Assembling corridor for vacuum pipe traffic

A technology of vacuum pipelines and corridors, which is applied in the field of rail transit and vacuum pipeline transportation, which can solve the problems of bulky loading and unloading and partition equipment, complicated operation, and high energy consumption, and achieve short train stay time at the station, small size, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

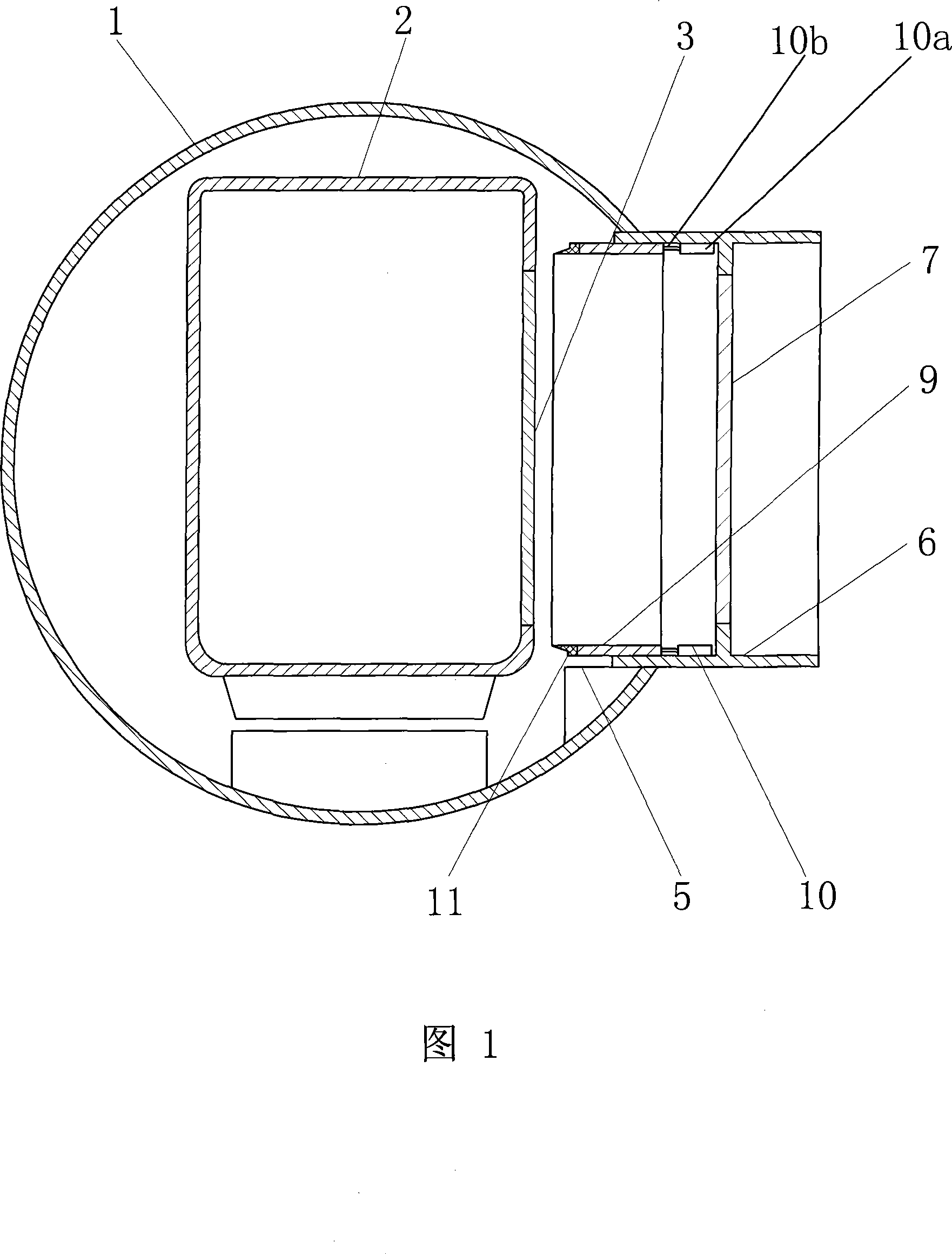

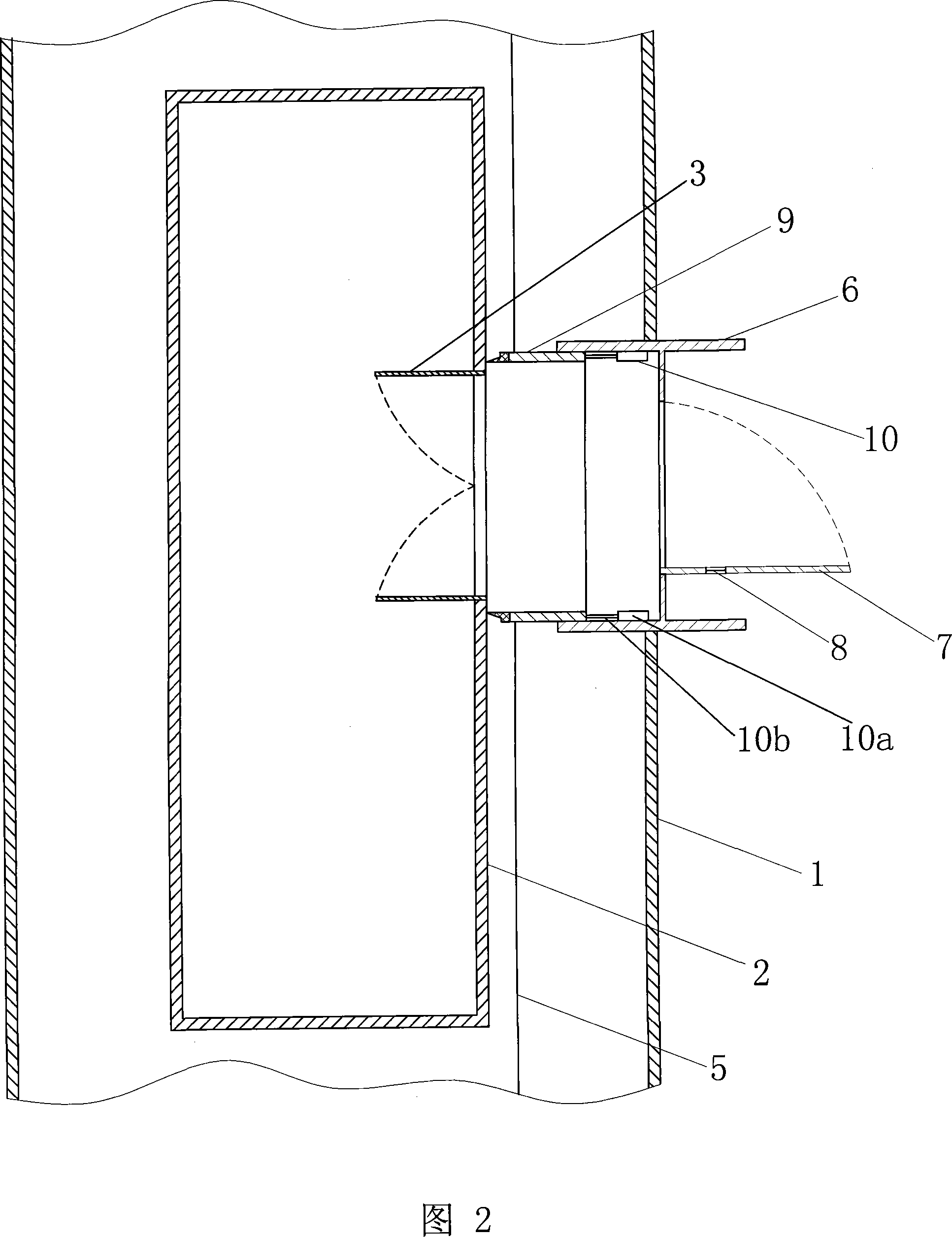

[0017] Figures 1 to 2 show that a specific embodiment of the present invention is: a connection corridor for vacuum pipeline traffic, which consists of: a cylindrical fixed corridor 6 with one end embedded in the vacuum pipeline 1 is provided at the station , the other end of the fixed corridor 6 is connected to the station platform, and the connection between the fixed corridor 6 and the vacuum pipe 1 is sealed; the inner wall of the front part of the fixed corridor 6 is sealed and fitted with the telescopic corridor 9; one end of the telescopic mechanism 10 is connected with the telescopic corridor 9, and the other end Linked to the fixed corridor 6, the inner cavity of the telescopic corridor 9 is larger than the door 3 of the train car 2, and its front end is adapted to the shape of the car around the door 3 and is provided with a sealing strip 11; the middle and rear part of the fixed corridor 6 is provided with a sealed door 7 , an air valve 8 is provided on the fixed cor...

Embodiment 2

[0020] This embodiment is basically the same as the first embodiment, except that the telescopic mechanism 10 is a rack and pinion telescopic mechanism. For making the space in the corridor succinct and attractive in appearance, the rack can be arranged below the bottom wall of the telescopic corridor 9, and the gear is located on the platform ground below the rack, and the driving device of the gear is also located on the platform 5 ground.

[0021] The fixed corridor 6 behind the airtight door of the present invention has no substantial function to the work of the present invention, and the length can be long or short, or even zero.

[0022] A plurality of connection corridors of the present invention can be installed simultaneously at the same station, and the specific number is determined according to the size of the train carriage door and the platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com