EGR (exhaust gas recirculation) mixing device

A mixing device and mixer technology, which is applied in the direction of charging system, adding non-fuel substances to fuel, internal combustion piston engine, etc., can solve the problem of short intake pipeline, recirculation exhaust gas and fresh air mixing uniformity can no longer meet the stability of the engine Work requirements and other issues, to achieve the effect of increasing kinetic energy, high mixing uniformity, and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

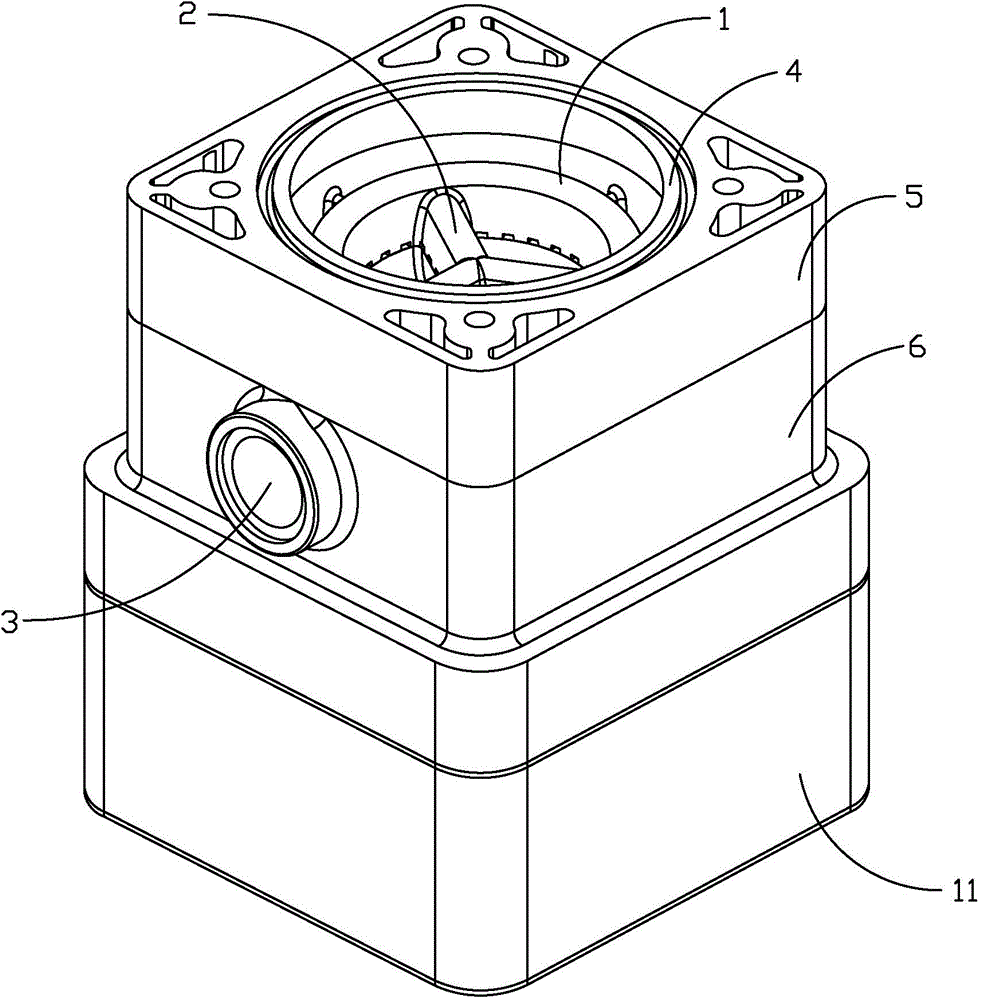

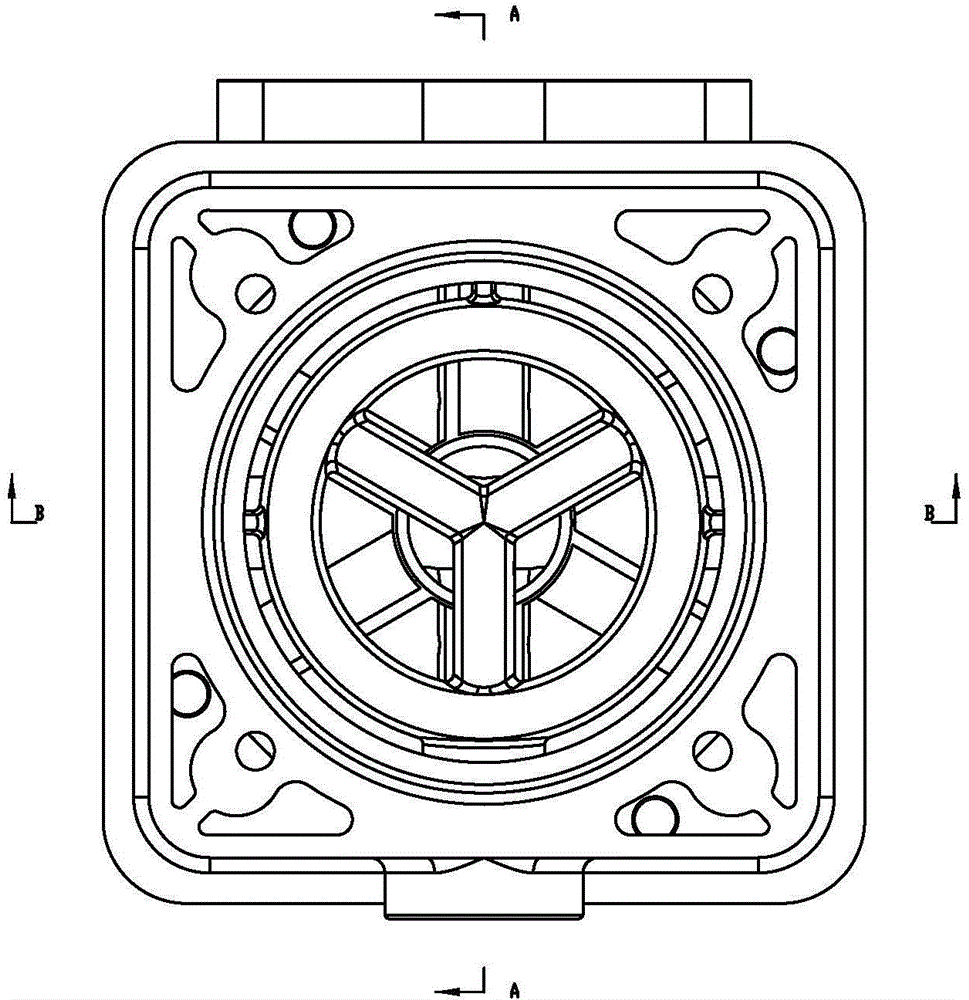

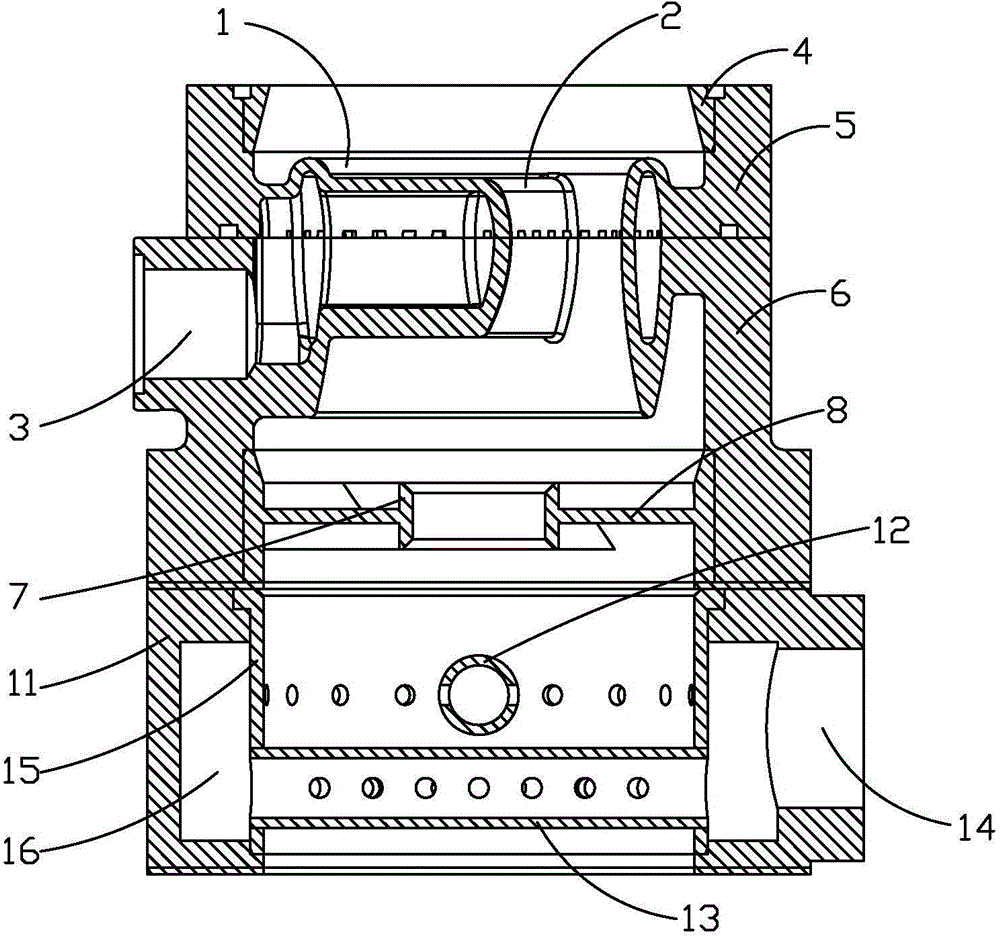

[0029] Such as Figure 1 to Figure 11 As shown, the EGR mixing device of the present invention includes a gas mixer and an EGR mixer, the gas mixer is used for mixing air and gas, the EGR mixer communicates with the mixed gas outlet of the gas mixer, and the EGR mixer is used for mixing exhaust gas and mixing gas.

[0030] The EGR mixer includes an EGR mixer body and an EGR branch pipe located in the EGR mixer body. The EGR branch pipe and the inner wall of the EGR mixer are equipped with a number of exhaust gas injection holes for spraying exhaust gas into the EGR mixer body. The EGR mixer body The side of the exhaust gas inlet 14 is provided, and the exhaust gas nozzles on the EGR branch pipe and the inner wall of the EGR mixer are all communicated with the exhaust gas inlet 14.

[0031] The EGR branch pipe includes a first EGR branch pipe 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com