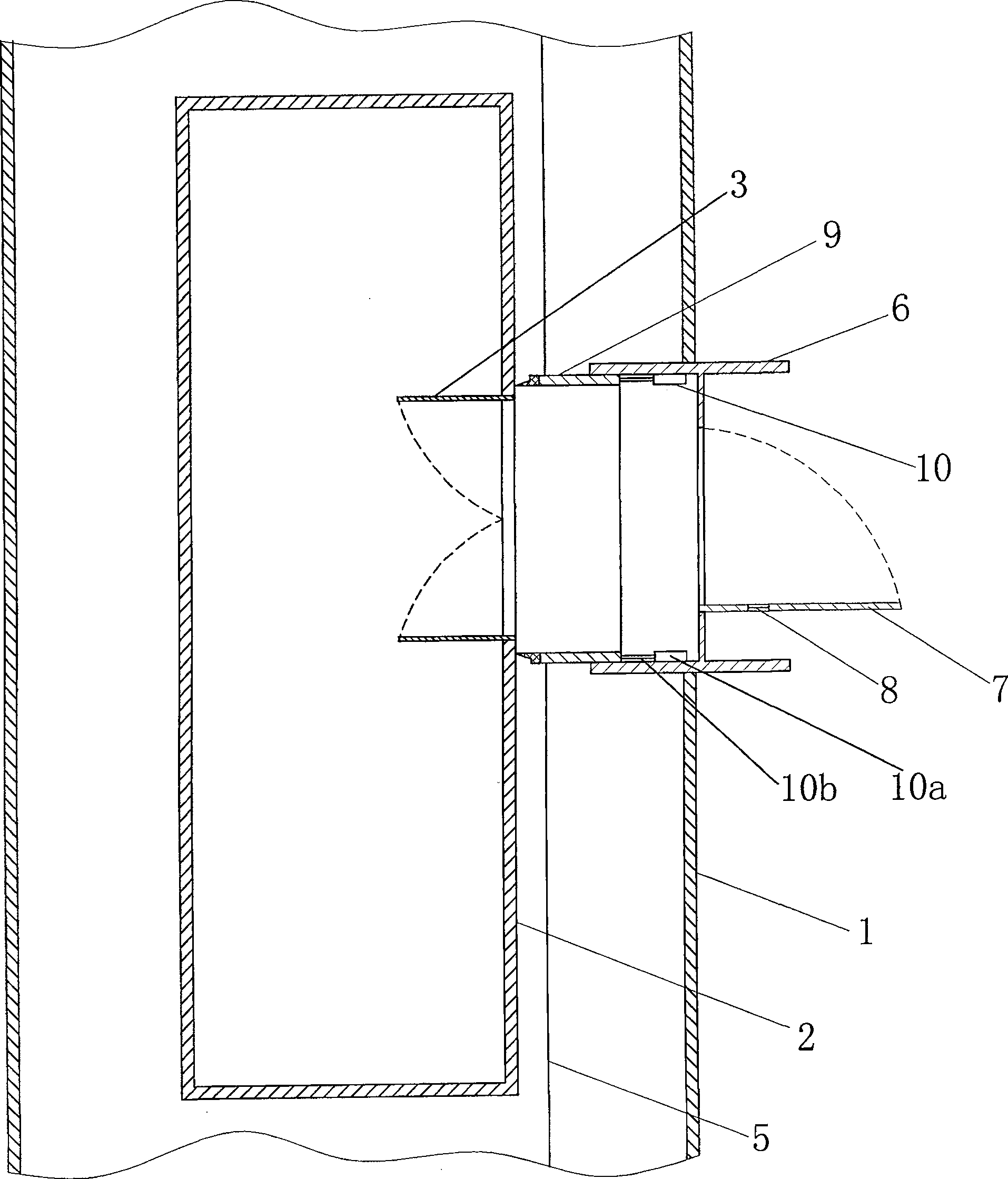

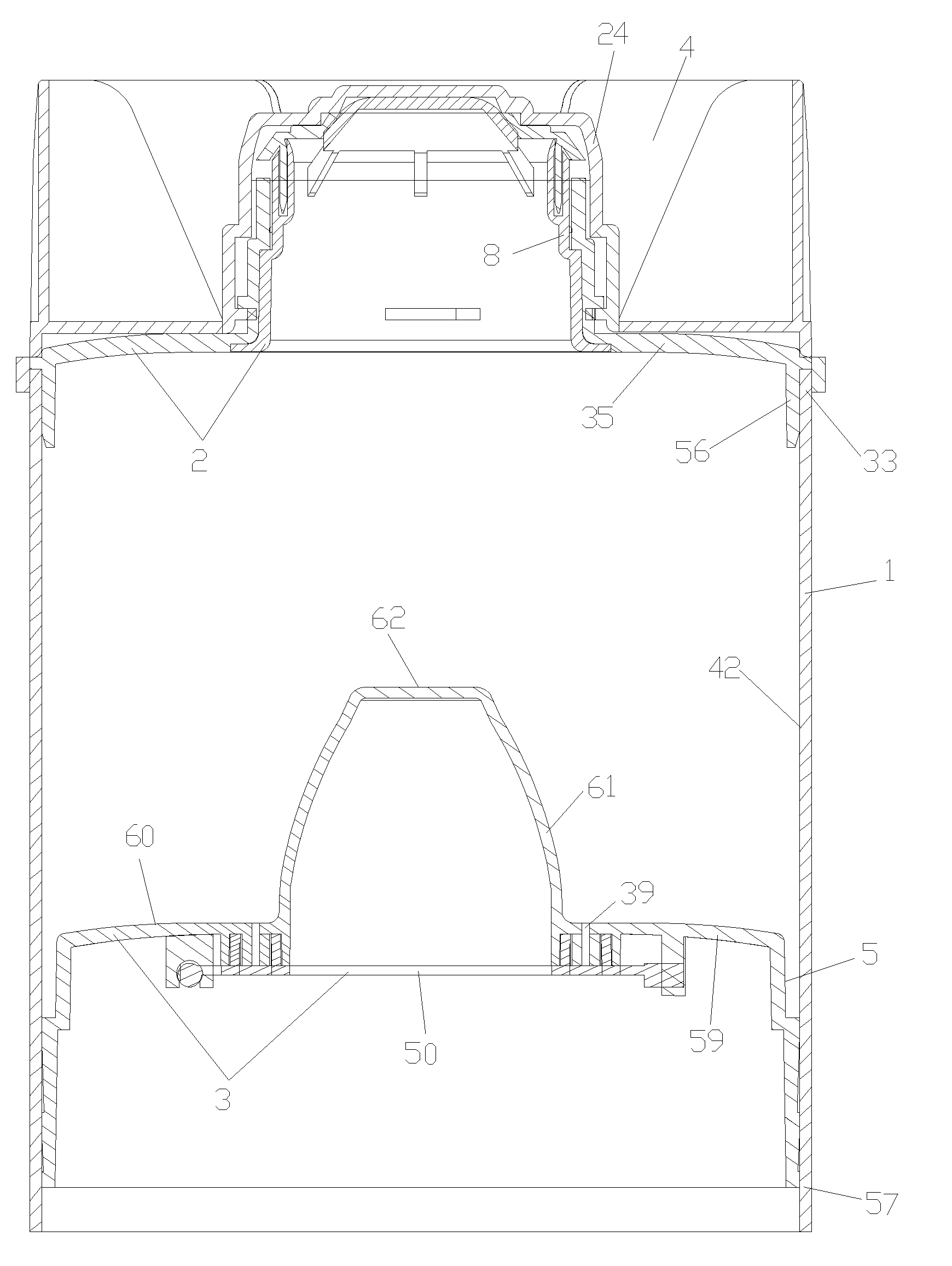

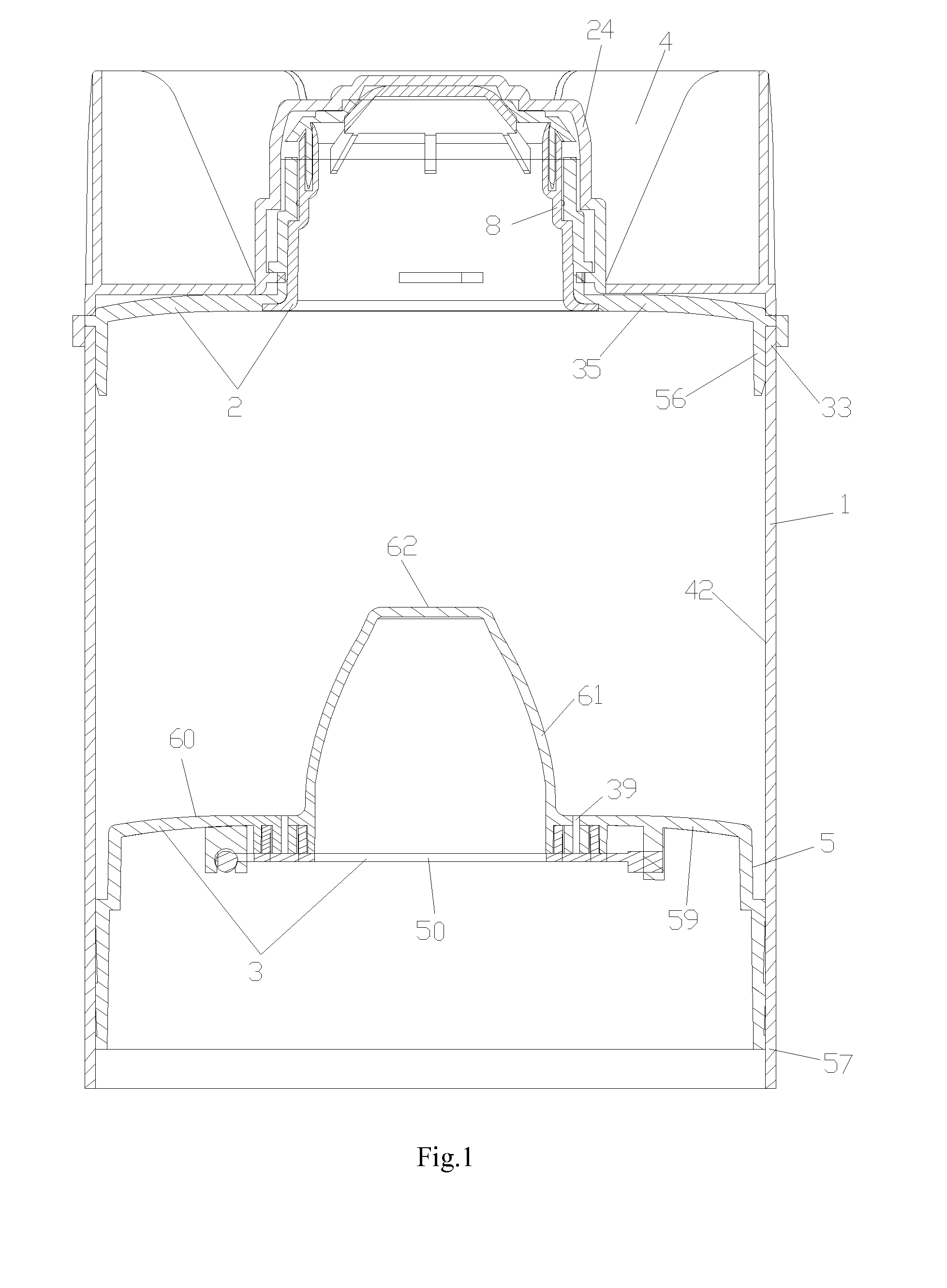

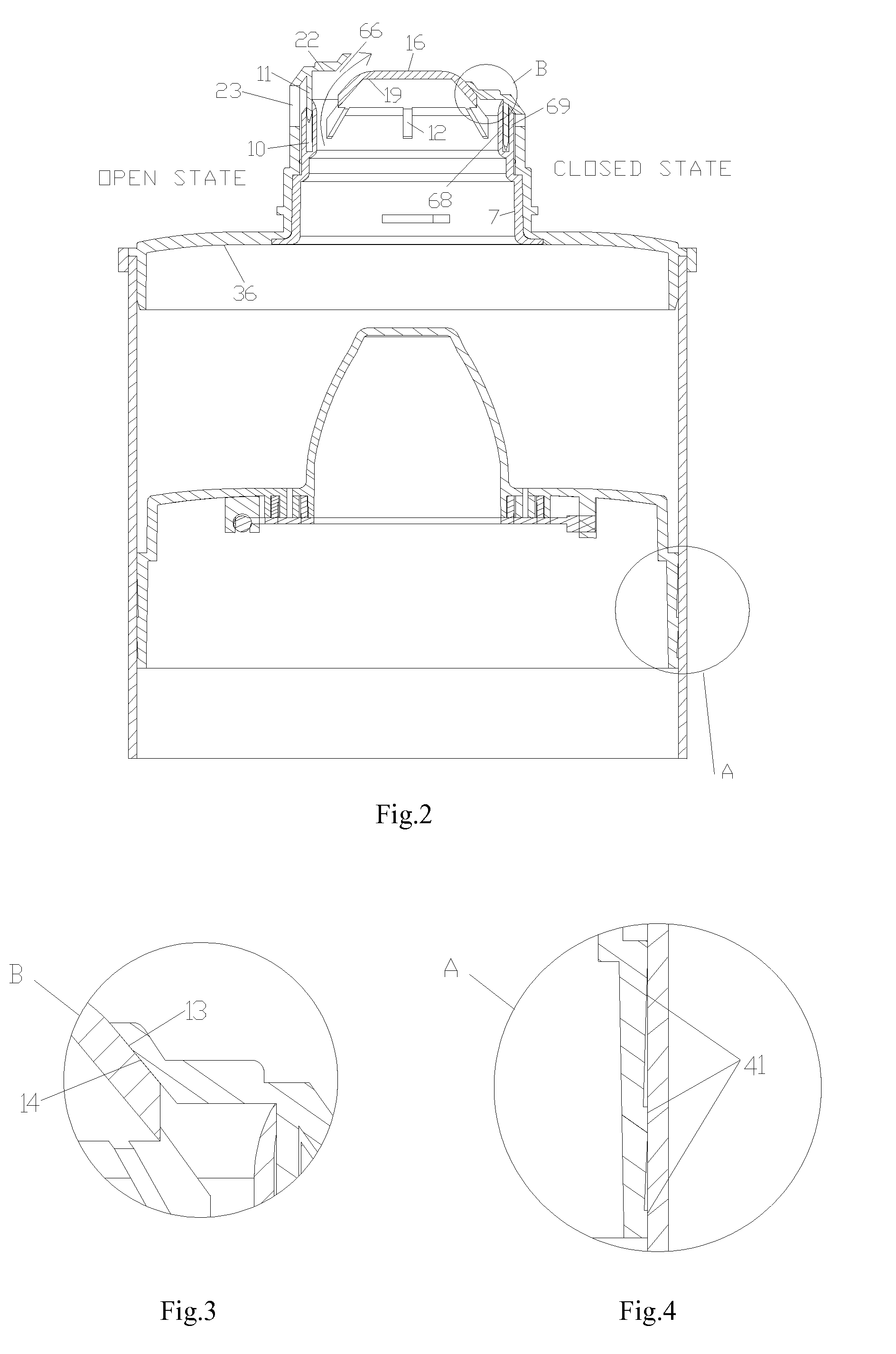

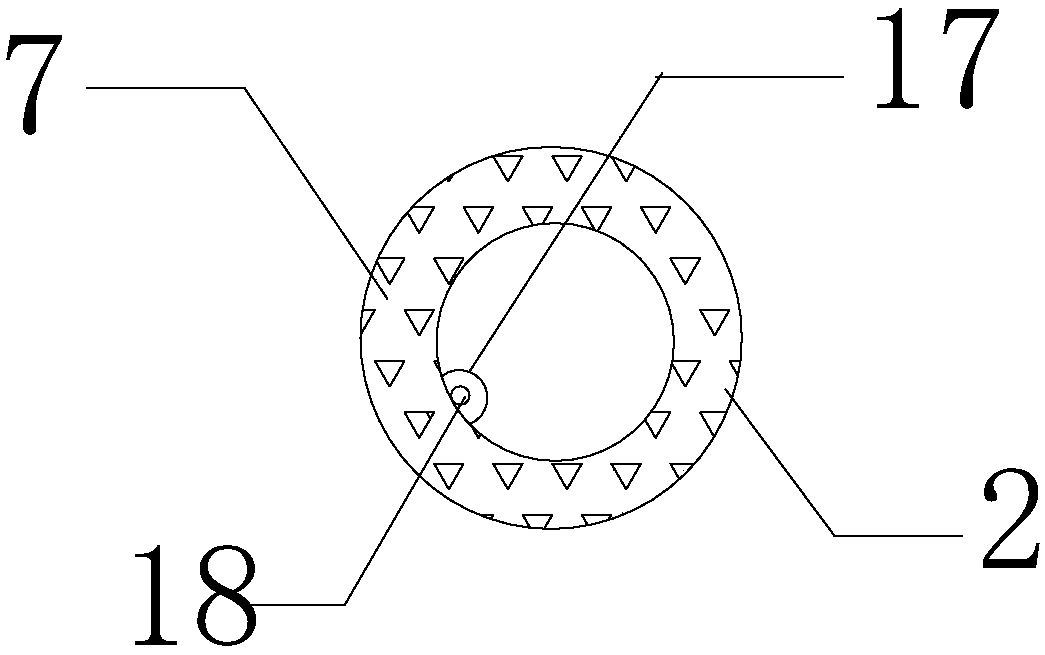

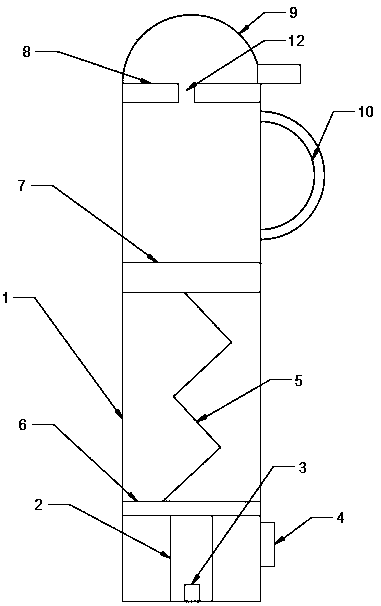

The invention discloses a plugging corridor used for the vacuum pipe traffic, which comprises: a tube-shape fixed corridor (6) is equipped in station department with one end embedded in a vacuum pipe (1), and another end is connected with the station platform, junction of the fixed corridor (6) and vacuum pipe (1) is sealed; a telescopic corridor (9) is sealing nested in anterior inner wall of the fixed corridor (6); One end of the flexible mechanism (10) is linked with the telescopic corridor (9), and another end is connected with the fixed corridor (6), and the front end of telescopic corridor (9) fits the peripheral shape around the door (3) of the train carriage (2) and is equipped with sealing strip (11); The middle rear part of the fixed corridor (6)is equipped with a sealing door (7), one pneumatic valve (8)is provided on the sealing door (7) or the fixed corridor (6) wall before the sealing door (7). Within a short period of time, it can accomplish getting on or off of passengers in vacuum pipe, and improves the running efficiency of train with little power consumption and simple structure.

Owner:SOUTHWEST JIAOTONG UNIV

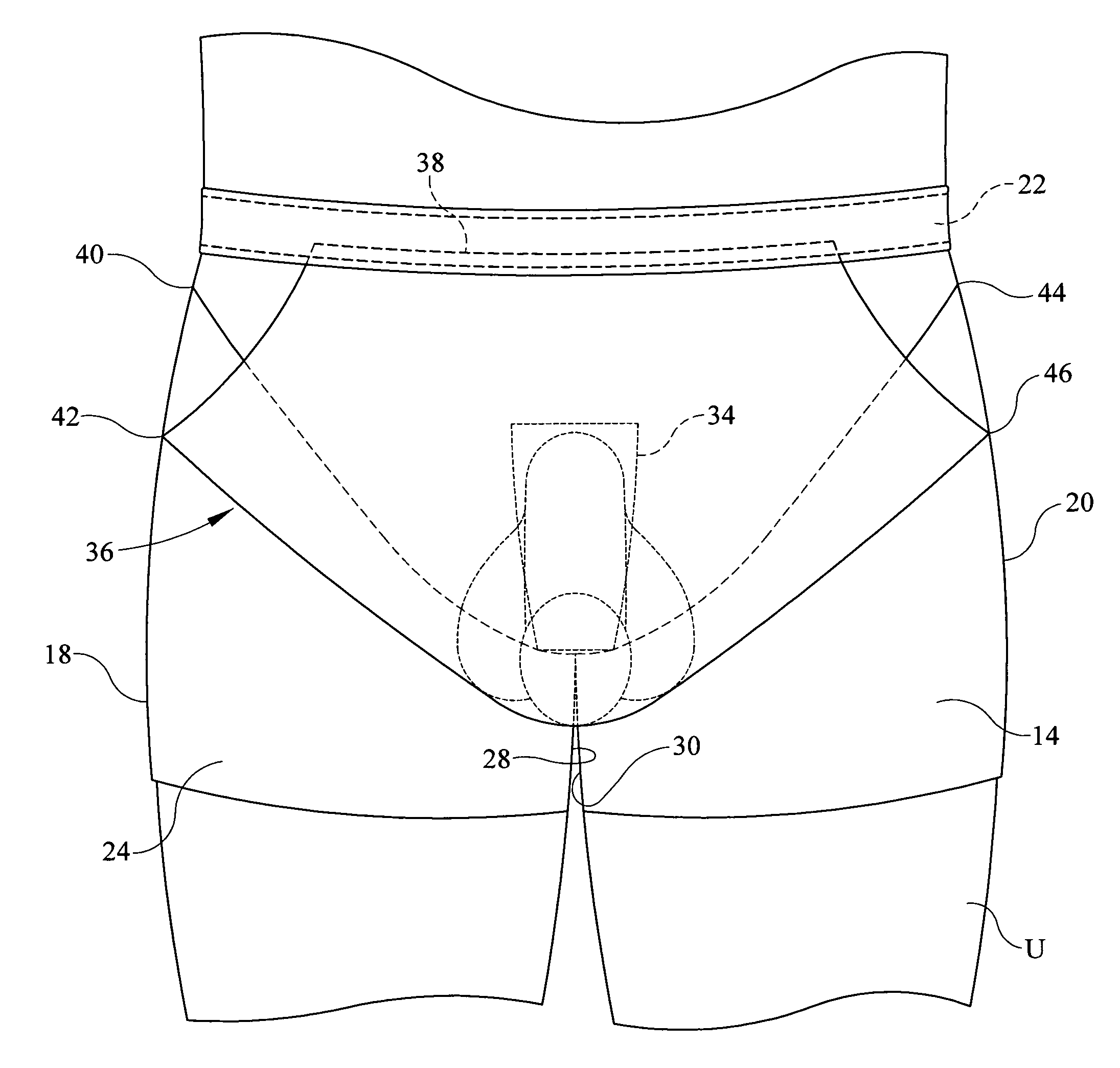

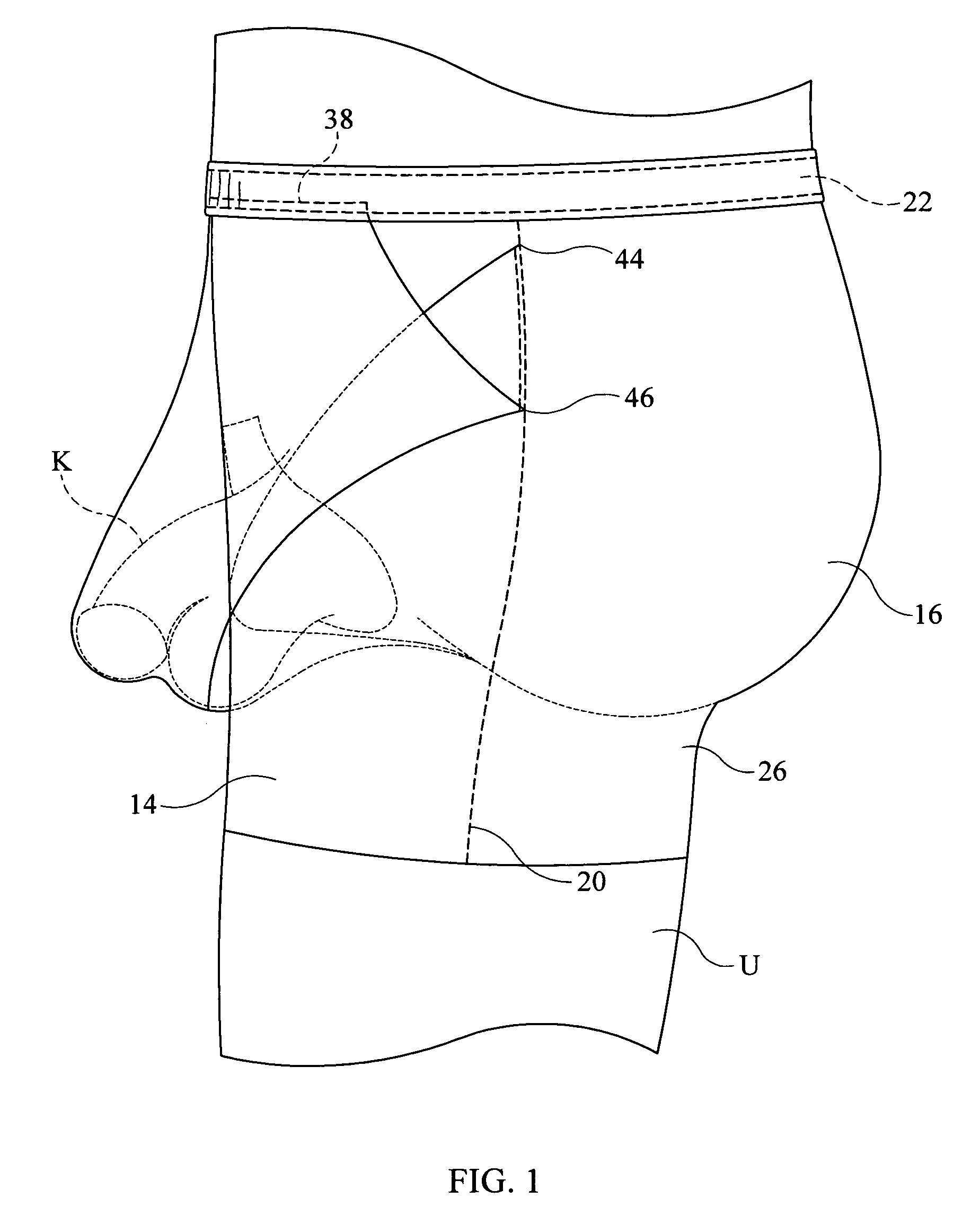

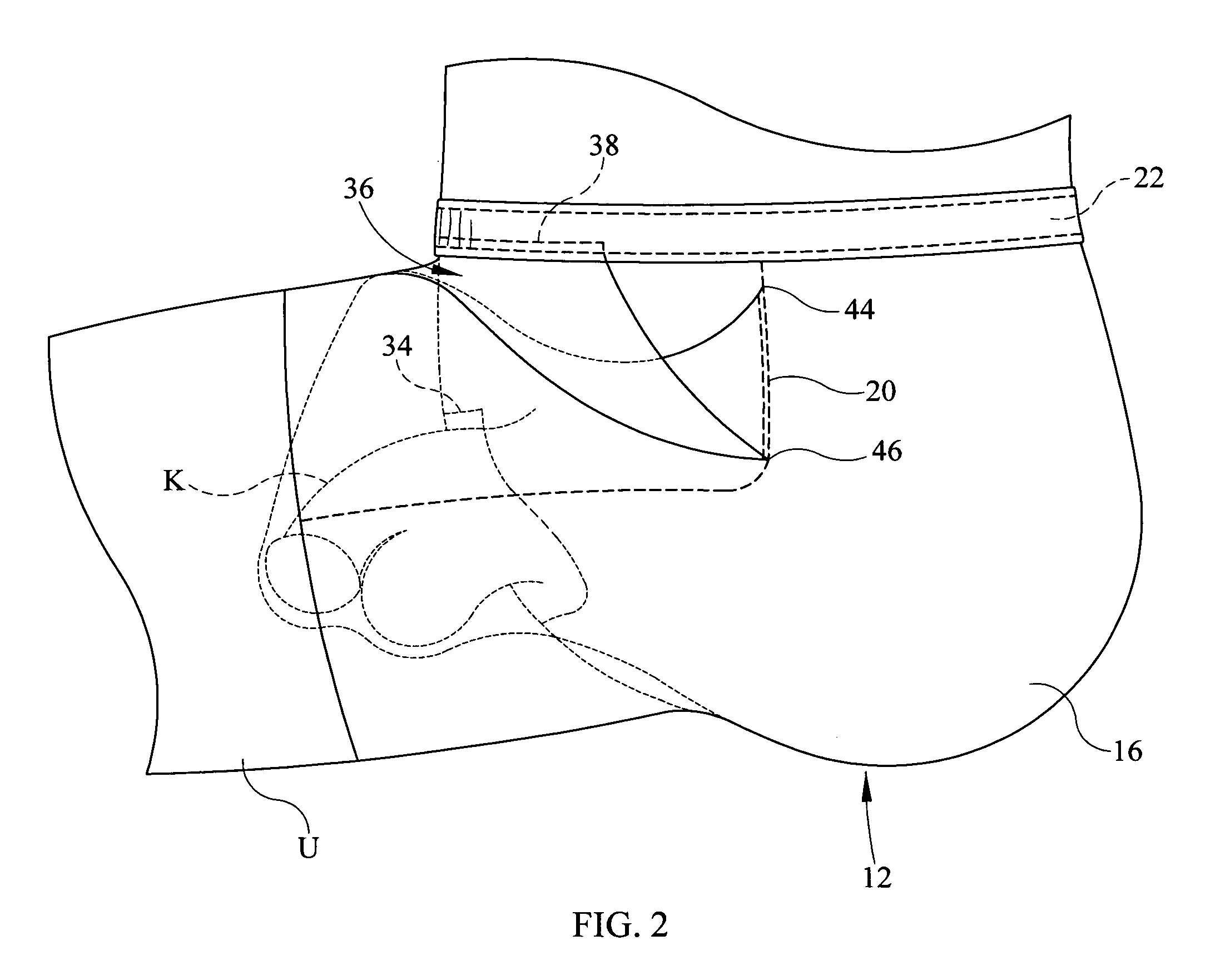

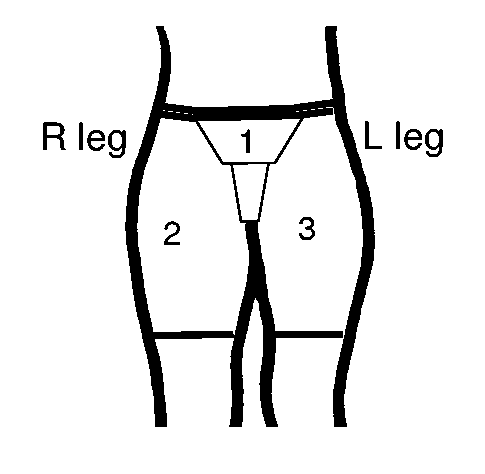

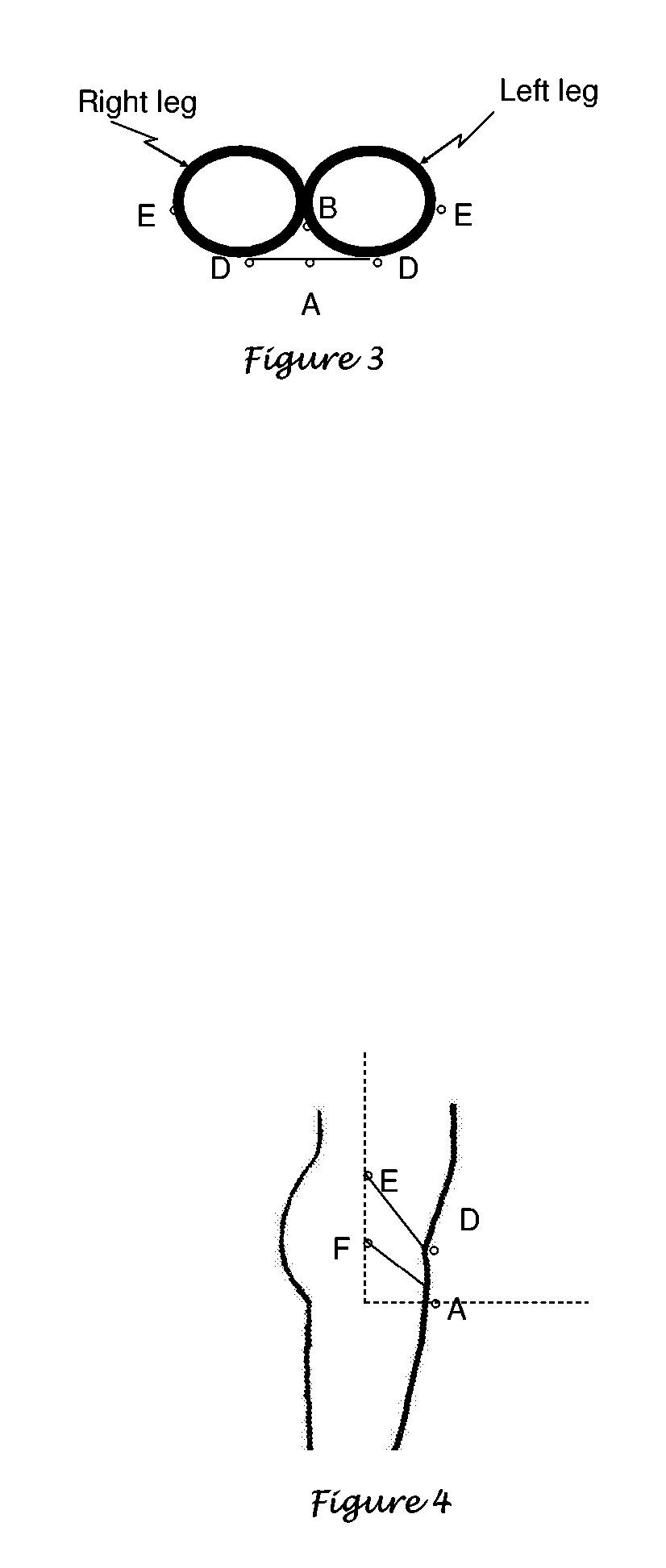

Athletic hammock

A pair of men s shorts, including under shorts, has a typical chassis with an abdomen opening, a right pant leg and a left pant leg. The user's genitals pass through an opening on the front of the chassis whenever the shorts are being worn. A hammock overlies the opening and is anchored to the chassis at two points on the right out seam, one point below the other, and two points on the left out seam, symmetrical with the right out seam attachment. The hammock is also attached to the chassis at the waist band and at the lower edge of the opening just above the left and right inseam joinder area. The hammock by being anchored at the out seams and being non-stretching in a transverse direction, acts as a sling in supporting the genitals of the user.

Owner:BOSTON JAMES LLOYD

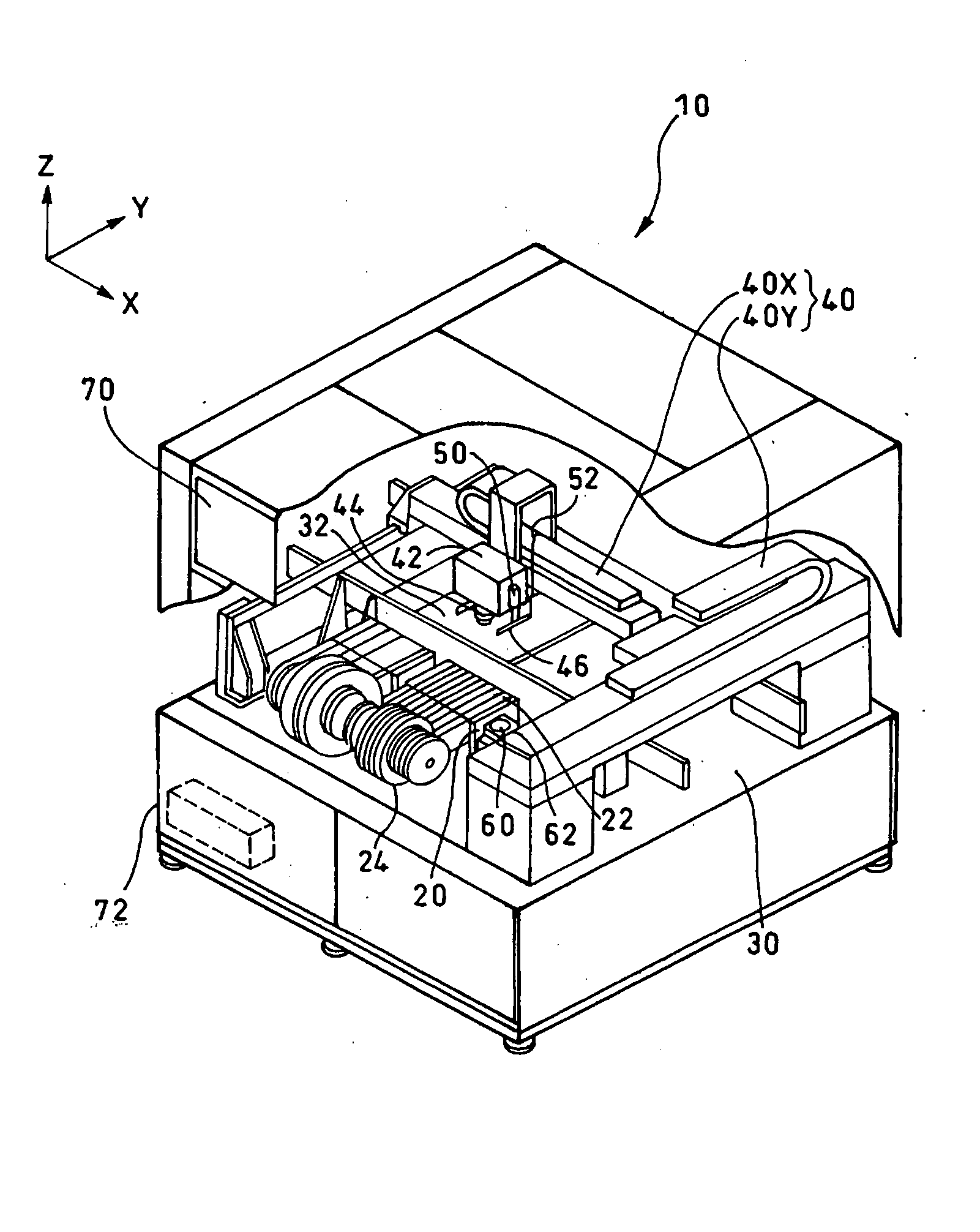

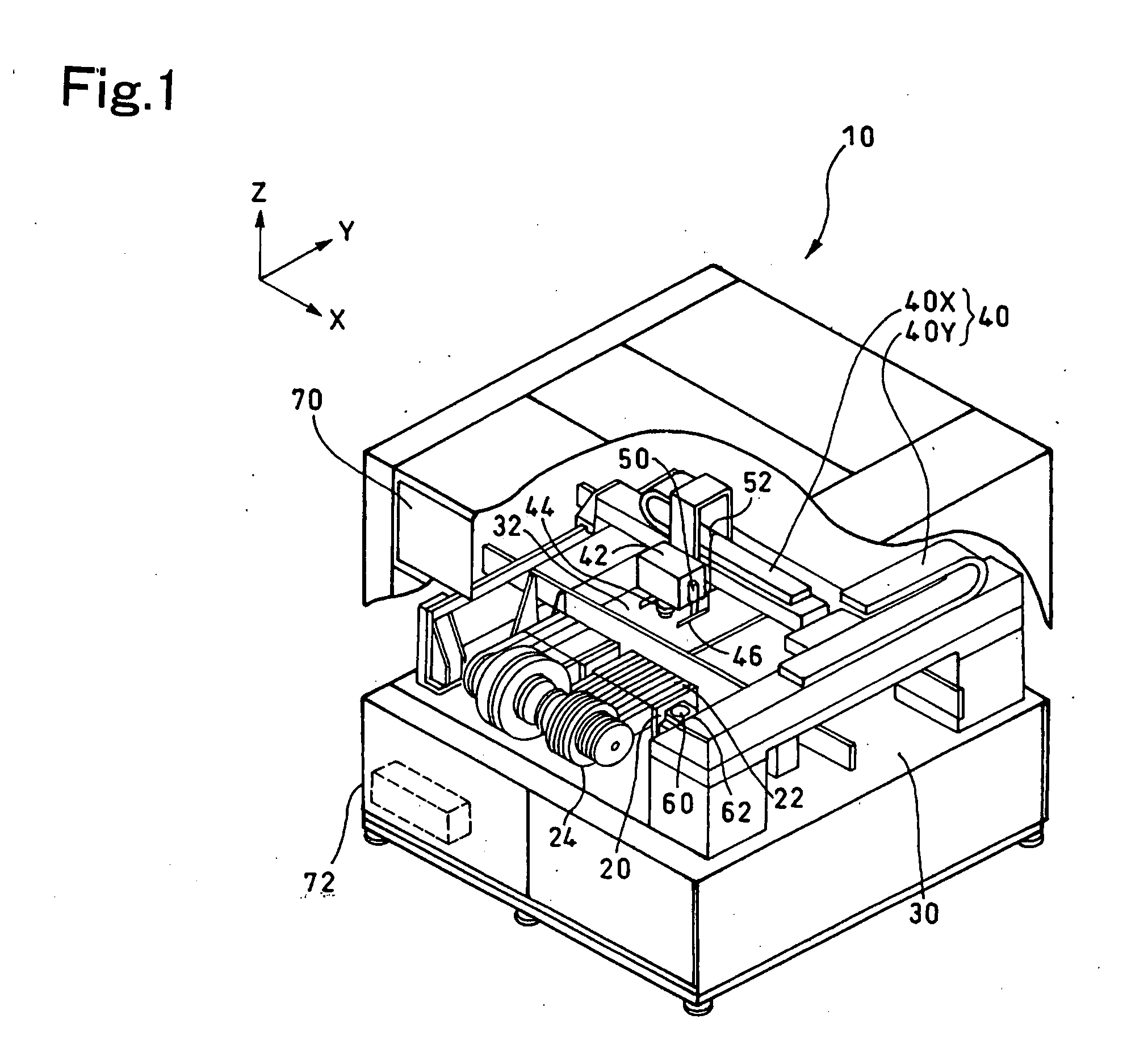

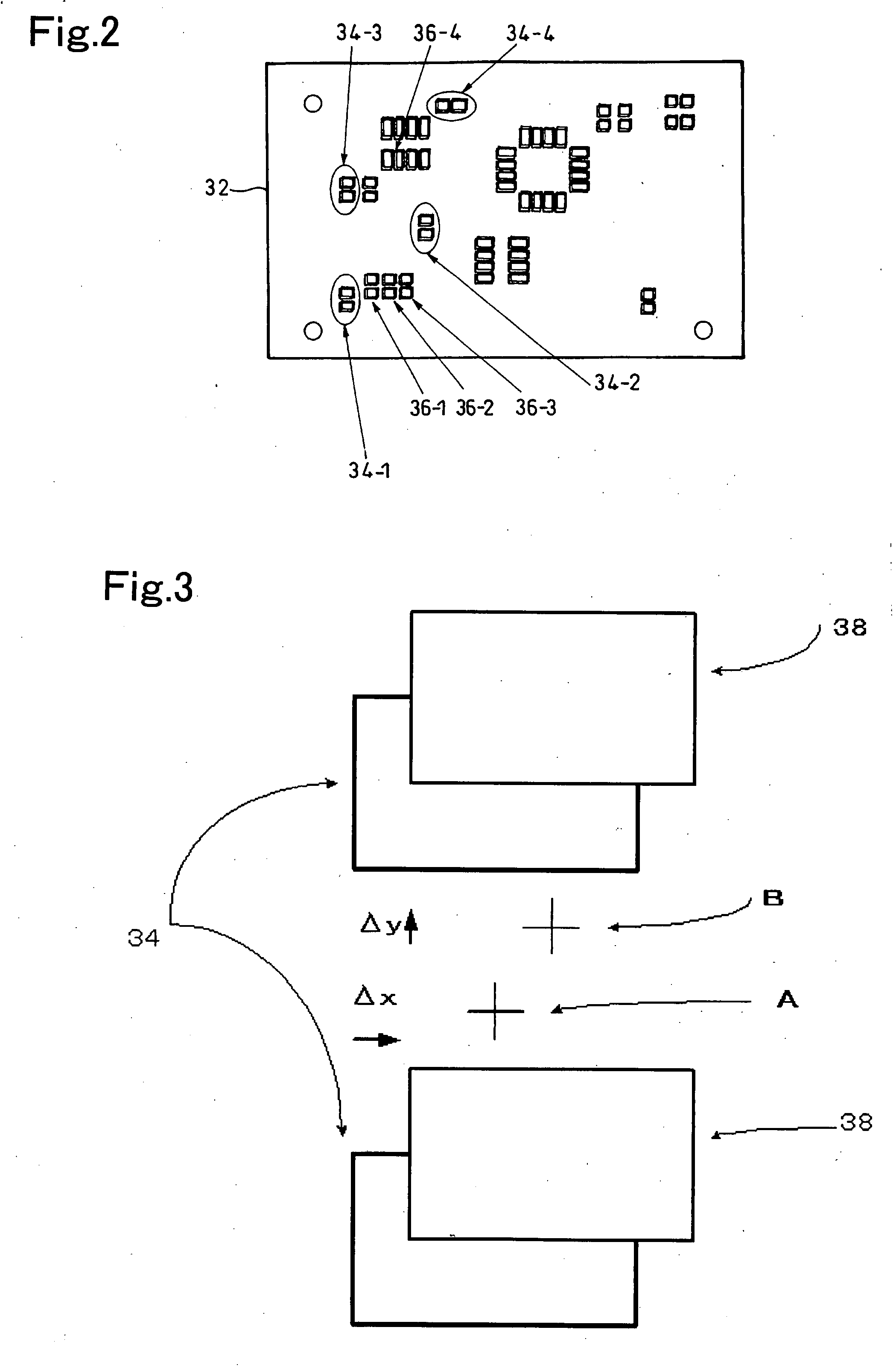

Component mounting position correcting method and component mouting apparatus

InactiveUS20080014772A1Small stretchShorten detection timeFinal product manufactureInspection/indentification of circuitsEngineeringElectrode

A component mounting position is corrected in accordance with a printing misalignment amount of a solder with respect to an original mounting position on a board at which a component is to be mounted. More specifically, a mounting position of a predetermined correction object component is corrected in accordance with the printing misalignment amount of the solder printed on a predetermined detection object electrode.

Owner:JUKI CORP

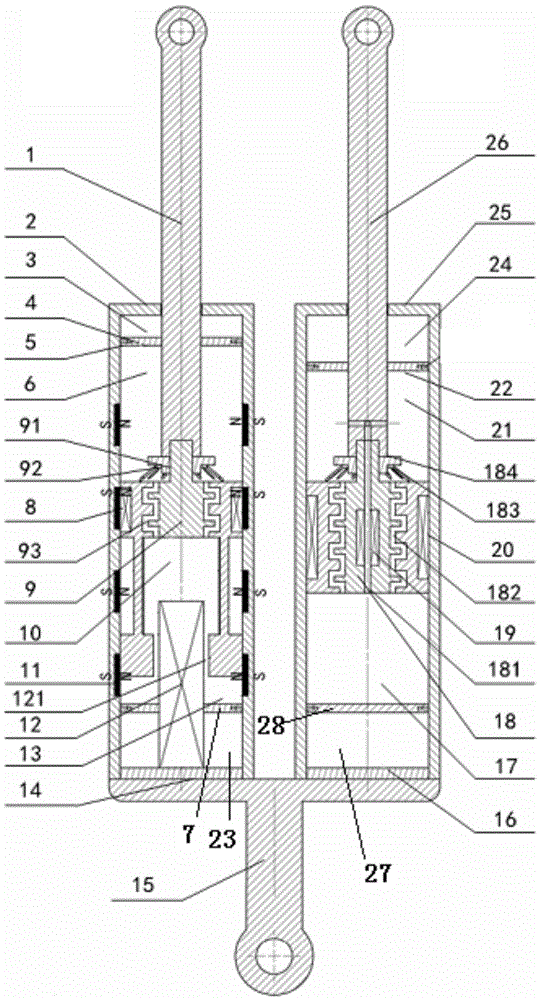

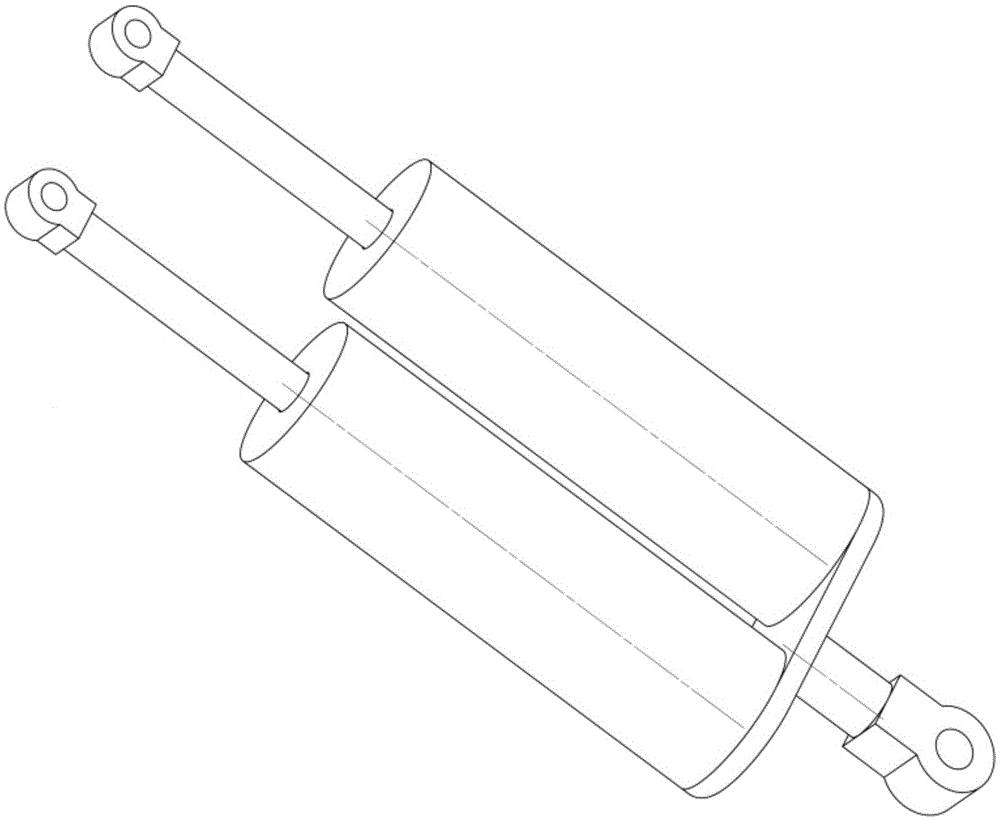

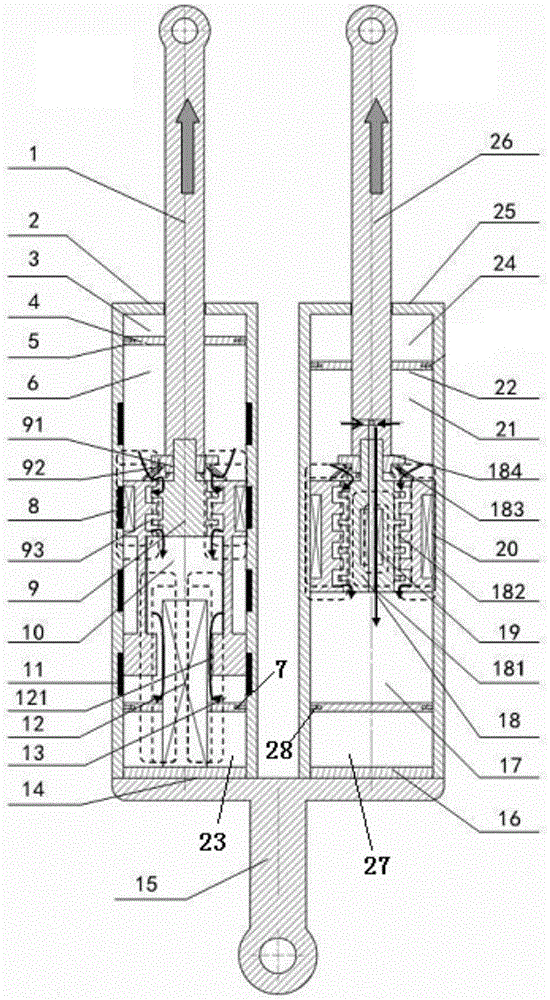

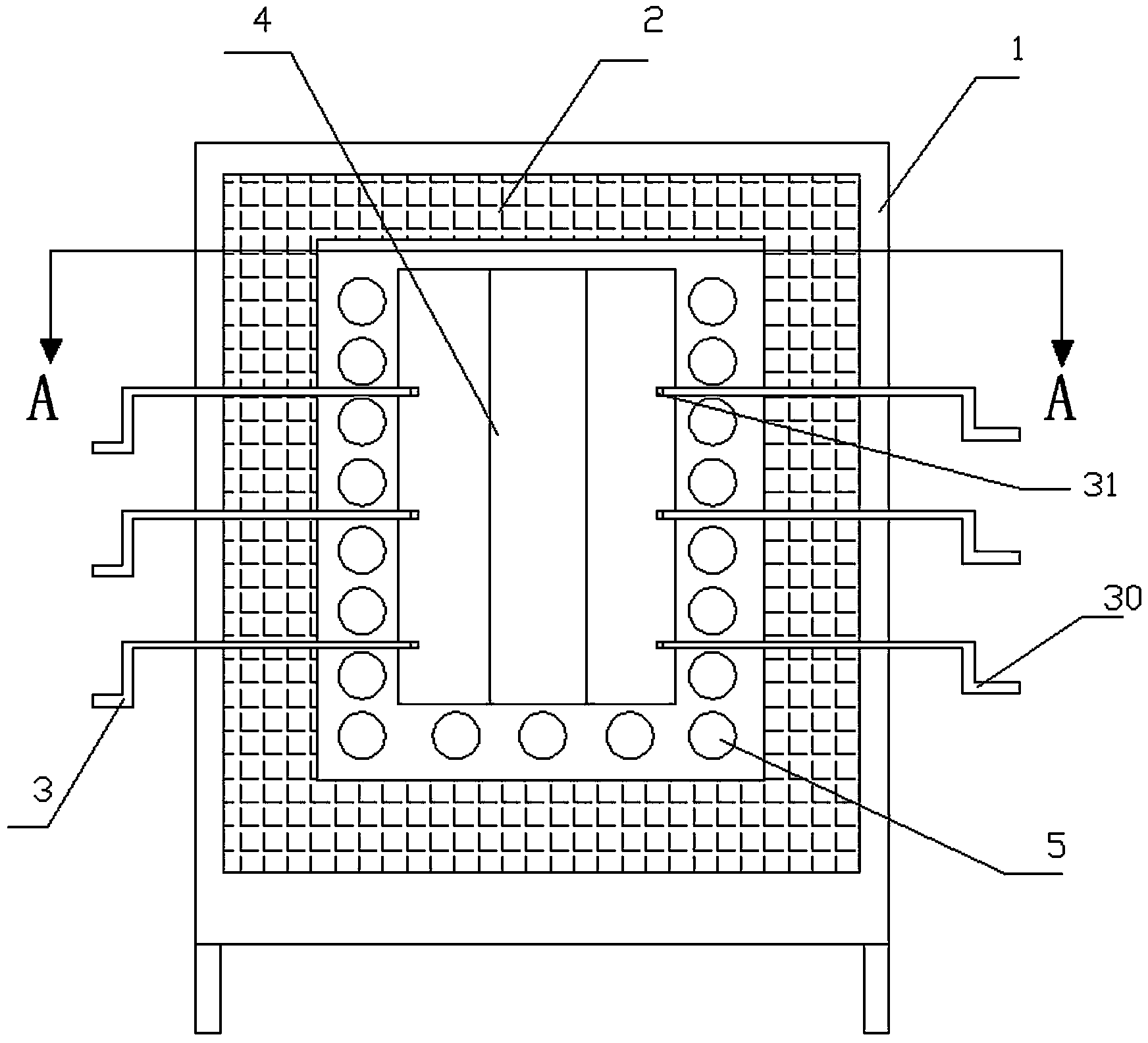

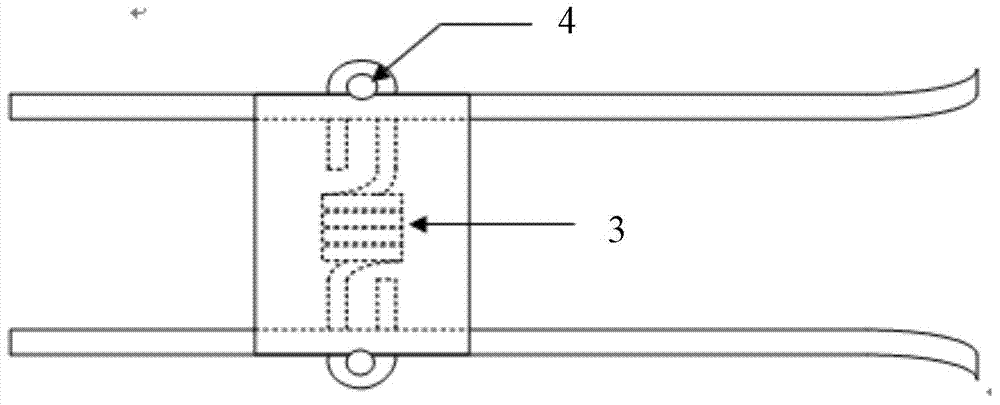

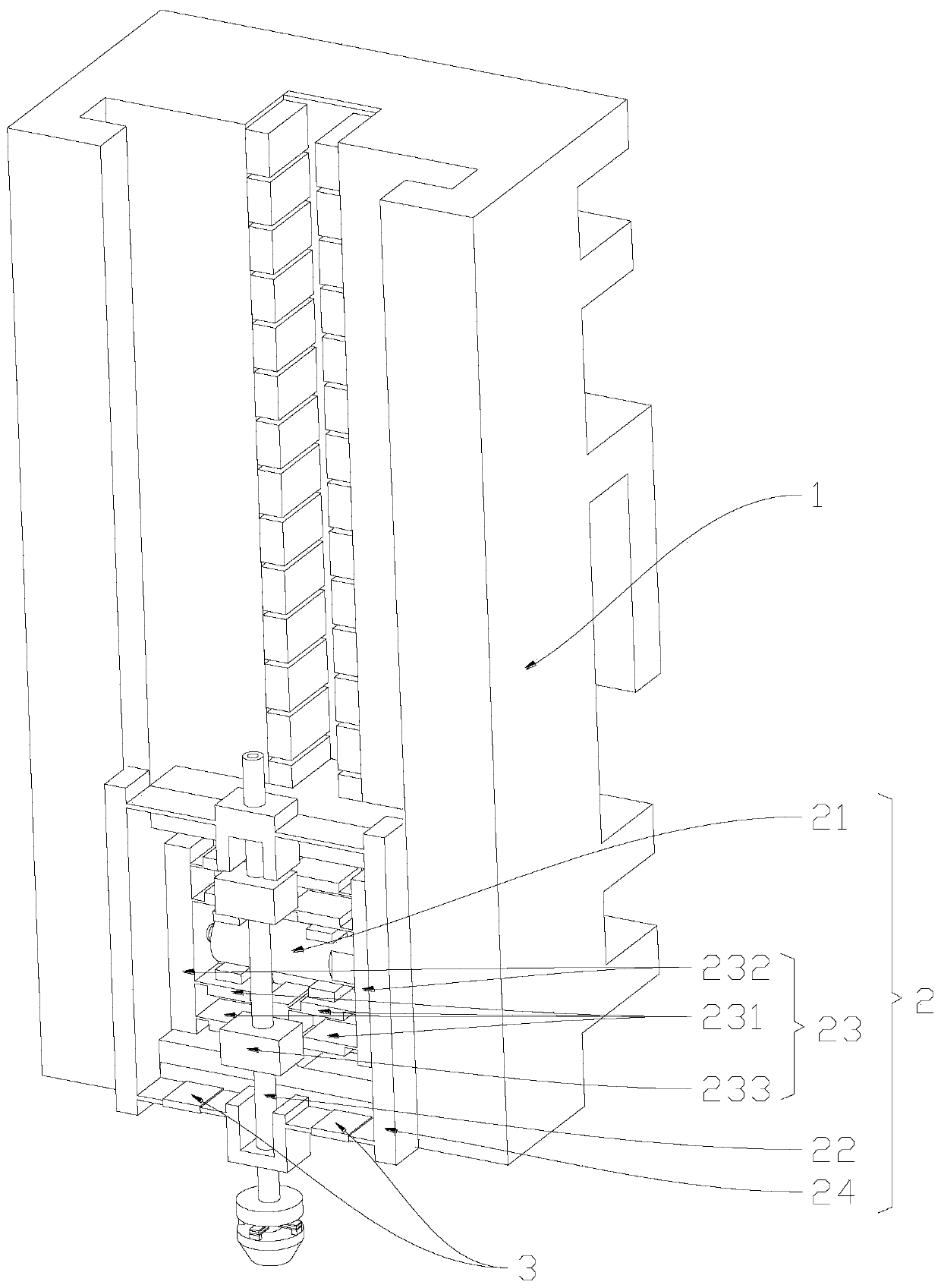

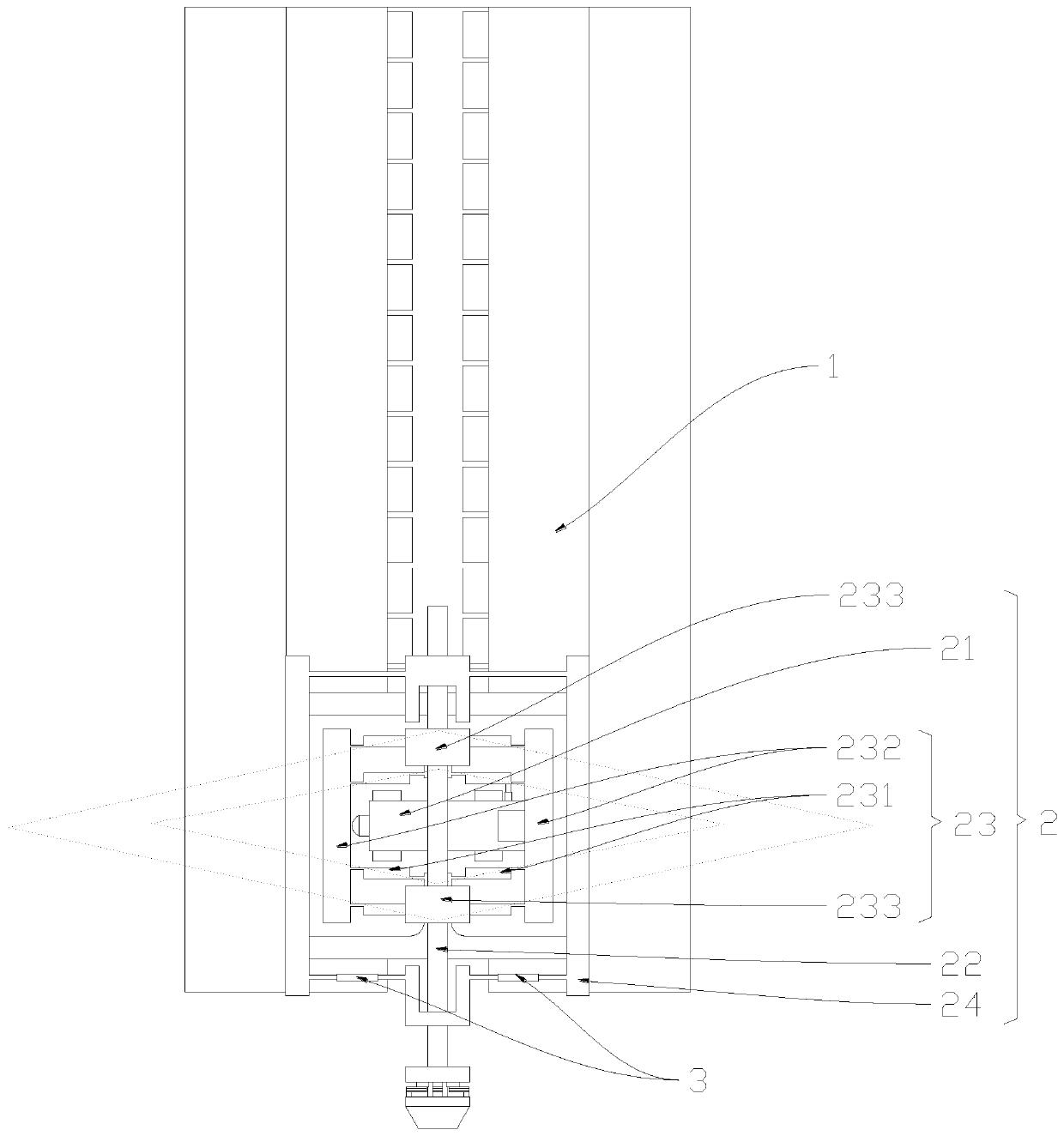

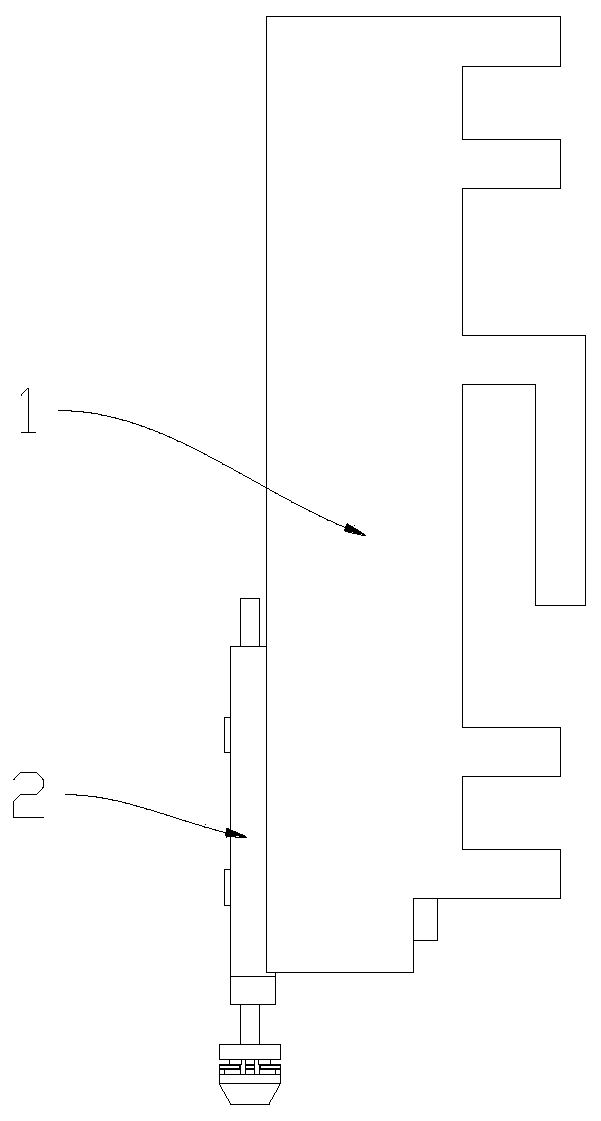

Multi-barrel magnetorheological damping shock absorber capable of achieving cooperative work

ActiveCN105605141AGuaranteed fail-safeSmall stretchSpringsNon-rotating vibration suppressionControl theoryCooperative work

The invention relates to a multi-barrel magnetorheological damping shock absorber capable of achieving cooperative work. The magnetorheological damping shock absorber comprises at least one first damper and at least one second damper which are arranged on a base in a parallel connection mode, each second damper comprises a second liquid storage cylinder arranged on the base, magnetorheological liquid is contained in the second liquid storage cylinders, second piston assemblies are arranged in the second liquid storage cylinders, the tops of the second piston assemblies are connected with second piston rods, the second piston rods stretch out of the tops of the second liquid storage cylinders and vertically move in the second liquid storage cylinders along with the second piston assemblies, second snakelike magnetorheological liquid channels are formed in the second piston assemblies, the portions, close to the inner surfaces of the second liquid storage cylinders, of the second piston assemblies are provided with second external magnet exciting coils, and the inner surfaces of the second liquid cylinders are provided with multiple sets of permanent magnetic rings with the same magnetic heading. Compared with the prior art, the multi-barrel magnetorheological damping shock absorber has the advantages that the regulating range of tensile resisting and compression resisting is wide, the universality is high, and the damping shock absorber is not prone to be damaged.

Owner:SHANGHAI UNIV OF ENG SCI

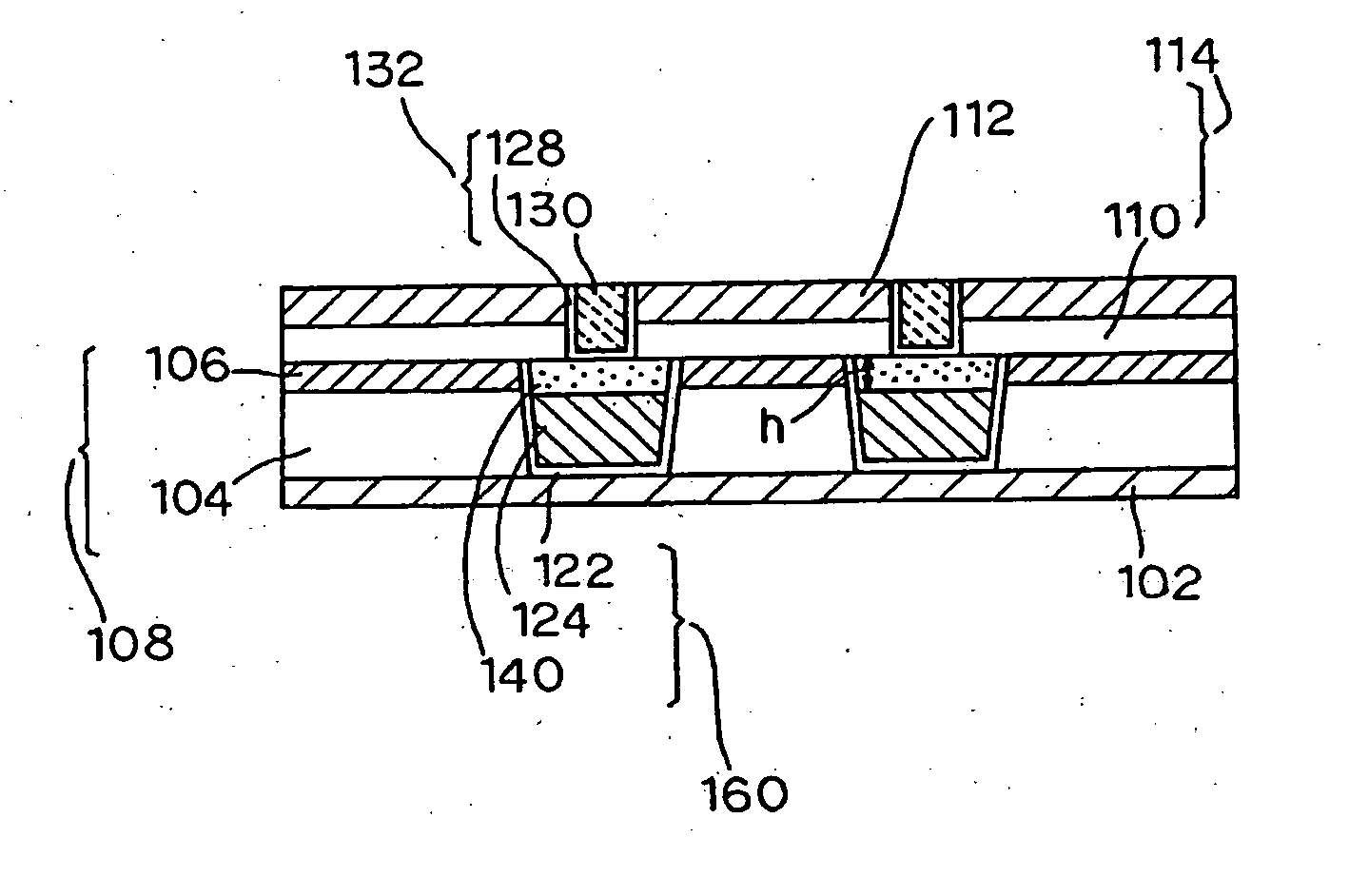

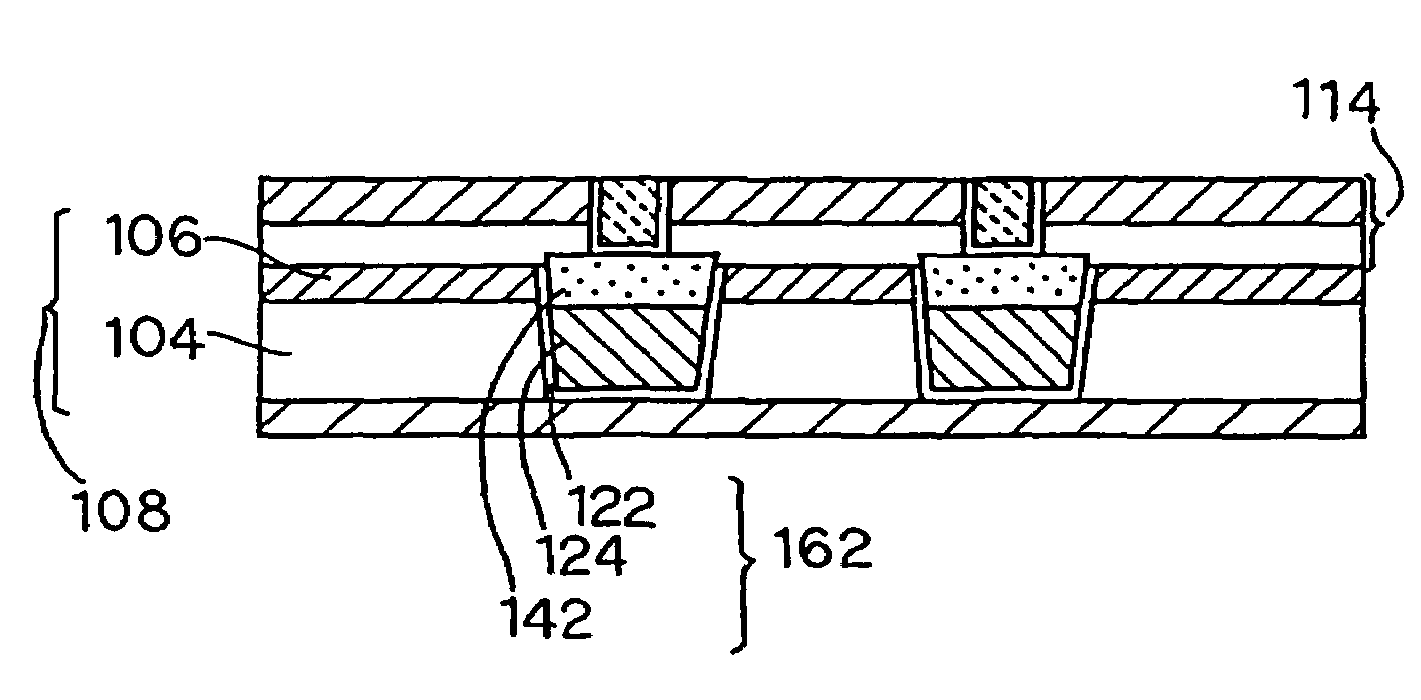

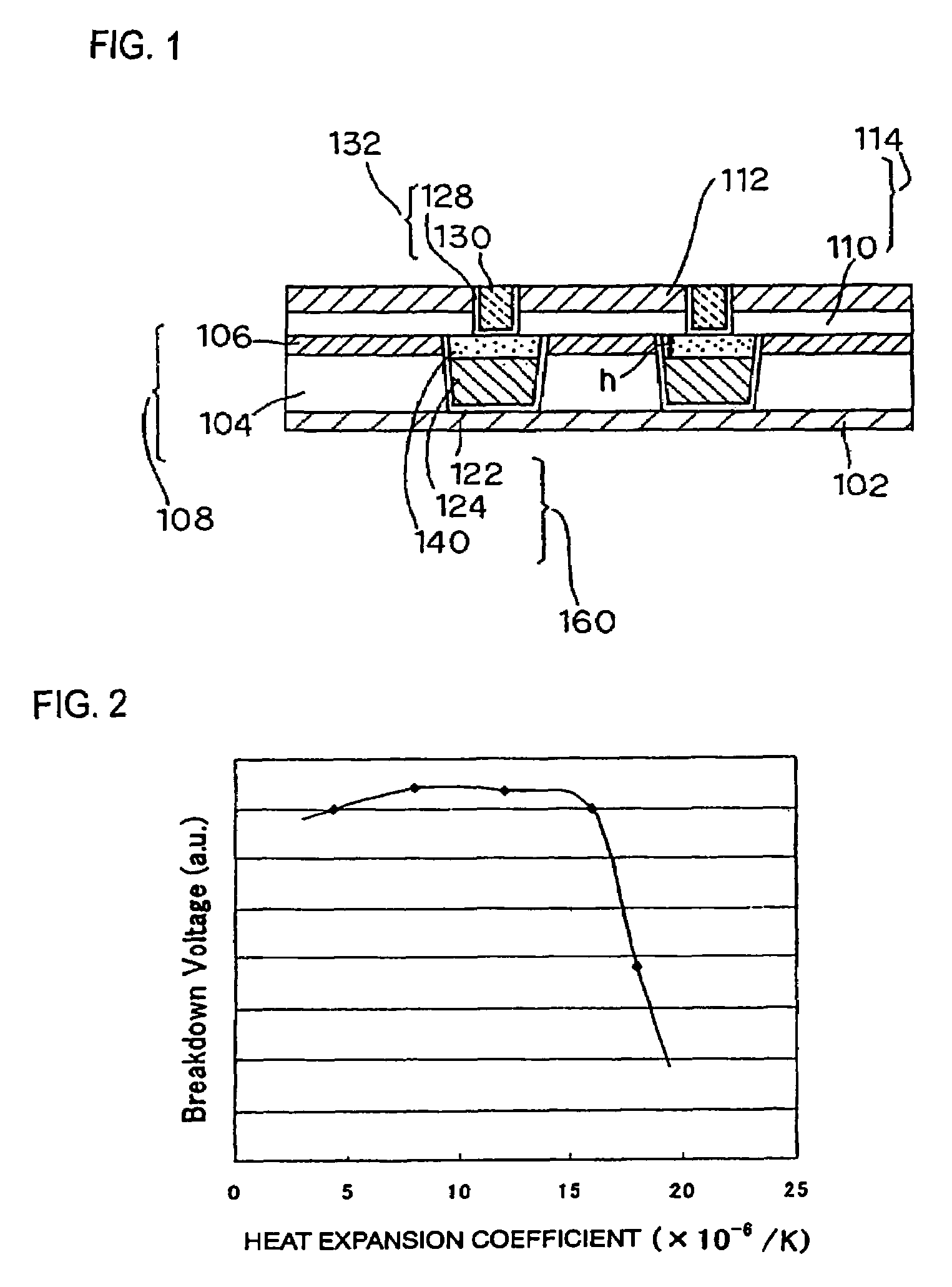

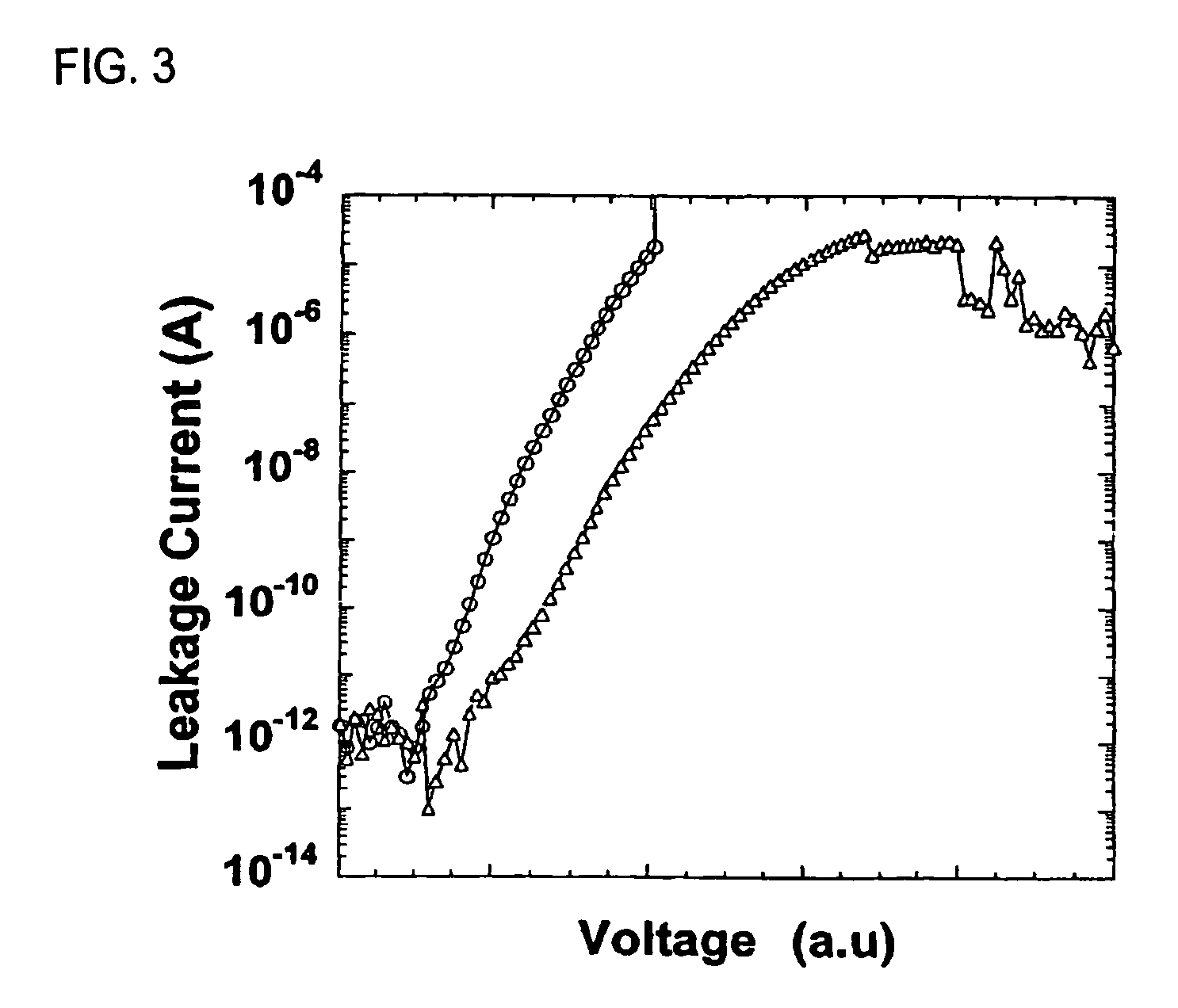

Semiconductor device and method of fabricating the same

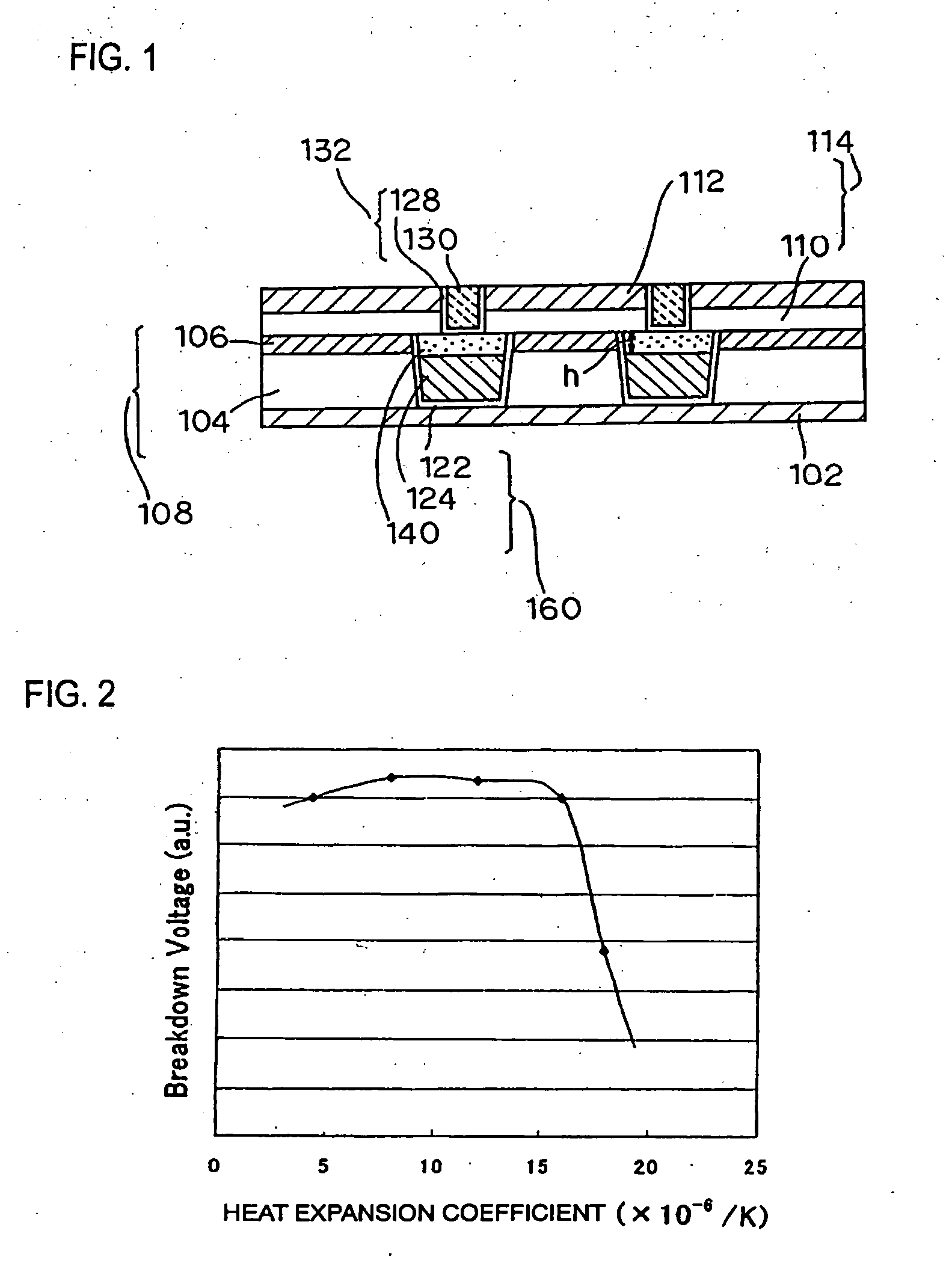

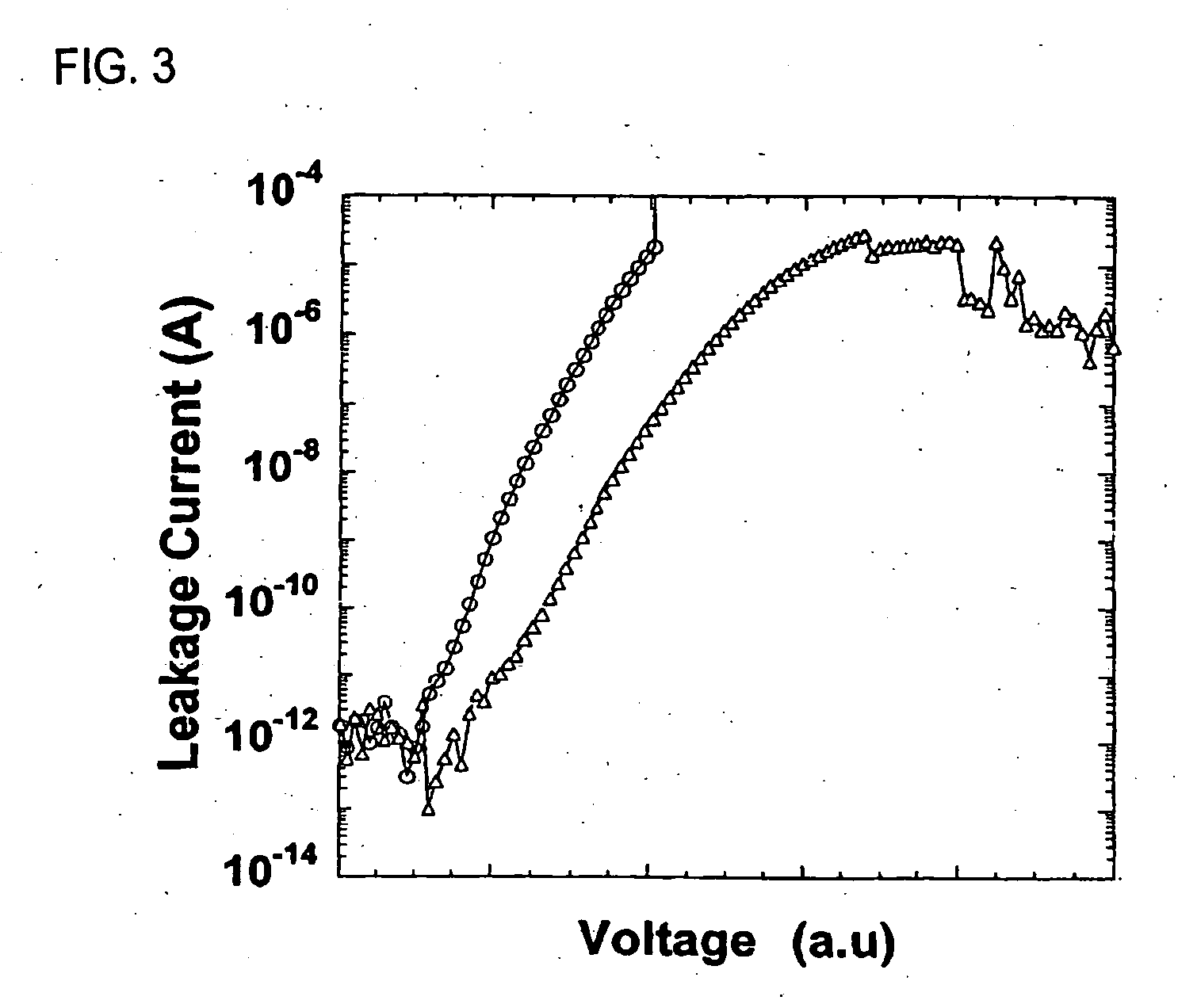

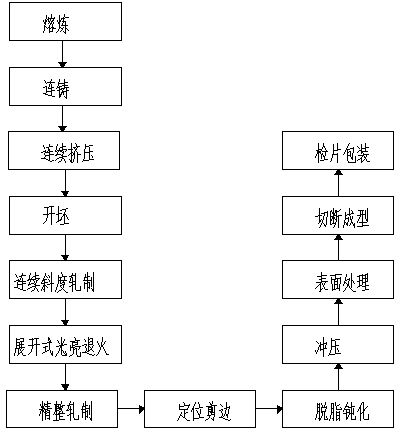

InactiveUS20050189654A1Suppresses stretching and shrinkageInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesDevice materialCopper

A semiconductor device having interconnects is reduced in leakage current between the interconnects and improved in the TDDB characteristic. It includes an insulating interlayer 108, and interconnects 160 filled in grooves formed in the insulating interlayer, including a copper layer 124 mainly composed of copper, having the thickness smaller than the depth of the grooves, and a low-expansion metal layer 140, which is a metal layer having a heat expansion coefficient smaller than that of the copper layer, formed on the copper layer.

Owner:RENESAS ELECTRONICS CORP

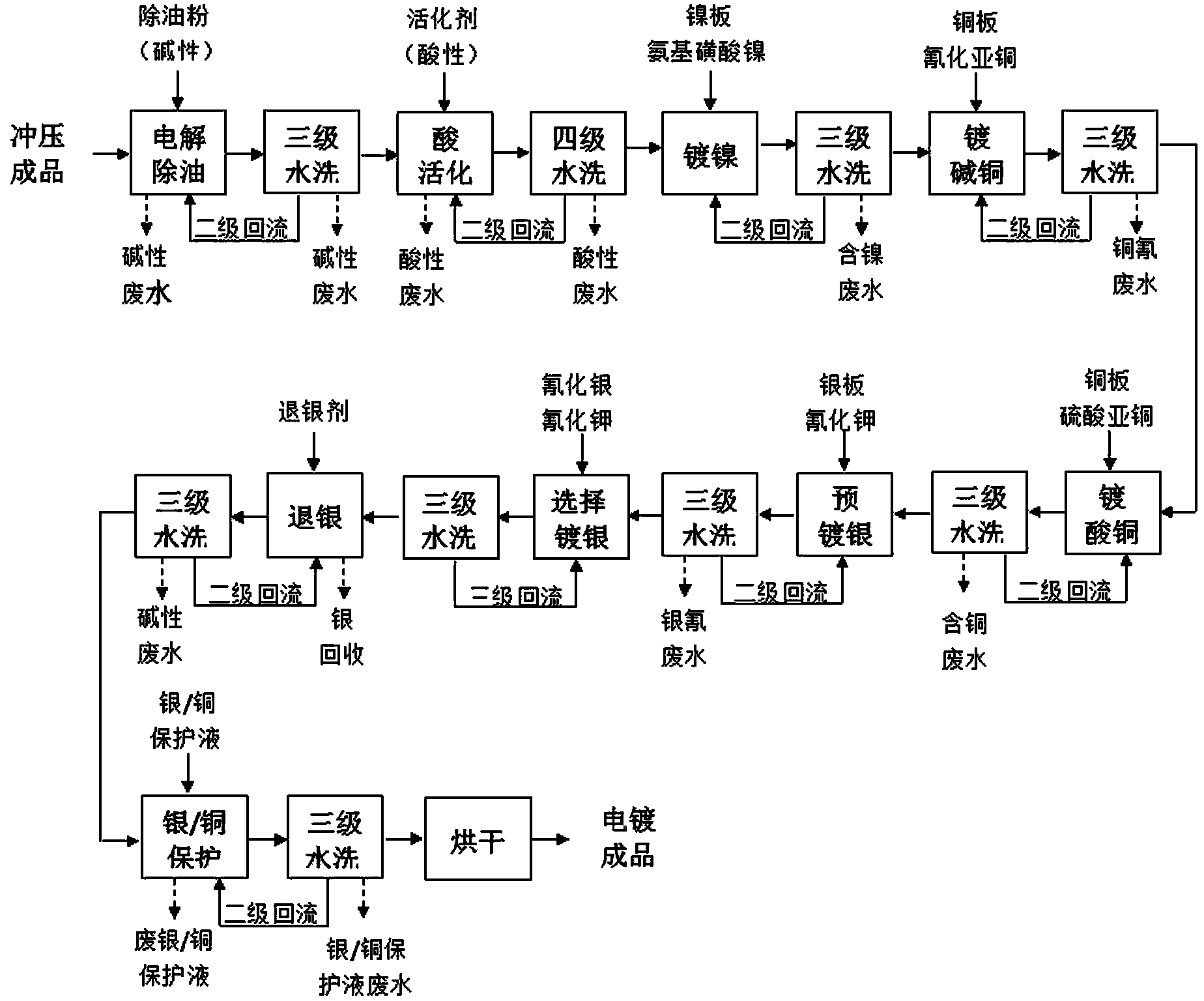

Semi-conductor lead framework production process

ActiveCN103928351AExact widthAdequate heat dissipationSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

The invention relates to a semi-conductor lead framework production process which includes the steps of smelting, continuous casting, continuous extrusion, cogging, severe convection annealing, continuous inclination rolling, spreading-type bright annealing, finishing rolling, positioning-type edge shearing, degreasing passivation, stamping, surface processing, cutting forming and detection piece packaging. The production process is characterized in that the two work procedures of finishing rolling and positioning-type edge shearing are provided with continuous grooving procedures, when continuous grooving is carried out, precise grooving processing is carried out through a grooving machine, the rotation speed of the grooving machine is 1800-2000 r / min, the flow of cooling liquid is 45-50 L / min, and dovetail groove forming achieving through the process cannot cause strip width changes after forming, and the size of a formed semi-conductor lead framework is accurate.

Owner:SICHUAN JINGJIAN ELECTRONICS MATERIAL

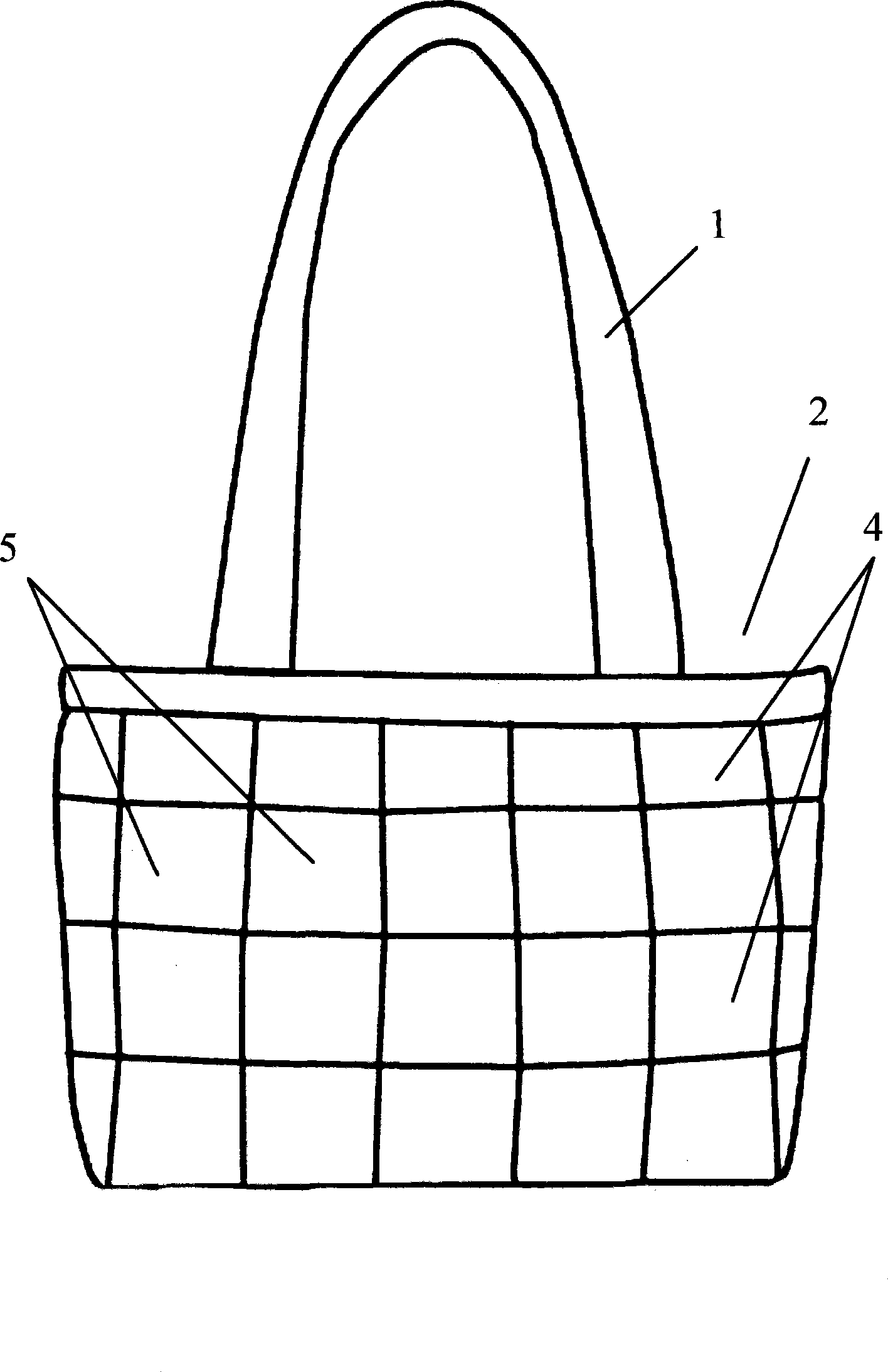

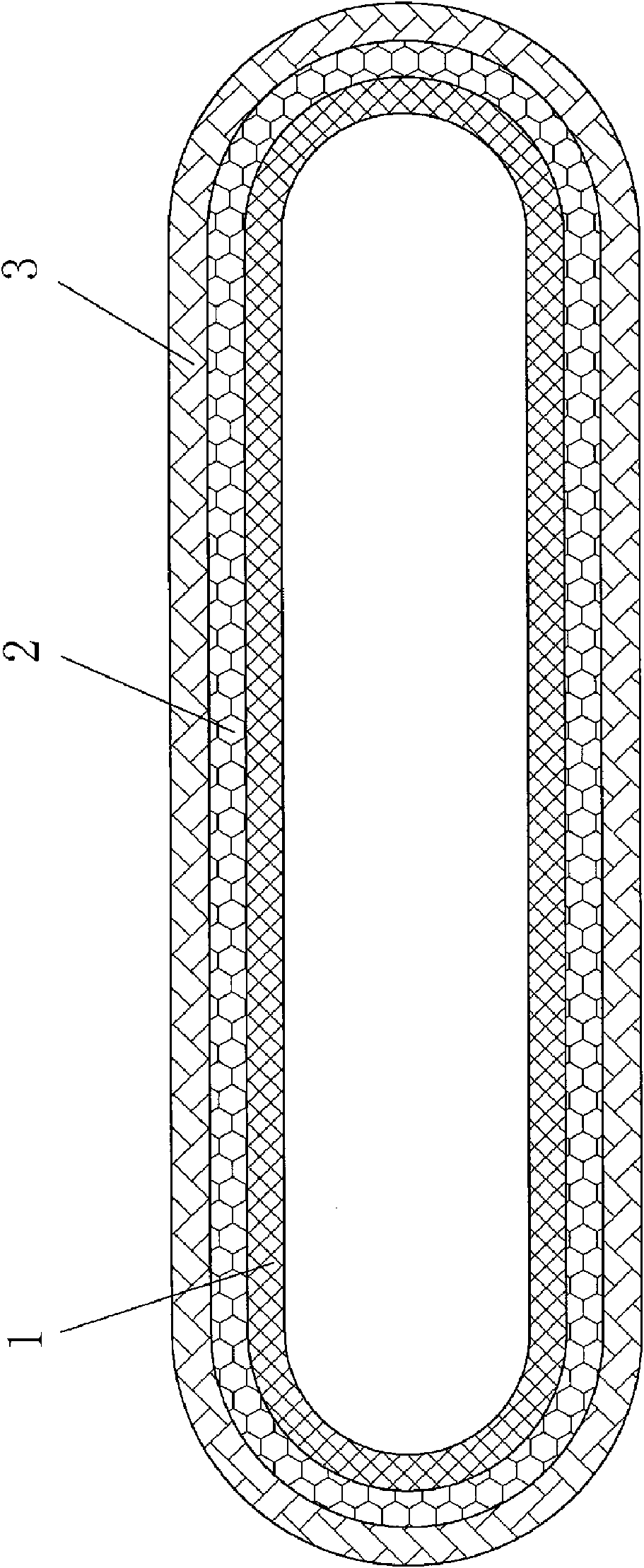

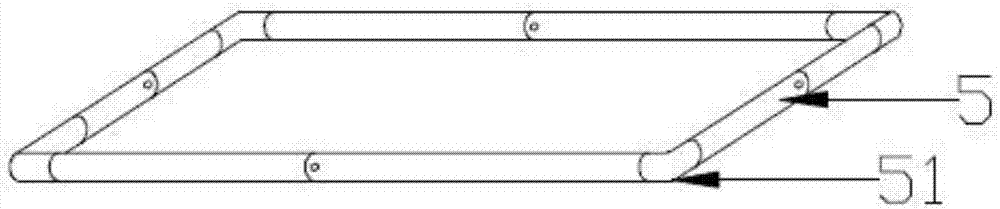

Safety band type luggage and weaving method thereof

InactiveCN101390678AHigh tensile strengthHigh strengthHandbagsLuggageEngineeringUltimate tensile strength

The invention relates to a safety belt-type bag and a weaving method thereof. The external bag body is mainly weaved from at least one longitude belt and one latitude belt. The whole fixed longitude belts present a ring structure, with the two ends respectively arranged at the edges of the external upper part of the internal bag body; and the latitude belts are respectively arranged at the inside parts or the surfaces of the longitude belts. The weaving method includes the following steps: cutting a plurality of longitude belts and latitude belts out into suitable length, arranging the longitude belts in order, and arranging the latitude belts on the bottoms and the surfaces of the longitude belts in order from top to bottom through interpenetration or superposition so as to form a desirable shape. The weaving method is simple and practical, not only avoids the problem that the splicing joints and the stitched parts are easy to break and craze, but also improves the overall tensile-strength of the bag, thus improving the overall fastness and the durability of the bag.

Owner:GUOXIN MINGTIAN BEIJING TECH

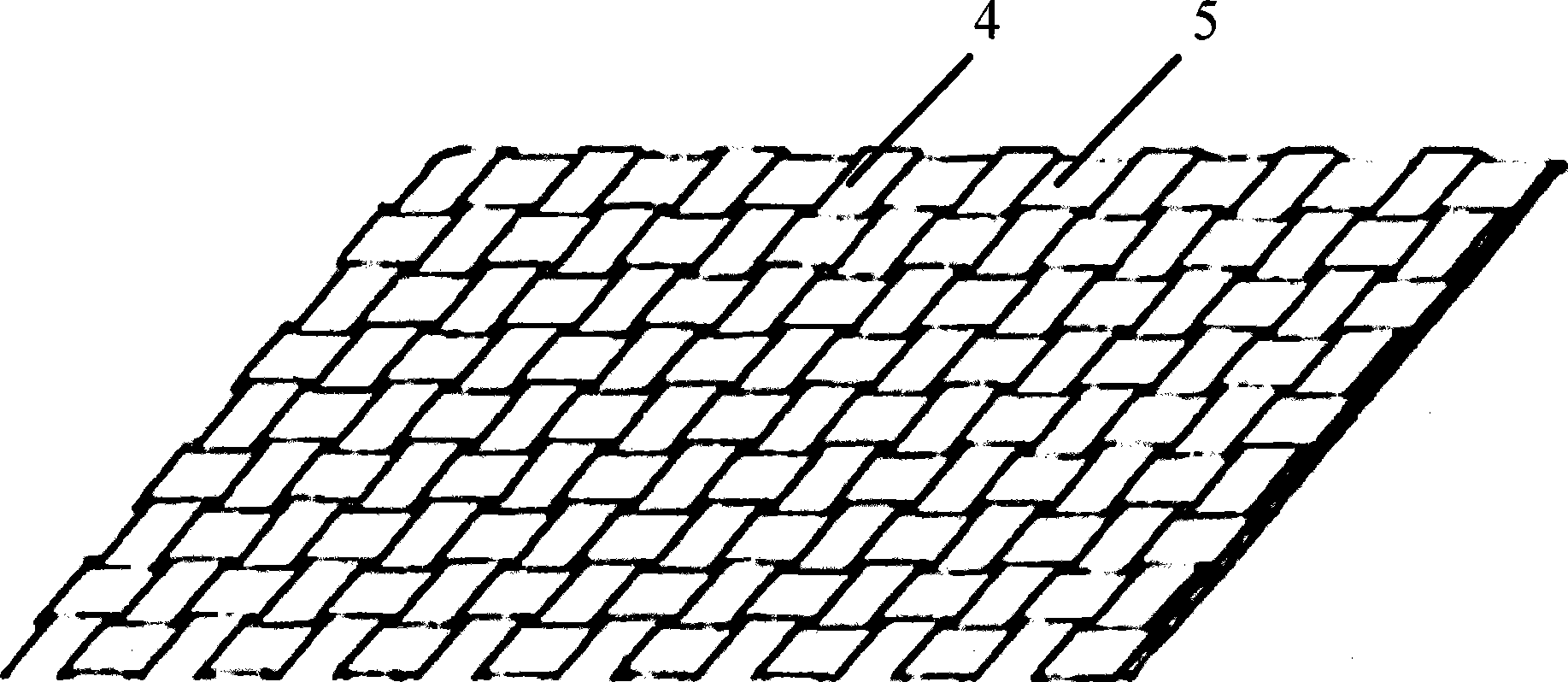

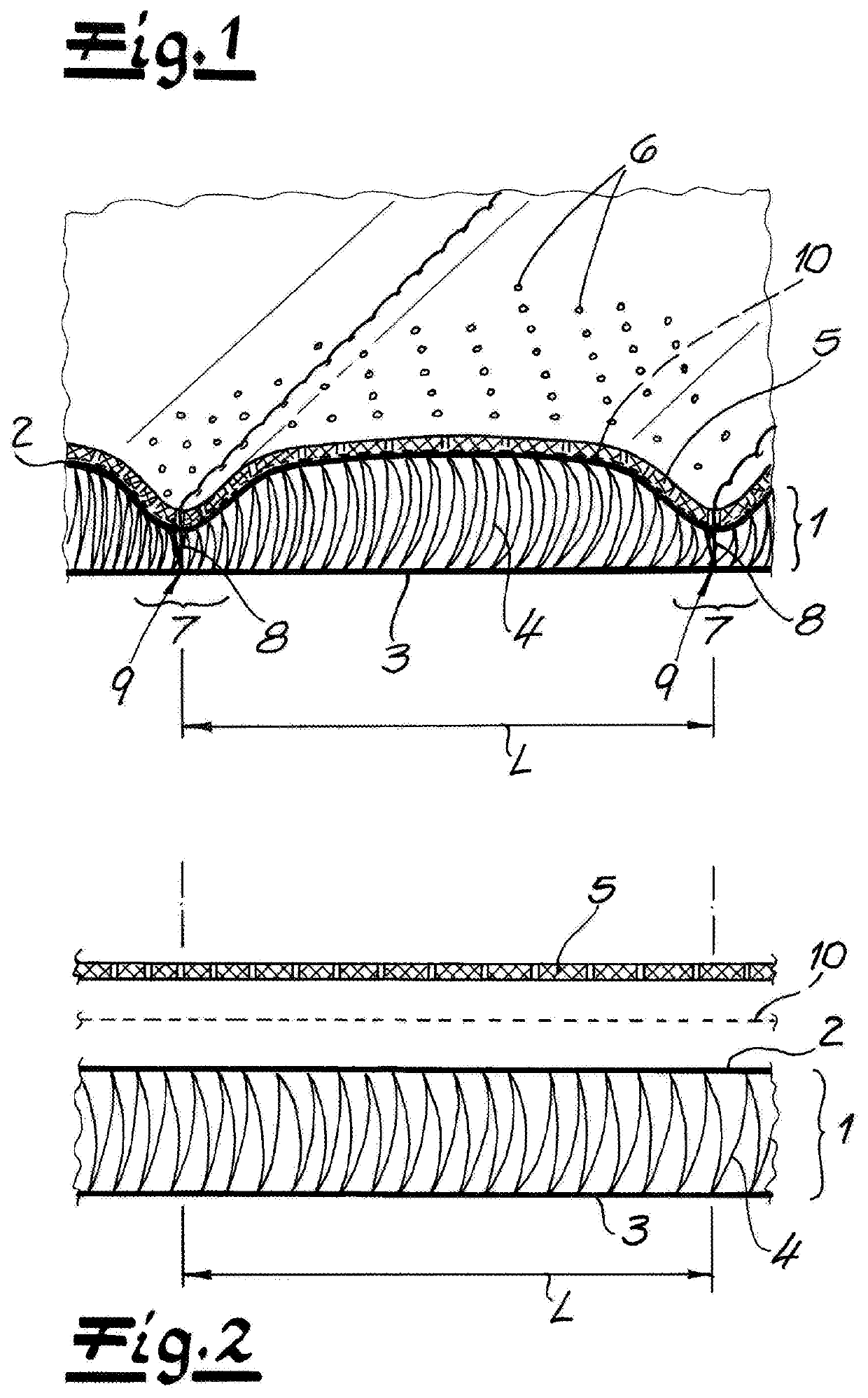

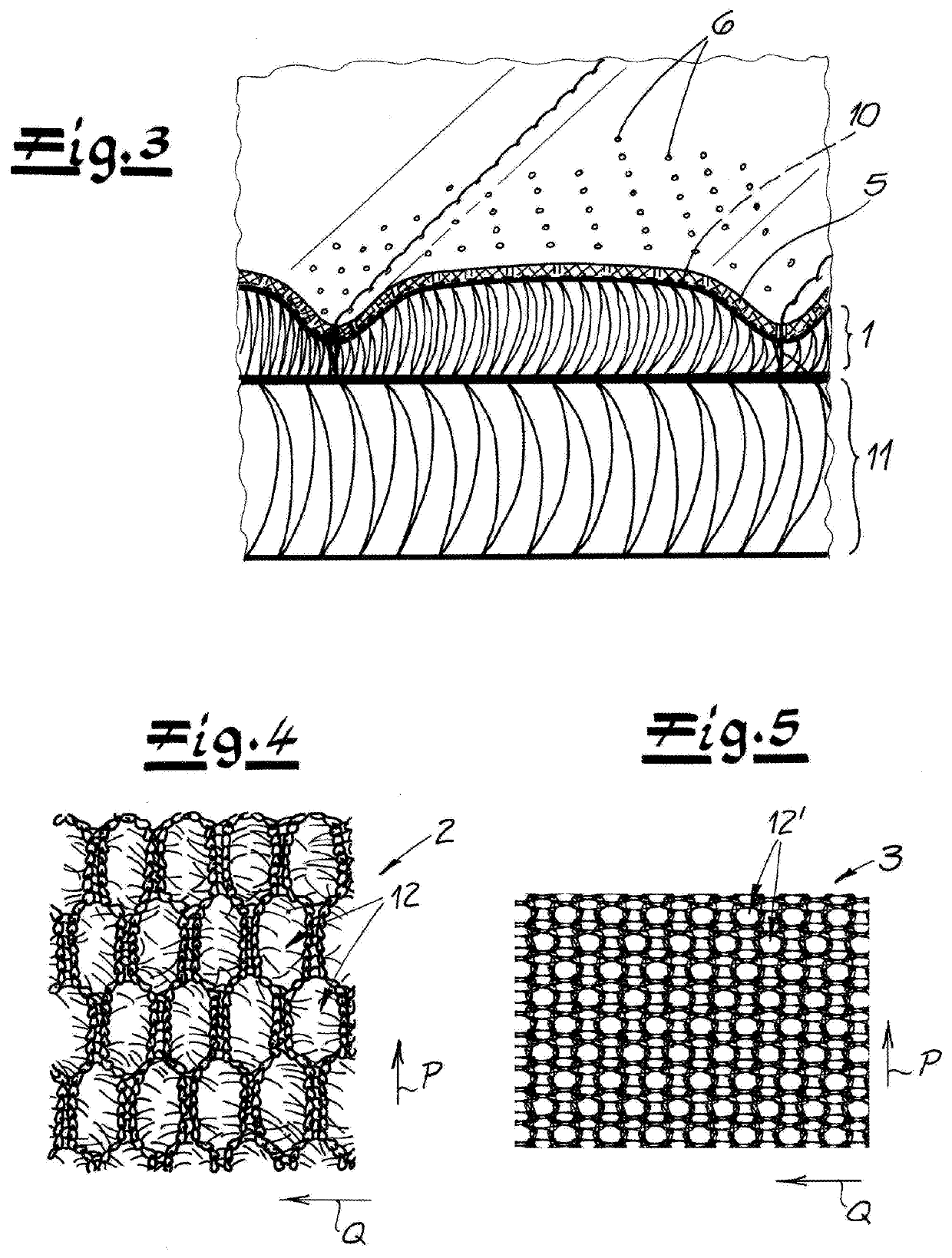

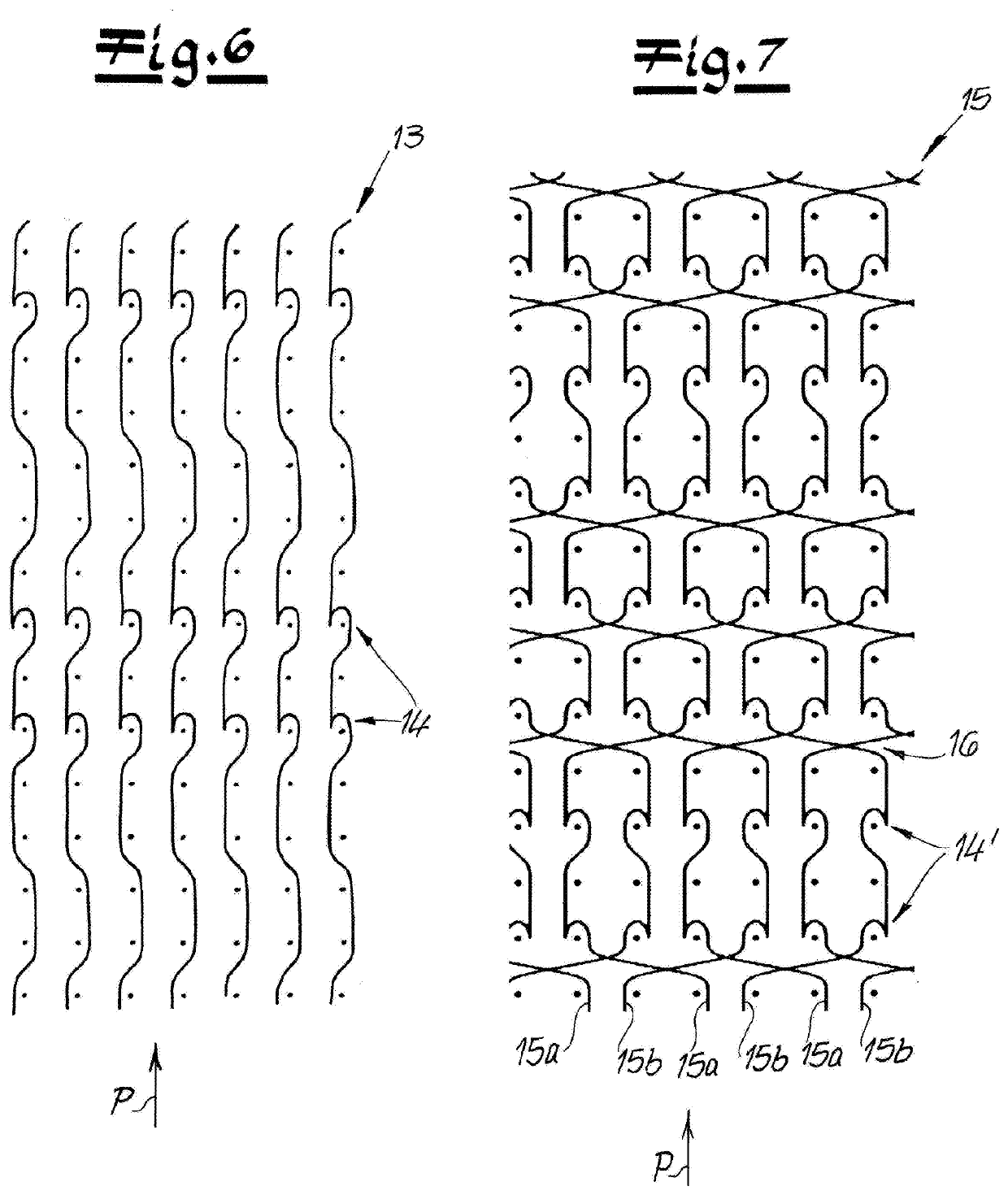

Composite spacer fabric

PendingUS20200338853A1Improve ventilationSmall stretchSeat coveringsOrnamental textile articlesPolymer sciencePolymer chemistry

A warp-knitted textile composite has a spacer fabric that extends in a production direction and a transverse direction and has an outer flat warp-knitted fabric layer of predetermined stretchability, an inner flat warp-knitted fabric layer of lesser stretchability in the production and transverse directions than the outer layer, and spacer threads interconnecting the warp-knitted fabric layers. A decorative cover layer is attached to the outer flat warp-knitted fabric layer and is formed with compressed areas where the spacer fabric is permanently at least partially compressed for structuring the decorative cover layer.

Owner:MULLER TEXTIL

Semiconductor device and method of fabricating the same

InactiveUS7388291B2Suppresses stretching and shrinkageInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesInter layerCopper

A semiconductor device having interconnects is reduced in leakage current between the interconnects and improved in the TDDB characteristic. It includes an insulating interlayer 108, and interconnects 160 filled in grooves formed in the insulating interlayer, including a copper layer 124 mainly composed of copper, having the thickness smaller than the depth of the grooves, and a low-expansion metal layer 140, which is a metal layer having a heat expansion coefficient smaller than that of the copper layer, formed on the copper layer.

Owner:RENESAS ELECTRONICS CORP

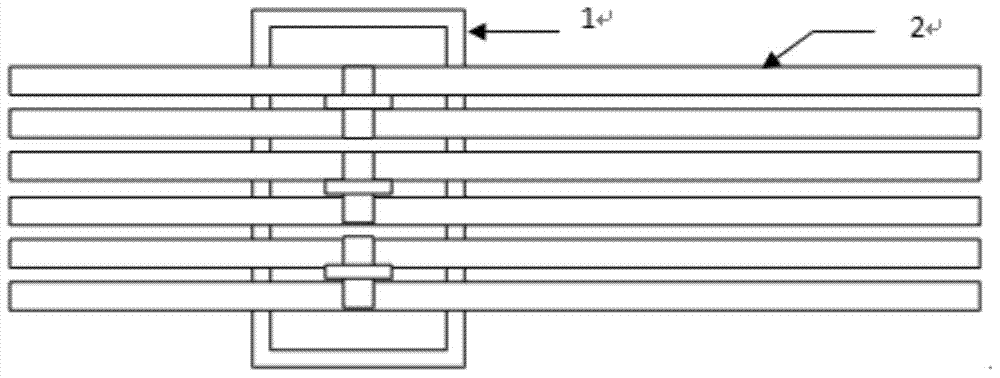

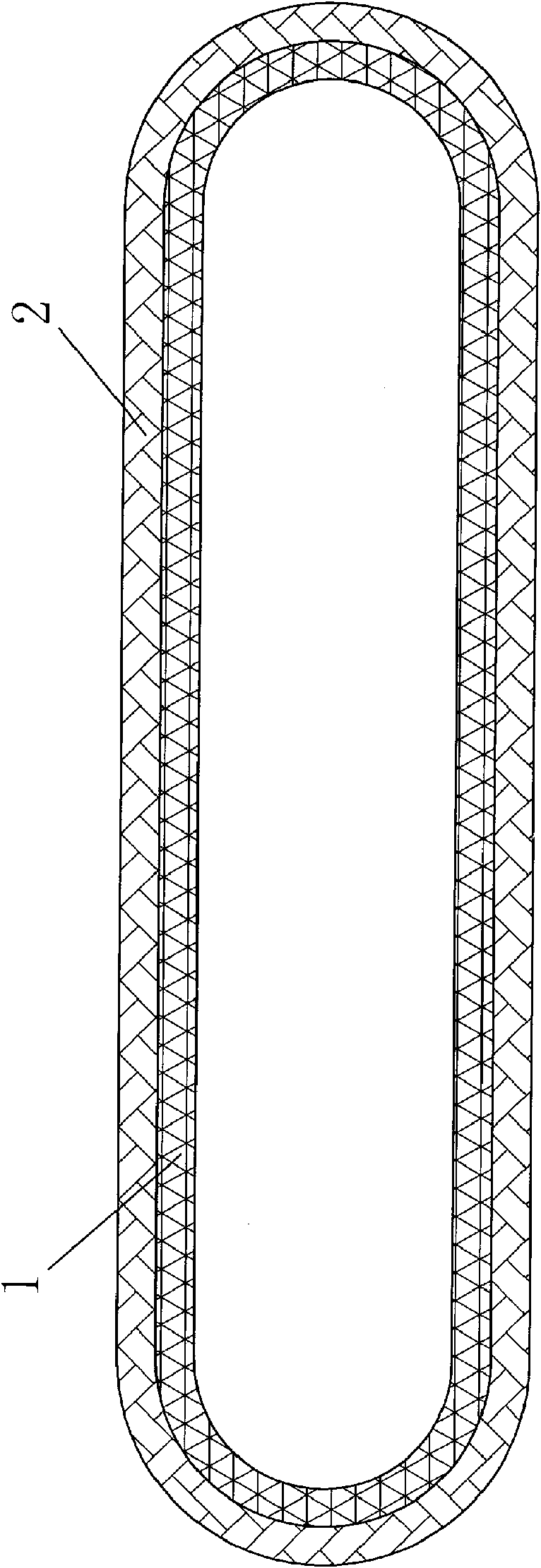

Seamless conveying belt and manufacture method thereof

InactiveCN101638171AImprove photoagingImprove thermal stabilityConveyorsTextiles and paperEngineeringSilica gel

The invention relates to a seamless conveying belt. The conveying belt forms a closed hybrid layer by a joint-free closed base belt and rubber, an outer rubber layer is designed on the outer surface of the closed hybrid layer, and an outer silica gel layer is designed on the outer surface of the outer rubber layer. The manufacture method of the conveying belt comprises the following steps: (1) selecting a plane annular woolen blanket as the joint-free closed base belt; (2) mounting the joint-free closed base belt on a rubber spreading machine; (3) starting the rubber spreading machine, pouringliquid rubber on the joint-free closed base belt and spreading the liquid rubber by a scraper; (4) spraying liquid silica gel on the outer surface of the outer rubber layer; (5) after the outer silica gel layer is solidified, abrading the outer surface of the outer silica gel layer by an abrading machine; (6) taking the product out of the machine and putting into a warehouse. The seamless conveying belt produced by the method has seamless integration and high strength and quality without sticking a conveying object and meets the requirement of a super wide and / or a super long product by a user. The invention has simple manufacture method, high production efficiency and less equipment investment.

Owner:周炳光

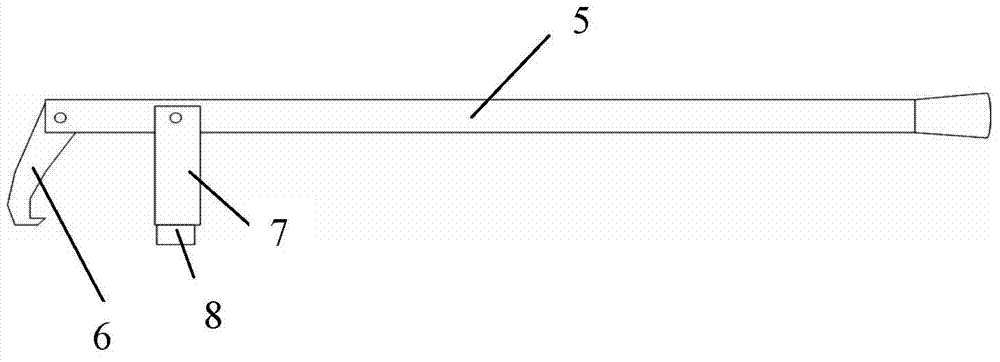

Special tool for disassembling and assembling static contact spring of disconnecting switch

Owner:STATE GRID CORP OF CHINA +1

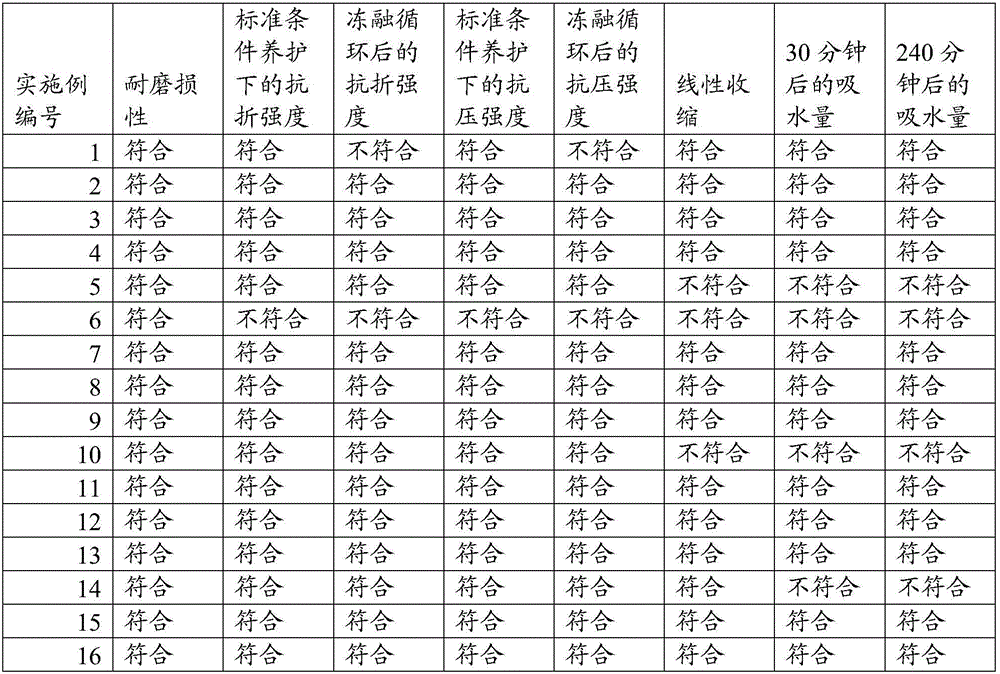

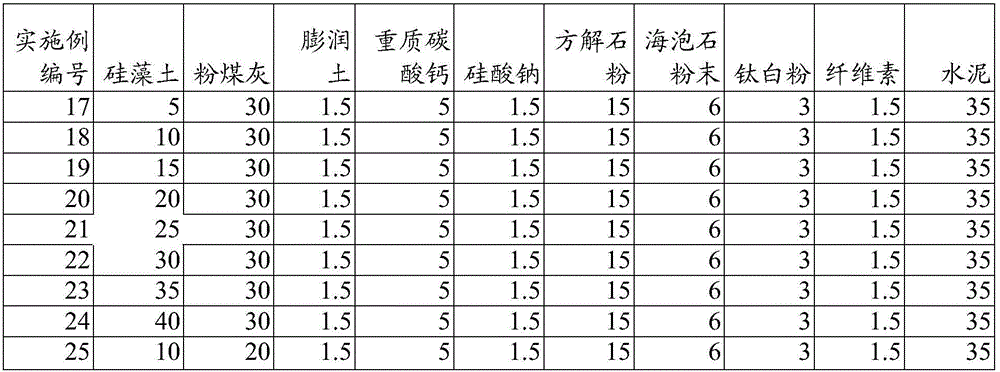

A kind of diatomite-fly ash type caulk composition and its application

ActiveCN105174840BImprove mixing uniformityHigh impact strengthCovering/liningsSolid waste managementSodium BentoniteCalcite

The invention provides a diatomite and fly ash type caulking agent composition and application thereof. The composition is composed of the following components by weight: (1) 20 to 40 parts of diatomite; (2) 10 to 15 parts of fly ash; (3) 0.5 to 2.5 parts of bentonite; (4) 4 to 6 parts of heavyweight calcium carbonate; (5) 1 to 2 parts of sodium silicate; (6) 10 to 20 parts of calcite powder; (7) 4 to 8 parts of sepiolite powder; (8) 2 to 4 parts of titanium dioxide; (9) 1 to 2 parts of cellulose, wherein the cellulose is at least one selected from the group consisting of hydroxyethyl cellulose, hydroxyethyl methyl cellulose and hydroxypropyl methyl cellulose; and (10) 30 to 40 parts of cement. The invention also provides the application of the composition in caulking operation. The cement-based caulking agent composition provided by the invention has various advantages of the diatomite, such as performances of the diatomite itself of light weight, sound insulation, wear resistance, etc.; meanwhile, the fly ash can be utilized to prepare the caulking agent in the invention, thereby reducing production cost of the caulking agent.

Owner:内蒙古东盛硅藻土科技创新产业园有限公司

Seamless silica gel conveying belt and manufacture method thereof

InactiveCN101638170AThere will be no phenomenon of sticking to the conveyed objectImprove thermal stabilityConveyorsTextiles and paperLiquid stateEngineering

The invention relates to a seamless silica gel conveying belt. The conveying belt forms a closed hybrid layer by a joint-free closed base belt and silica gel, an outer silica gel layer is designed onthe outer surface of the closed hybrid layer, and the closed hybrid layer and the outer silica gel layer are integrally molded into a whole in such a way that liquid silica gel is poured and spread onthe joint-free closed base belt. The manufacture method of the conveying belt comprises the following steps: (1) connecting the head and the tail of a plane strip base belt to be woven into the joint-free closed base belt; (2) mounting the joint-free closed base belt on a gel spreading machine; (3) starting the gel spreading machine, pouring the liquid silica gel on the joint-free closed base belt and spreading the liquid silica gel by a scraper on the gel spreading machine; (4) after the silica gel is solidified, abrading the outer surface of the outer silica gel layer by an abrading machine; (5) taking the product out of the machine and putting into a warehouse. The seamless silica gel conveying belt produced by the method has seamless integration and high strength and quality without sticking a conveying object and meets the requirement of a super wide and / or a super long product by a user. The manufacture method has simpler working procedures.

Owner:周炳光

Athletic Hammock

The invention is a garment which has the characteristic of supporting the male genitals in a cradle created by a suspension of cloth which does not pull towards the abdomen, but rather is itself supported by anchoring points at the waistline at the maximum width of the torso. This forms a sling-like platform which functions much like a hammock stretched between two trees, and the wearer's genitals rest on the hammock. The structure necessary to support the hammock is a form-fitting athletic short, with certain modifications to support the improvement of the invention.

Owner:BOSTON JAMES LLOYD

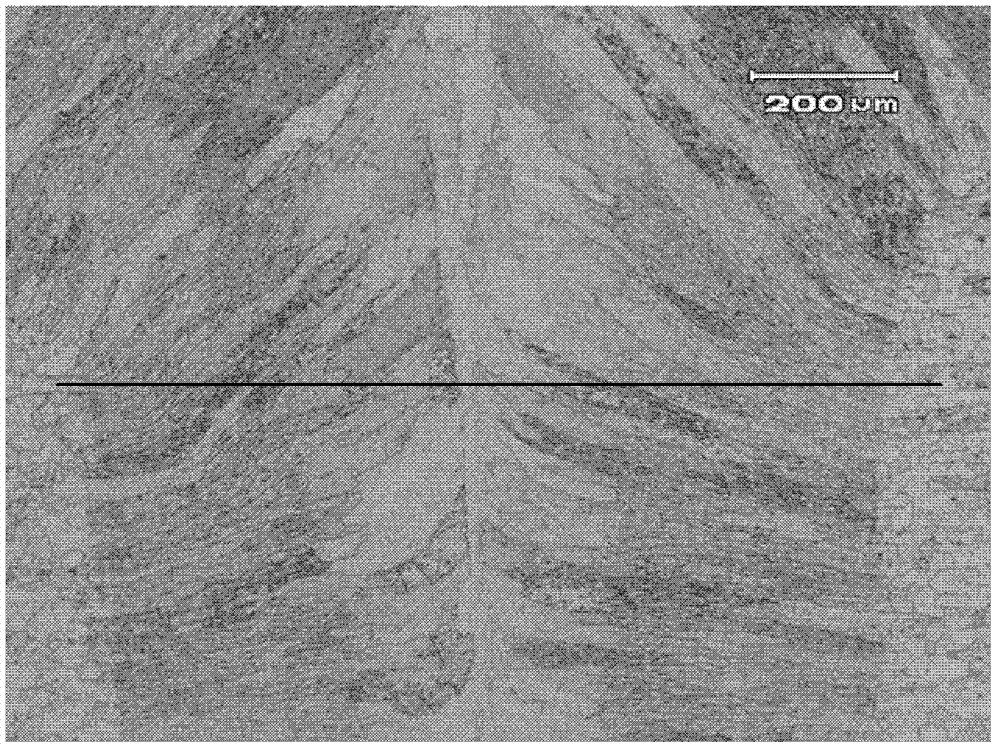

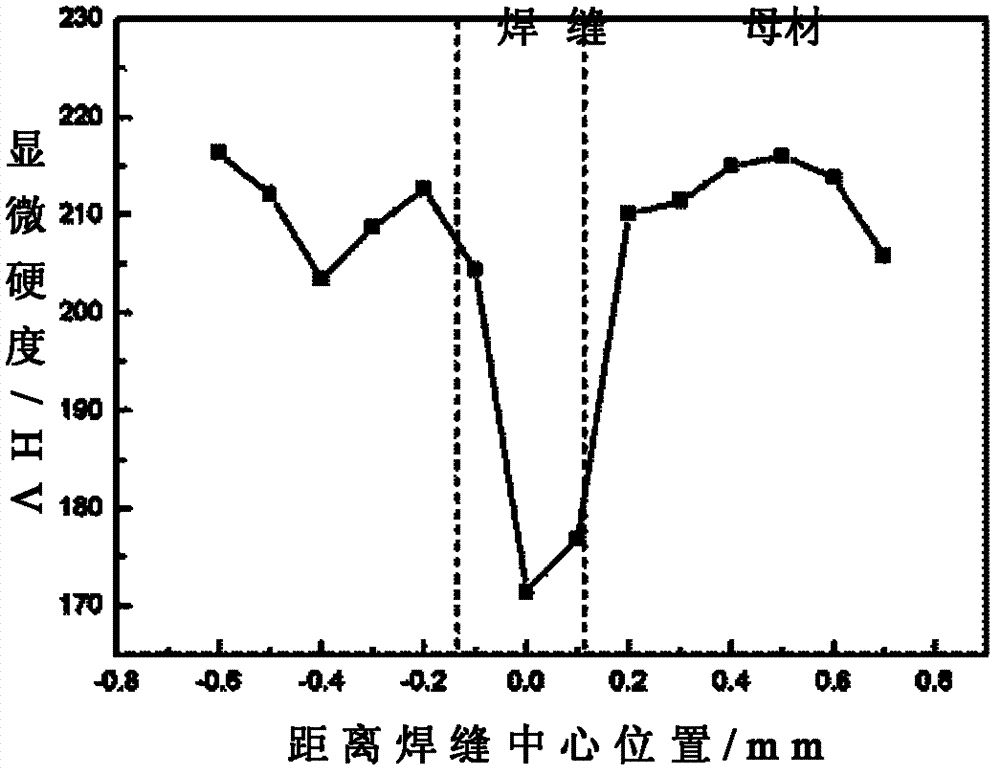

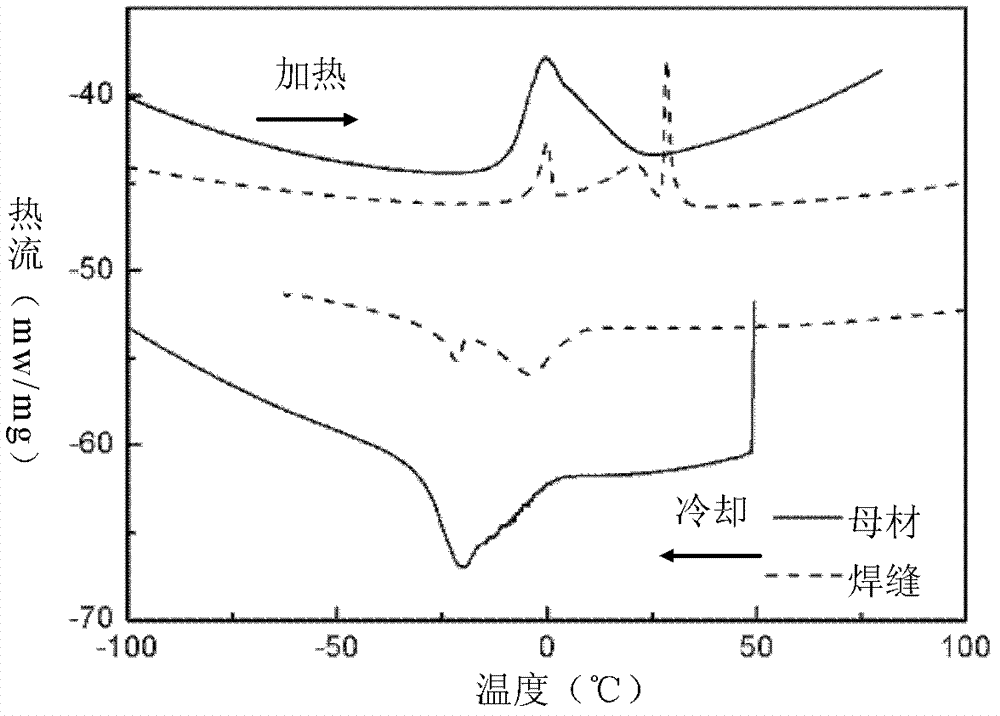

Ti-Ni based shape memory alloy vacuum electron beam connecting technology

InactiveCN103358013ASmall stretchReduced memory lossElectron beam welding apparatusHeat-affected zoneShape-memory alloy

The invention provides a Ti-Ni based shape memory alloy vacuum electron beam connecting technology. Concretely, vacuum electron beams are used for achieving connection of Ti-Ni-X alloy, wherein X can be Nb, Mo, Cu, Hf and the like. An existing connecting mode of Ti-Ni based shape memory alloy has the problems of being low in weld strength, thick and big in grain structure, prone to generating cracks and the like. The electron beams which are strong in penetrating power, high in energy transformation ratio and good in controllability are adopted as a welding hot source, therefore, time of the whole connecting process is shortened, a heat affected zone is reduced, weld defects are reduced, moreover, narrow weld seams can be obtained (the width is smaller than 1mm), mechanical performance and the memory effect of welded material are ensured to the maximum extent, after parameter optimization, the strength of a electron beam welding connector can reach over 75% that of parent material, and the memory effect can reach over 85% that of the parent material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

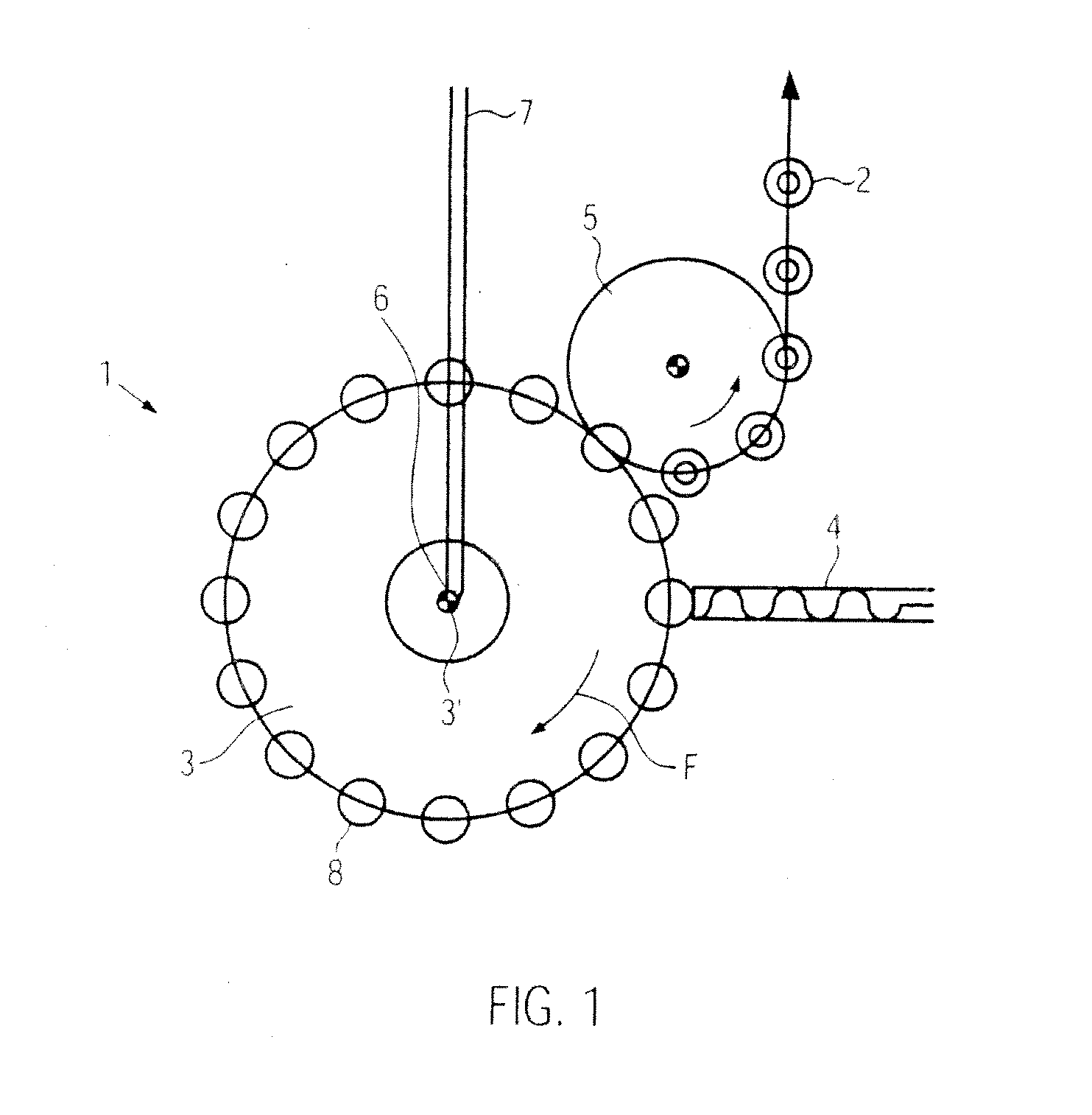

Device and Method for Manufacturing Plastic Containers

A device and a method for manufacturing plastic containers, where a preform is manufactured in a casting mold and finished in a blow mold, and to ensure a constructively simple realization and an improved temperature control, the casting mold and the blow mold are lined up to form a mold complex.

Owner:KRONES AG

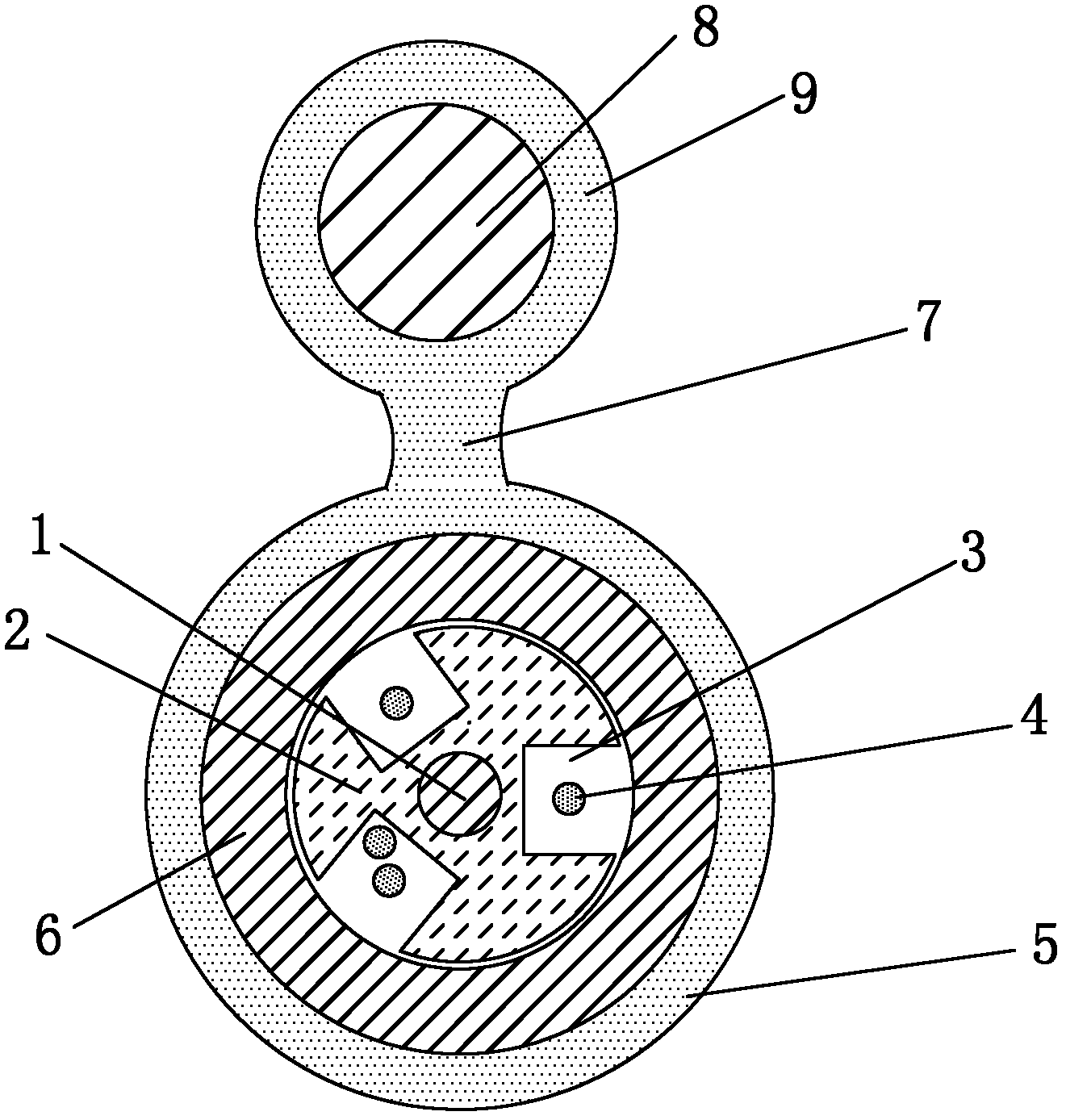

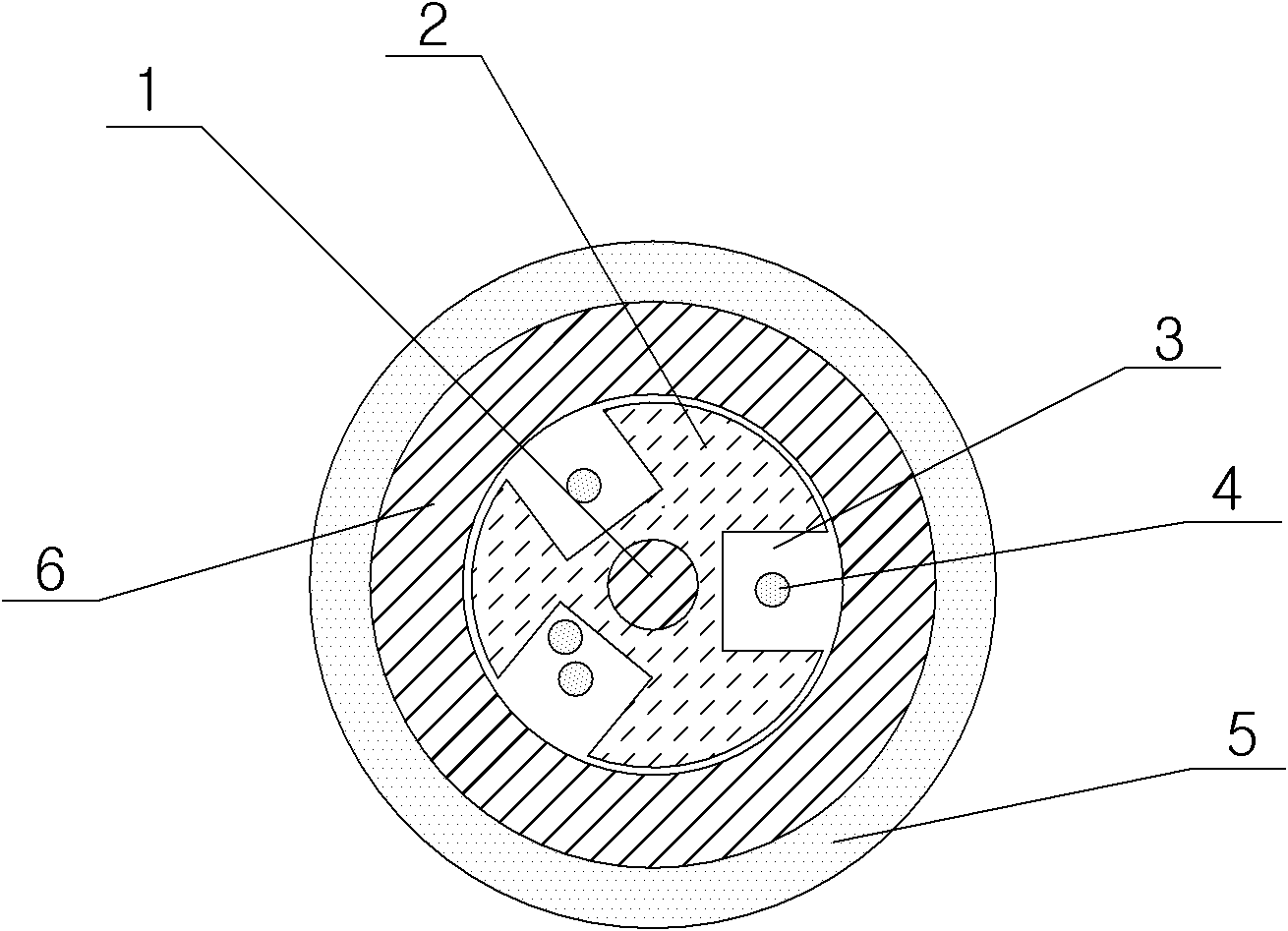

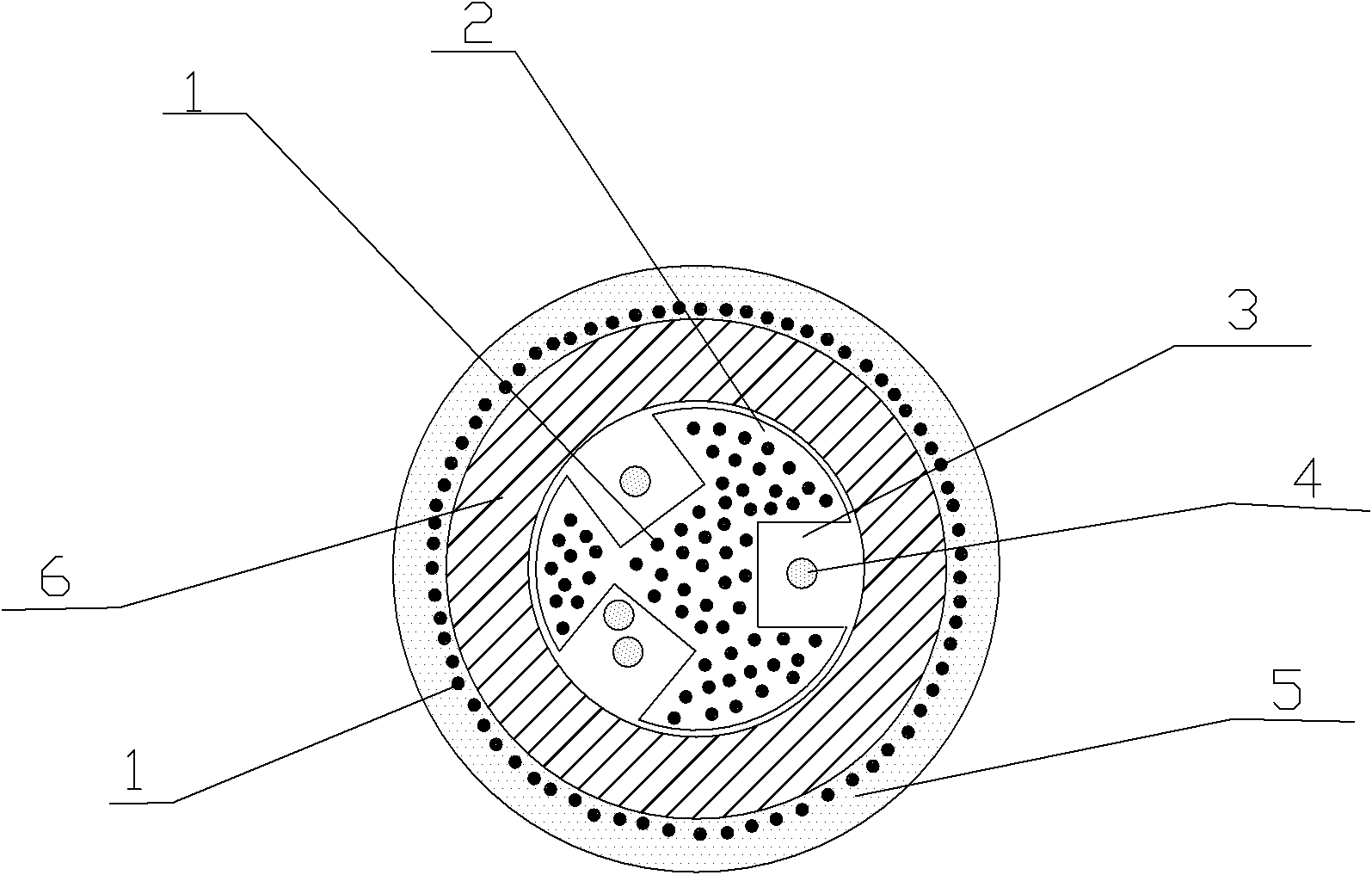

8-shaped low-addition decay type optical cable

InactiveCN103163606ASmall expansion coefficientReduce weightFibre mechanical structuresEngineeringHigh intensity

The invention discloses an 8-shaped low-addition decay type optical cable which comprises a cable core and a suspension wire, wherein the cable core is connected with the suspension wire through a suspension band, the cable core comprises a first reinforcement piece, a first outer protection layer and transmission optical fibers, the suspension wire comprises a second reinforcement piece and a second outer protection layer, the first reinforcement piece is made of non-metal high-strength fibers, a column body is arranged on the periphery of the first reinforcement piece, the column body is tightly combined with the first reinforcement piece, longitudinally extends along the first reinforcement piece, and is made of macromolecule materials, at least one groove is formed in the outer surface of the column body, at least one transmission optical fiber is placed inside the groove, the first outer protection layer which is made of the macromolecule materials is arranged on the periphery of the column body, and the second reinforcement piece is made of the non-metal high-strength fibers. The 8-shaped low-addition decay type optical cable has the advantages of being simple in structure, reasonable in design, low in cost, flexible in use mode, good in use effect, capable of effectively reducing additional decay changes, caused by environmental factors, of the transmission fibers, and wide in market application prospect.

Owner:XIAN JINHE OPTICAL TECH

Additional attenuation type optical cable for sensing

InactiveCN102486557ASmall stretchSmall expansion coefficientFibre mechanical structuresConverting sensor output opticallyUltrasound attenuationEngineering

The invention discloses an additional attenuation type optical cable for sensing. The optical cable comprises a reinforcement member, an over sheath, a cylinder and transmission fibers. The cylinder, which is arranged on the external surface of the reinforcement member, is tightly combined with the reinforcement member and extends vertically along the reinforcement member; at least one groove is arranged on the surface of the cylinder and at least one transmission fiber is placed in the groove; and the over sheath is arranged at outer surface of the cylinder. According to the invention, the provided optical cable has advantages of simple structure, reasonable design, low cost, flexible using mode and good using effect; and moreover, changes of additional attenuation of transmission fibers in an optical cable can be effectively eliminated, wherein the changes are caused by an environmental factor. Therefore, the provided optical cable has wide market application prospects.

Owner:XIAN JINHE OPTICAL TECH

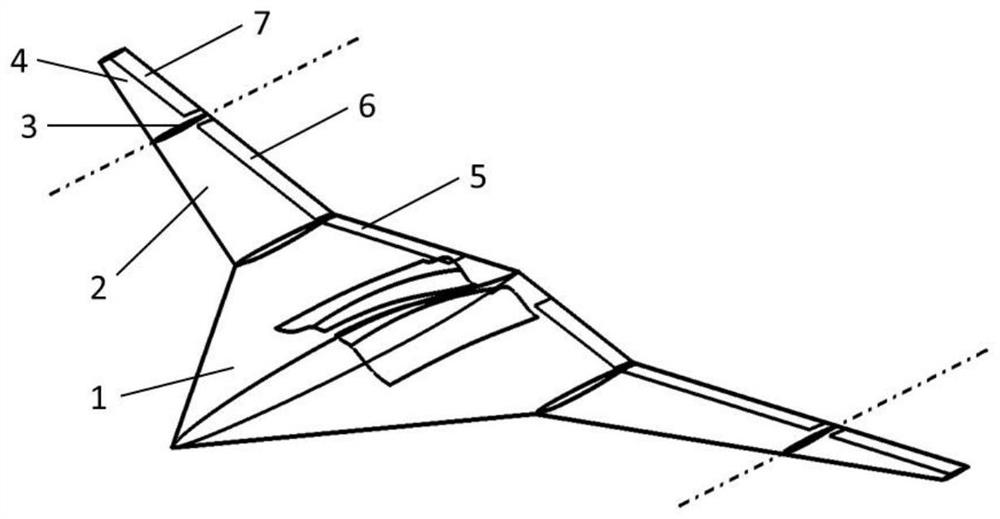

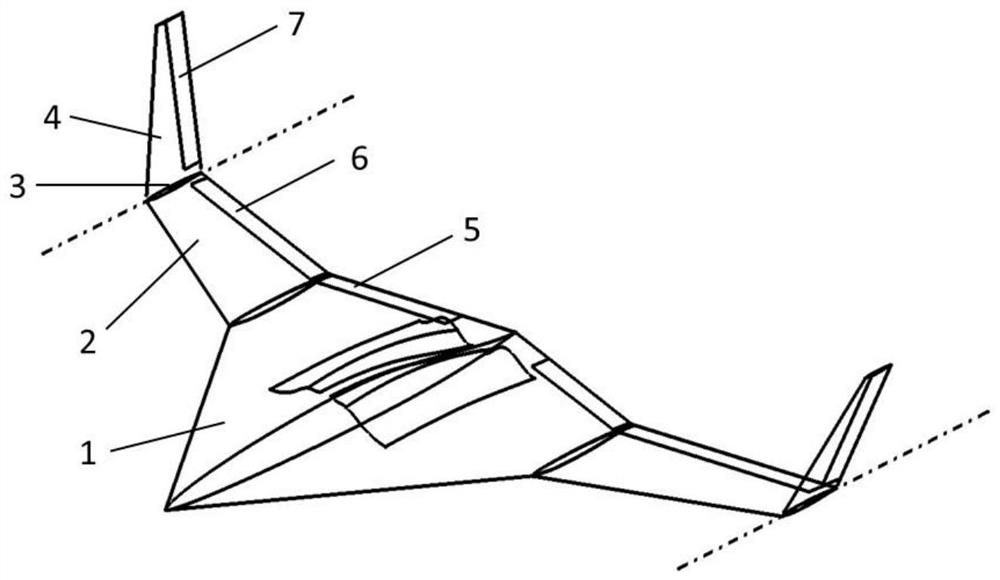

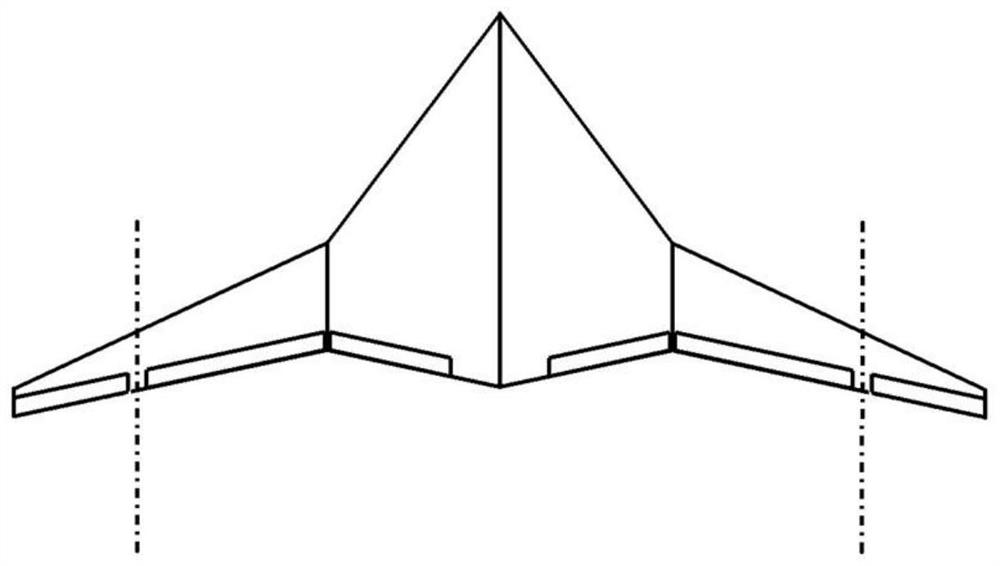

Flying wing layout wide-speed-domain pneumatic operation stability characteristic structure

InactiveCN112606995AReduce areaSolve the problem of layout heading stabilityWing shapesWing adjustmentsAviationLeading edge

The invention belongs to the technical field of aviation aircraft design, and discloses a flying wing layout wide-speed-range aerodynamic operation stability characteristic structure, a wing body and flying wing layout integrated aircraft body, double wings of the aircraft body adopt double sweepback layout, the wings are divided into inner wing sections and outer wing sections, the inner wing sections are wing sections fused with the aircraft body, and the sweepback angles of the front edges of the inner wing sections are large; the sweepback angle of the front edge of the outer wing section is small; the outer wing section is further divided into an outer wing section fixing section and an outer wing section foldable section, the outer wing section fixing section is fixedly connected with the inner wing section, the outer wing section foldable section is in shaft driving connection with the outer wing section fixing section through an outer wing section rotating shaft, and the outer wing section foldable section rotates relative to the outer wing section rotating shaft so as to be folded upwards. When the structure is applied, different aerodynamic and operation stability performance requirements of low-speed take-off and landing, high subsonic speed cruise and supersonic speed cruise design points can be considered.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

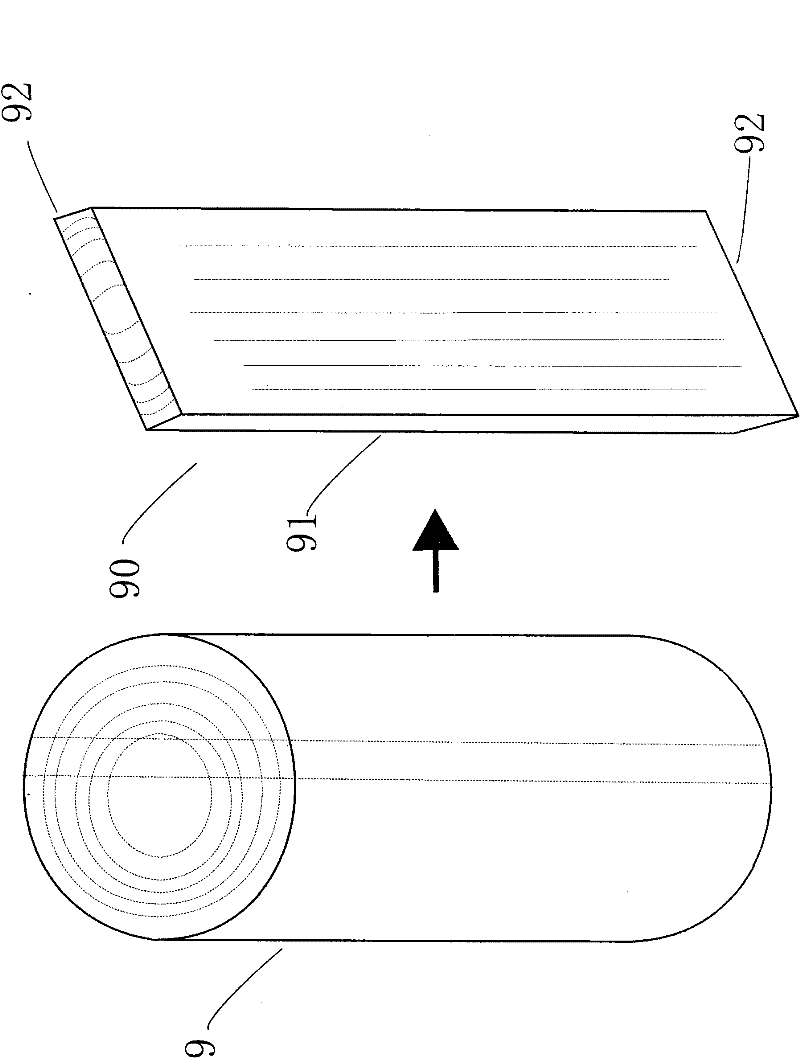

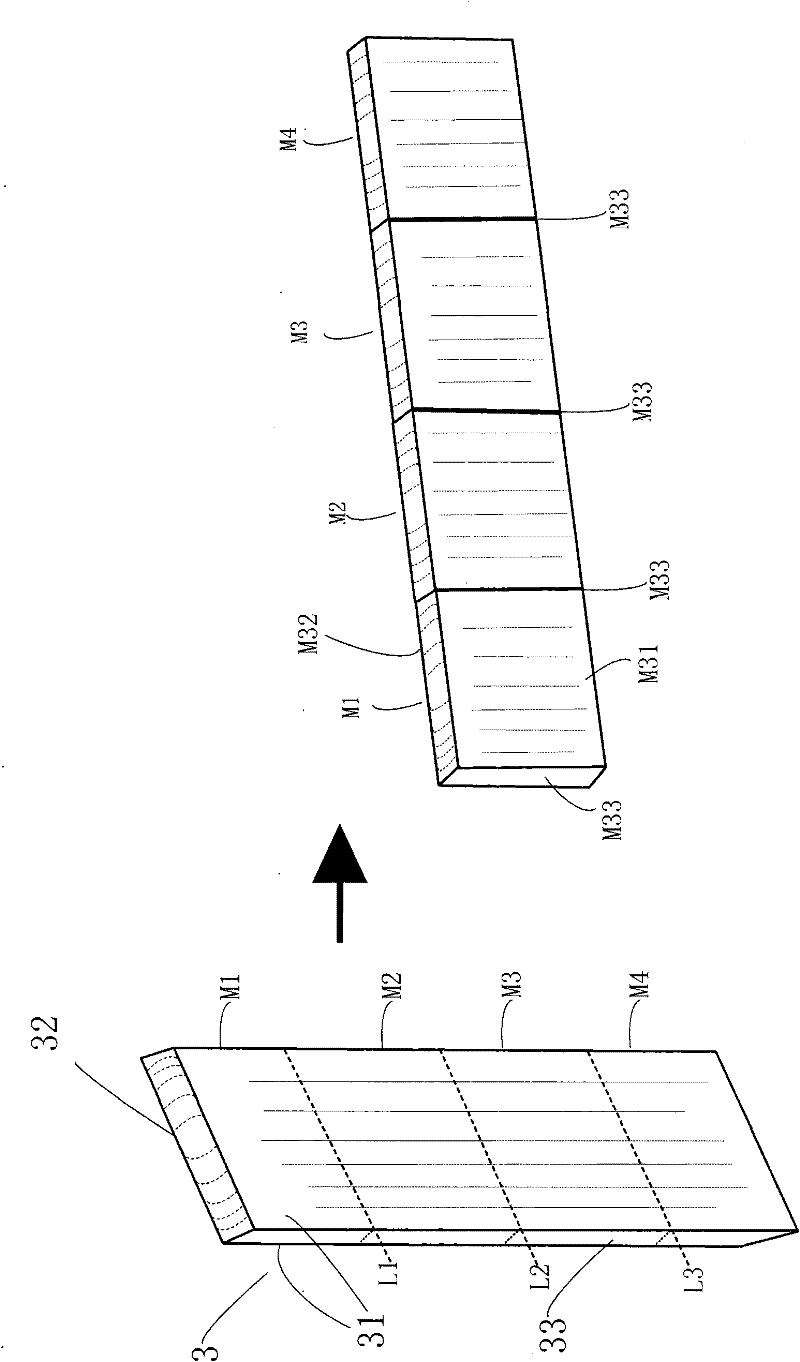

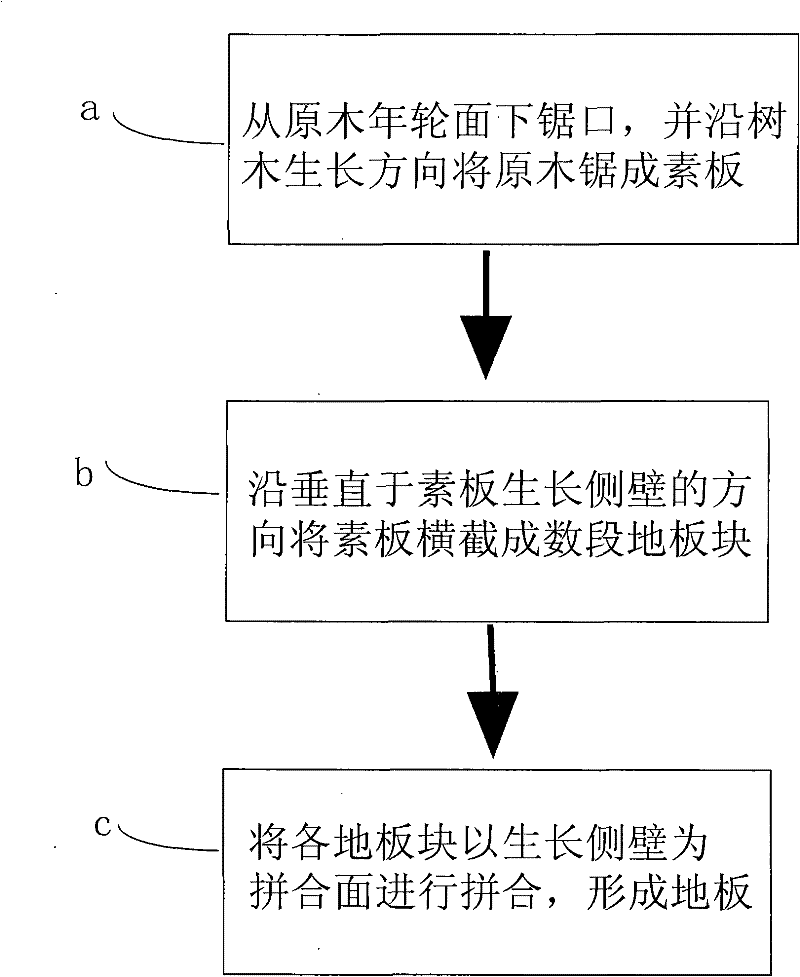

Anti-stretch solid wood floor and manufacturing method thereof

The invention relates to a stretch-resistant solid wood floor and a manufacturing method thereof. The solid wood floor includes a body, which is composed of several floor boards made of logs, and the floor boards have two upper and lower board surfaces opposite to each other. And two sets of opposite side walls, the two panels are parallel to the tree growth direction, wherein a set of side walls formed along the tree growth direction is the splicing surface, and a set of side walls formed along the tree ring direction is the annual ring side Each of the floor boards is joined together to form the floor by means of corresponding splicing surfaces, and each annual ring side wall is located on both sides of the floor. In this way, the expansion and contraction of trees in the growth direction is much smaller than that in the growth ring direction, so that the formed floor is not easy to expand and deform in the width direction. To absorb the expansion and deformation of the floor in the length direction, so as to avoid defects such as warping, deformation, and arching after the floor is paved.

Owner:李濬筬

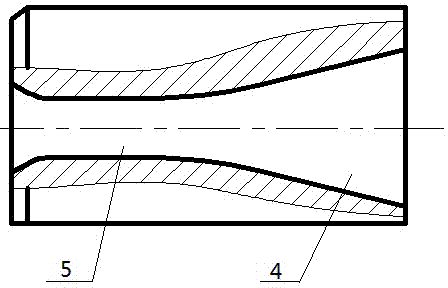

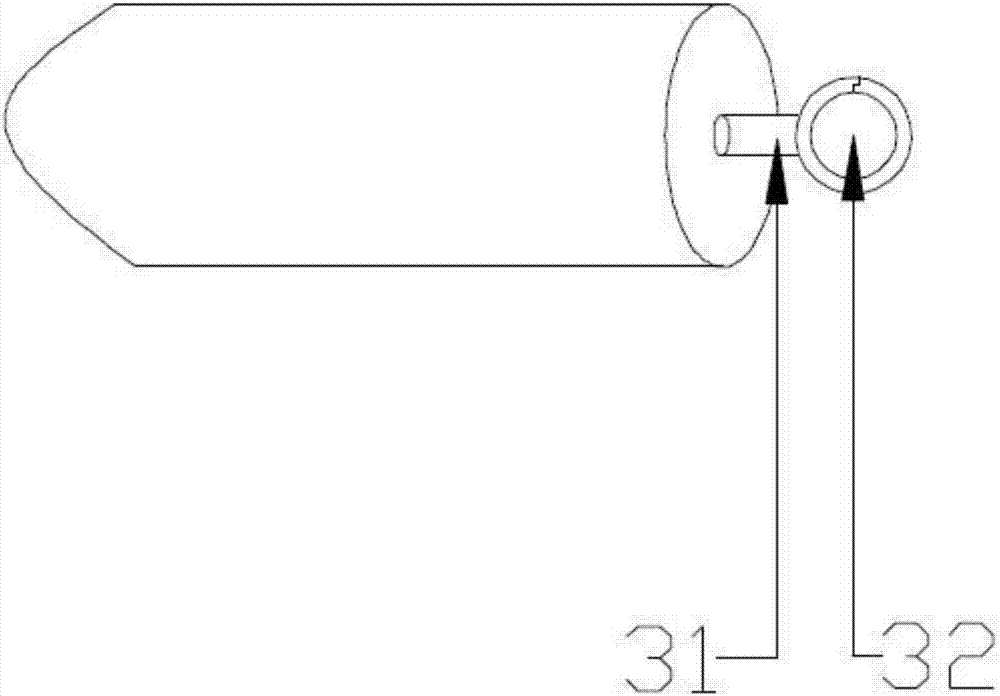

Method for manufacturing cold-drawing formed sealing pad

ActiveCN103612122AGood size consistencyImprove pass rateOther manufacturing equipments/toolsSteel beltManufacturing engineering

The invention discloses a method for manufacturing a cold-drawing formed sealing pad. The method comprises the following steps that firstly, a strip is manufactured, wherein one end of a steel belt (1) is coiled, and a braided rope (2) is cut off according to the length of the steel belt (1) and placed in the coiled steel belt to be wrapped tightly; secondly, a drawing die is fixed to a lathe; thirdly, drawing die formation is carried out, wherein the strip partially makes contact with the drawing die, the included angle of 7-15 degrees is formed between the strip and the center line of the drawing die, and then a part is drawn and manufactured in the drawing die of the lathe; fourthly, the part is straightened. In the step of drawing die formation, the lathe is in a self-acting feed mode, the strip can pass through the drawing die at a constant speed, the cross section of the strip is firstly drawn to be circular, and then the strip is drawn to be the part in a needed shape. Parts machined according to the method are good in size consistency, the oversize phenomenon barely occurs, and the qualified rate of the parts is high.

Owner:AVIC STANDARD PARTS MFG

Application of cellulose to occasion of graphite grinding particles

ActiveCN107213698AImprove separation qualityImprove protectionFiltration separationCelluloseGraphite particle

The invention discloses application of cellulose in an occasion of graphite grinding particles, and in particular relates to the technical field of grinding oil recovery and filtration. Specifically, the cellulose is used as a filter aid during recovery and filtration of graphite grinding oil for grinding, the cellulose controls the content of fine graphite particles in the grinding oil, the usage period of the grinding oil is prolonged, the reasonable additive amount is increased, the usage cost of equipment and the environment pollution are reduced, and the production efficiency is improved.

Owner:江苏威泽智能科技股份有限公司

Force feedback closed-loop control composite bonding device

ActiveCN110034032ASmall stretchRelieve stressSolid-state devicesSemiconductor/solid-state device manufacturingLoop controlMagnetostrictive actuator

The invention discloses a force feedback closed-loop control composite bonding device. A micro-moving device is driven by a macro-moving device to perform transverse translation and vertical translation; the micro-moving device comprises a giant magnetostrictive actuator, and the length of the giant magnetostrictive actuator is changed to drive a mounting rod to move, and the telescopic amplitudeof the giant magnetostrictive actuator is very small, so that the giant magnetostrictive actuator is used for driving the mounting rod to accurately move in a small range; a strain gauge is used for detecting the contact force between the mounting rod and a substrate; the strain gauge is used for providing feedback for the micro-moving device, and the telescopic amount of the giant magnetostrictive actuator is controlled according to detection signals; when a chip is relatively far away from the substrate, the macro-moving device moves quickly, the macro-moving device is stopped when reachinga relatively close distance from the substrate, the micro-moving device drives the chip to move, and when the chip contacts the substrate, a contact force is generated, and feedback is formed throughthe contact force, so that larger pressure is avoided on the chip; and the macro-moving device or the micro-moving device is used for driving in different stages of mounting, so that the contact force is accurately controlled on the basis of guaranteeing the mounting efficiency, and the chips are prevented from being crushed.

Owner:GUANGDONG UNIV OF TECH

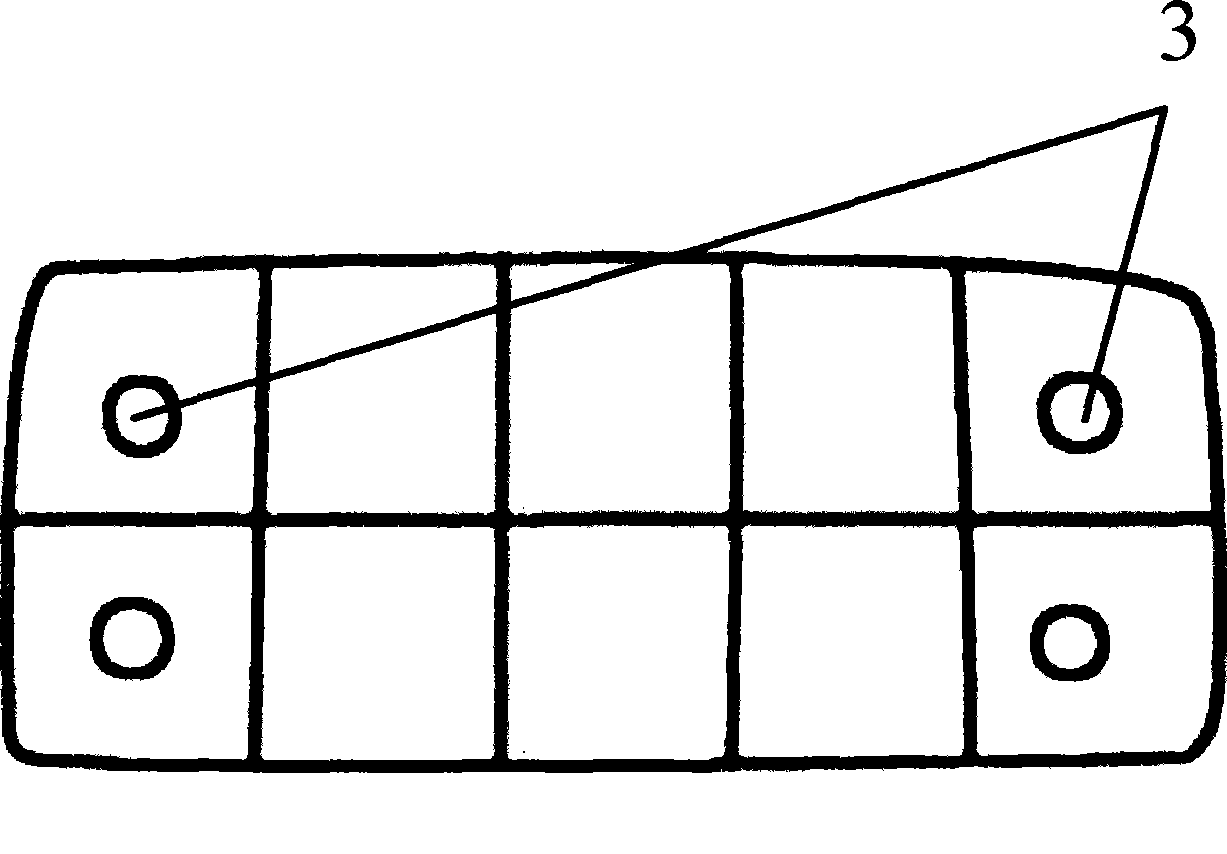

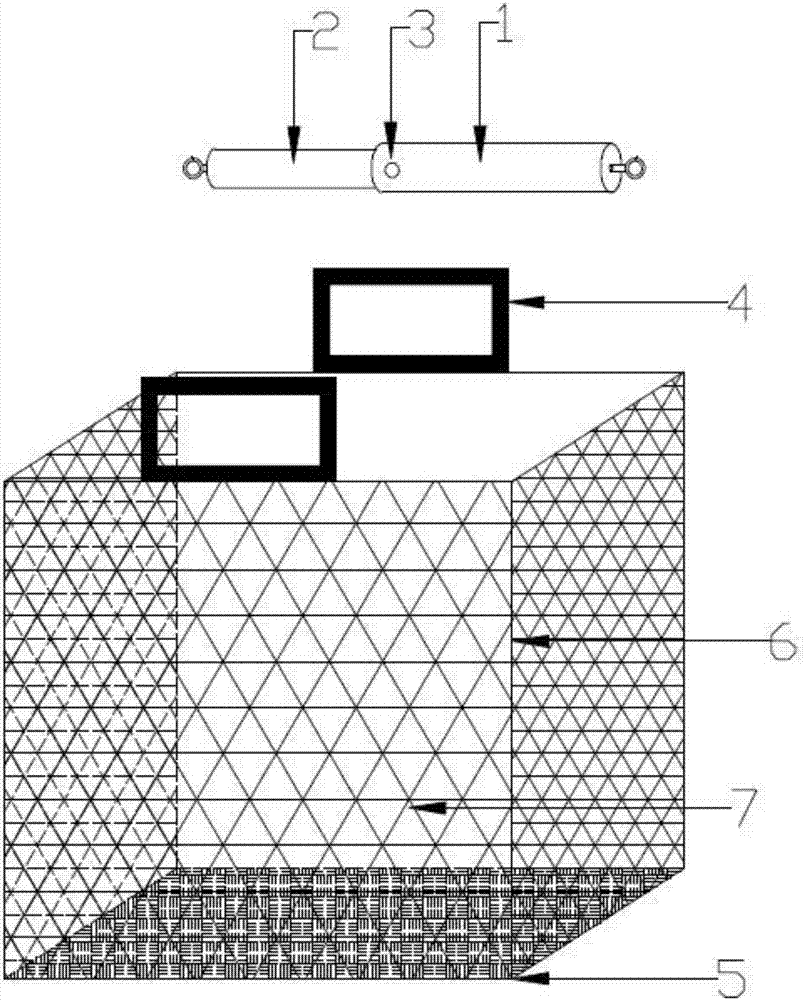

Packaging mesh bag

The invention relates to a packaging mesh bag and belongs to the technical field of shopping bags. The packaging mesh bag comprises a plurality of positioning rods (3), a plurality of support rods (5), a plurality of vertical rods (6) and breathable meshes (7), wherein the plurality of positioning rods (3), the plurality of support rods (5) and the plurality of vertical rods (6) are telescopic rods; the plurality of support rods (5) are fixedly connected with each other from head to tail to form a polygon; a vertical rod (6) is vertically and fixedly connected with each junction between the plurality of support rods (5); the support rods (5) and the vertical rods (6) are sleeved with the breathable meshes (7); two ends of each positioning rod (3) are fixedly connected with two corresponding side walls of each breathable mesh (7). The packaging mesh bag is a telescopic structure and is convenient to store and small in occupied area; when the packaging mesh bag is used, the positioning rods are used for expanding the breathable meshes, so that the breathable meshes cannot squeeze commodities under the action of tension of hands; the situation that the commodities are squeezed and damaged can be avoided; the commodities can be fastened on the positioning rods, so that the commodities can be neatly and uniformly stored.

Owner:JURONG WANFUDA ARTS & CRAFTS PLANT

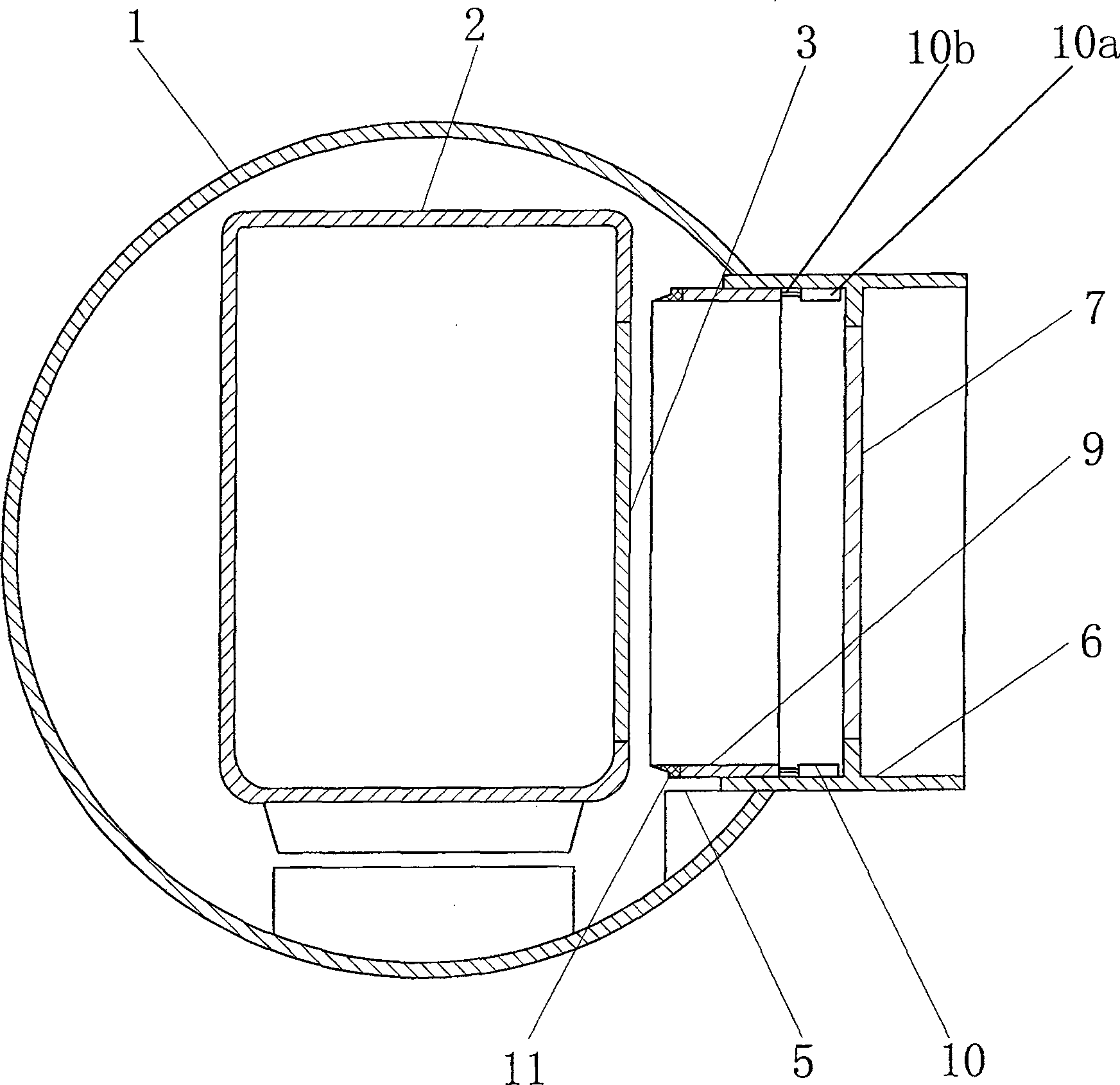

Assembling corridor for vacuum pipe traffic

InactiveCN100484812CReduce volumeImprove operational efficiencyRailway tunnelsRailway componentsEngineeringPneumatic valve

The invention discloses a plugging corridor used for the vacuum pipe traffic, which comprises: a tube-shape fixed corridor (6) is equipped in station department with one end embedded in a vacuum pipe (1), and another end is connected with the station platform, junction of the fixed corridor (6) and vacuum pipe (1) is sealed; a telescopic corridor (9) is sealing nested in anterior inner wall of the fixed corridor (6); One end of the flexible mechanism (10) is linked with the telescopic corridor (9), and another end is connected with the fixed corridor (6), and the front end of telescopic corridor (9) fits the peripheral shape around the door (3) of the train carriage (2) and is equipped with sealing strip (11); The middle rear part of the fixed corridor (6)is equipped with a sealing door (7), one pneumatic valve (8)is provided on the sealing door (7) or the fixed corridor (6) wall before the sealing door (7). Within a short period of time, it can accomplish getting on or off of passengers in vacuum pipe, and improves the running efficiency of train with little power consumption and simple structure.

Owner:SOUTHWEST JIAOTONG UNIV

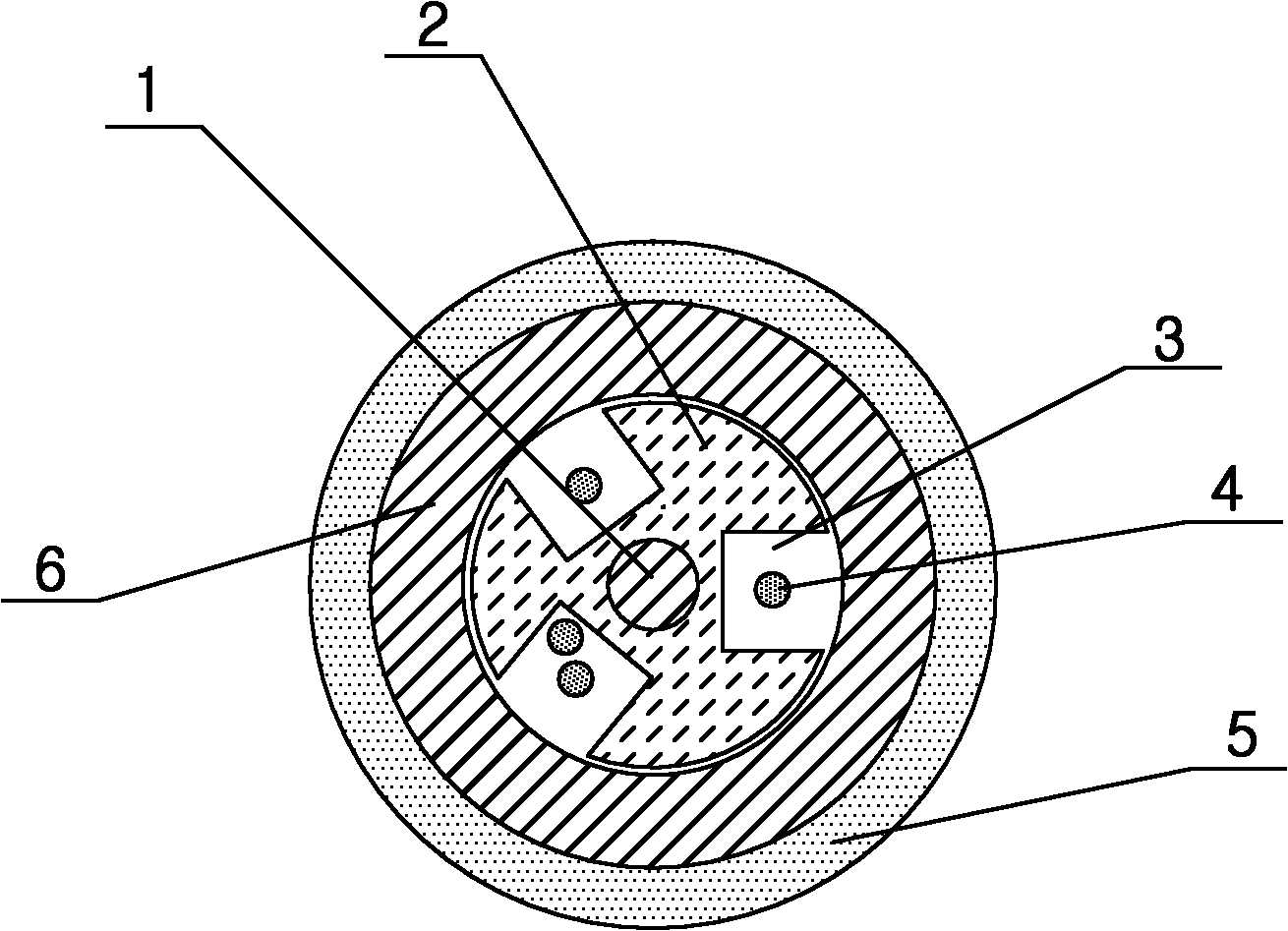

Vacuum piston device

A vacuum piston device used in ink supply system, includes: a cylindrical piston body; a conic bulge set at a central area of a frontal end face of the cylindrical piston body; and a piston lid mounted at a rear end face of the cylindrical piston body; at least one exhaust pore is set on the frontal end face around the conic bulge and all the way goes through to the rear end face; an annular groove is formed on the rear end face in such a manner that inner and outer walls of the annular groove project out from the rear end face; the piston lid is for covering the annular groove, and eventually for sealing the whole piston.

Owner:NORTH AMERICA WALES GROUP INT +1

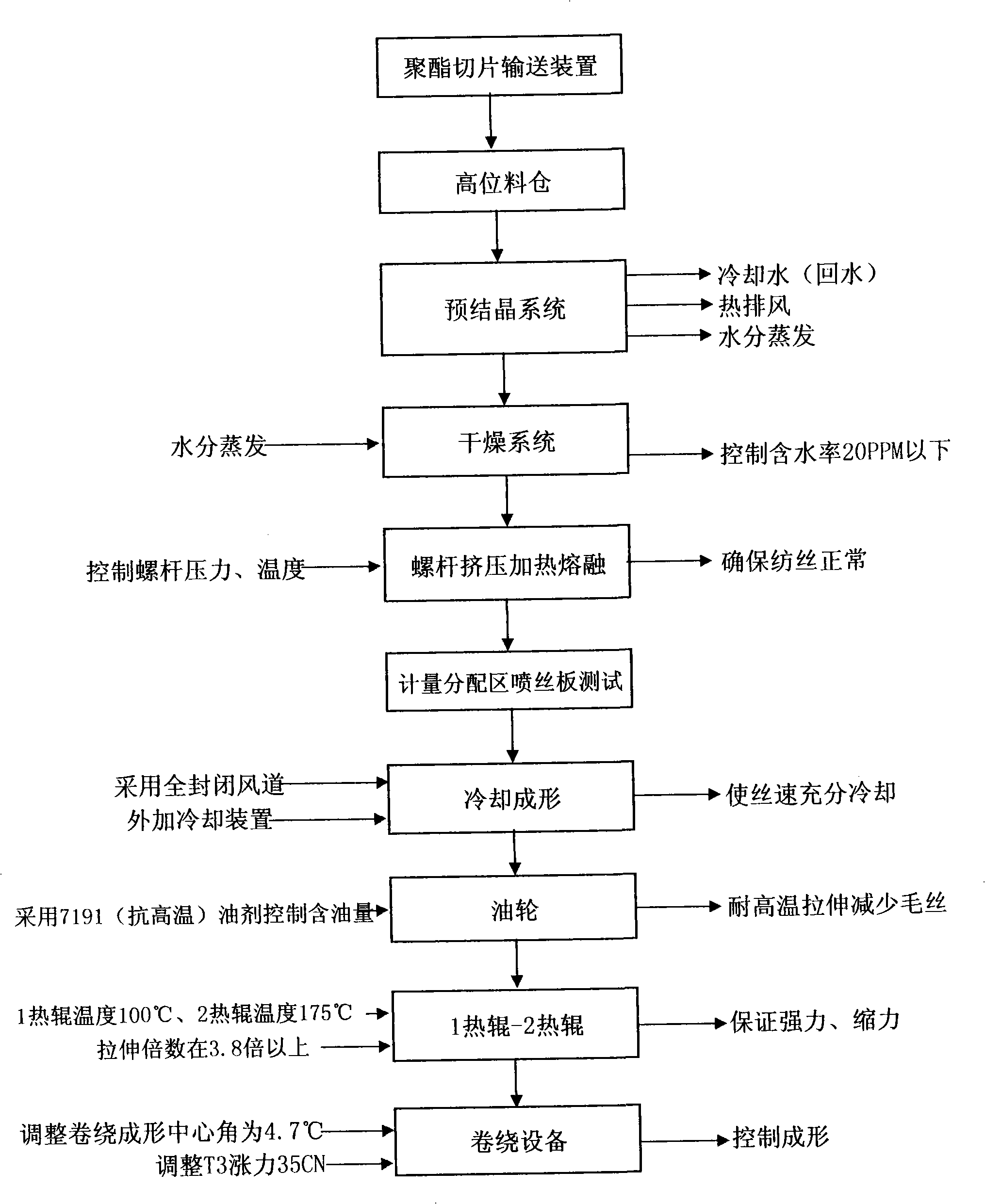

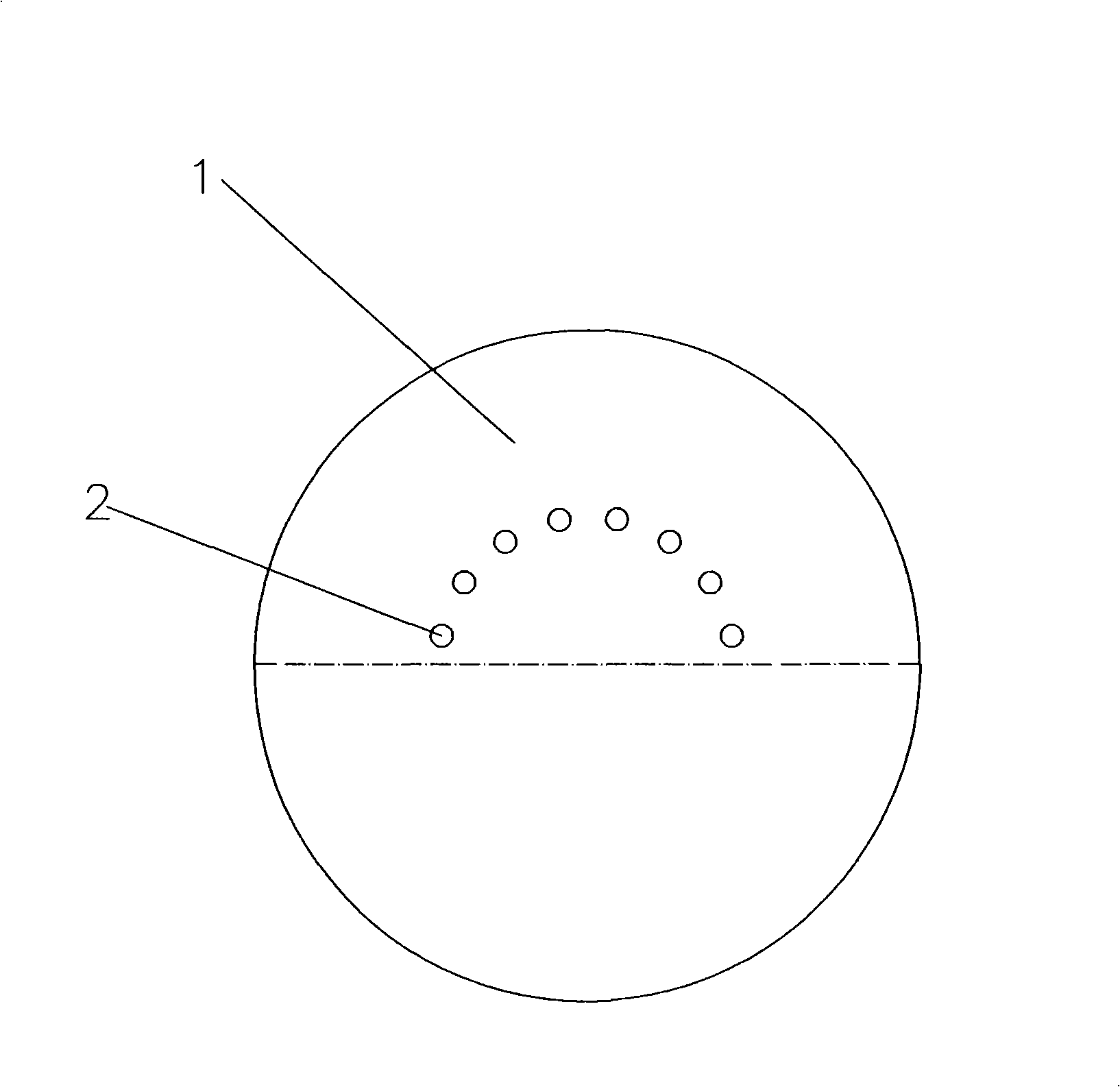

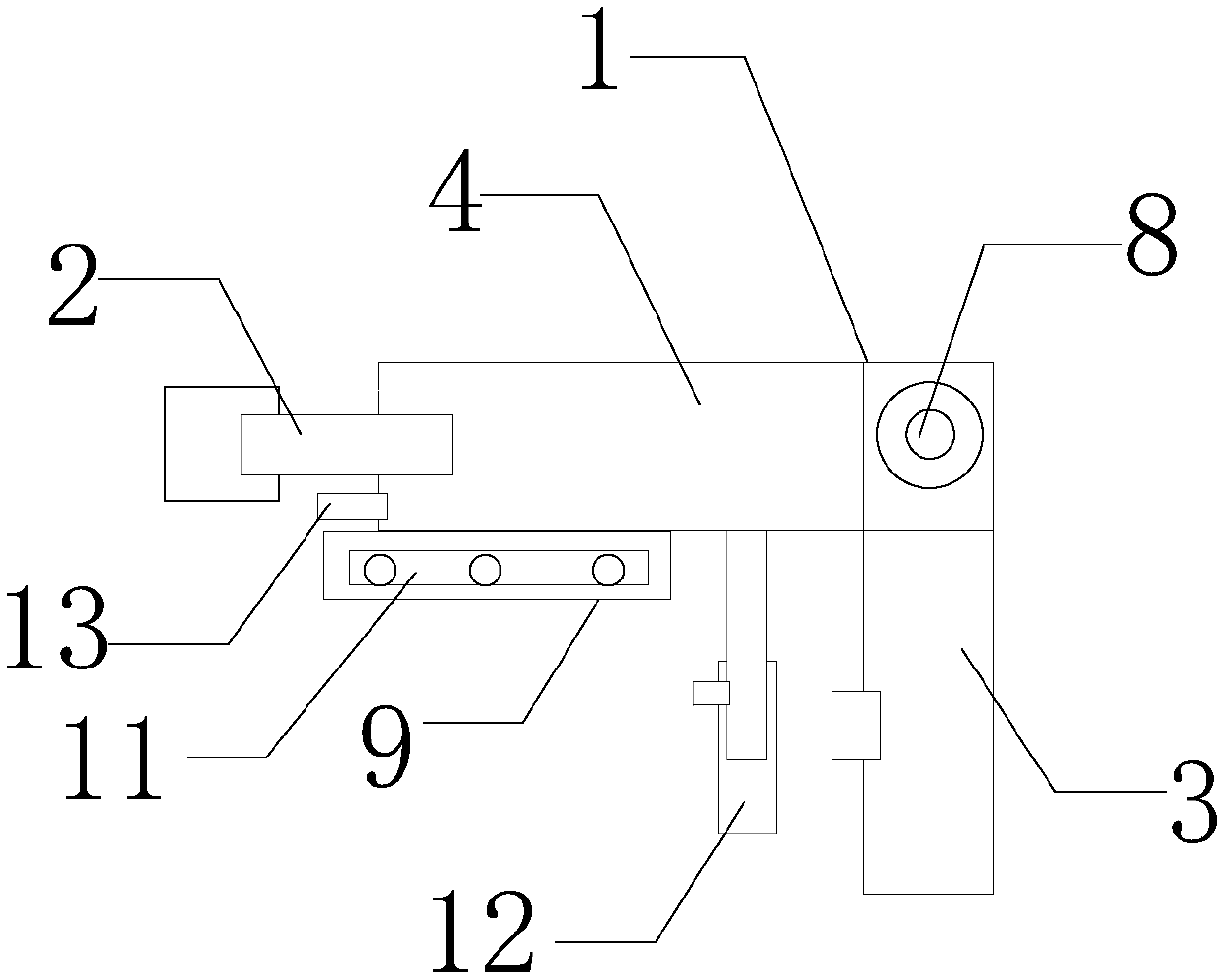

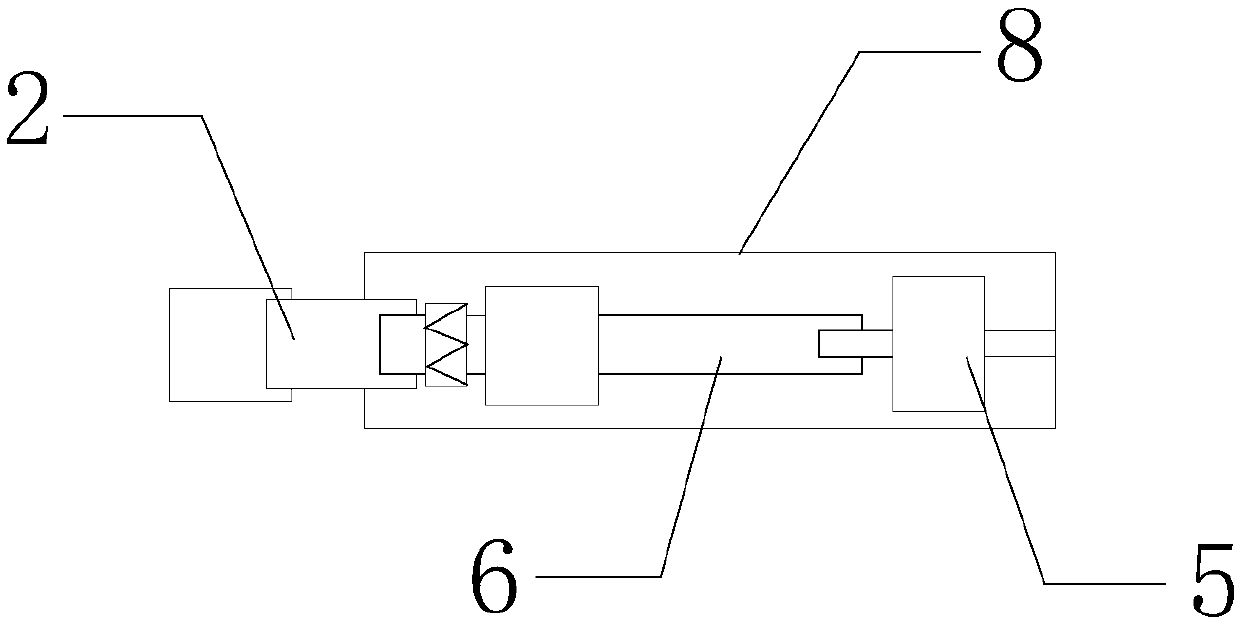

Hart dacron thread and its production technique

The invention designs hart polyester yarns, wherein, specification parameters thereof are: the dezitex of a single tow is 308DTEX; the joint stock number is 16; the single fiber number is 19.25DTEX; the strength is 5.3CN / DTEX; the elongation is 13 percent; and the boiling water shrinkage is 3.5 percent. The technique for manufacturing the hart polyester yarns designed by the invention mainly comprises the procedures of slice transportation, drying, screw spinning box spinning, stretching, and convolution, and the like; the spinning viscosity loss is controlled to be less than or equal to 0.01dl / g; the screw pressure of the screw spinning box is controlled at 12 plus or minus 0.5MPA; the spinning speed is 4200m / min; spinneret orifices of a spinneret plate are arranged in U shape; high temperature resistant oil is adopted for the oiling technology and the oil tanker speed is 15r / min; a totally enclosed air duct is adopted for a lateral blow cooling device which is cooled by an additional cooling device; the drafting multiple during all-drafting involution is controlled to be more than 3.8 times; the temperature of a first hot roller is set to be 100 DEG C; the temperature of a second hot roller is set to be 175 DEG C; an involution forming central angle is controlled to be 4.7 degrees; and the molding tension for controlling a spinning cake is controlled to be below 35CN. The hart polyester yarns obtained in the invention is terylene filament between industry yarn and apparel screen. The hart polyester manufacturing technique of the invention conquers former technical difficulty that the hart polyester yarns with the specification can only be manufactured by using industry yarn equipment or by two-step textile.

Owner:TONGXIANG ZHONGWEI CHEM FIBER

Portable household electric drill

InactiveCN107717008AExtended service lifeFlexible movementPortable drilling machinesElectricityElectric machinery

The invention discloses a portable household electric drill, which includes a drill body and a drill clip. The drill body includes a handle and a placement cavity. A motor is installed in the placement cavity. Blocks and metal gears, the inner wall of the drill clip is provided with a scratch-resistant layer, and the top of the handle is connected to a placement cavity through the shaft body, a frame-shaped frame is installed at the bottom of the outer side of the cavity, and a folding organ protective cover is installed in the frame-shaped frame. Both ends of the foldable organ protective cover are fixed with hard plates, a support positioning rod is installed under the storage cavity, a limit block is installed at the front end of the storage cavity, and a central control circuit board is installed in the storage cavity, and the central control circuit board is electrically connected to a The signal transmission device is connected with a speed regulating device, and the inner wall of the drill bit holder is provided with shrapnel. The invention has the characteristics that the drill bit can work at multiple angles, has strong flexibility, can optimize the surrounding environment at the same time, and can ensure the safety of workers when replacing the drill bit.

Owner:徐应盈

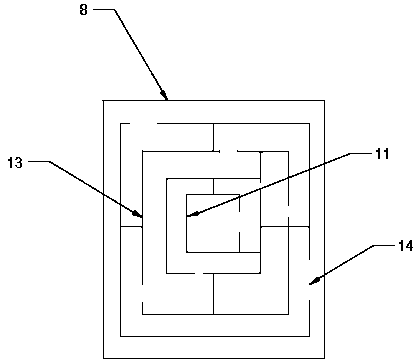

Wooden puzzle maze candy bottle

The invention discloses a wooden puzzle maze candy bottle, which comprises a candy bottle. A lighting lamp is installed at the bottom of the candy bottle. The lower half of the lighting lamp is equipped with a battery. A first Bottom plate, the upper surface of the first bottom plate is connected with a spring, the other end of the spring is connected to the lower surface of the bearing plate, the first bottom plate and the bearing plate are arranged parallel to each other, and the spring is located between the first bottom plate and the bearing plate In the middle position, the mouth of the candy bottle is equipped with a second bottom plate, the center of the second bottom plate is provided with a through opening, the second bottom plate and the first bottom plate are arranged parallel to each other, and the upper surface of the second bottom plate is installed A labyrinth channel, a labyrinth entrance is arranged at the center of the labyrinth channel, and the labyrinth entrance is connected with a port to form a channel. The present invention arranges a spring and a lighting lamp inside the candy bottle, realizes the functions of picking up the candy and illuminating it, and has the advantages of simple structure and good use effect.

Owner:鄢海军

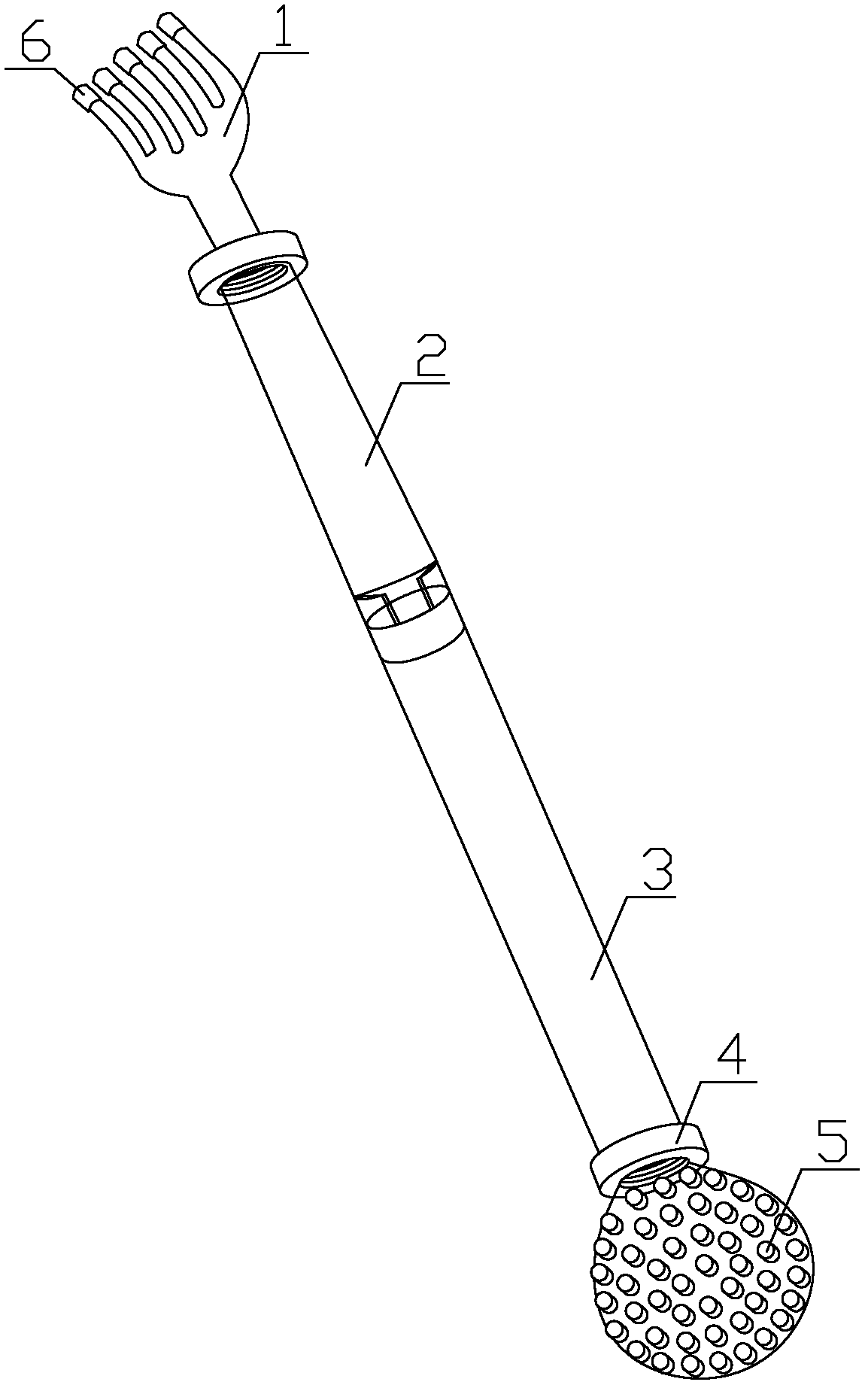

Multifunctional massager

The invention discloses a multifunctional massager which comprises massage bodies and a handle. The handle is composed of a first handle and a second handle. One end of the first handle is connected with a claw-shaped massage body, one end of the second handle is connected with a hammer-shaped massage body, the first handle is in thread connection with the claw-shaped massage body, and the second handle is in thread connection with the hammer-shaped massage body. A grabbling sleeve is arranged on a claw head of the claw-shaped massage body, and an elastic column-shaped body is arranged on the hammer-shaped massage body. The handle of the multifunctional massager is formed by two parts and is relatively long. An arm is not needed to be stretched highly, the stretching and contracting range of the arm is small, strength is saved, a massage effect is good, and utilization is quite convenient. The handle of the multifunctional massager can be divided into two handles which are respectively provided with a massage body, so people can conveniently massage a body by hand through the massager simultaneously so as to improve massage efficiency. A rubber body is arranged on surfaces of the massage bodies, so damage to skin is not easily caused when the body is massaged.

Owner:罗会财

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com