Special tool for disassembling and assembling static contact spring of disconnecting switch

A technology of isolating switches and special tools, applied in switch devices, electrical components and other directions, can solve the problems of spring 3 fatigue deformation, low work efficiency, laborious and other problems, and achieve the effect of small stretch and short working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

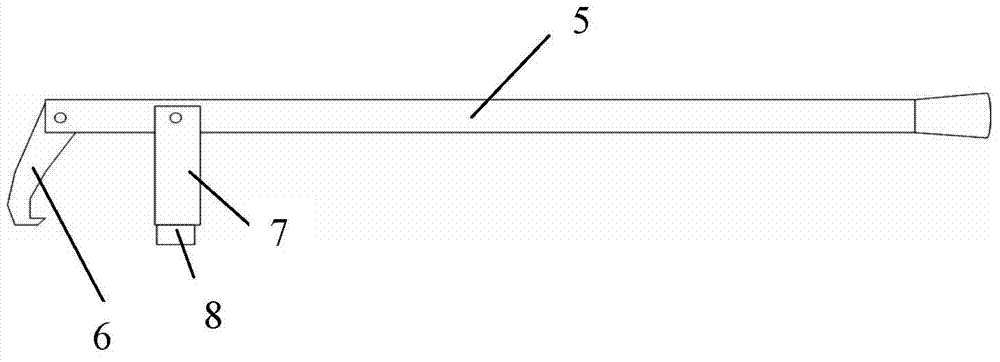

[0010] The special tool for disassembling and assembling the static contact spring of the isolating switch provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The same reference numerals are used for the same components as in the prior art.

[0011] like image 3 As shown, the special tool for disassembling the static contact spring of the isolating switch provided by the present invention includes an operating arm 5, a front hook 6 and a pressing block 7; wherein the rear end of the front hook 6 is hinged on the front end of the operating arm 5, and the front end The hook tip is formed inward; the upper end of the pressure block 7 is hinged on the front part of the operating arm 5, and a rectangular boss 8 is formed on the middle part of the lower end surface protruding outward.

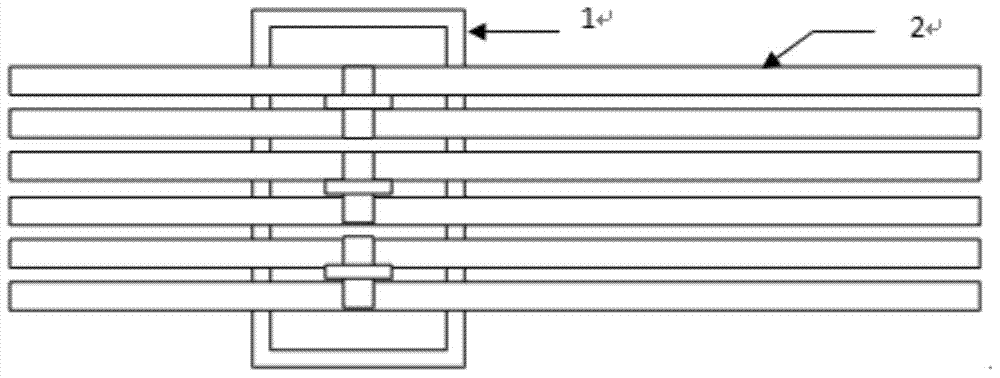

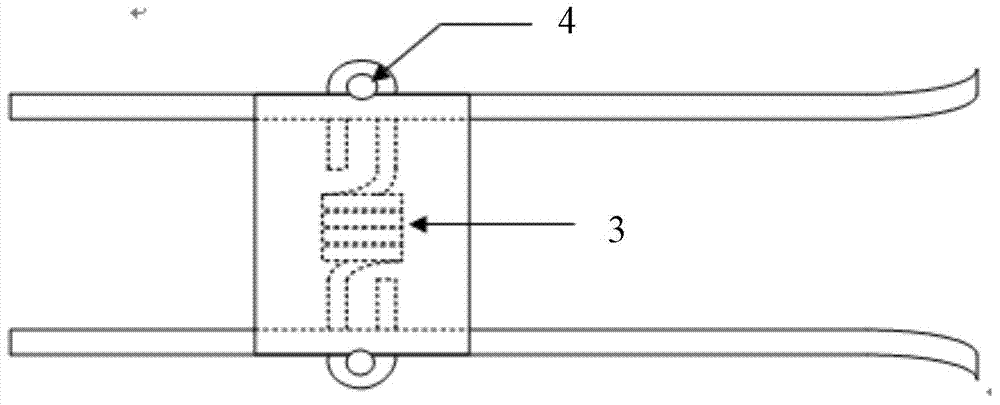

[0012] The width of the boss 8 is equal to the distance between two adjacent contact fingers 2 on the static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com