Oil fume purifying integrated machine

An oil fume purification and all-in-one machine technology, which is applied in the field of range hoods, can solve problems such as inconvenient installation, large space occupation, troublesome maintenance, etc., and achieve the effect of convenient installation and reduced space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

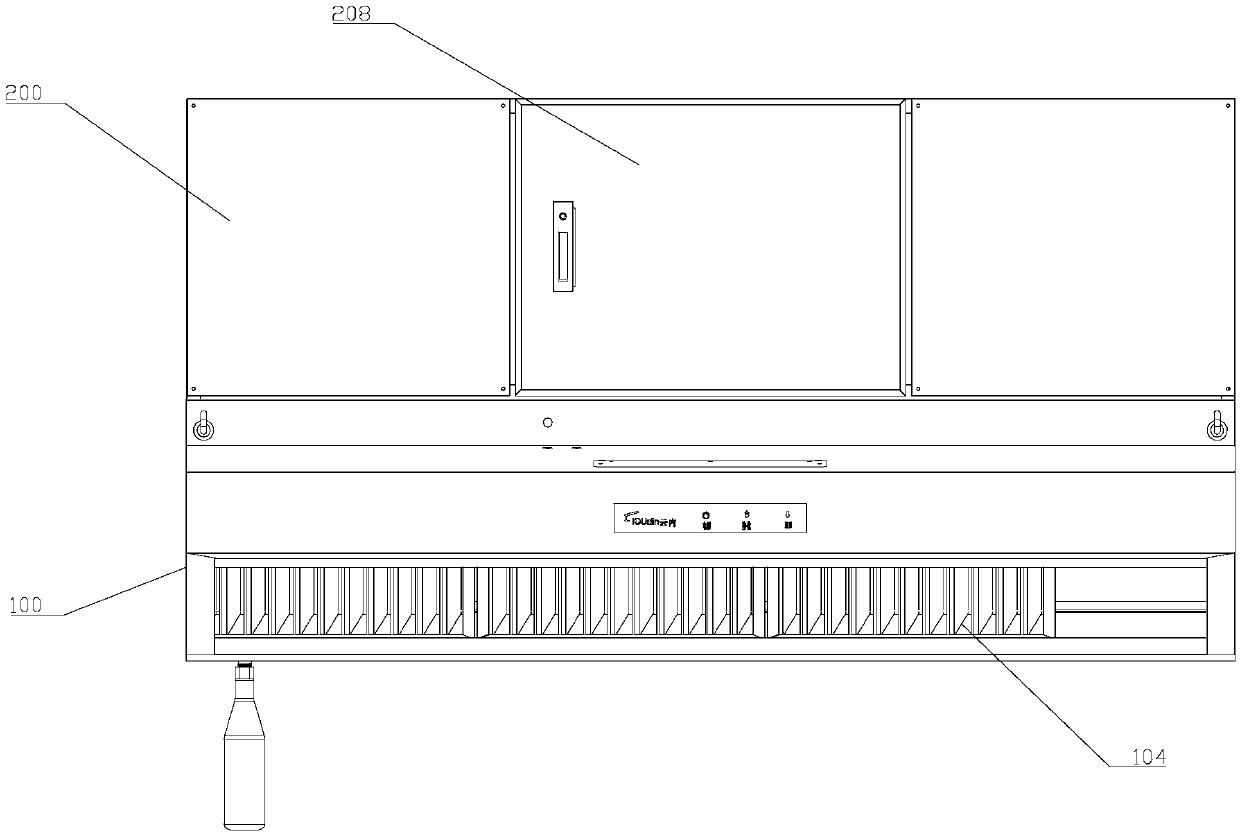

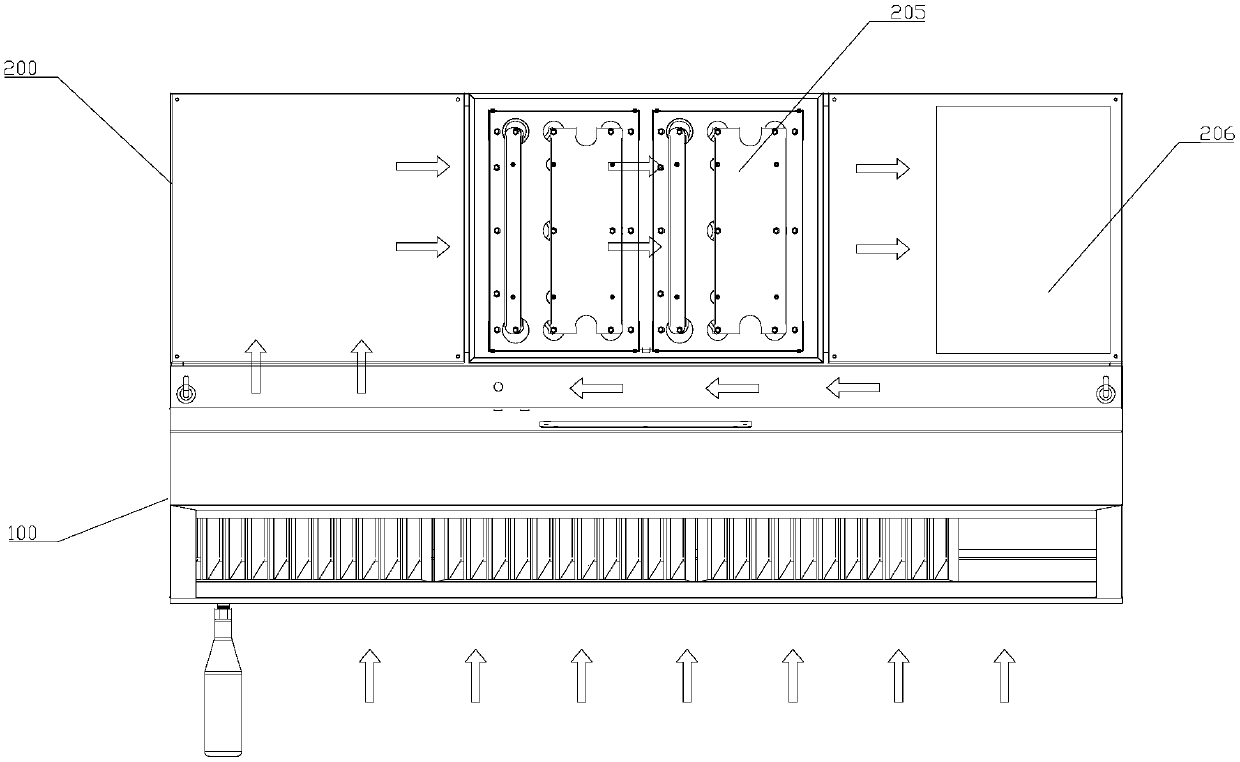

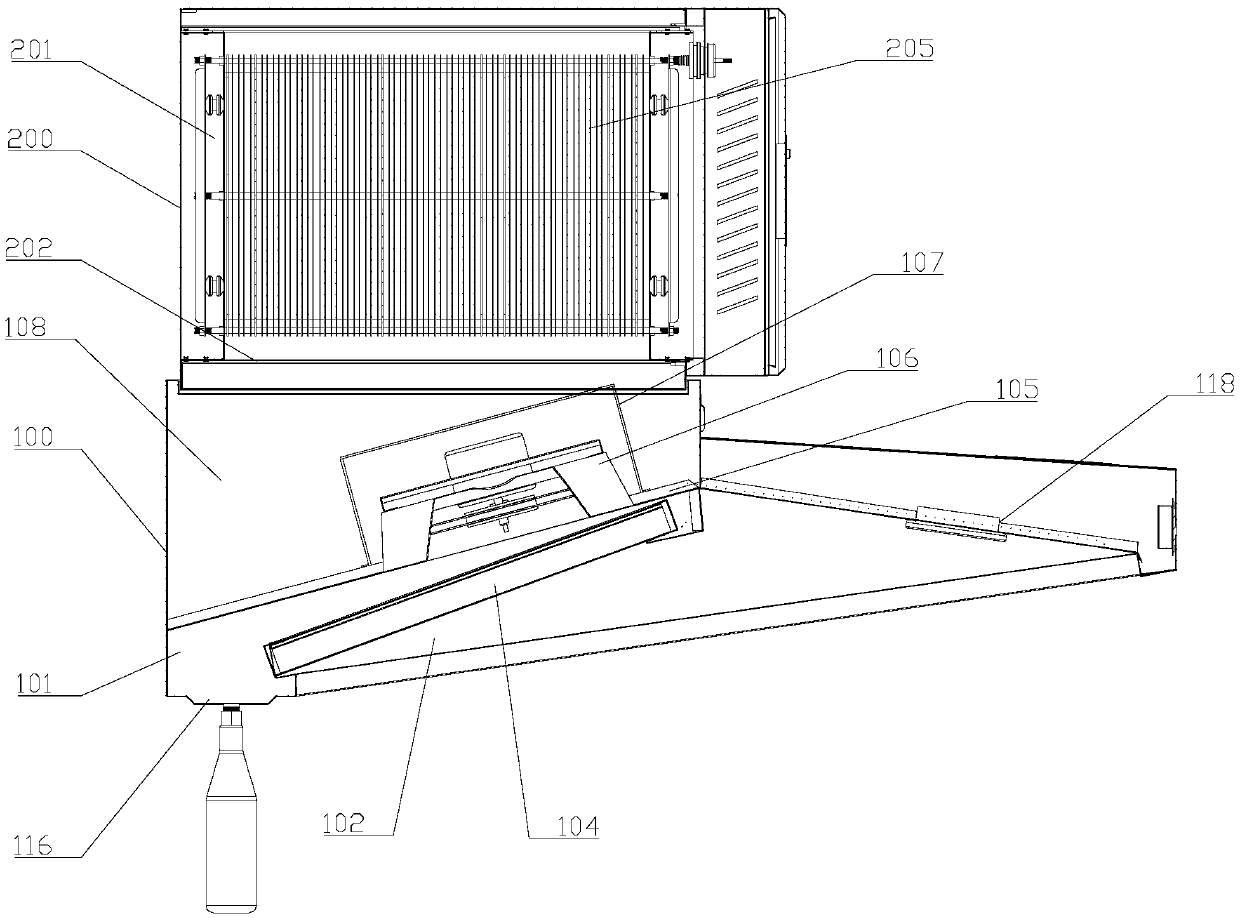

[0062] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, a lampblack purification integrated machine, which includes:

[0063] The oil fume collecting part 100 and the oil fume purifying part 200 arranged above the oil fume collecting part 100;

[0064] The oil fume collecting part 100 is provided with an oil fume processing chamber 101; the bottom of the oil fume processing chamber 101 is provided with a processing chamber inlet 102, and its upper part is provided with a processing chamber outlet 103;

[0065] The oil fume treatment chamber 101 is provided with an oil retaining mechanism 104 and an oil fume pretreatment mechanism 105 sequentially from bottom to top; the oil fume pretreatment mechanism 105 includes a plurality of oil fume separation assemblies 106 arranged side by side;

[0066] The oil fume purification unit 200 is provided with an oil fume purification chamber 201; the bottom of the oil fume purification...

Embodiment 2

[0085] The technical solution described in this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0086] Such as Figure 8 , Figure 9 with Figure 10 As shown, the oil fume pretreatment mechanism 105 also includes an installation panel 108 arranged parallel to the bottom plate 202 of the clean chamber, and the installation panel 108 is provided with a plurality of installation holes 109 matching the oil fume separation assembly 106 . The installation panel is arranged parallel to the bottom plate 202 of the purification chamber, so that the oil fume separation assembly can fully contact with the oil fume, so as to better disperse large particles of oil fume.

[0087] Further, the windshield mechanism 107 includes: a windshield 110 matched with the oil fume separation assembly 106 and a plurality of connecting brackets 111 arranged at intervals;

[0088] The connection bracket 111 has a fixed end and an installation end, the fixed end is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com