Evacuating drum-type tank washer

A drum-type washing tank technology, which is applied to the processing of textile material containers, liquid/gas/steam fiber/sliver/roving processing, etc., can solve problems such as unreasonable structure of the washing tank, uneven rewashing of wool tops, etc., and achieve pumping The suction is uniform, the suction is good, and the effect of preventing the loss of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

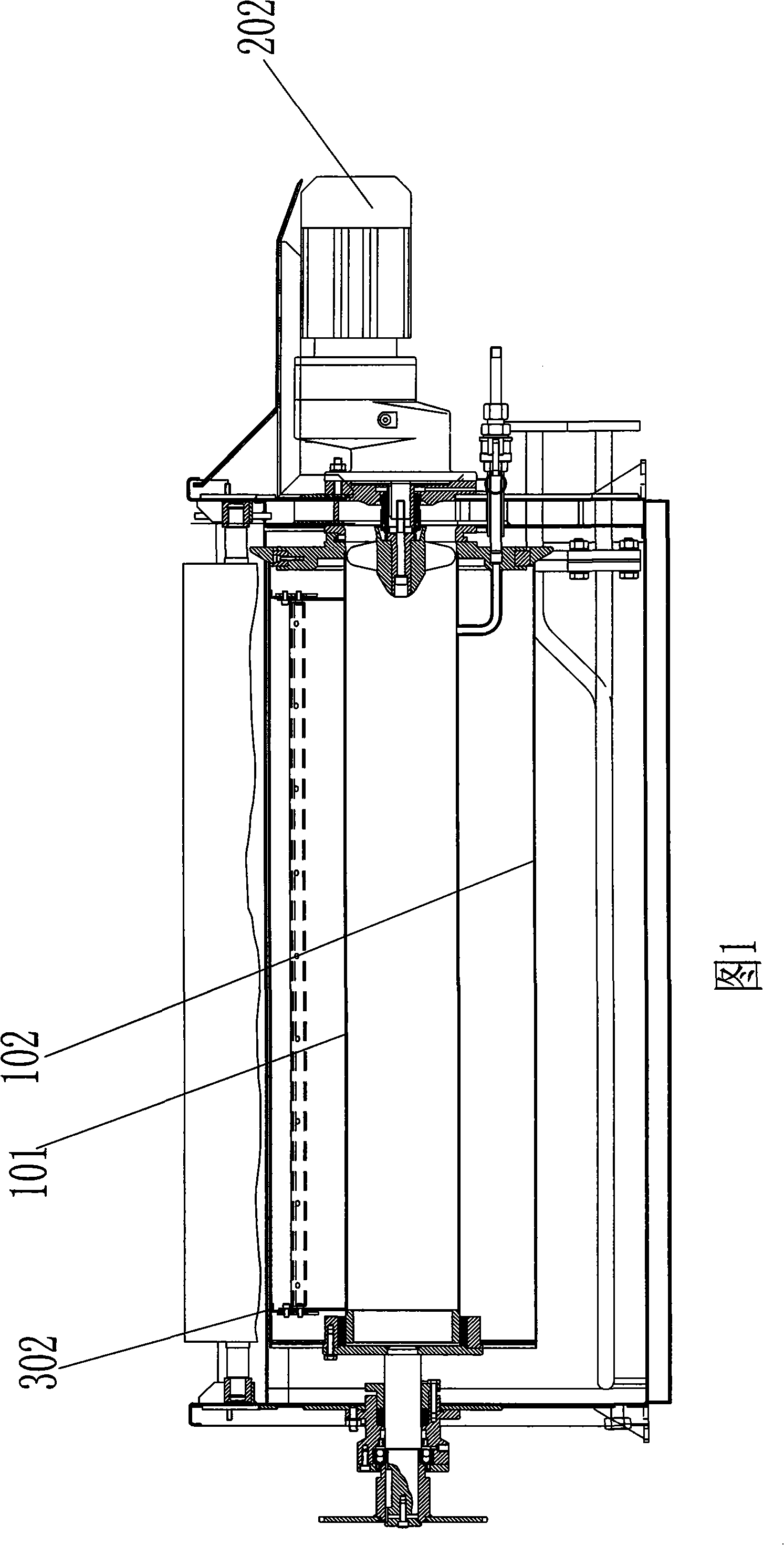

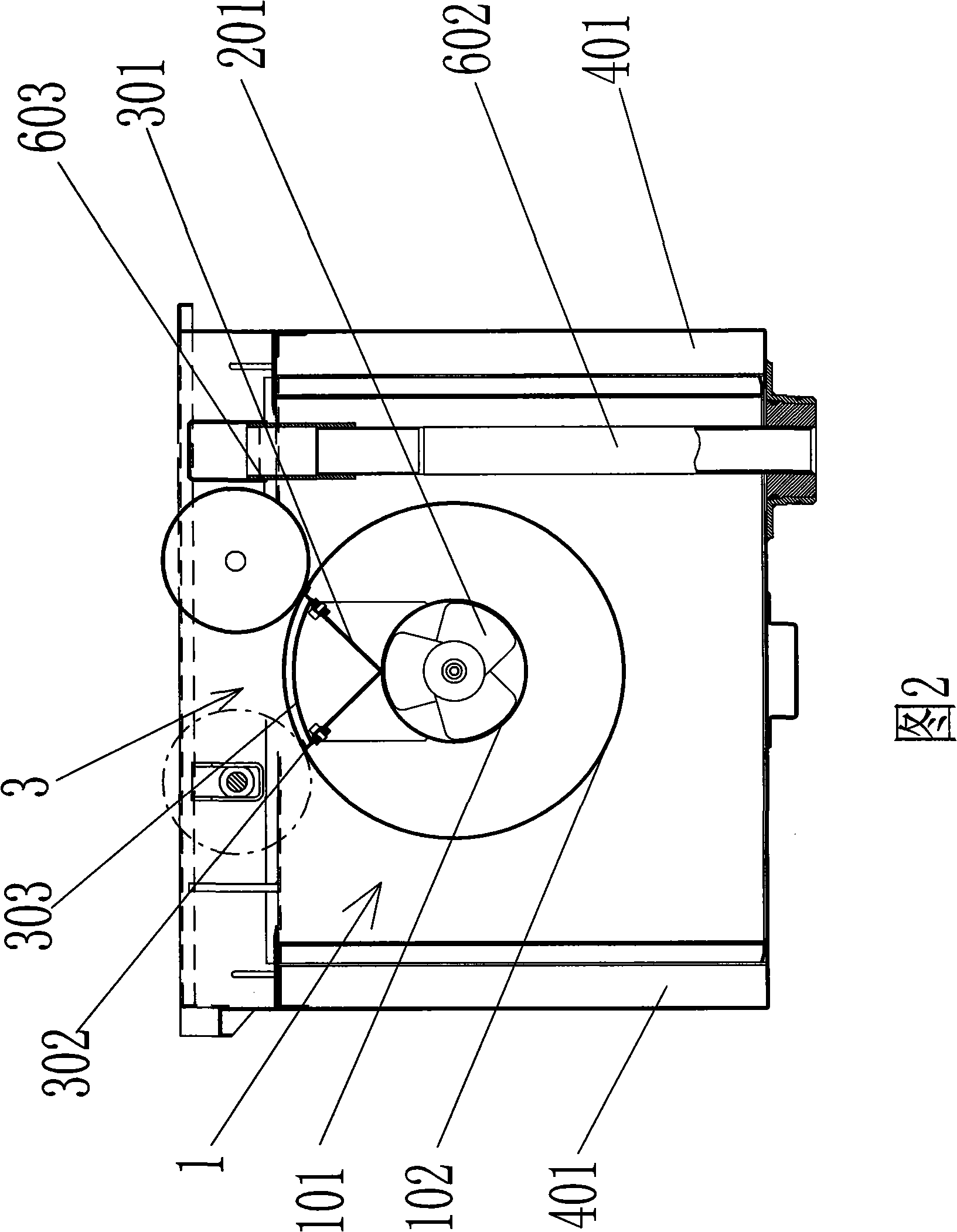

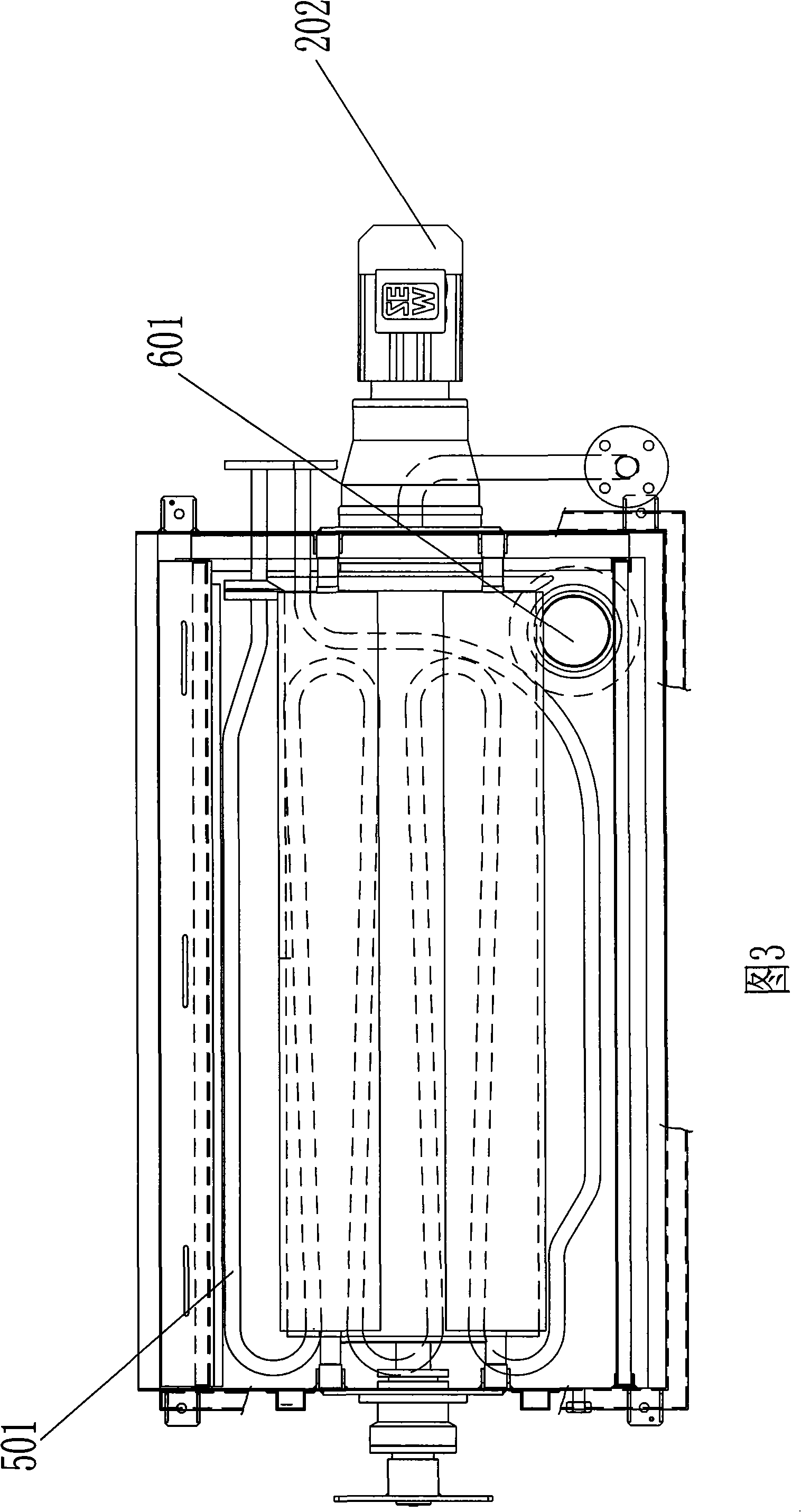

[0022] Combined with Figure 1, Figure 2 and Figure 3, the suction drum type washing tank includes: suction device and drum 1, drum 1 has an inner cylinder 101 and an outer cylinder 102, flanges are installed at both ends of the outer cylinder 102, and linings are installed inside The inner cylinder 101 cooperates with the outer cylinder 102 through the bushing, the inner cylinder 101 is fixed, and the outer cylinder 102 can rotate around the inner cylinder 101 under the action of the transmission drive device. The suction device includes a propeller 201 and a gear motor 202. The propeller 201 is installed at the liquid outlet of the inner tube 101 , and the rotating shaft of the reduction motor 202 is connected with the propeller 201 . Both the above-mentioned inner cylinder 101 and outer cylinder 102 are provided with ventilation holes, and the ventilation holes on the inner cylinder 101 are gradually denser from one end close to the suction device to the other end, and the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com