Patents

Literature

109results about How to "Uniform suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

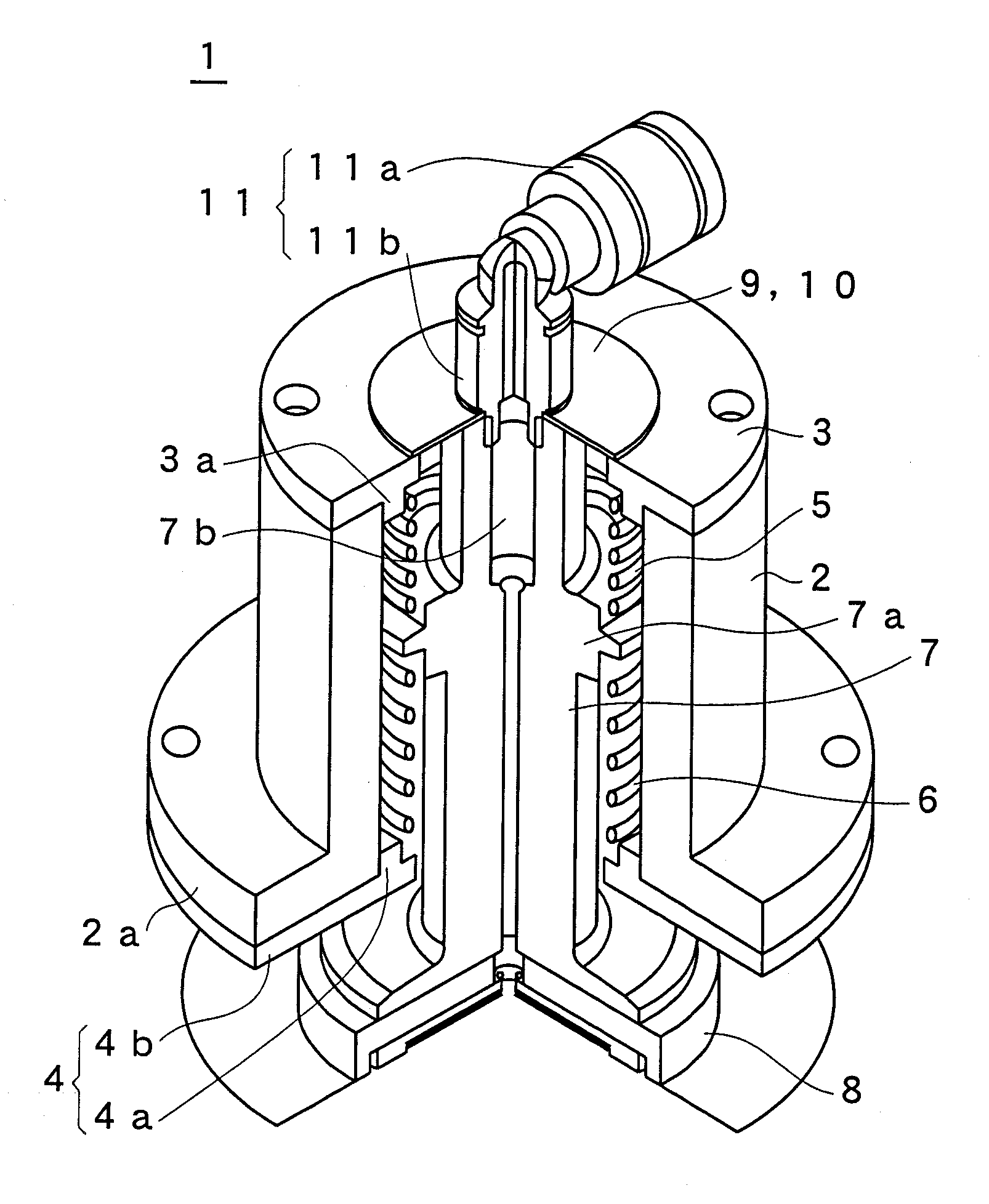

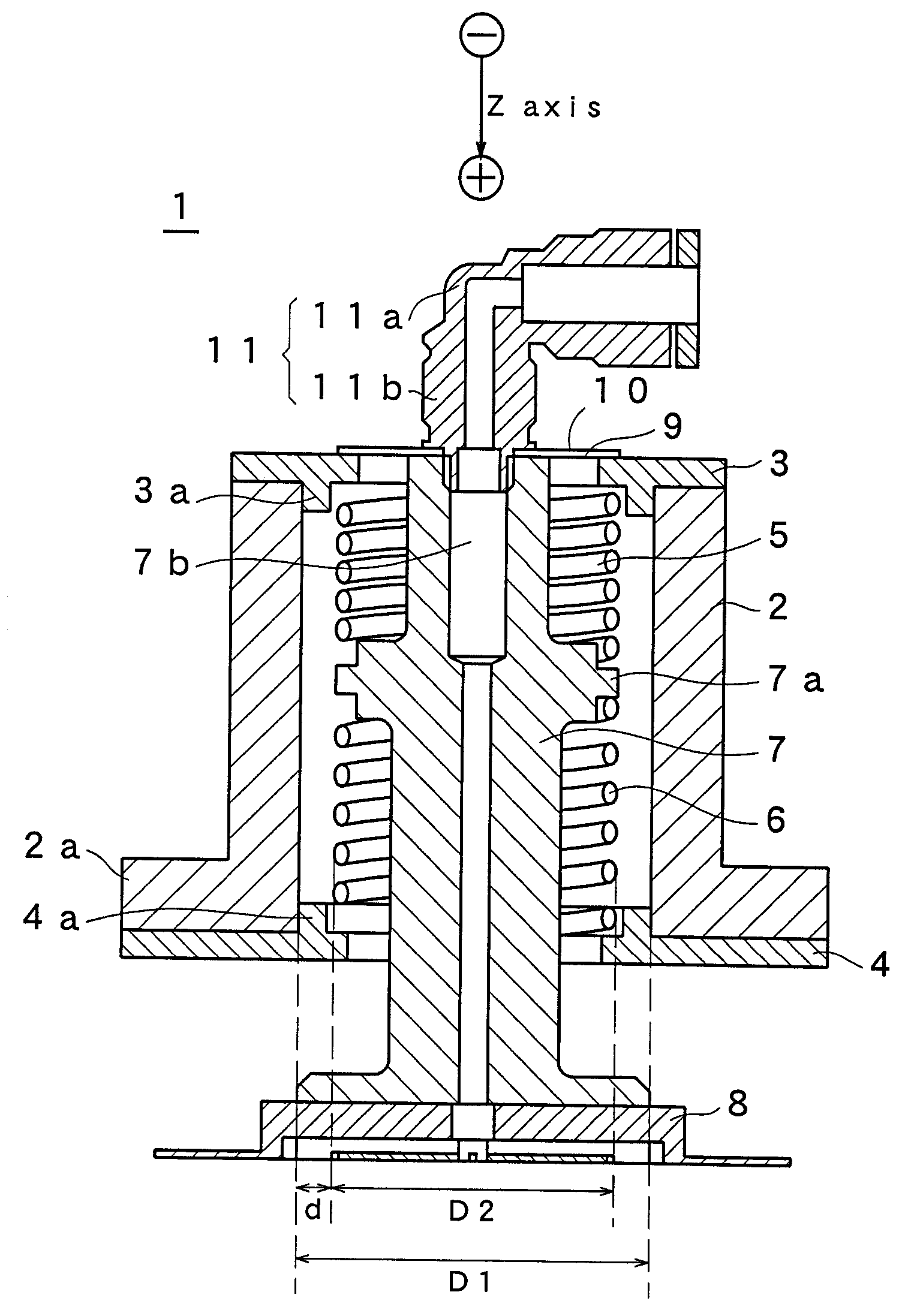

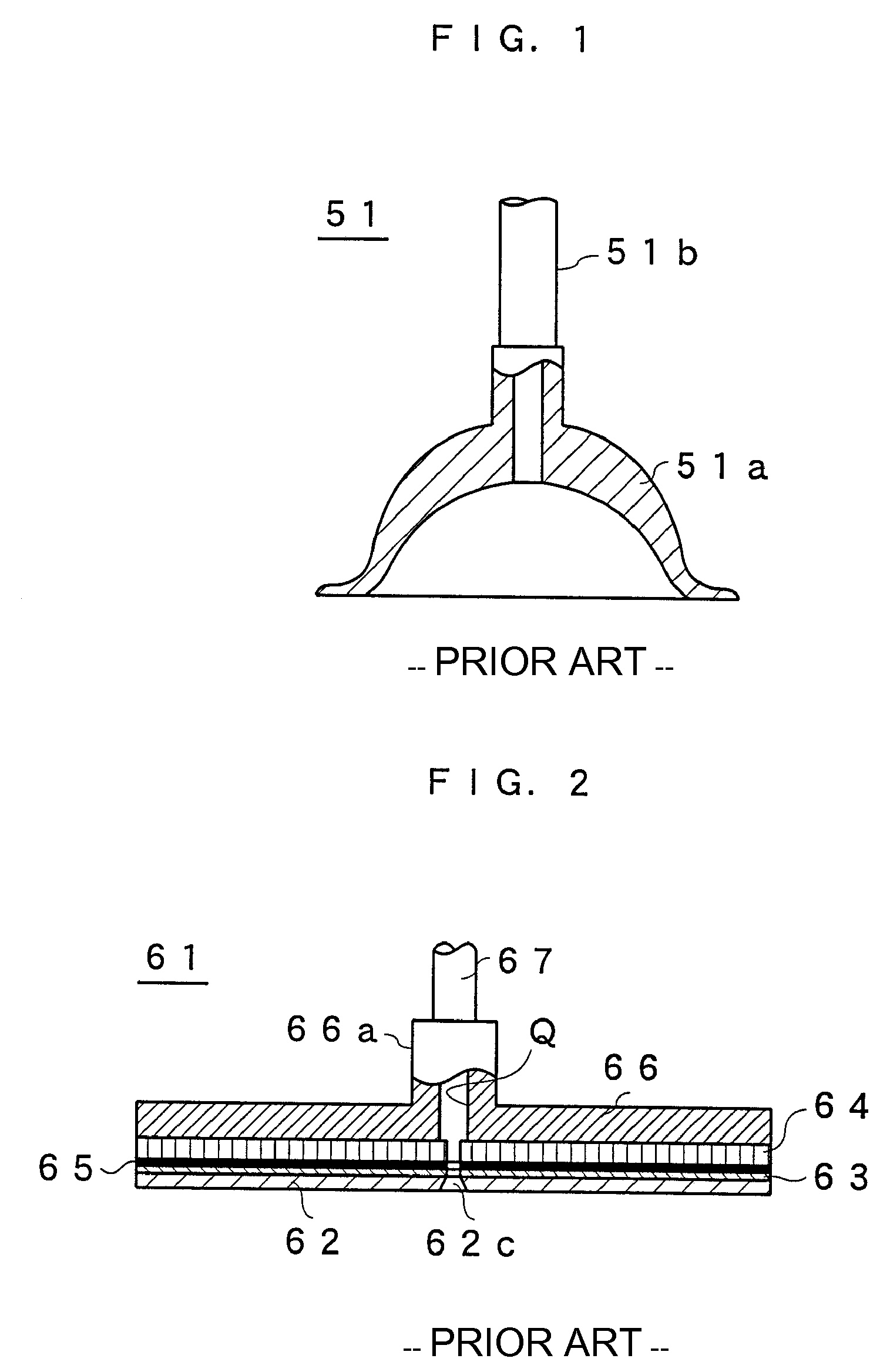

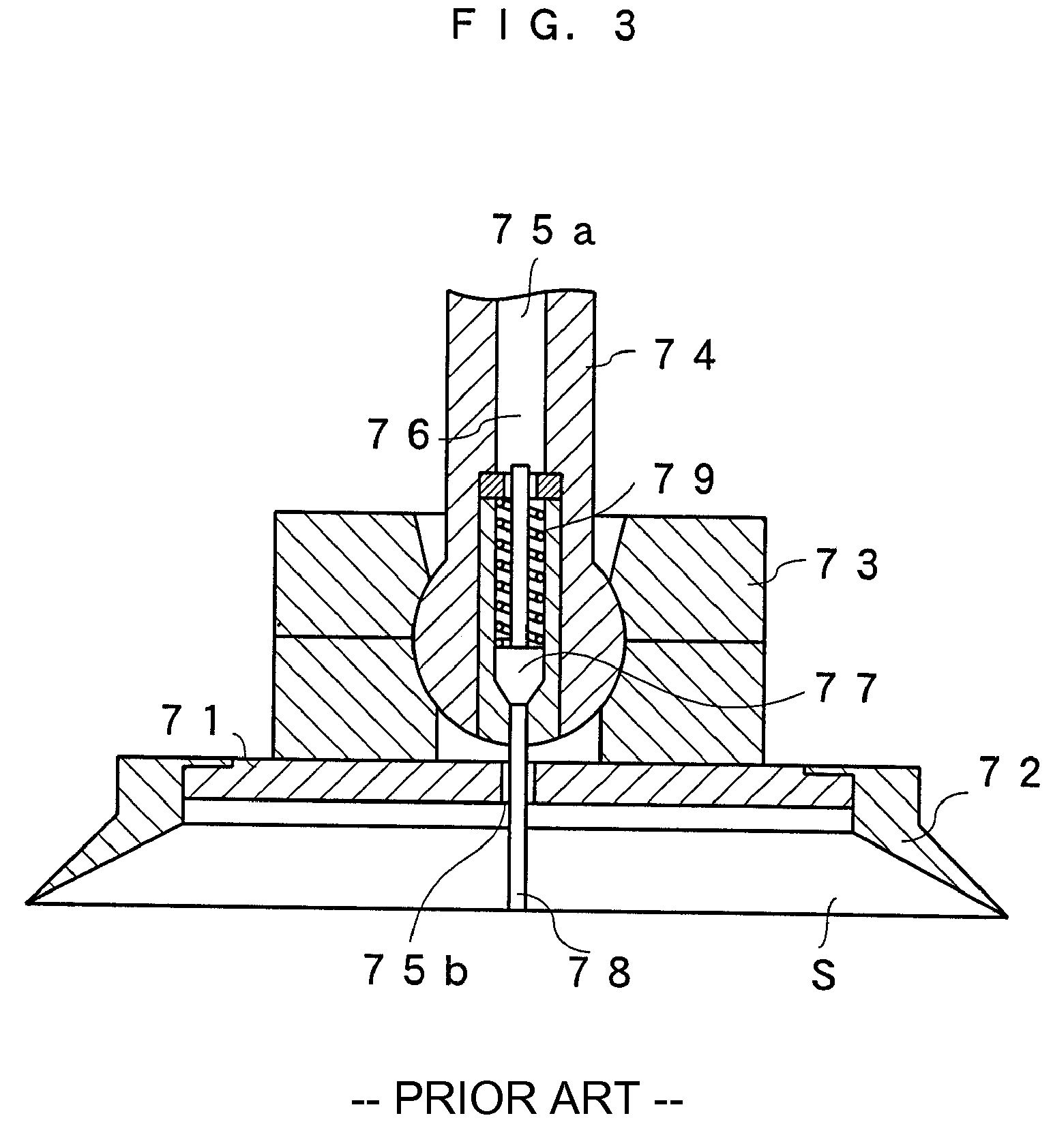

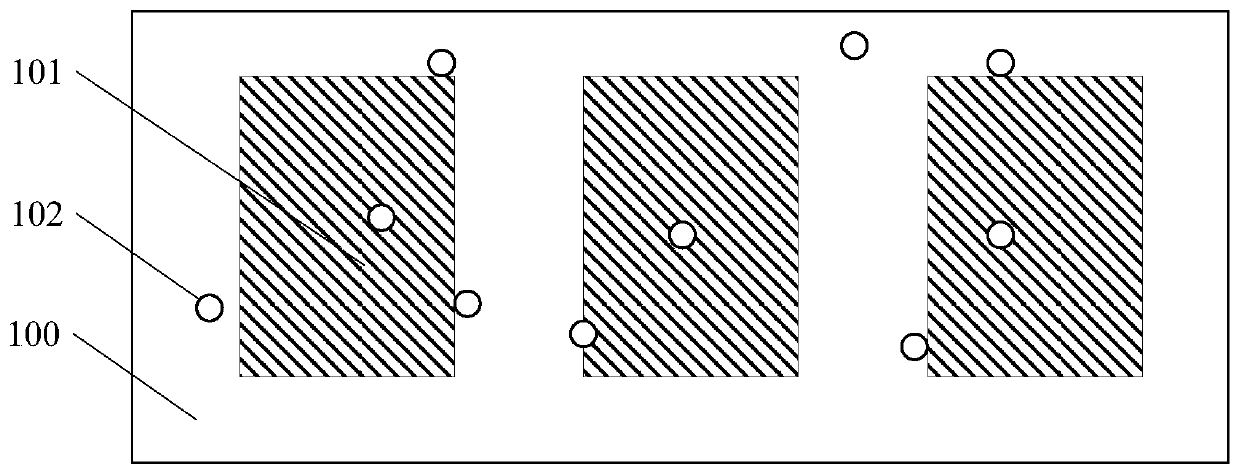

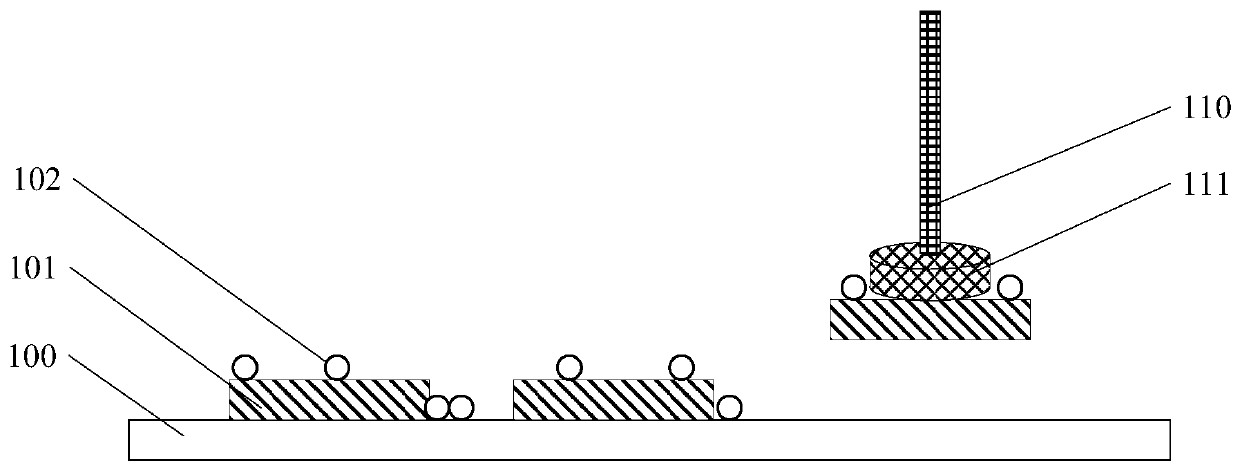

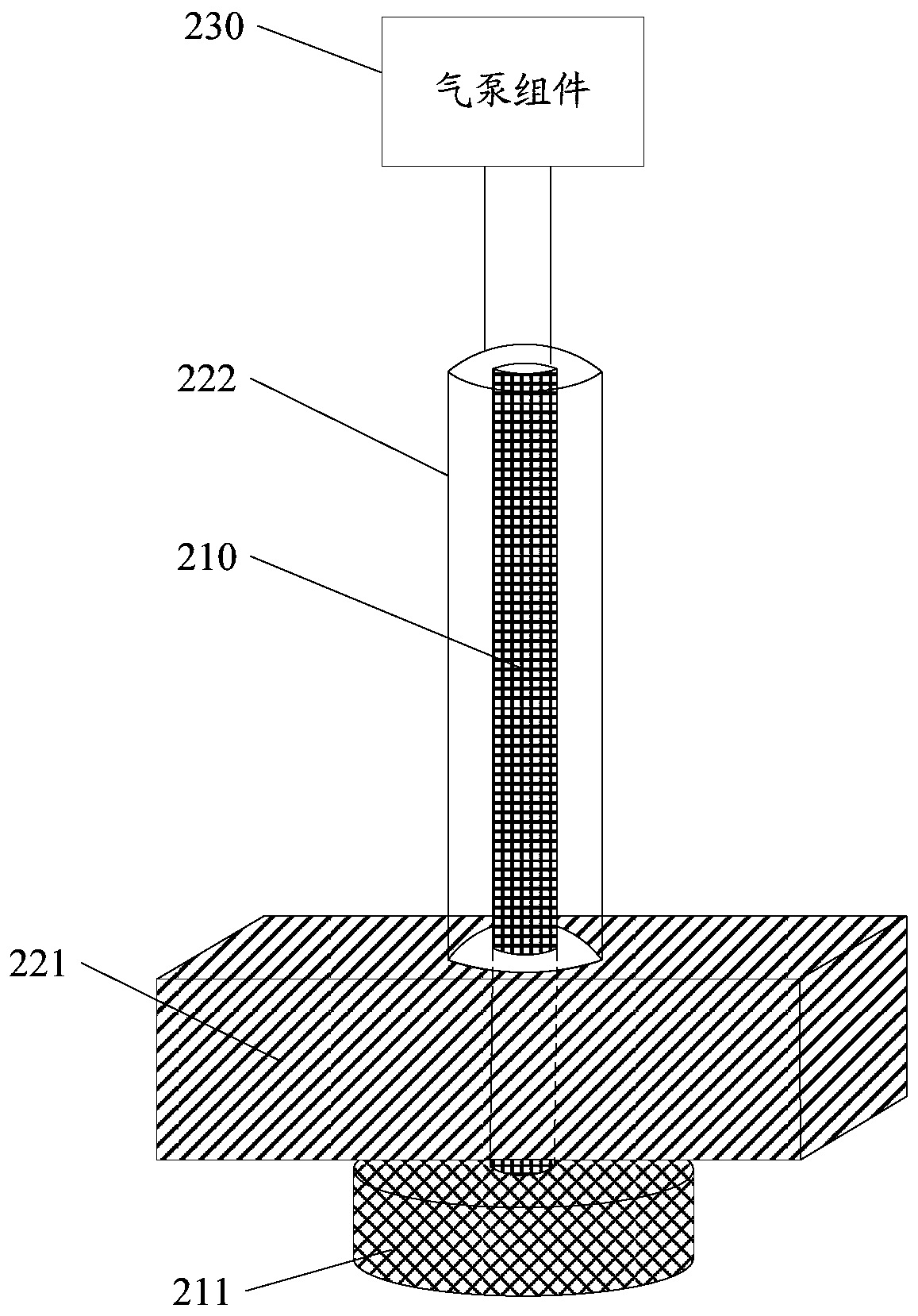

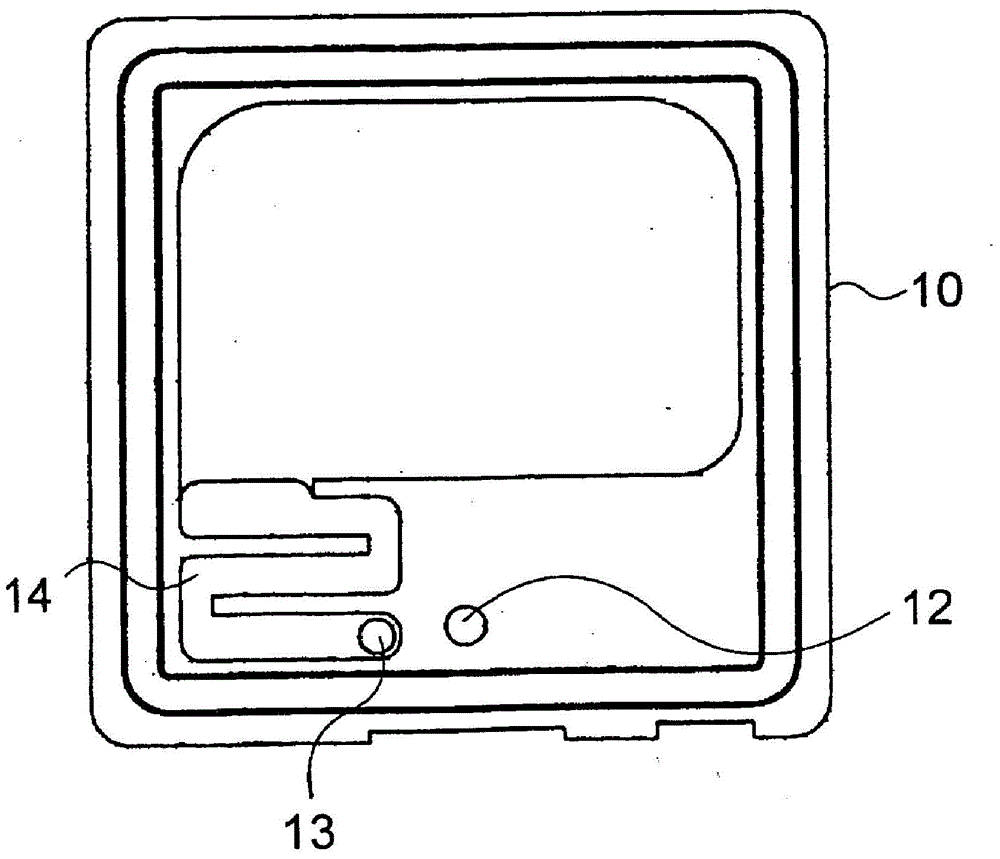

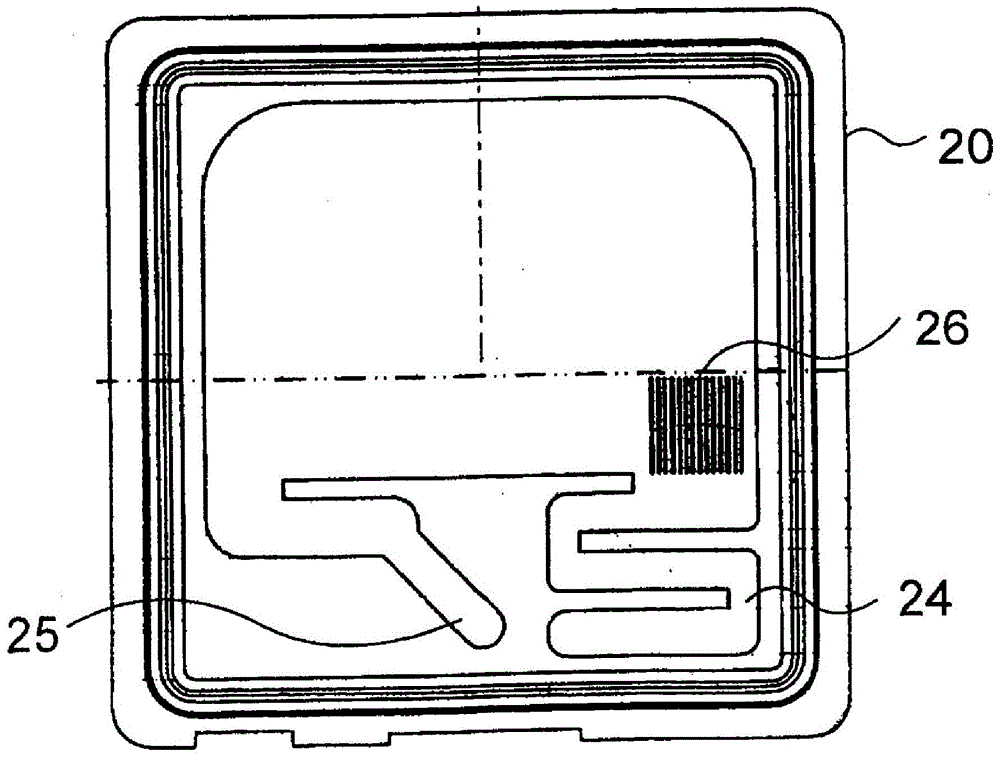

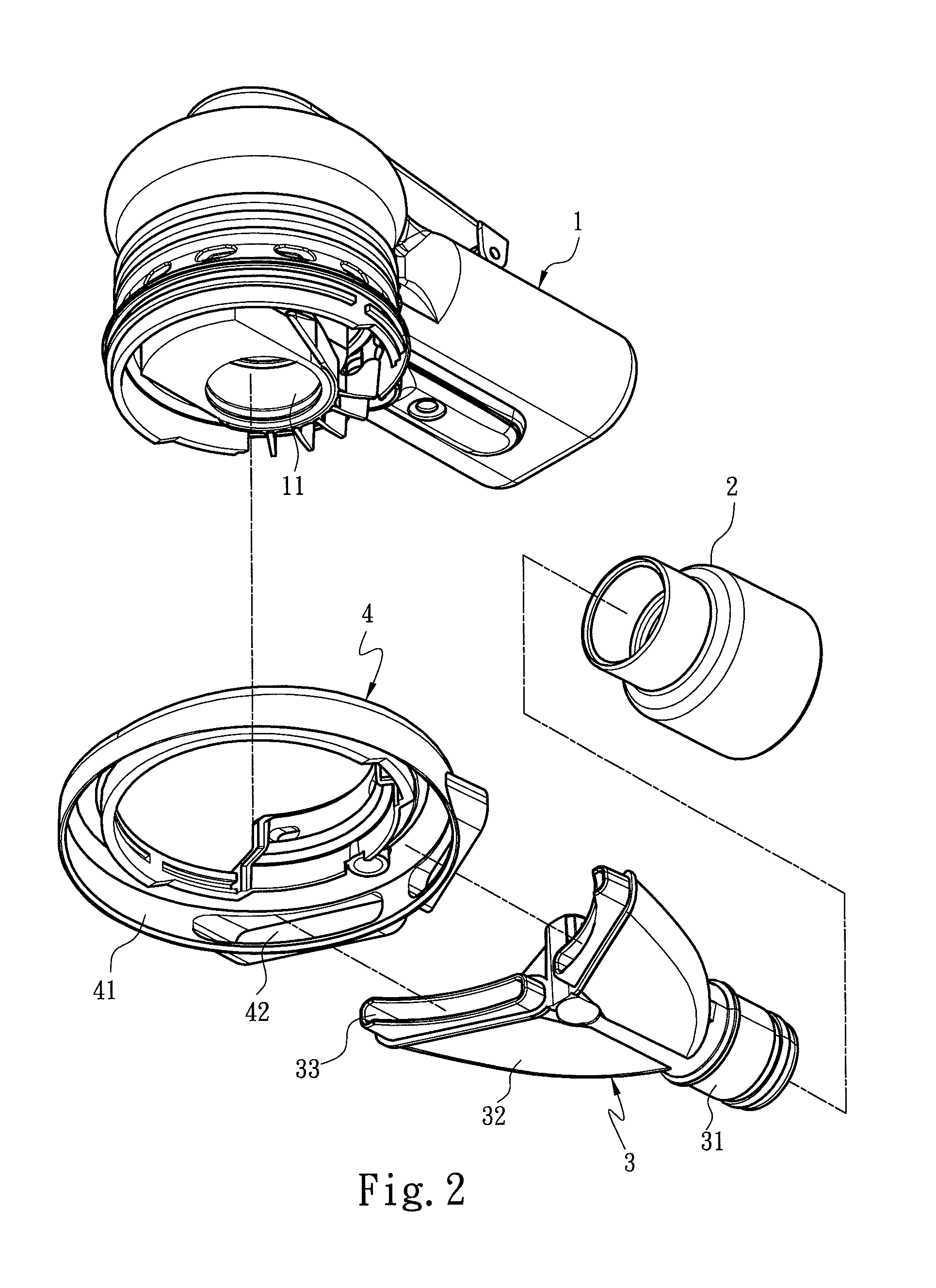

Vacuum Suction Head, And Vacuum Suction Device And Table Using The Same

InactiveUS20070200377A1AdhesivenessImprove adhesionGripping headsSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A vacuum suction head of the present invention can be applied to a large-sized liquid crystal display panel and can reliably suck an object to be sucked even if the object has undulation or flexure. The suction head has a shaft, which holds a suction pad, and gas is charged into and discharged from the suction pad through a suction hole. A casing holds the shaft through first and second springs so as to be movable in the axial direction. Since the suction pad is elastically supported by the springs, the suction pad can reliably suck the object to be sucked having undulation or flexure. The vacuum suction head can be used for a vacuum suction device and a working table.

Owner:MITSUBOSHI DIAMOND IND CO LTD

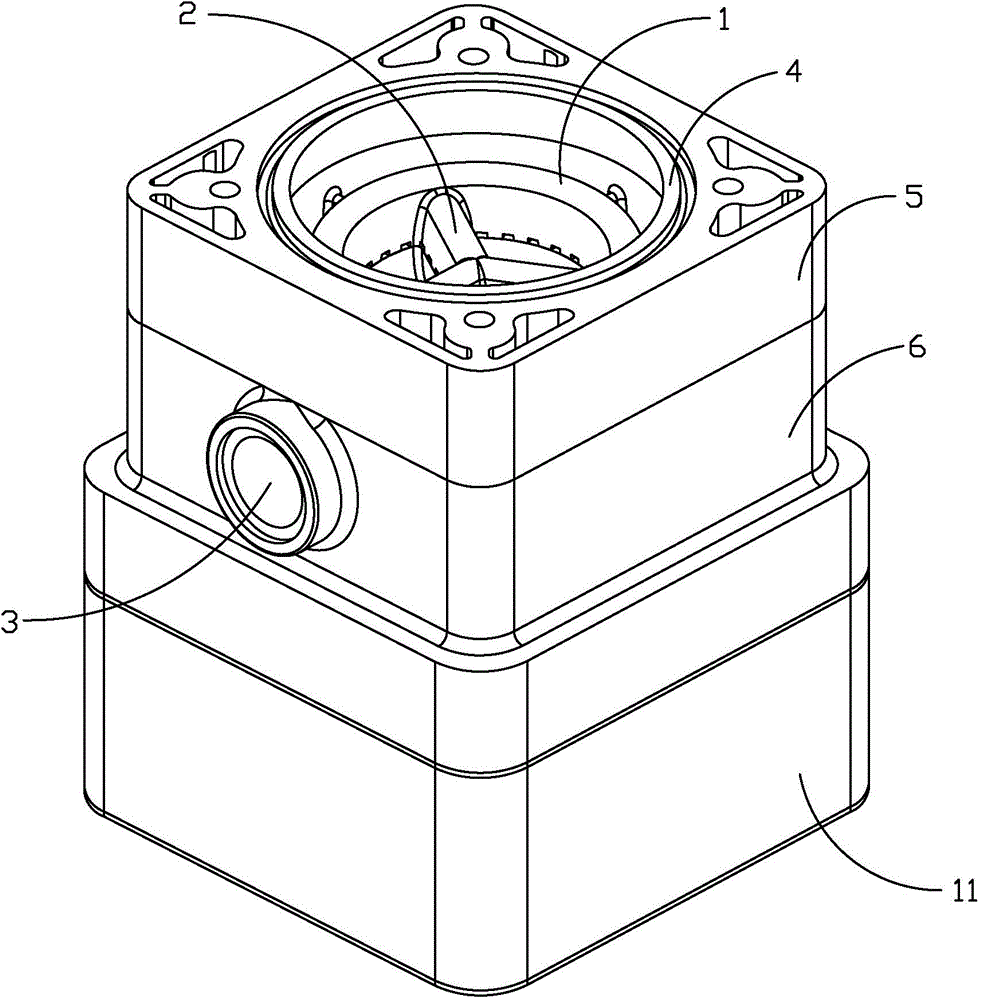

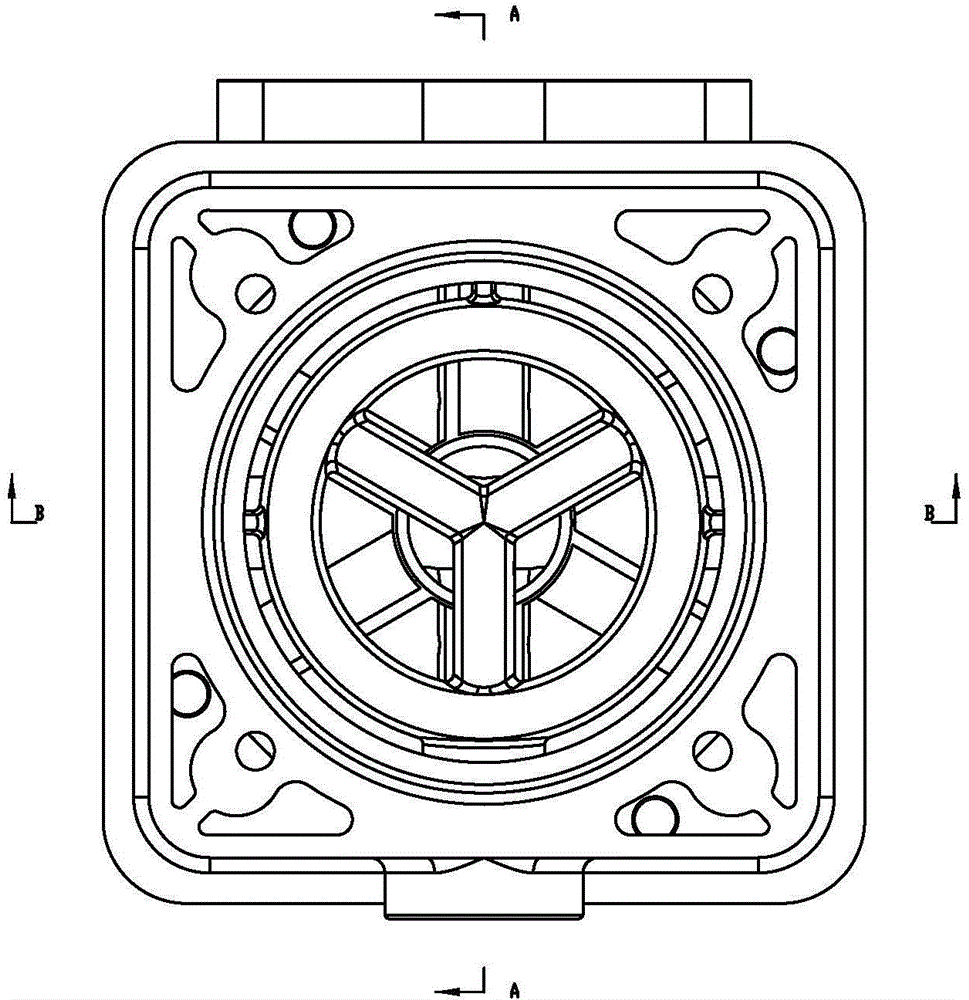

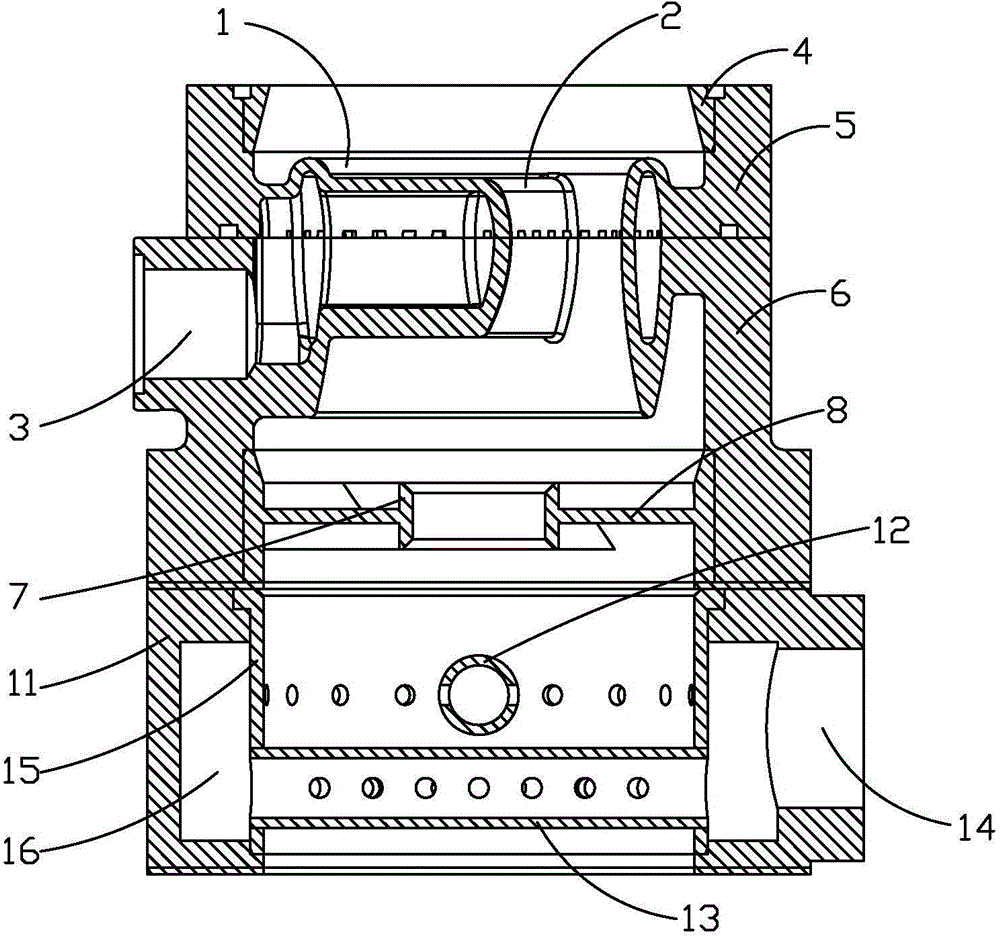

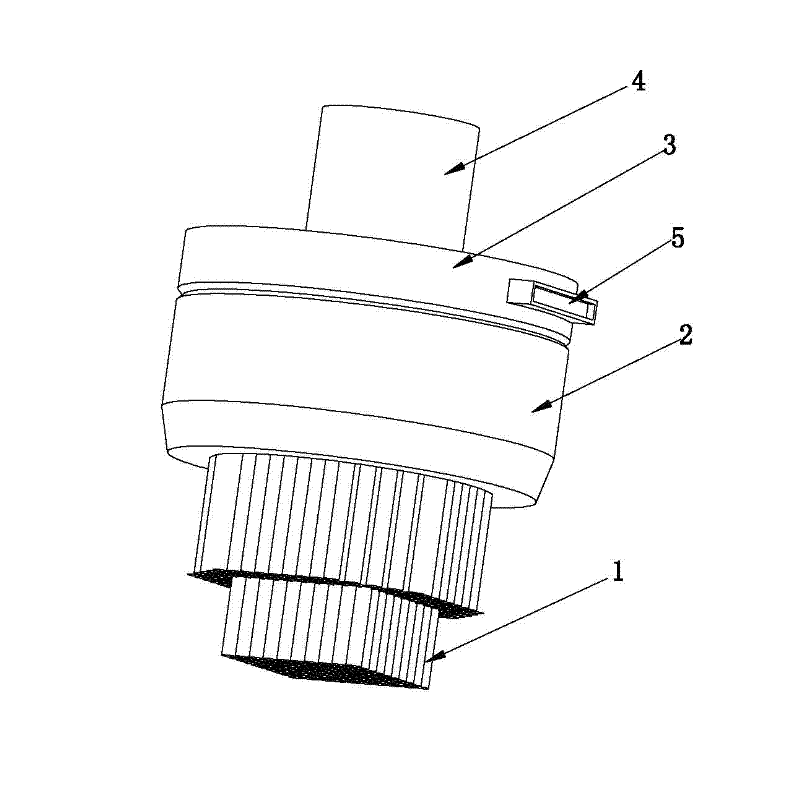

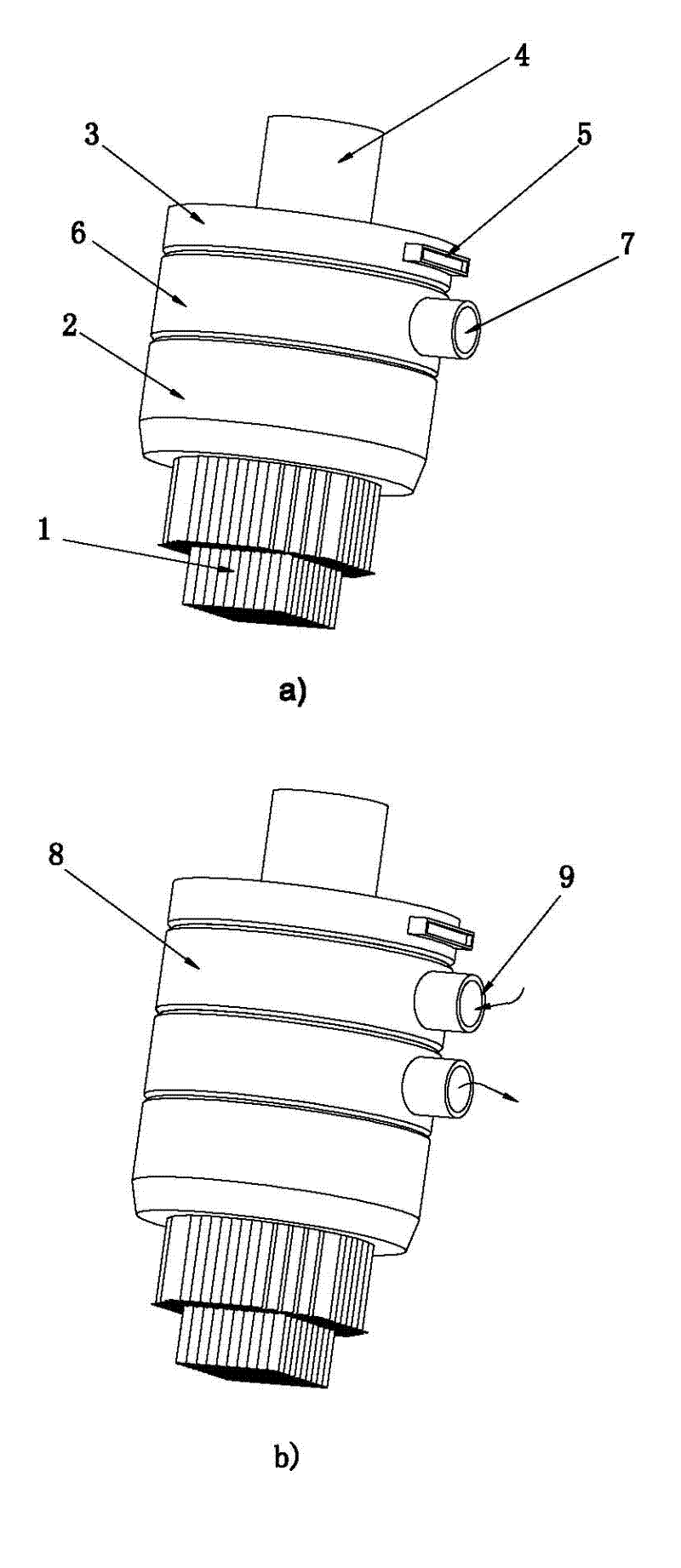

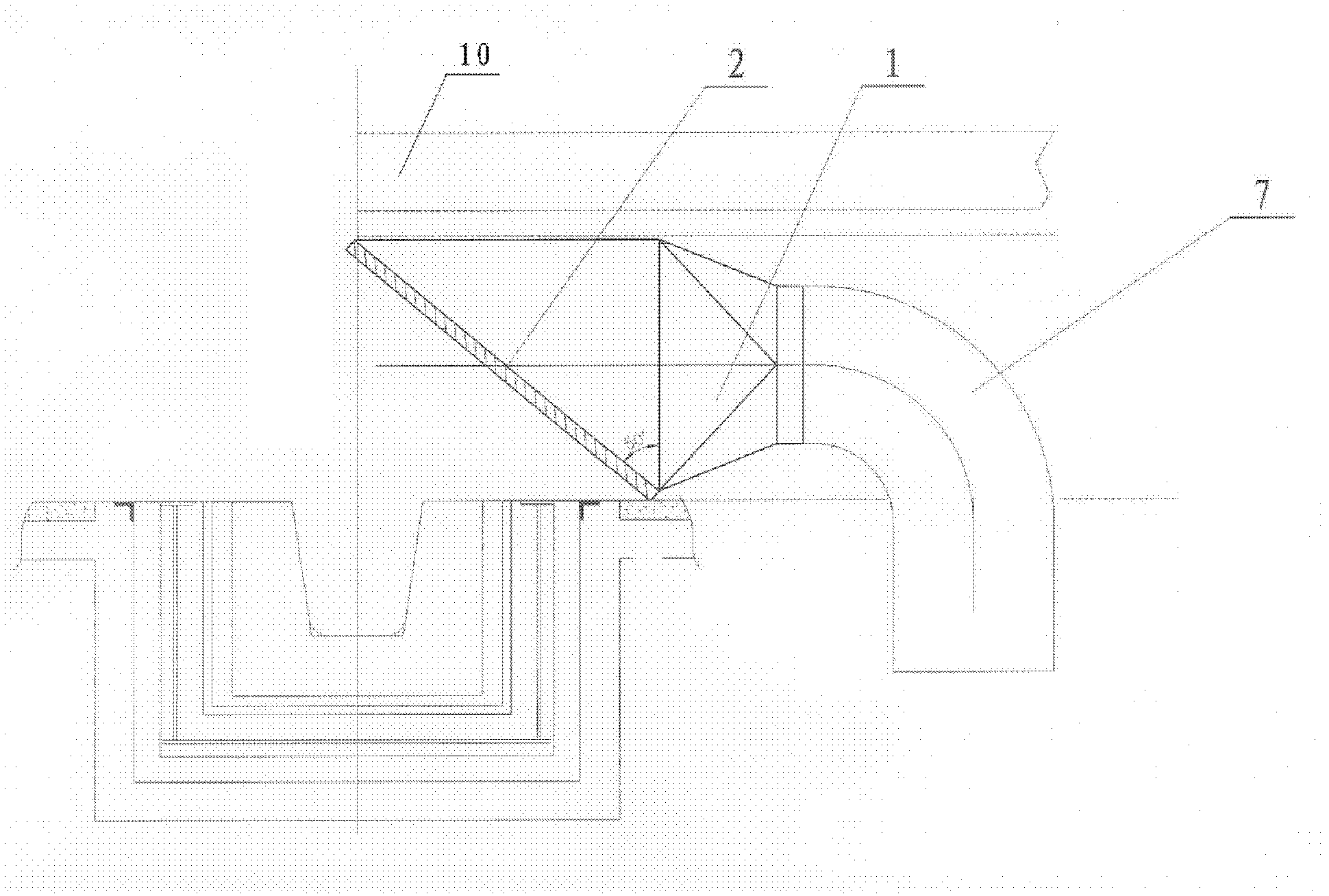

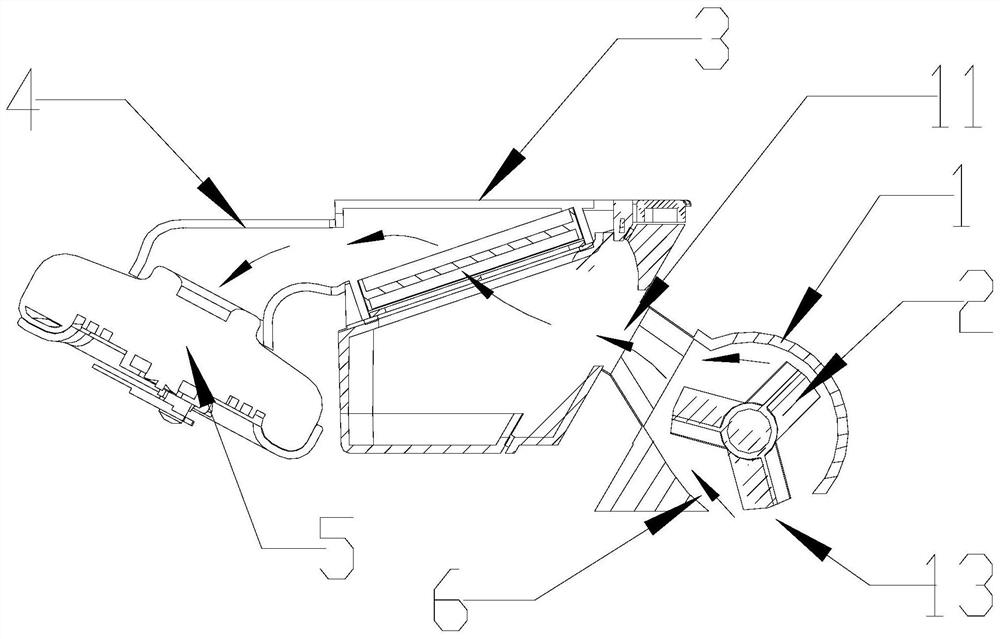

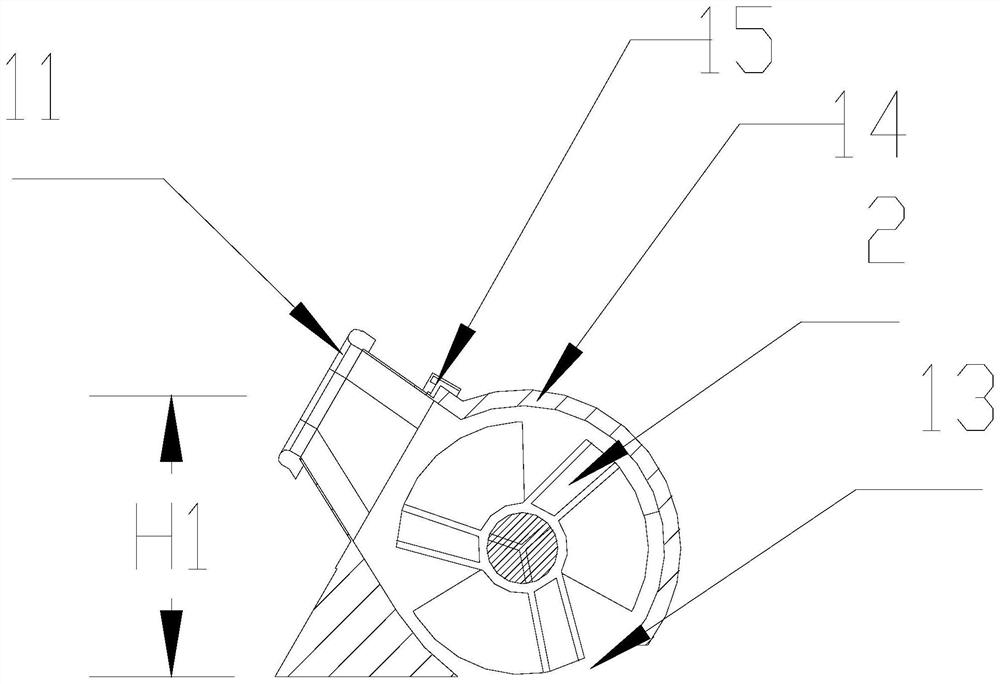

EGR (exhaust gas recirculation) mixing device

ActiveCN104653354AWell mixedImprove mixing uniformityInternal combustion piston enginesNon-fuel substance addition to fuelProcess engineeringExhaust gas recirculation

The invention discloses an EGR (exhaust gas recirculation) mixing device, which comprises a gas mixer and an EGR mixer, wherein the gas mixer is used for mixing air and gas; the EGR mixer is communicated with a mixture gas outlet of the gas mixer; the EGR mixer comprises an EGR mixer body and EGR branch pipes arranged in the EGR mixer body; the inner wall of each EGR branch pipe and the inner wall of the EGR mixer body are both provided with a plurality of waste gas orifices used for spraying waste gas into the EGR mixer body. According to the EGR mixing device, the mixing evenness degree of the waste gas, the air and natural gas is higher, and reaches a top level in the industry.

Owner:成都耐尔特科技有限公司

Vacuum suction head, and vacuum suction device and table using the same

InactiveUS7665783B2AdhesivenessImprove adhesionGripping headsSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A vacuum suction head of the present invention can be applied to a large-sized liquid crystal display panel and can reliably suck an object to be sucked even if the object has undulation or flexure. The suction head has a shaft, which holds a suction pad, and gas is charged into and discharged from the suction pad through a suction hole. A casing holds the shaft through first and second springs so as to be movable in the axial direction. Since the suction pad is elastically supported by the springs, the suction pad can reliably suck the object to be sucked having undulation or flexure. The vacuum suction head can be used for a vacuum suction device and a working table.

Owner:MITSUBOSHI DIAMOND IND CO LTD

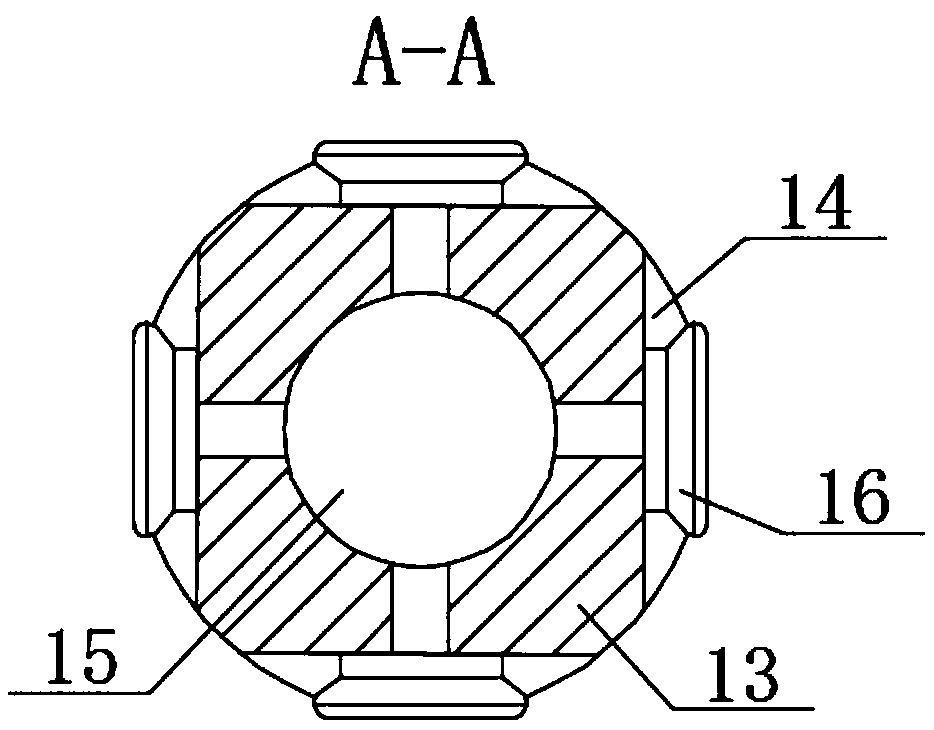

Electrochemical machining array electrode

InactiveCN102357689AEasy to processShort manufacturing cycleMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses an electrochemical machining array electrode which is characterized by comprising electrode units, an array electrode clamp, a power module and an electrode clamp joint. The electrode unit is a strip-shaped solid, or a thin-wall hollow or grooved structure; the electrode units are clustered to form an array electrode unit cluster; the array electrode unit cluster is clamped by an electrode unit clamp; the bottom end of the array electrode unit cluster can form an end surface of any contour shape; and if the electrode unit is a thin-wall hollow structure or grooved structure, the electromechanical machining array electrode also comprises an electrolyte module so that the electrode units realize liquid flushing or absorption, or partial liquid flushing and partial liquid absorption. Through the invention, the electrode production time of electrolytic formation machining can be obviously shortened, the cost and difficulty in the electrode production are reduced, the utilization rate of the electrode material is improved, and the machining efficiency and speed are improved; and meanwhile, the electric field and flow field during the electromechanical machining are homogenized, selective machining can be realized at different positions of the electrode, and the machining accuracy and quality are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

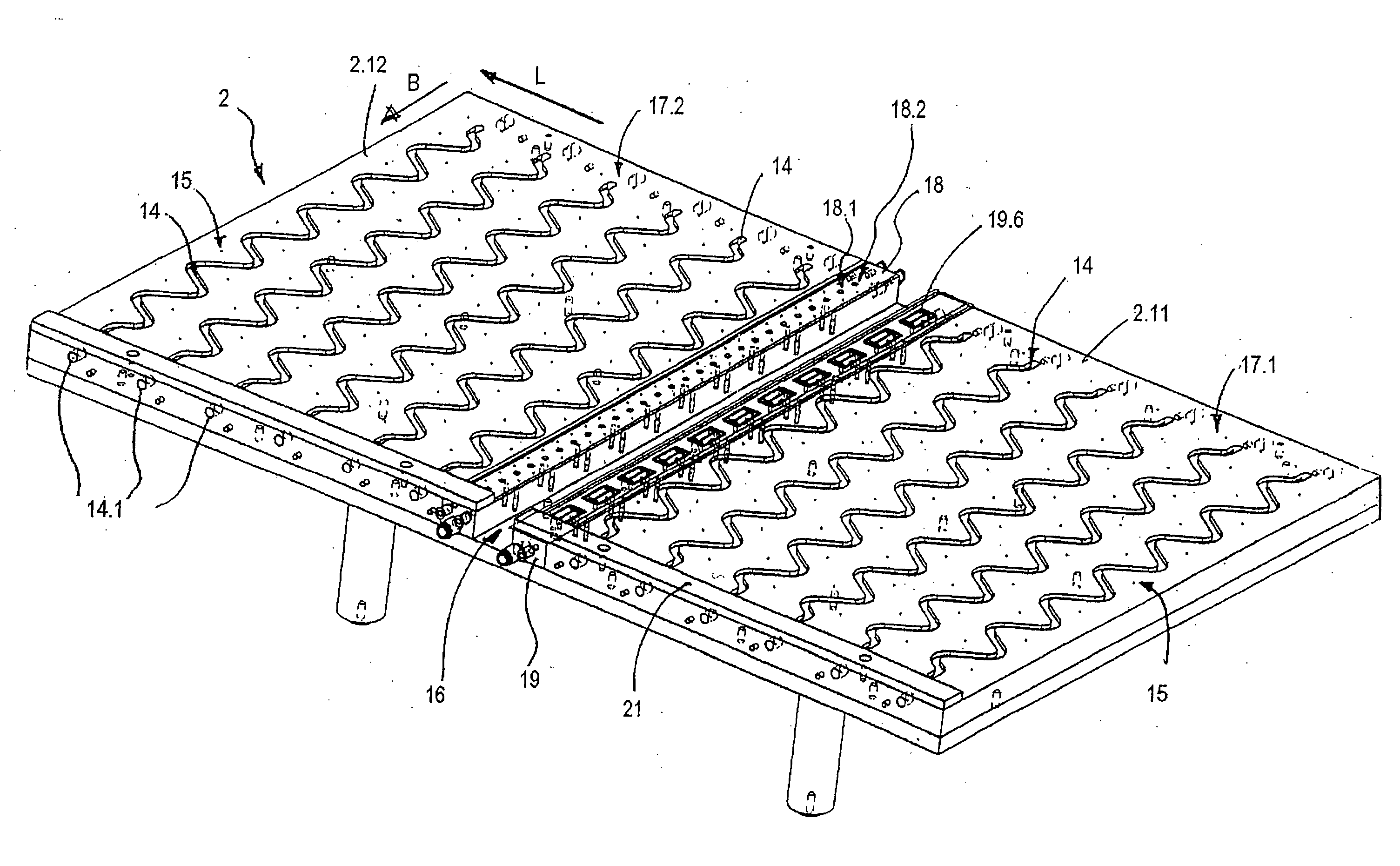

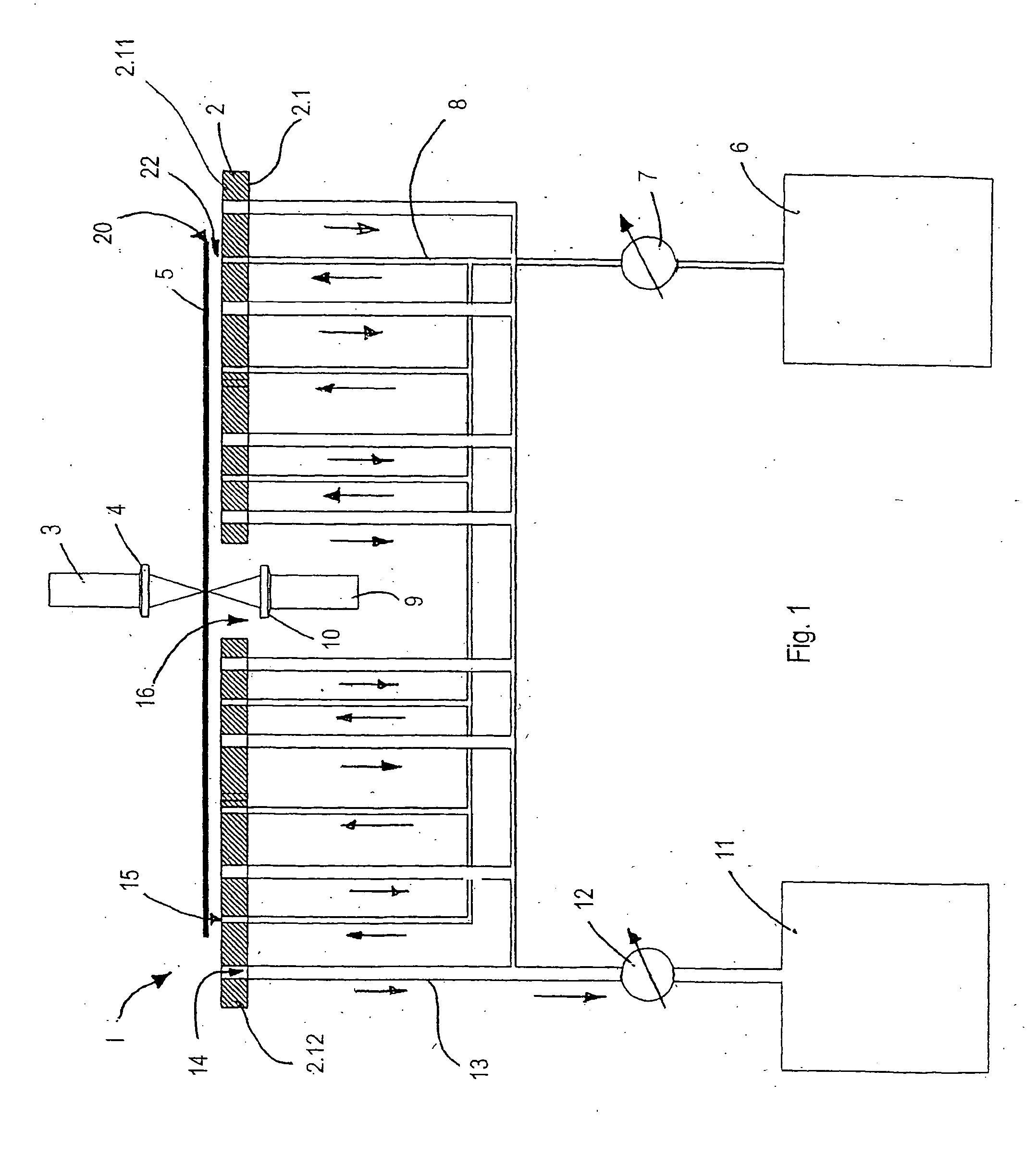

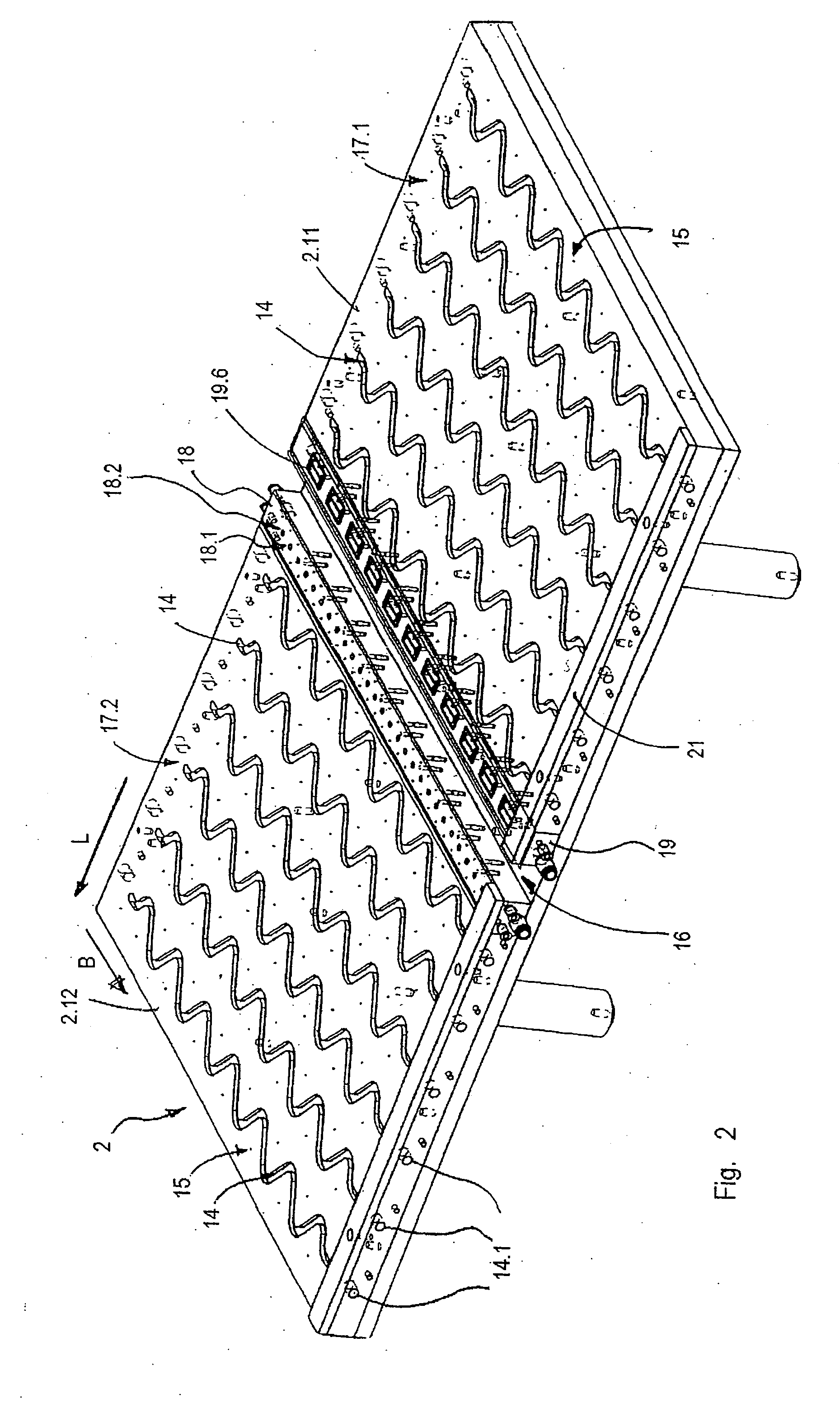

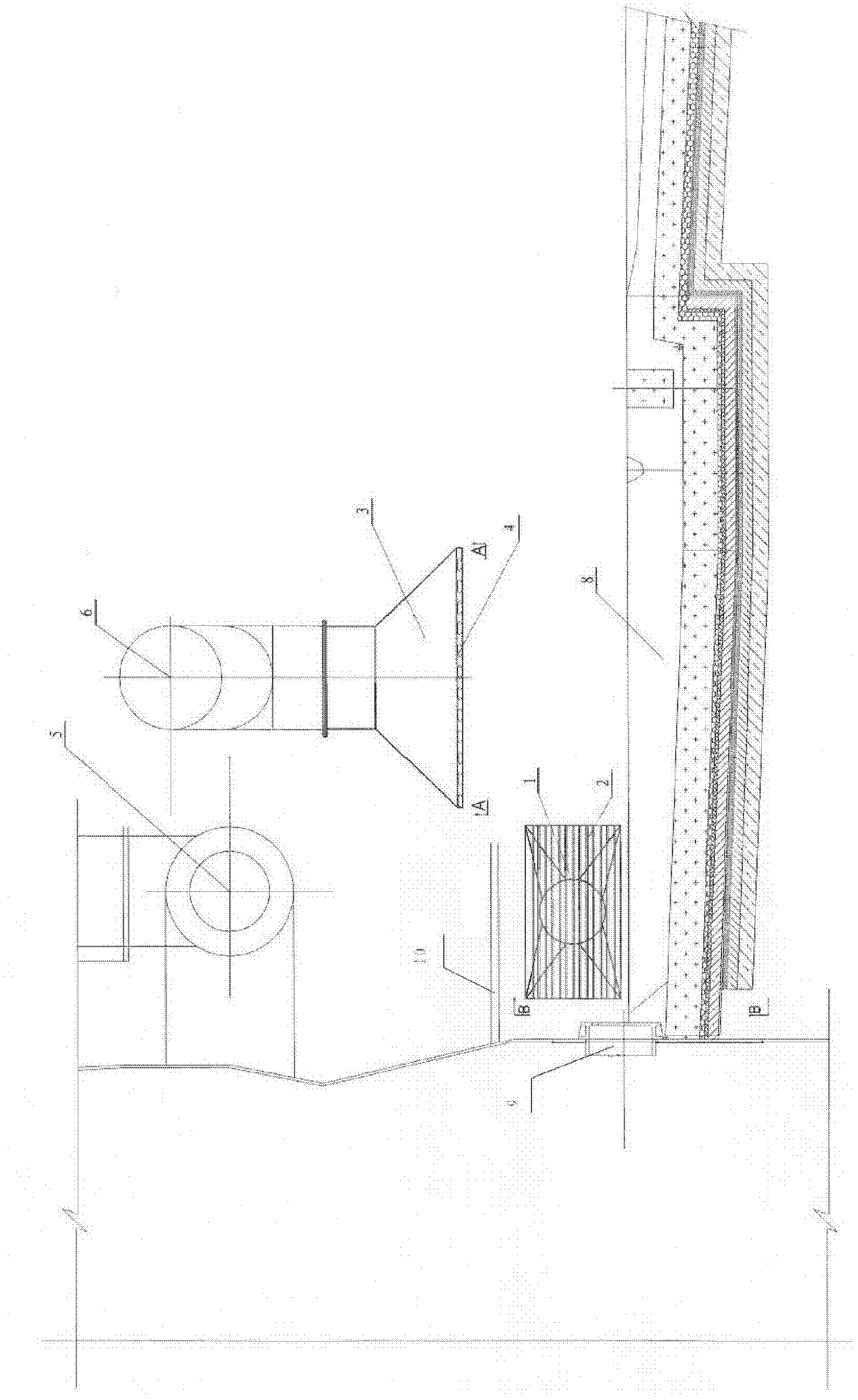

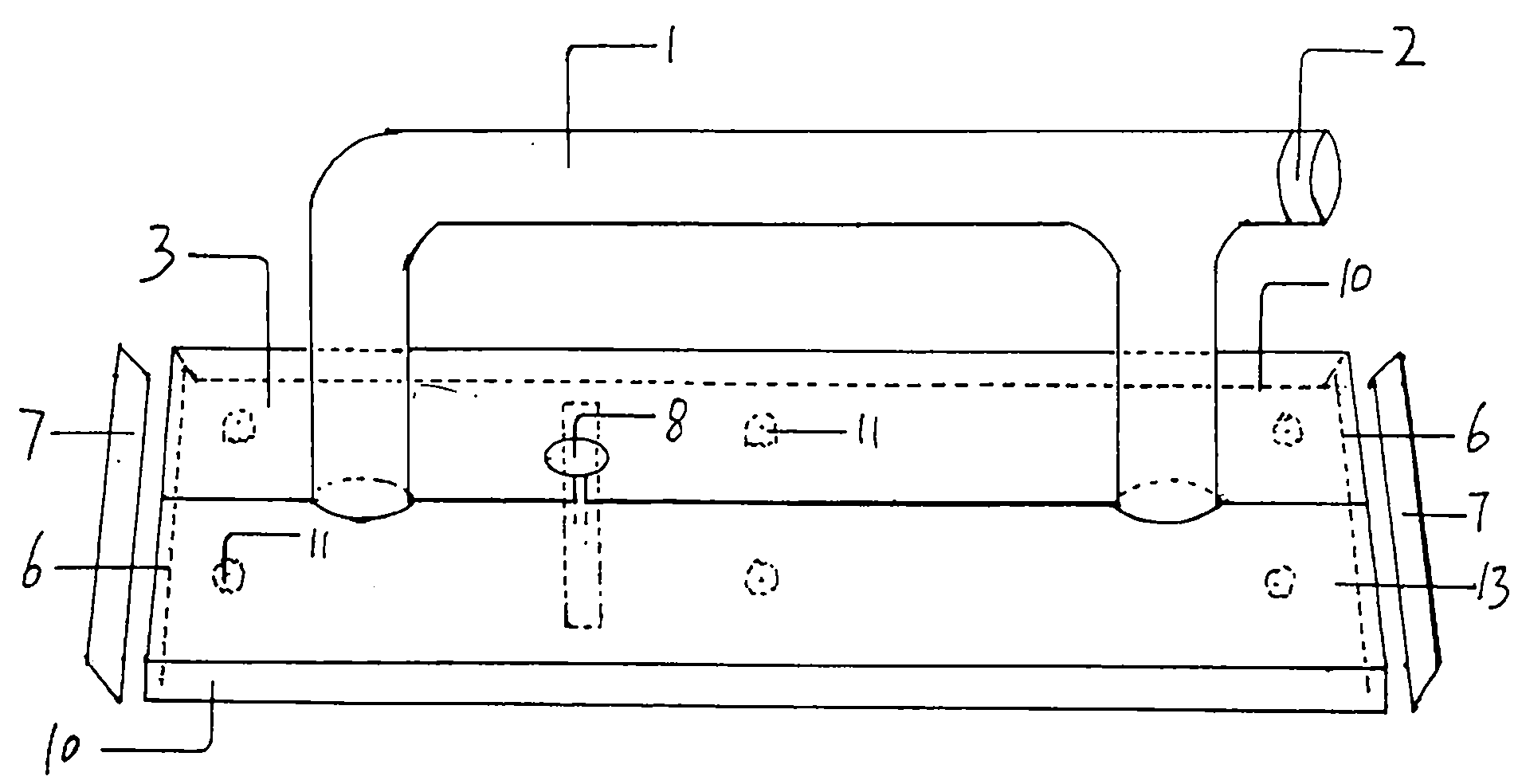

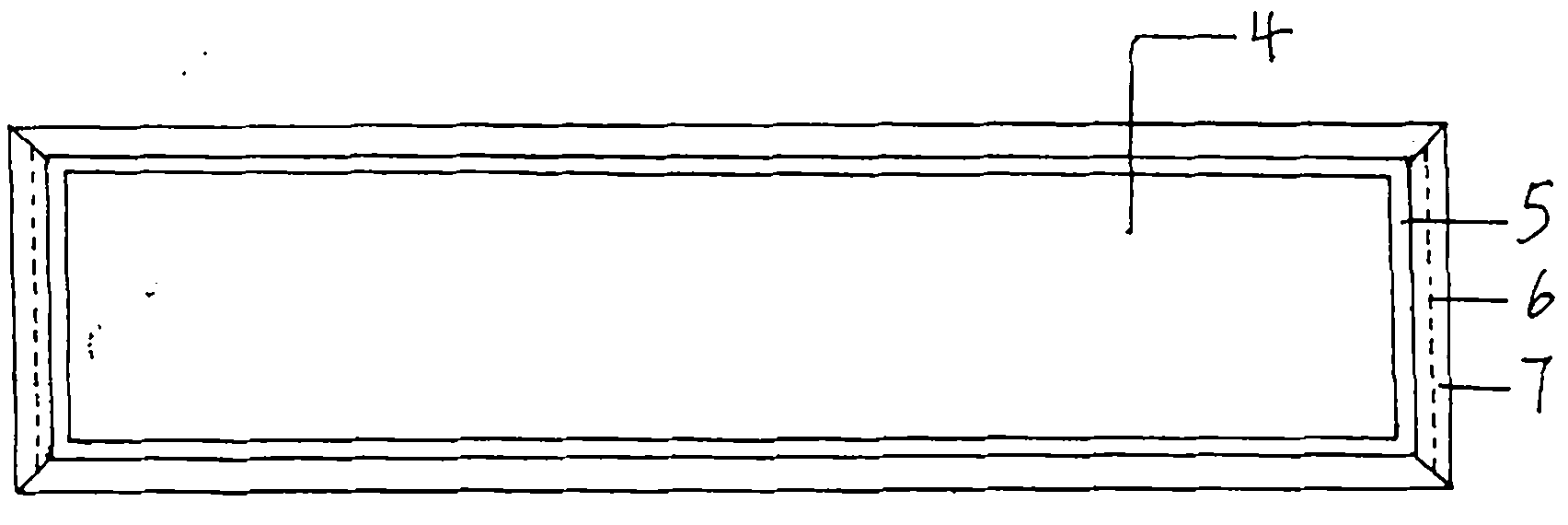

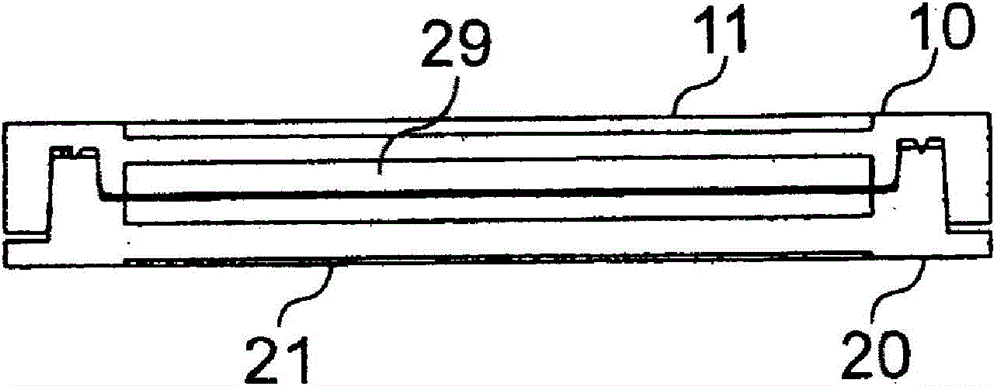

Table for Receiving a Workpiece and Method for Processing a Workpiece on Such Table

InactiveUS20070228630A1Uniform pressureUniform suctionConveyorsSemiconductor/solid-state device manufacturingMechanical engineeringWorkbench

Owner:OERLIKON SOLAR AG (TRUEBBACH)

Dust hood for blast furnace tap hole

InactiveCN102586522AImprove capture efficiencyImprove working environmentDischarge devicesDust arrestersWorking environmentEngineering

The invention discloses a dust hood for a blast furnace tap hole. The dust hood for the blast furnace tap hole comprises a top-suction dust hood and a side-suction dust hood, wherein the top-suction dust hood is arranged above the outer side of the blast furnace tap hole, and the side-suction dust hood is arranged at one side of a molten iron trough, which is connected with the blast furnace tap hole; the top-suction dust hood comprises a first dust removal pipe and a first dust hood connected with the first dust removal pipe; the side-suction dust hood comprises a second dust removal pipe and a second dust hood connected with the second dust removal pipe; and the hood mouth of the side-suction dust hood is inclined. According to the dust hood for the blast furnace tap hole, the energy consumption can be reduced, the working environment of a casting house is improved and the smoke dust collection efficiency can be increased.

Owner:WISDRI ENG & RES INC LTD

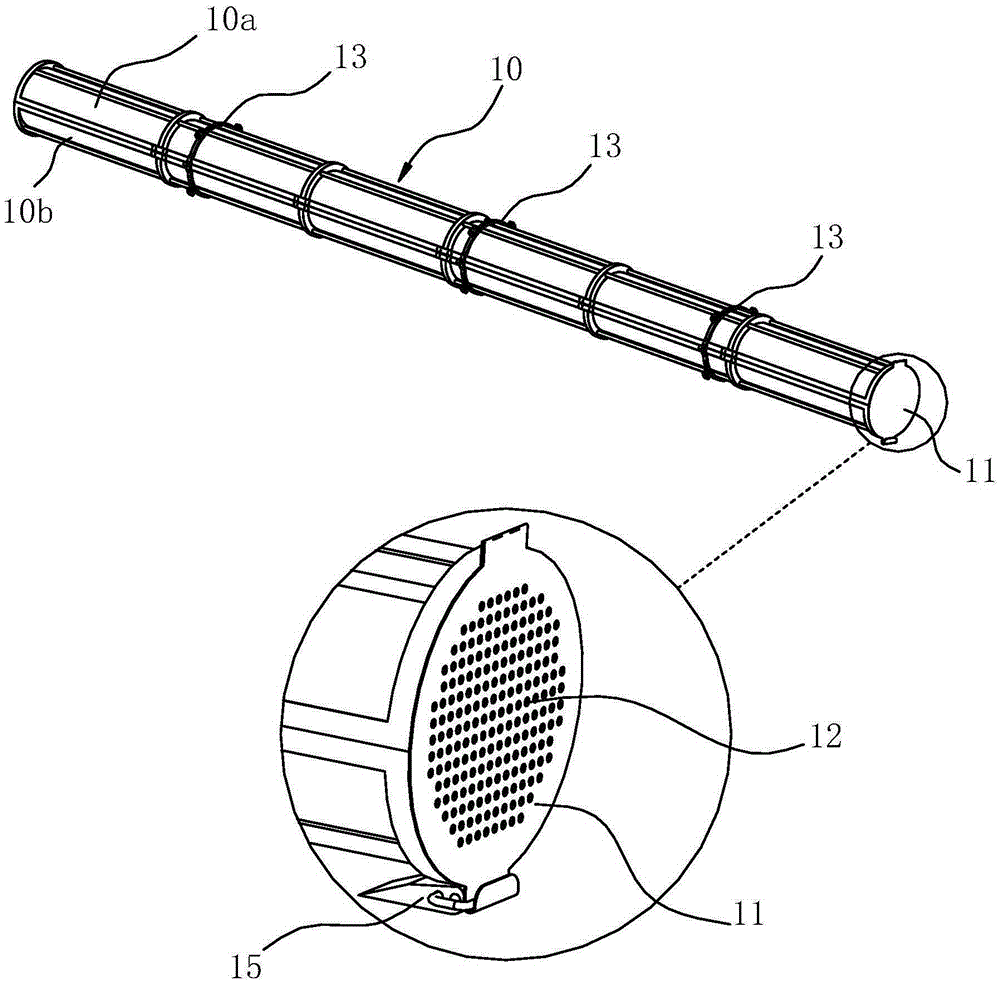

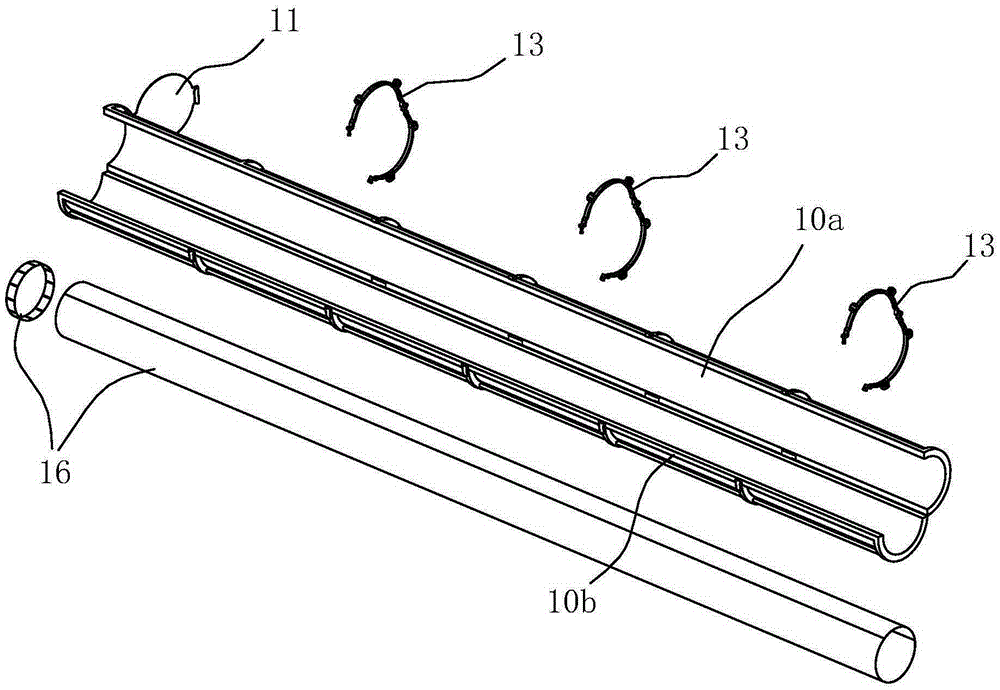

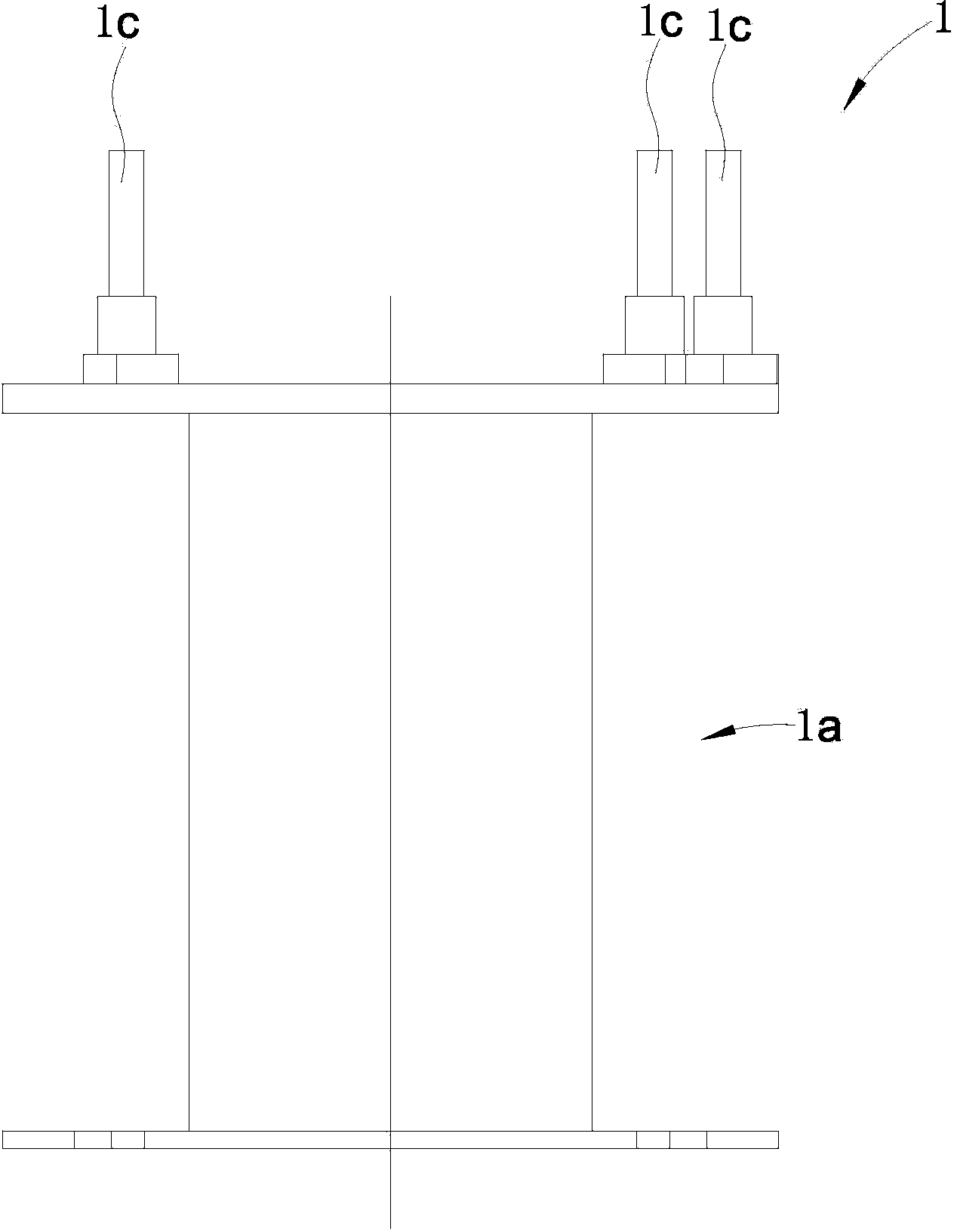

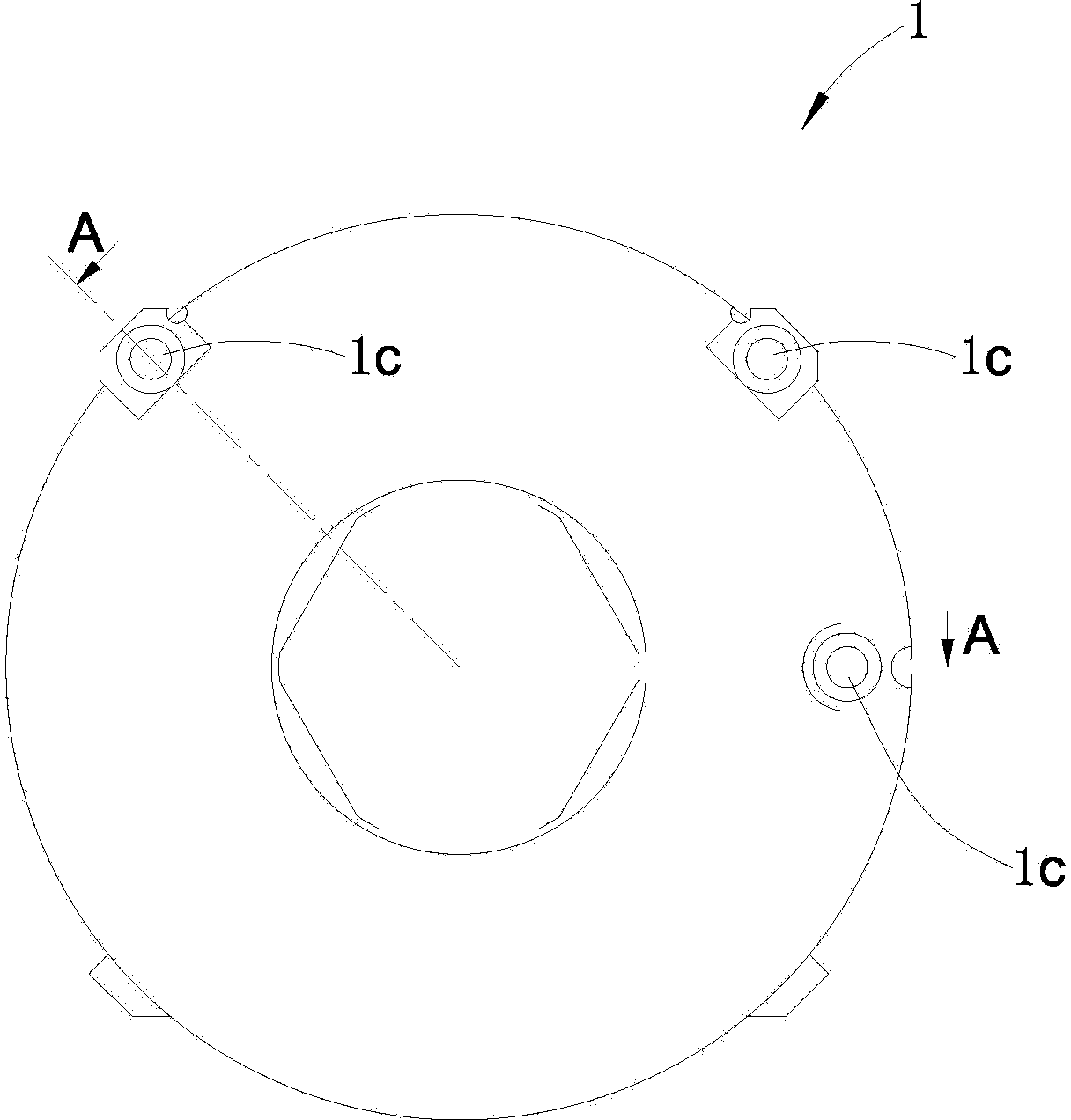

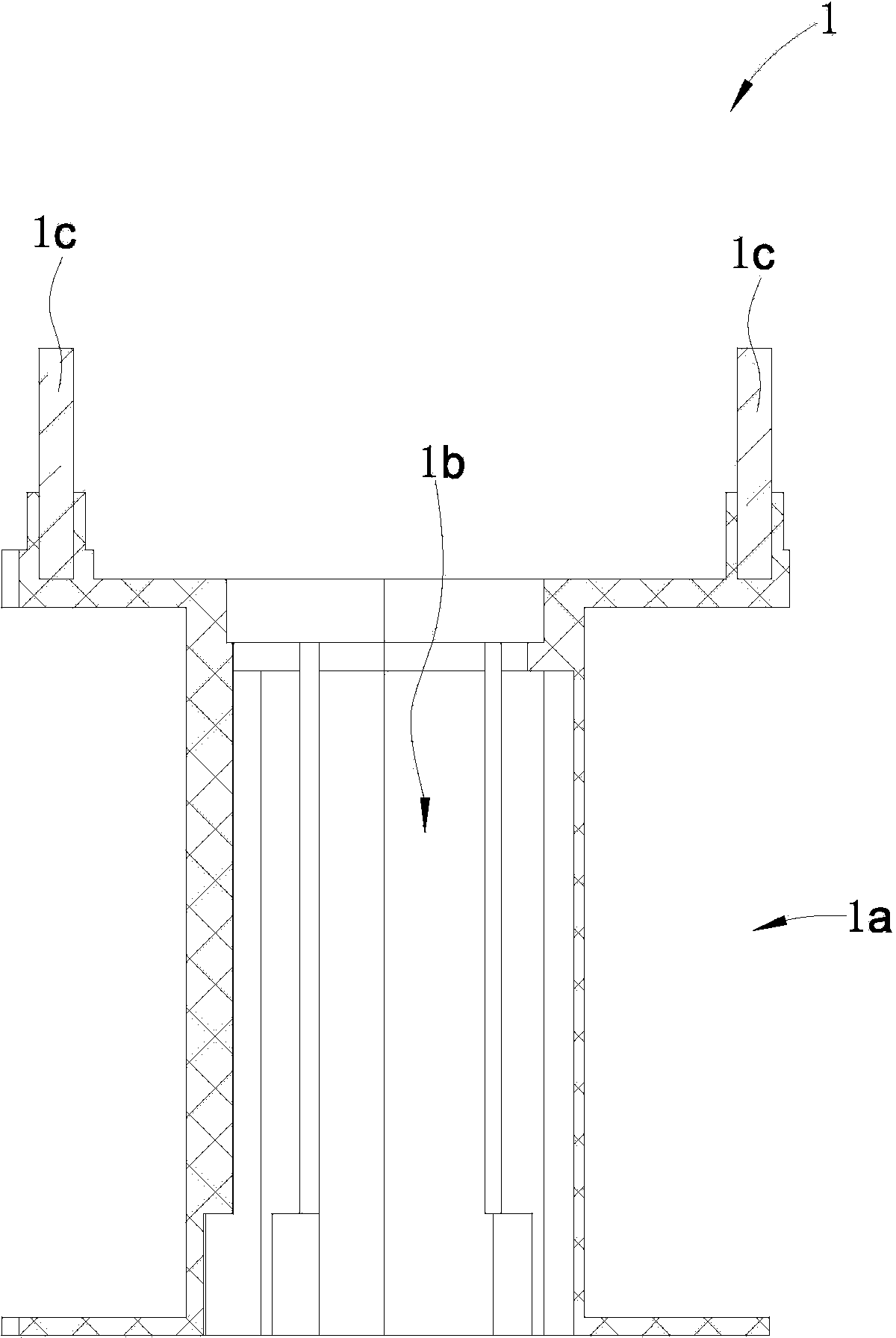

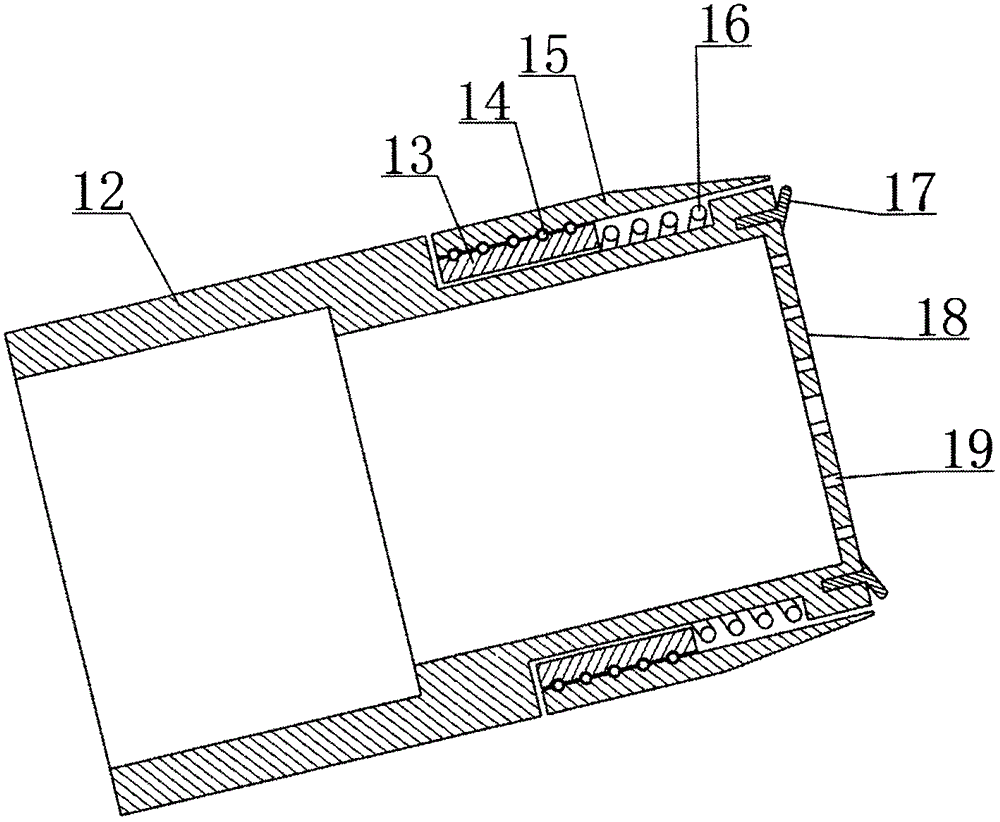

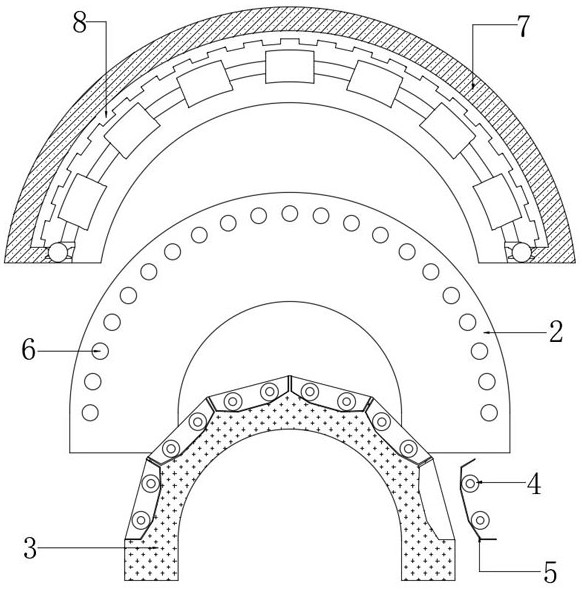

Molding die for ceramic fiber filtering pipe

The invention belongs to a production device for ceramic fiber high-temperature gas filtering materials, and particularly relates to a molding die for a ceramic fiber filtering pipe. The molding die comprises a pipe-shaped body formed by buckling two half pipes. One end of the pipe-shaped body is provided with an end cover. The molding die further comprises a locking unit used for detachably locking the two half pipes and the end cover. Small pumping filtration holes are evenly distributed in the two half pipes and the end cover. Filtering cloth is laid on the inner wall of the pipe-shaped body and the inner wall of the end cover. Small pumping filtration holes are evenly distributed in the pipe-shaped body and the end cover, and when the die is filled with size containing ceramic fibers and is arranged in a negative-pressure environment, even suction force is generated on the pipe-shaped body and the end cover, the size in the die is sucked out, meanwhile, the ceramic fibers in the size can be attached to the filtering cloth laid in the die, the size containing ceramic fibers of different specifications is poured into the die multiple times to be subjected to pumping filtration, and a pipe wall with pores gradually changing can be formed.

Owner:HEFEI FOUND TECH

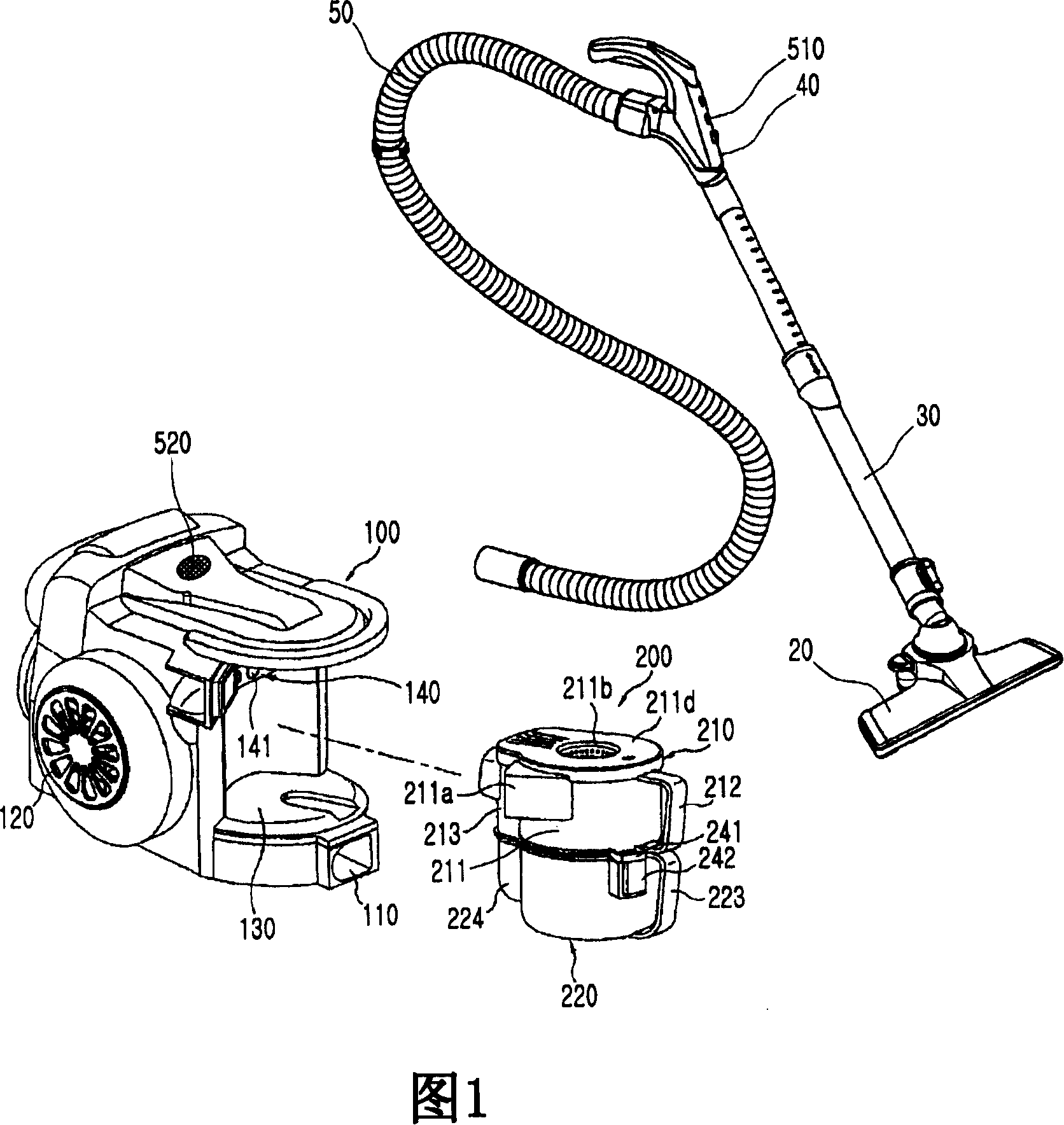

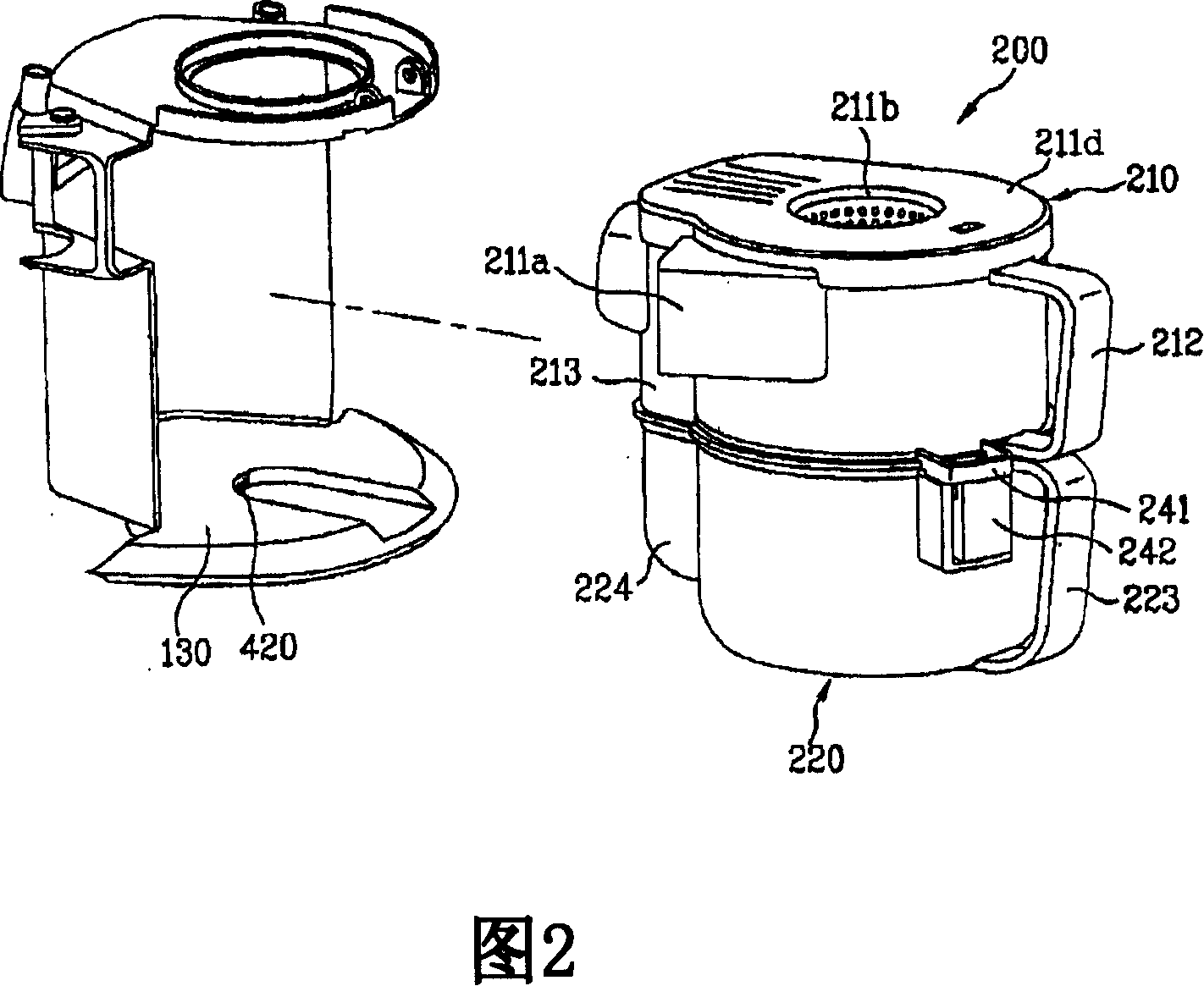

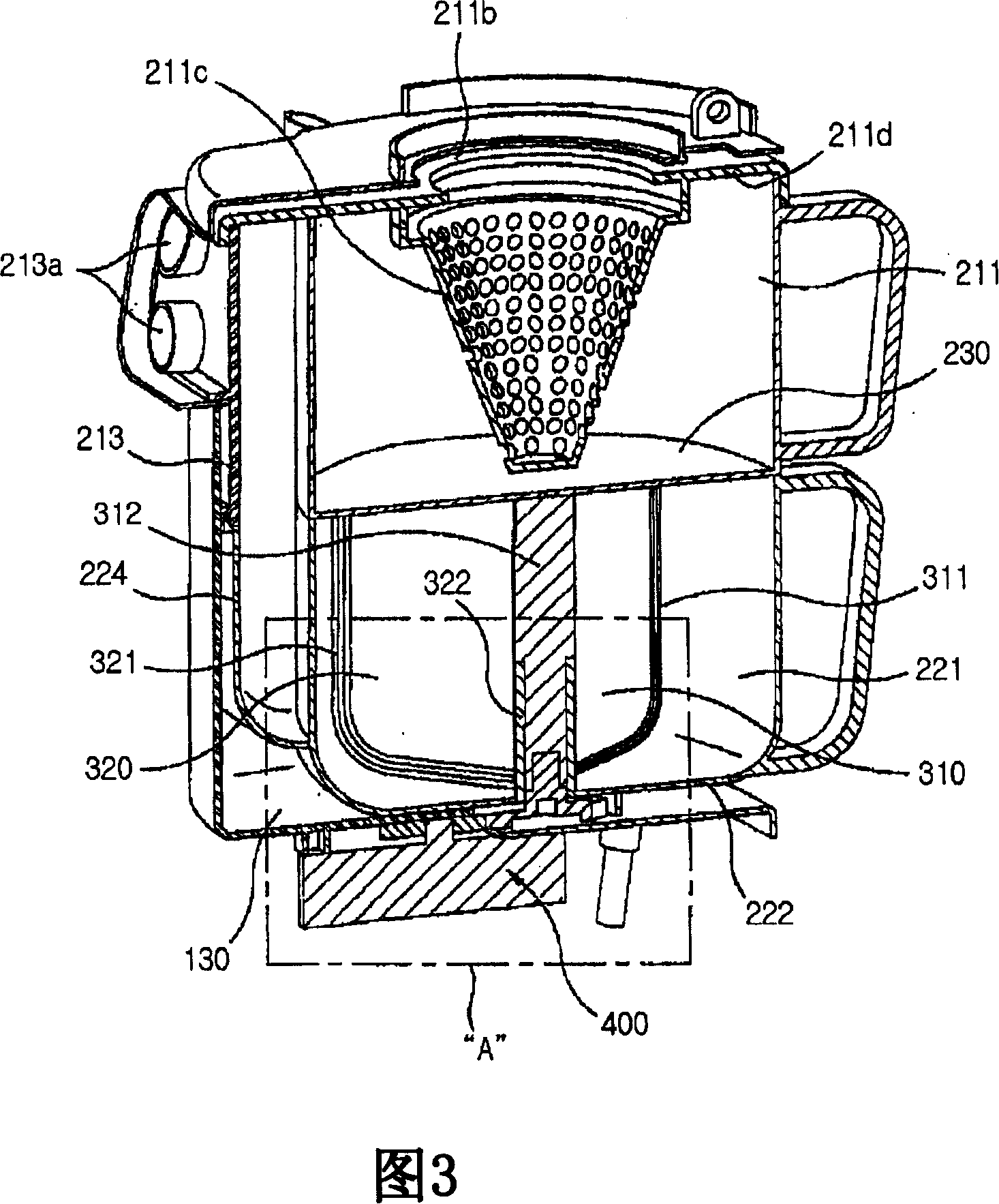

Method of controlling vacuum cleaner

InactiveCN101138478AMaximize collection capacityReduce volumeSuction filtersSuction nozzlesInspired gasVacuum cleaner

There is provided a method of controlling a vacuum cleaner having a dust collection unit in which dusts separated from air sucked by a suction motor are stored. The method includes operating the suction motor with a first driving force, determining an amount of the dusts stored in the dust collection unit, and operating the suction motor with a second driving force greater than the first driving force as the amount of the dusts increases.

Owner:LG ELECTRONICS INC

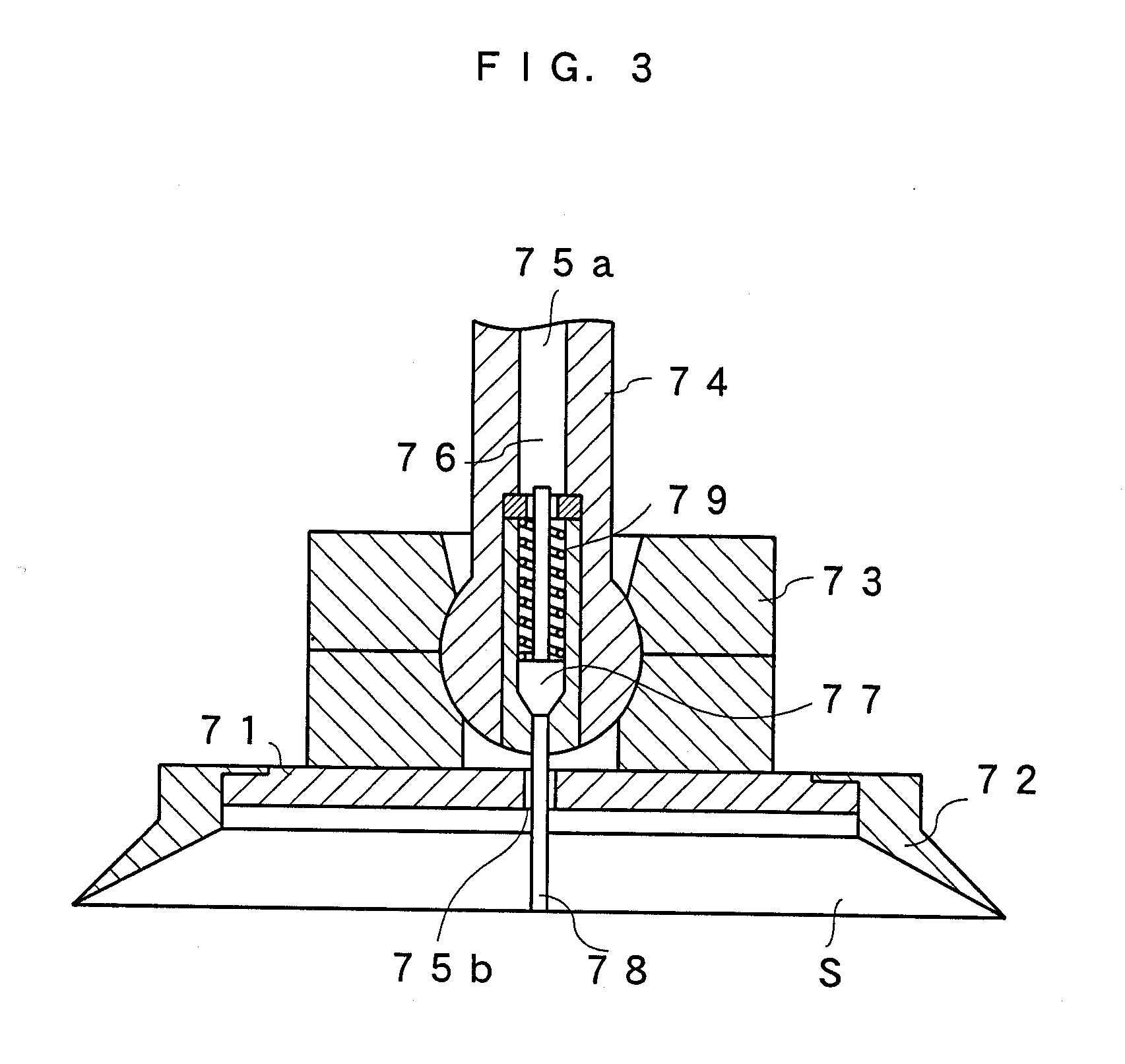

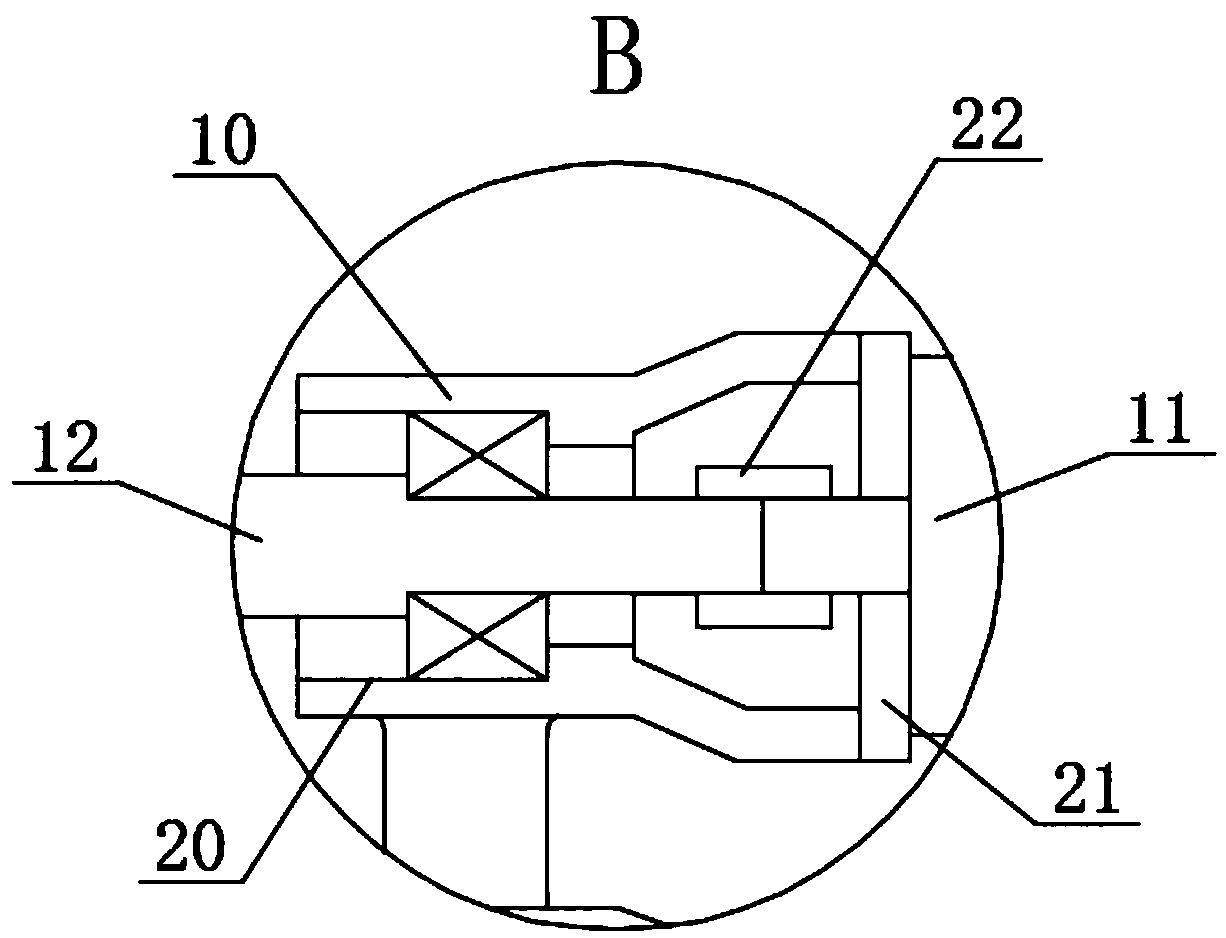

Driving device of electromagnetic relay

ActiveCN103367047ALarge travel displacementSimple structureElectromagnetic relay detailsPower flowReciprocating motion

The invention provides a driving device of an electromagnetic relay. The driving device comprises an iron core, a coil, a guide rod and a coil framework, wherein the coil is wound on the coil framework, the coil framework is internally provided with the iron core, the coil framework is internally sleeved with a sleeve, a plurality of permanent magnets are fixedly arranged between the sleeve and the coil framework, the iron core is arranged in the sleeve, the axial length of the sleeve is larger than the length of the iron core, the guide rod penetrates through two sides of the coil framework along an axial direction of the sleeve, and the guide rod and the iron core are fixedly connected. The iron core can be magnetized by the permanent magnets by utilizing homopolar opposite arrangement of the permanent magnets, a magnetic field can be generated in the coil when current flows through the coil, the magnetized iron core can be driven to do reciprocating motion along the axial direction of the coil framework, the iron core and the guide rod can restore to original status without reset devices such as a spring, the structure of the whole device is simplified, the stroke displacement of the iron core driving the guide rod to move is large, the requirement on long stroke is realized, and the flux leakage of the driving device of the electromagnetic relay, which is provided by the invention, is greatly reduced.

Owner:中国电子科技集团公司第四十研究所

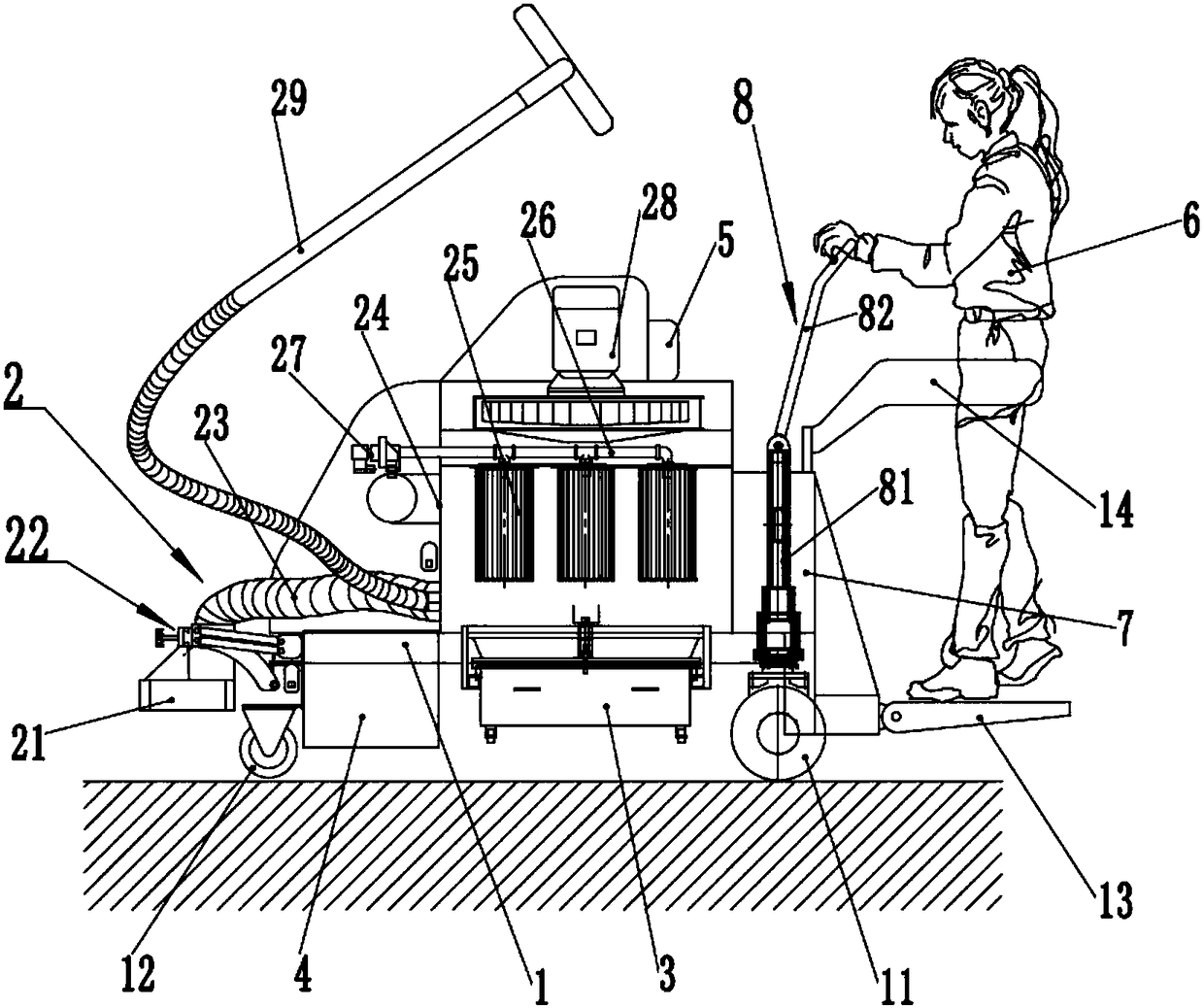

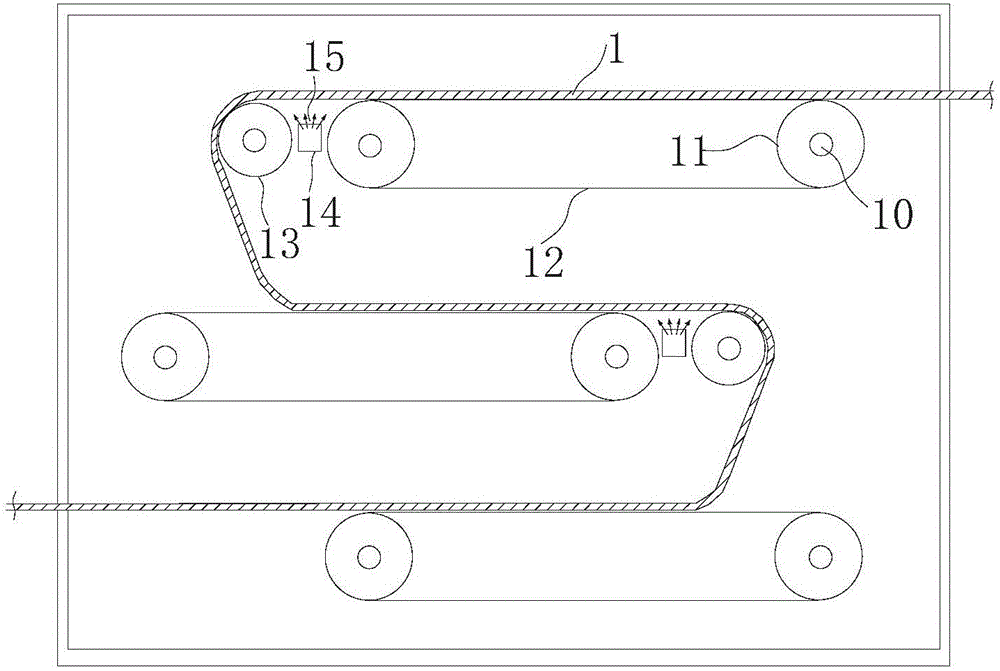

Vacuum sweeper

The invention discloses a vacuum sweeper. The vacuum sweeper comprises a vehicle body, a dust collecting system, a driving system, a steering system and an electrical box provided with a control circuit. The driving system drives the vehicle body to move, and the steering system controls the moving direction of the vehicle body. A foot plate for supporting an operator is arranged on the rear portion of the vehicle body. The dust collecting system comprises a suction cup, a suction cup lifting and swinging mechanism, a dust suction box, a filter and a suction fan. The suction cup is mounted onthe suction cup lifting and swinging mechanism, and the suction cup lifting and swinging mechanism is installed on the front portion of the vehicle body. The suction cup lifting and swinging mechanismdrives the suction cup to perform lifting movement, and the dust suction box is installed in the vehicle body. The suction cup is connected to the dust suction box through a dust suction pipe, and the filter is installed inside the dust suction box. The suction fan is installed on the vehicle body, and the suction fan is electrically connected with the control circuit. The filter is connected with an inlet of the suction fan, and a dust collecting box which can be pulled is arranged below a dust outlet of the dust suction box on the vehicle body. The vacuum sweeper has the characteristics ofgood dust suction effect, flexible and convenient use, small size and attractive appearance.

Owner:佛山市巨石集尘机器有限公司

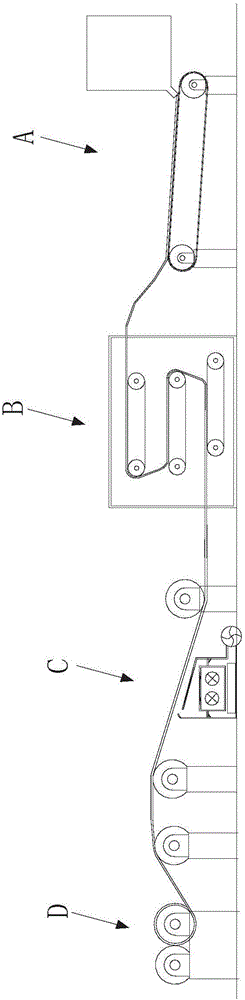

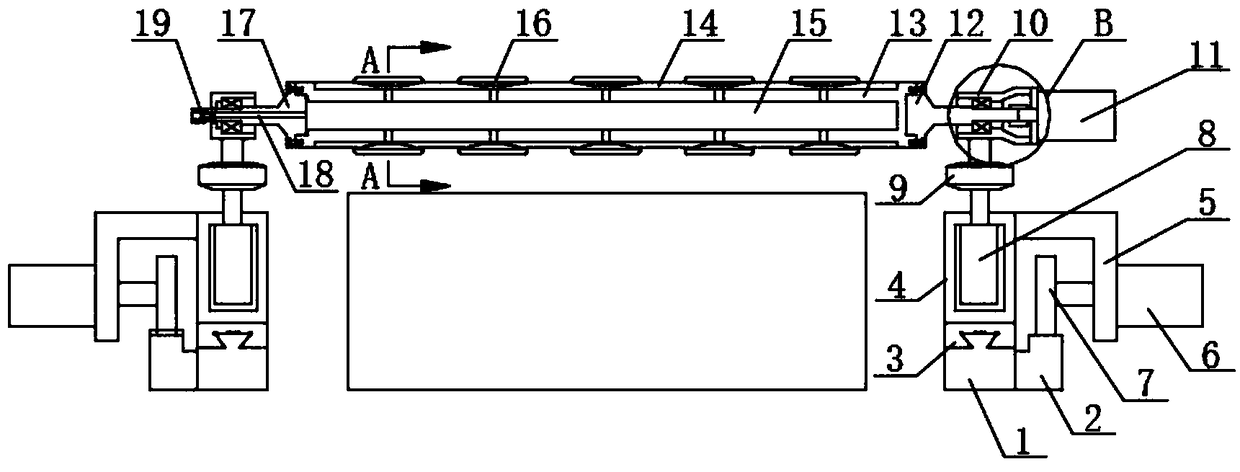

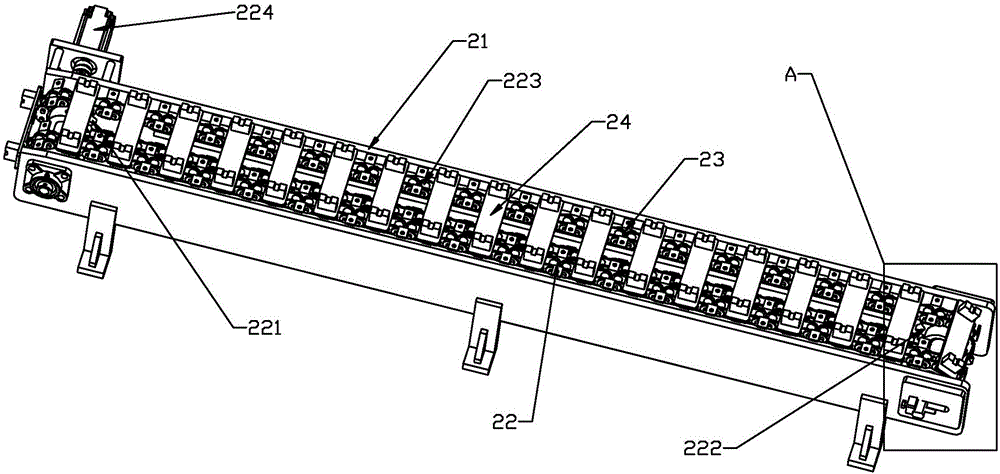

Battery separator producing system and method

ActiveCN105006540AFast molding speedShorten drying timeCell component detailsPulp and paper industrySlurry

The invention discloses a battery separator producing system and method. The battery separator producing system comprises an AGM separator molding device, a drying device and an optical inspection device which are sequentially connected. The AGM separator molding device comprises a conveying net belt, two sets of vacuum water suction boxes and a circulation net belt, wherein the conveying net belt is used for driving an AGM separator, the vacuum water suction box is used for dewatering the AGM separator, and the circulation net belt is arranged above the conveying net belt and abuts against the top face of the AGM separator. The first set of vacuum water suction boxes act with the bottom face of the conveying net belt, and the second set of vacuum water suction boxes act with the side, opposite to the AGM separator, of the circulation net belt. The optical inspection device comprises a lamp box internally provided with a light emitting element. The side, facing the AGM separator, of the lamp box is provided with an inclined light inlet window. An air inlet is formed in the bottom of the lamp box and communicated with an air feeder. The top of the lamp box is provided with an air outlet facing the AGM separator. The slurry drying time can be shortened, the upper and lower planes of the molded AGM separator are flat, and the AGM separator performance is improved.

Owner:ZHEJIANG CHANGTONG SCI & TECH

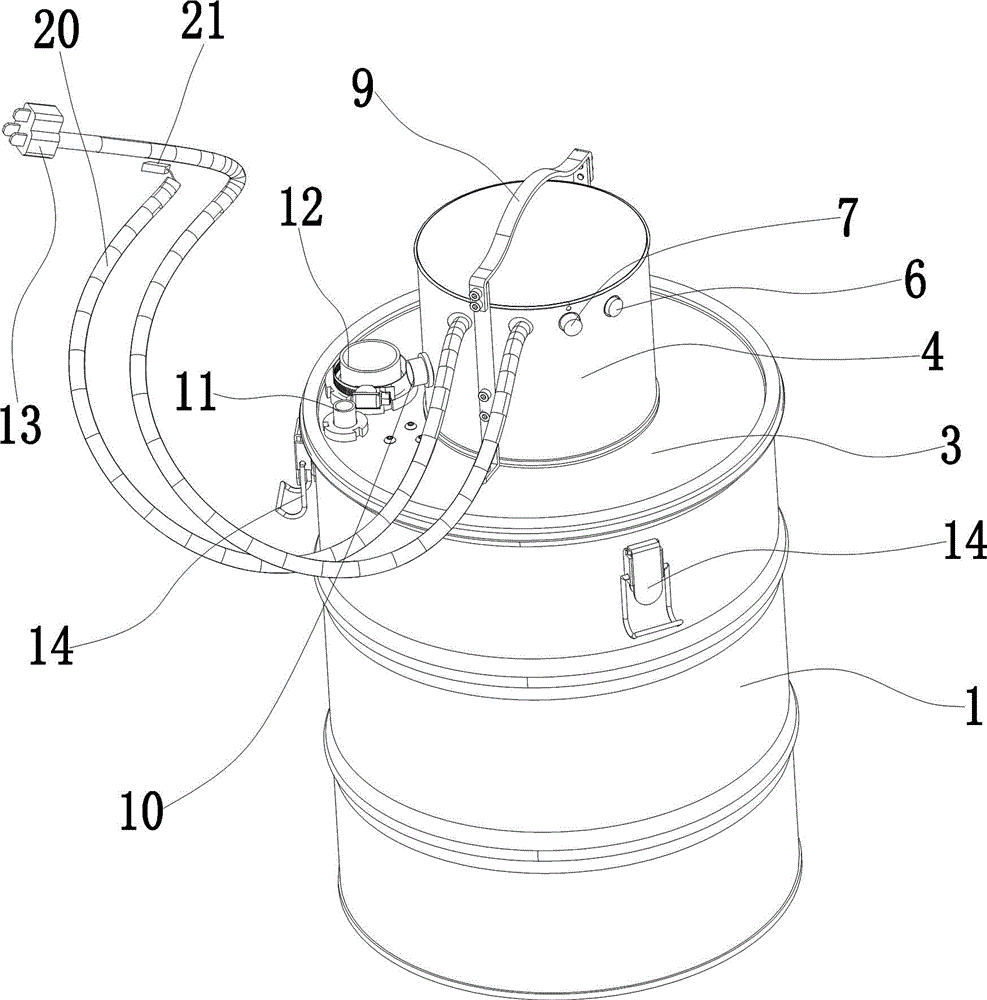

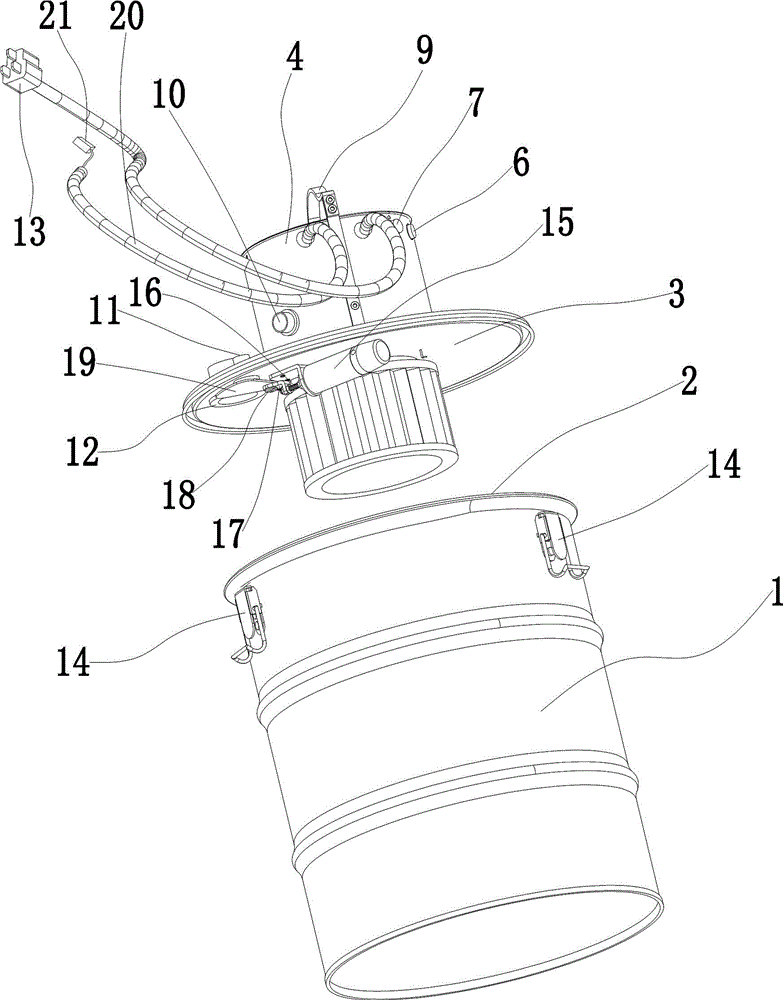

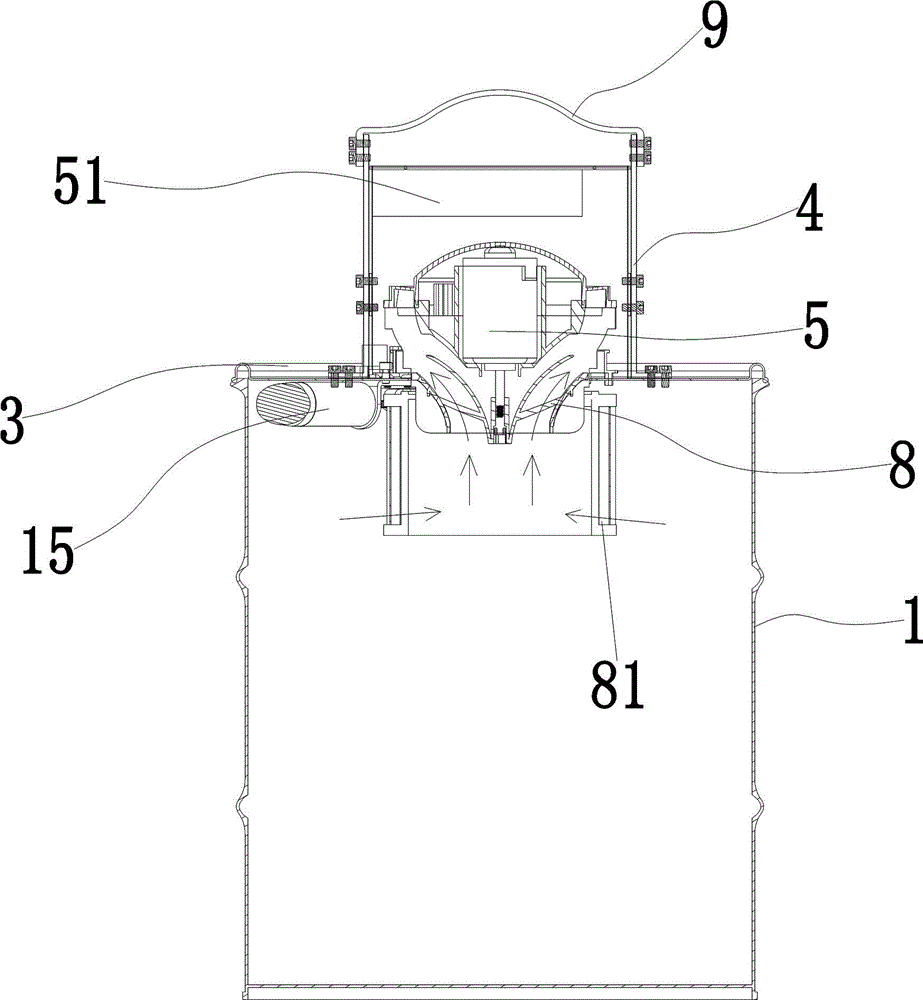

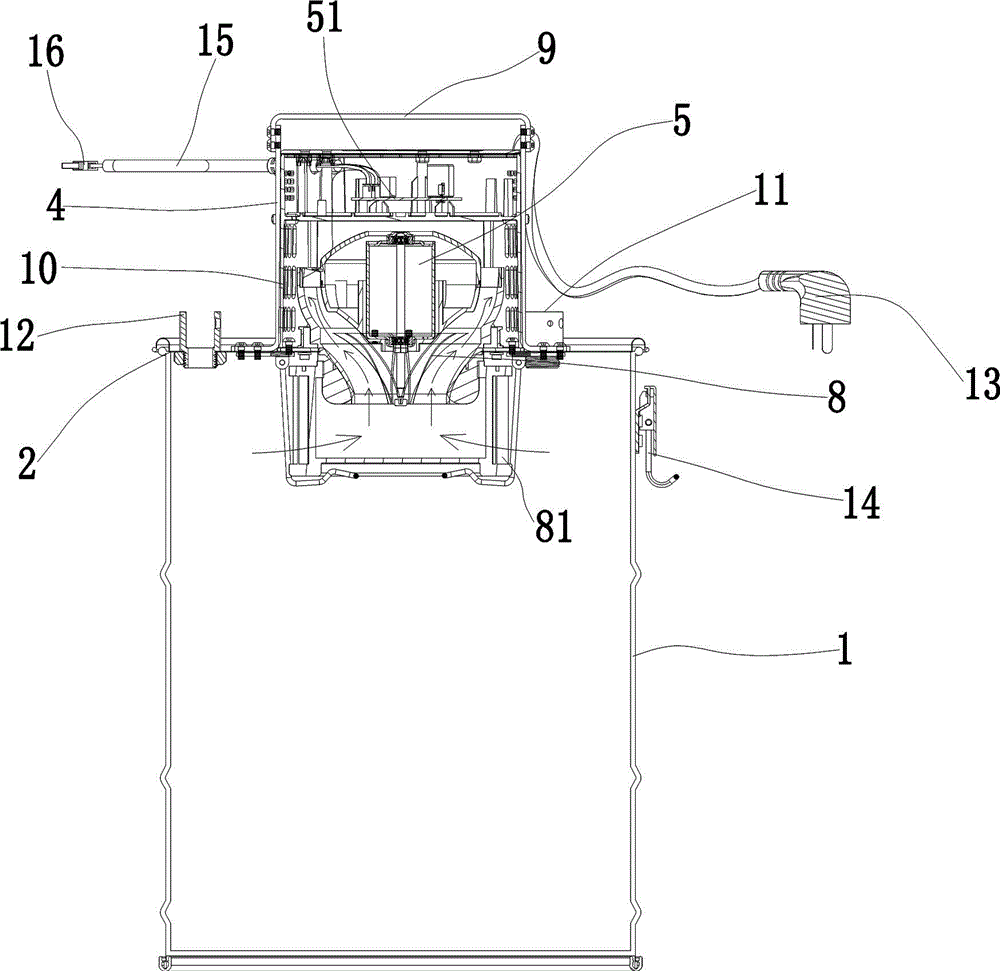

Dust barrel for a sewing machine

ActiveCN105002675AExtended service lifeReduce noiseSewing-machine elementsBrushless motorsInterior space

The invention discloses a dust barrel for a sewing machine. The barrel comprises a sewing machine, a controller arranged on the sewing machine and a barrel body, and the upper end of the barrel body is provided with an opening; the opening of the barrel body is provided with a barrel cover, and a protective hood is fixedly mounted above the barrel cover; the protective hood is provided with a brushless motor therein; the brushless motor is connected to a control system; the control system is connected to a switch, and a speed-adjustment knob; the brushless motor is connected to a fan blade which is positioned inside the barrel body; the fan blade is covered with a filtering cartridge; the protective hood is provided with a lifting handle; the protective hood is provided with an air exhaust opening; the barrel cover is provided with a first air opening and a second air opening thereon; the first air opening and the second air opening are communicated with the inner space of the barrel body; the control system is connected to a plug. The dust barrel of the invention can collect dust without the cooperation with an external air source, thus preventing the problem of loud noise in dust collection. The dust barrel has a wide range of application and is not subject to any limitation.

Owner:YUHUAN YI ELECTRONICS

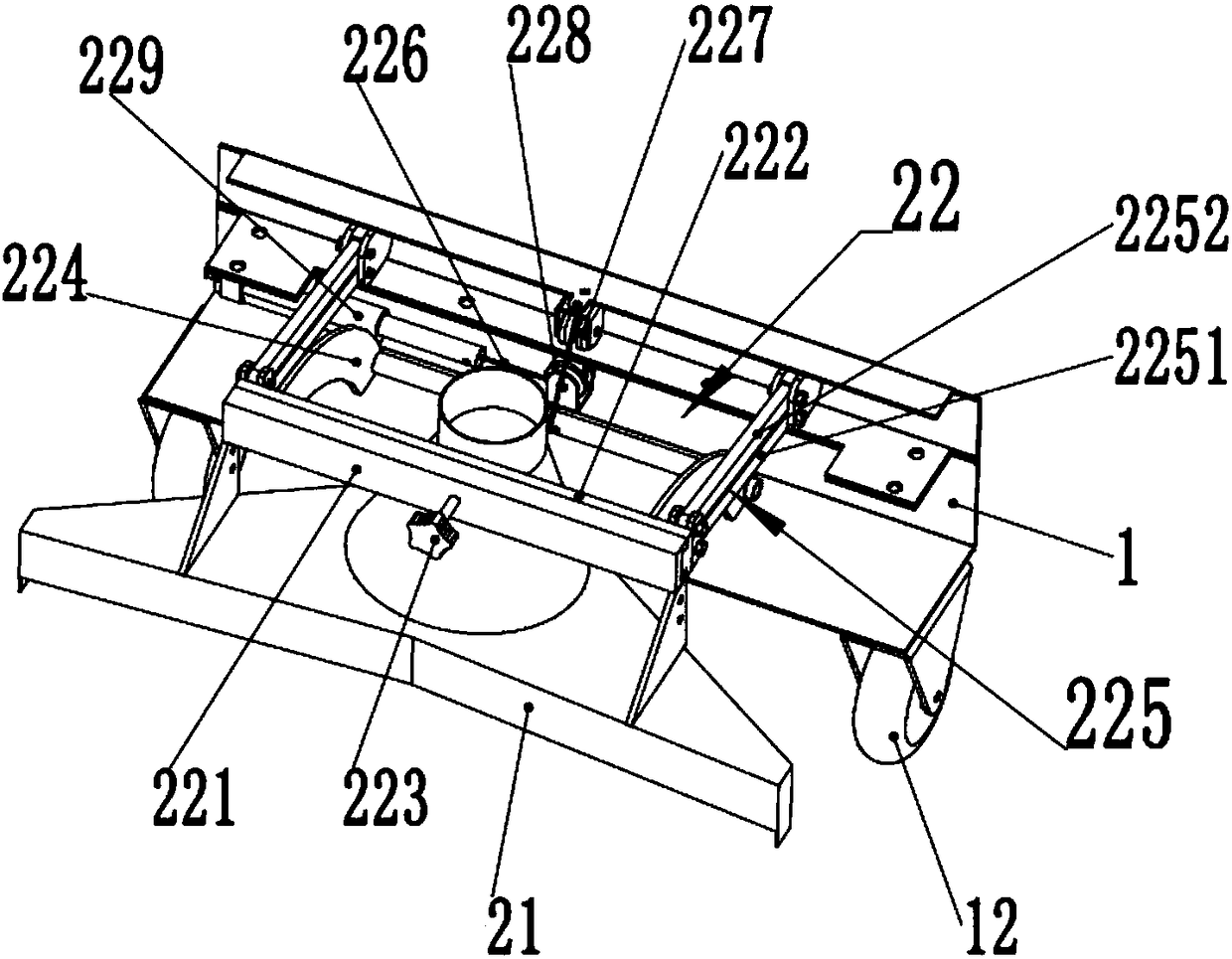

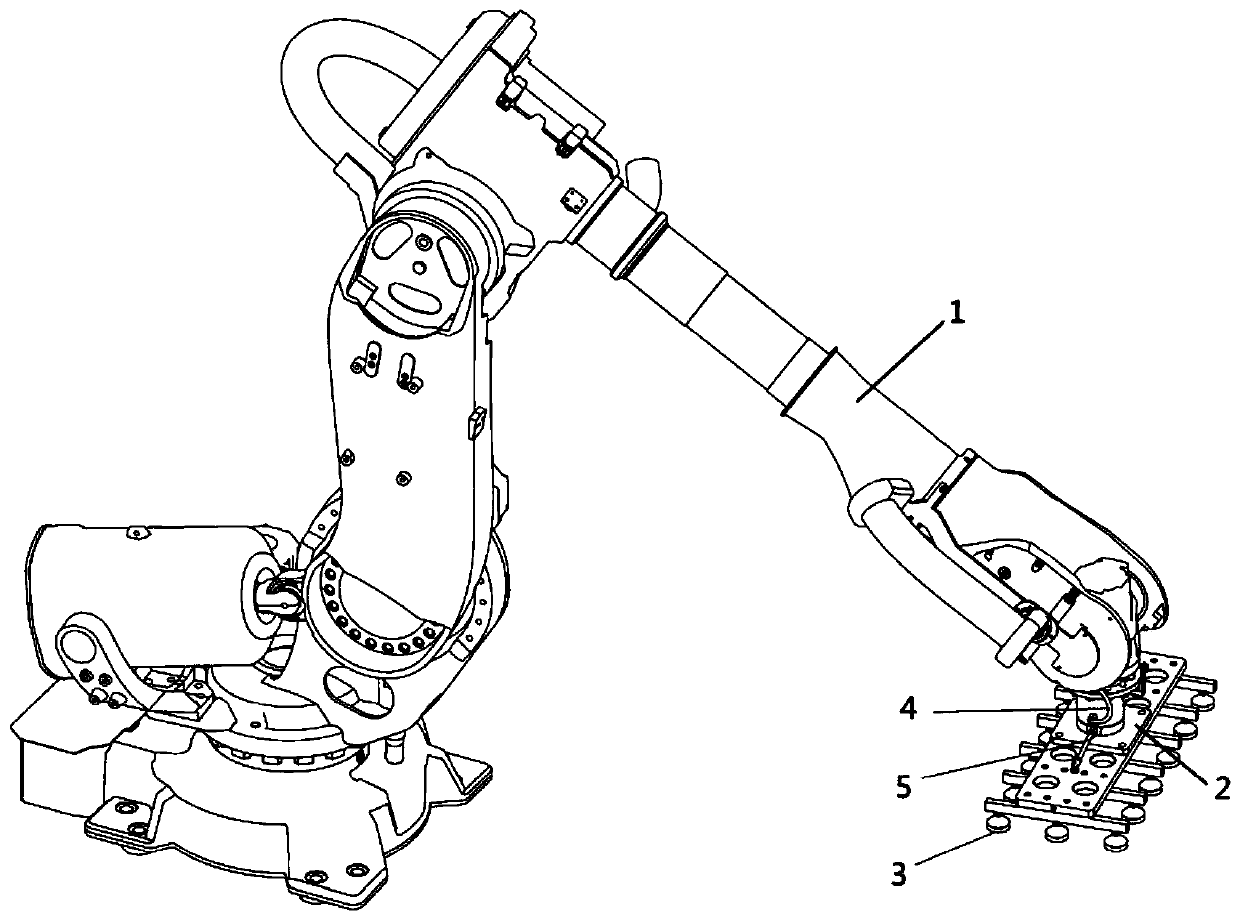

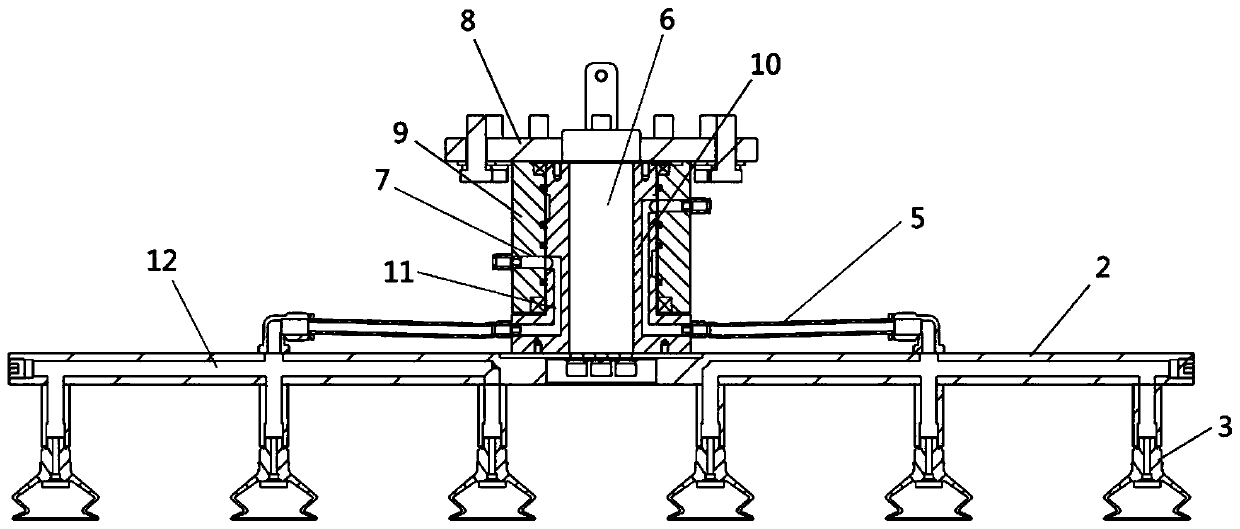

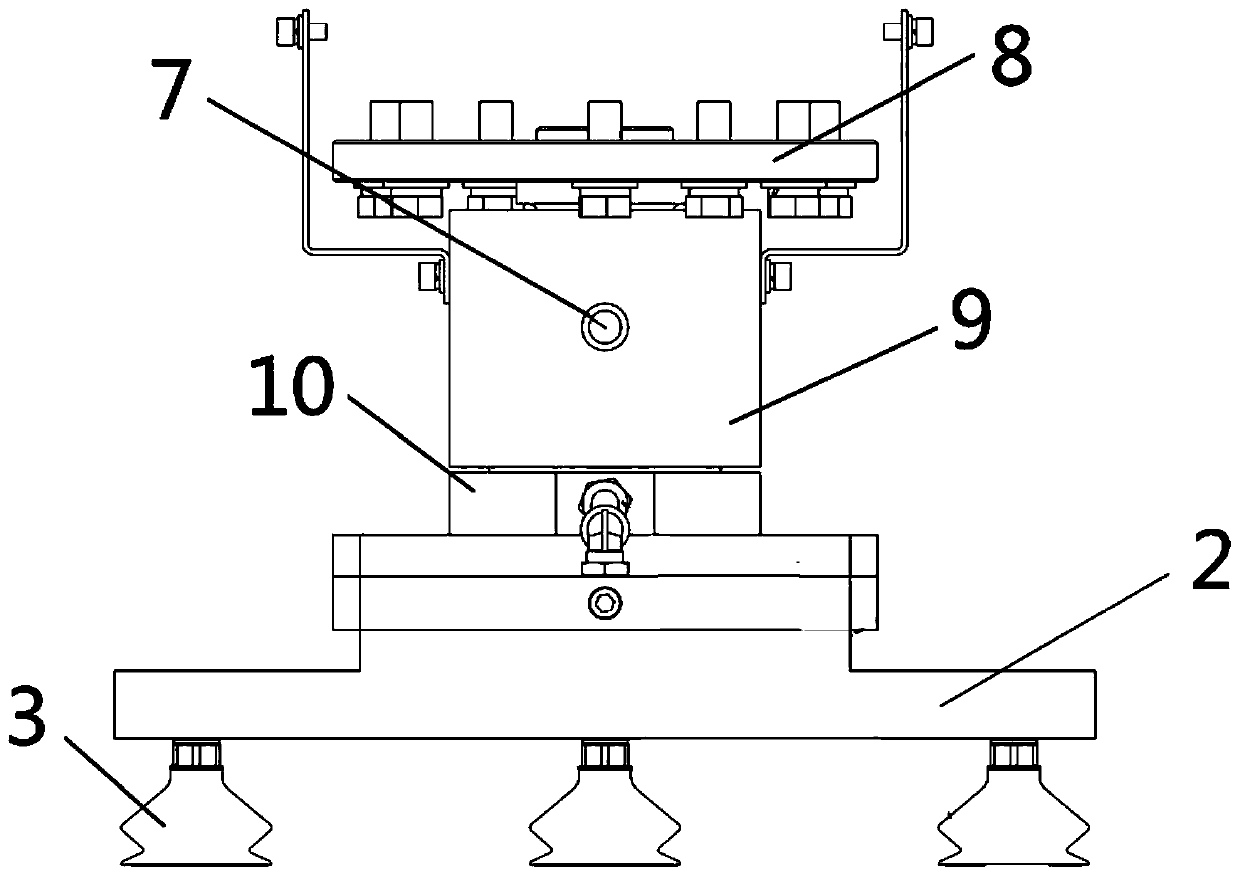

Mechanical arm rotating sucker conveying device

The invention relates to the technical field of conveying devices, in particular to a mechanical arm rotating sucker conveying device. The mechanical arm rotating sucker conveying device comprises a mechanical arm main body, a sucker assembly, an air pipeline assembly and a first air pipe, wherein the sucker assembly comprises a fixed component fixedly connected with the mechanical arm main body, a rotating component which is connected with the mechanical arm main body and rotates relative to the fixed component and a plurality of suckers which are connected with the rotating component and synchronously rotate with the rotating component; the air pipeline assembly comprises a plurality of first air pipeline structures arranged on the fixed component and a plurality of second air pipeline structures arranged on the rotating component, and the second air pipeline structures separately communicate with the suckers and an air path formed by the first air pipeline structures; and the first air pipe is connected with the first air pipeline structures of the fixed component. The service life of the mechanical arm rotating sucker conveying device is longer, economical losses can be reduced, and the production efficiency is increased.

Owner:CHINA TOBACCO GUANGXI IND

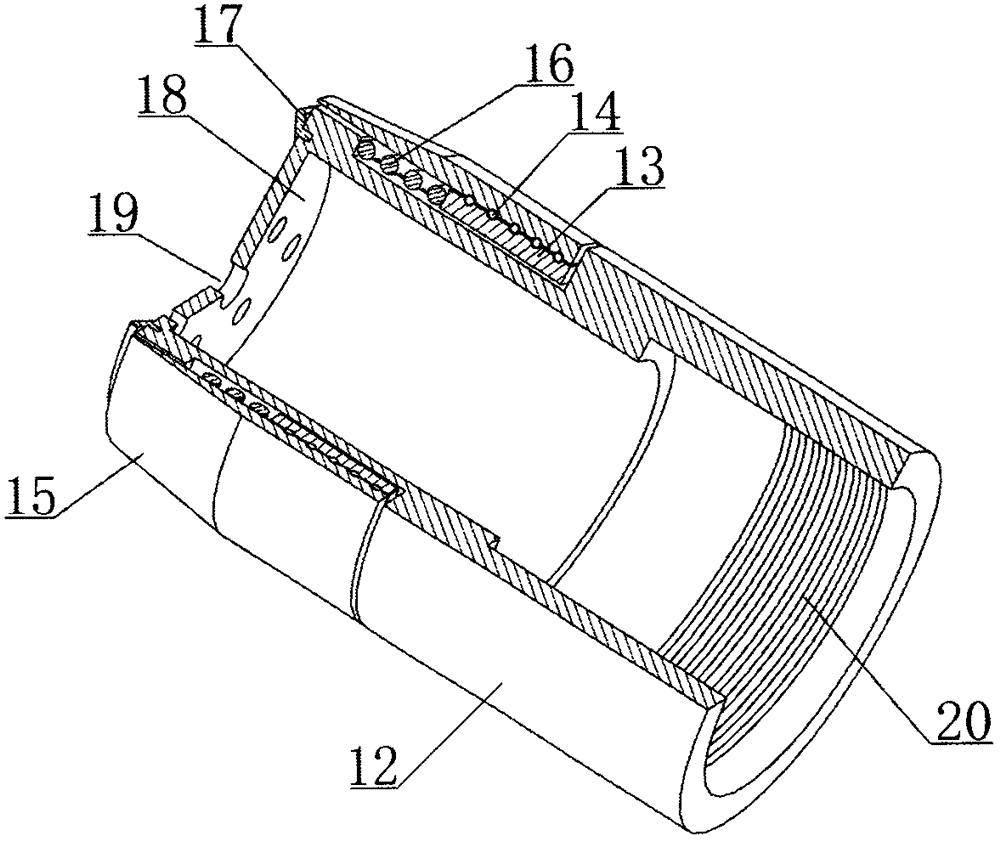

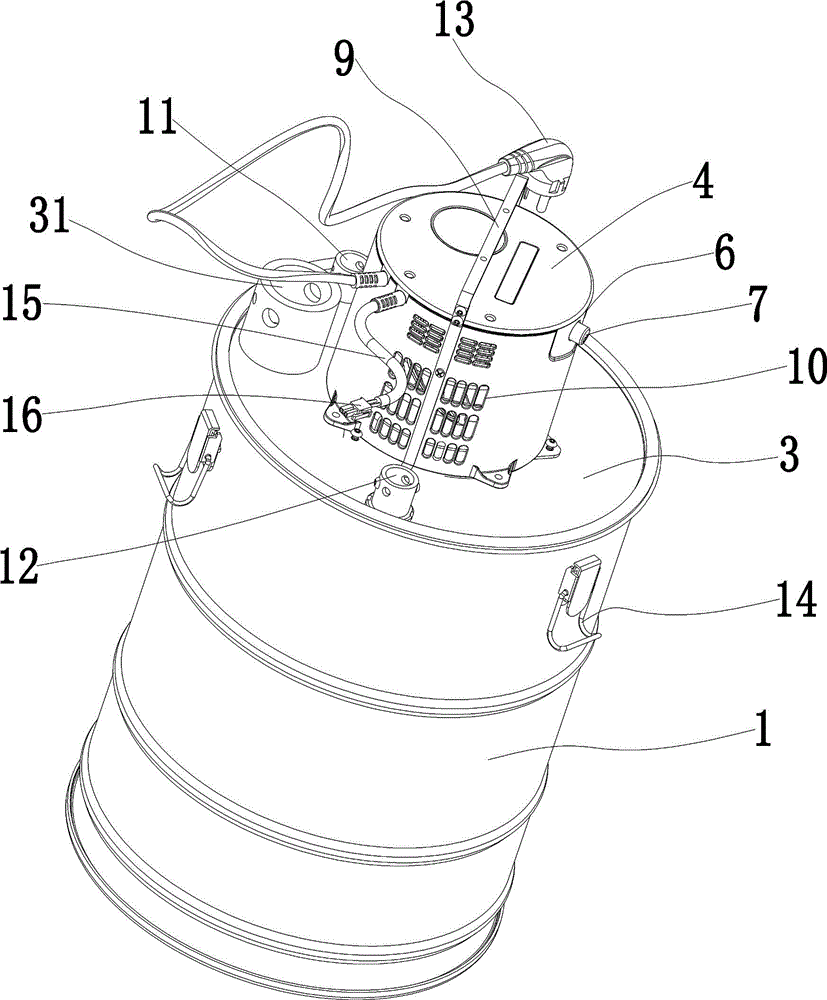

Cylindrical vacuum charger

InactiveCN101283836AUniform suctionSuction process is fastTobacco preparationTobacco treatmentVacuum extractionTar

The invention relates to an automatic tobacco charging machine, which belongs to the main equipment in the tobacco shredding process. The charging machine comprises a charging barrel adopting a cylindrical barrel with an interlayer; a rotating shaft arranged at the position of the horizontal cross corner of the barrel; a pair of material covers arranged at the position of the other vertical cross corner of the barrel; a vacuum extraction pipe, a feed liquid pipe and a steam pipe feeding into the barrel; a material liquid sprayer and a steam sprayer positioned on the upper section of the barrel; and a hot water inlet and outlet communicating with the interface of the barrel. The automatic tobacco charging machine can receive the feed liquid sprayed from the above sprayer according to a set ratio in a vacuum environment of the tobacco material, in a continuous turning stage and in an environment at a certain temperature, thus making the material absorption process of tobacco laminas more uniform, faster and more complete, improving the chemical property of tobacco laminas, further removing damage, reducing tar, and improving taste.

Owner:王昌林

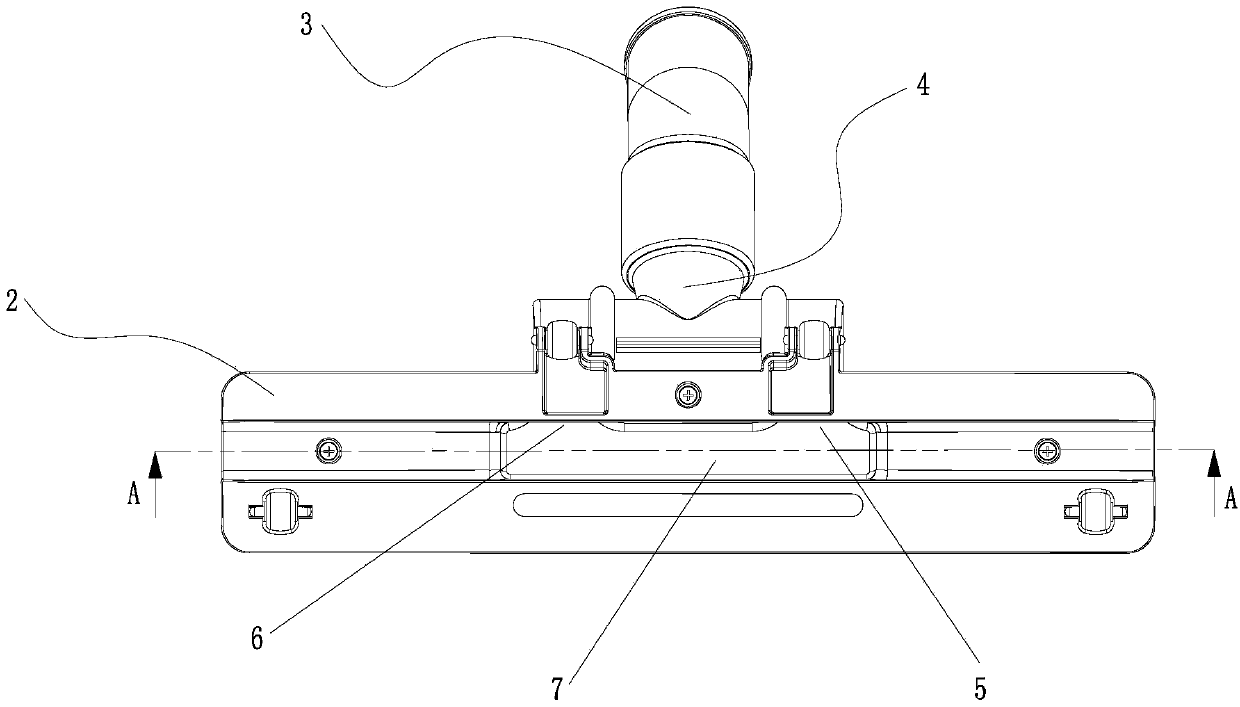

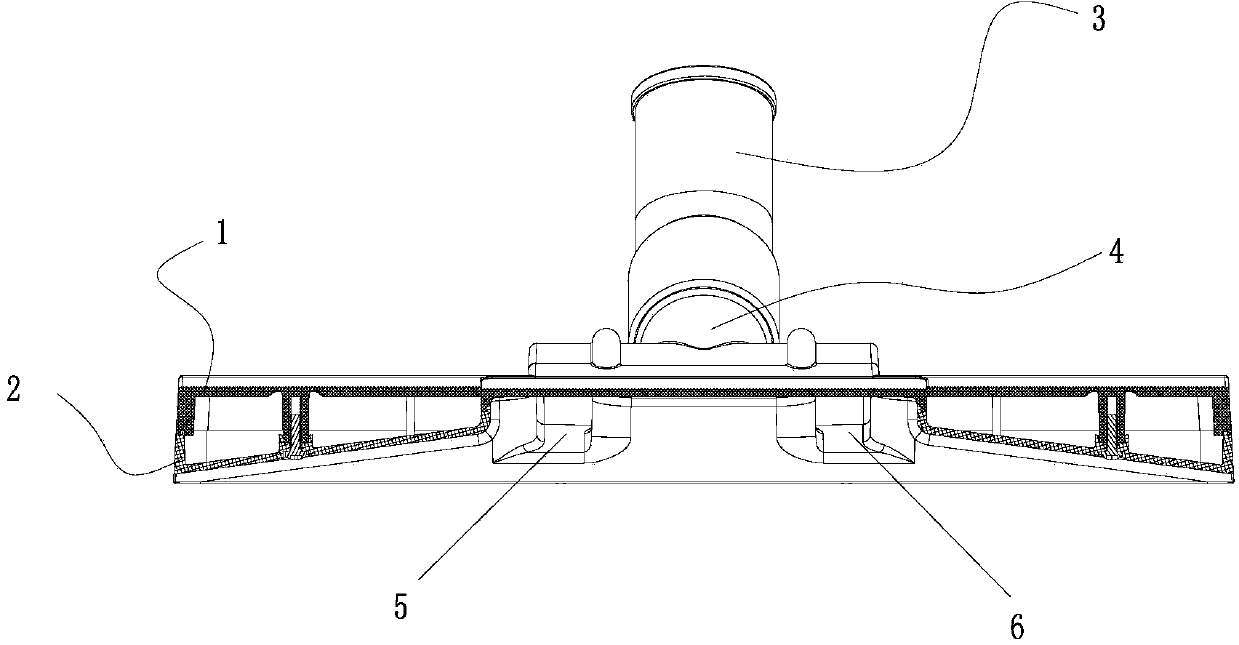

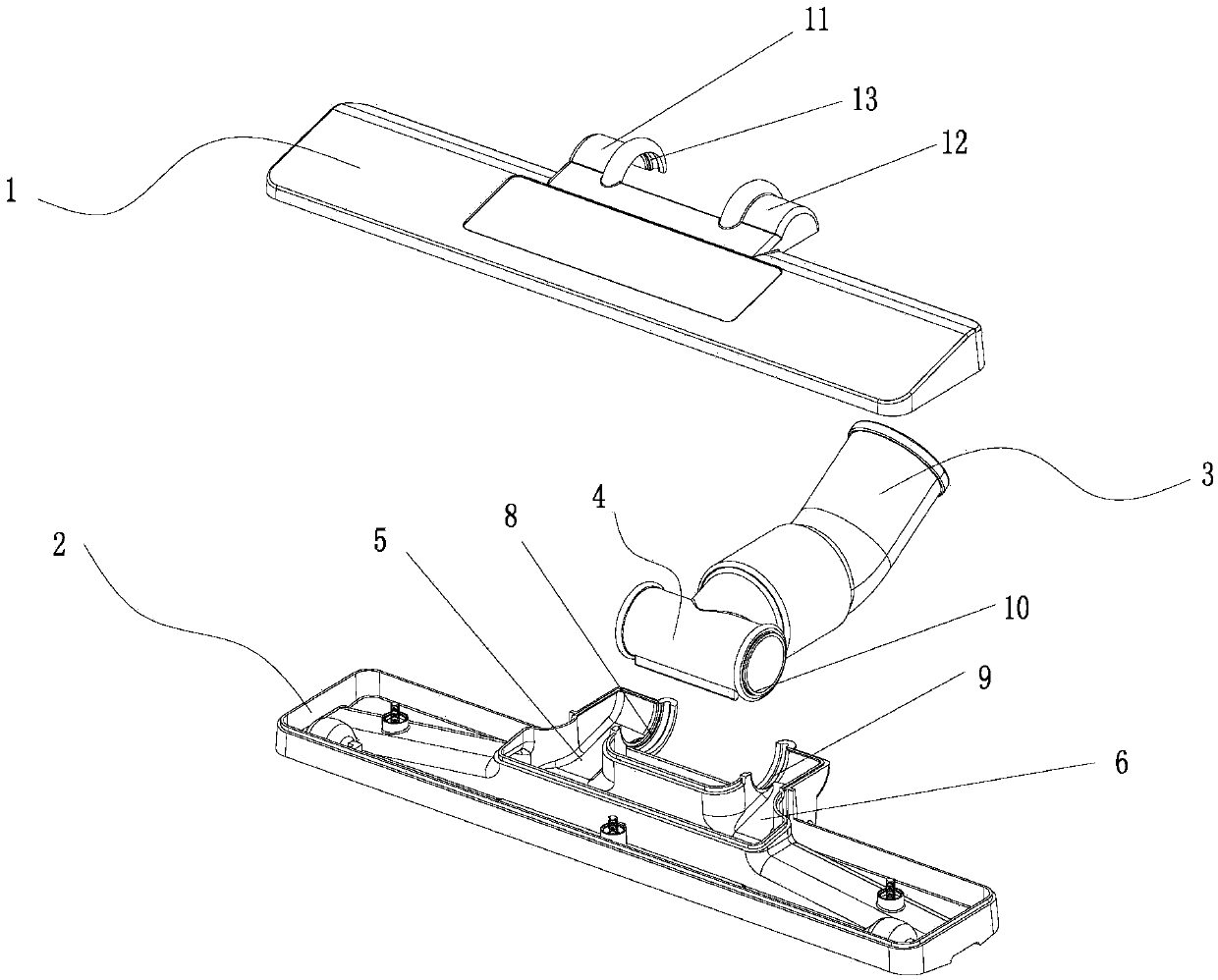

Suction nozzle assembly and cleaning robot

PendingCN112690696AGreat suctionUniform suctionSuction nozzlesElectric equipment installationDust particlesSuction force

The invention discloses a suction nozzle assembly, and the assembly comprises a suction nozzle body; a shell is arranged on the suction nozzle body, an inclined side wall is arranged on the shell, a dust collection cavity is formed by the suction nozzle body and the shell, an air inlet is formed in the bottom face of the suction nozzle body, and an air outlet is formed in the shell; airflow enters from the air inlet, flows through the dust collection chamber and is discharged from the air outlet, so the airflow flowing through the dust collection chamber is uniformly distributed. The invention further discloses a cleaning robot. The cleaning robot comprises the suction nozzle assembly. According to the suction nozzle assembly, the height from the air outlet to the ground is reduced, the average air speed in the dust collection cavity is increased, vortex airflow can be generated, the entrainment effect is enhanced, and therefore, the suction force to the ground and the negative pressure level are improved, the suction force below the air outlet is enhanced, and the dust particle conveying capacity is enhanced; transition areas from the two sides to the suction nozzle body are enlarged, so the suction force level is more balanced, and dust particle leakage caused by weak suction force is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

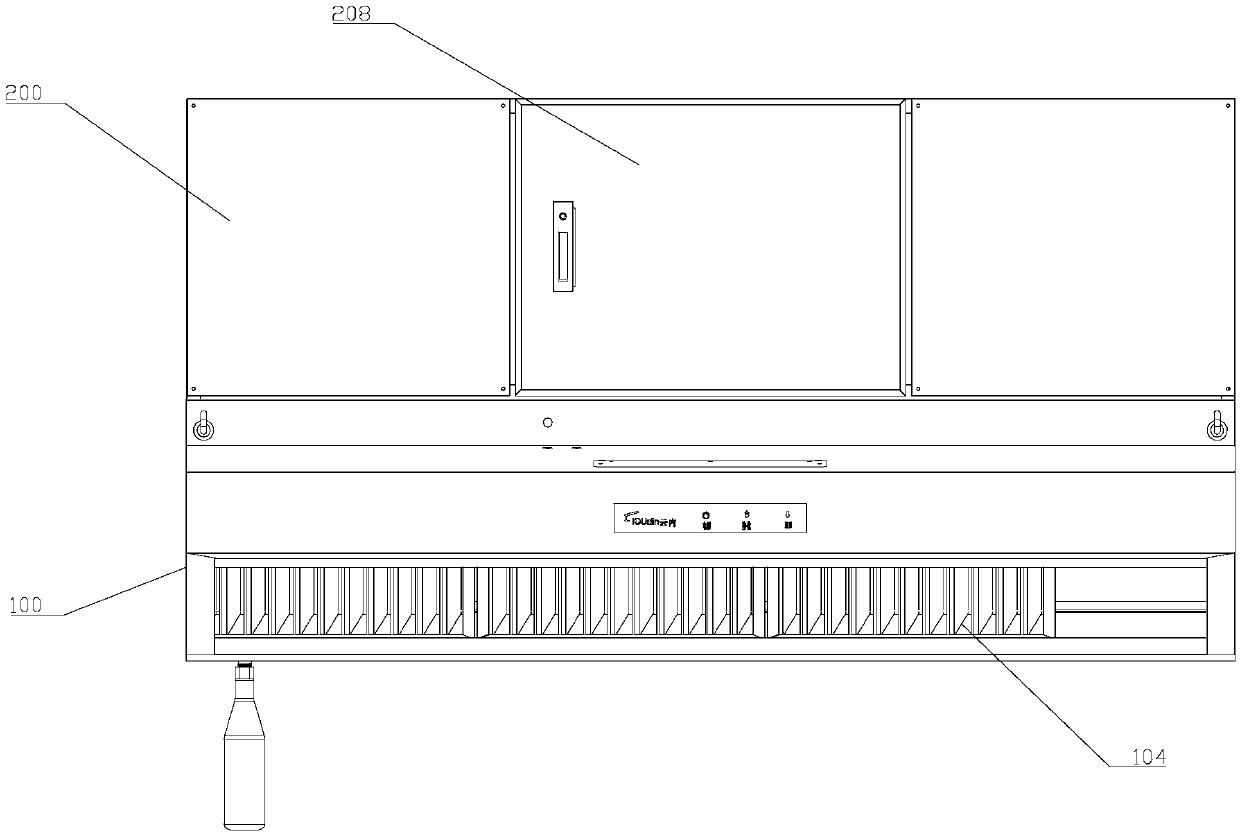

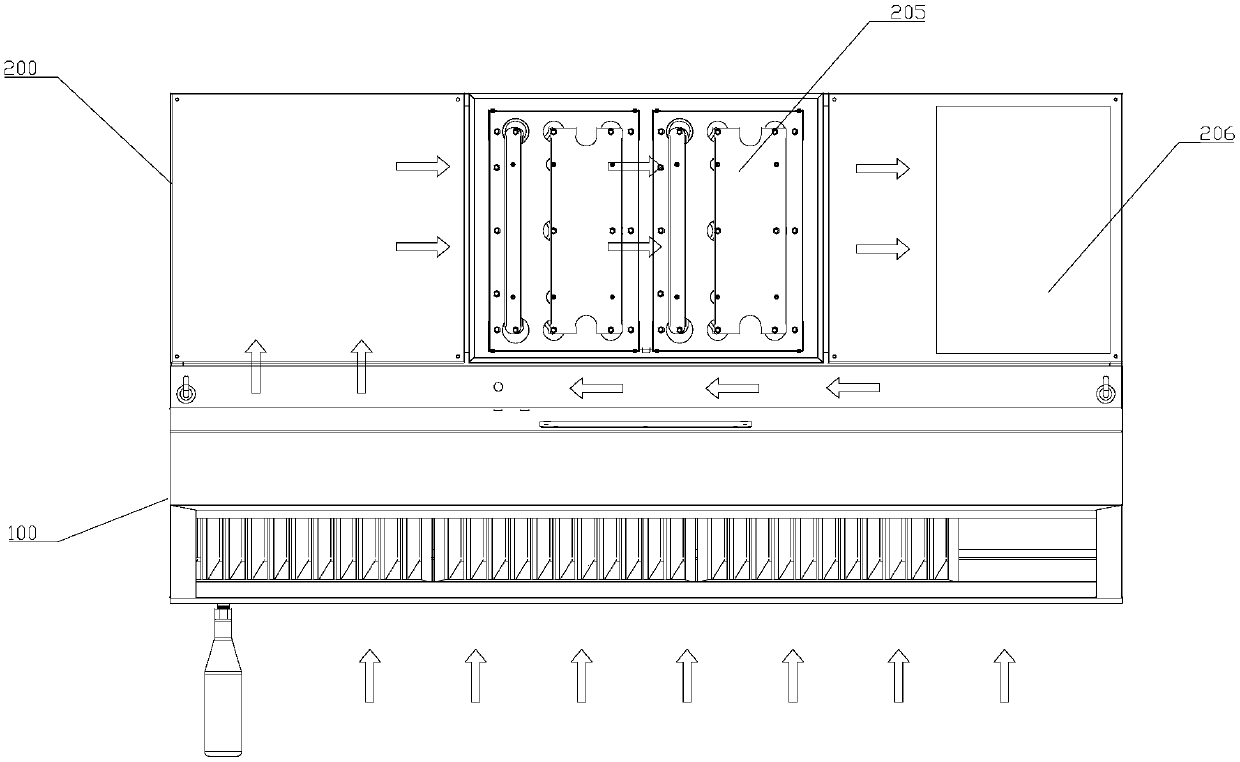

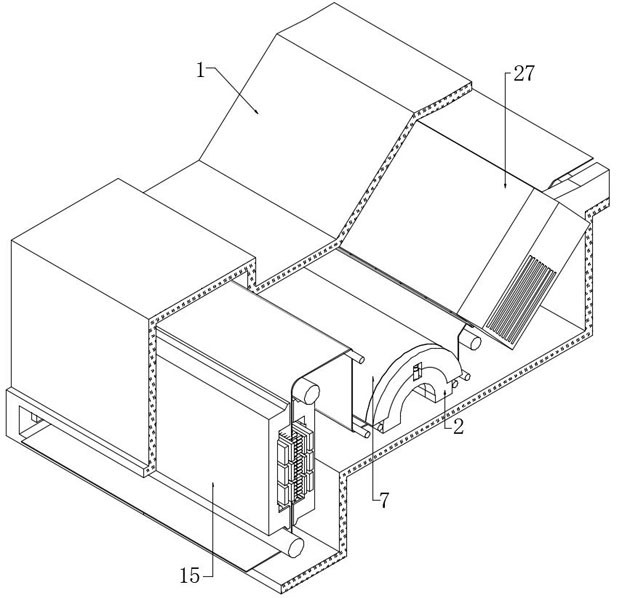

Oil fume purifying integrated machine

PendingCN109654571ASmall footprintEasy to installDomestic stoves or rangesLighting and heating apparatusElectric fieldWaste management

The invention discloses an oil fume purifying integrated machine. The oil fume purifying integrated machine comprises an oil fume collecting part and an oil fume purifying part, wherein an oil fume processing cavity is arranged in the oil fume collecting part; a processing cavity inlet is formed below the oil fume processing cavity, and a processing cavity outlet is formed above the oil fume processing cavity; an oil blocking mechanism and an oil fume pretreatment mechanism are sequentially arranged in the oil fume processing cavity from bottom to top; the oil fume pretreatment mechanism comprises a plurality of oil fume separation components; the oil fume purifying part is provided with a purifying cavity inlet located at the left end of an oil fume purifying cavity; a purifying cavity outlet is formed in the right end of the oil fume purifying cavity; an electric field module and a draught fan are arranged in the oil fume purifying cavity from left to right in sequence; an air inletof the draught fan directly faces the electric field module; an air outlet of the draught fan communicates with the purifying cavity outlet; the processing cavity outlet is connected to the purifyingcavity inlet, so that the oil fume processing cavity communicates with the oil fume purifying cavity; and an air blocking mechanism is arranged above the oil fume separation components located directly below the purifying cavity inlet. The oil fume purifying integrated machine improves the efficiency of oil fume purification, reduces the occupied space, and is convenient to install by adopting integrated setting.

Owner:佛山市云厨环保科技有限公司

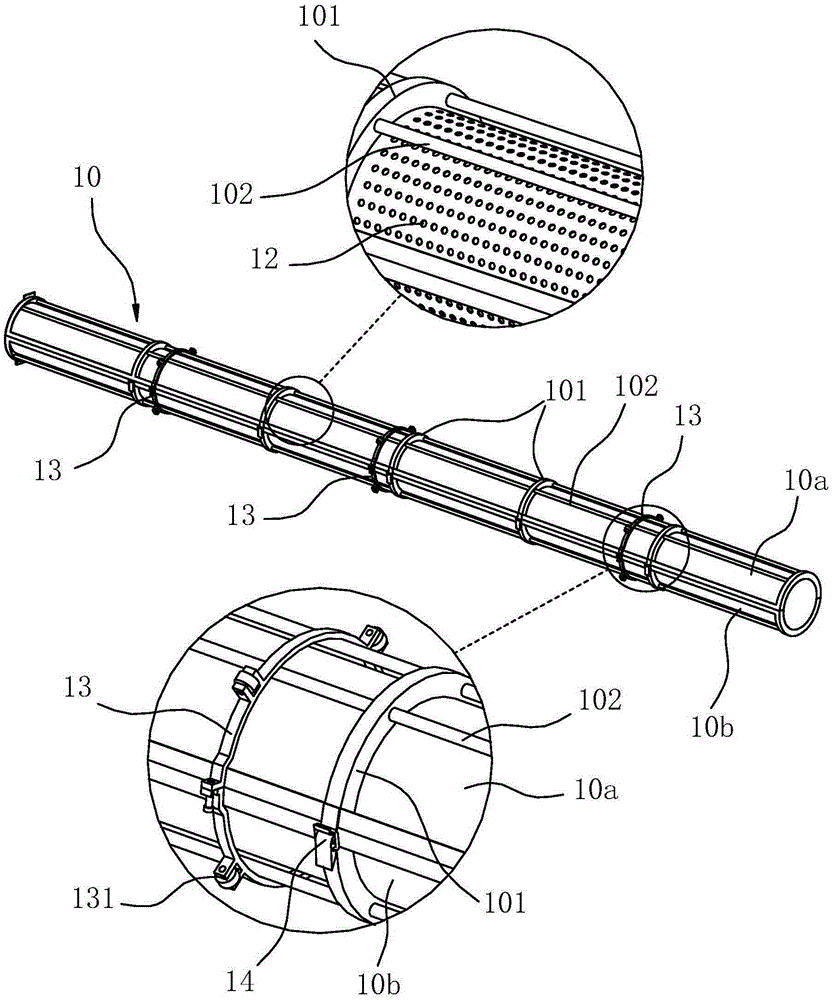

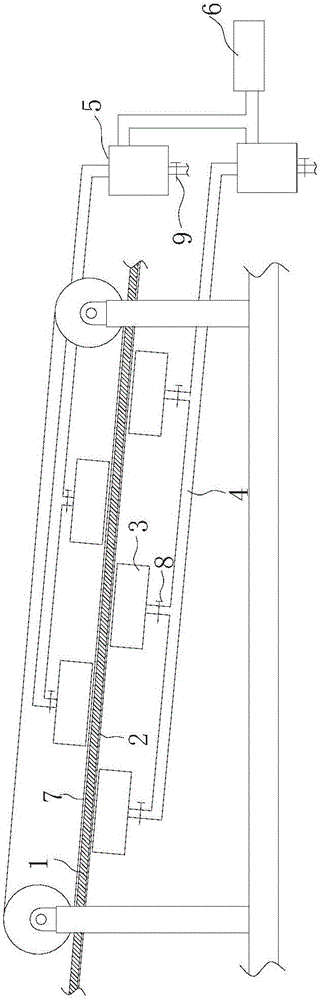

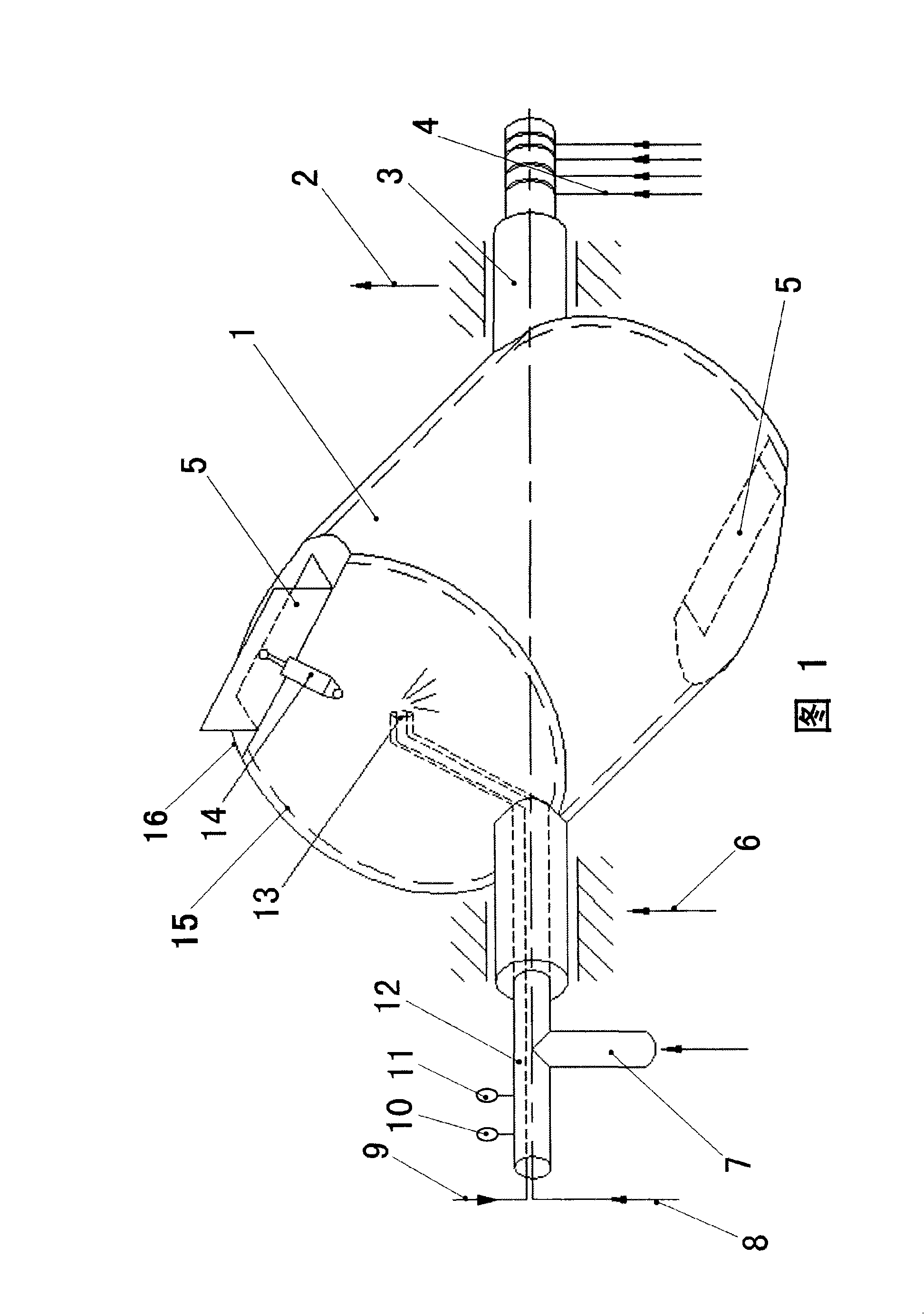

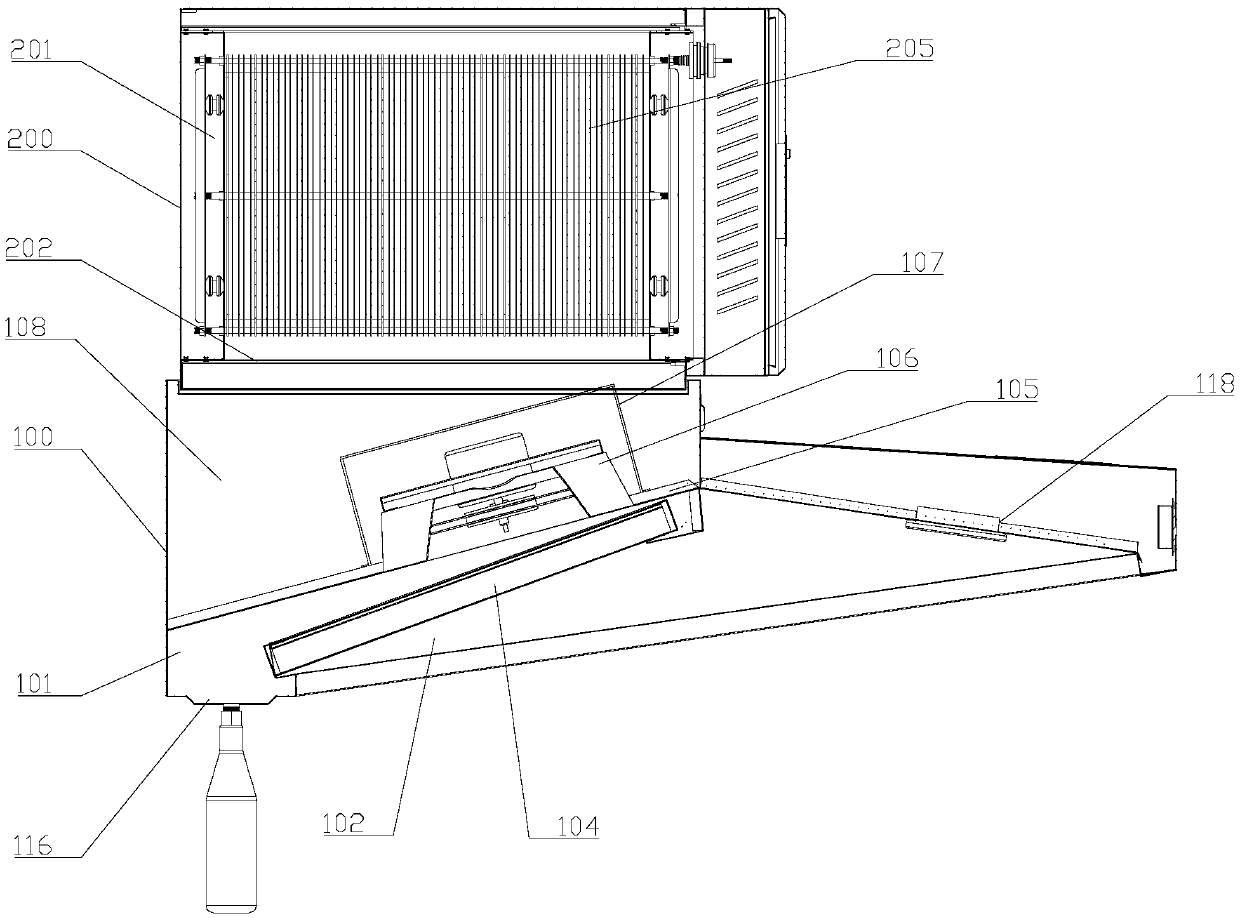

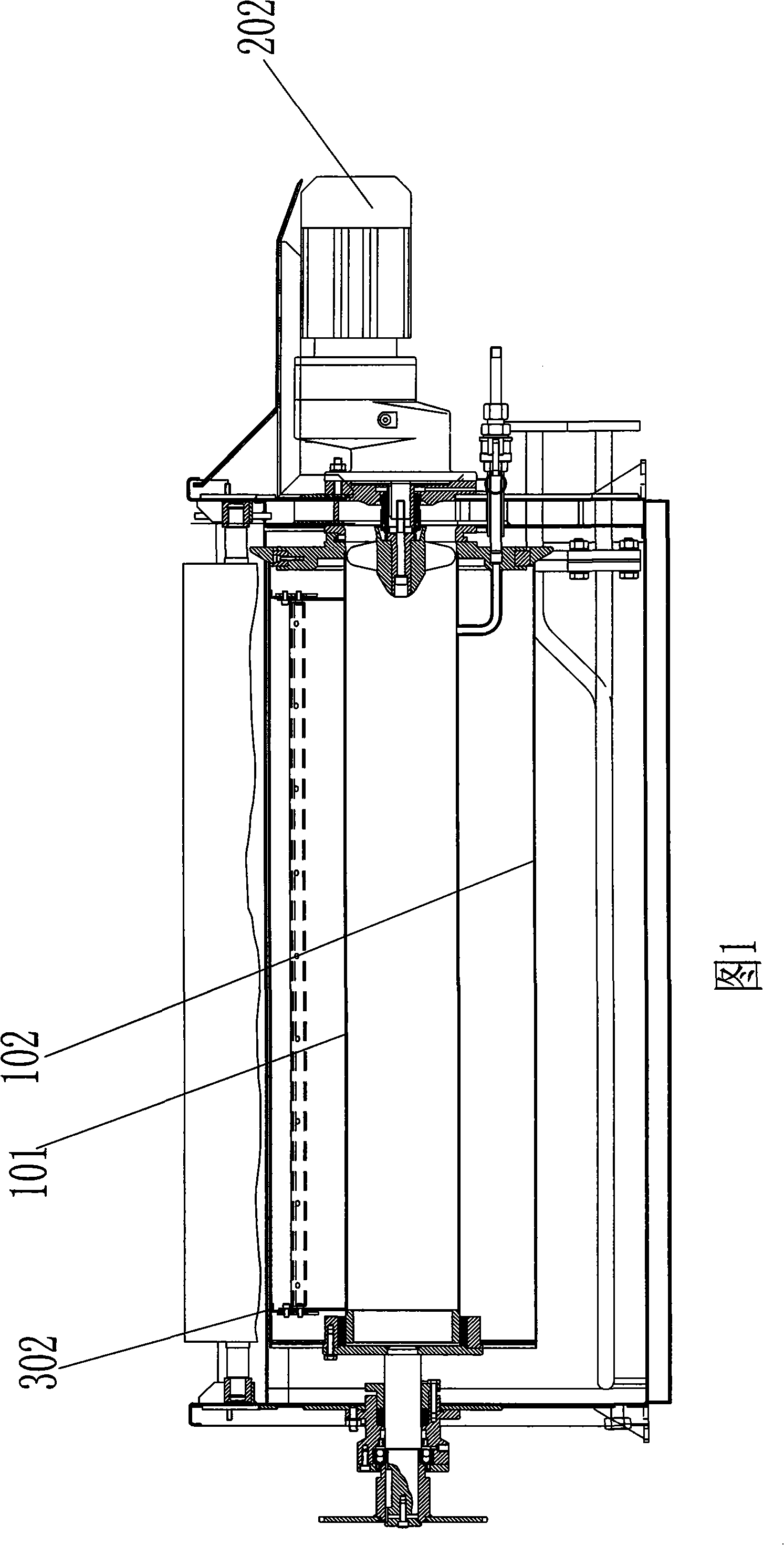

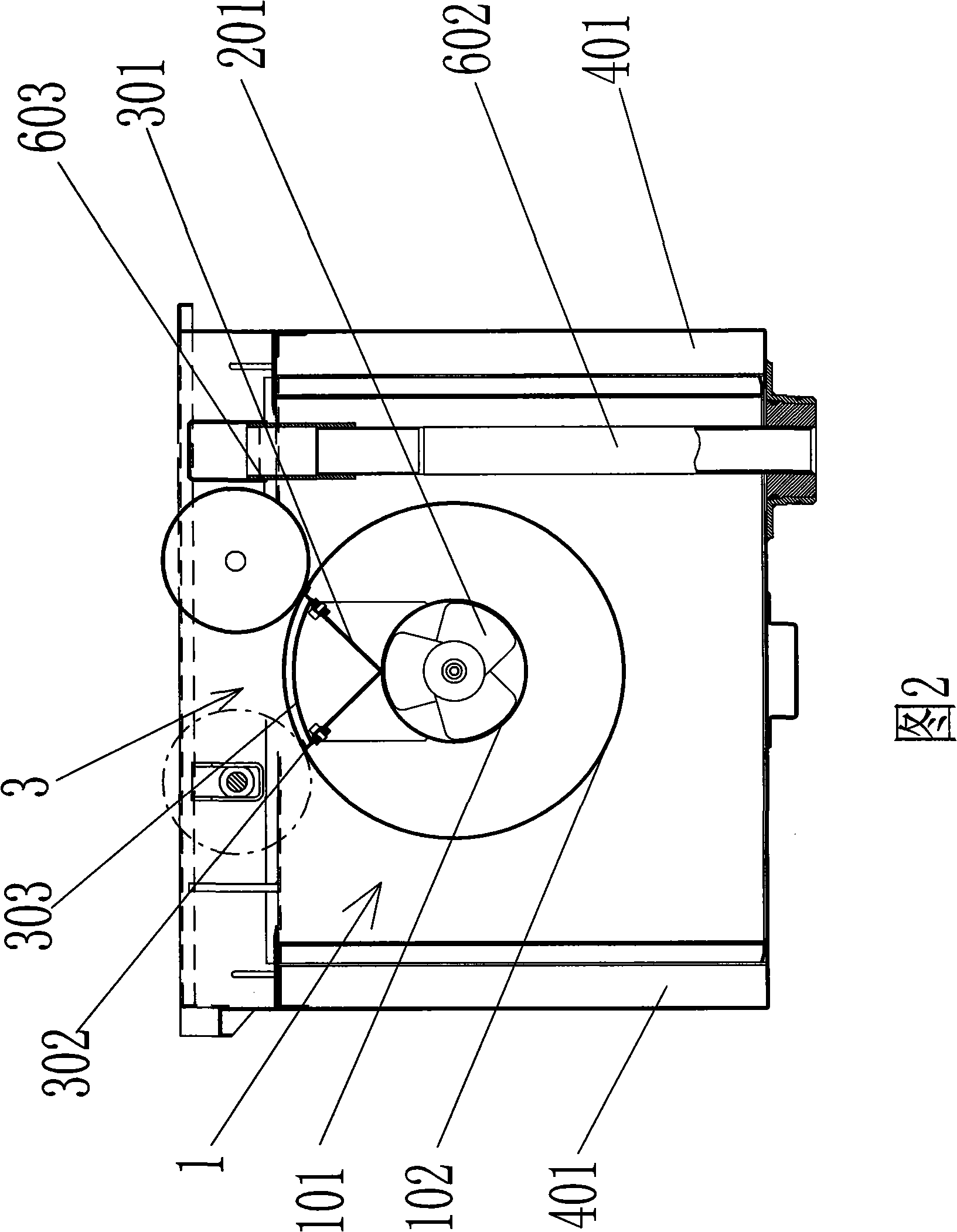

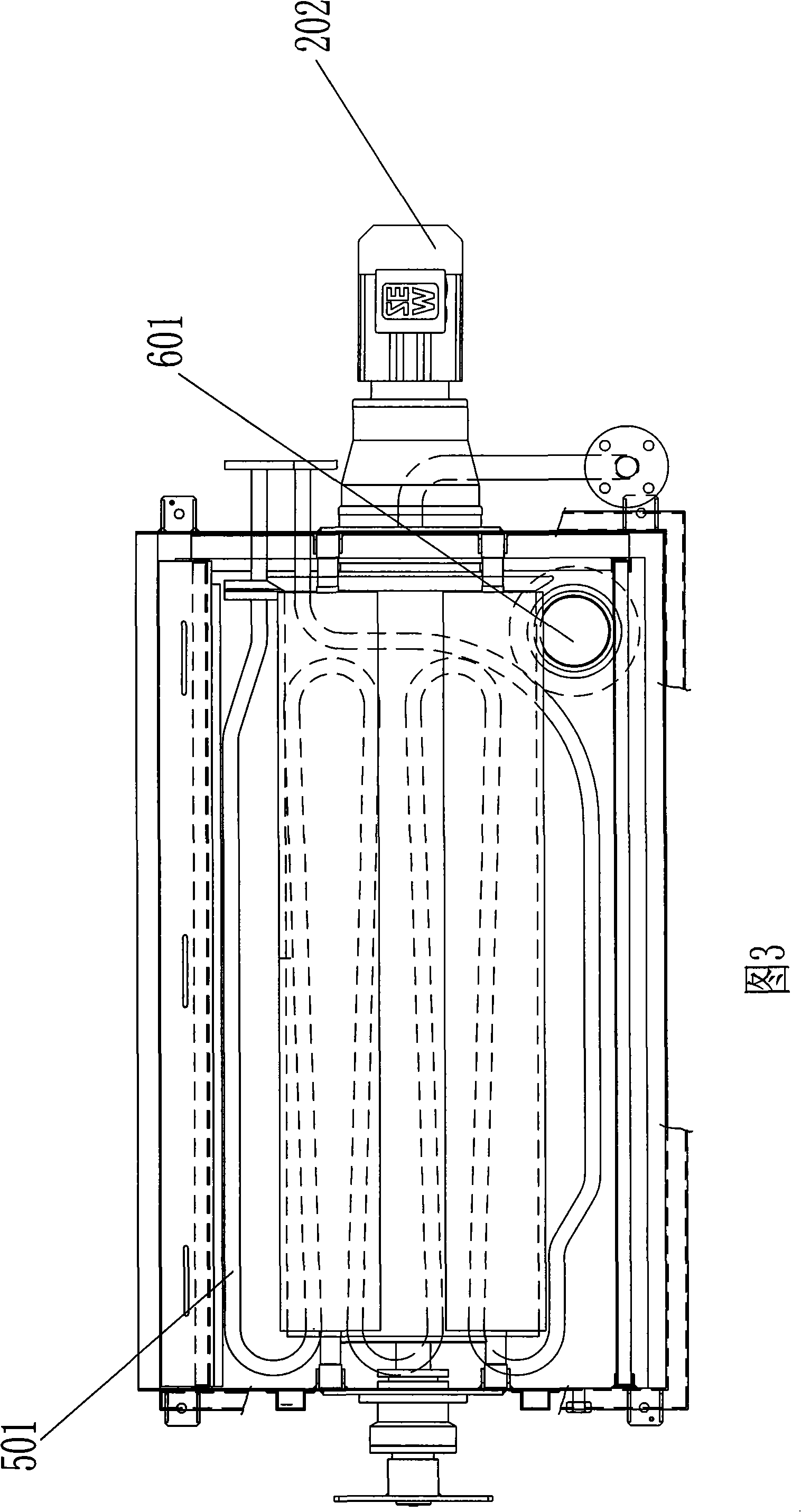

Evacuating drum-type tank washer

InactiveCN101255638AUniform suctionSolve the problem of uneven rewashingTextile treatment containersLiquid/gas/vapor fibres/slivers/rovings treatmentSuction forcePropeller

The invention discloses a suction roller type tank washer, comprising: a suction device and a roller; the roller includes an inner roller and an outer roller, two ends of the outer roller is installed with a flange disc which is installed with a lining inside, the inner roller is cooperated with the outer roller; the outer roller can surround the immovable inner roller to rotate, the suction device comprises an airscrew and a deceleration electric engine, the airscrew is installed on a liquid outlet of the inner roller, the rotating shaft of the deceleration electric engine is connected with the airscrew. Both the inner roller and the outer roller are provided with ventholes; the ventholes on the inner roller are gradually dense from one end near the suction device to the other end, the ventholes on the outer roller are uniformly arrayed. Such structure leads to sparser distribution of the ventholes on the surface of the inner roller where the suction force is larger, and leads to denser distribution of ventholes at the position where the suction force is smaller so that the suction force on the outer roller is uniform and consistent, thus solving the problem about asymmetry of wool tops backwashing.

Owner:QINGDAO HICORP GROUP CO LTD

Double-duct dust collector floor brush

The invention relates to a double-duct dust collector floor brush which comprises a shell and a pipe connector arranged at the rear end of the shell. The shell comprises an upper cover and a lower cover provided with air inlet ducts, the upper cover is fixedly connected with the lower cover, the lower cover is provided with a dust collection port, the pipe connector is provided with a pipe cavity, the dust collection port is communicated with a pipe cavity through the air inlet ducts, the air inlet ducts are two in number and include the first air inlet duct and the second air inlet duct, and the first air inlet duct and the second air inlet duct are arranged on the two sides of the lower cover respectively side by side. The dust collector floor brush is provided with the two air inlet ducts, so that suction force of the ducts is uniform, and dust collection is efficient.

Owner:SUZHOU SHUANGRONG RUBBER & PLASTIC

Large film pressing machine waste film recovering device

The invention discloses a large film pressing machine waste film recovering device which comprises sliding rails, racks installed on the side faces of the sliding rails in a matched manner, a slidingtable installed on the upper end faces of the sliding rails in a matched manner and a frame base installed at the upper end of the sliding table in a matched manner, and the sliding rails are symmetrically arranged on the two sides of a film pressing platform; sucking discs which are evenly arranged are arranged on four installing grooves formed in a winding barrel outer circle, when winding barrel rotates around the waste film surface, the sucking discs can attract a waste film to the winding barrel outer circle, the waste film is wound from the film pressing platform through winding of the winding barrel, the film taking process is simple, even sucking force is applied at multiple points, connectivity of the waste film cannot be damaged, and the waste film can be recovered more efficiently; in the overall waste film recovering process, redundant manual operation is not needed, and manpower cost is saved; and the overall process of recycling the waste film through the waste film recovering device is short, operation is relatively simple, man-hour errors generated when the waste film is manually recycled are avoided, the operation manner is further optimized, and the overall machining link is more smooth.

Owner:SHENZHEN ZHILING WEIYE TECH

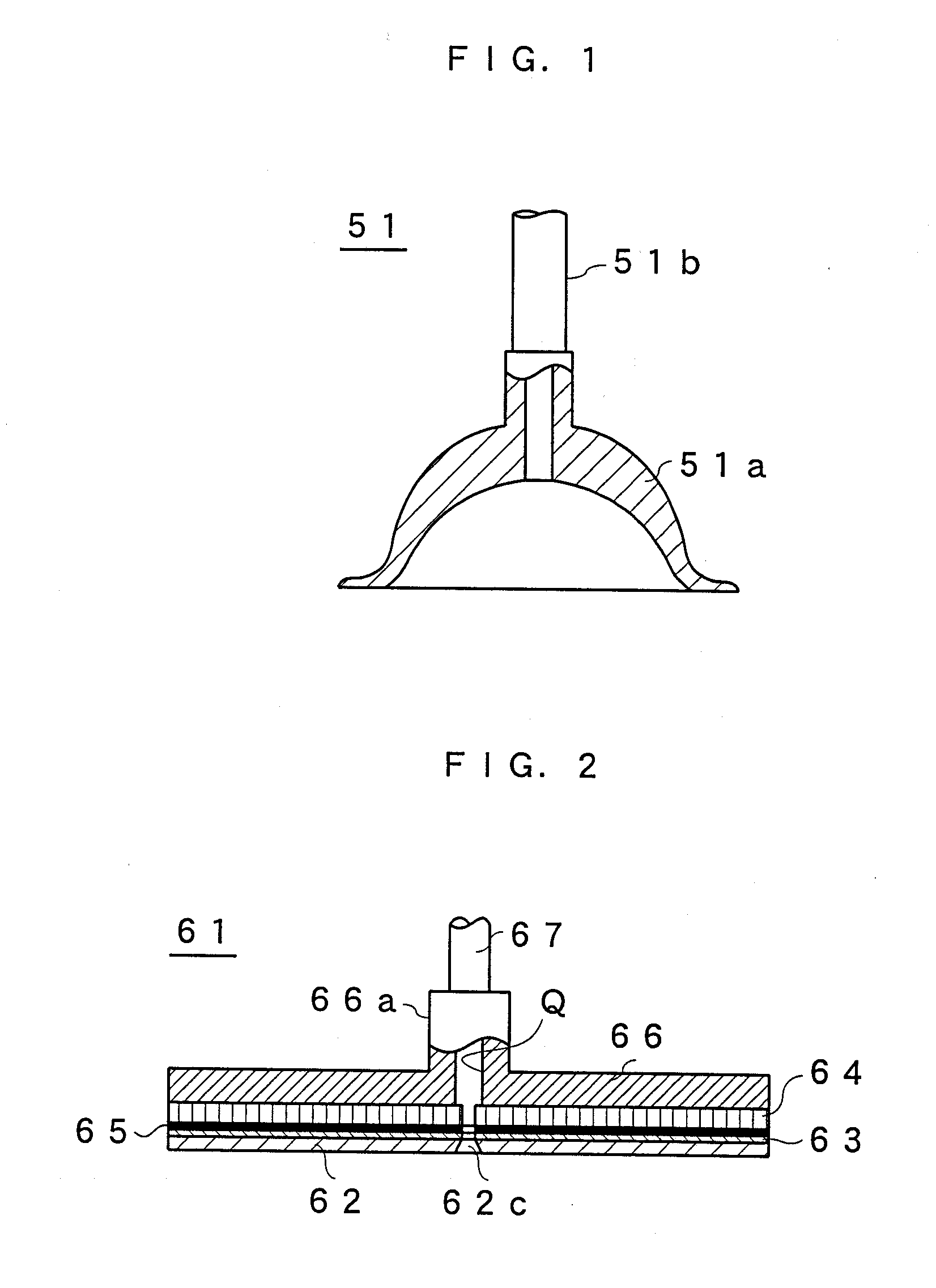

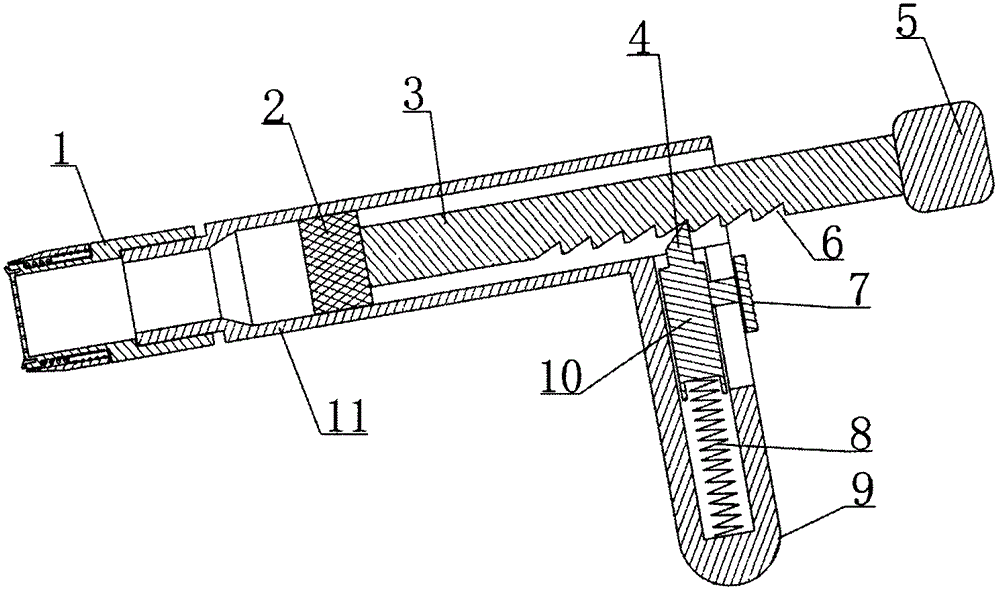

Skin biopsy trepan

InactiveCN102743195AUniform suctionImprove sampling efficiencySurgical needlesEngineeringSkin biopsy

The invention discloses a skin biopsy trepan, belonging to a medical instrument. The skin biopsy trepan comprises a drill rod, a drill bit and a handle, wherein a piston and a push-pull rod are arranged in the drill rod; the handle is vertically arranged on one side of the upper end of the drill rod; a sliding pin is arranged in the handle and is provided with a wedged head for positioning the push-pull rod; the drill bit comprises a drill bit main body, a circular cutter and a slide bushing; the slide bushing is positioned outside the drill bit main body; a return spring is arranged below the slide bushing; the circular cutter is arranged outside the slide bushing; the lower end of the drill bit main body is provided with a perforated plate; and the lower end of the perforated plate is provided with a rubber pad. The skin biopsy trepan has the advantages of rational structure, convenience in operation and capabilities of greatly improving the sampling efficiency of pathological specimens and reliving the pain of a patient.

Owner:李国英

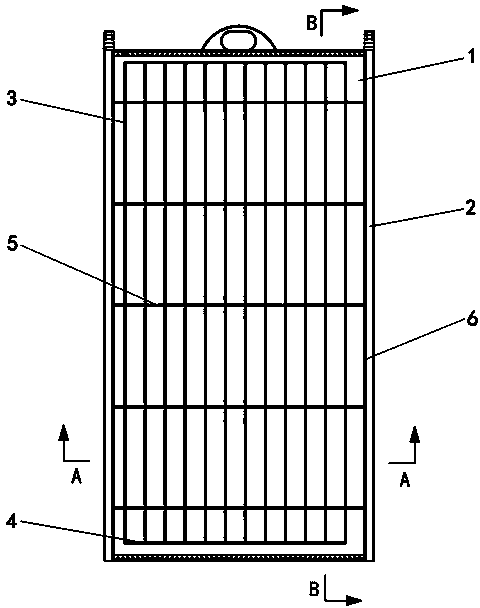

Abrasive paper holder

InactiveCN103862337AUniform suctionPlane surface grinding machinesGrinding/polishing safety devicesSoft bodySandpaper

The invention discloses an abrasive paper holder used for the process of manually polishing the wall top surface of a living room. The abrasive paper holder comprises a handle, an air outlet device, bottom plates, a soft body, bottom plate cover plates and an air inlet device, wherein the air outlet device is matched with the cross section of a hose of a dust suction device, and the air inlet device is arranged at the position, around the soft body, of the bottom faces of the bottom plates. The abrasive paper holder is hollow, the air outlet device, the air inlet device and a cavity inside the abrasive paper holder are communicated, devices for fixing abrasive paper are arranged inside the front portions and the rear portions of the bottom plates of the abrasive paper holder, and demountable devices are arranged at the positions, adjacent to the devices for fixing the abrasive paper, of the front portions and the rear portions of the bottom plates.

Owner:林大坤

Dust collecting barrel of sewing machine

InactiveCN105063912AExtended service lifeReduce noiseSewing-machine elementsBrushless motorsInterior space

The invention provides a dust collecting barrel of a sewing machine. The dust collecting barrel comprises a sewing machine, a controller arranged on the sewing machine and a barrel body. An opening is arranged in the upper end of the barrel body. A barrel cover covers the opening of the barrel body. A protection cover is fixedly installed on the barrel cover. A brushless motor is erected in the protection cover. A control system is connected to the brushless motor, a switch and a speed adjusting knob. A wind blade is connected to the brushless motor and arranged in the barrel body. A filtering core covers the wind blade. A handle is arranged on the protection cover. Multiple air discharging openings are arranged in the protection cover. A cloth sucking mouth, a first line sucking mouth and a second line sucking mouth are arranged in the barrel cover, and are communicated with interior space of the barrel body. The control system is connected with a plug. The dust collecting barrel is capable of collecting dust without cooperation of an external air source, so a problem of high noise during dust collection is avoided and the dust collecting device is applicable more widely.

Owner:YUHUAN YI ELECTRONICS

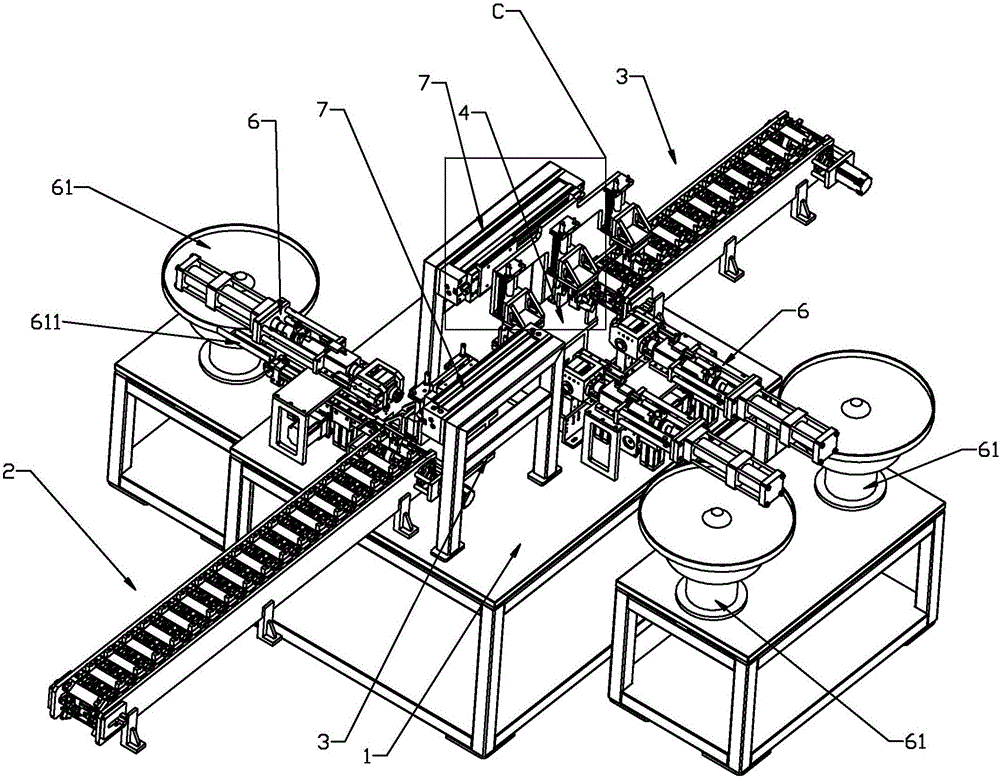

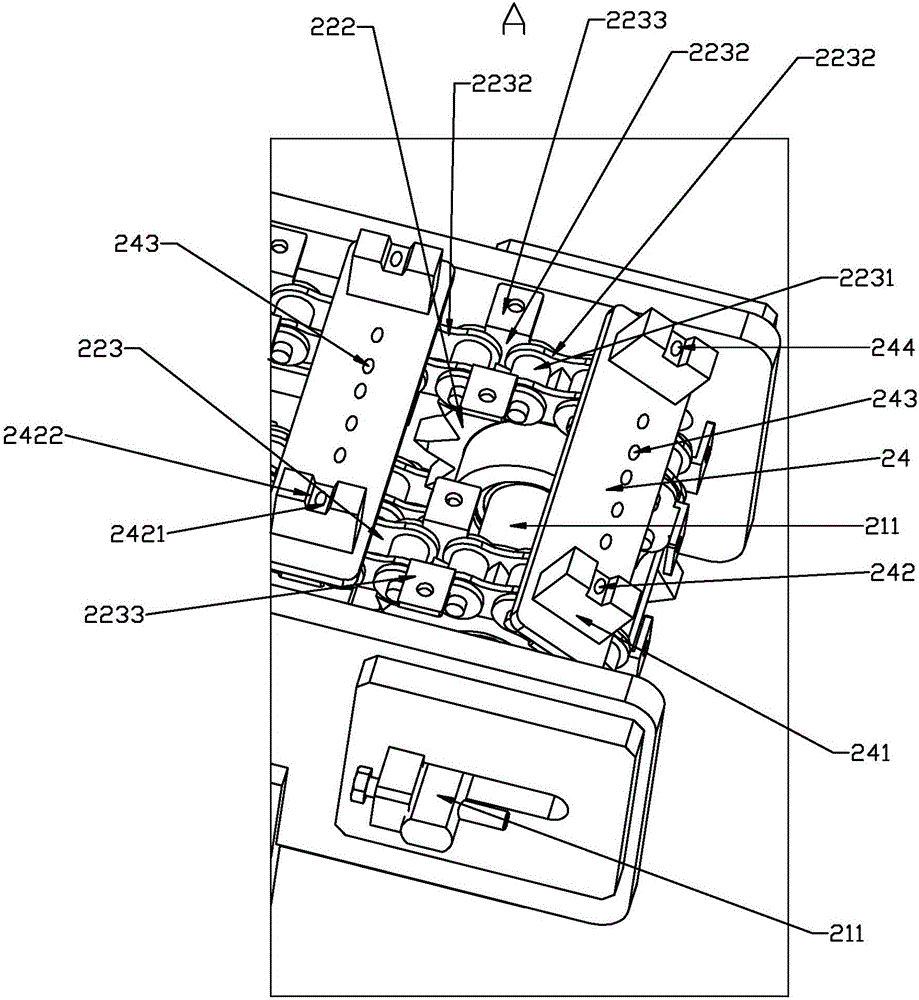

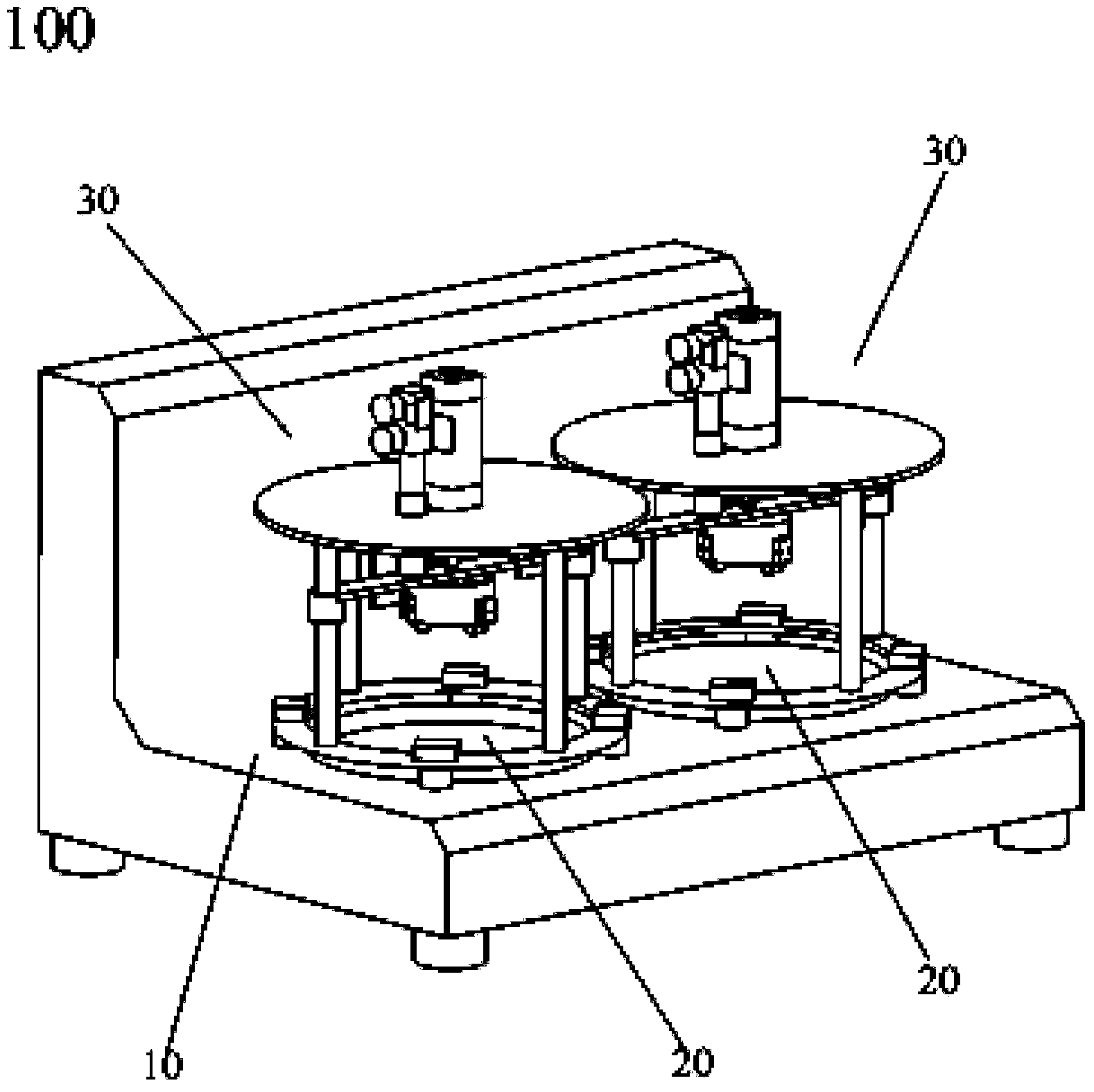

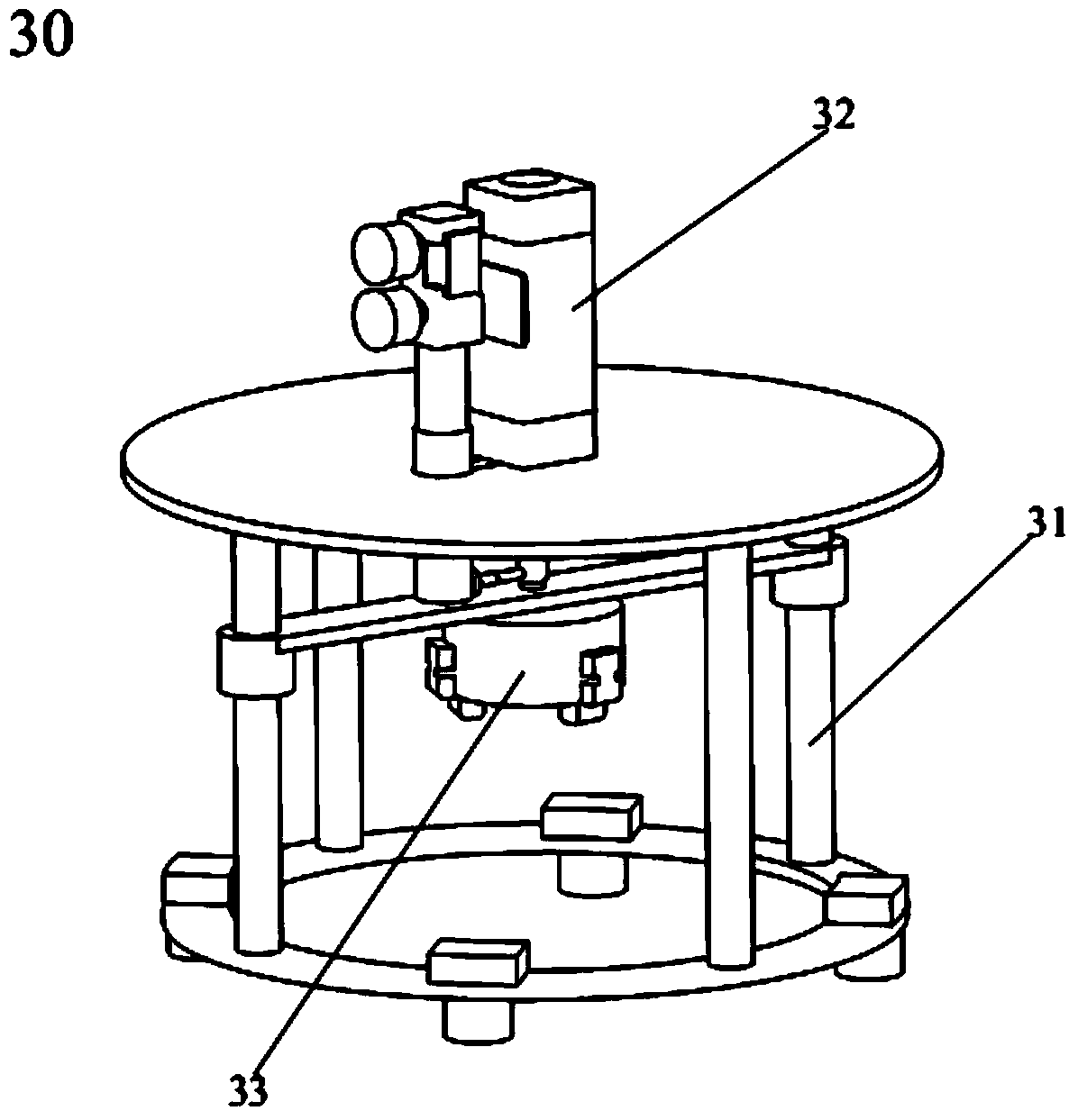

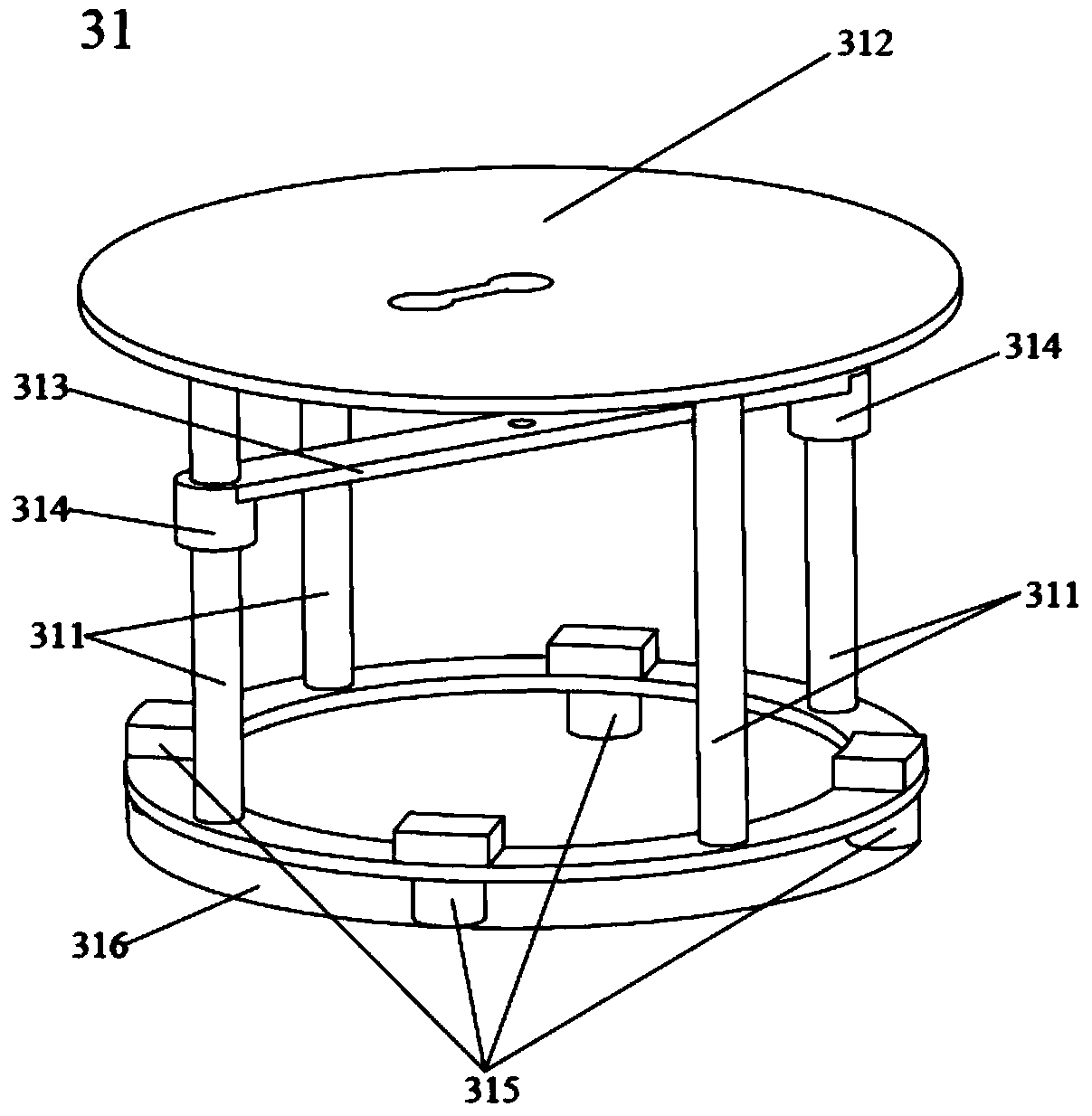

Automatic assembling machine with product protection for multiple components of motor rotor spindle

ActiveCN106685155AImprove processing efficiencyFirmly assembledAssembly machinesManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention relates to an automatic assembling machine with product protection for the multiple components of a motor rotor spindle. The automatic assembling machine comprises a work mesa which is provided with a feeding device, a first processing base, a second processing base and a discharge device in turn. The side of the work mesa, located in the first processing base and the second processing base, are provided with an assembling device. A pro-transporter for switching a location of the motor rotor spindle in turn is arranged between the feeding device and the first processing base. A post- transporter for switching a location of the motor rotor spindle in turn is arranged among the first processing base, the second processing base and the discharge device. Each motor rotor spindle holder is provided with a first electromagnet with same distance, and each inside of a placed groove is provided with a second electromagnet. According to the above scheme, the automatic assembling machine with product protection for the multiple components of the motor rotor spindle is provided, which can avoid the product dropping out in a transit.

Owner:周胡琴

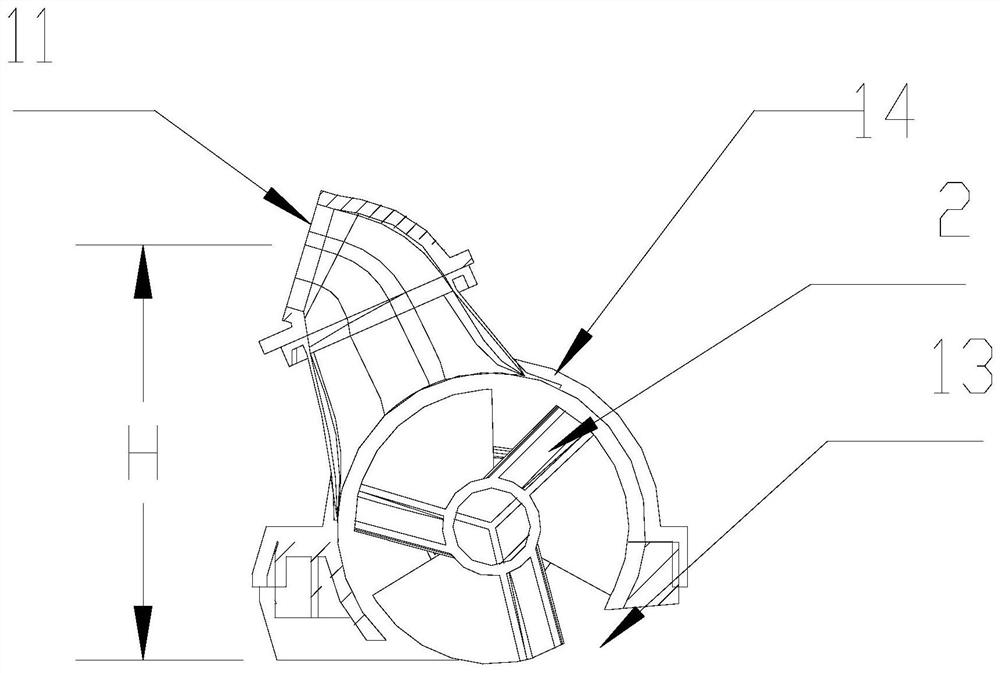

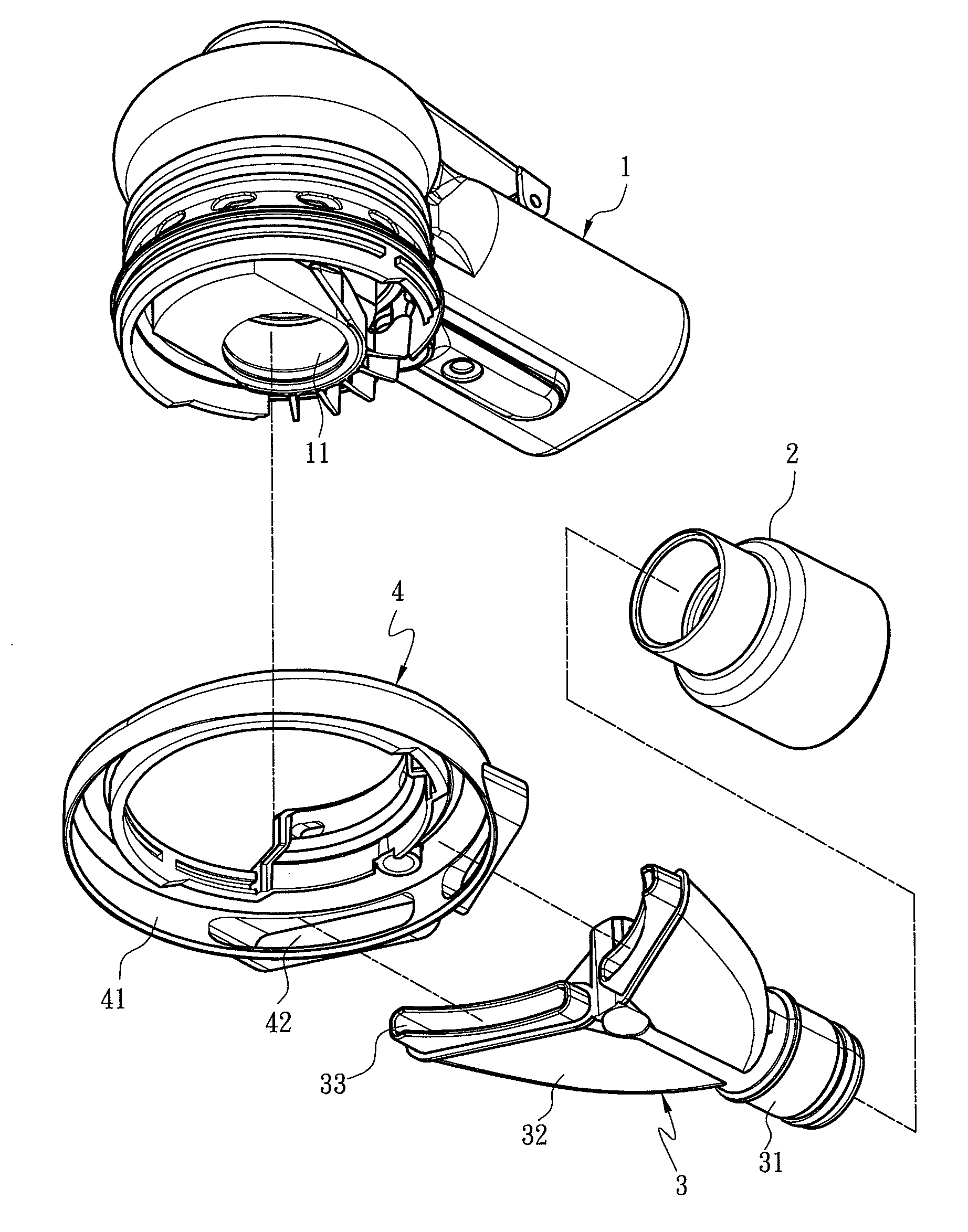

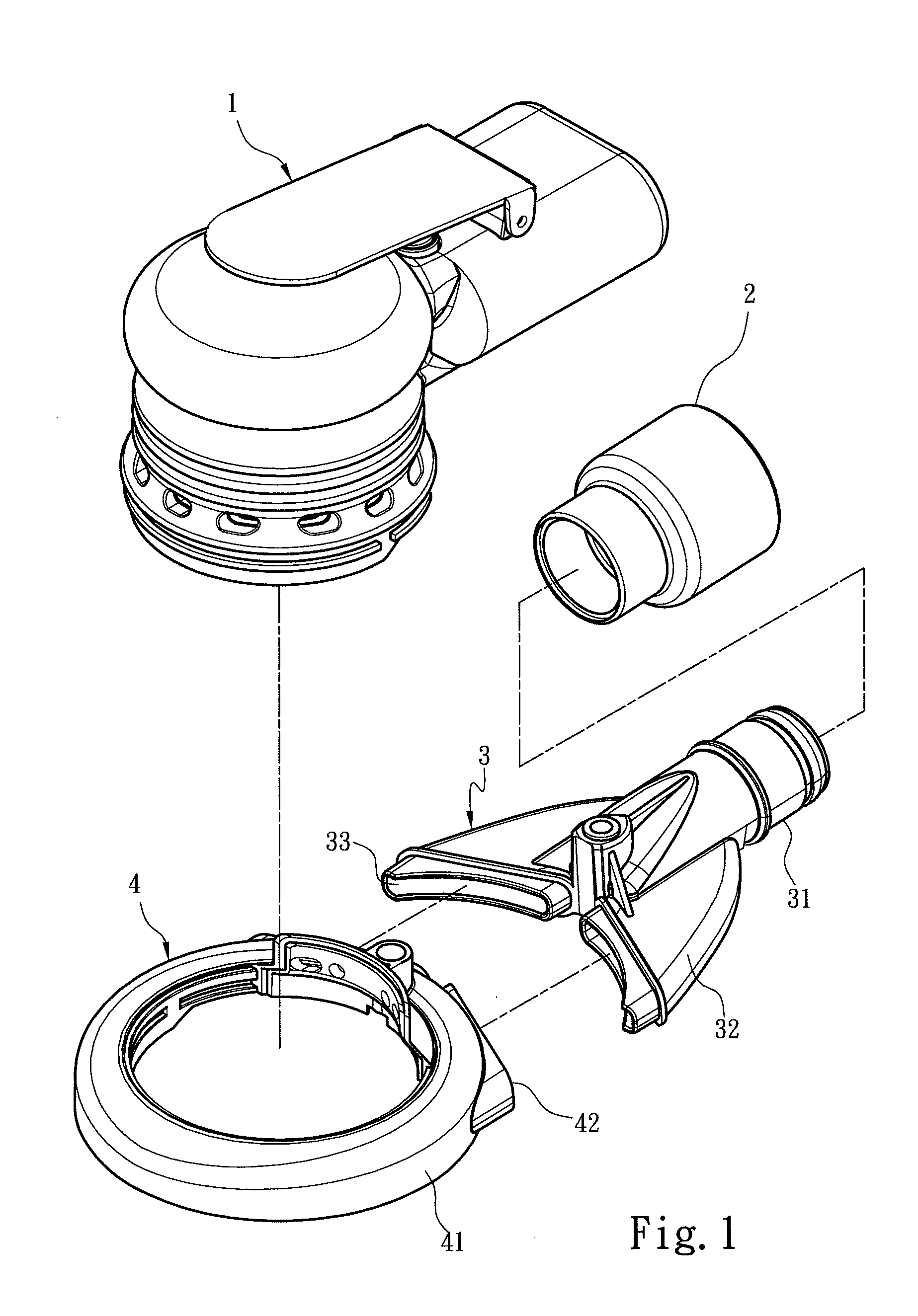

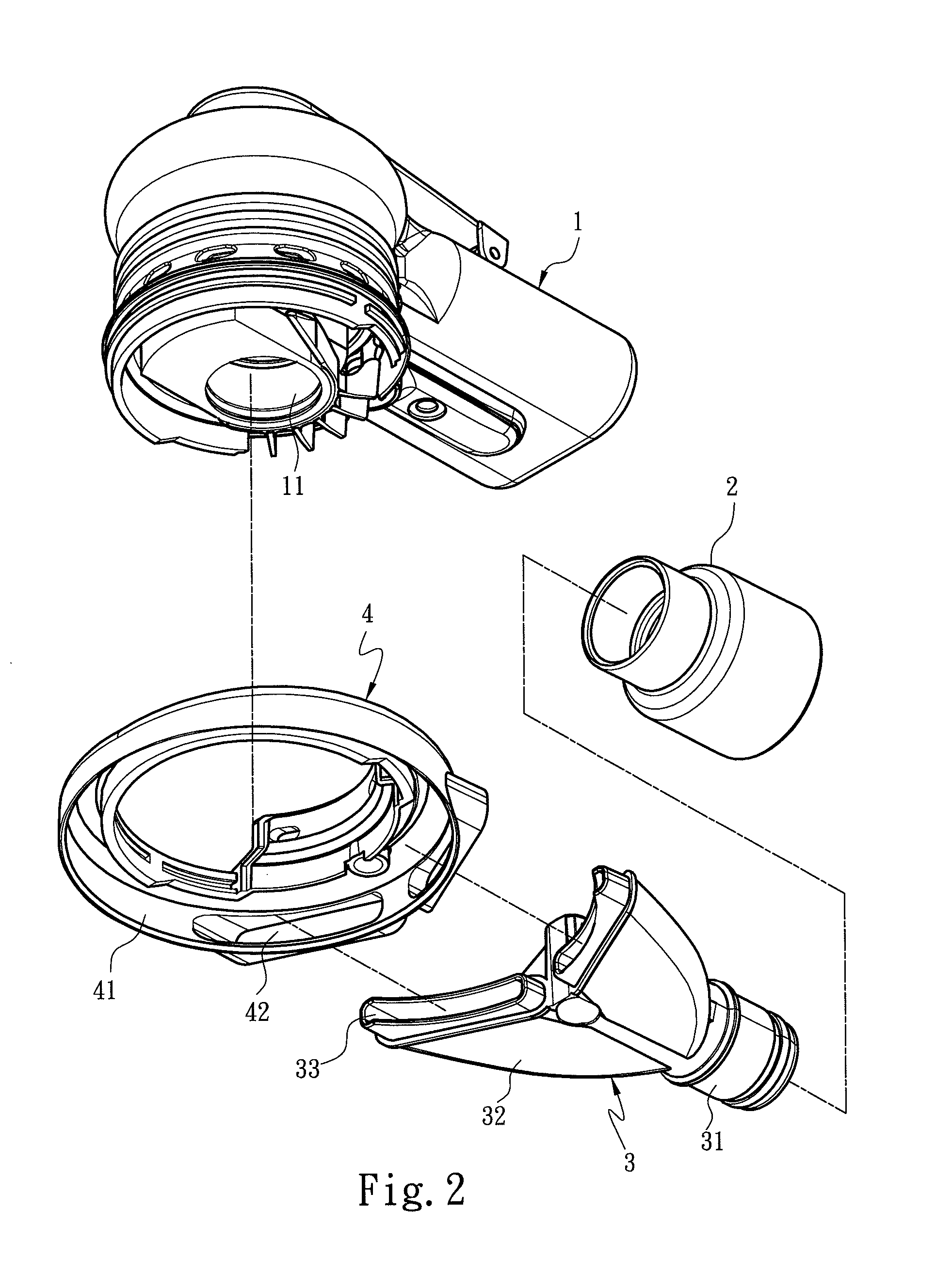

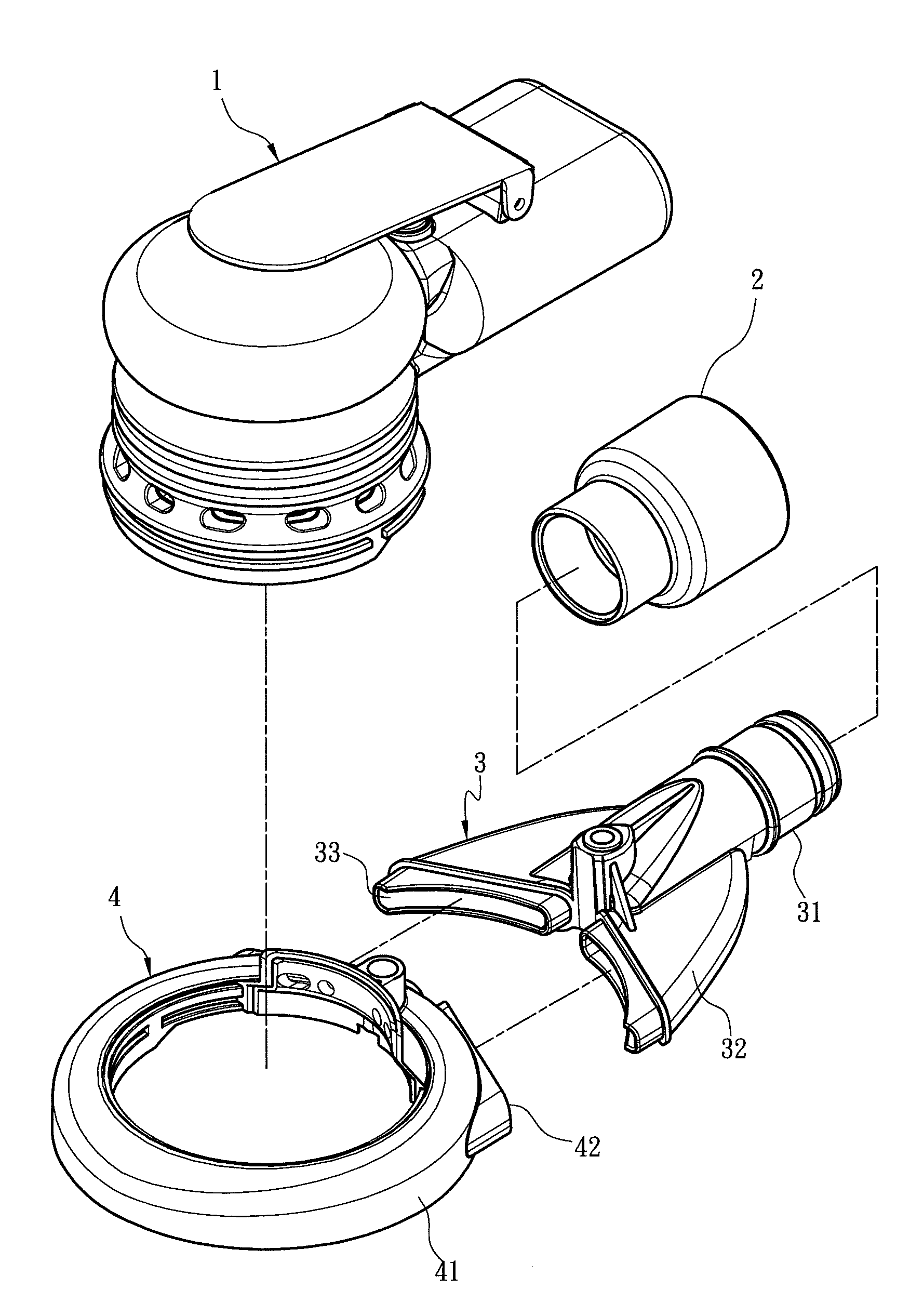

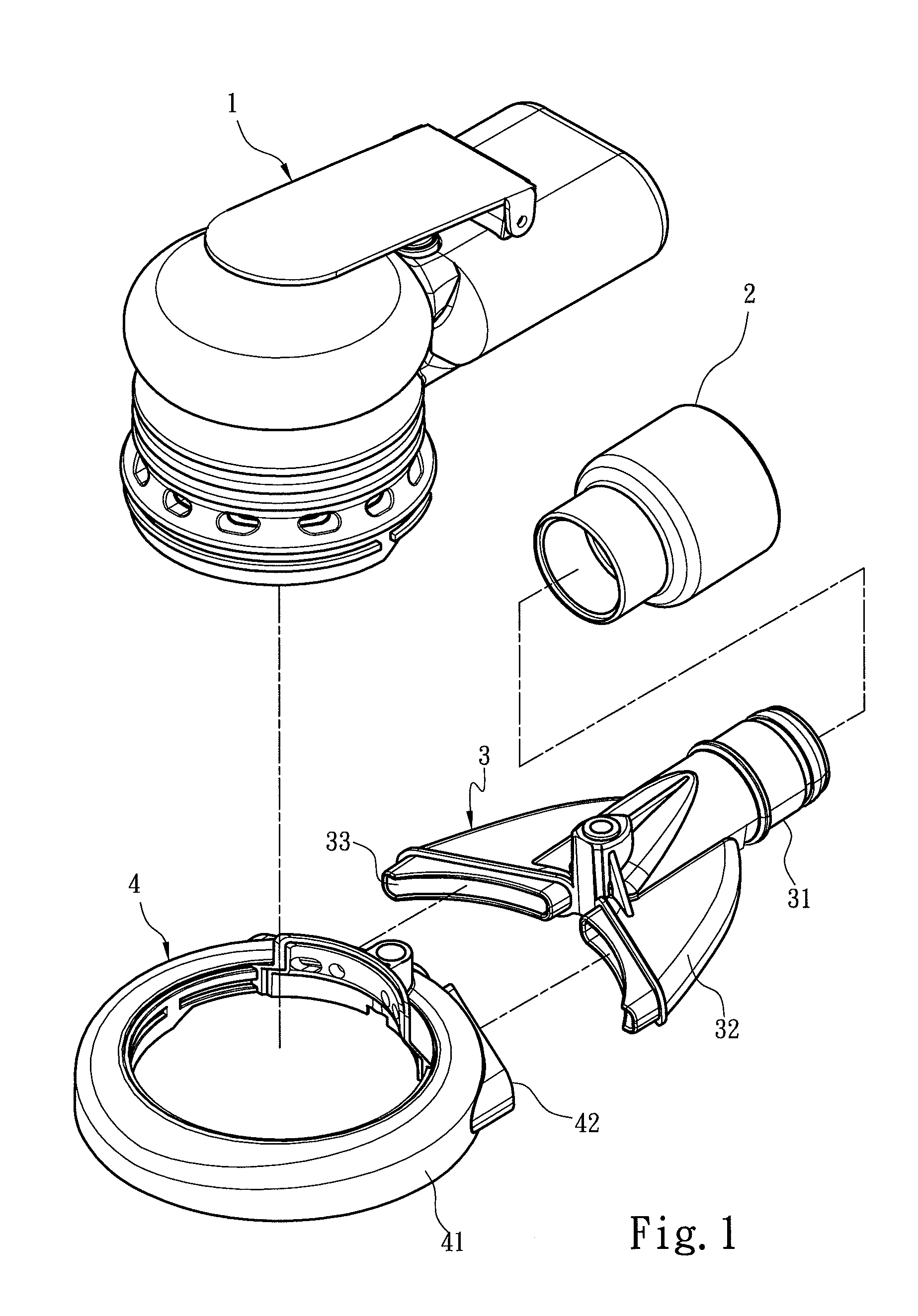

Negative pressure dust collection structure for power tools

ActiveUS20110250828A1Improve efficiencyIncrease rangePortable grinding machinesMaintainance and safety accessoriesSuction stressEngineering

A negative pressure dust collection structure aims to be used on a power tool which is coupled with an application tool operable in a working space surrounded by a dust collection hood. The dust collection hood includes at least one flow conduction vent communicating with an airflow duct through a negative pressure enhancing duct. The negative pressure enhancing duct has a negative pressure enhancing chamber communicating with the flow conduction vent. The negative pressure enhancing chamber is formed at a cross section shrunk gradually from the flow conduction vent towards the airflow duct to increase suction of the negative pressure enhancing duct to collect dust in the dust collection hood. Moreover, the negative pressure enhancing chamber has an opening edge mating the shape of the inner side of the wall of the dust collection hood to increase covering range of the airflow.

Owner:XPOLE PRECISION TOOLS

Chip suction device and chip suction method thereof

InactiveCN109860094AQuality improvementInhibit sheddingSemiconductor/solid-state device manufacturingEmbedded systemScrap

The invention relates to a chip suction device and a chip suction method thereof. The device comprises a chip suction part and a particle suction head part; the chip suction part comprises a chip suction pipeline; the first end of the chip suction pipeline is used for adsorbing the top surface of a chip to be sucked; the particle suction head part comprises a particle suction pipeline and a suction head connected with the first end of the particle suction pipeline; the suction head is used for containing the chip adsorbed by the first end of the chip suction pipeline; and the particle suctionpipeline is used for performing particle suction on the chip contained in the chip. By means of the scheme in the invention, the possibility that particles and scraps fall into the chip or an adjacentchip can be reduced; and the quality of the chip can be increased.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Container for liquid analysis

ActiveCN105327722AEase the momentumSpeed up the flowMaterial analysis by optical meansLaboratory glasswaresInlet channelEngineering

The present invention discloses a container for liquid analysis. The container comprises a first container portion and a second container, which are connected; a first groove, a first through hole and a second through hole are arranged on the first container portion; the second container portion is provided with a second groove; the space between the first groove and the second groove forms an analysis cavity, an inlet channel and an outlet channel; a channel port from the inlet channel to the analysis cavity and a channel port from the analysis cavity to the outlet channel are respectively distributed on both sides of a line between the center of the on the space between the first through hole and the analysis cavity; the inlet channel includes a gradually expanding first channel section; and the distance between the two through holes is not less than half of the distance between the two channel ports. A gradually expanding channel section is adopted in the invention to ease the impulsive force of the liquid entering into the inlet channel; a certain distance is between the two through holes, so that suction heads placed between two through holes can uniformly adsorb liquid overflowing from the two through holes. Therefore, the container ensures accurate and reliable results on liquid optical analysis.

Owner:COBIO SMARTER HEALTHCARE TECH

Negative pressure dust collection structure for power tools

ActiveUS8382559B2Effective structureImprove efficiencyPortable grinding machinesMaintainance and safety accessoriesEngineeringPower tool

A negative pressure dust collection structure aims to be used on a power tool which is coupled with an application tool operable in a working space surrounded by a dust collection hood. The dust collection hood includes at least one flow conduction vent communicating with an airflow duct through a negative pressure enhancing duct. The negative pressure enhancing duct has a negative pressure enhancing chamber communicating with the flow conduction vent. The negative pressure enhancing chamber is formed at a cross section shrunk gradually from the flow conduction vent towards the airflow duct to increase suction of the negative pressure enhancing duct to collect dust in the dust collection hood. Moreover, the negative pressure enhancing chamber has an opening edge mating the shape of the inner side of the wall of the dust collection hood to increase covering range of the airflow.

Owner:XPOLE PRECISION TOOLS

Hydraulic semi-automatic constant-pressure grinding and polishing equipment

InactiveCN103753378ASimple structureEasy to operatePreparing sample for investigationLapping machinesTest sampleSemi automatic

The invention discloses hydraulic semi-automatic constant-pressure grinding and polishing equipment which is used for preliminarily grinding and polishing test samples and comprises a mounting seat, fixing devices and turntables. The turntables are rotationally arranged on the mounting seat, each fixing device comprises a support, a first driving device and a clamping mechanism connected with the driving device, both each first driving device and the corresponding clamping mechanism are mounted on the corresponding support, the supports are detachably arranged on the mounting seat, the test samples are fixedly clamped by the claming mechanisms, the first driving devices drive the clamping mechanisms to drive the test samples to approach to the turntables or leave away from the turntables, and the test samples are preliminarily ground and polished by the turntables. The hydraulic semi-automatic constant-pressure grinding and polishing equipment has the advantages that the hydraulic semi-automatic constant-pressure grinding and polishing equipment is simple in structure and small in occupied space, can be operated easily and conveniently and is safe, stable and portable, the test samples can be automatically ground and polished by the hydraulic semi-automatic constant-pressure grinding and polishing equipment, the test sample manufacturing efficiency and qualification can be improved, and the practicality of the hydraulic semi-automatic constant-pressure grinding and polishing equipment can be enhanced.

Owner:CENT TESTING INT GRP CO LTD

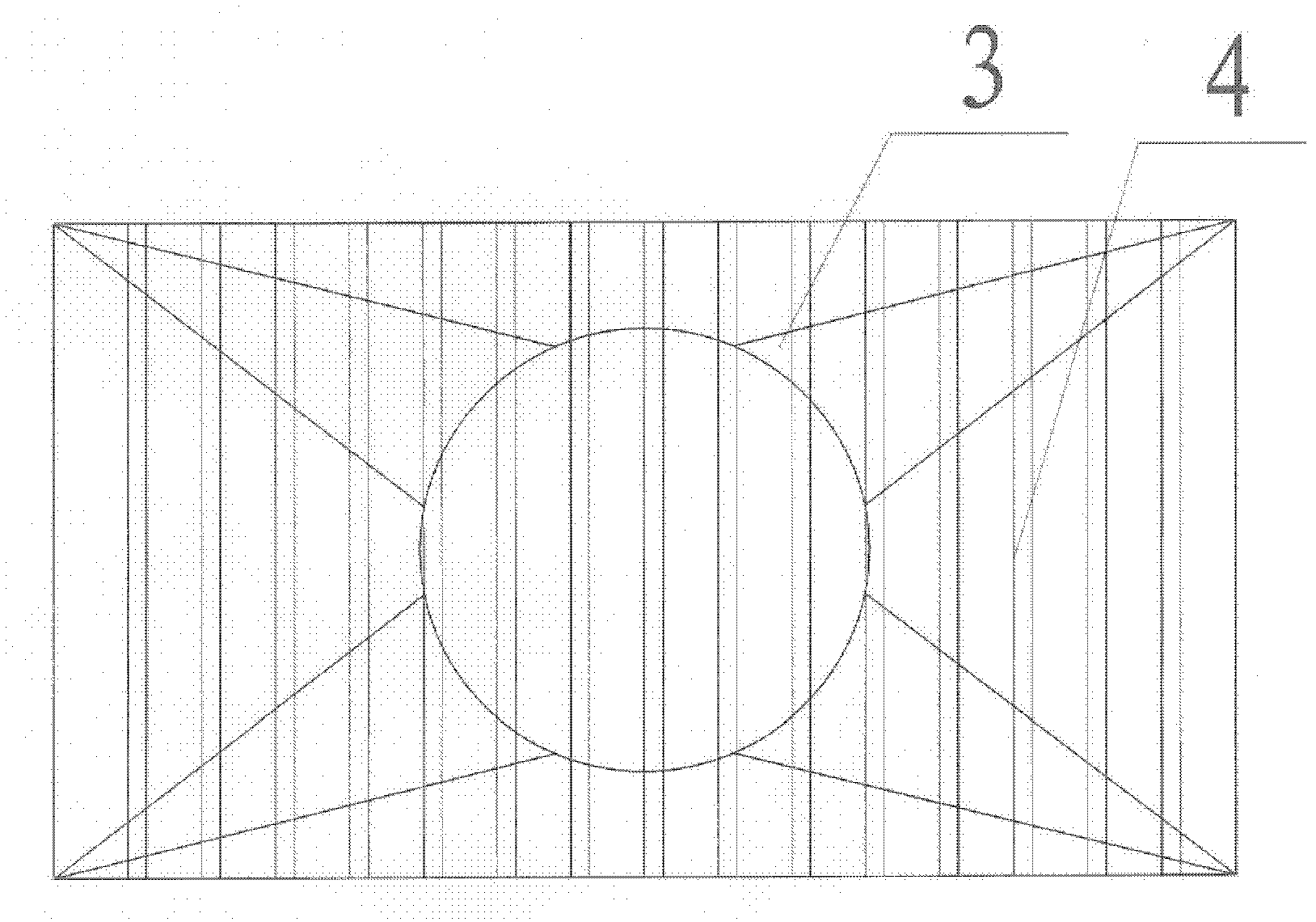

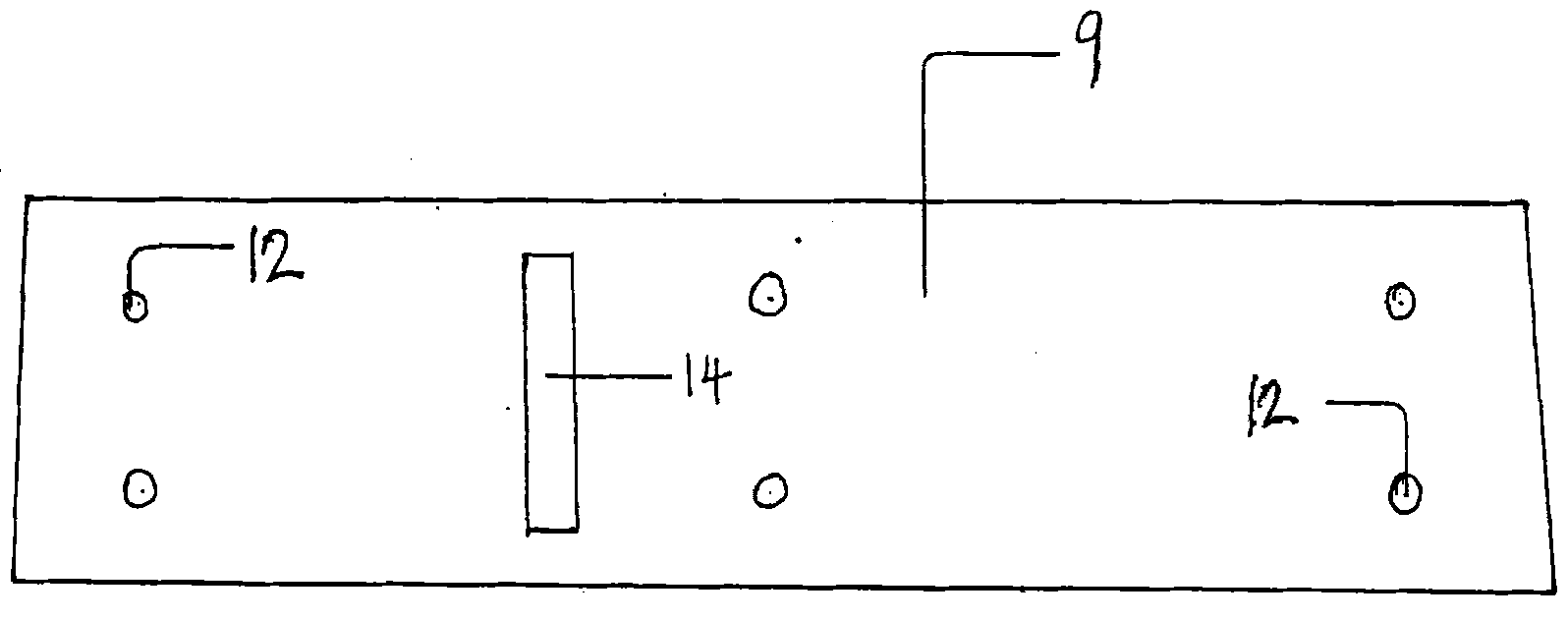

Double water collection type flat sheet membrane element and support plate thereof

ActiveCN104190263AAvoid pollutionReduce pollutionSemi-permeable membranesBiological water/sewage treatmentComing outWater production

The invention provides a support plate for a flat sheet membrane element. The support plate comprises a rectangular main body and two water collection pipes, wherein the two water collection pipes are respectively fixed on the left side and the right side of the rectangular main body; ten to twelve first longitudinal flow guide grooves and two first transverse flow guide grooves are formed in the front surface of the rectangular main body; the two first transverse flow guide grooves are respectively positioned at the upper end and the lower end of the ten to twelve first longitudinal flow guide grooves and are respectively communicated with the ten to twelve first longitudinal flow guide grooves. According to the double water collection type flat sheet membrane element and the support plate thereof, flow guide passages are utilized for running through the longitudinal flow guide grooves and the transverse flow guide grooves in the two surfaces of the support plate, so that water can smoothly flows in the flow guide grooves during water collection, and the subjected resistance is greatly reduced when the water comes out, so that the transmembrane pressure of the system is reduced, the operation consumption of the system can be greatly reduced during suction and drainage, and the water production efficiency is also improved.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

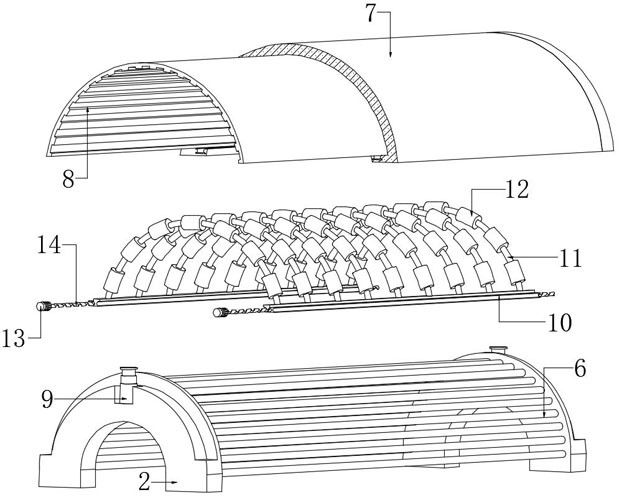

Steam sterilization device for furniture surface cloth production

ActiveCN113521325AIncrease temperatureIncrease humidityMechanical cleaningPressure cleaningInfrared lampProcess engineering

The invention belongs to the technical field of cloth production and processing, particularly relates to a steam sterilization device for furniture surface cloth production, and aims to solve the problems that the humidity of cloth is greatly increased, the follow-up drying process is slow, and the overall treatment efficiency of the cloth is reduced due to the fact that the surface wall temperature of the cloth is relatively low and steam is liquefied when cooled in the steam sterilization process. According to the scheme, the device comprises an outer box, a semicircular base is fixedly connected to the inner wall of the bottom of the outer box, a lamp box is fixedly connected between the inner walls of the two sides of the semicircular base, a plurality of grooves are circumferentially formed in the outer wall of the lamp box at equal intervals, and an infrared lamp tube is fixedly connected between the inner walls of the two sides of each groove. Cloth before steam sterilization is heated through the infrared lamp tubes, the temperature of the cloth is increased, and the situation that in the subsequent steam sterilization process, due to the fact that a large amount of steam is condensed and liquefied due to the low temperature of the surface of the cloth, the humidity of the cloth is greatly increased, the drying time after steam sterilization is prolonged, and the treatment efficiency of the cloth is reduced is avoided.

Owner:JIANGSU ZHONGSHI HOME TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com