Vacuum cleaner head

A technology of vacuum cleaners and suction pipes, applied in the directions of vacuum cleaners, nozzles, cleaning equipment, etc., can solve problems such as noise, friction, increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

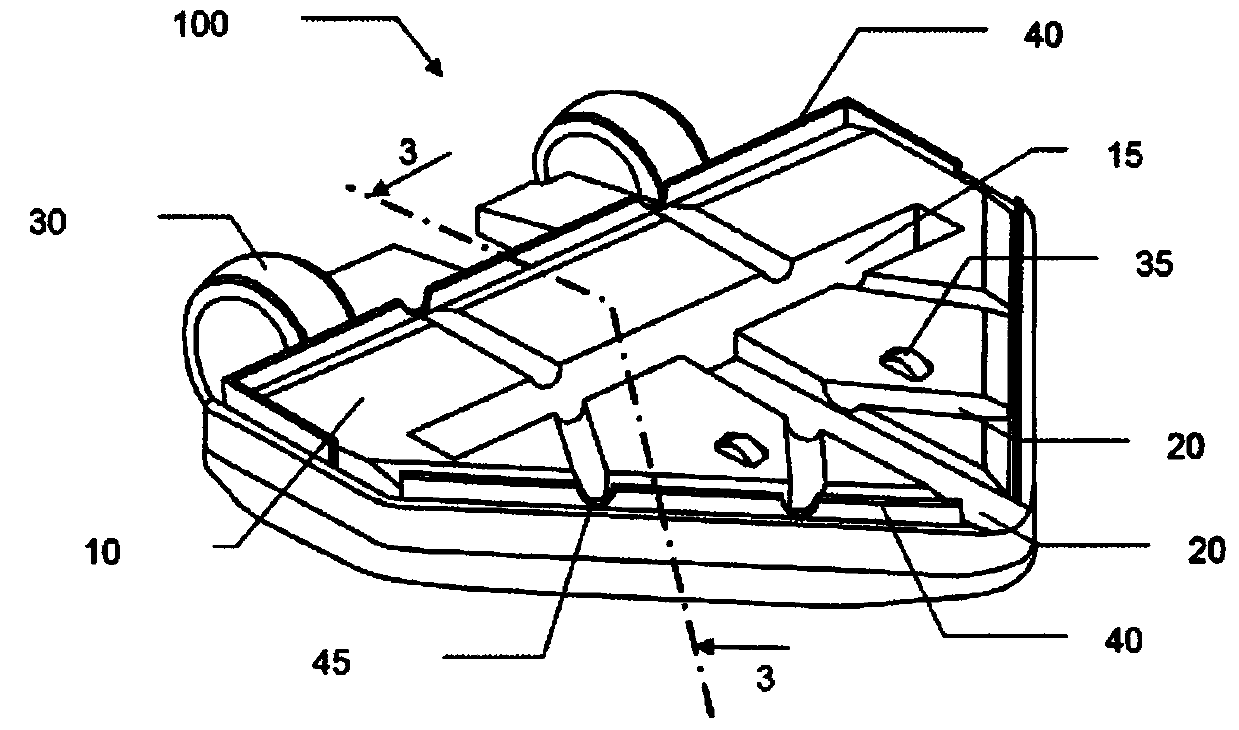

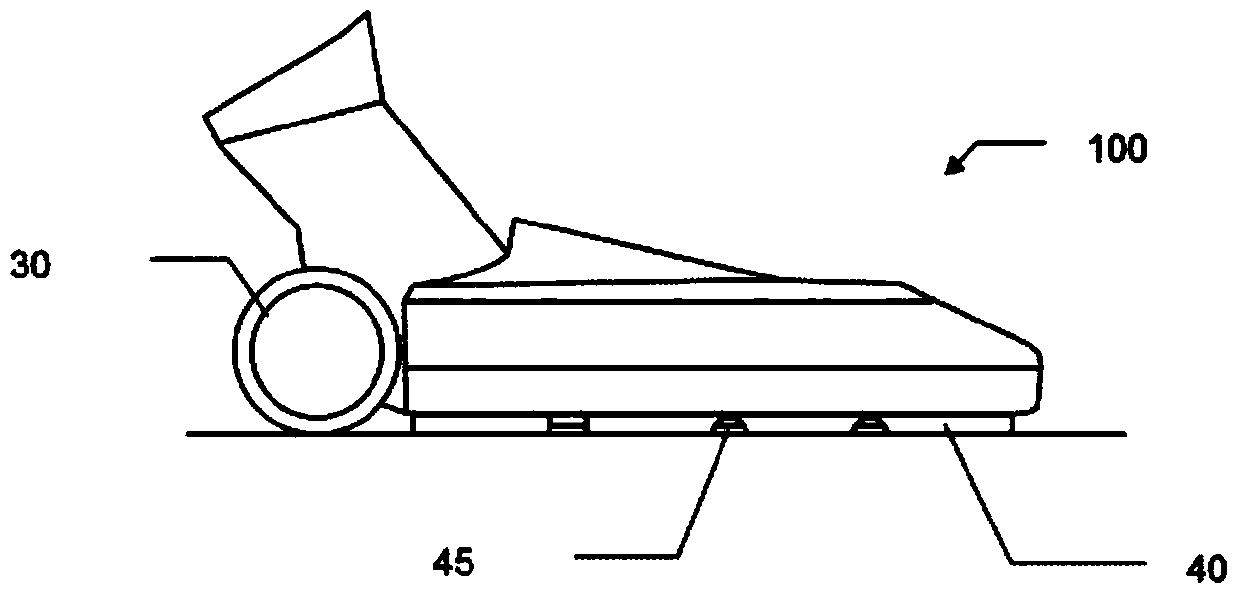

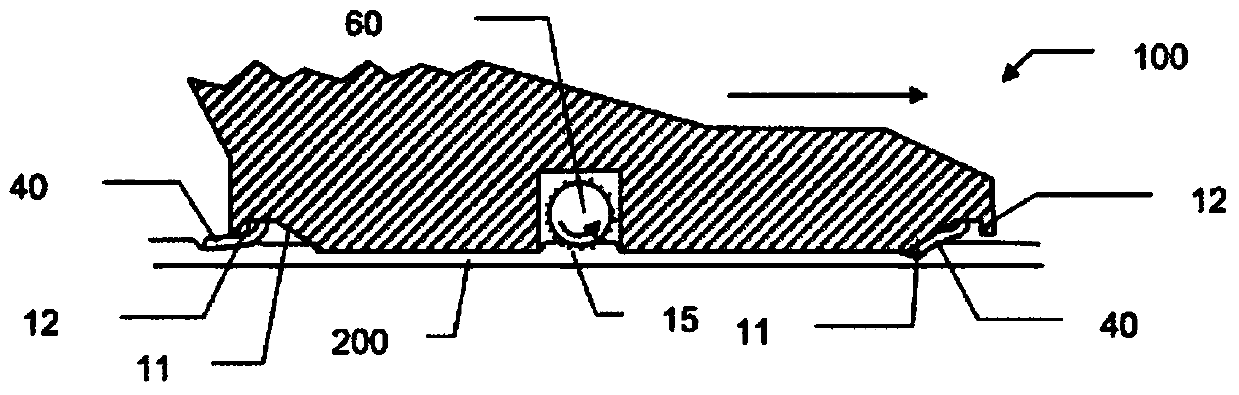

[0020] figure 1 A suction head 100 of a vacuum cleaner according to the invention is shown. The suction head 100 includes a lower base plate 10 with a plurality of suction ducts 20 opening towards the ground. The suction head also comprises wheels 30, 35, the contour of the rolling area of which is barrel-shaped and which define the ground clearance of the base plate 10 when the suction head is placed on a smooth surface. (garde au sol). The tip is generally triangular in shape and at least one of the conduits 20 leads to the tip of the tip. Each duct 20 connects, eg, a slit-shaped suction opening 15 towards the outside of the floor 10, so that the air sucked by the motor of the vacuum cleaner preferably travels in the duct of the floor. In order to have a good suction efficiency, the invention provides, inter alia, that a sealing lip or sealing skirt 40 is provided around the bottom plate. The sealing skirt 40 eliminates the leakage between the smooth ground and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com