Hart dacron thread and its production technique

A technology of polyester yarn and production method, applied in the field of chemical fiber polyester yarn, can solve the problems of small use range, high production difficulty, low production rate, etc., and achieve the effects of reducing production cost, small expansion and large monofilament fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The Hart polyester yarn described in this embodiment is 308DTEX in a single bundle, the number of plies is 16, the single fineness is 19.25DTEX, the strength is 5.3CN / DTEX, the elongation is 13%, and the boiling water shrinkage is 3.5%.

Embodiment 2

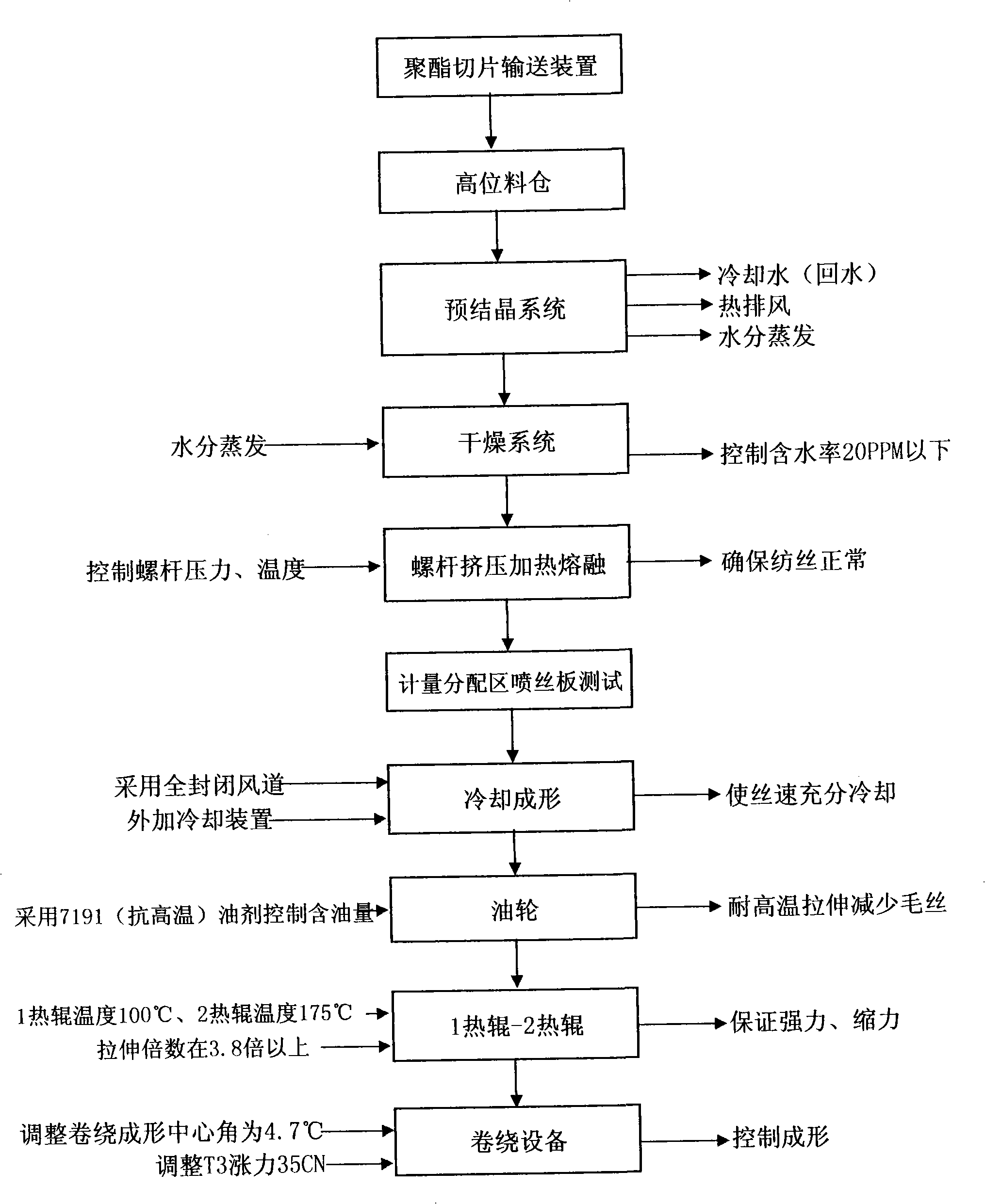

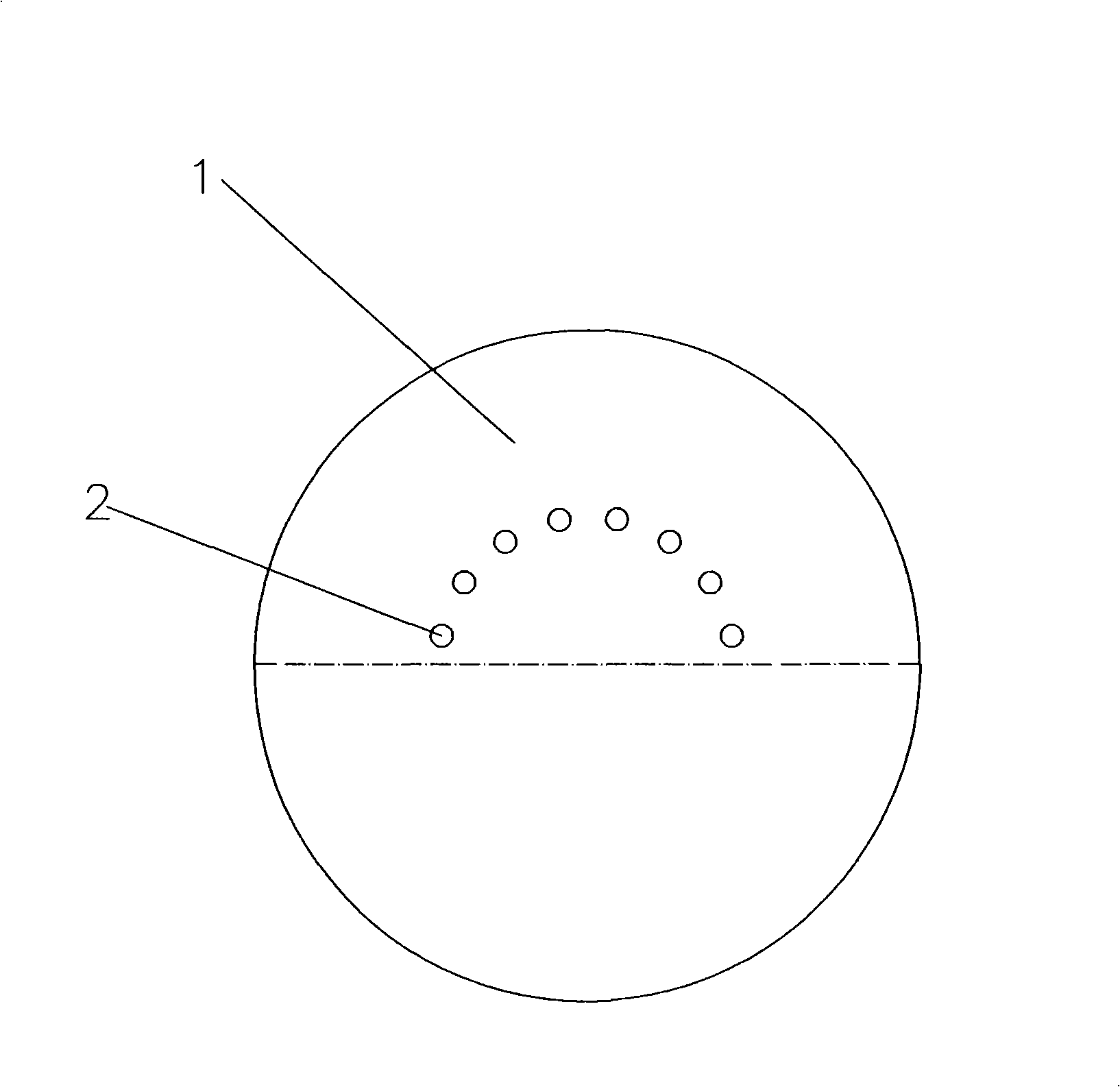

[0013] Such as figure 1 , figure 2 The production technology of the Hart polyester yarn described in this embodiment is mainly composed of steps such as slice conveying, drying, screw spinning box spinning, stretching and winding, etc. The moisture content of the slices is controlled below 20ppm, and the temperature of the spinning box is controlled at 295°C, so that the spinning viscosity drop is controlled at ≤0.01dl / g, the screw pressure of the screw spinning box is 12.0MPA, the spinning speed is 4200m / min, and two spinning plates 1 with 8 spinneret holes 2 are used , the spinneret holes are arranged in a U shape; the oiling process uses a high-temperature resistant oil agent of the type DElionF-7190-S, and the tanker rotates at 15r / min; the side blowing cooling device adopts a fully enclosed air duct, and an additional cooling device When cooling the full-stretch winding, the stretching ratio is controlled at more than 3.8 times, the temperature of the first hot roll is ...

Embodiment 3

[0015] In the production technology of the Hart polyester yarn described in this embodiment, the pressure of the screw spinning box is controlled at 12.0MPA, and the tension for controlling the forming of the silk cake is 28CN. The wind temperature of the side blowing cooling device is controlled below 20°C, and the wind speed is controlled below 0.4m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com