Suction nozzle sliding base plate of a vacuum cleaner

A technology of vacuum cleaners and sealing plates, applied in the direction of suction nozzles, etc., can solve the problems of expensive, non-scratching, and complicated suction nozzle structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

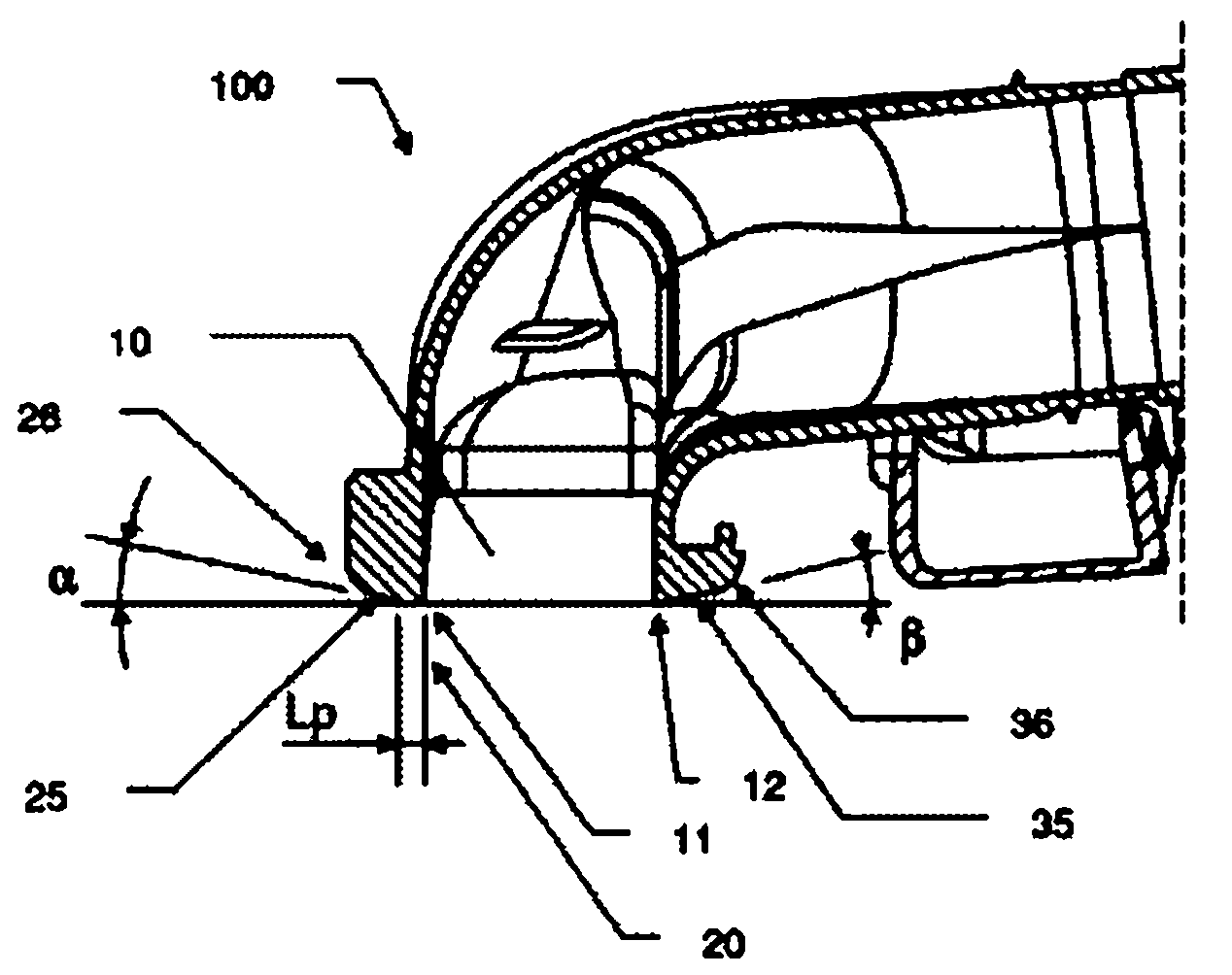

[0016] figure 1 A cutaway view of a vacuum cleaner nozzle base 100 for cleaning textile floors is shown. The base 100 has a suction channel 10 arranged along the entire base 100 . The channel is bounded at the front by a front scraping edge 11 and at the rear by a rear scraping edge 12 . The pressure drop and the air flow rate in the suction channel 10 produced by the suction of the vacuum cleaner motor have values determined in particular according to the resistance loss imposed on the air flow entering into the suction channel 10 . This drag loss depends on the airflow path, which is defined according to the contour of the base 100 . The air flow entering through the front passes under the front scraping edge 11 , but also under the sealing plate 20 . This sealing plate 20 is contained in the wiping plane defined by the two wiping edges 11 and 12 . The width of the sealing panel 20 in contact with the ground requires that the air flow passes over the textile floor at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com