Drying and dust collecting device for textile fabric

A technology for textile fabrics and dust collectors, which is applied in the directions of drying, dryer, drying gas arrangement, etc., can solve the problems that textile fabrics cannot be effectively dried, dust collection, effective moving distance, and single structure, etc. To achieve the effect of efficient dust collection and drying, reasonable structure and extended transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

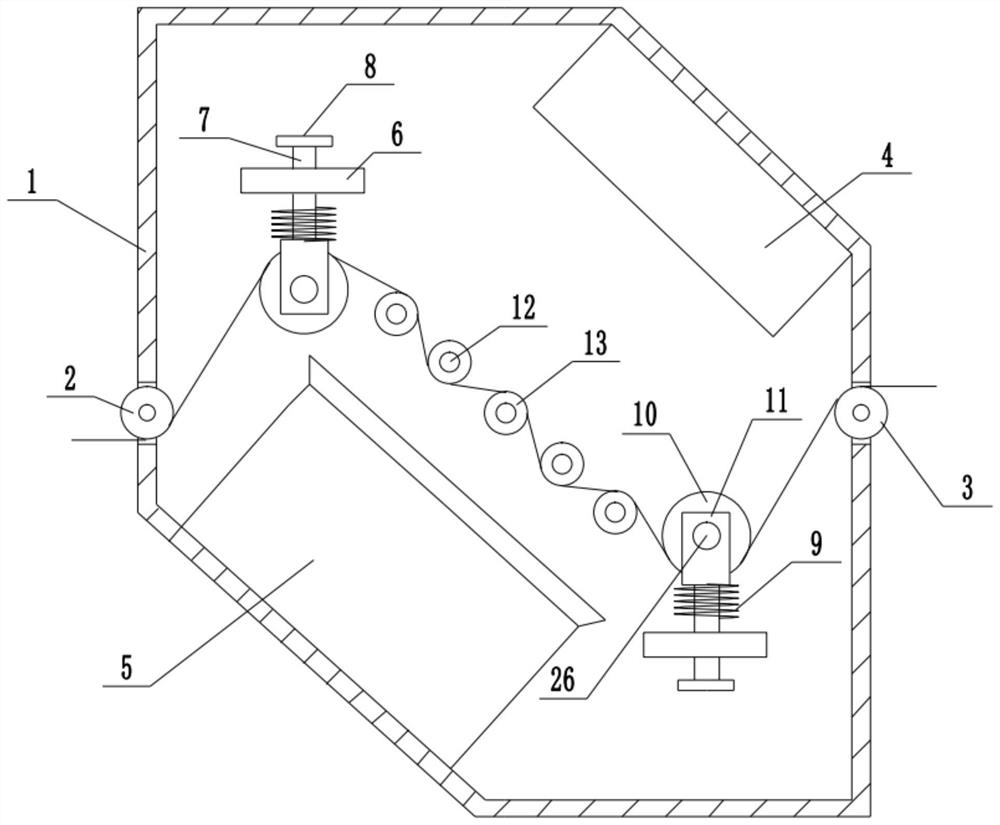

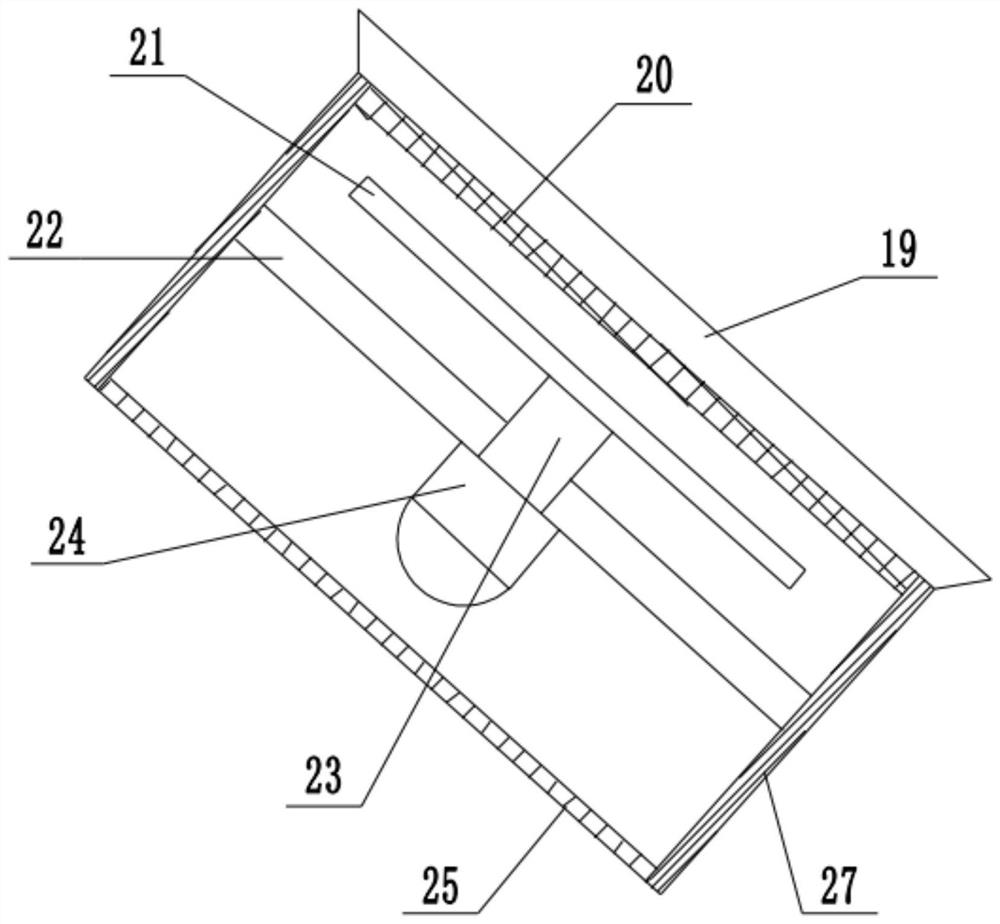

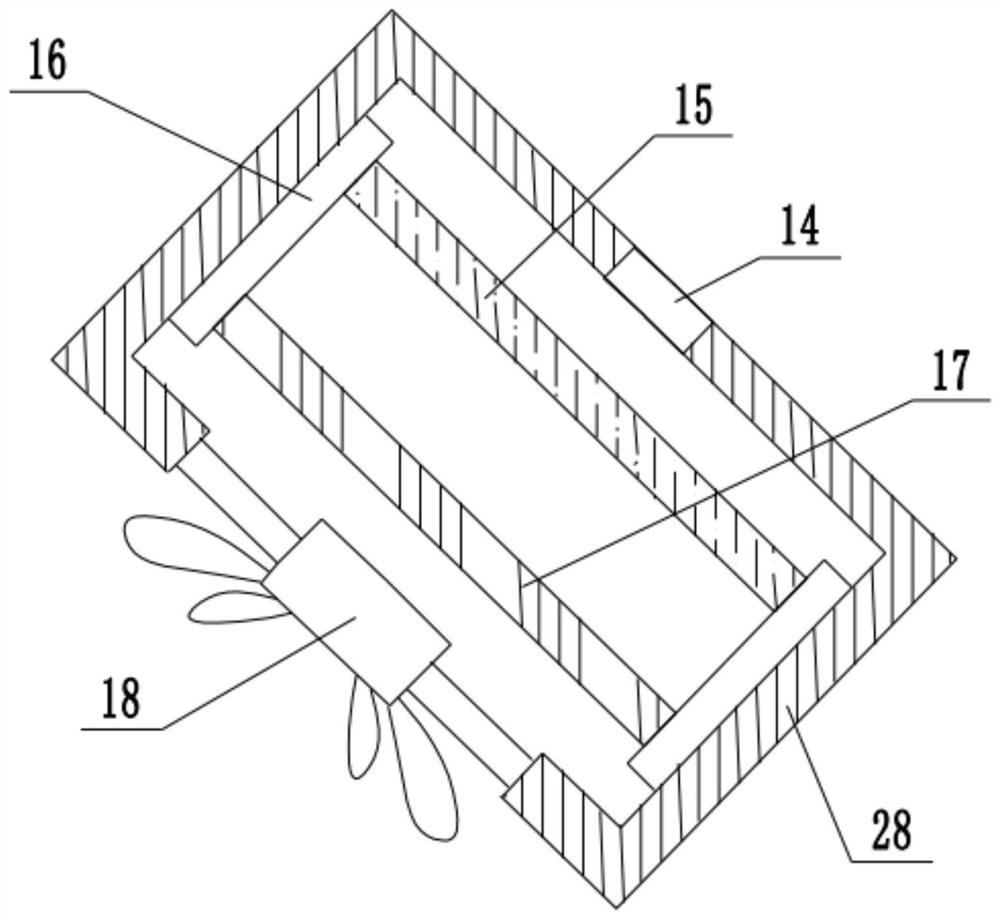

[0029] refer to Figure 1~4 , in an embodiment of the present invention, a drying and dust collection device for textile fabrics includes a drying and dust collection box 1, a feed roller 2 is installed at the left end of the drying and dust collection box 1, and an outlet roller is installed at the right end of the drying and dust collection box 1. The feed roller 3, the feed roller 2 and the discharge roller 3 are connected by a belt, and the output shaft of the same motor is connected, the transmission of the textile fabric is ensured by the feed roller 2 and the discharge roller 3, A tensioning mechanism 1 is installed at the diagonal position inside the drying and dust-absorbing box. The tensioning mechanism includes a baffle 6, and the middle part of the baffle 6 is slidingly provided with a telescopic column 7, and one end of the telescopic column 7 passes through the baffle 6 Be connected with block 8, the other end passes through baffle plate 6 and is connected with t...

Embodiment 2

[0033]In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that, wherein, the outer wall of the dust suction cylinder 13 is provided with a friction pattern area, and setting the friction pattern area can make the dust suction cylinder 13 The dust on the fabric can be effectively scraped during the rubbing and rolling process of the fabric, and then the dust removal mechanism 4 can effectively remove dust.

[0034] In the present invention, when working, the textile fabric is conveyed, and then the fabric is conveyed in an orderly manner under the action of the rotating wheel 10 and the guide roller 12. Under the action of the drying mechanism 5, the hot air is discharged to dry the fabric, and at the same time, the generated hot air flow leads the dust into the dust removal mechanism 4, and then effectively removes dust under the action of the dust removal mechanism 4. The whole process is reliable and eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com