A kind of diatomite-fly ash type caulk composition and its application

A technology of composition and diatomite, which is applied in the field of caulking agent, can solve the problems of high porosity and extensibility, affecting the appearance of tiles, mildew and other problems, and achieves light weight, softness, good wear resistance, good mixing uniformity, and good compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The caulking agent composition of the present invention was prepared according to the combination and dosage shown in Table 1 below. Wherein, the particle size of the diatomite and the quartz sand or the fly ash is about 40 microns, and the silicon dioxide content of the diatomite is about 80% by mass, and the pulverized coal The ash is based on (GB / T1596-2005) standard and meets the requirements of Table 2 in item 4.2 (that is, the ignition loss % is not more than 5%, the water content is not more than 1%, the sulfur trioxide % is not more than 3%, 28 Class I fly ash used as an active admixture in the production of cement in which the compressive strength ratio % is not more than 75%; the particle size of the sepiolite powder is about 30 microns; the cement is type I portland cement ; The 200-mesh sieve remainder of other raw materials is less than 1% by mass, and the cellulose is hydroxyethyl cellulose. The above raw materials were ground and mixed at a speed of 200 ...

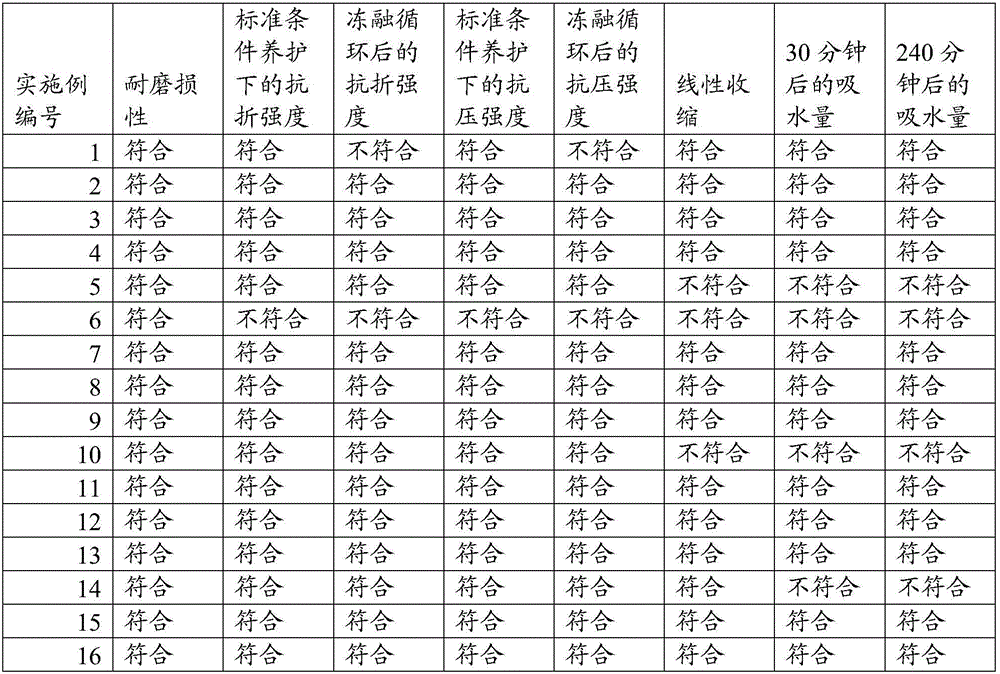

Embodiment 2 to 16

[0045] Except for the contents shown in Table 1, the compositions were prepared in the same manner as in Examples and various performance indexes were measured.

[0046] Components and consumption (parts by weight) used in the manufacture of the caulk composition in Table 1 Examples 1 to 16

[0047]

[0048] Table 2 Cement-based joint filler standard

[0049] Performance

Require

testing method

≤2000mm 3

water absorption test

Flexural strength under standard conditions of curing

≥3.5N / mm 2

Flexural Strength and Compressive Strength Testing

Flexural strength after freeze-thaw cycles

≥3.5N / mm 2

Flexural Strength and Compressive Strength Testing

Compressive strength under standard conditions of curing

≥15N / mm 2

Flexural Strength and Compressive Strength Testing

Compressive strength after freeze-thaw cycles

≥15N / mm 2

Flexural Strength and Compressive Strength Tes...

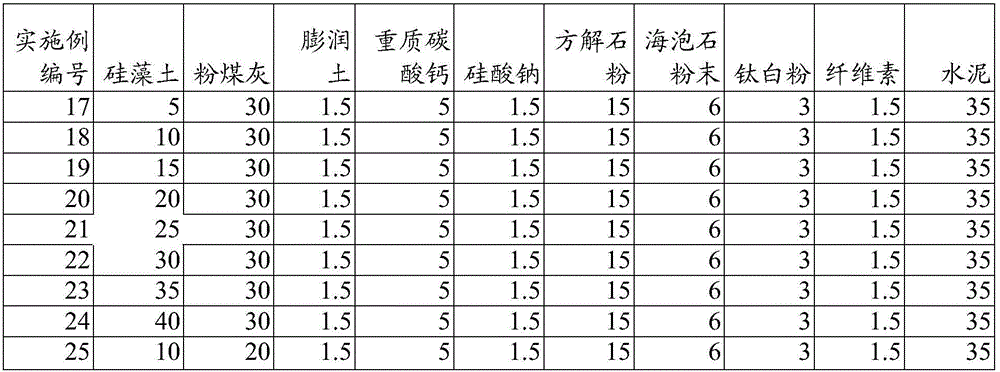

Embodiment 17 to 25

[0054] Based on the results in Examples 1 to 16, and in view of the low price of fly ash and the need for waste utilization, the inventors used fly ash instead of quartz sand to manufacture joint fillers in a similar manner to Example 1 and tested the filling. Performance indicators of caulking agent (see Tables 4 and 5).

[0055] Components and consumption (parts by weight) used in the manufacture of the caulk composition in Table 4 Examples 17 to 25

[0056]

[0057] The performance of the cement-based joint filler composition prepared in the embodiment 17 to 25 of table 5

[0058]

[0059] As can be seen from the results in Table 5, although in the above system, the utilization of fly ash is mainly limited by the problem of insufficient strength, it is possible to use fly ash to manufacture joint fillers, for example, it can be used in 10 parts by weight to Fly ash was used in 15 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com