Metal surface combustor and gas premixing method thereof

A metal surface and burner technology, applied in the direction of combustion methods, burners, gas fuel burners, etc., can solve the problems of short mixing section, prone to local high temperature, high NOx emissions, etc., to improve mixing uniformity and avoid flames Temperature unevenness, effect of reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present examples are not intended to limit the present invention, and any adoption of structures similar to the present invention and similar changes thereof should be included in the scope of protection of the present invention.

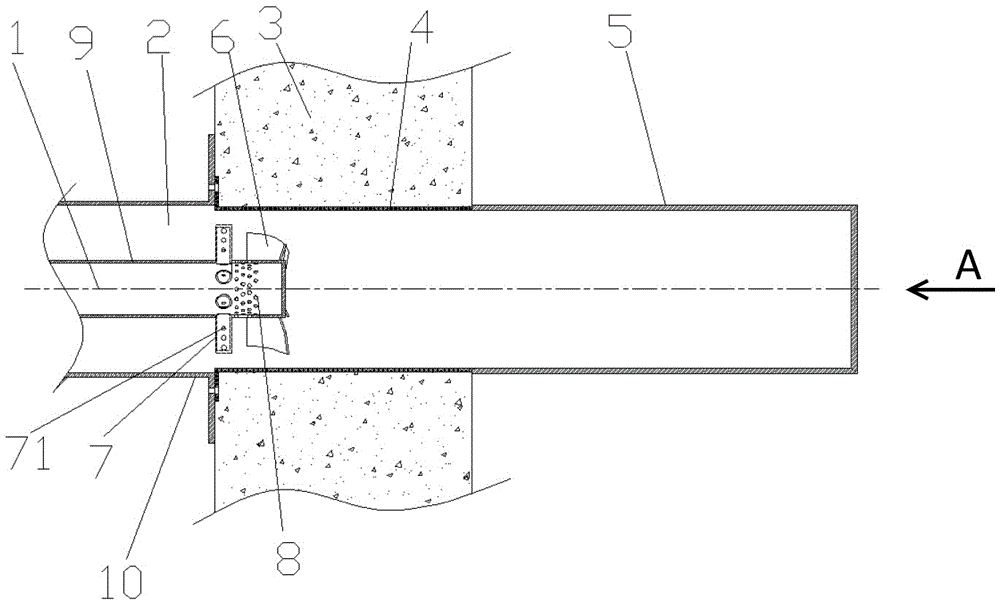

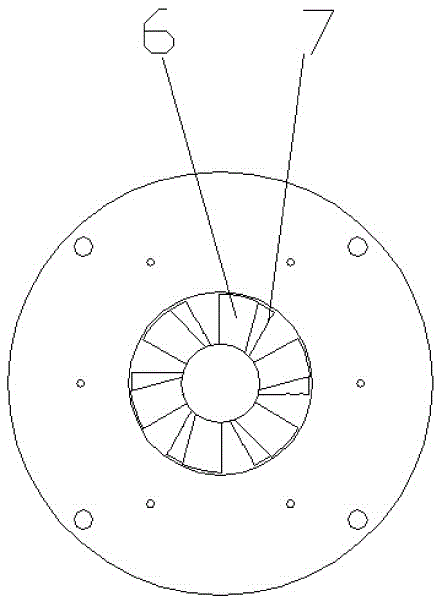

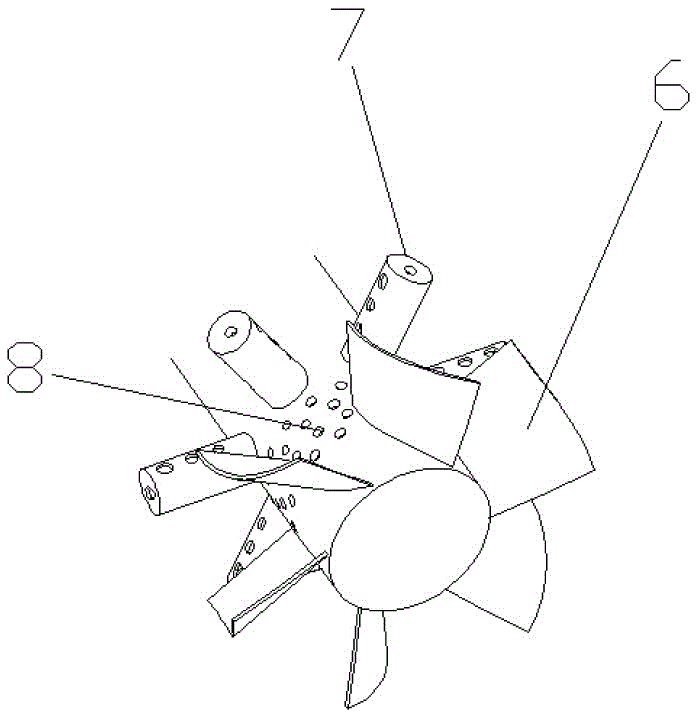

[0015] figure 1 It is a schematic diagram of the structure of the present invention. It can be seen from the figure that a metal surface burner includes a microporous metal cylinder 5, an air pipe 10, a gas pipe 9, a metal throat 4 and a swirl vane 6, and is characterized in that: the gas pipe 9, the air pipe 10 and the metal throat 4 are set coaxially from the inside to the outside; the metal throat 4 is a cylindrical channel, the outer surface of which is connected to the front wall of the boiler 3, and the part extending into the furnace is a microporous metal cylinder 5 sealed. , the other end of the metal throat 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com