Vacuum-type rotary slide pump

A technology of rotary vane vacuum pump and sliding vane, which is applied in the direction of rotary piston pump, rotary piston machine, pump, etc., can solve the problems of cost and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

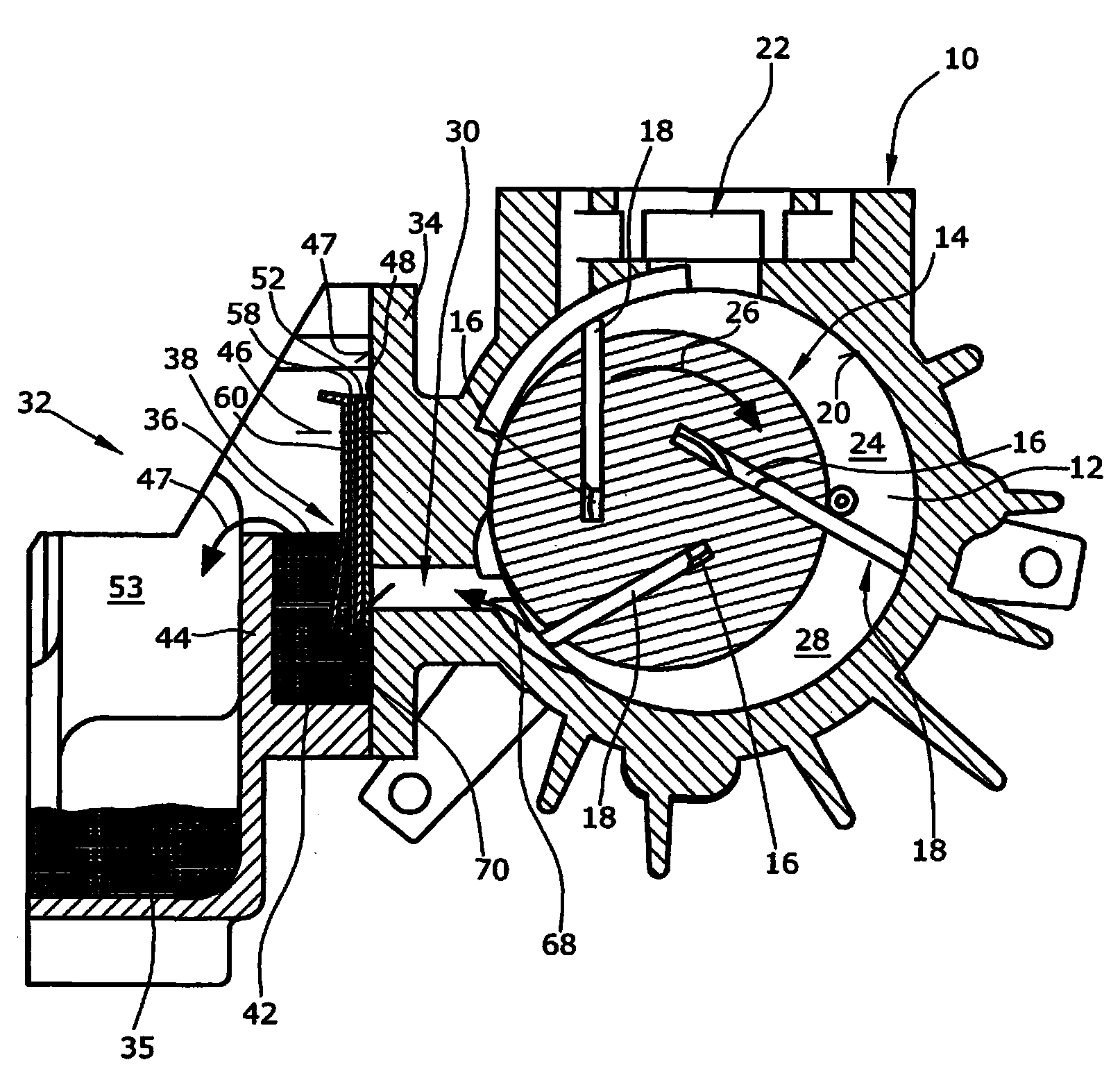

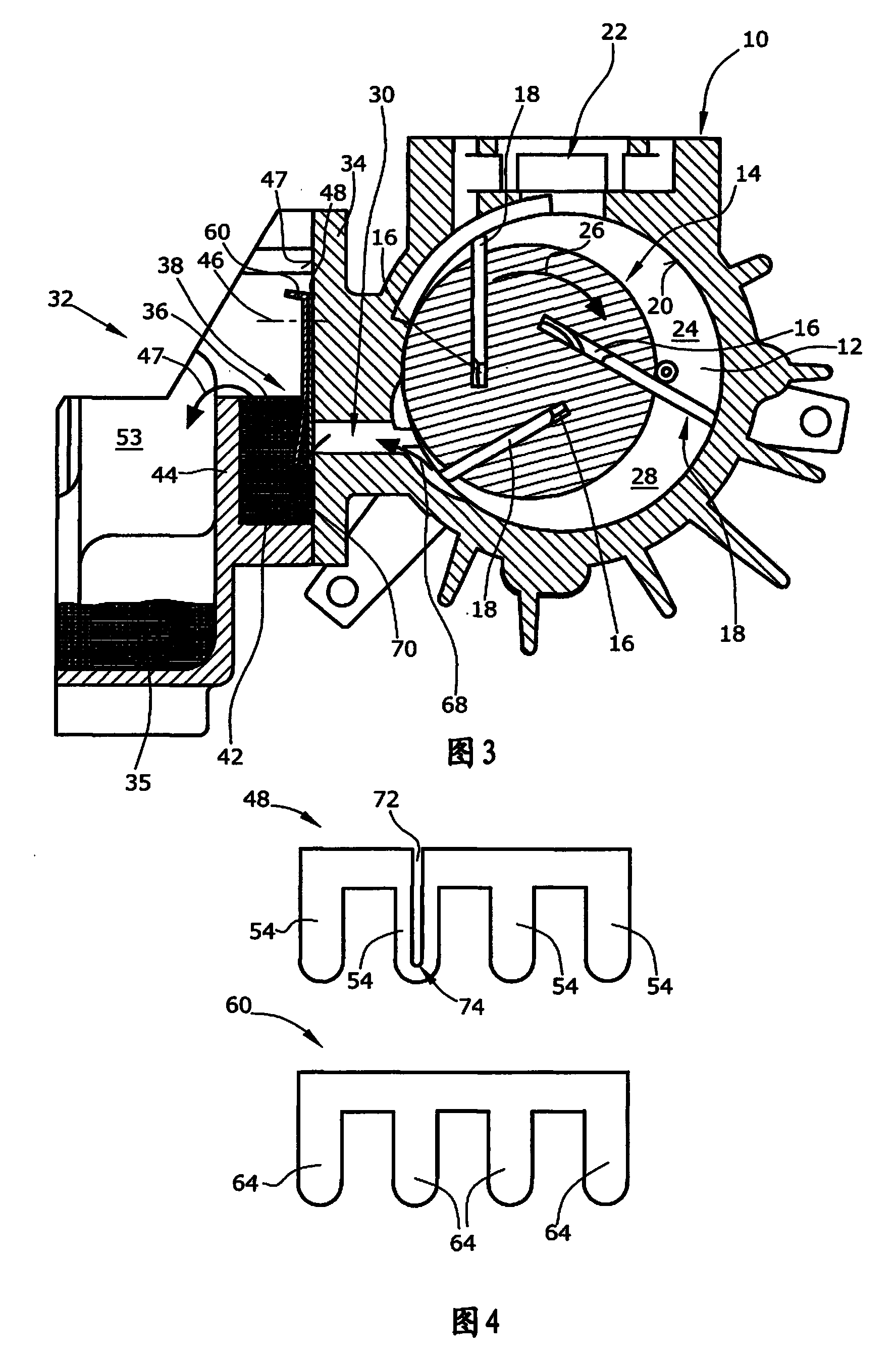

[0028] Rotary vane vacuum pump ( figure 1 ) has a housing 10. Inside the housing 10 there is a rotor 14 in the suction chamber 12 . In the exemplary embodiment shown, the rotor 14 has three vane gaps 16 , in which vane gaps 18 are respectively arranged. The slide 18 is pressed against the inner wall 20 of the suction chamber due to the centrifugal force by the rotation of the rotor 14 .

[0029] The medium is sucked from the chamber to be evacuated into a first region 24 of the suction chamber 12 via a suction opening 22 connected to the chamber to be evacuated. The area 24 of the suction chamber 12 is delimited by two adjacent slides 18 . A region 28 of the suction chamber 12 that is located upstream of the region 24 in the direction of rotation 26 is reduced by the rotation of the rotor 14 , so that the medium located therein is compressed. The medium is conveyed from the area 28 through the outlet channel 30 from the suction chamber 12 in the direction of the oil chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com