Patents

Literature

82results about How to "Efficient vacuuming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

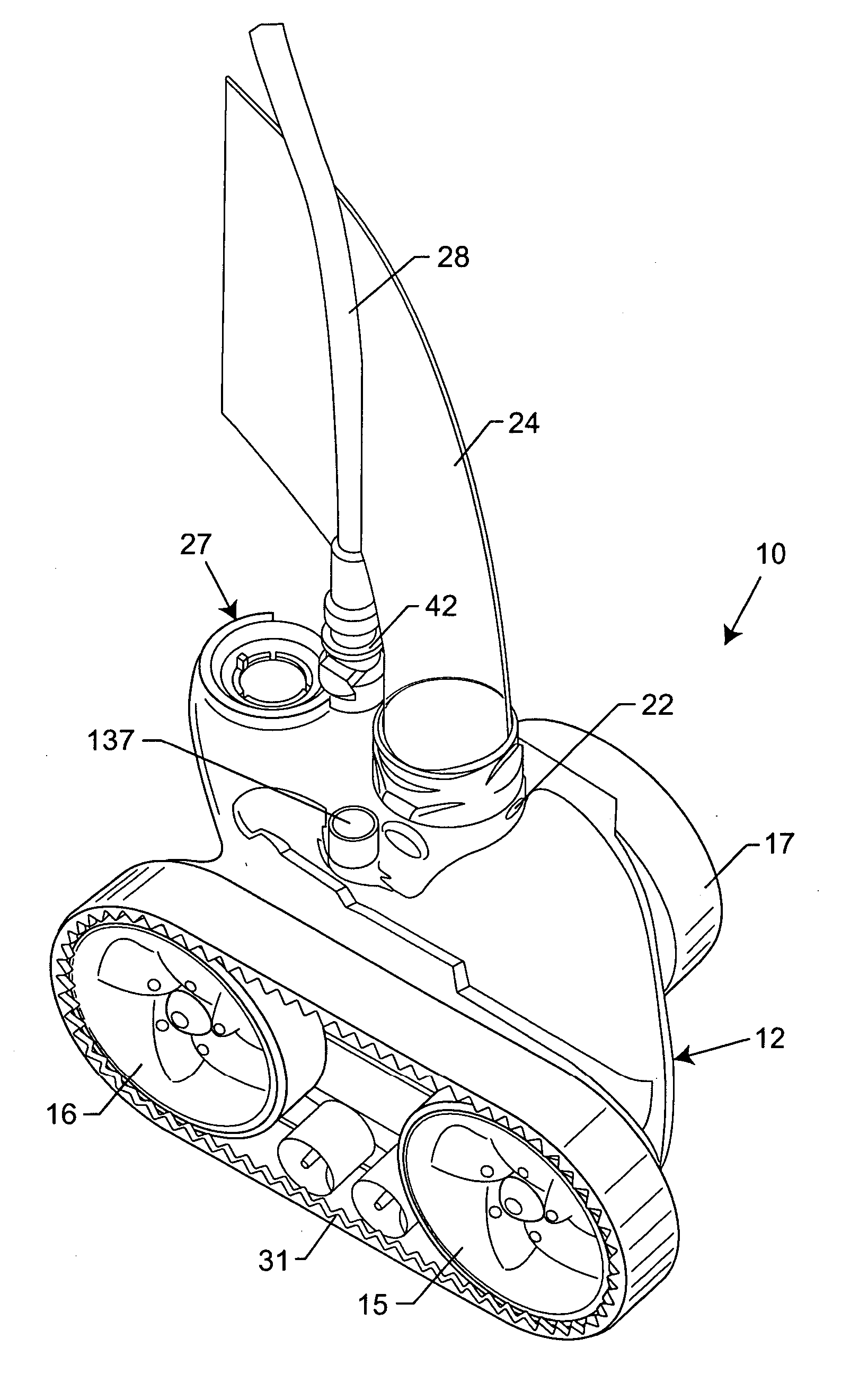

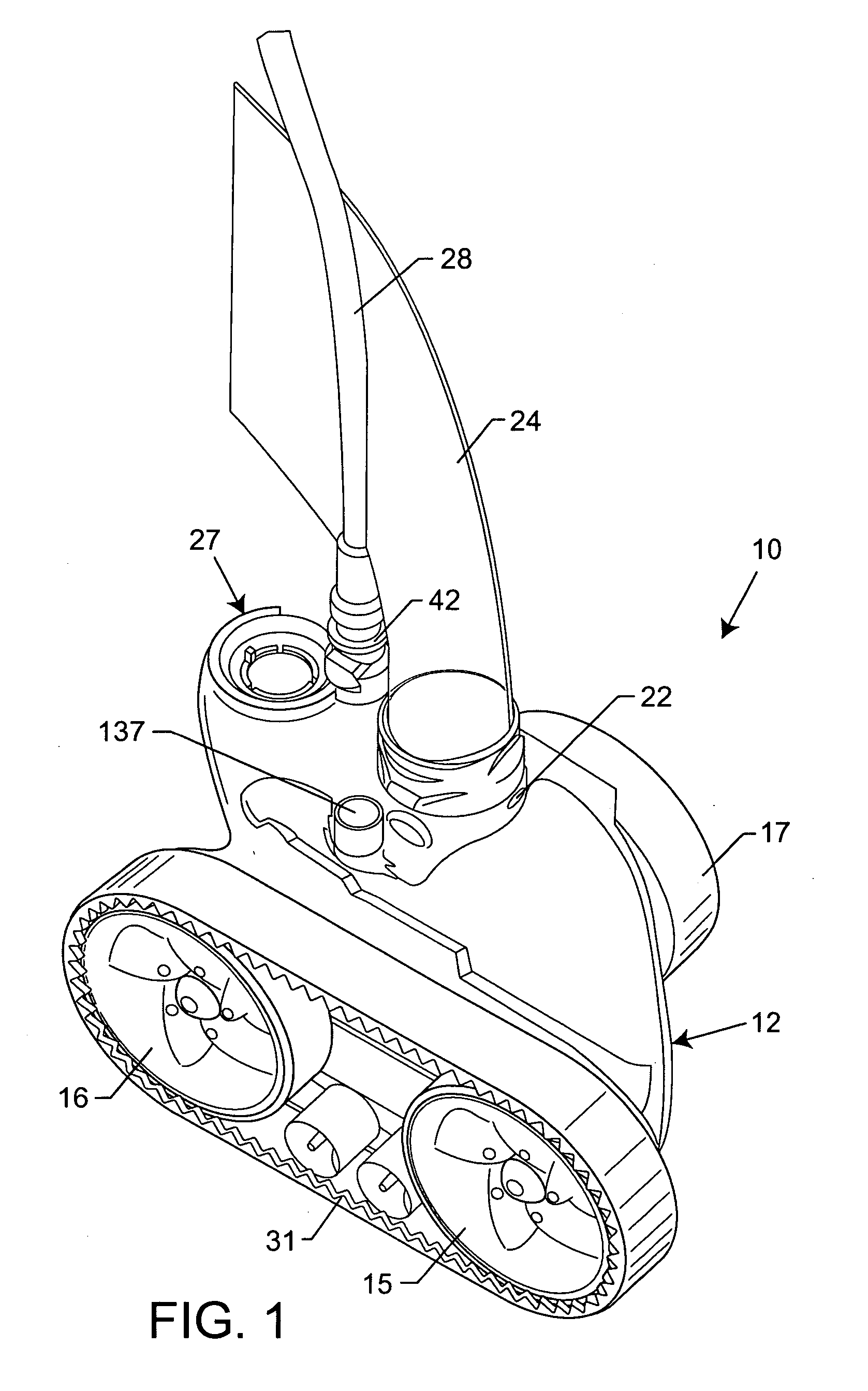

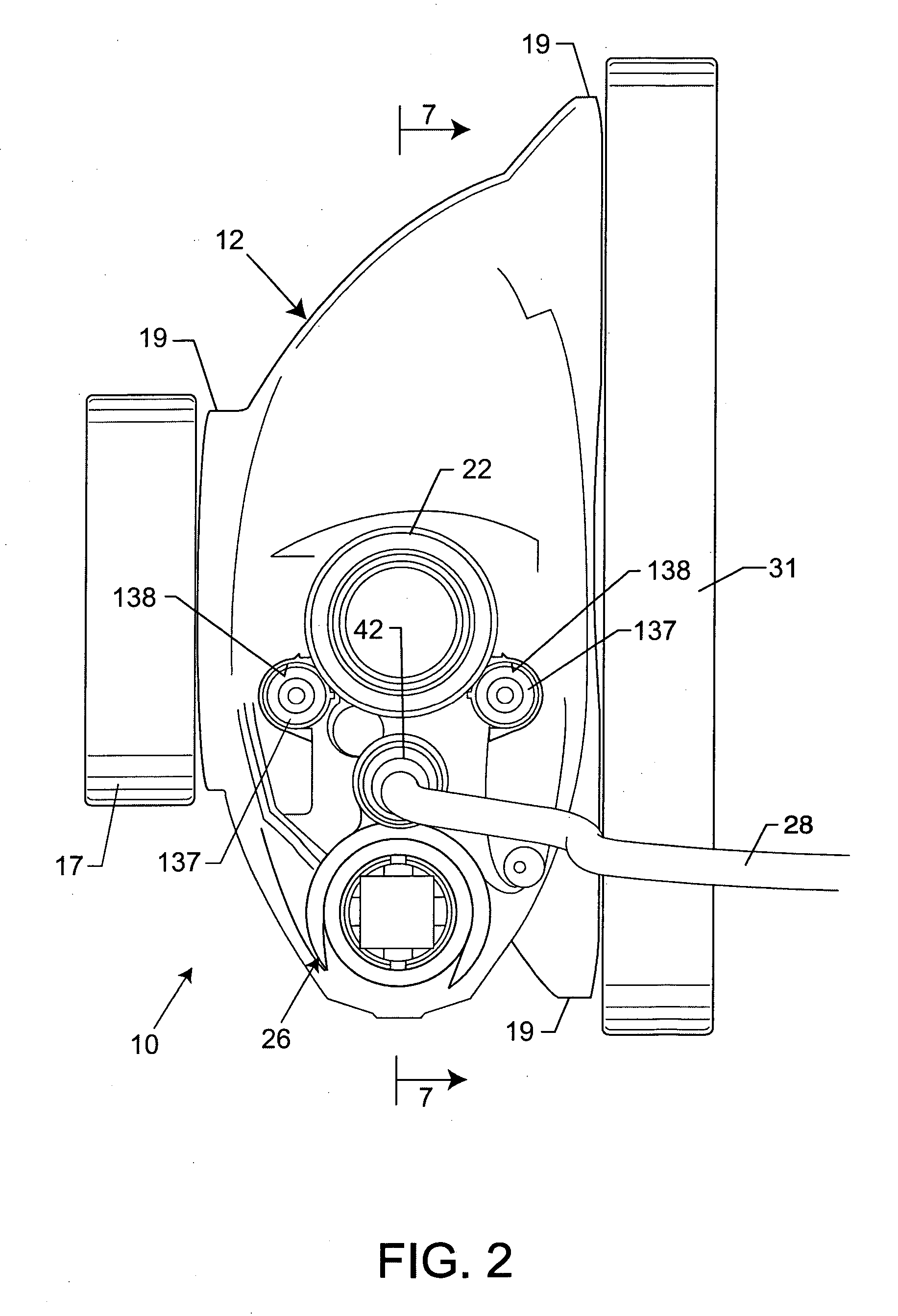

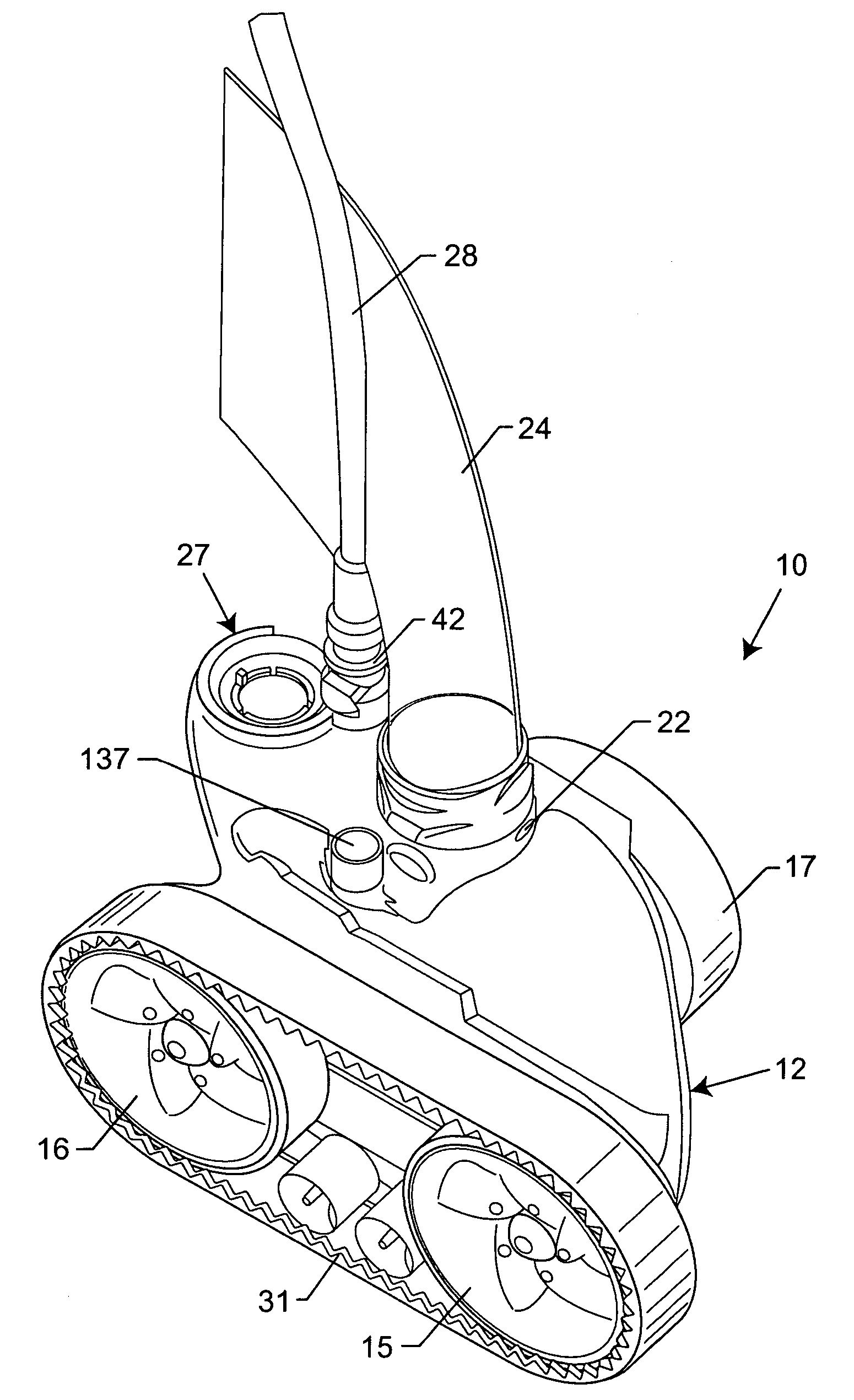

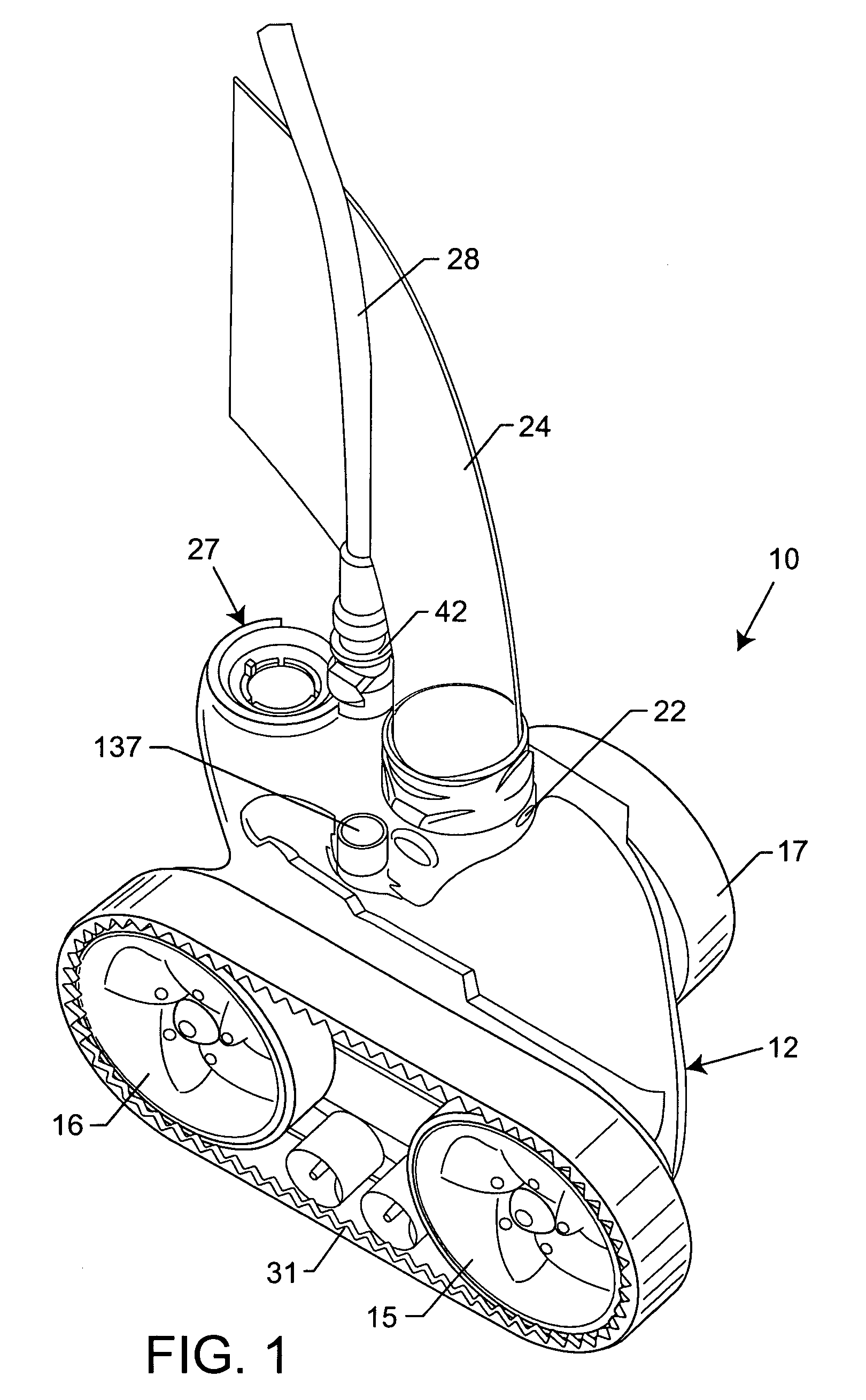

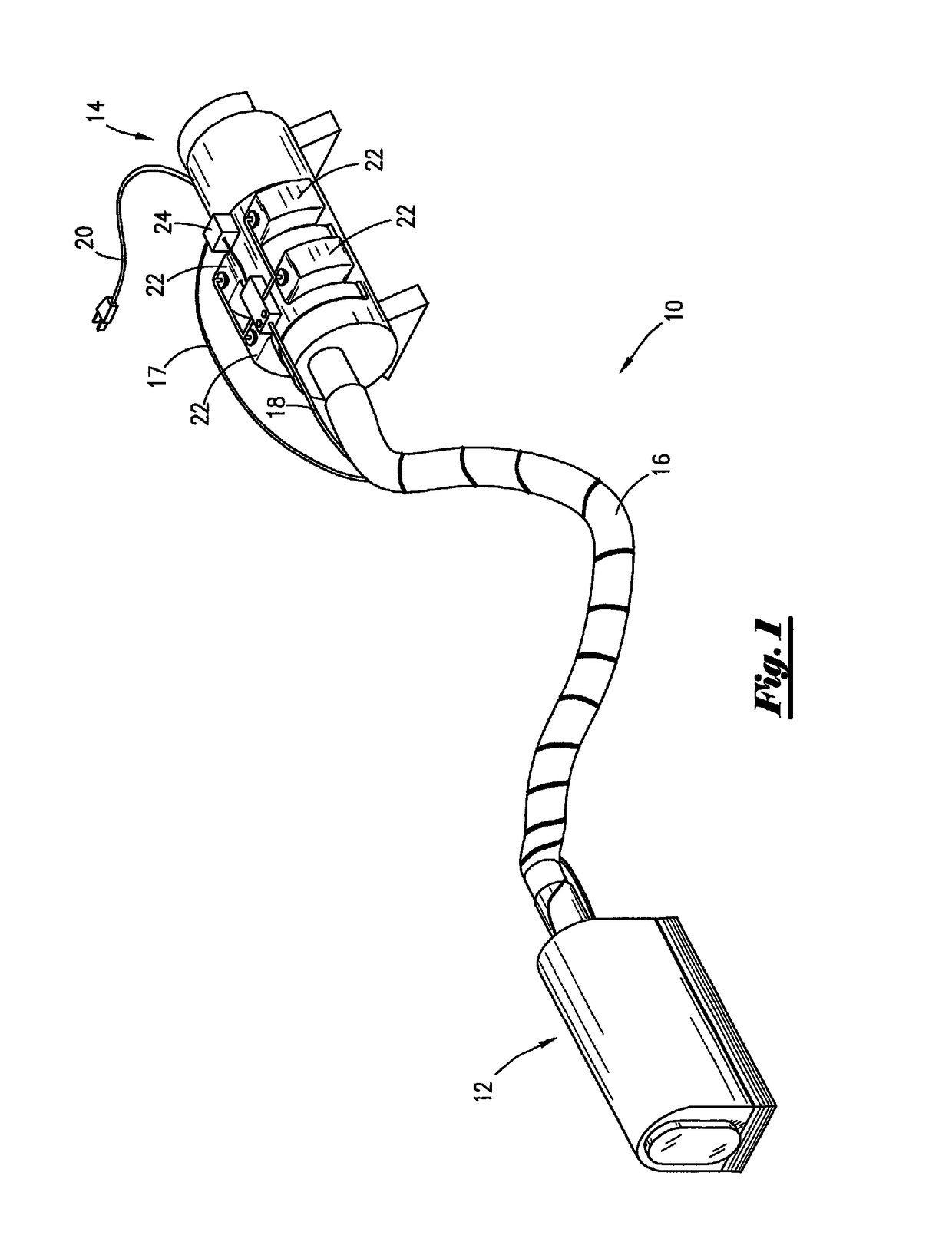

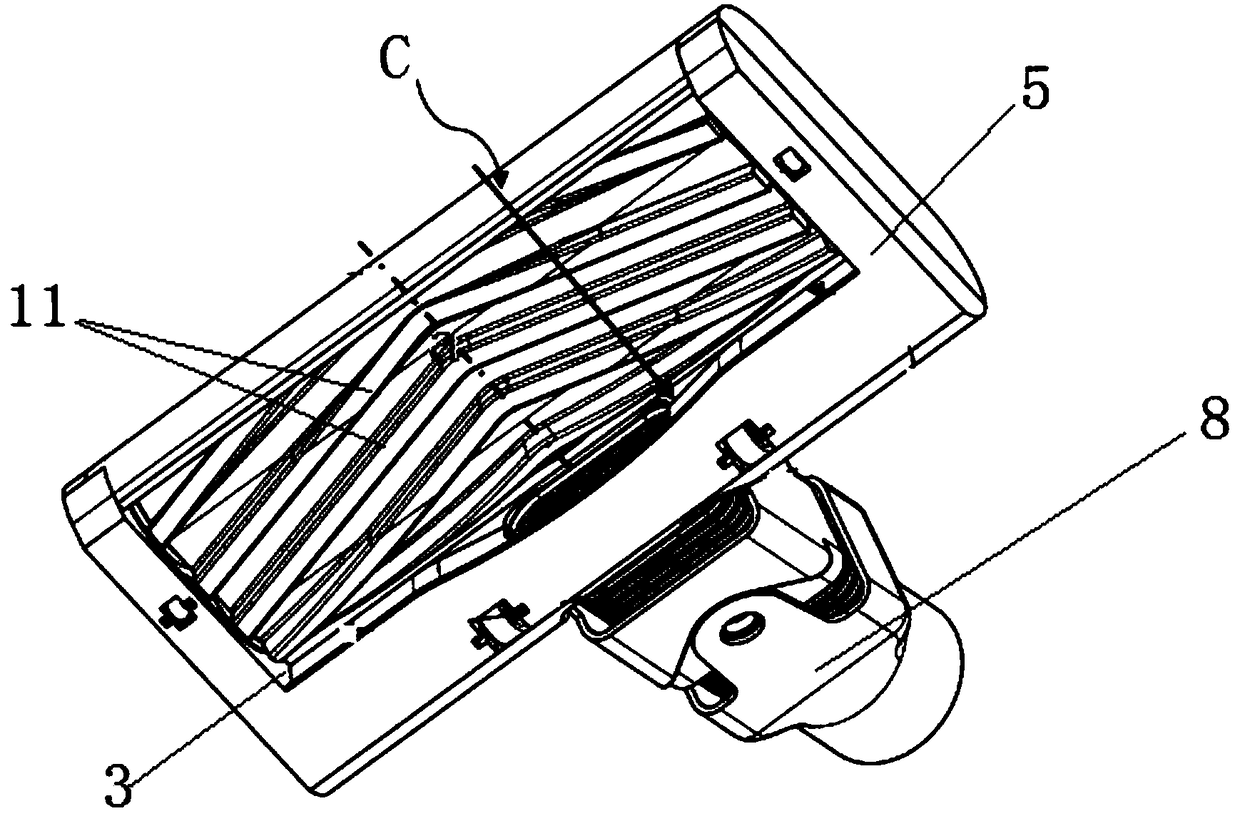

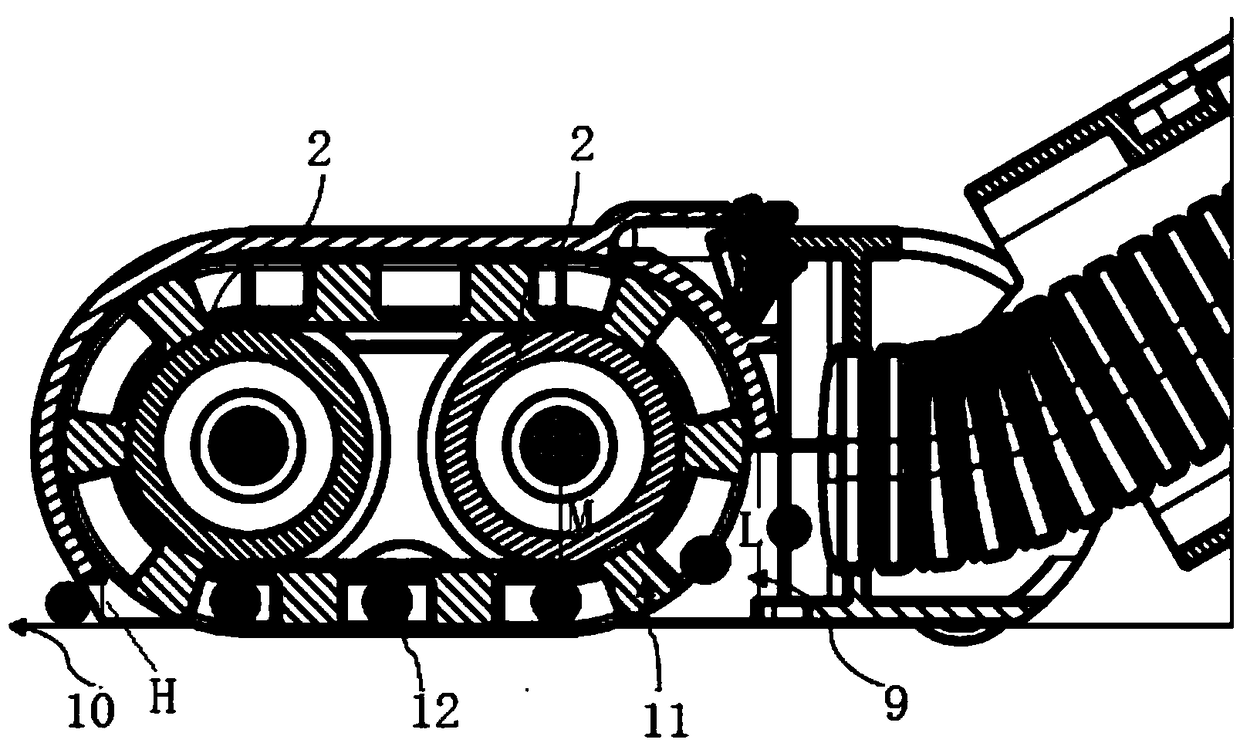

Automatic pool cleaner

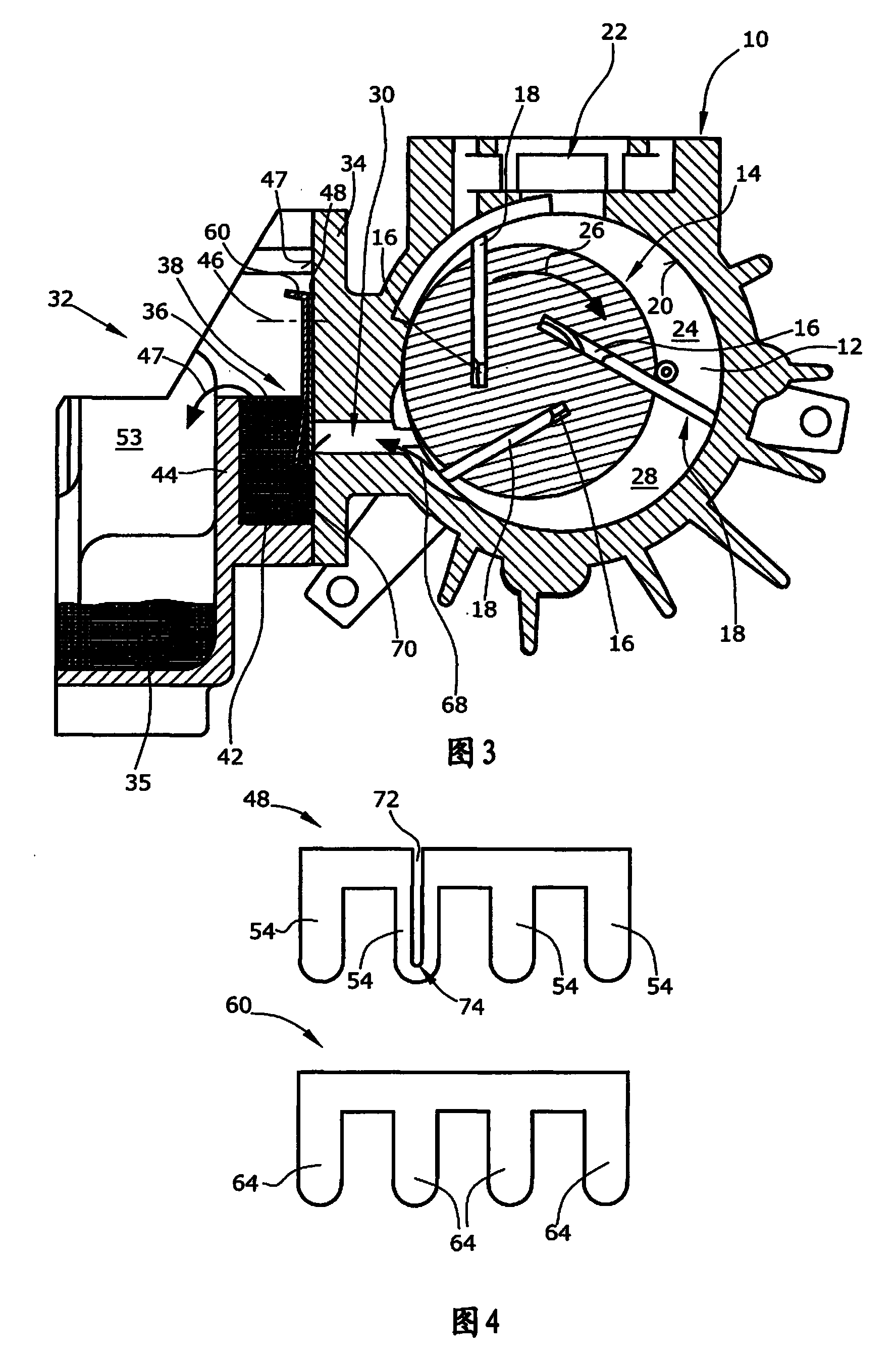

ActiveUS20070094817A1Prevent movementEfficient vacuumingGymnasiumSwimming poolsPower cableMarine engineering

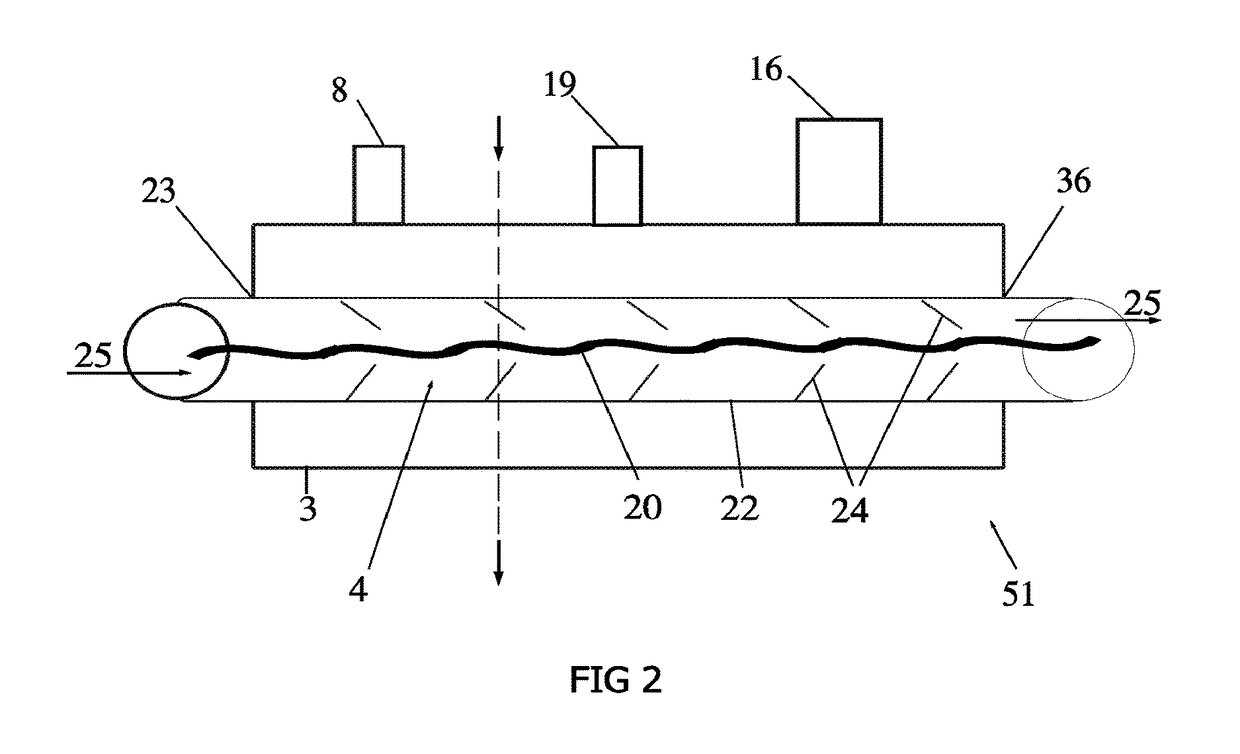

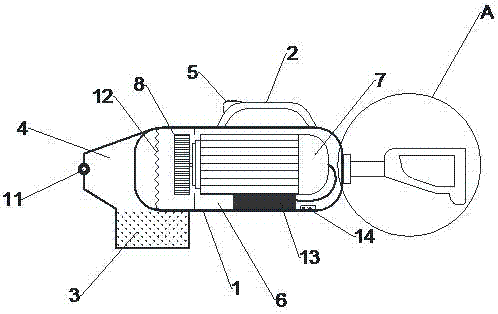

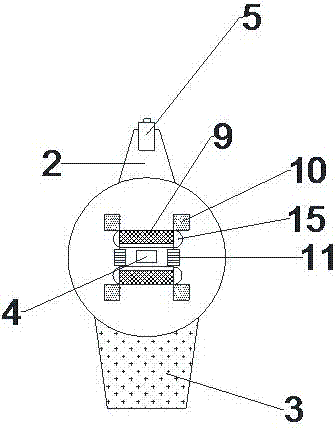

An automatic pool cleaner is provided of the type for random travel over submerged floor and side wall surfaces of a swimming pool or the like to dislodge and collect debris. The pool cleaner includes an electric-powered traction drive system for rotatably driving cleaner wheels, and an electric-powered water management system including a water supply pump and related manifold unit for venturi-vacuuming and collection of settled debris within a porous filter bag. A directional control system including an on-board compass monitors turning movements of the pool cleaner during normal random travel operation, and functions to regulate the traction drive system in a manner to prevent, e.g., excess twisting of a conduit such as a power cable tethered to the pool cleaner.

Owner:ZODIAC POOL SYST LLC

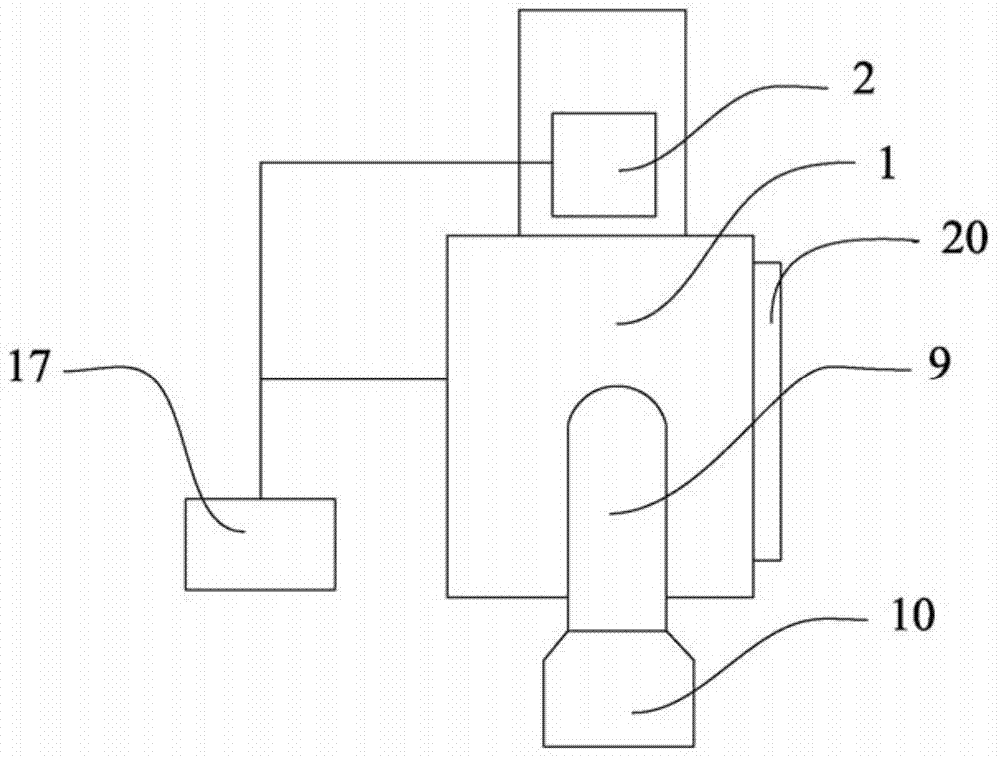

Automatic pool cleaner

ActiveUS7690066B2Prevent movementEfficient vacuumingGymnasiumSwimming poolsAutomated pool cleanerPower cable

An automatic pool cleaner is provided of the type for random travel over submerged floor and side wall surfaces of a swimming pool or the like to dislodge and collect debris. The pool cleaner includes an electric-powered traction drive system for rotatably driving cleaner wheels, and an electric-powered water management system including a water supply pump and related manifold unit for venturi-vacuuming and collection of settled debris within a porous filter bag. A directional control system including an on-board compass monitors turning movements of the pool cleaner during normal random travel operation, and functions to regulate the traction drive system in a manner to prevent, e.g., excess twisting of a conduit such as a power cable tethered to the pool cleaner.

Owner:ZODIAC POOL SYST LLC

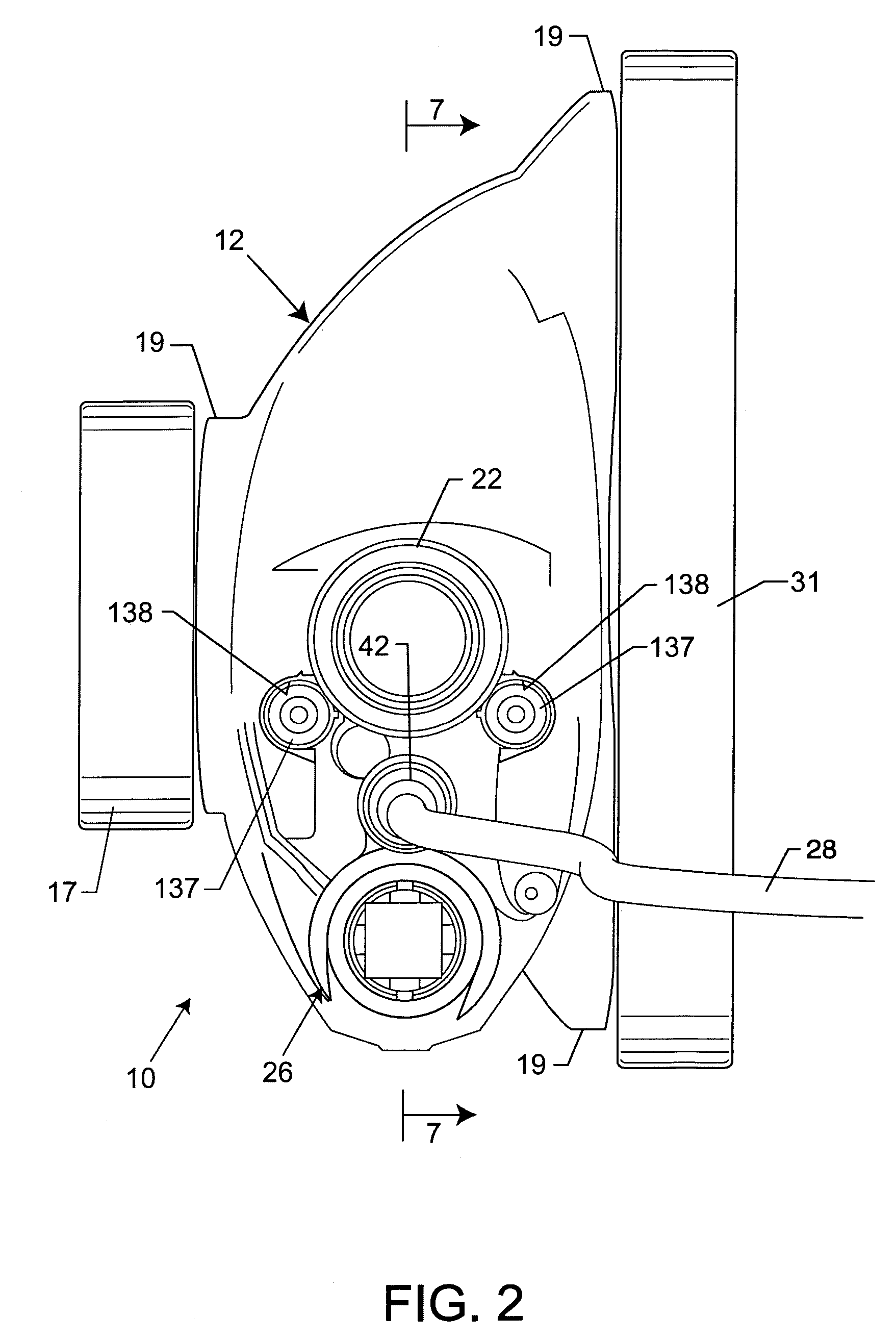

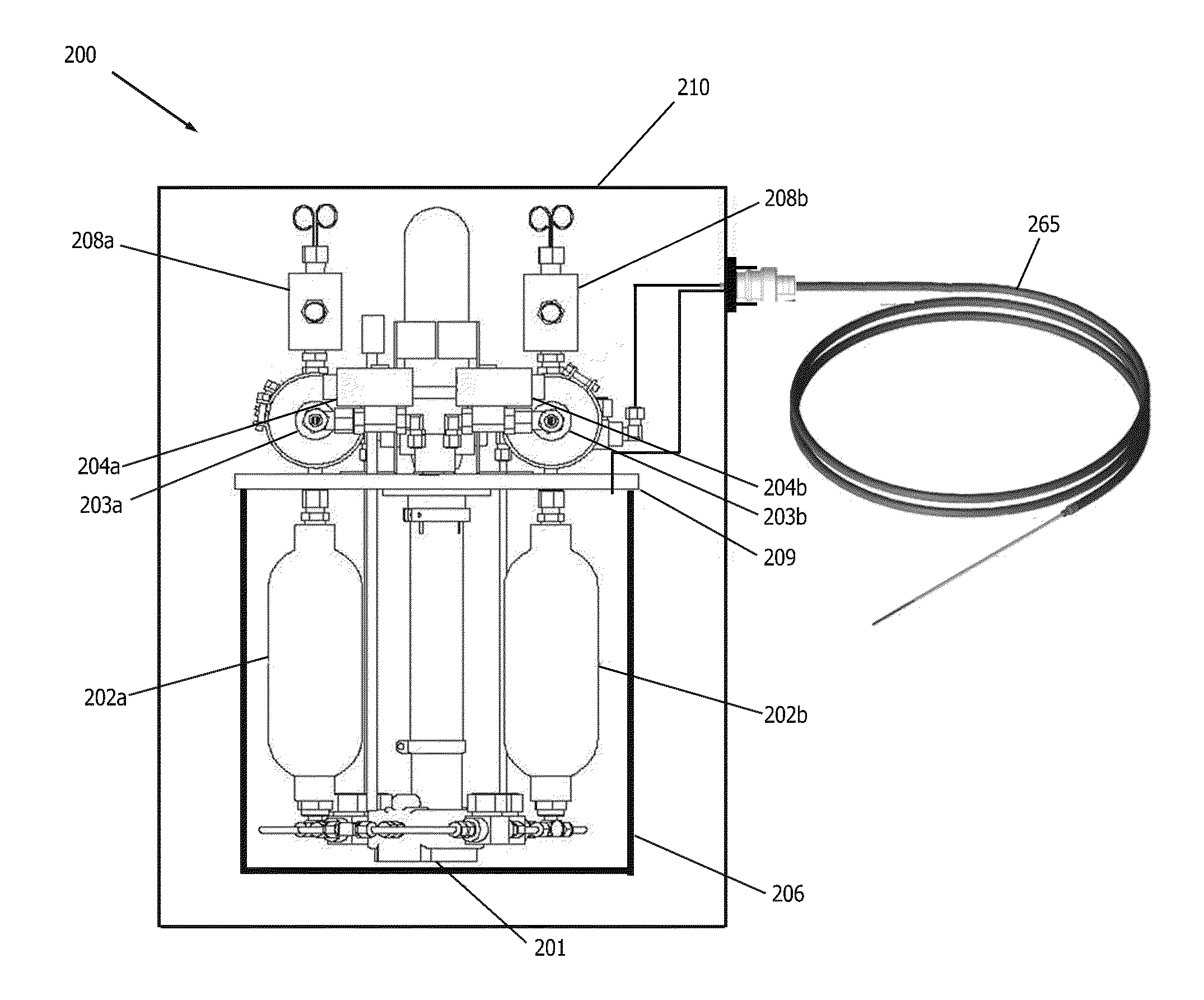

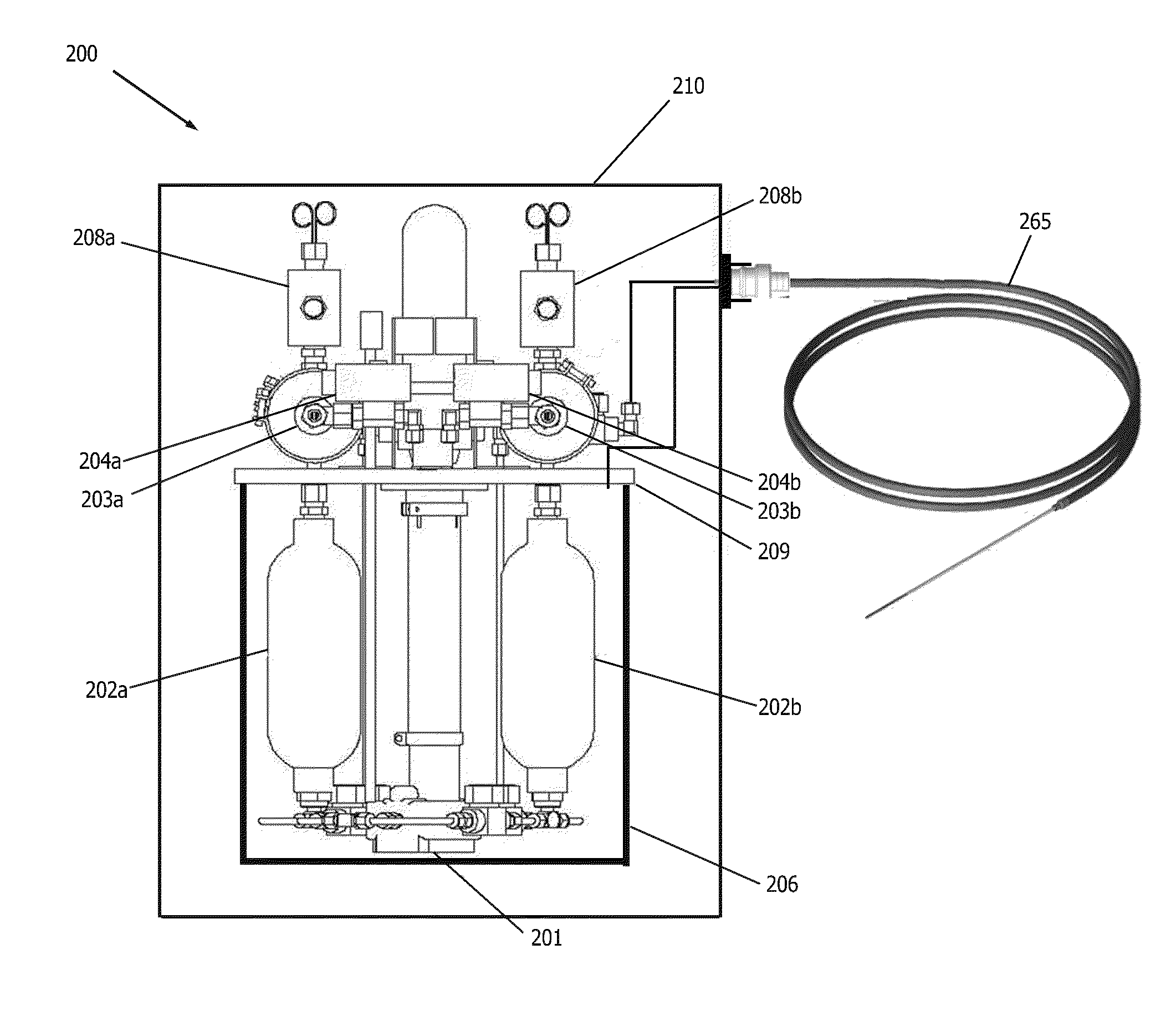

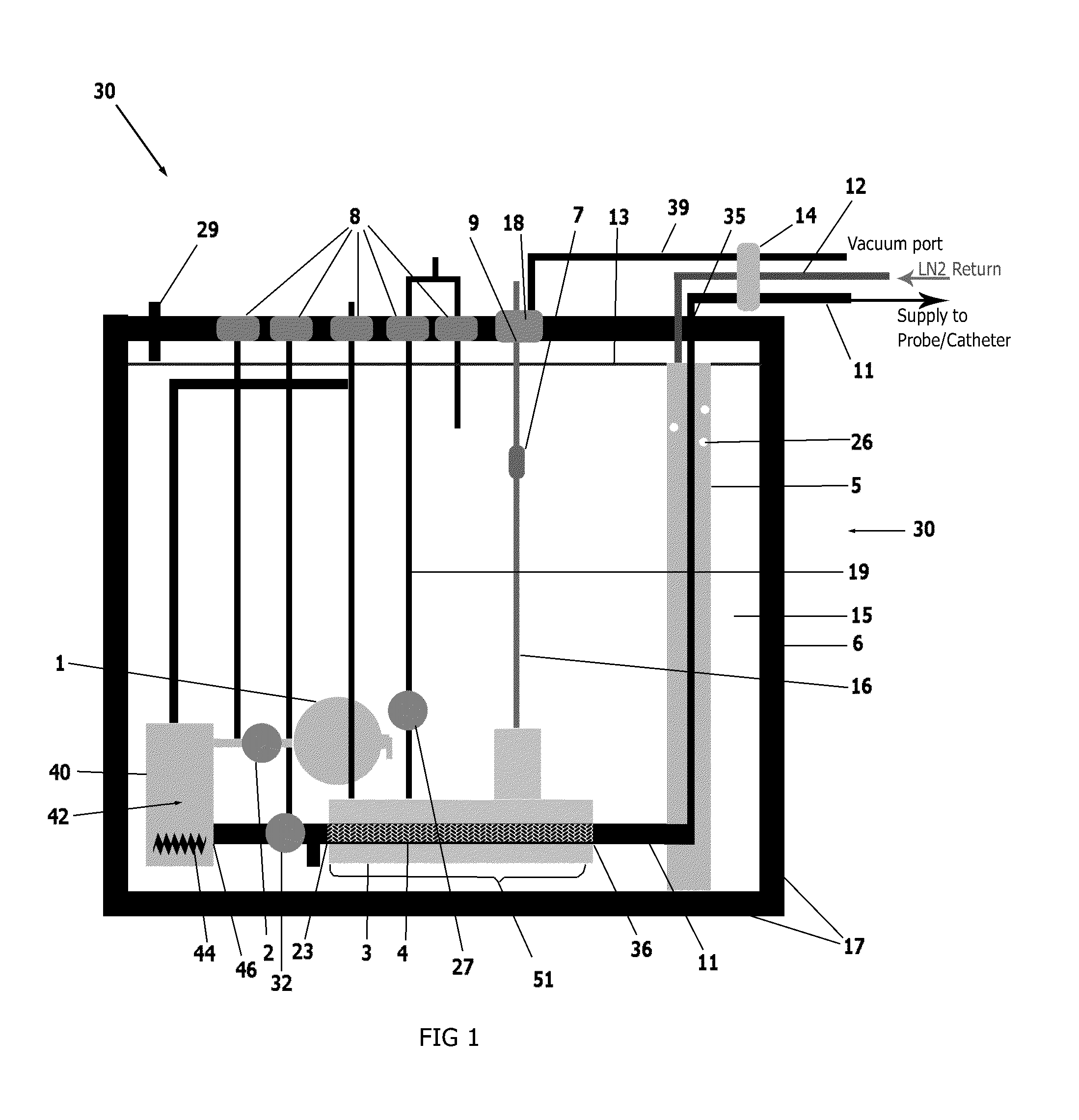

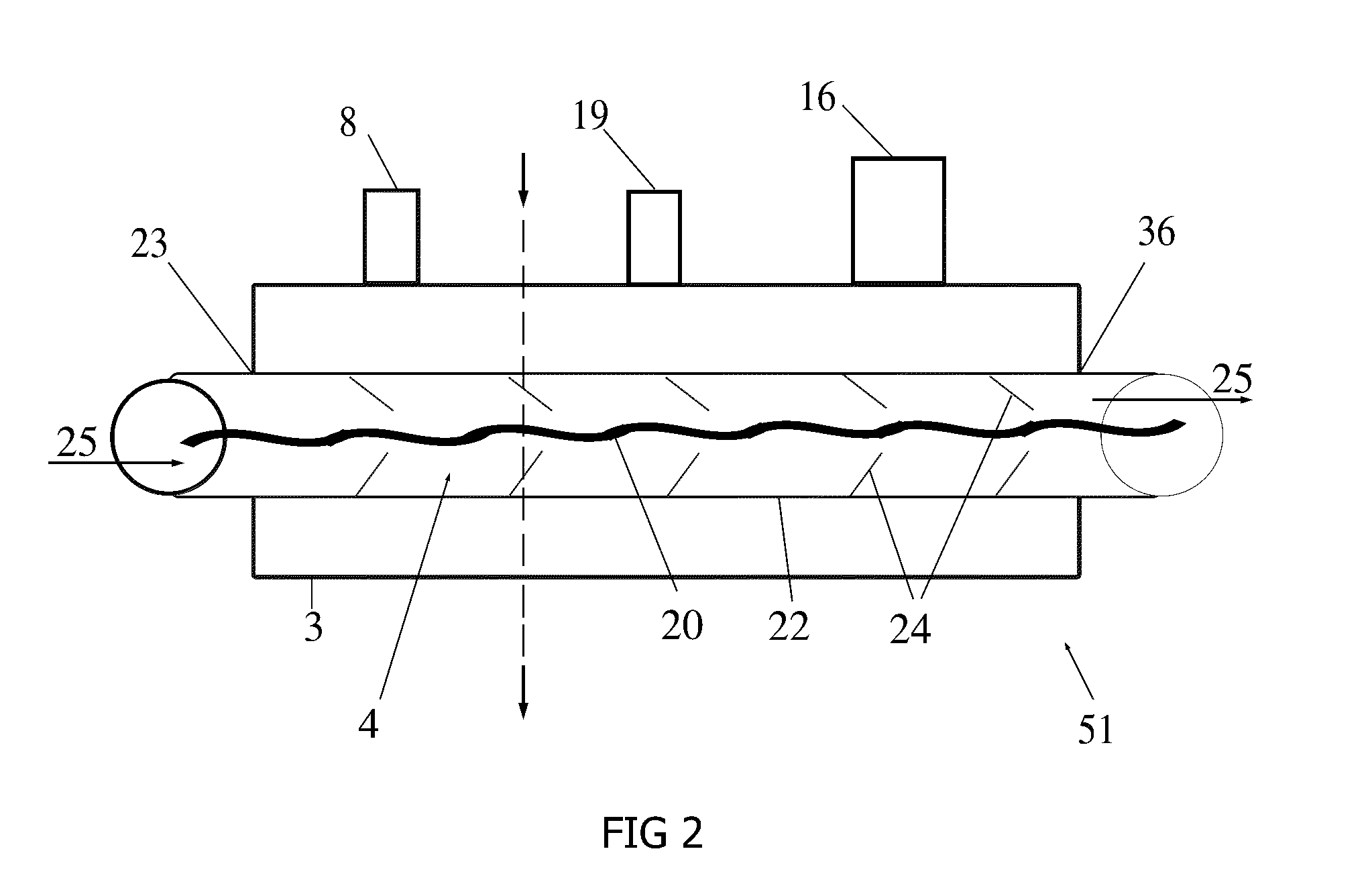

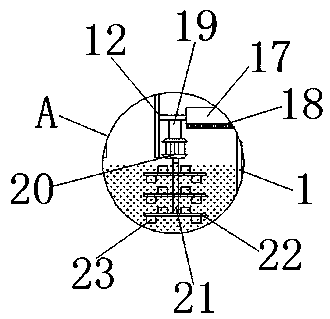

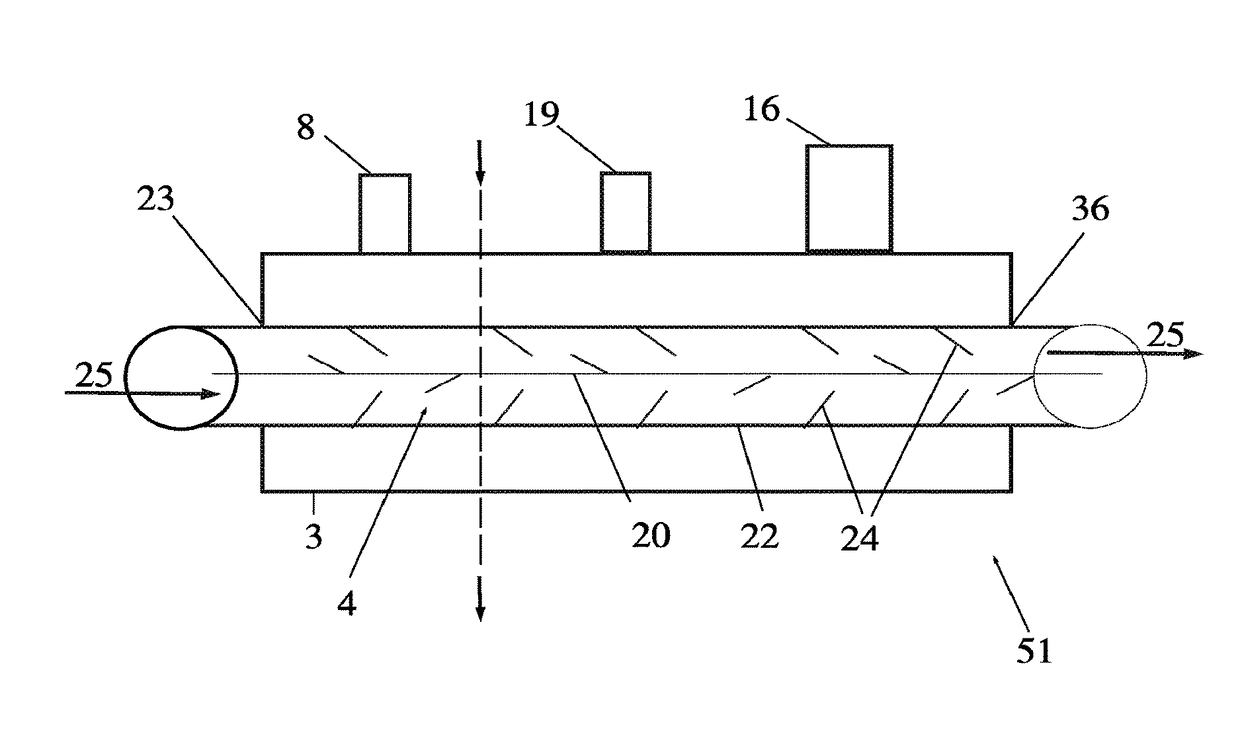

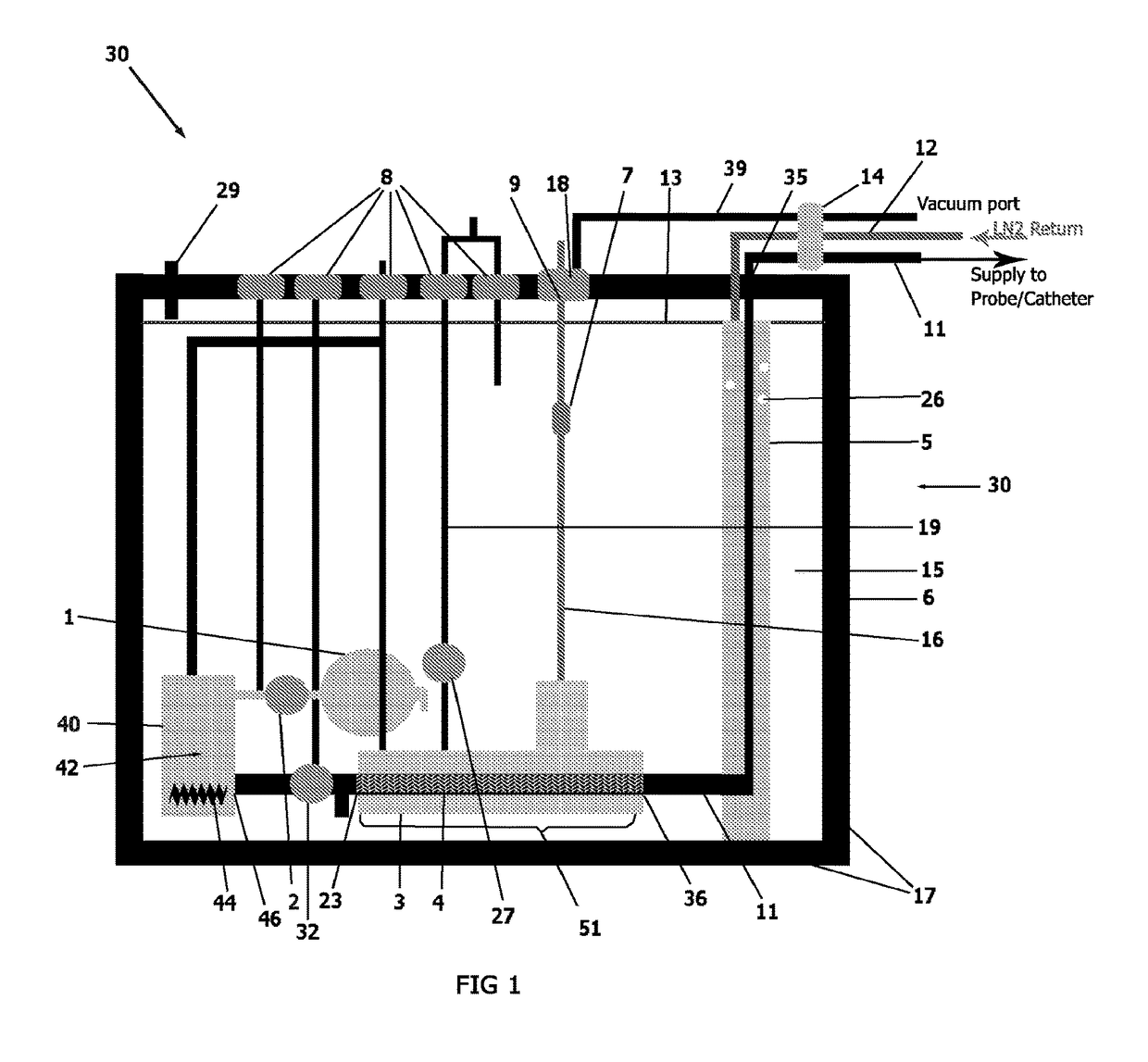

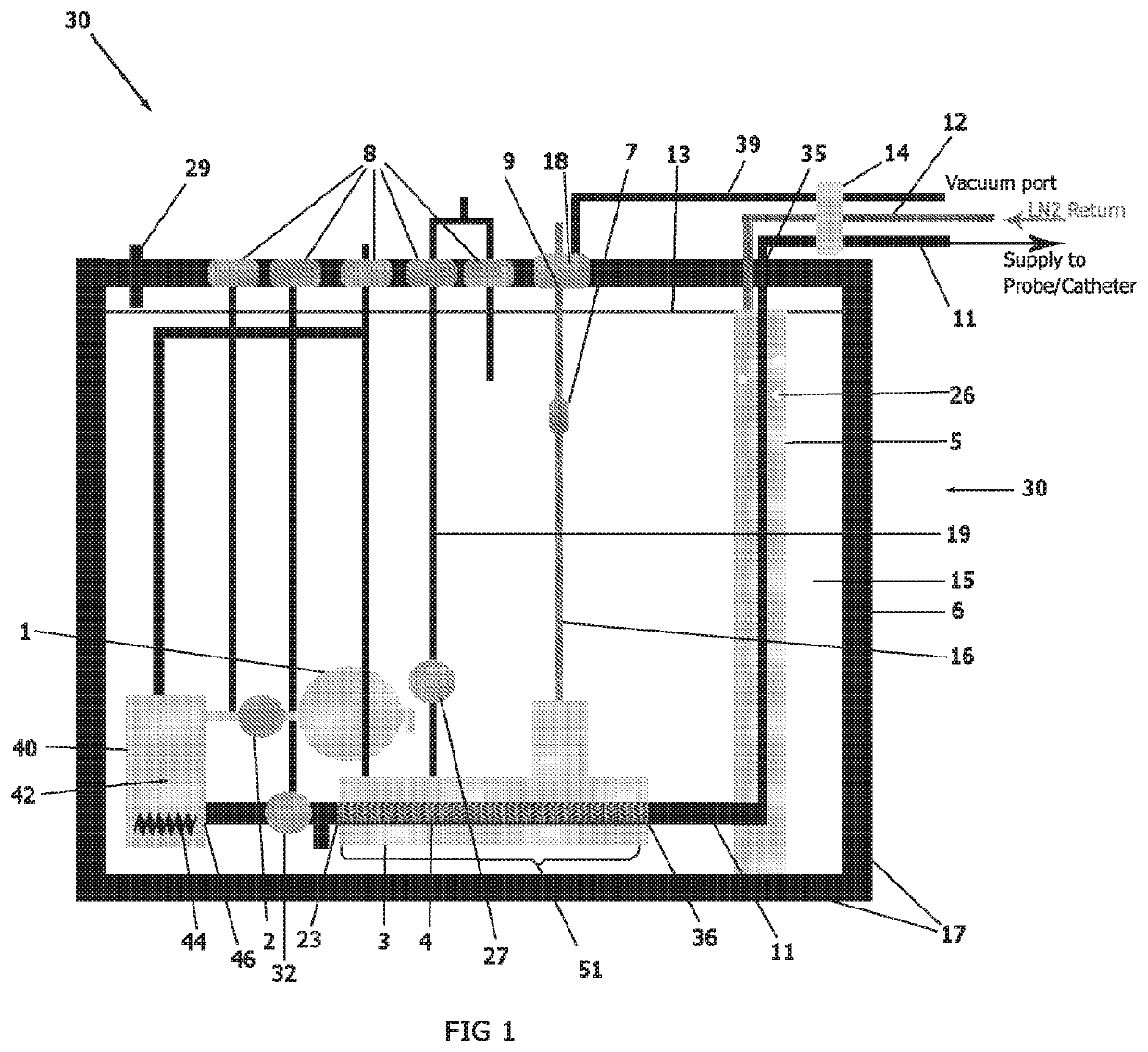

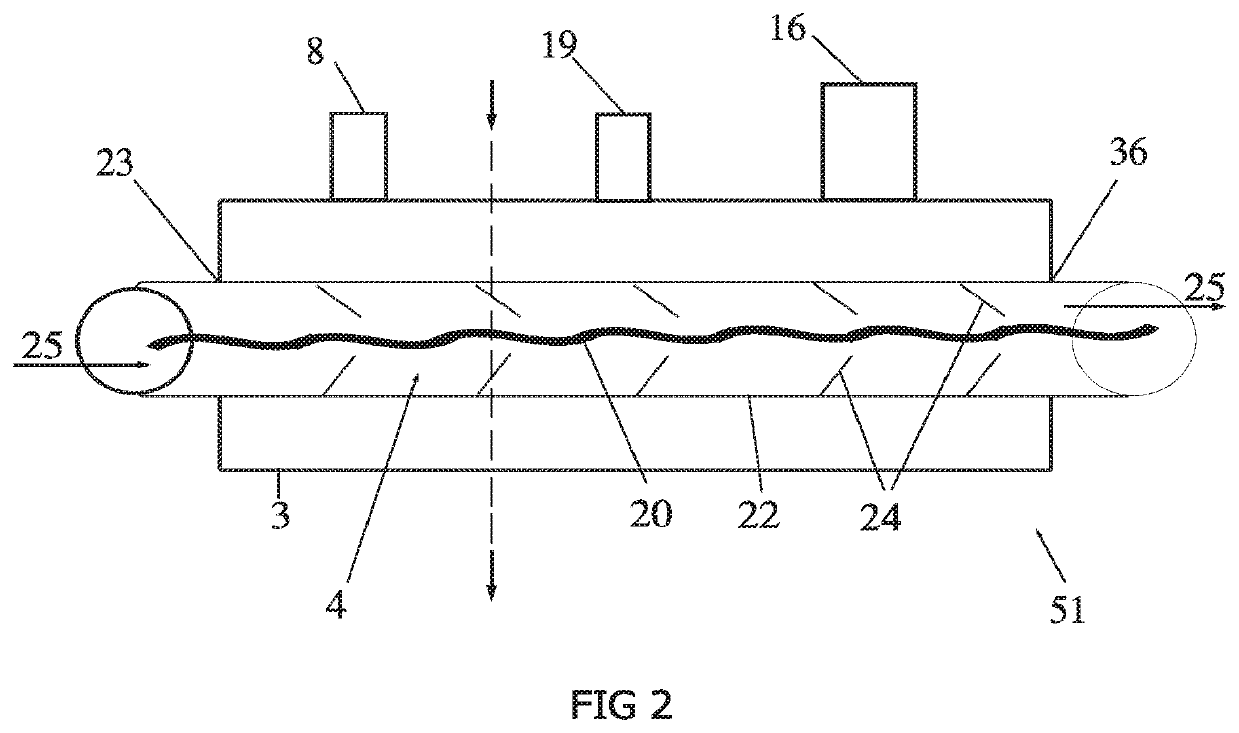

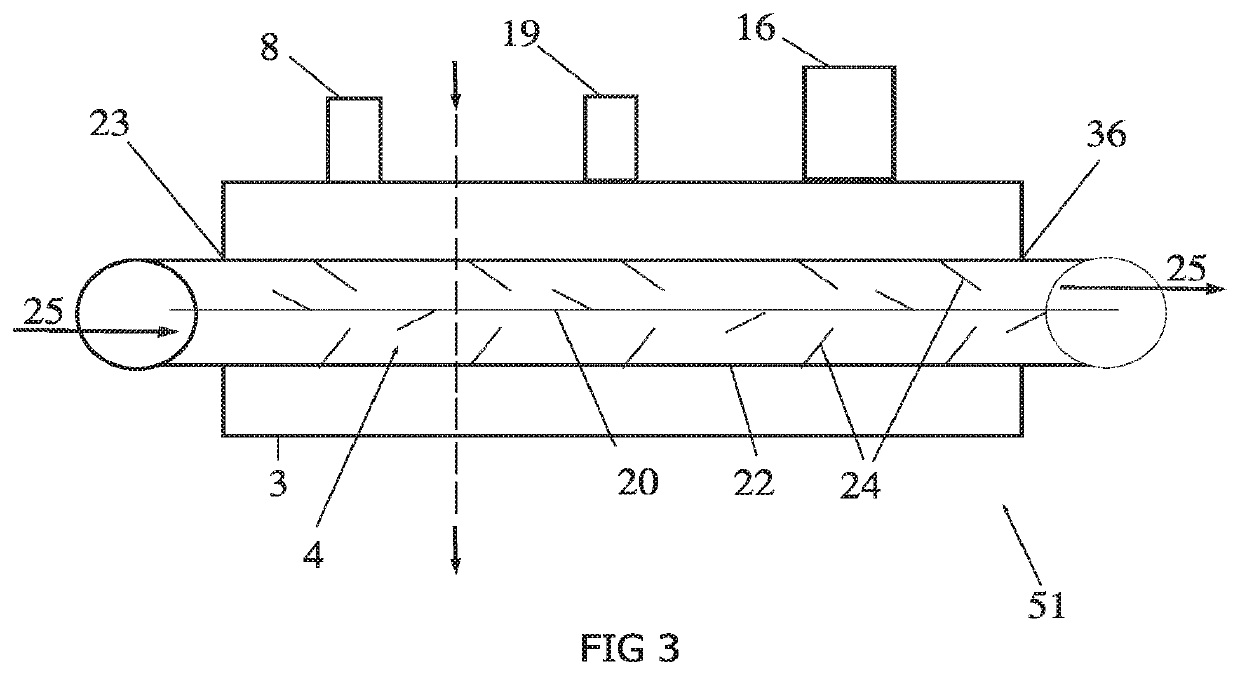

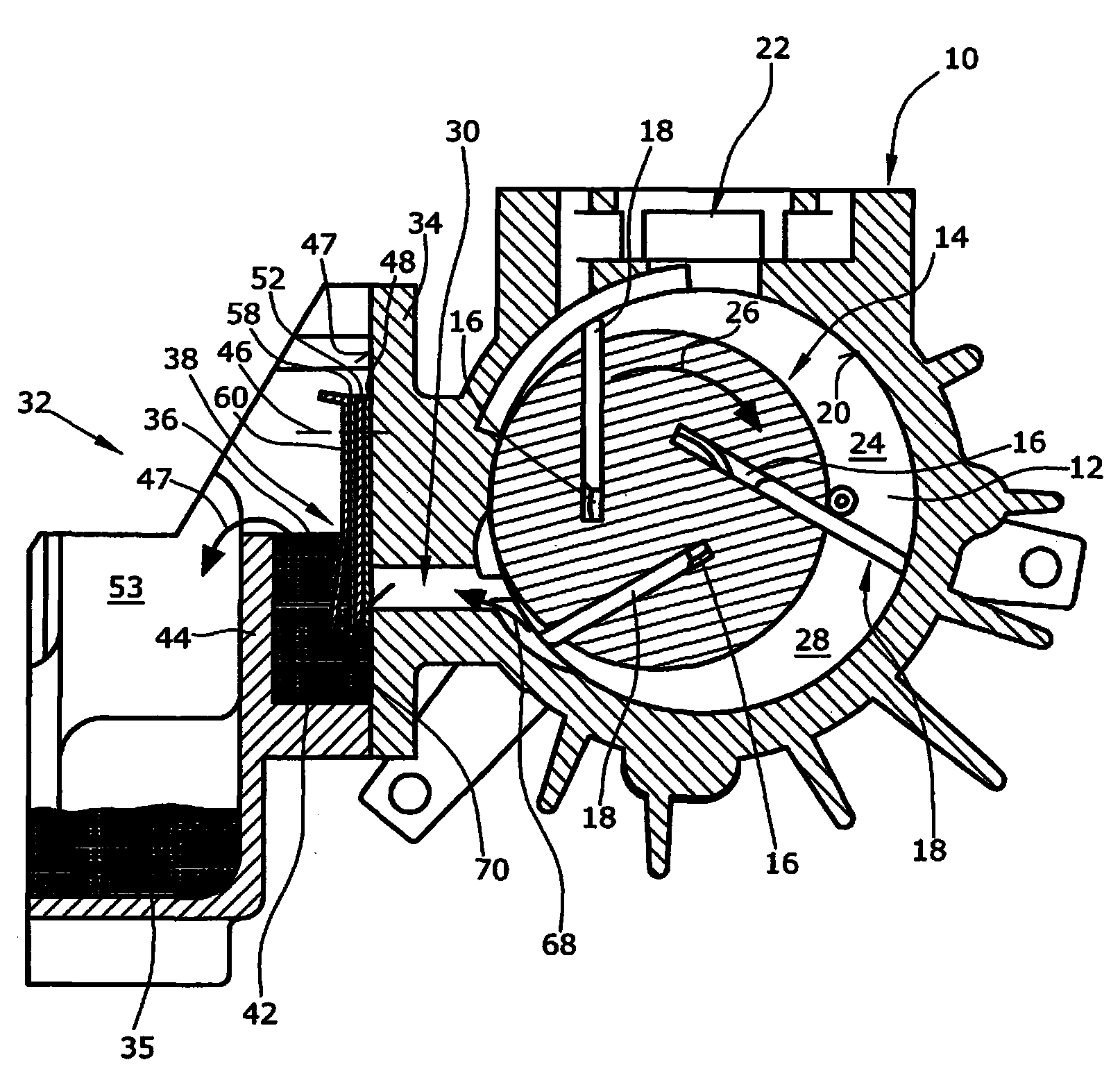

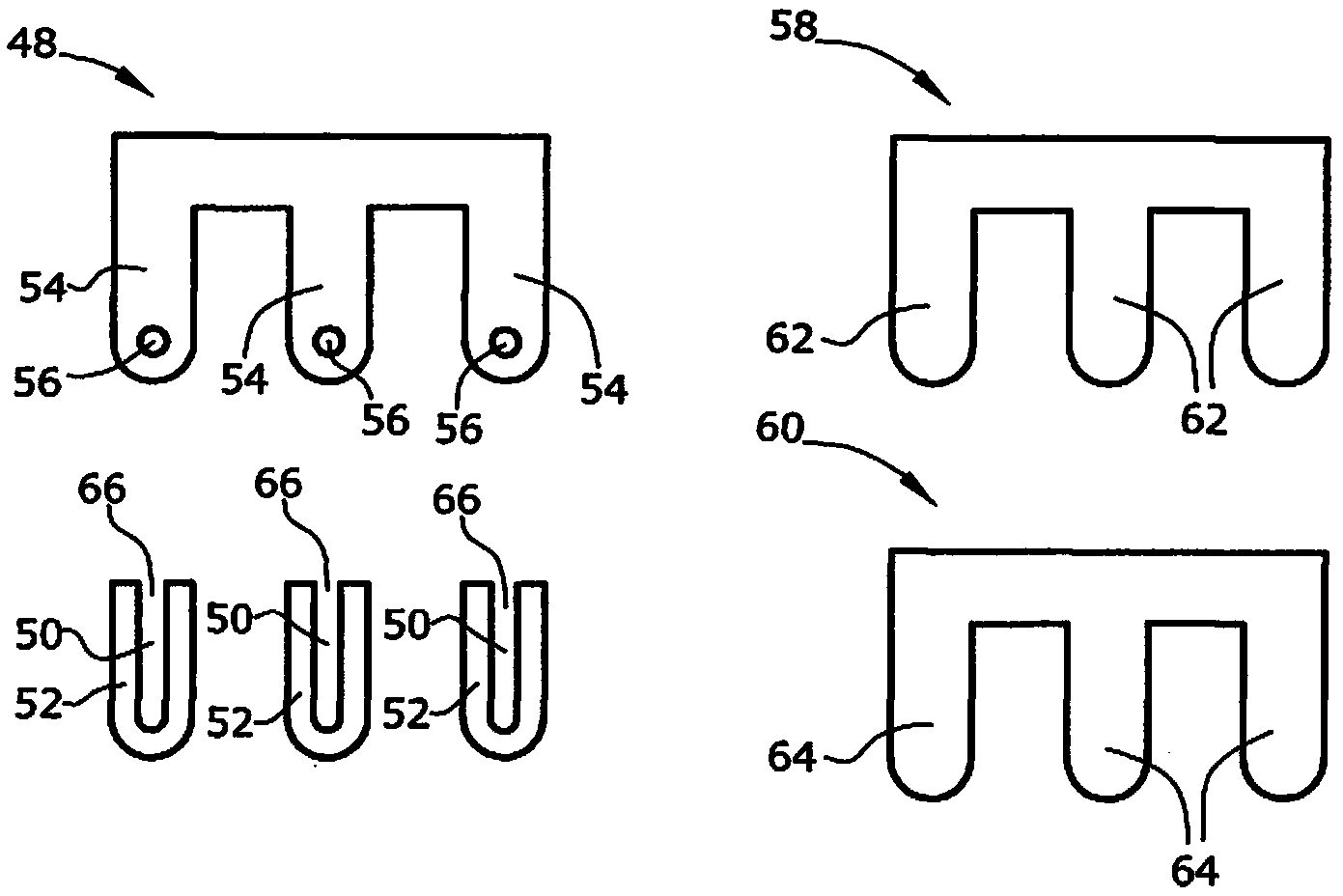

Cryogenic System and Method of Use

ActiveUS20110152849A1Enhance nucleation and depositionIncrease depositionCatheterNon-pressured vesselsMedicineLiquid state

A cryogenic medical device for delivery of subcooled liquid cryogen to various configurations of cryoprobes is designed for the treatment of damaged, diseased, cancerous or other unwanted tissues. The device is a closed or semi-closed system in which the liquid cryogen is contained in both the supply and return stages. The device is capable of generating cryogen to a supercritical state and may be utilized in any rapid cooling systems. As designed, the device comprises a number of parts including a vacuum insulated outer dewar, submersible cryogen pump, baffled linear heat exchanger, multiple pressurization cartridges, a return chamber, and a series of valves to control the flow of the liquid cryogen interconnected with cryotreatment devices including cryoprobes and catheters. The cryogenic medical device promotes subcooling to the tips of various external cryogenic instrument configurations.

Owner:VARIAN MEDICAL SYSTEMS

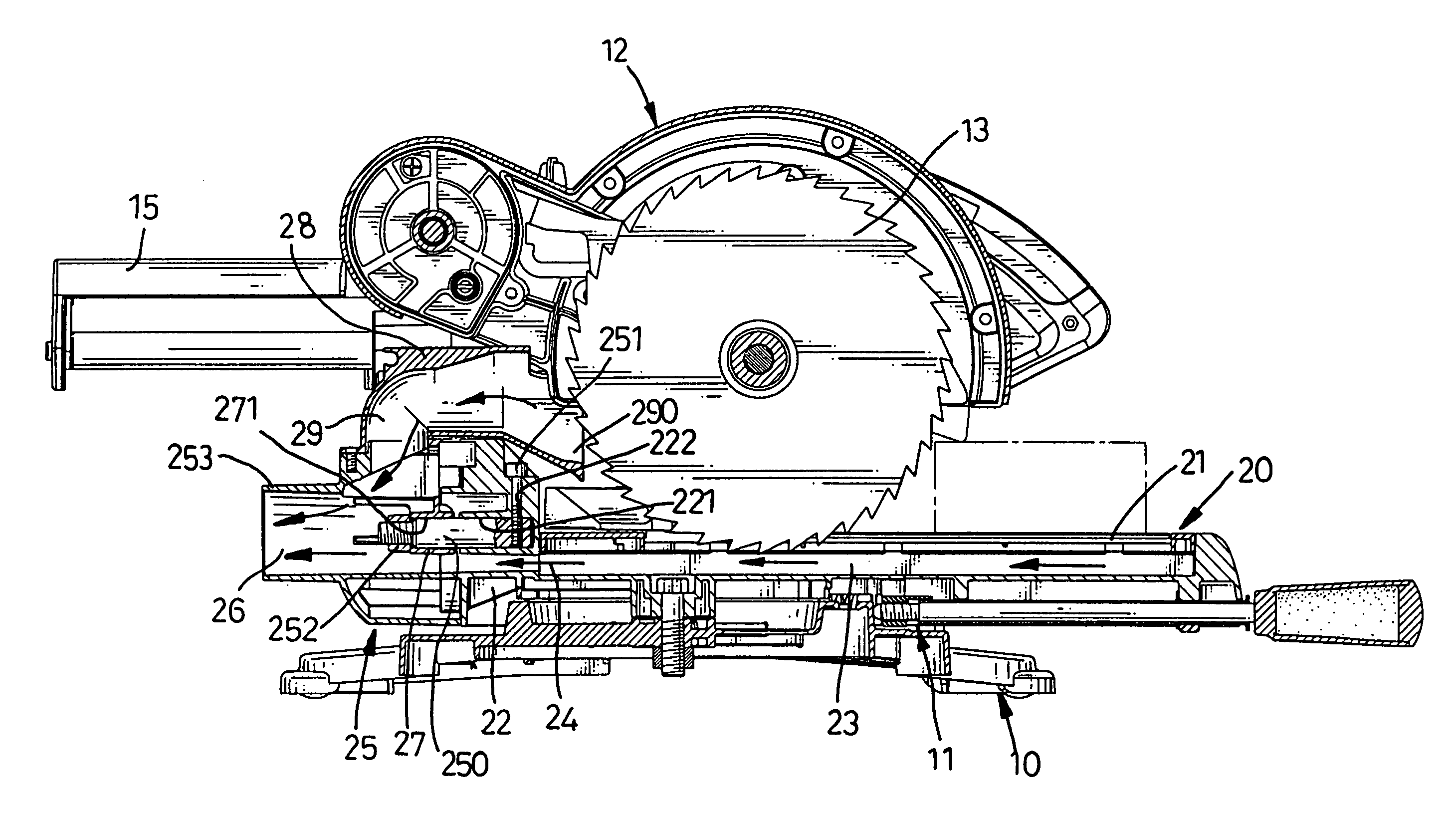

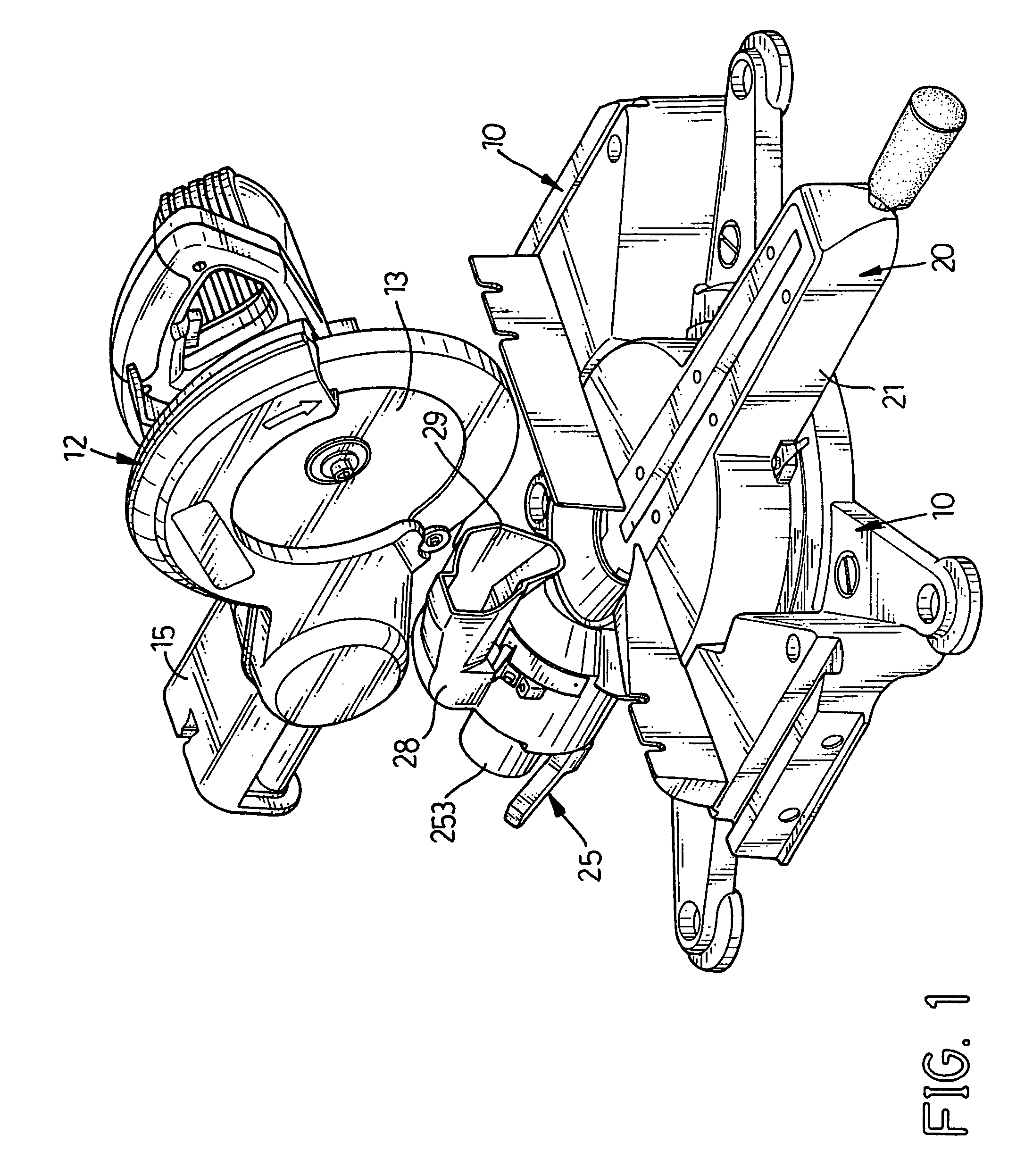

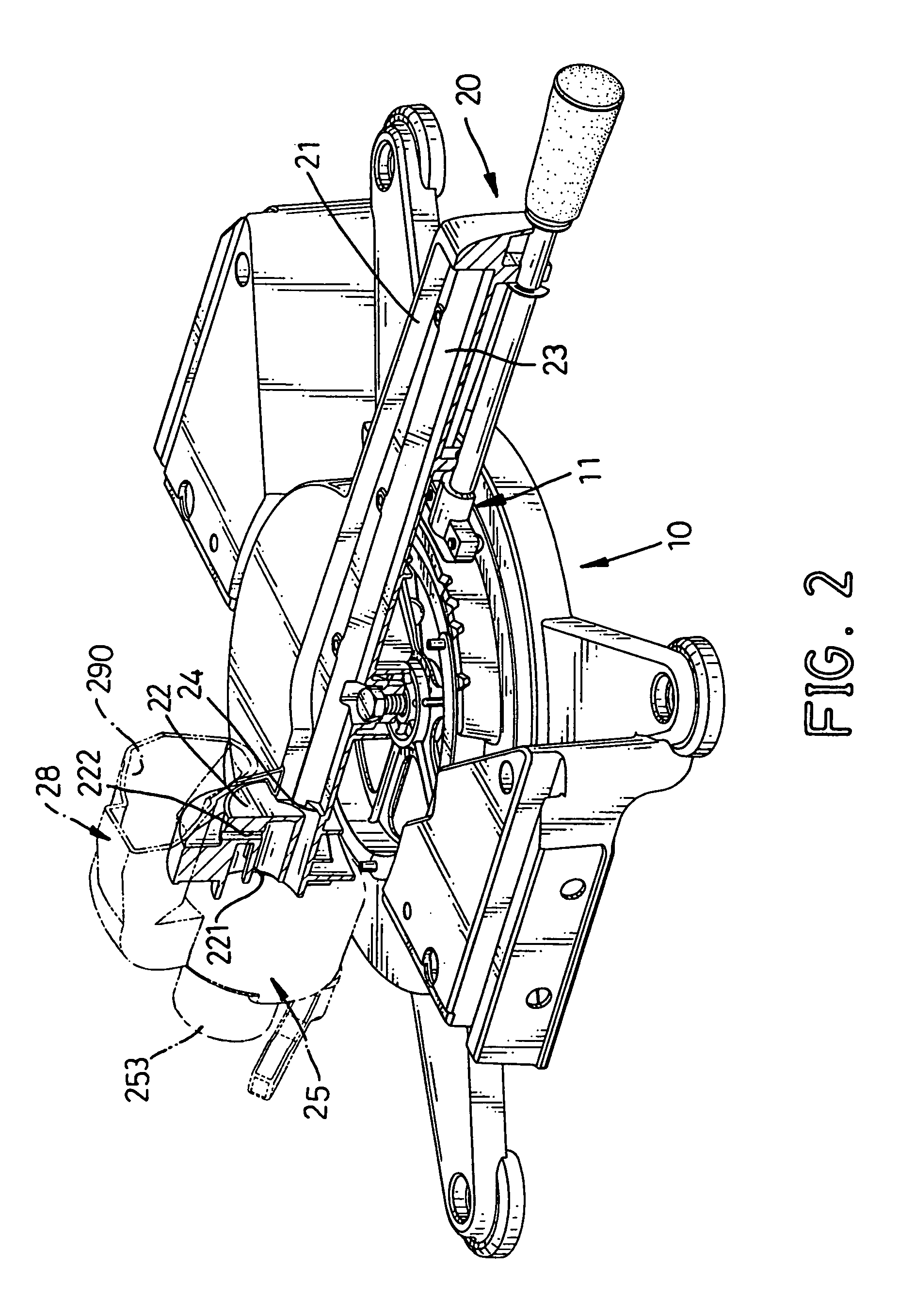

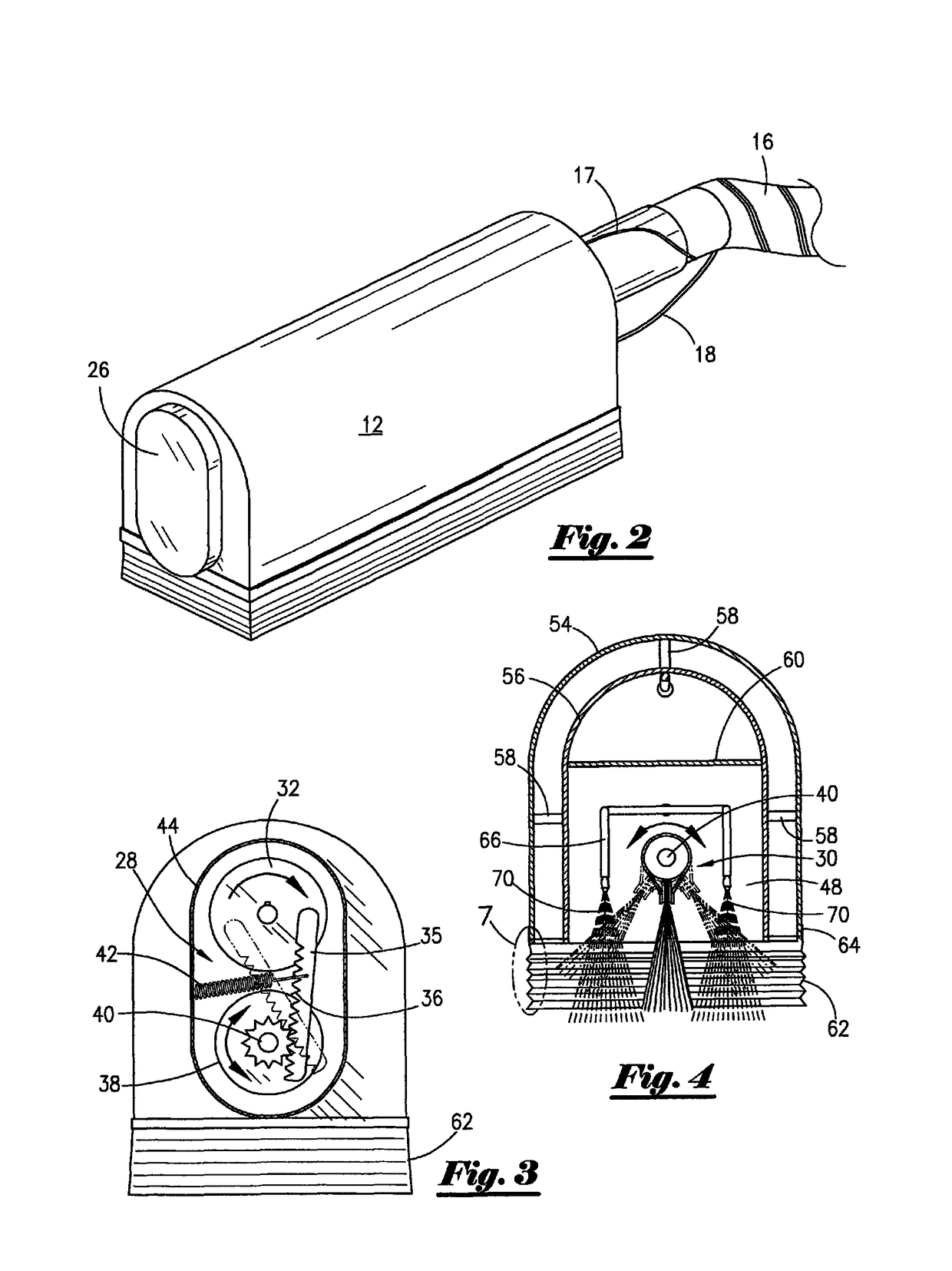

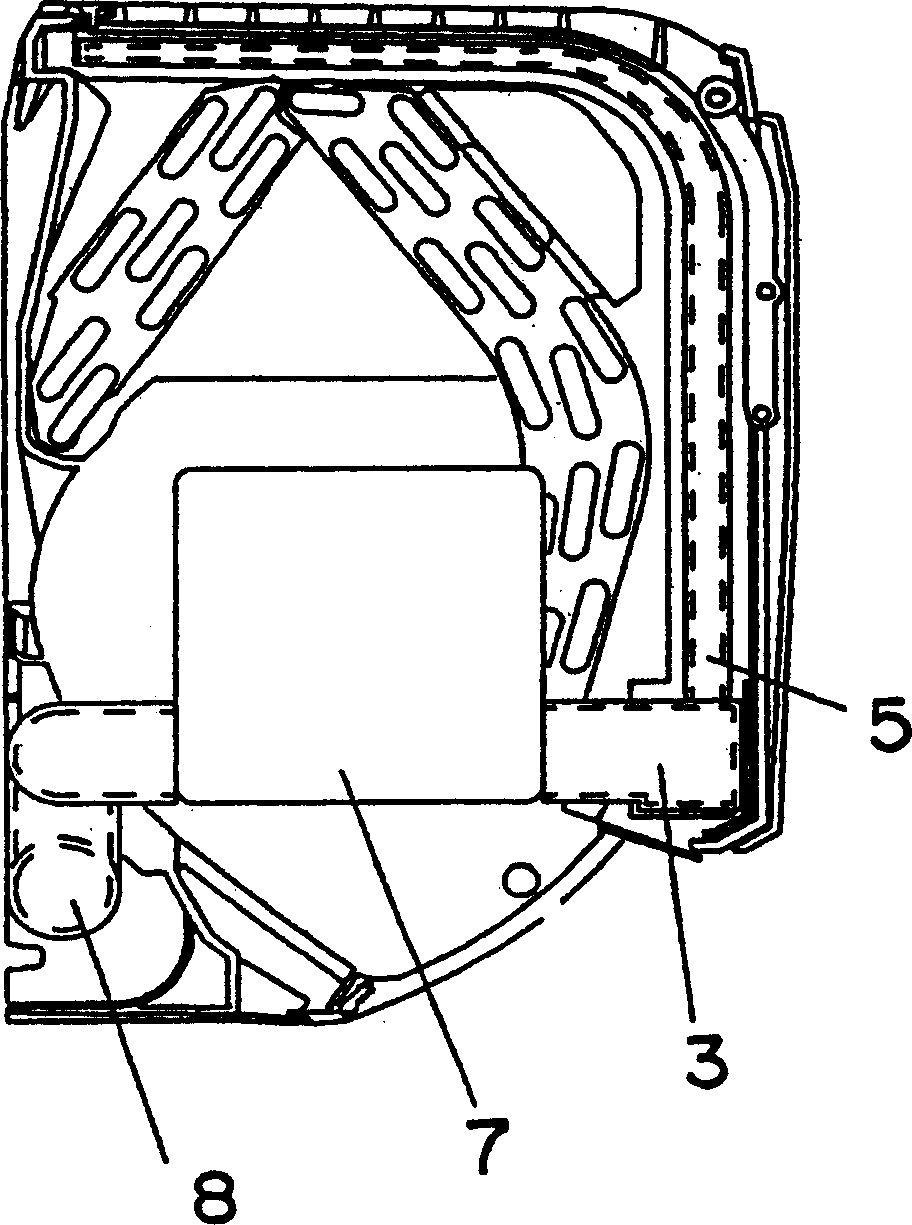

Sawdust collection assembly for a compound miter saw

InactiveUS6988435B2Efficient vacuumingMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

A sawdust collection apparatus for a compound miter saw includes a turntable and a sawdust collection assembly. The turntable is rotatably mounted on a base and has a cutting groove defined in the turntable and a sawdust guide communicating with the cutting groove. The sawdust collection assembly has a hollow sawdust duct with a sawdust channel communicating with the sawdust guide and a hollow sawdust entry duct with a sawdust entry port to receive sawdust and debris and a sawdust passage to communicate with the sawdust entry port. The sawdust channel is connected to a vacuum cleaner to efficiently pull sawdust and debris out of the miter saw through the sawdust channel and the sawdust passage.

Owner:P & F BROTHER INDAL

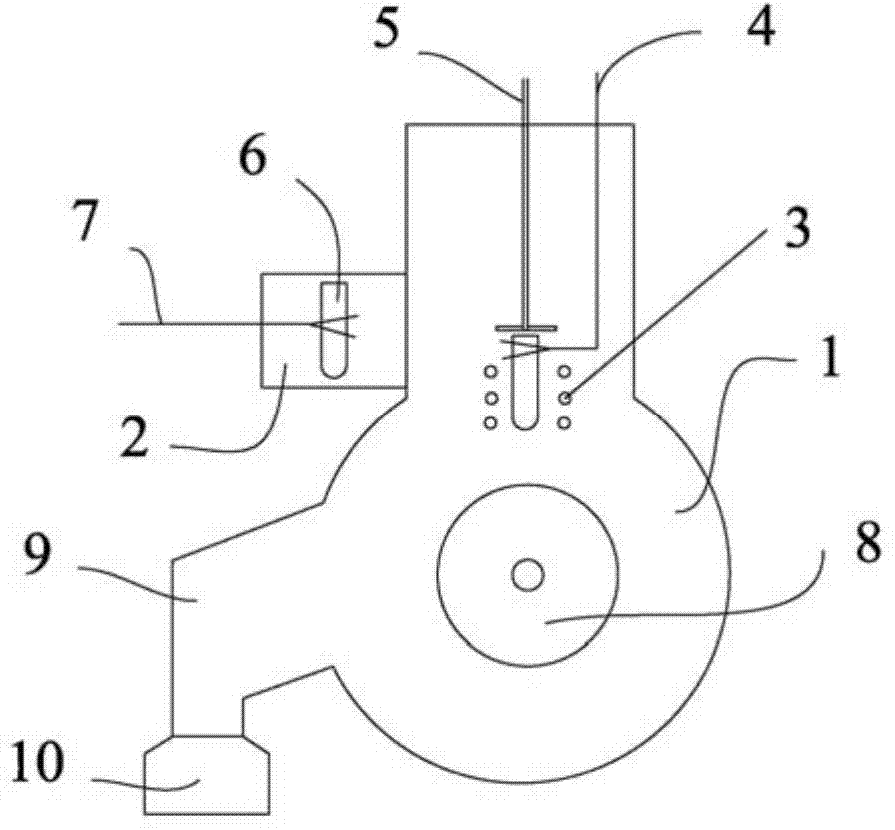

Device

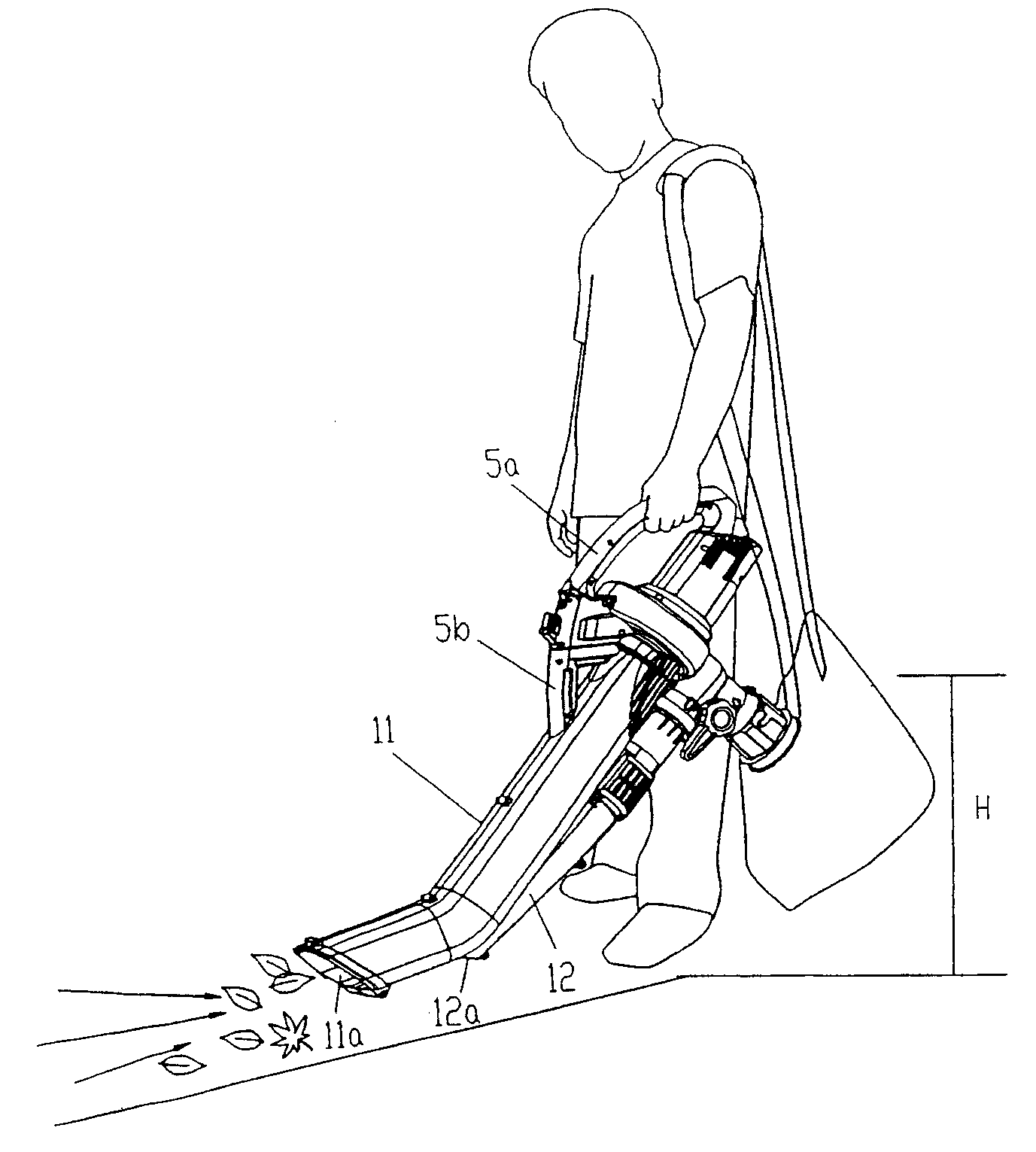

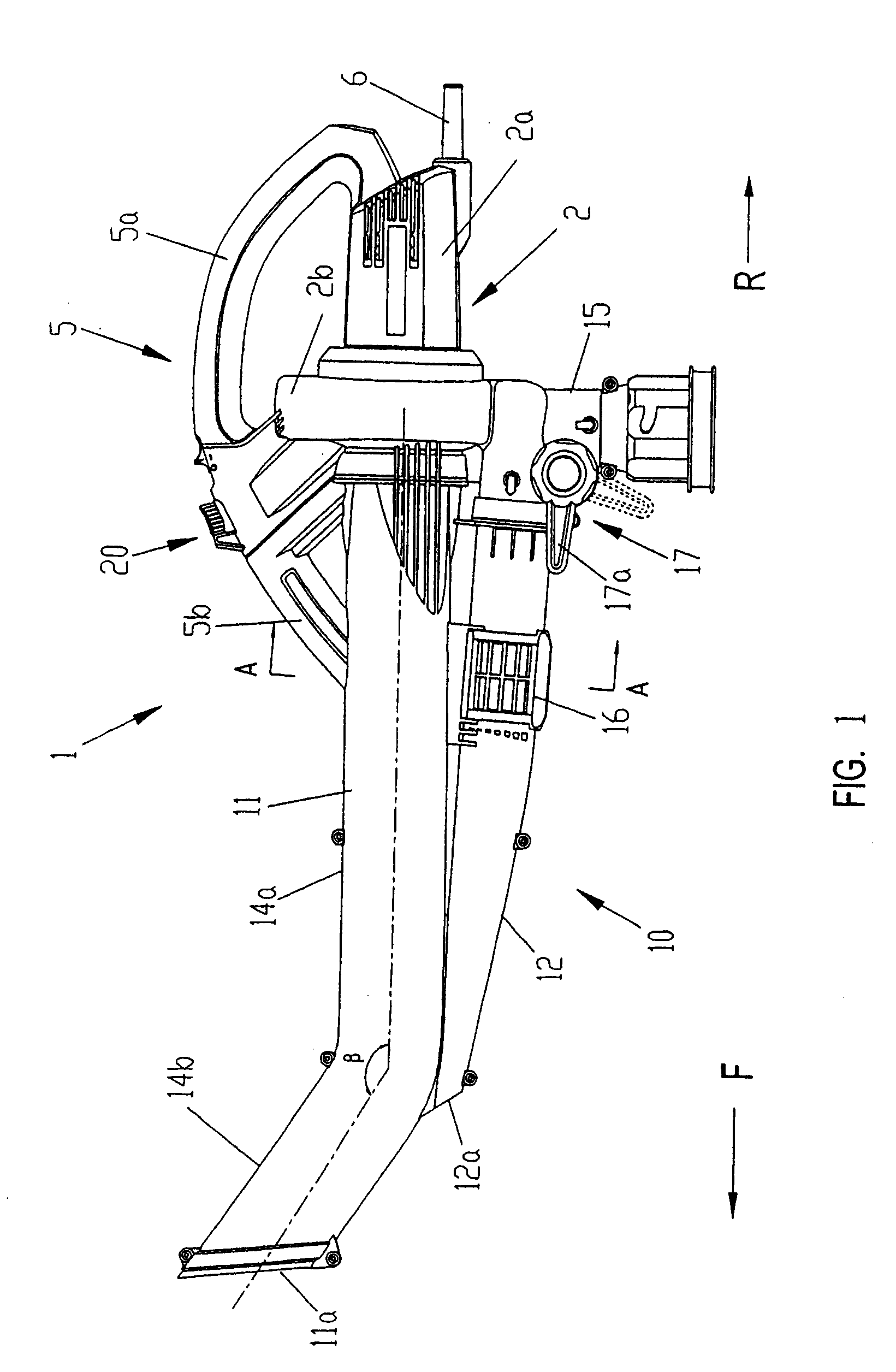

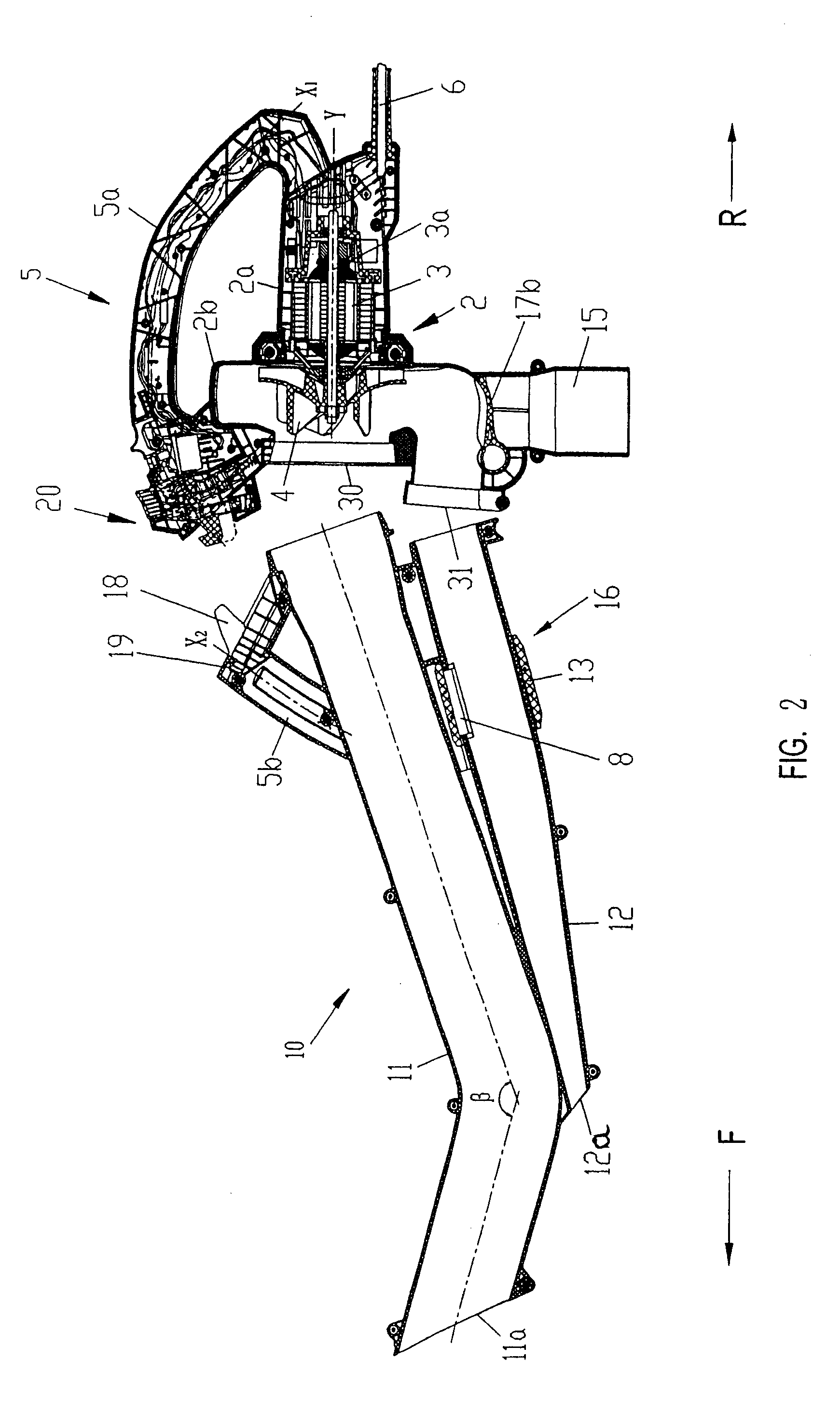

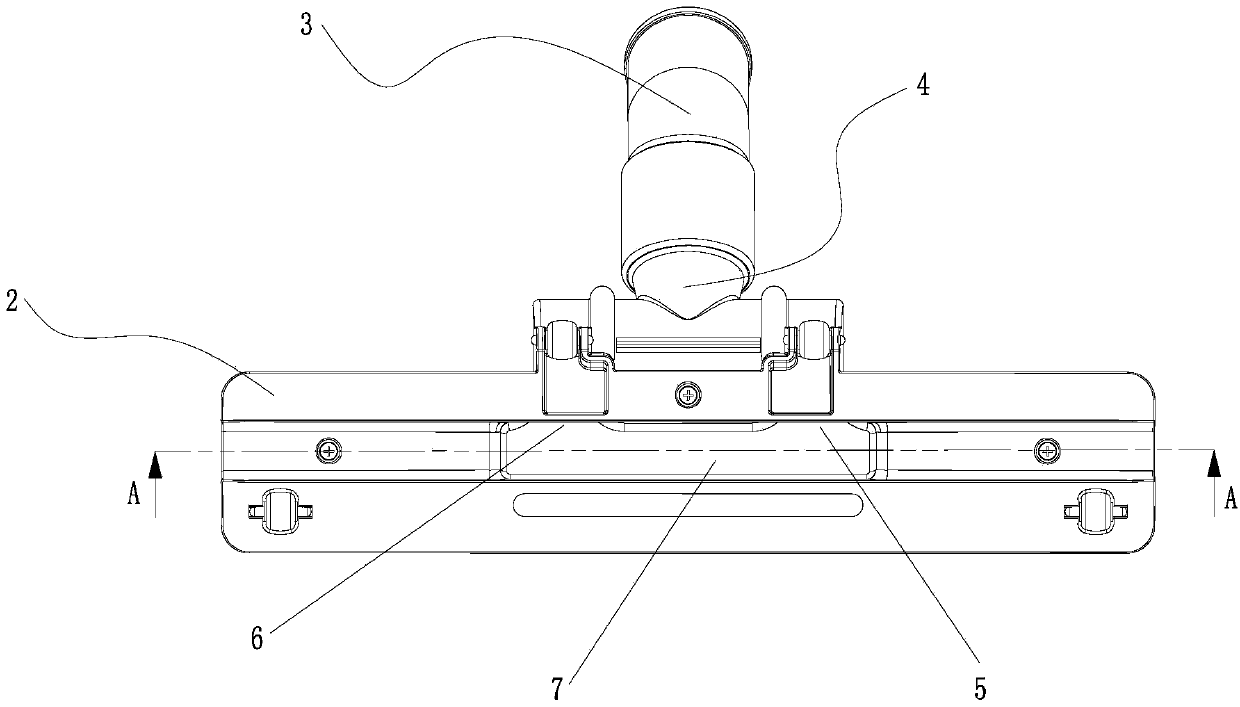

ActiveUS20080307602A1Length minimizationEfficient vacuumingBowling gamesCarpet cleanersEngineeringNozzle

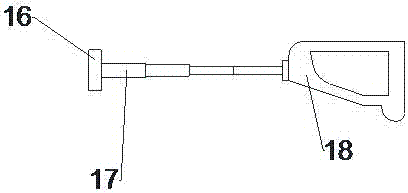

The present invention relates to a portable blower-vacuum device which comprises a motor (3) operated by a switch (7) and located in a main body (2) and a fan (4) drivable by the motor. A vacuum nozzle (11) and a blower nozzle (12) are associated with the main body and the vacuum nozzle comprises a main portion (14a) extending in a direction of an axis (Z1) of the main portion and a terminal portion (14b) with an axis (Z2) angularly disposed with respect to the axis (Z1) of the main portion.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Cryogenic system and method of use

ActiveUS8784409B2Enhance nucleation and depositionIncrease depositionCatheterNon-pressured vesselsProcess engineeringMedical device

A cryogenic medical device for delivery of subcooled liquid cryogen to various configurations of cryoprobes is designed for the treatment of damaged, diseased, cancerous or other unwanted tissues. The device is a closed or semi-closed system in which the liquid cryogen is contained in both the supply and return stages. The device is capable of generating cryogen to a supercritical state and may be utilized in any rapid cooling systems. As designed, the device comprises a number of parts including a vacuum insulated outer dewar, submersible cryogen pump, baffled linear heat exchanger, multiple pressurization cartridges, a return chamber, and a series of valves to control the flow of the liquid cryogen interconnected with cryotreatment devices including cryoprobes and catheters. The cryogenic medical device promotes subcooling to the tips of various external cryogenic instrument configurations.

Owner:VARIAN MEDICAL SYSTEMS

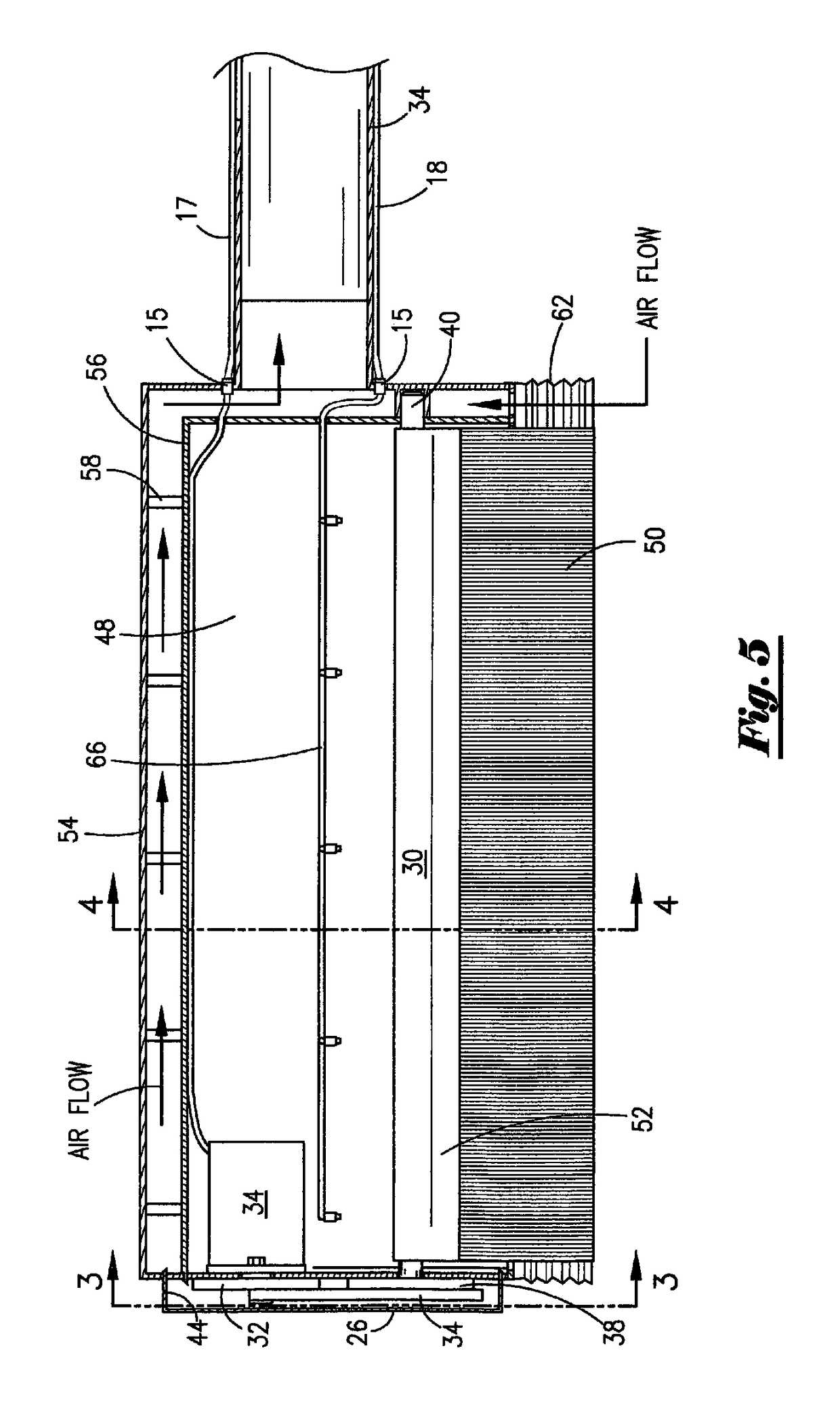

Method and apparatus for cleaning air conditioner evaporator coils

InactiveUS8468648B1Improve abilitiesStrong vacuumLighting and heating apparatusSuction nozzlesEvaporatorEngineering

An air conditioning coil cleaning system including a portable vacuum blower equipped with a plurality of fluid supply reservoirs and a fluid pump, a suction hose with an electric power cord and fluid supply lines attached to a remote hand held brush head containing an elongated oscillating wiper brush. Fluids may be selectively sprayed onto coils being cleaned while vacuuming to reduce airborne debris and debris accumulation in the coil catch pan.

Owner:SMITH RICKY D +1

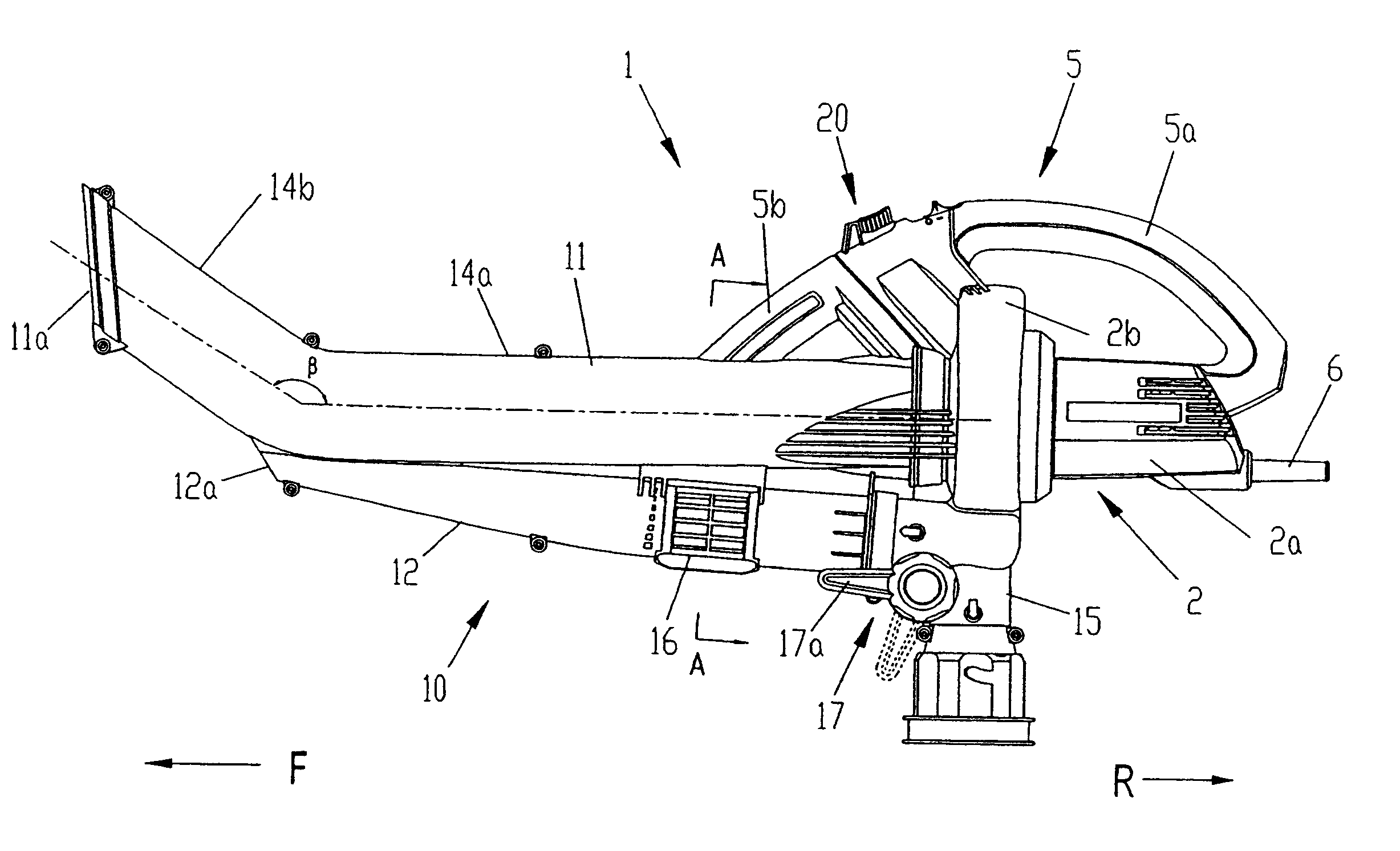

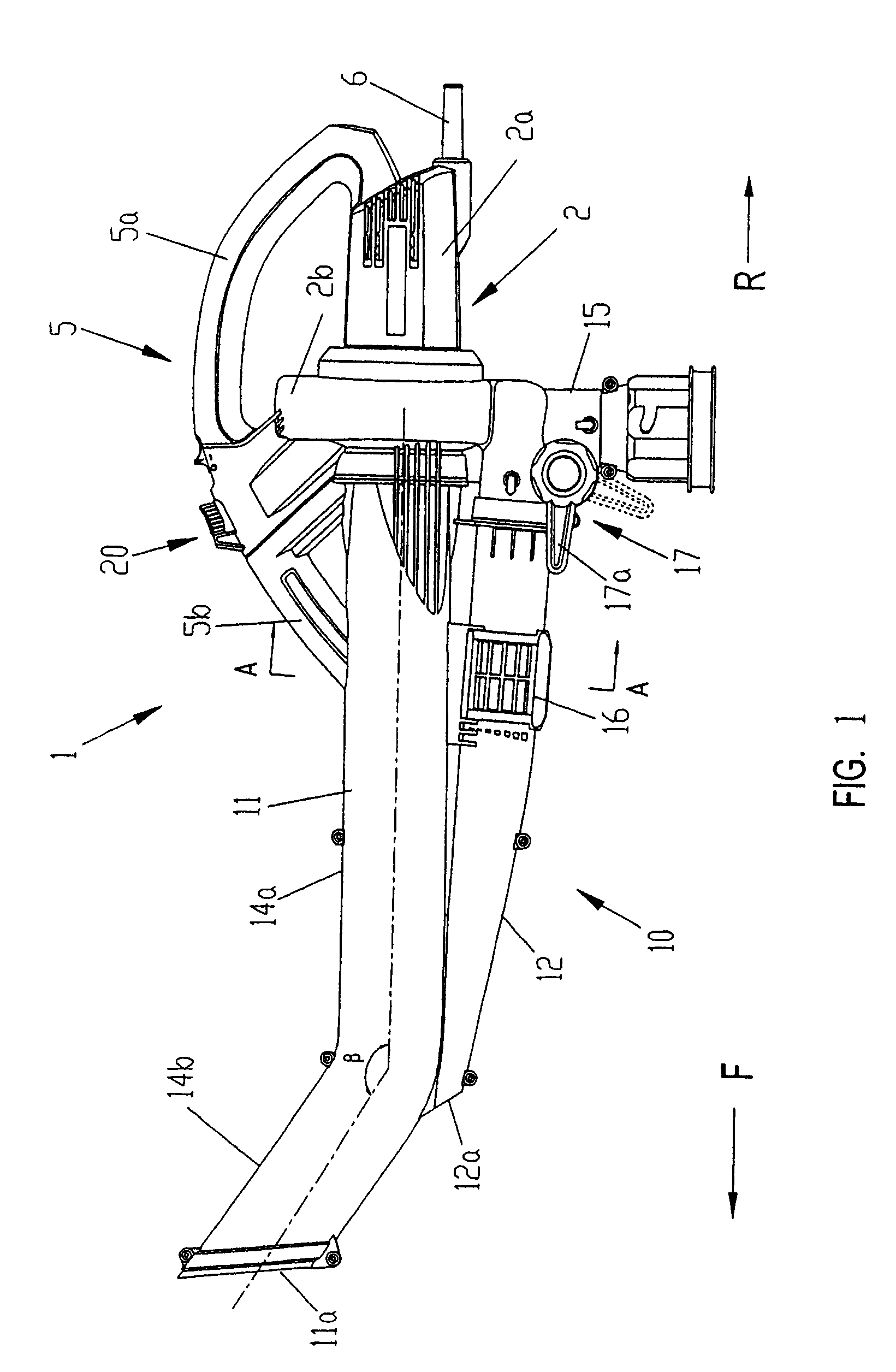

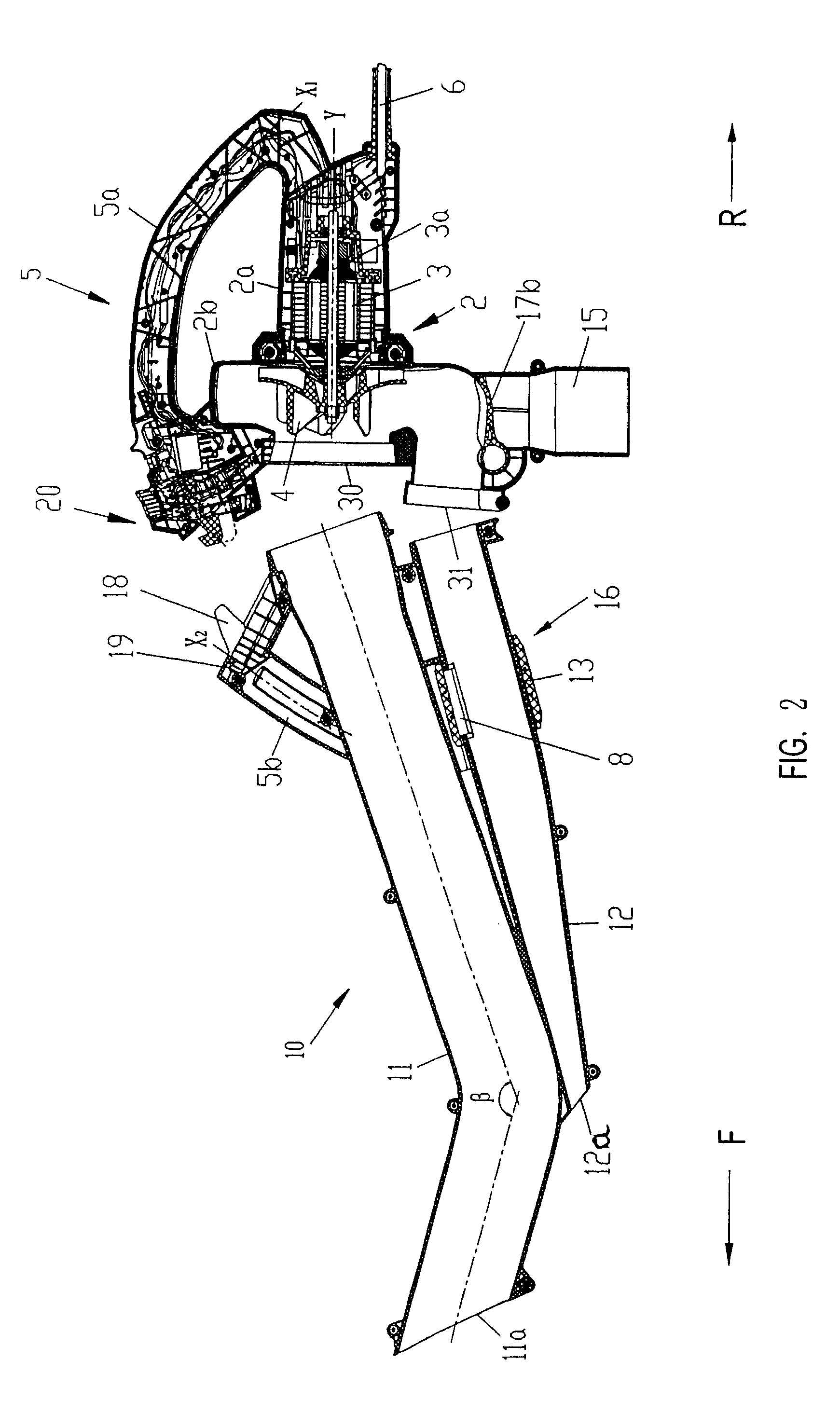

Blower-vacuum device

ActiveUS7748078B2Length minimizationEfficient vacuumingHops/wine cultivationSuction cleanersEngineeringNozzle

The present invention relates to a portable blower-vacuum device which comprises a motor (3) operated by a switch (7) and located in a main body (2) and a fan (4) drivable by the motor. A vacuum nozzle (11) and a blower nozzle (12) are associated with the main body and the vacuum nozzle comprises a main portion (14a) extending in a direction of an axis (Z1) of the main portion and a terminal portion (14b) with an axis (Z2) angularly disposed with respect to the axis (Z1) of the main portion.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

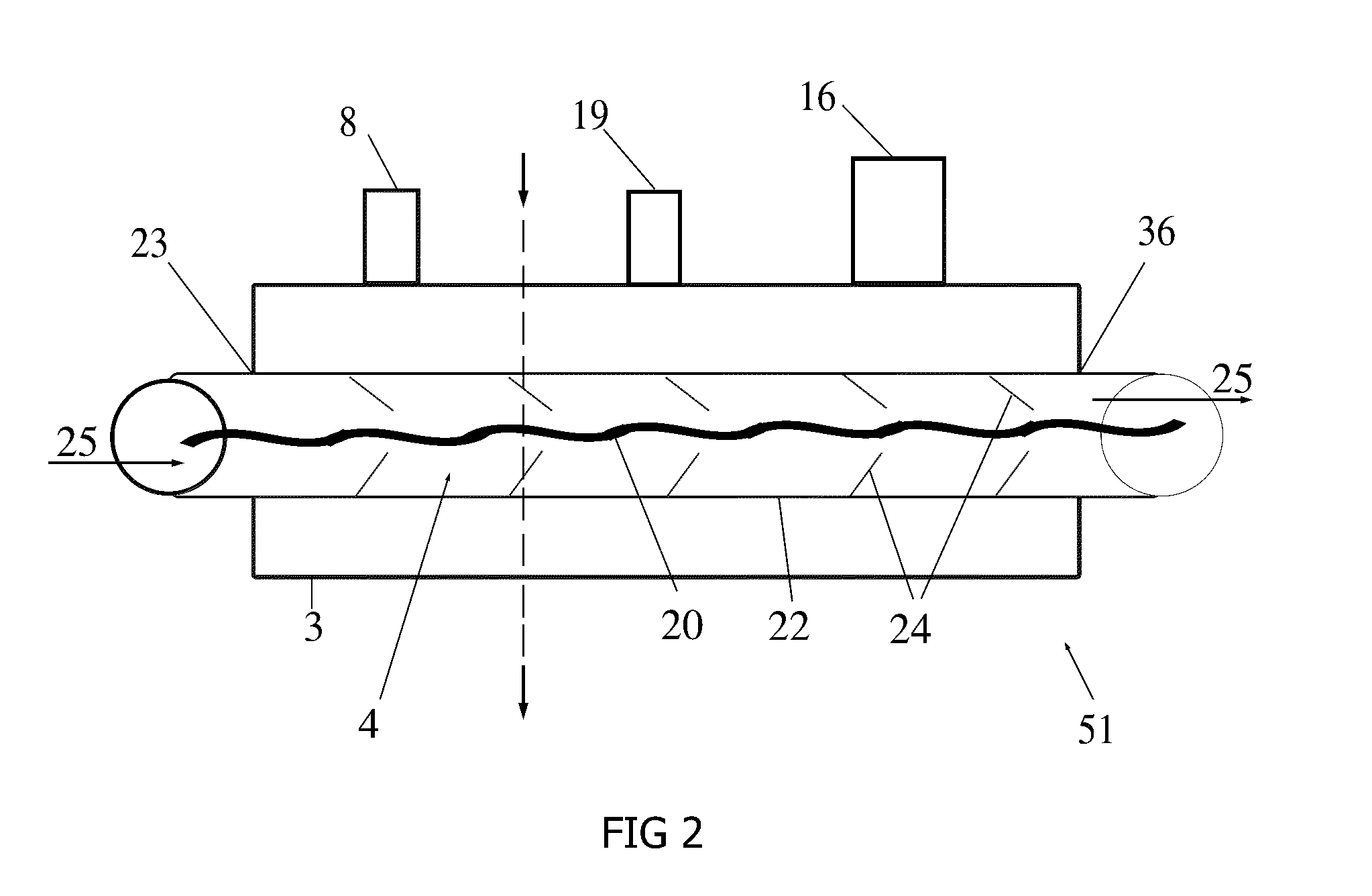

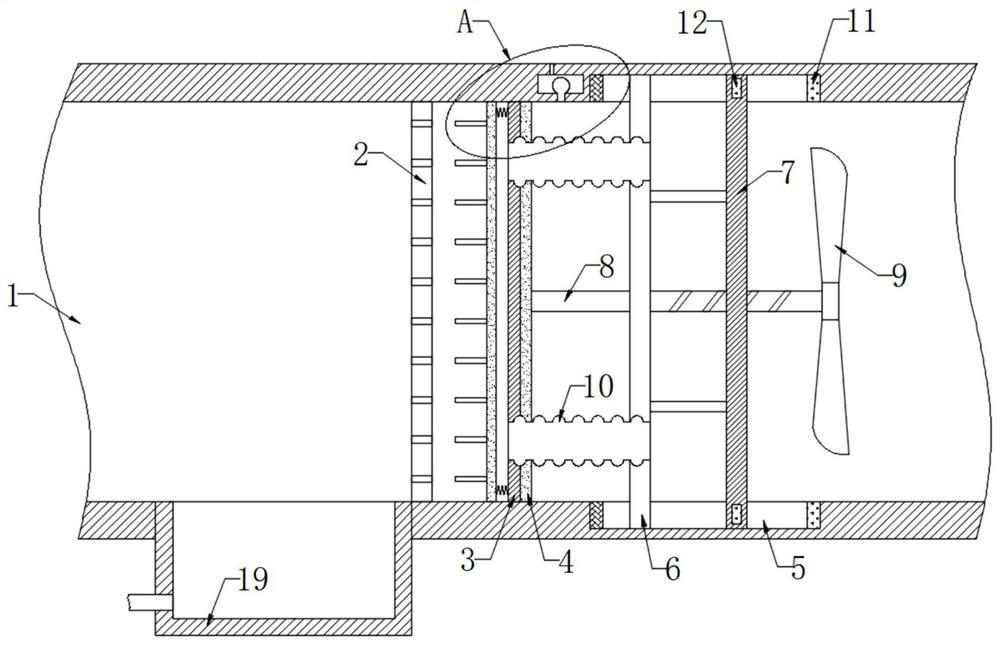

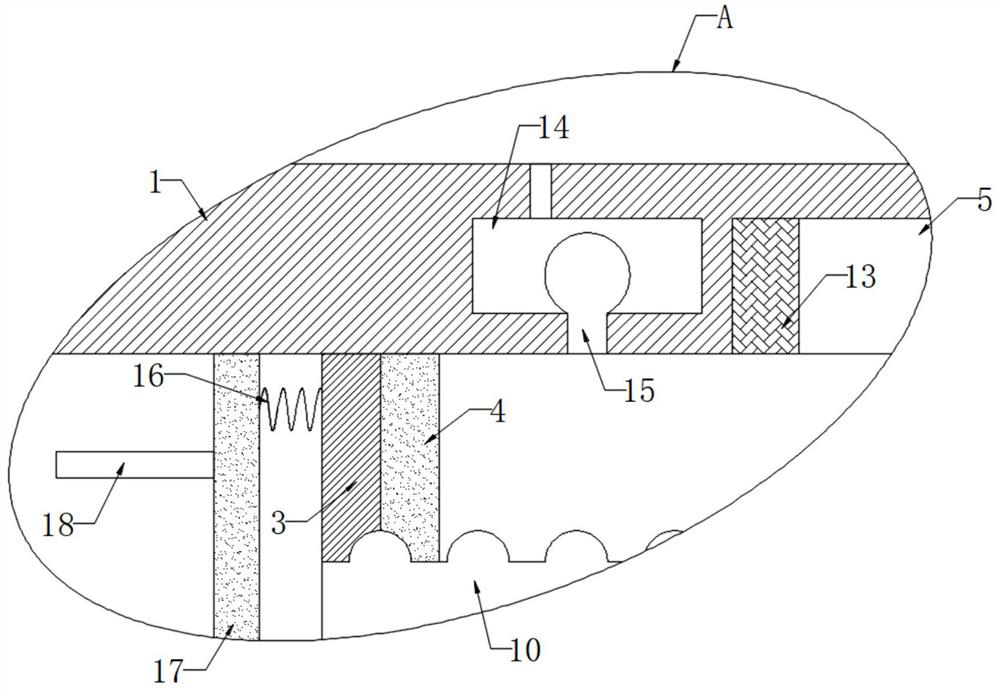

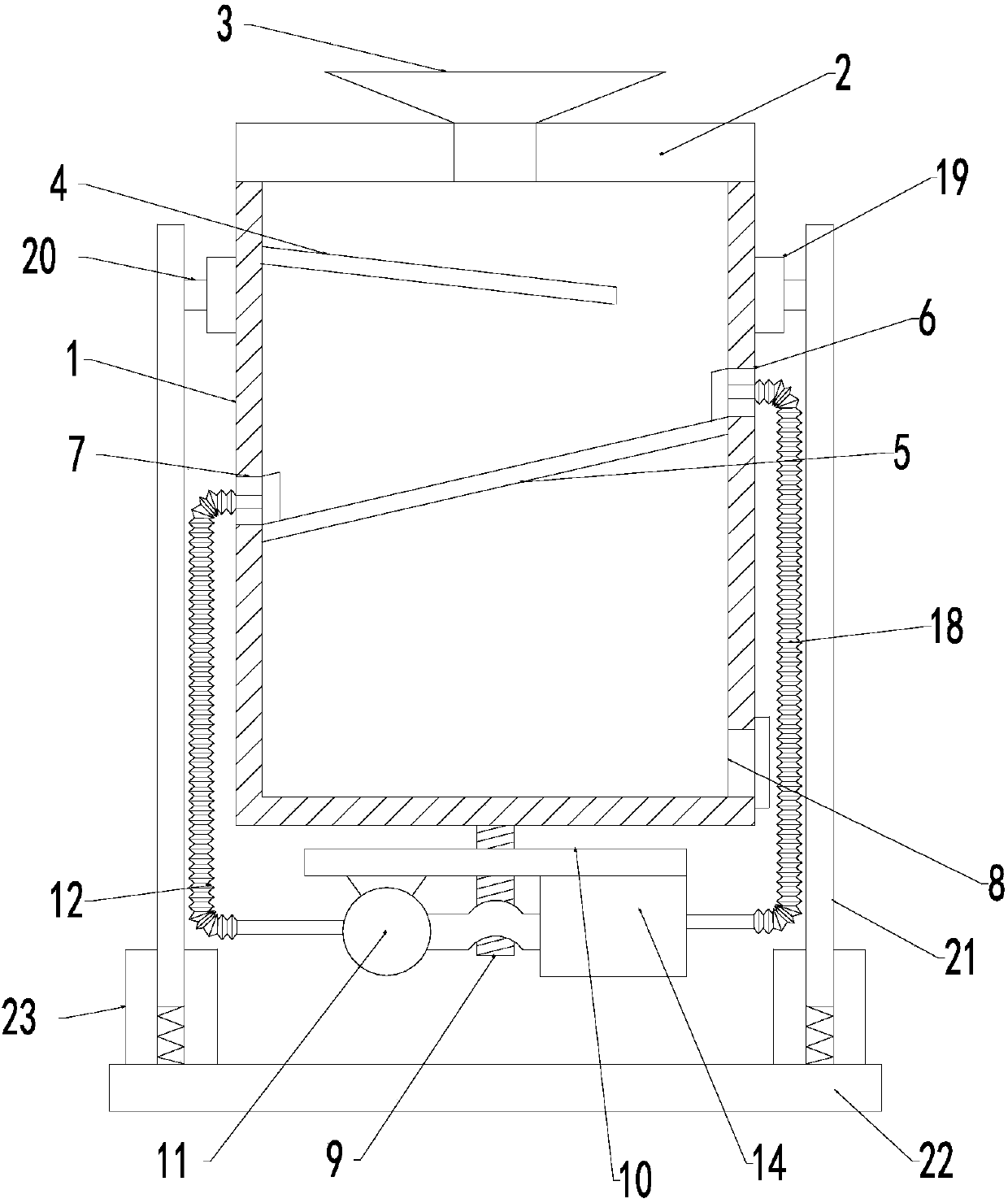

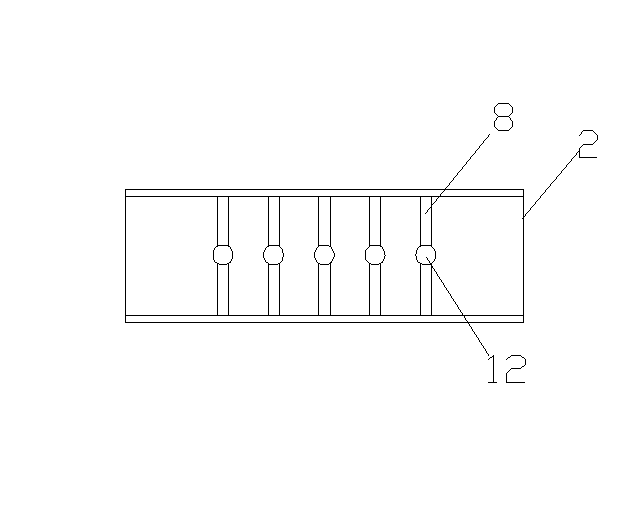

Self-cleaning type dust collection pipeline for textile dust collection equipment

ActiveCN112044905AEnvironmentally friendlyReduce the temperatureDispersed particle filtrationTransportation and packagingParallel plateStructural engineering

The invention discloses a self-cleaning type dust collection pipeline for textile dust collection equipment. The self-cleaning type dust collection pipeline for the textile dust collection equipment comprises a pipe body. A filter plate is fixedly connected to the inner wall of the pipe body, a fixed plate is fixedly connected to the inner wall of the pipe body, a permanent magnet plate is fixedlyconnected to the side wall of the fixed plate, an annular groove is formed in the inner wall of the pipe body, and a sliding plate is hermetically and slidably connected to the inner wall of the annular groove. The side wall of the sliding plate is fixedly connected with a vertical rod through connecting rods, the vertical rod is slidably connected with the inner wall of the annular groove, the side wall of the permanent magnet plate is rotatably connected with a lead screw, and one end of the lead screw is fixedly connected with fan blades. When filter holes in the filter plate are blocked,the sliding plate slides leftwards to extrude piezoelectric ceramic, so that the piezoelectric ceramic charges and breaks down a parallel plate capacitor formed between the fixed plate and the slidingplate, the permanent magnet plate is demagnetized under the action of heat generated after breakdown, and a magnetic plate slides leftwards under the action of springs. Ejector pins are inserted intothe filter holes to push out dust from the filter holes and clean the filter holes.

Owner:湖南科创纺织股份有限公司

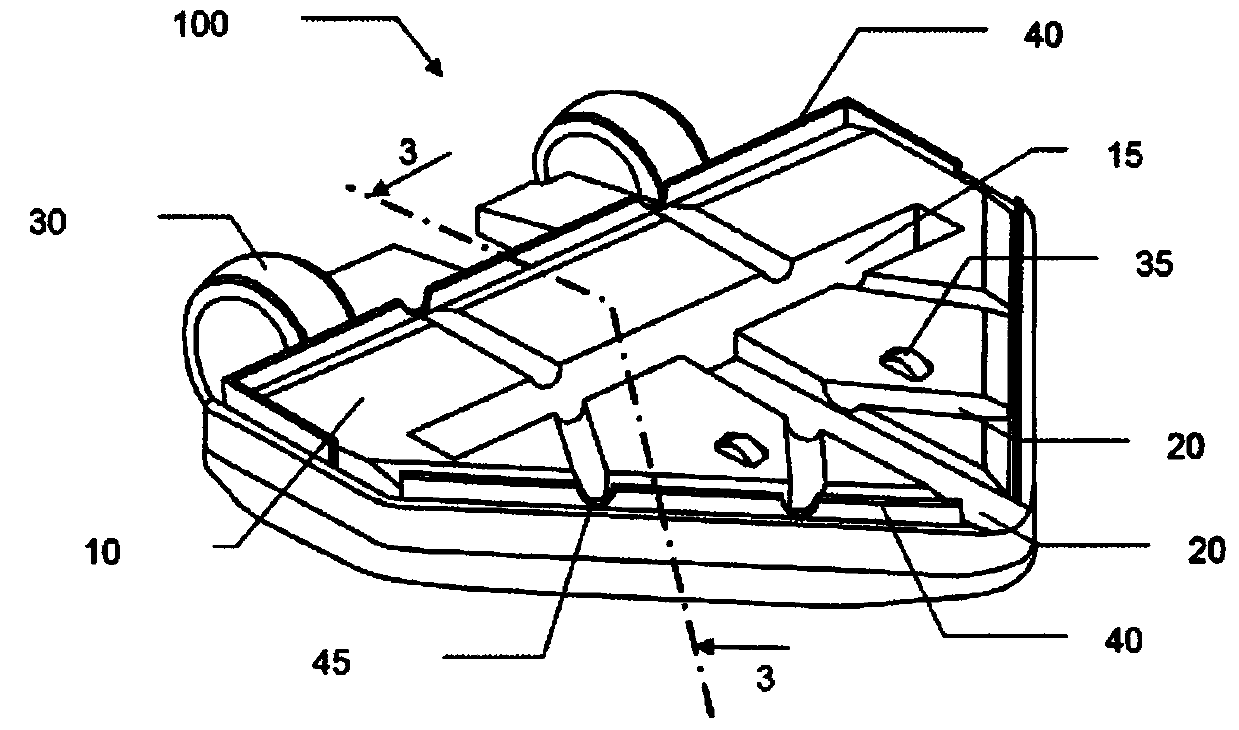

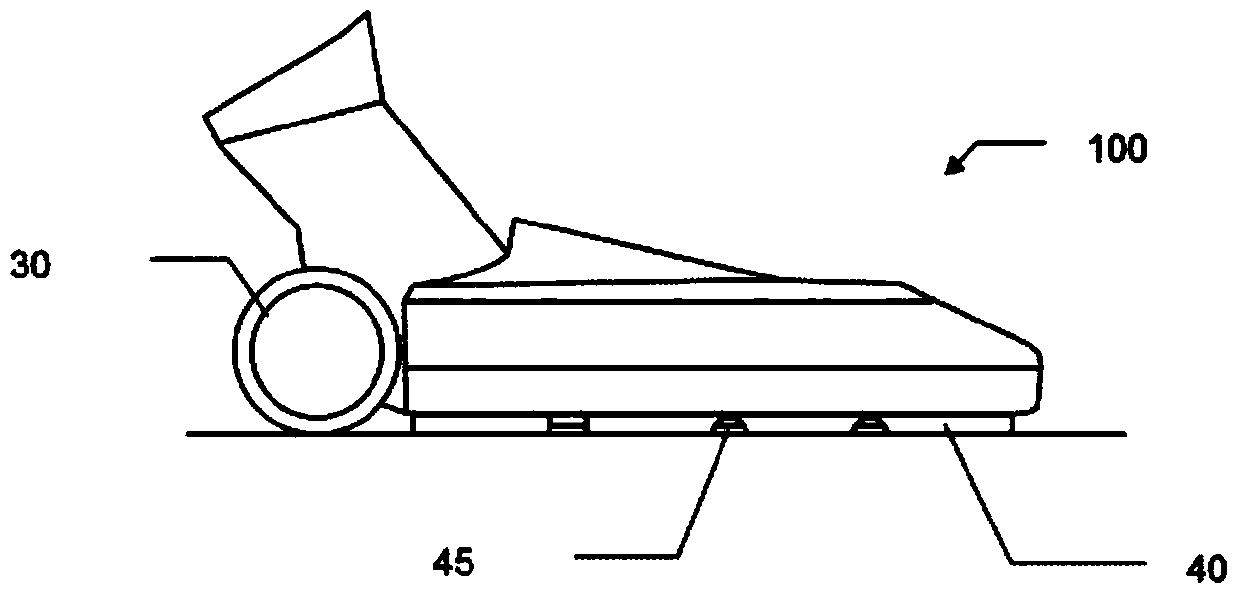

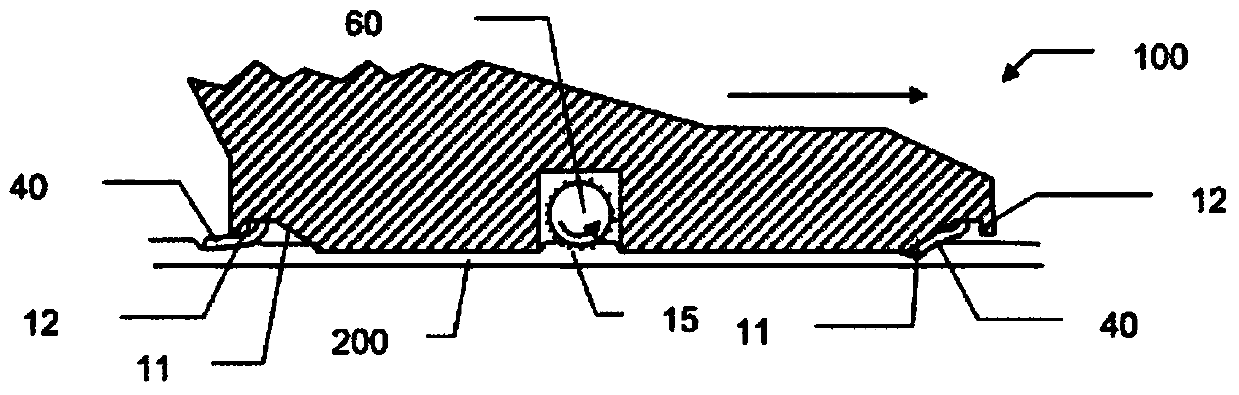

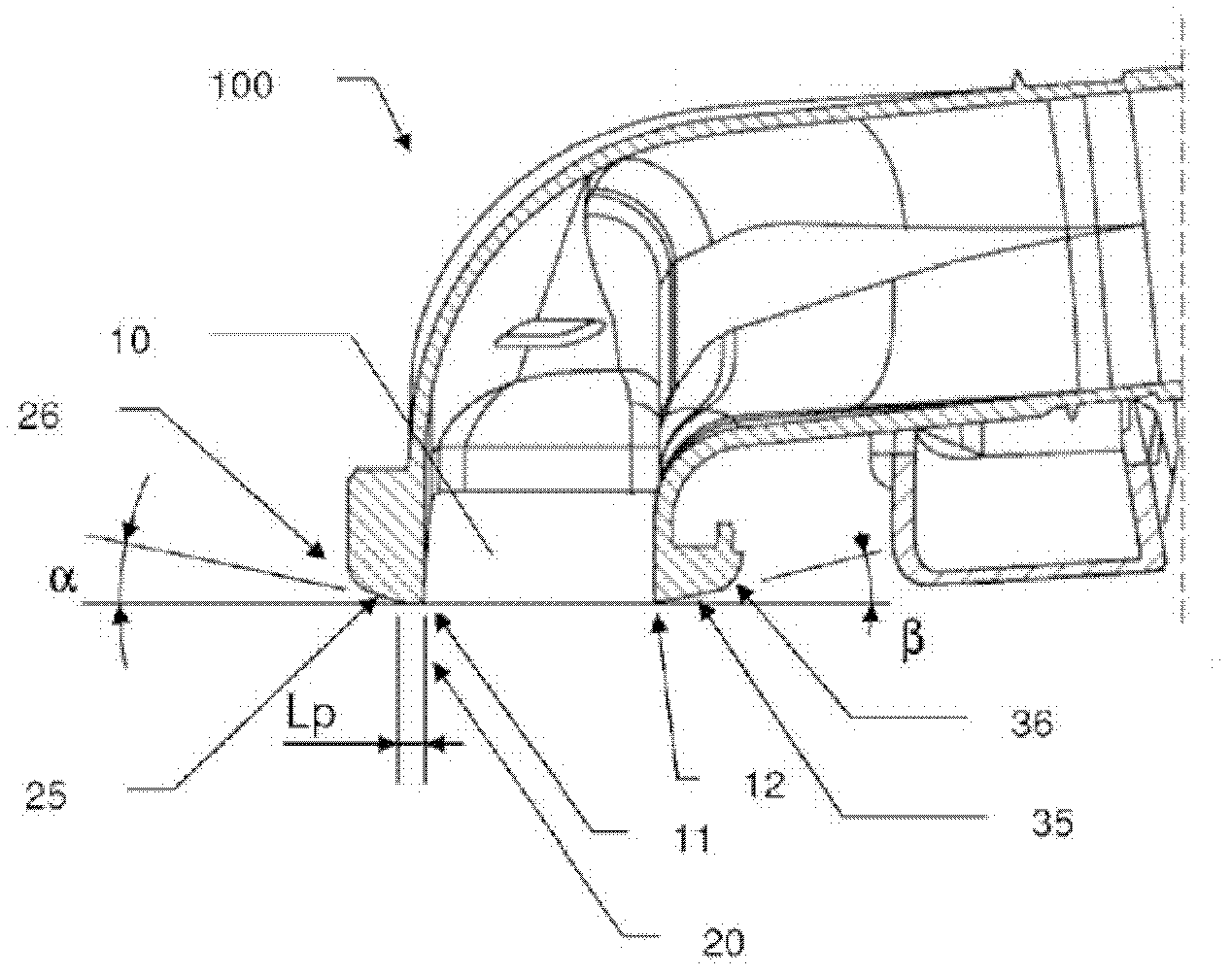

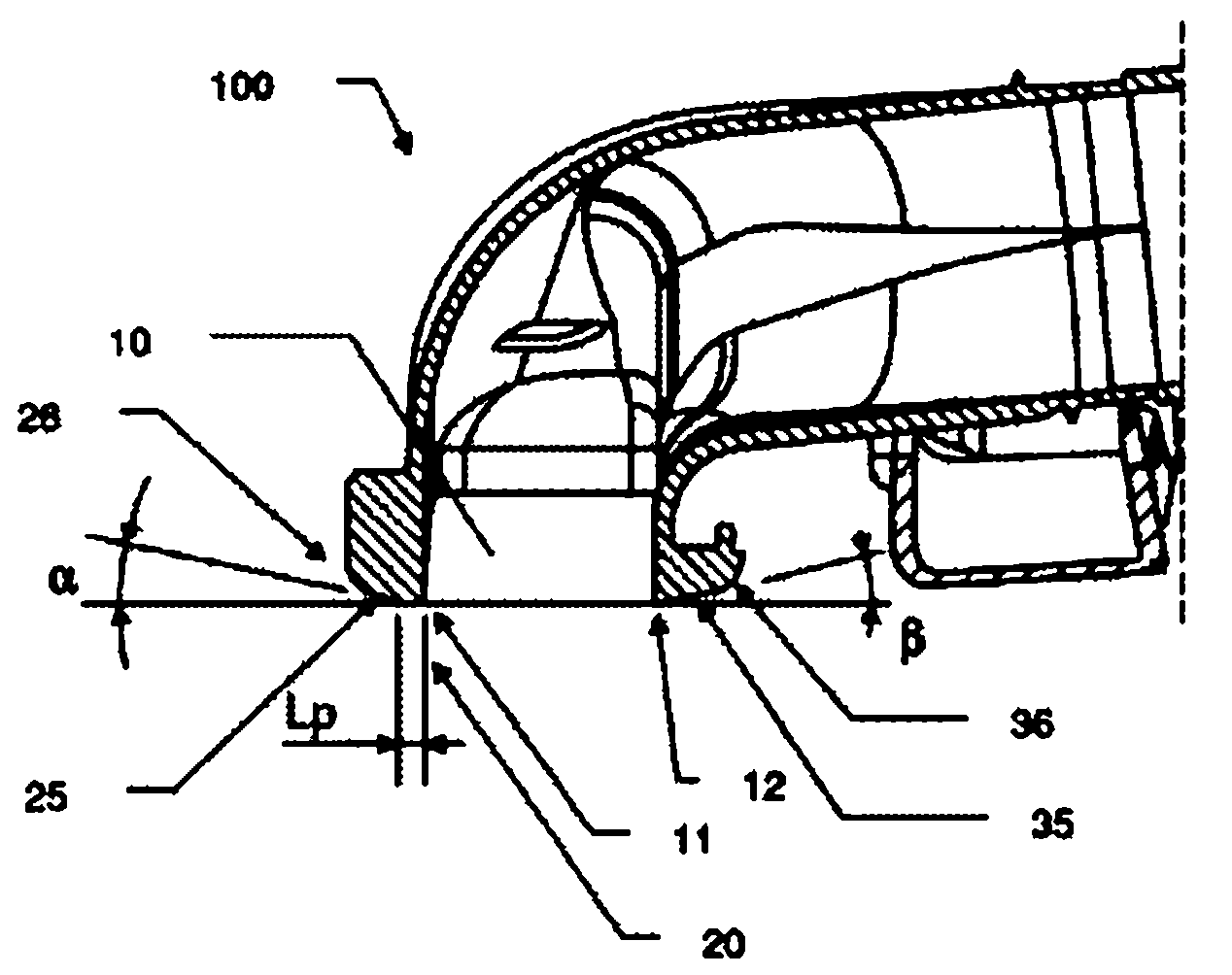

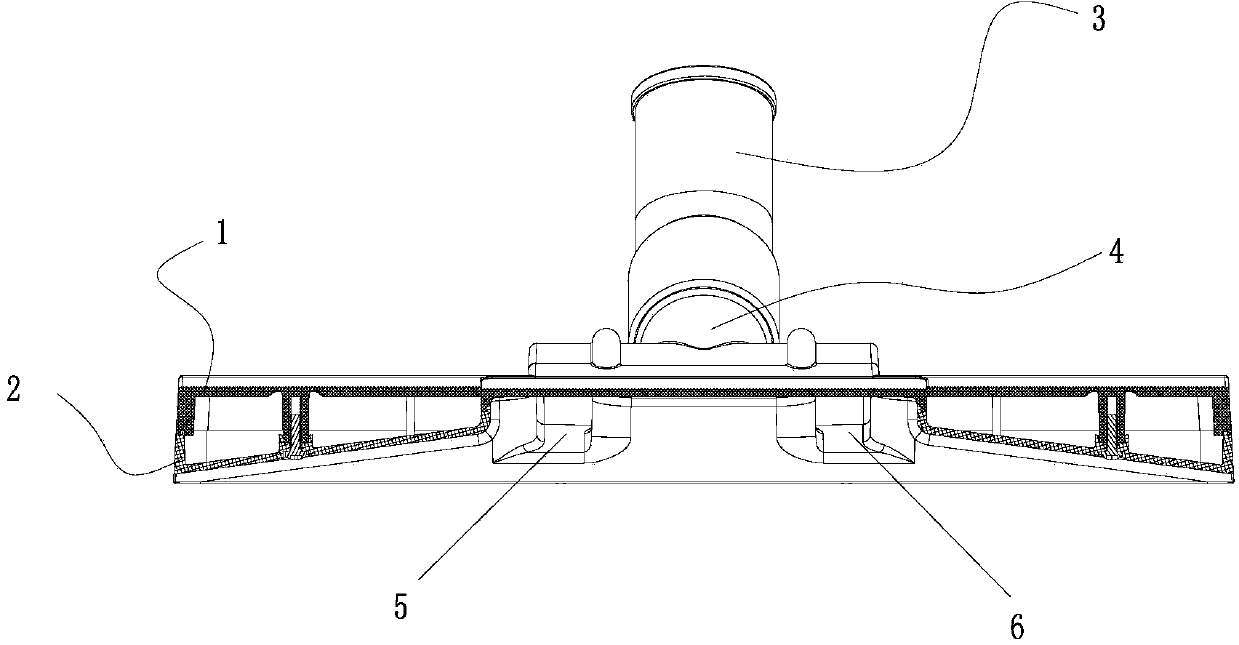

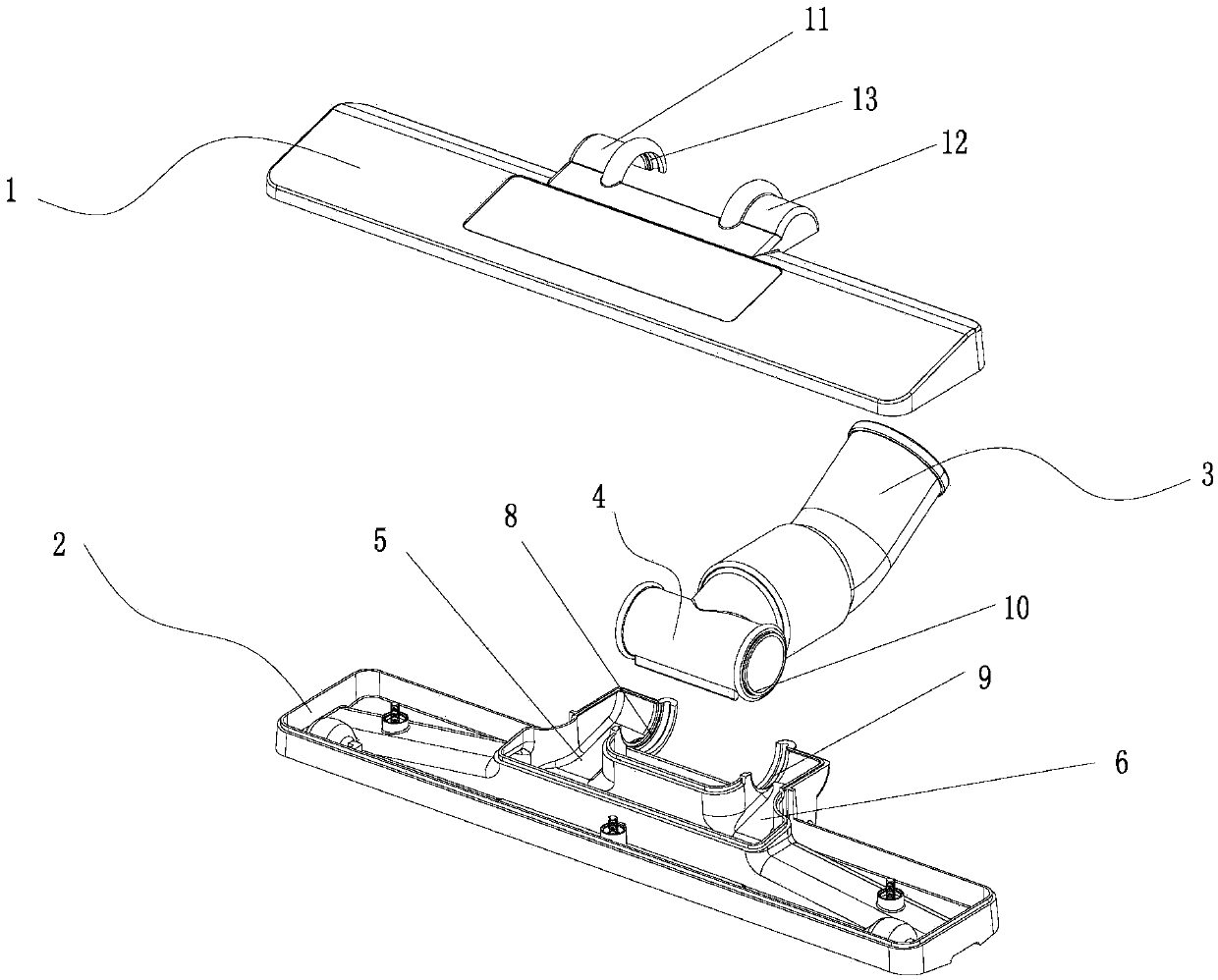

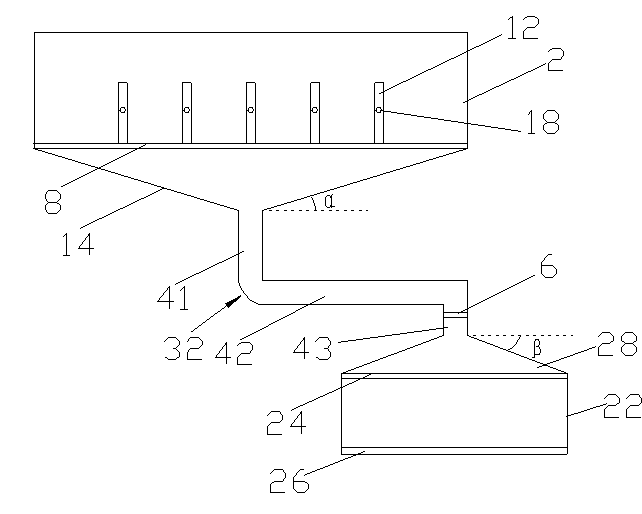

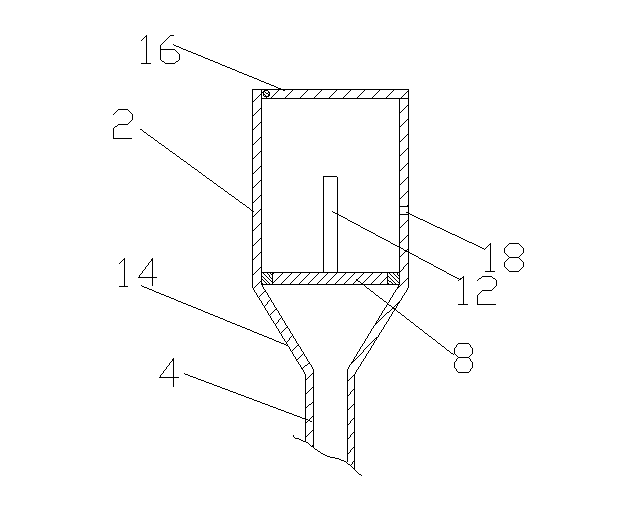

Vacuum cleaner head

InactiveCN103826517AEfficient suctionEfficient vacuumingSuction nozzlesEngineeringMechanical engineering

Vacuum cleaner head (100) comprising a bottom sole (10) and wheels (30, 35) defining the ground clearance of the bottom sole and comprising at least one suction duct (20) open toward the ground and converging from an outer edge of the bottom sole (10) toward a suction orifice (15) connected to the vacuum cleaner, characterized in that the suction head comprises a sealing skirt (40) arranged around the periphery of the bottom sole (10), and in that the sealing skirt (40) has at least one opening (45) positioned opposite said at least one suction duct (20).

Owner:SEB SA

Suction nozzle sliding base plate of a vacuum cleaner

The soleplate (100) has a suction channel (10) that is defined at a front by a front scrapping edge (11) and at a rear by a rear scrapping edge (12). A regulating unit regulates flow-pressure torque of air sucked in the suction channel, where the regulating unit has a sealing cover (20) comprised in a scrapping plane. An advanced effort limiting unit has a front attack chamfer (25) arranged at a front of the sealing cover forming an angle (beta) with the scrapping plane, where the angle is lower than 20 degrees.

Owner:SEB SA

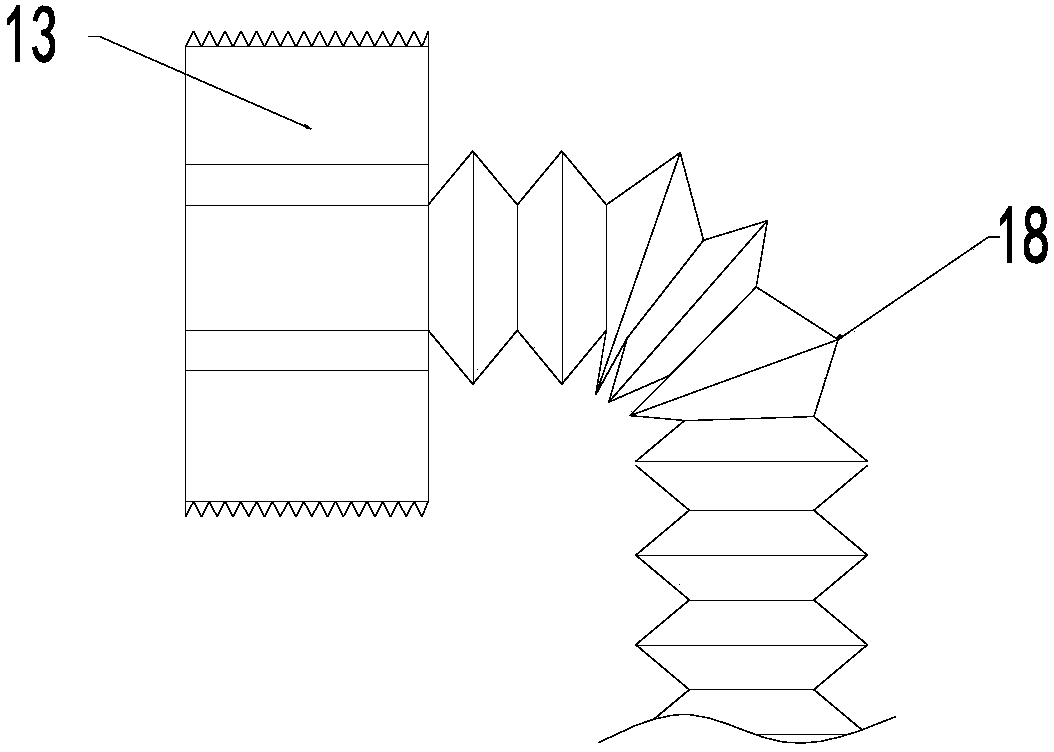

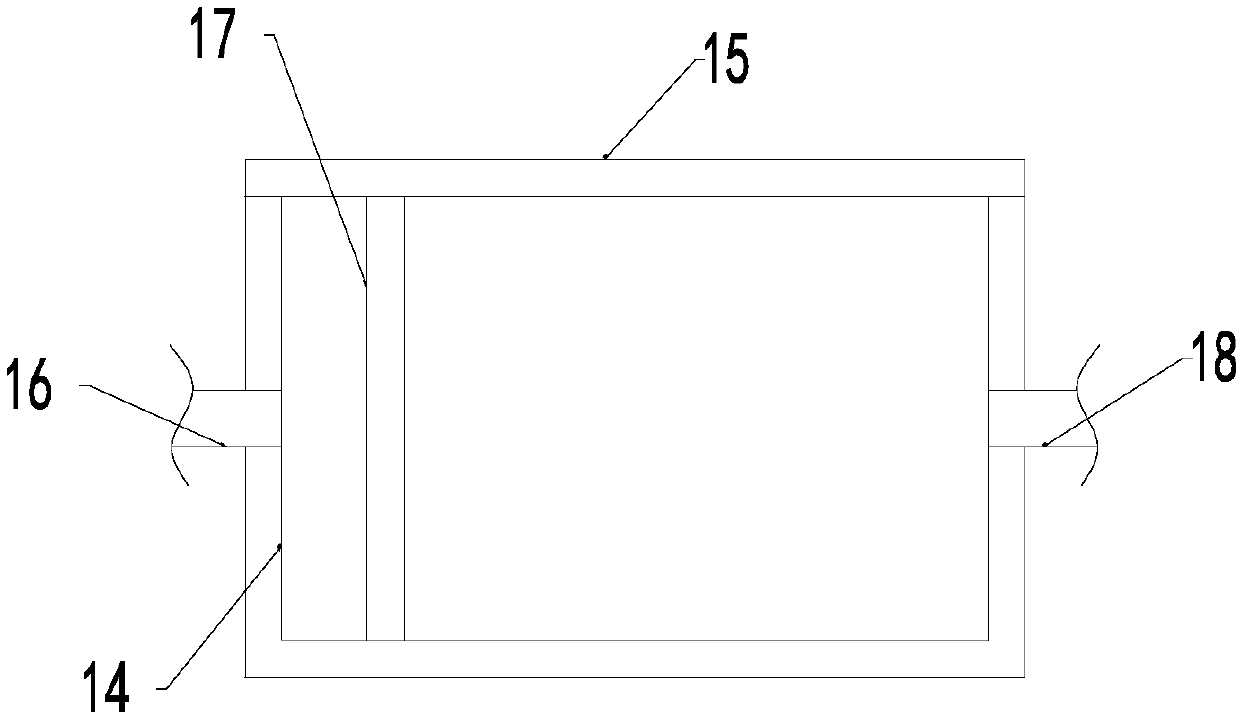

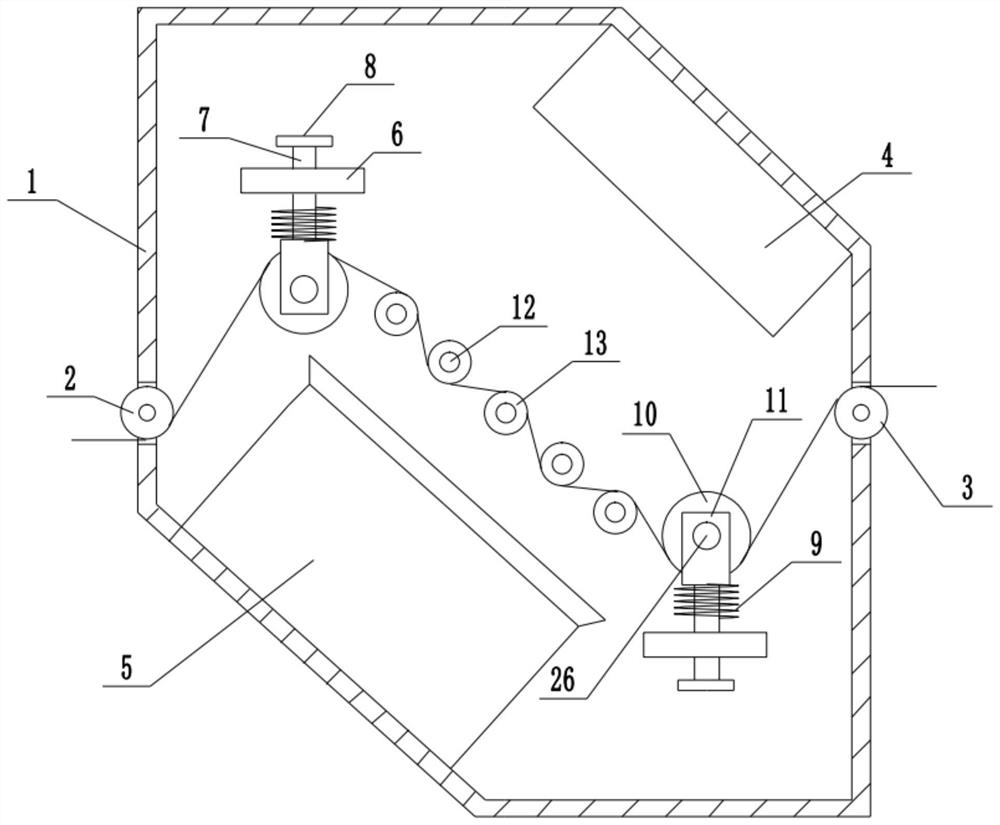

Airflow impact type yellow sand screening and drying device

InactiveCN108114896AAffect healthGood for healthGas current separationDrying gas arrangementsAir pumpEngineering

The invention discloses an airflow impact type yellow sand screening and drying device. The airflow impact type yellow sand screening and drying device comprises a shell, a circulating air pump, an air outlet corrugated pipe, a filtering box body and an air inlet corrugated pipe, wherein an upper cover, a feeding hole, a sliding baffle plate, a right air connecting port, a left air connecting portand a discharging port are arranged on the shell; a vertical rod, a circulating air pump, an air outlet corrugated pipe, a filtering box body and a connecting air pipe are arranged at the lower end of the shell; a movable cover, an electric heating wire and an air inlet corrugated pipe are arranged on the filtering box body; the tail end of the air outlet corrugated pipe and the tail end of the air inlet corrugated pipe are provided with threaded joints; and lining plates, rotating shafts, supporting frames, bottom plates and supporting sleeves are arranged on the two sides of the shell. Thethreaded joints of the tail end of the air outlet corrugated pipe and the tail end of the air inlet corrugated pipe are matched with the left air connecting port and the right air connecting port, sothat the materials can be promoted to pass through and dust is synchronously removed under the action of the circulating air pump, and impurities can be recycled after the screening is completed, so that the device is convenient and efficient to use, and can improve the machining efficiency.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

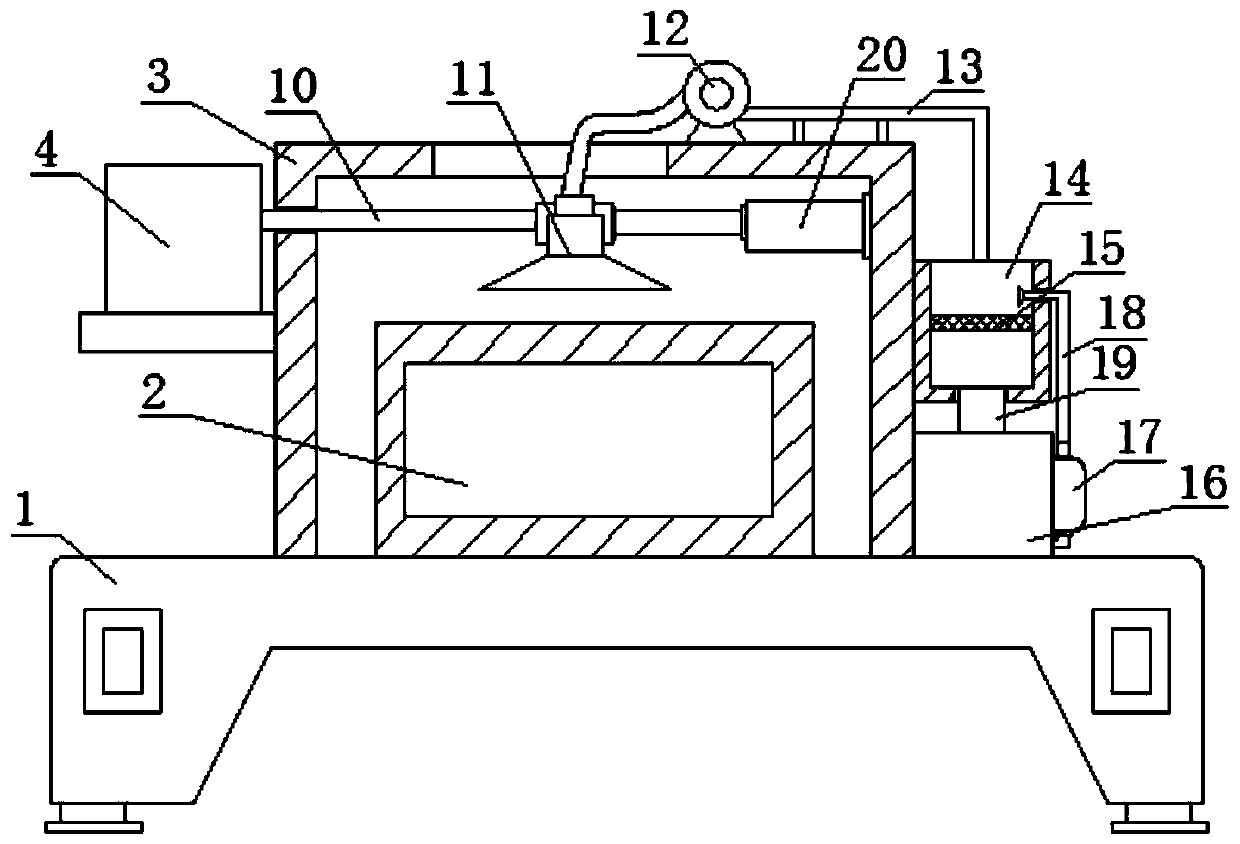

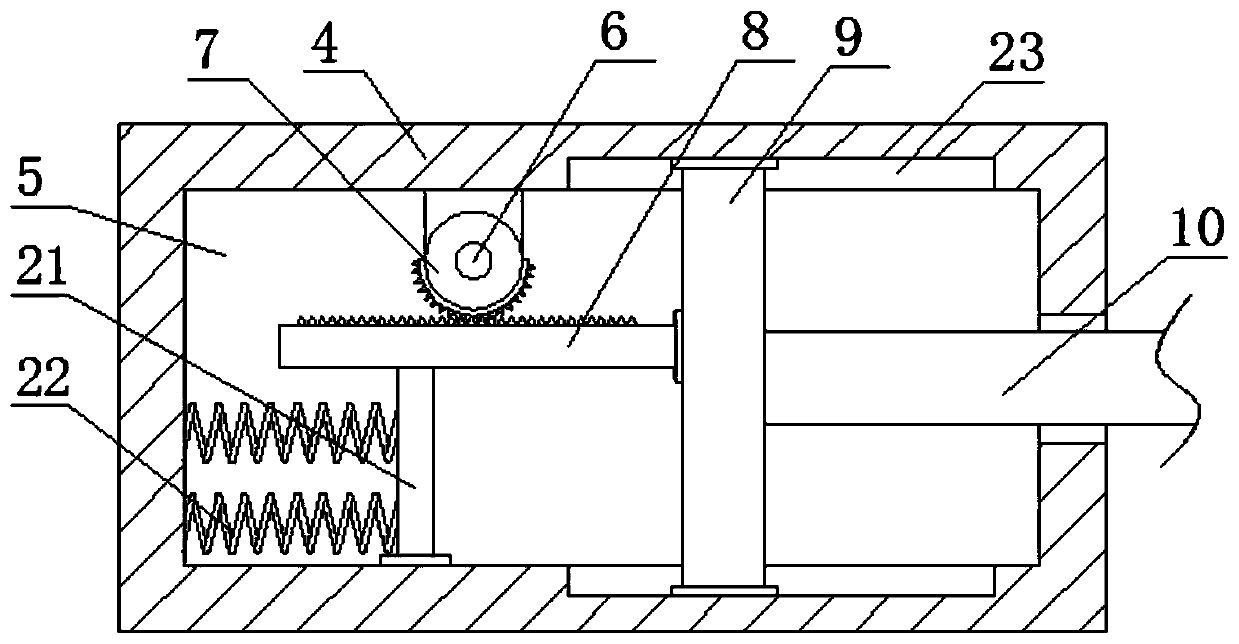

Grinding machine with efficient dust removing function

PendingCN111546201AImprove adsorption capacityWill not affect healthUsing liquid separation agentDirt cleaningPhysical healthReciprocating motion

The invention belongs to the field of grinding machines, and particularly relates to a grinding machine with an efficient dust removing function. The grinding machine aims at the problems that in theprocess that raw materials are machined by an existing grinding machine, dust is generated, serious pollution is caused, and therefore the physical health of operators is influenced; and meanwhile thedust falls onto mechanical equipment to be accumulated, and the mechanical equipment is likely to be damaged. According to the following scheme, the grinding machine comprises an operation table, thetop of the operation table is fixedly connected with a grinding machine body, and the top of the operation table is fixedly connected with a dustproof frame; and the grinding machine body is locatedin the dustproof frame, and one side of the dustproof frame is fixedly connected with a supporting plate. The grinding machine is reasonable in structure and easy to operate, a driving motor can drivea dust suction cover to do transverse reciprocating motion, and therefore the dust suction area is increased, dust removal is more efficient, then the physical health of the operators cannot be influenced, and harm of the dust to the mechanical equipment can be avoided.

Owner:YANCHENG INST OF IND TECH

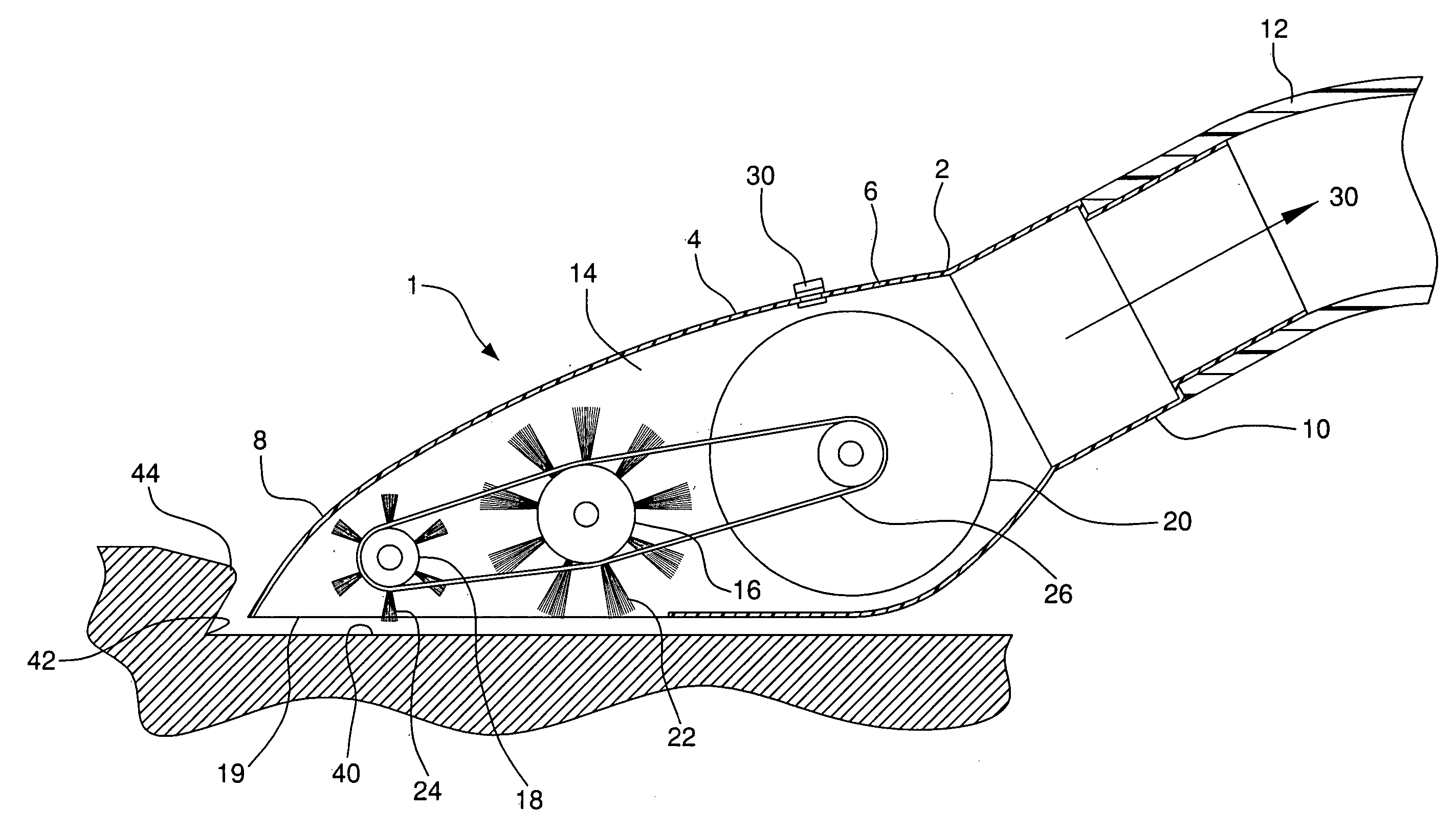

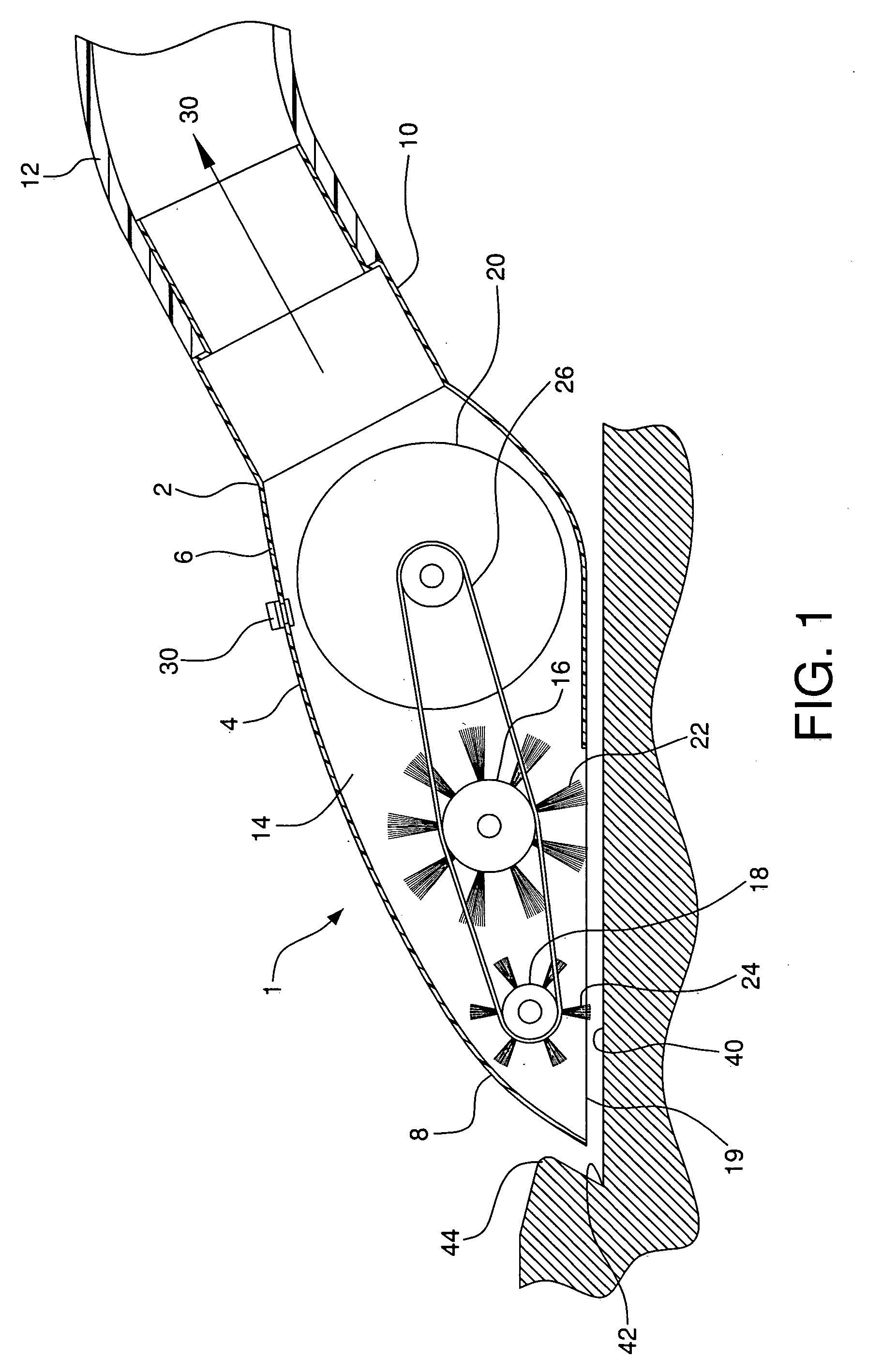

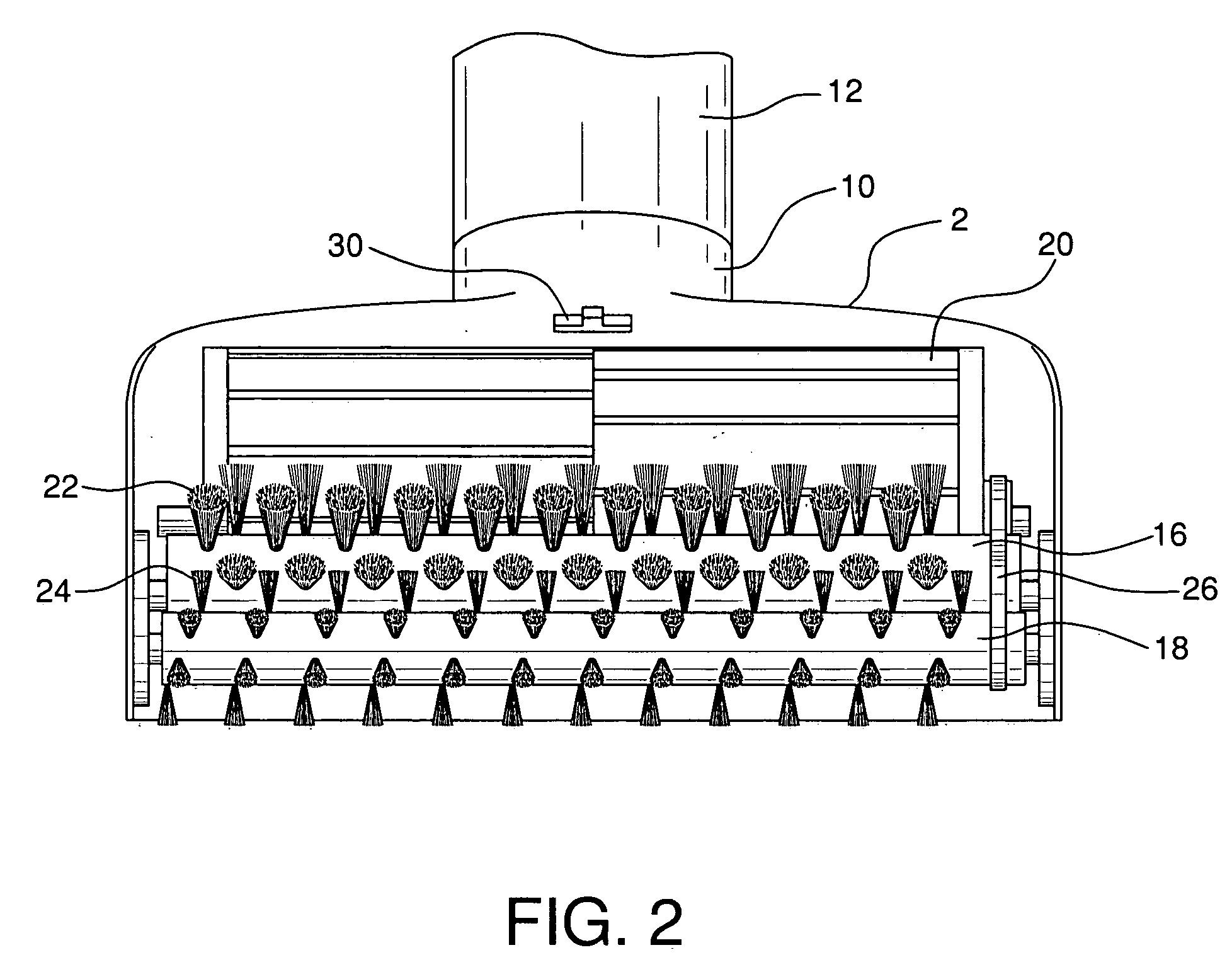

Precision vacuum cleaner head

A precision vacuum cleaner head is to be employed on a variety of vacuum cleaning units, the head being especially adaptable for use with portable, handheld vacuum cleaning units. The head has a tapered outer housing configured to enter and clean corners. The housing encloses a chamber which has two different sized rotary brush members, the smaller of which is located at the tapered end of the housing. Airflow suction from the vacuum cleaner provides a vacuum suction airflow in the housing. This airflow acts on a turbo drive wheel to rotate both brush members. The tapered housing permits efficient and effective cleaning of both flat surfaces and corners.

Owner:SMITH RICHARD A

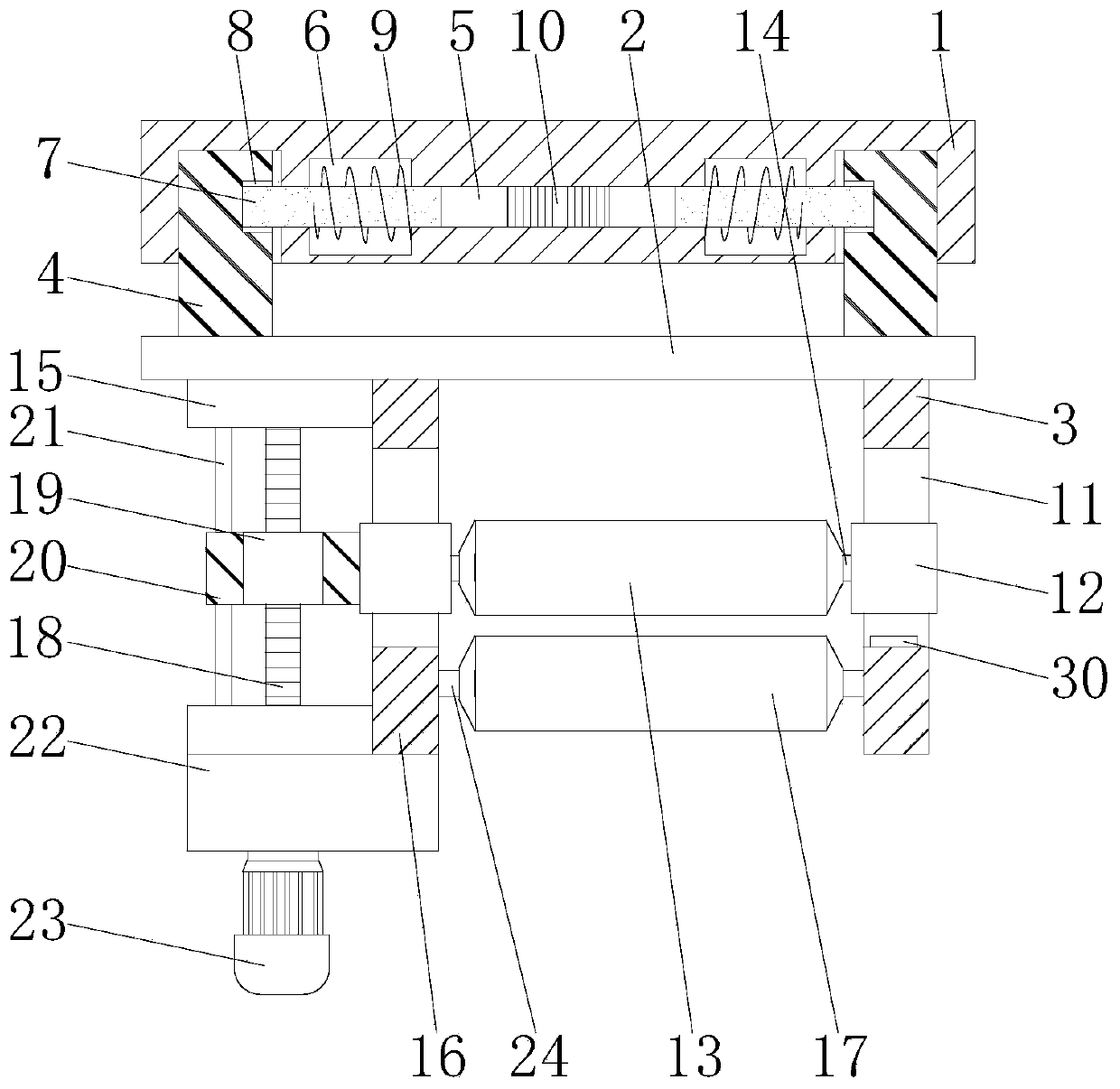

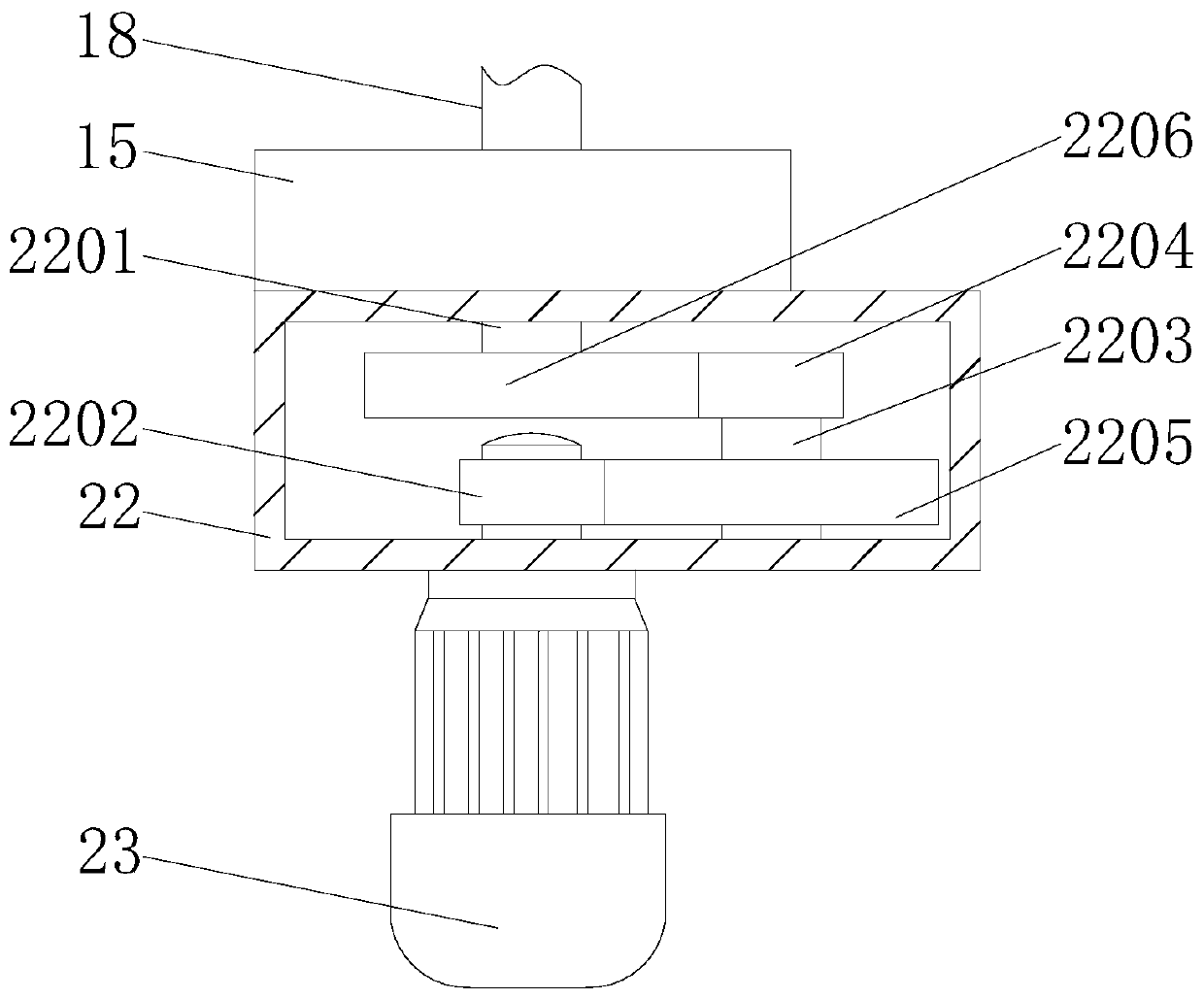

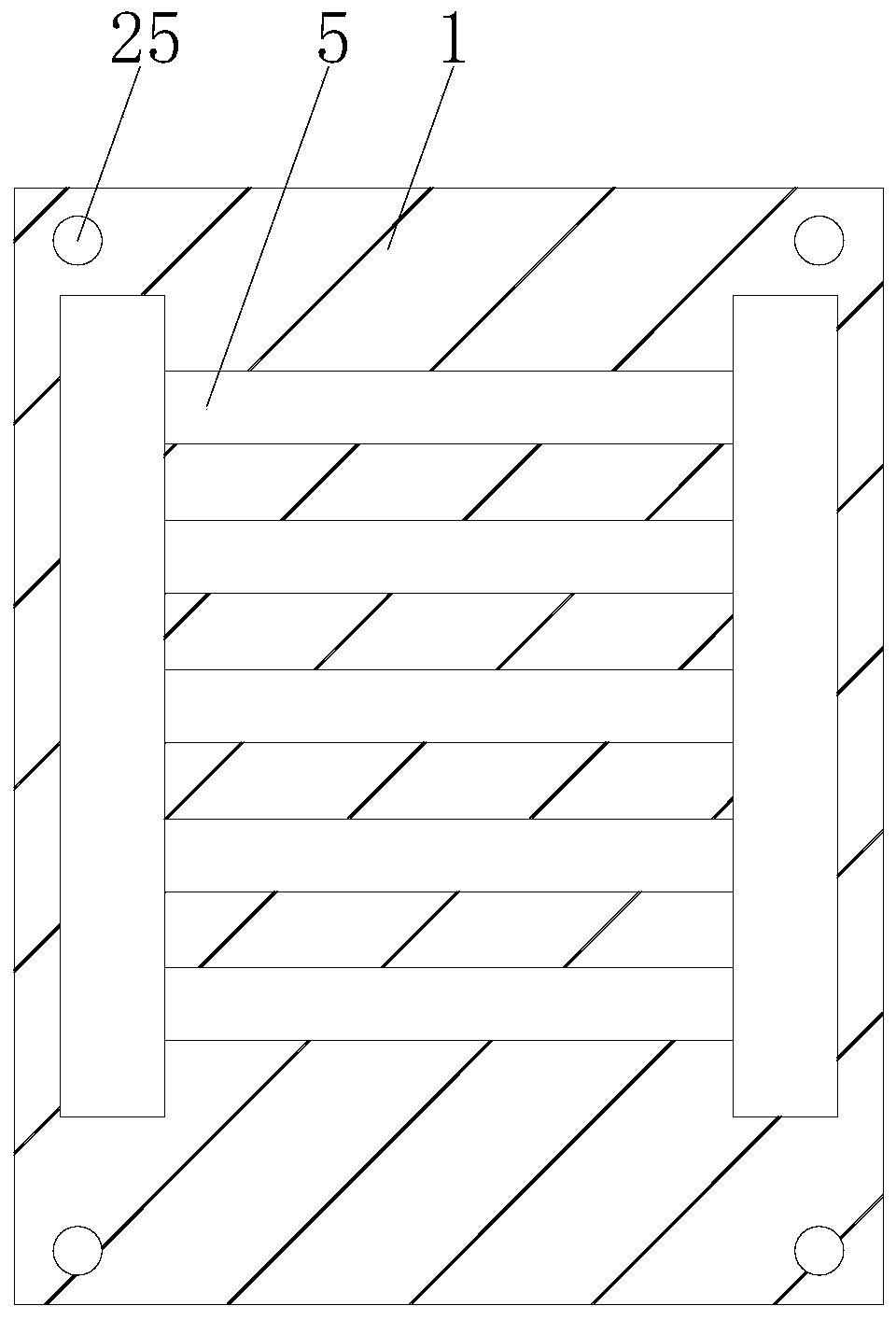

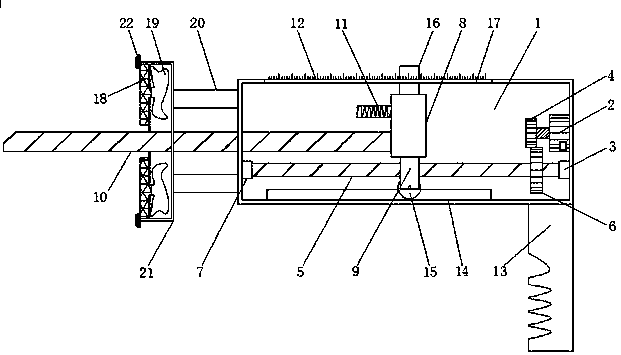

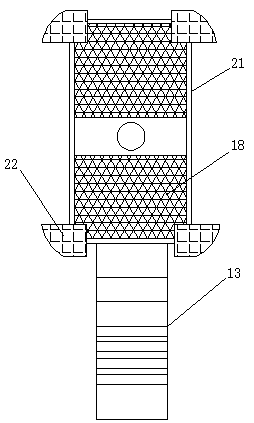

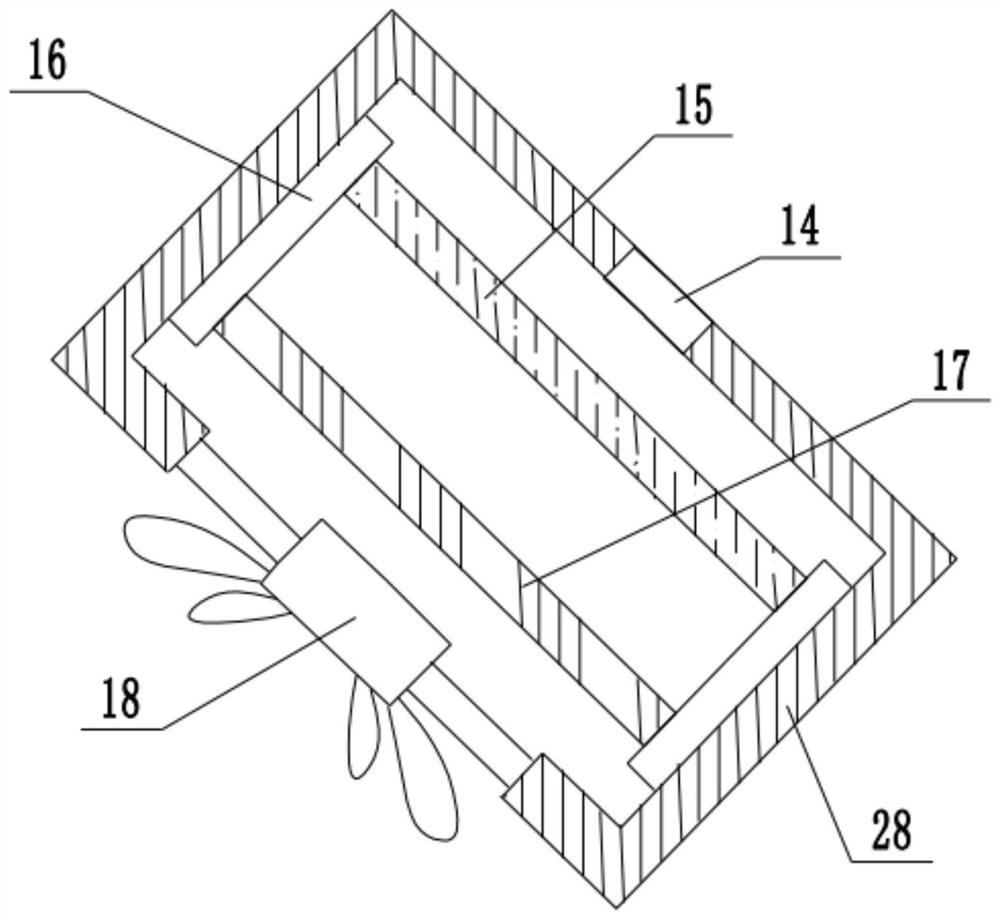

Pole piece cold-pressing device for lithium battery production

InactiveCN109786671AEffective liftingDeceleration is effectiveElectrode manufacturing processesImpellerMicrocomputer

The invention discloses a pole piece cold-pressing device for lithium battery production. The device comprises an installing plate, a flat plate, a first vertical plate, fixed strips, round holes, concave holes, iron rods, mating holes, springs, an electromagnet, sliding slots, sliding blocks, a first roller, a first connecting shaft, fixed plates, a second vertical plate, a second roller, a screw, a ball nut, a lantern ring, a guide rod, a reduction box, a first rotary shaft, a first gear, a second rotary shaft, a second gear, a third gear, a fourth gear, a servo motor, a second connecting shaft, installing holes, straight pipes, suction nozzles, connecting rods, fixed covers, distance sensors, connecting pipes, T-pipes, suction motors, a display screen, a single-chip microcomputer and centrifugal impellers. According to the device, through a lifting structure and the internal structure of the reduction box, ascending and descending of the first roller in the vertical direction can beeffectively realized, therefore, the distance between the first roller and the second roller can be adjusted, a pole piece can be pressed into a required thickness, and meanwhile the adjusted numbercan be displayed on the display screen in real time.

Owner:NANJING CHUQING ELECTRONICS TECH CO LTD

Double-duct dust collector floor brush

The invention relates to a double-duct dust collector floor brush which comprises a shell and a pipe connector arranged at the rear end of the shell. The shell comprises an upper cover and a lower cover provided with air inlet ducts, the upper cover is fixedly connected with the lower cover, the lower cover is provided with a dust collection port, the pipe connector is provided with a pipe cavity, the dust collection port is communicated with a pipe cavity through the air inlet ducts, the air inlet ducts are two in number and include the first air inlet duct and the second air inlet duct, and the first air inlet duct and the second air inlet duct are arranged on the two sides of the lower cover respectively side by side. The dust collector floor brush is provided with the two air inlet ducts, so that suction force of the ducts is uniform, and dust collection is efficient.

Owner:SUZHOU SHUANGRONG RUBBER & PLASTIC

Dust exhaust apparatus of yarn drum group

The invention relates to a dust exhaust apparatus of a yarn drum group. The dust exhaust apparatus of the yarn drum group is characterized by comprising a strip-shaped dust cage, a dust filtering structure communicated with the dust cage through a dust collecting pipe, and a suction ventilator arranged in the dust collecting pipe. The dust cage is internally provided with a yarn drum bracket and a plurality of yarn vertical shafts. A yarn outlet hole is formed in the side wall of the dust cage. The dust filtering structure comprises a boxy shell, a filtering plate arranged in the shell and an air outlet net arranged outside the filtering plate. According to the dust exhaust apparatus of the yarn drum group according to the invention, the whole yarn drum group can be placed in the dust cage, dust generated in the yarn drums in a relatively sealed space is collected, and the dust generating source is controlled. The dust exhaust apparatus of the yarn drum group collects dust more immediately, efficiently and thoroughly. One dust cage corresponds to the yarn drums in the yarn drum group, so that the dust exhaust apparatus of the yarn drum group is large in dust collecting range, and the structure is simplified, and the cost is lowered.

Owner:WUJIANG KESHIDA TEXTILE

Dust removal device of grinding machine

InactiveCN109397097AEasy to collectEasy to collect and processGrinding/polishing safety devicesArchitectural engineeringMechanical equipment

The invention provides a dust removal device of a grinding machine, and relates to the technical field of mechanical equipment. The dust removal device of the grinding machine comprises a base, the top of the base is fixedly connected with the bottom of a supporting column, an electric telescopic rod is fixedly arranged at the top of the supporting column, the top of the electric telescopic rod isfixedly provided with a supporting frame, the top of the supporting frame is fixedly provided with a motor, an output shaft of the motor penetrates through the top of the supporting frame to extend to the bottom of the supporting frame and to be fixedly connected with the top of a grinding disk, and a grinding platform is fixedly arranged at the top of the base and located right below the grinding disk. According to the dust removal device of the grinding machine, dust generated by grinding is discharged into a purification liquid through arranging a dust sucking pipe, the influence of diffusion on the health of a human body is prevented; a first fan is arranged, so that the dust is promoted to enter the purification liquid; the wind power of the first fan is more concentrated through a fan cover; and a liquid discharging pipe is arranged, so that the liquid with the dust can be discharged conveniently, and the purification liquid in a storage box can be conveniently replaced.

Owner:扬州天伟新材料有限公司

Continuous vacuum rapid quenching equipment and method for metal rapid quenching by using equipment

The invention provides continuous vacuum rapid quenching equipment. Based on traditional rapid quenching equipment, the equipment is additionally provided with a transition cavity, a clamping device, a collecting device and a vacuuming device; the equipment improves such problems as need of opening / closing a main cavity door in each operation, manual loading of a heating body and manual collection of quenching products in the traditional equipment; and the equipment can realize continuous operation to reduce the energy and time consumption and to improve the production efficiency.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Handheld drilling machine for house building

InactiveCN108687967AAchieve graspSimple structureWorking accessoriesStone-like material working toolsHouse buildingMechanical engineering

The invention provides a handheld drilling machine for house building, and relates to the technical field of drilling equipment. The handheld drilling machine for house building comprises a machine body; a motor is fixedly mounted on the right side of the inner wall of the machine body; a first bearing seat is fixedly mounted on the right side of the inner wall of the machine body; a first gear isfixedly mounted at the output end of the motor; a rotating rod is fixedly inserted in the first bearing seat; a second gear is fixedly mounted on the surface of the rotating rod; and the second gearand the first gear are mutually engaged. The handheld drilling machine for house building is simple in structure and convenient to operate, a scale plate and a scale block are arranged, thus the drilling depth can be effectively grasped, the hole depth is mastered, and the drilling efficiency is effectively improved; and by arranging a dust adsorbing plate and a dust collecting bag, dust drilled down by a drill bit in the drilling process can be effectively adsorbed, thus an operator is prevented from inhaling the dust, and the problem of dust scattering is effectively solved.

Owner:芜湖市涵润智能科技有限公司

Carriage band sawing machine body with self-cleaning function

PendingCN107984549AEasy to cleanReduce resistanceBand sawsBark-zones/chip/dust/waste removalEngineeringMachine tool

The invention relates to a carriage band sawing machine body with a self-cleaning function. The carriage band sawing machine body comprises a machine frame and a cleaning mechanism, and walking wheelgroups are transversely rotationally arranged on the front side and the rear side of the lower end of the machine frame respectively. Two parallel tracks are arranged under the machine frame, and thewalking wheels of the two ends of each walking wheel group are respectively arranged on the two tracks in a rolling mode. One walking wheel group is connected with a driving mechanism used for drivingthe walking wheel group to rotate in a transmitting mode. The cleaning mechanism is arranged on the machine frame and is used for respectively clearing away wood chips attached to the two tracks in the sawing process. The carriage band sawing machine body has the advantages of simple structure and convenience in operation and use, can effectively clear the wood chips attached to the tracks in thesawing process, and reduces the resistance of the walking wheels rolling along the tracks so as to enable the whole machine frame to walk smoothly. The production process is sanitary and environment-friendly.

Owner:湖北金成光电科技股份有限公司

Cryogenic System and Method of Use

InactiveUS20170172791A1Enhance nucleation and depositionIncrease depositionEndoscopesCatheterProcess engineeringMedical device

A cryogenic medical device for delivery of subcooled liquid cryogen to various configurations of cryoprobes is designed for the treatment of damaged, diseased, cancerous or other unwanted tissues. The device is a closed or semi-closed system in which the liquid cryogen is contained in both the supply and return stages. The device is capable of generating cryogen to a supercritical state and may be utilized in any rapid cooling systems. As designed, the device comprises a number of parts including a vacuum insulated outer dewar, submersible cryogen pump, baffled linear heat exchanger, multiple pressurization cartridges, a return chamber, and a series of valves to control the flow of the liquid cryogen interconnected with cryotreatment devices including cryoprobes and catheters. The cryogenic medical device promotes subcooling to the tips of various external cryogenic instrument configurations.

Owner:ENDOCARE

Automatic welding and cutting workshop

ActiveCN104588924AEasy to replaceImprove cleanlinessWelding/cutting auxillary devicesDirt cleaningEngineeringBreathing process

The invention discloses an automatic welding and cutting workshop. A sealed house is arranged. A workbench is arranged in the house. The workbench is arranged on the rotating disk and connected through a magnetic block, so that the workbench is convenient to replace. Sound absorbing cotton is arranged on the side walls of the house and absorbs sounds. A dust collecting pipe arranged on the roof of the house collects dust on an upper dust layer. The bottom of the house is a net layer. Dust reaches the dust layer via the net layer. Dust concentration sensors are arranged in the bottom of the house and the dust layer of the house respectively. Once it is sensed that the concentration of the dust is large, an air draft tube arranged on the dust layer conducts air draft to suck the dust. The dust in the house can be effectively collected through the two modes. Besides, the air draft tube will not continuously conduct air draft, the air draft tube conducts air draft only if the concentration is large, and therefore energy is saved; ventilation pipes are further arranged on the roof of the house and directly reach the outside of the workshop, the dust collecting pipe collects dust, the ventilation pipe feeds air, air in the house can be changed, and therefore it is guaranteed that production personal breathe clean air. The automatic welding and cutting workshop is suitable for production.

Owner:WUHU POWER TECH

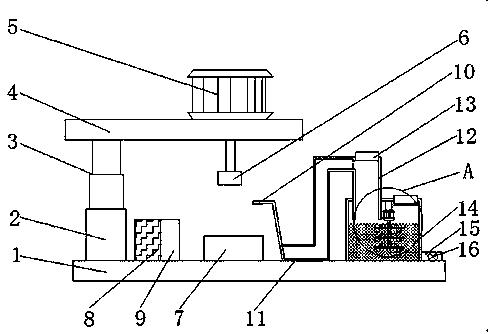

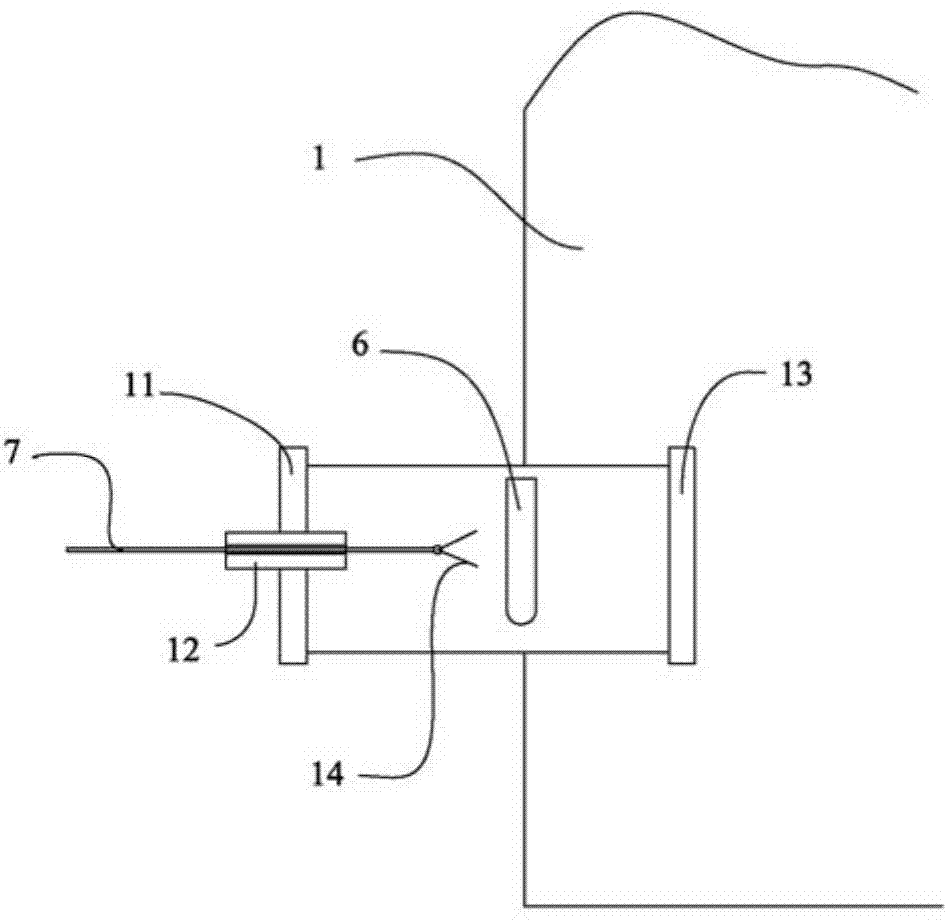

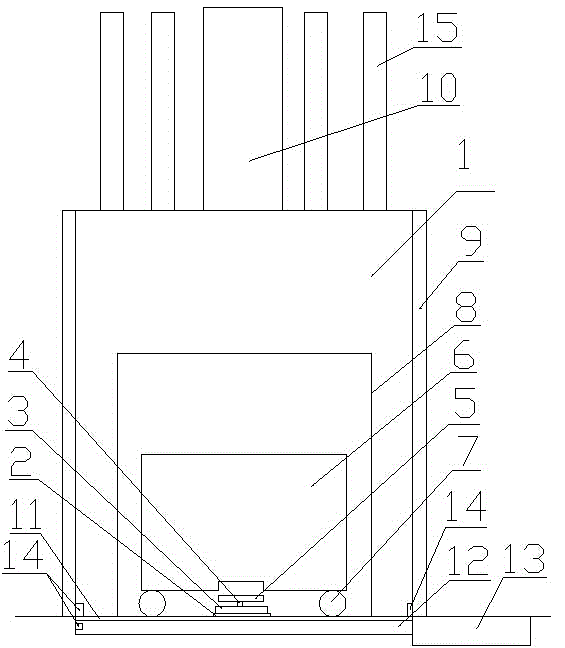

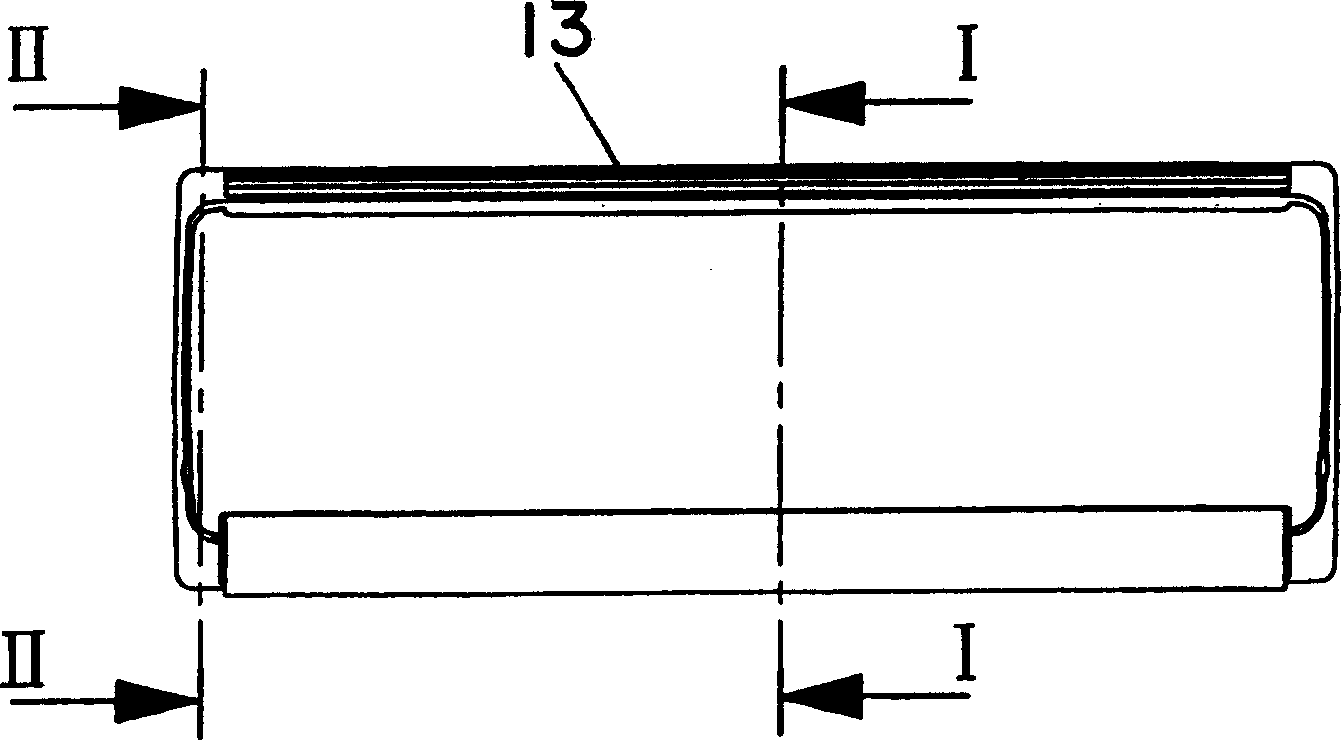

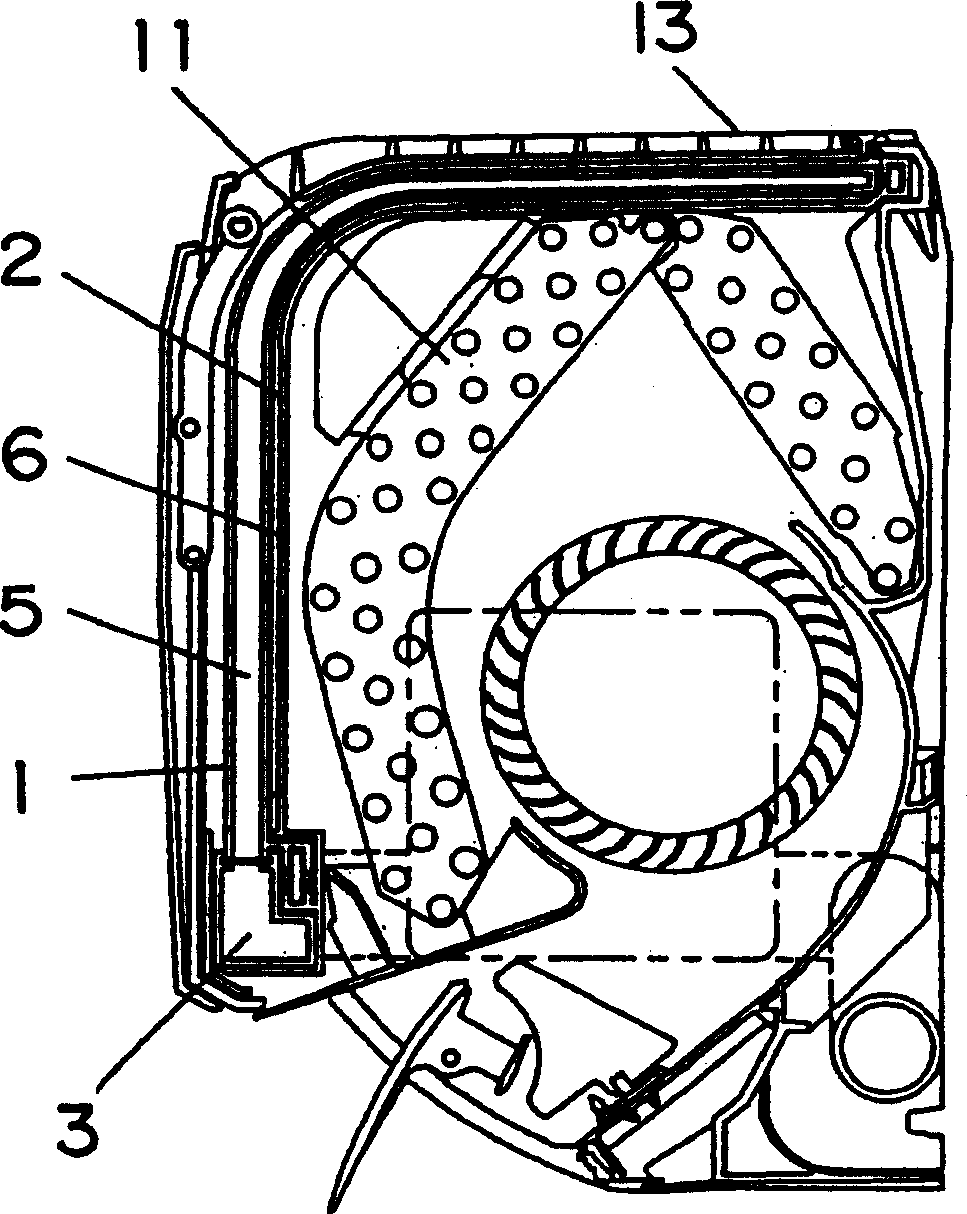

Air conditioner having indoor unit with automatic air filter celaning function

InactiveCN1756928AEfficient vacuumingImprove cleanlinessDispersed particle filtrationLighting and heating apparatusPlate heat exchangerAir filter

An air conditioner, wherein a heat exchanger and a fan blowing air heat-exchanged in the heat exchanger into a room are stored in an indoor unit body, and an air filter is installed in the body on the upstream side of the heat exchanger. Also, the air conditioner comprises a sucking and exhausting device in which a suction nozzle having a suction port facing the air filter and sucking dirt adhered to the air filter is slidably fitted, communicating with the suction nozzle, and sucking and exhausting the dirt together with the air.

Owner:PANASONIC CORP

Cryogenic System and Method of Use

InactiveUS20200121498A1Extend the flow pathRelieve stressElectrocardiographyEndoscopesMedicineLiquid state

A cryogenic medical device for delivery of subcooled liquid cryogen to various configurations of cryoprobes is designed for the treatment of damaged, diseased, cancerous or other unwanted tissues. The device is a closed or semi-closed system in which the liquid cryogen is contained in both the supply and return stages. The device is capable of generating cryogen to a supercritical state and may be utilized in any rapid cooling systems. As designed, the device comprises a number of parts including a vacuum insulated outer dewar, submersible cryogen pump, baffled linear heat exchanger, multiple pressurization cartridges, a return chamber, and a series of valves to control the flow of the liquid cryogen interconnected with cryotreatment devices including cryoprobes and catheters. The cryogenic medical device promotes subcooling to the tips of various external cryogenic instrument configurations.

Owner:ENDOCARE

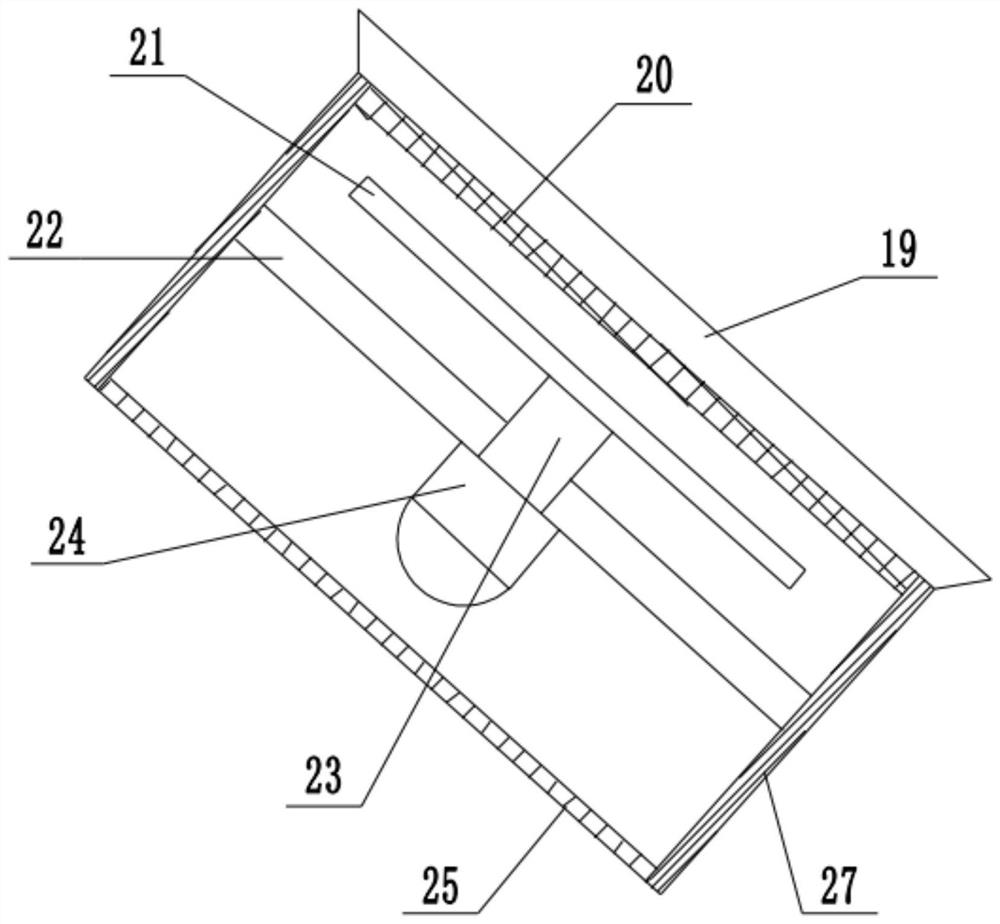

Drying and dust collecting device for textile fabric

InactiveCN113108578AEfficient vacuumingEfficient dryingDrying gas arrangementsDrying chambers/containersStructural engineeringProcess engineering

The invention relates to the technical field of textile processing equipment, and discloses a drying and dust collecting device for a textile fabric. The device comprises a drying and dust collecting box, a feeding roller is installed at one end of the drying and dust collecting box, a discharging roller is installed at the other end of the drying and dust collecting box, and tensioning mechanisms are installed at the diagonal positions in the drying and dust collecting box respectively. A plurality of guide rollers are installed between the inner walls of the drying and dust collecting box between the tensioning mechanisms, dust collecting cylinders are installed on the outer sides of the guide rollers, and a drying mechanism and a dust collecting mechanism are installed in the drying and dust collecting box along the opposite positions of the two sides of the guide rollers correspondingly. According to the device, rotating wheels are arranged in the drying and dust collecting box and are matched with the multiple guide rollers, the conveying distance of the placed fabric in the drying and dust collecting box can be prolonged, and meanwhile under the cooperation of the dust collecting mechanism and the drying mechanism, the efficient dust collection and drying effects of the whole textile fabric are ensured.

Owner:吴江市潇湘纺织有限公司

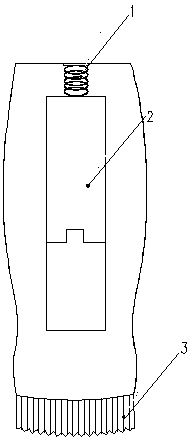

Electric dust collecting brush

InactiveCN103844998AReduce manual effortRealize dust removal automationSuction cleanersEngineeringElectrical and Electronics engineering

The invention relates to an electric dust collecting brush. The power drive function of a motor is utilized in generously, manual strength of a user can be reduced, automatic and even dust collecting is achieved to the maximum extent, effect dust collect is achieved, and the electric dust collecting brush is convenient and easy to carry.

Owner:CHONGQING BEIBEI DISTRICT WANGPU MIDDLE SCHOOL

Dust collector

A vacuum cleaner, comprising a main body of the vacuum cleaner, a hand handle, a dust storage room, a dust suction port, a hand handle connected above the main body of the vacuum cleaner, a motor accommodating chamber inside the main body of the vacuum cleaner, a dust storage room and a dust storage room below the main body of the vacuum cleaner Connected with the dust suction port, the motor housing chamber is equipped with a motor, the front end of the motor shaft is connected to the wind impeller, the dust filter is placed between the wind impeller and the dust suction port, the dust suction port is equipped with a lamp compartment, and the lamp compartment is equipped with an ultraviolet lamp . The vacuum cleaner of the present invention can effectively remove dust in places with narrow spaces, many gaps, and high positions, and utilizes ultraviolet radiation to kill bacteria and mites, so as to improve cleaning efficiency and achieve the effect of sterilizing and removing mites.

Owner:贾之远

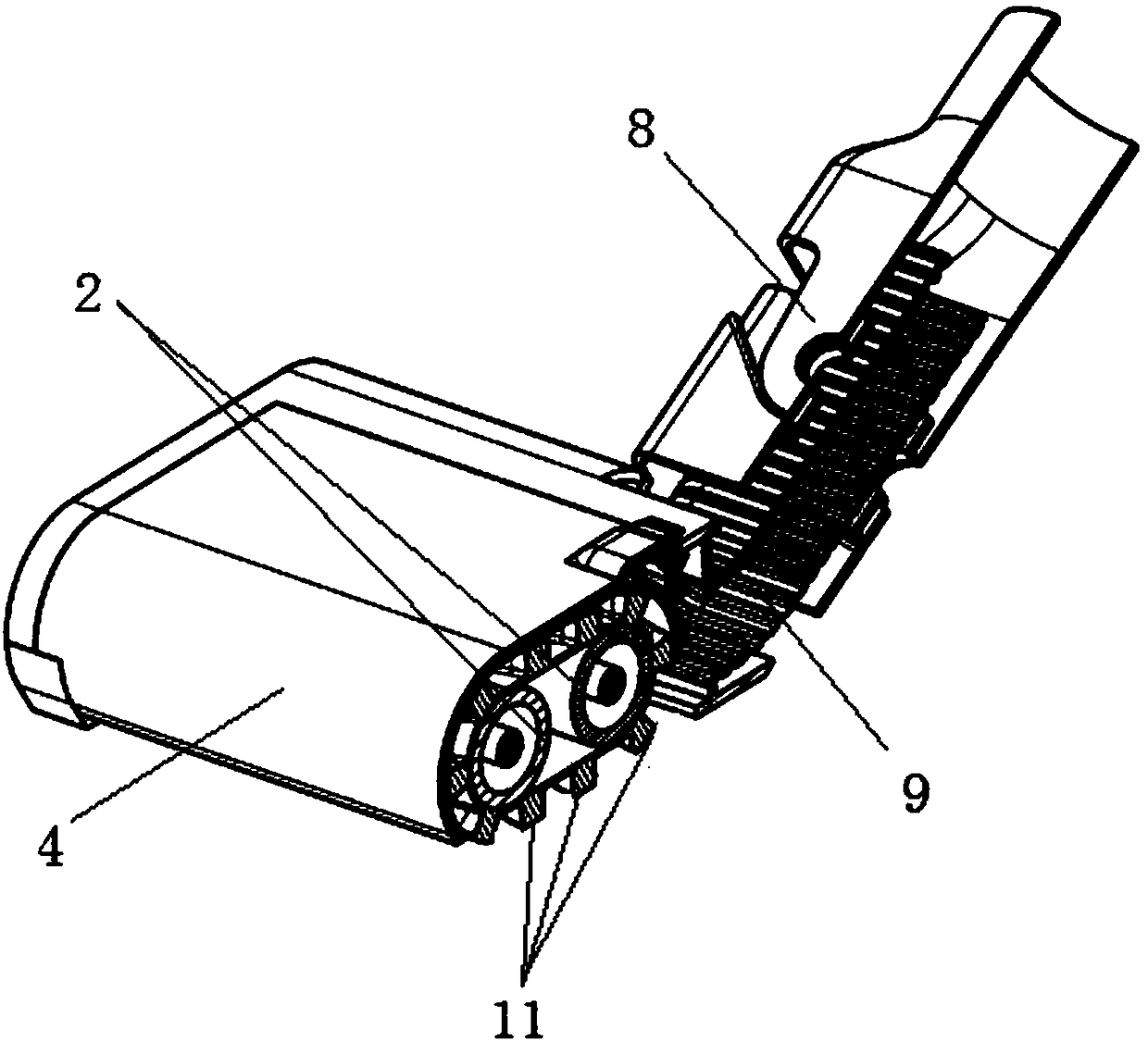

Rolling brush and dust collector with rolling brush

PendingCN108402999ASave materialReduce manufacturing costSuction nozzlesMechanical engineeringLarge particle

The invention discloses a rolling brush and a dust collector with the rolling brush. The rolling brush comprises a rolling brush shell, a driving assembly and a rolling brush body, wherein the drivingassembly is installed on the rolling brush shell; the rolling brush body comprises an annular belt installed on the driving assembly and a plurality of protruding brush strips arranged on the outer surface of the annular belt through protruding, the two adjacent protruding brush strips are arranged at intervals, the annular belt rotates under supporting and driving of the driving assembly, and the contact portion between at least one protruding brush strip and a cleaned surface is kept being planar. The dust collector comprises the rolling brush, when large-particle dustiness is swept, the dust collector is not required to be lifted off from the ground, the large-particle dustiness can be sucked, and therefore the dust collector is more conveniently used and capable of saving labor; in addition, as the protruding brush strips on the rolling brush are arranged at intervals, a manufacturing material of the rolling brush is also reduced, and the cost of the dust collector is further reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Vacuum-type rotary slide pump

ActiveCN104204533AAvoid damageAvoid the disadvantage of increased torqueRotary piston pumpsRotary piston liquid enginesPump chamberEngineering

A vacuum-type rotary slide pump has a pump chamber (12) in a housing (10). A rotor (14) is eccentrically mounted in the pump chamber (12). Slides (18) are connected in a displaceable manner to the rotor (14). Furthermore, a discharge duct (30) is connected to the pump chamber (12) and to an oil chamber (32). Between the discharge duct (30) and the oil chamber (32) there is arranged a valve device (38) for preventing a return flow of medium from the oil chamber (32) into the pump chamber (12). According to invention, at least one compensation duct (50, 72) is provided which is connected to the discharge duct (30) and to the oil chamber (32) and which is integrated into the valve device (38).

Owner:LEYBOLD HERAEUS GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com