Dust collecting barrel of sewing machine

A technology for sewing machines and dust collectors, applied in sewing machine components, sewing equipment, textiles and papermaking, etc., can solve problems such as high noise, and achieve the effects of low noise, improved service life, and guaranteed service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

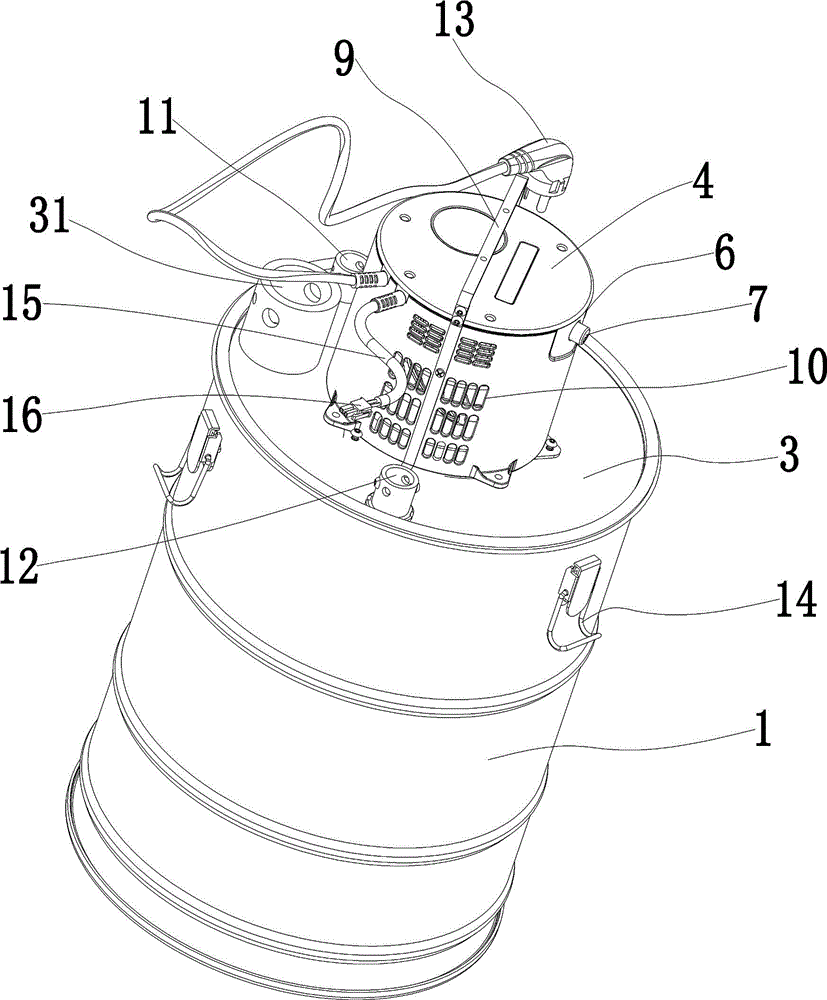

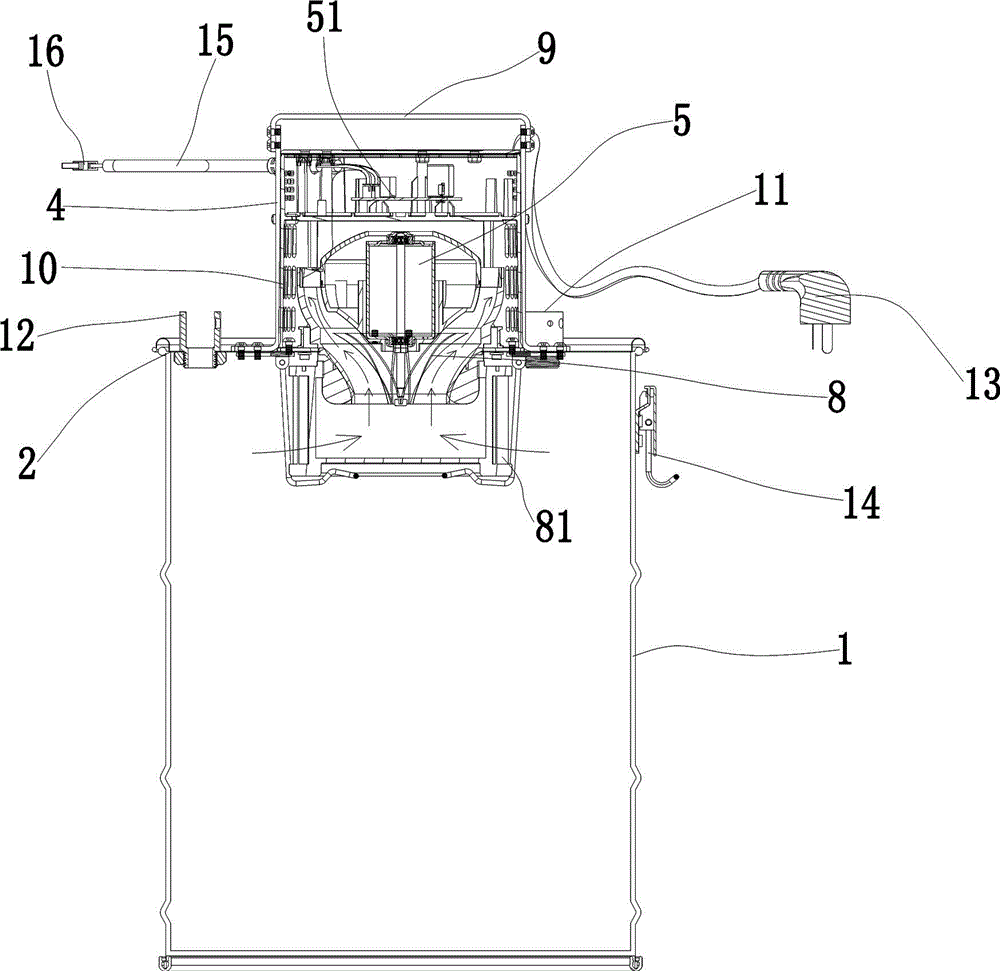

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0019] see figure 1 , figure 2 , the present invention provides a sewing machine dust collection barrel, comprising a sewing machine, a controller disposed on the sewing machine, and a barrel body 1, an opening 2 is opened at the upper end of the barrel body 1; a barrel cover 3 is covered at the opening 2 of the barrel body, A protective cover 4 is installed and fixed above the bung 3; a brushless motor 5 is mounted inside the protective cover 4; the brushless motor 5 is connected with a control system 51; the control system 51 is connected with a switch 6 and a speed regulating knob 7 The brushless motor 5 is connected with a fan blade 8, and the fan blade 8 is located in the bucket body 1; the fan blade 8 is covered with a filter element 81; the protective cover 4 is provided with a handle 9; Several exhaust ports 10 are provided; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com