Patents

Literature

190results about How to "Extend the flow path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

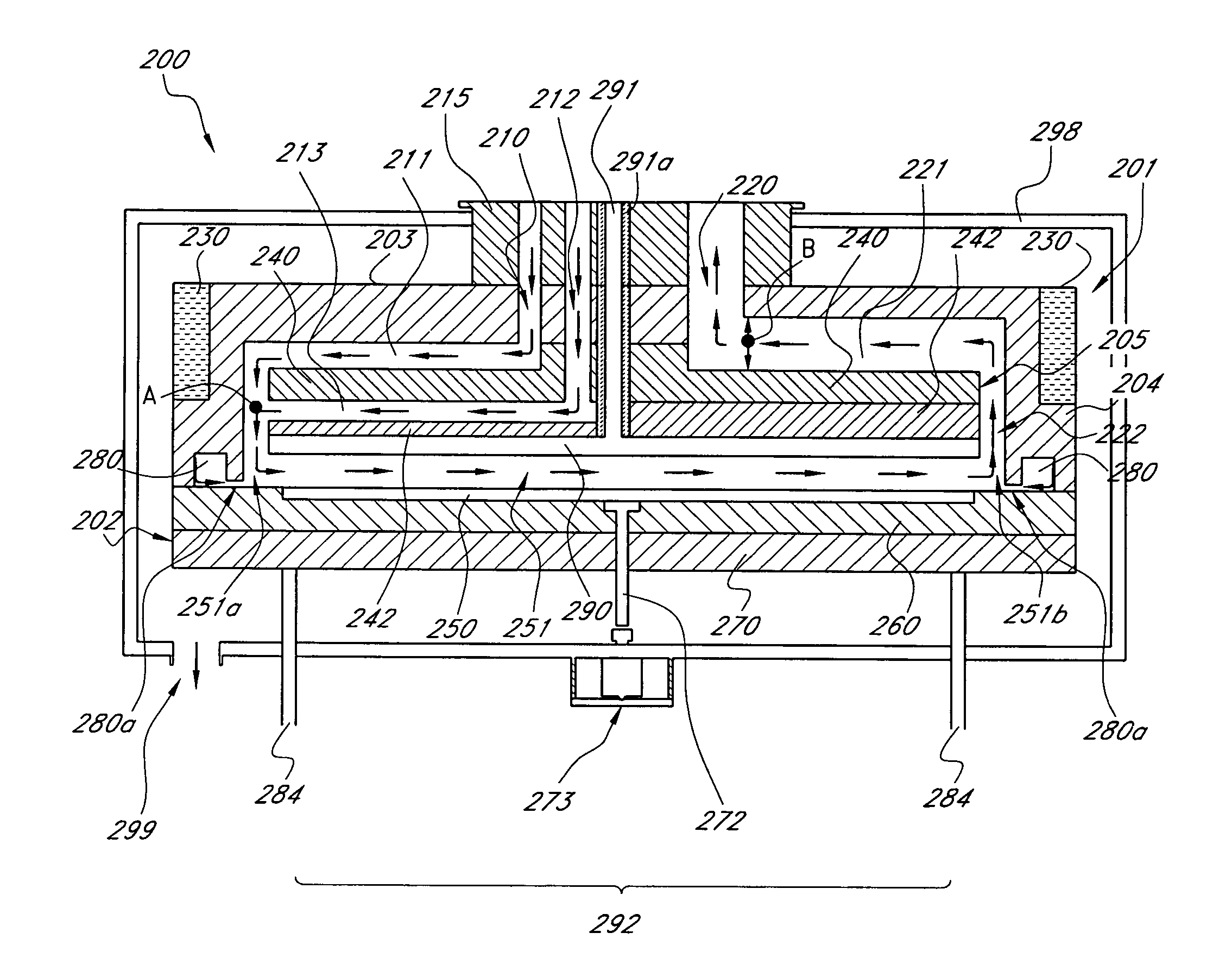

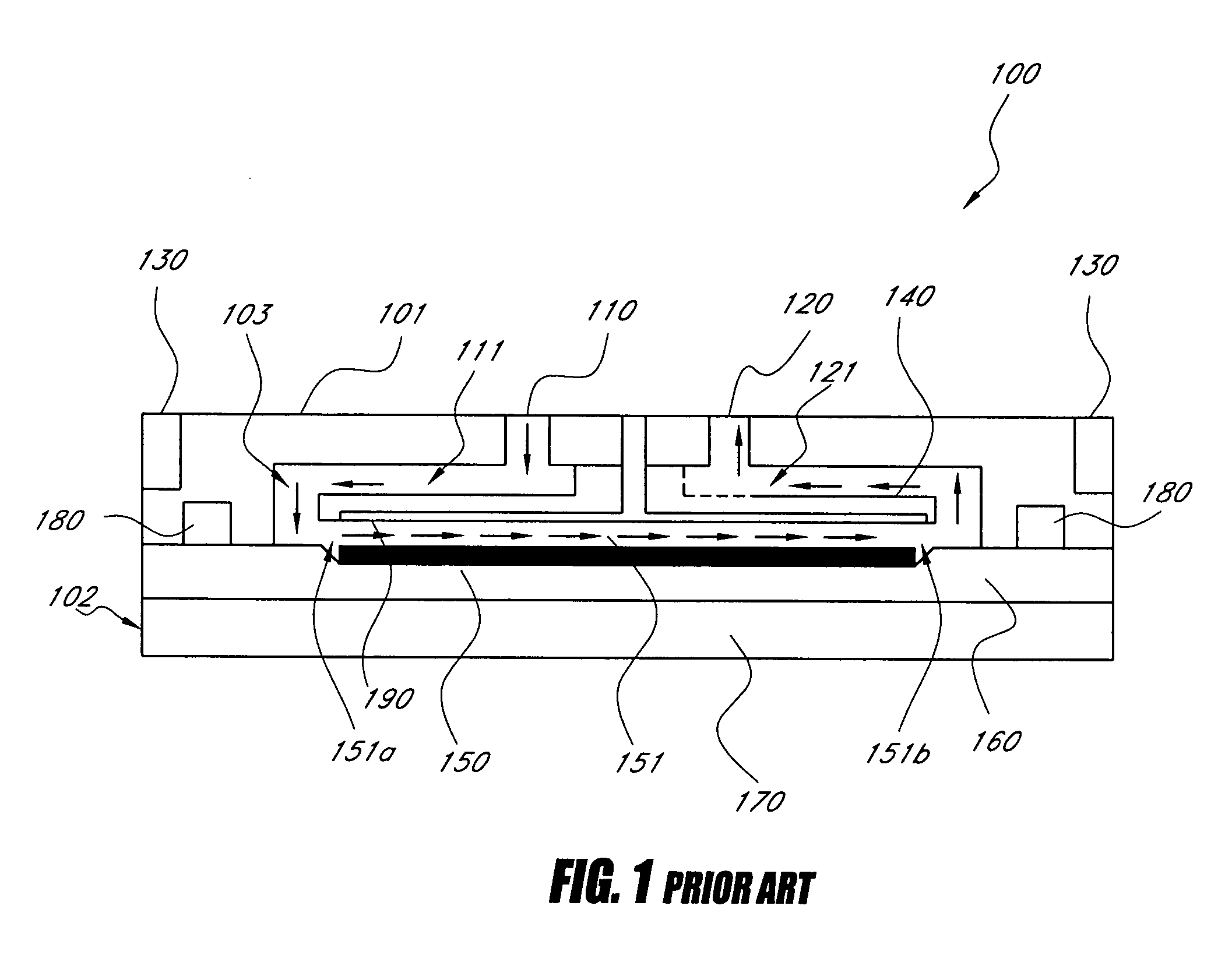

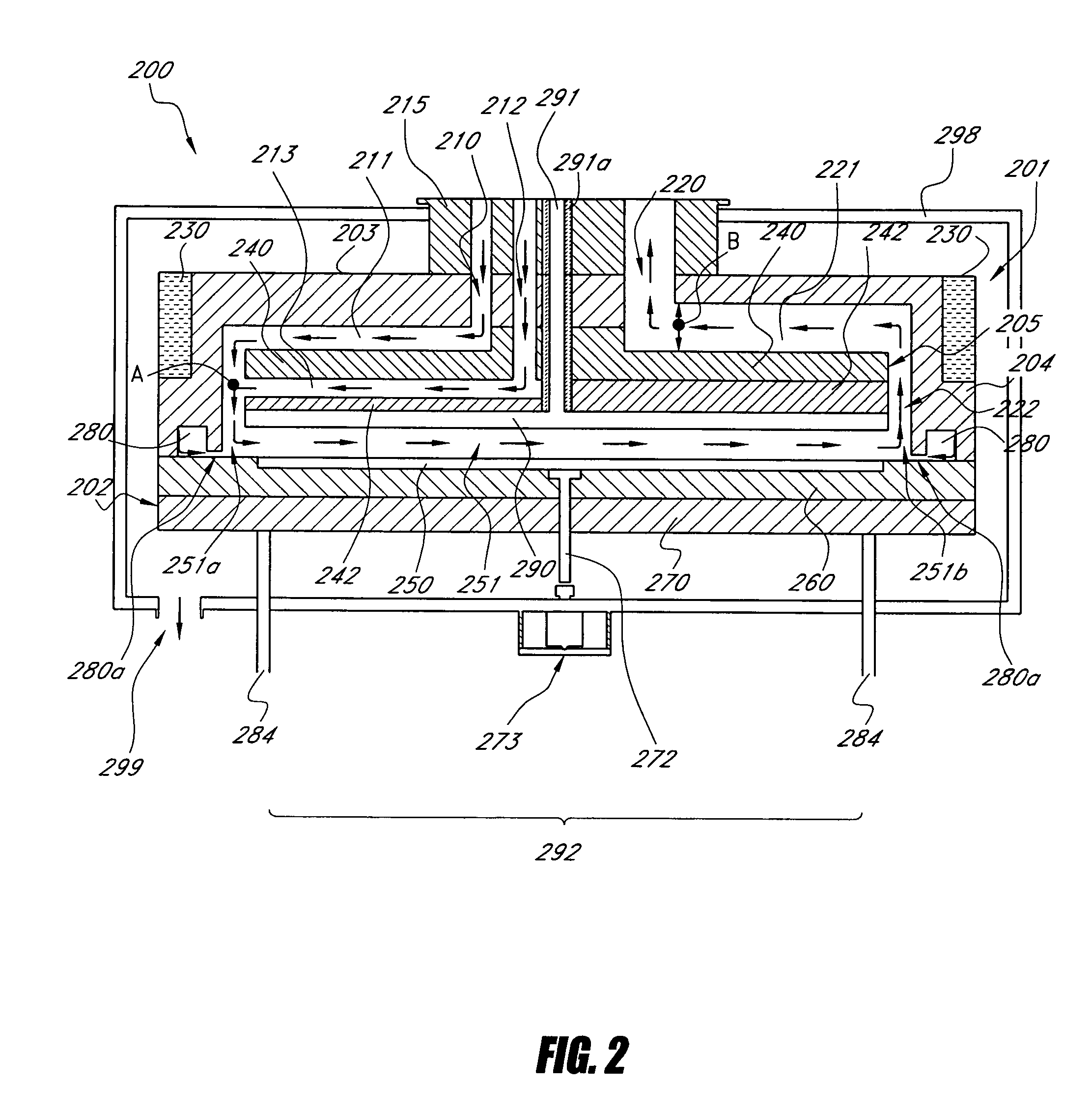

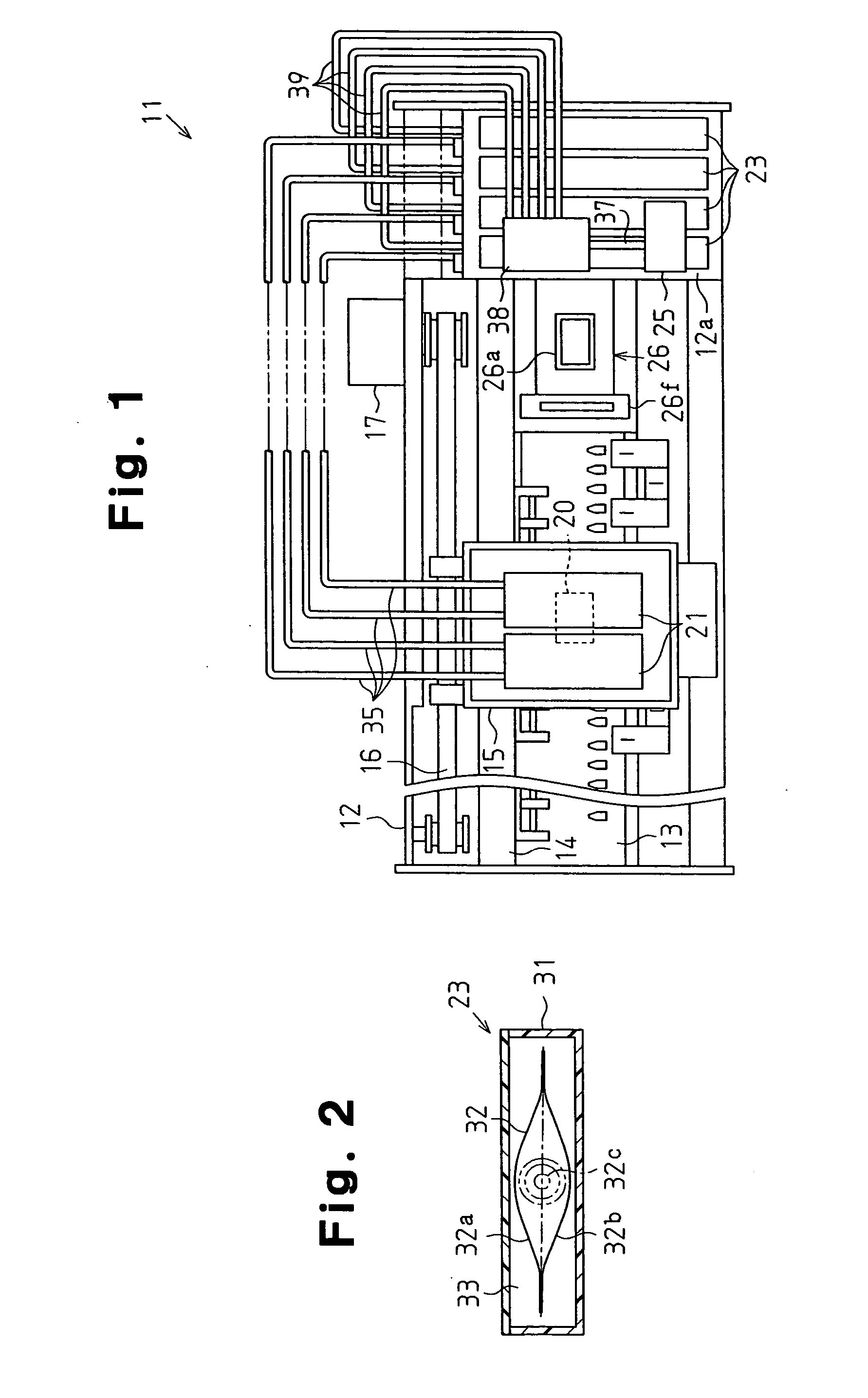

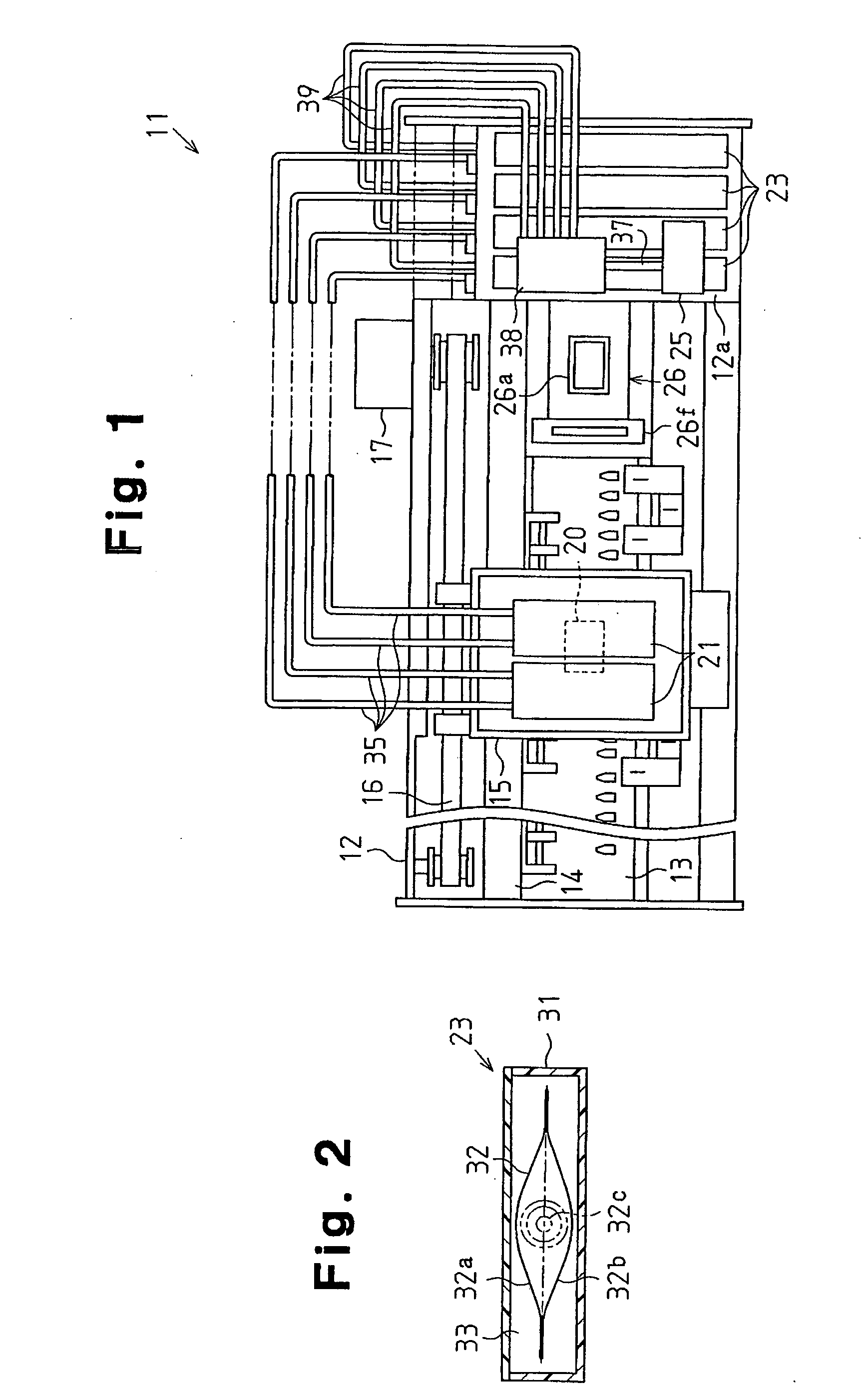

Multiple inlet atomic layer deposition reactor

InactiveUS20060249077A1Flow is rather complicatedQuick switchSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNuclear engineeringVapor phase

A reactor configured to subject a substrate to alternately repeated surface reactions of vapor-phase reactants is disclosed. The reactor includes a reaction chamber, a plurality of inlets, and an exhaust outlet. The reaction chamber includes a reaction space. The reactor also includes a gas flow control guide structure within the reaction chamber. The gas flow control guide structure resides over the reaction space and is interposed between the plurality of inlets and the reaction space. The gas flow control guide structure includes a plurality of channels, and each of the channels extends from one of the inlets to an upstream periphery of the reaction space. Each of the channels progressively widens as the channel extends from the inlet to the reaction space. The reactor further includes a substrate holder in the reaction space.

Owner:ASM GENITECH KOREA

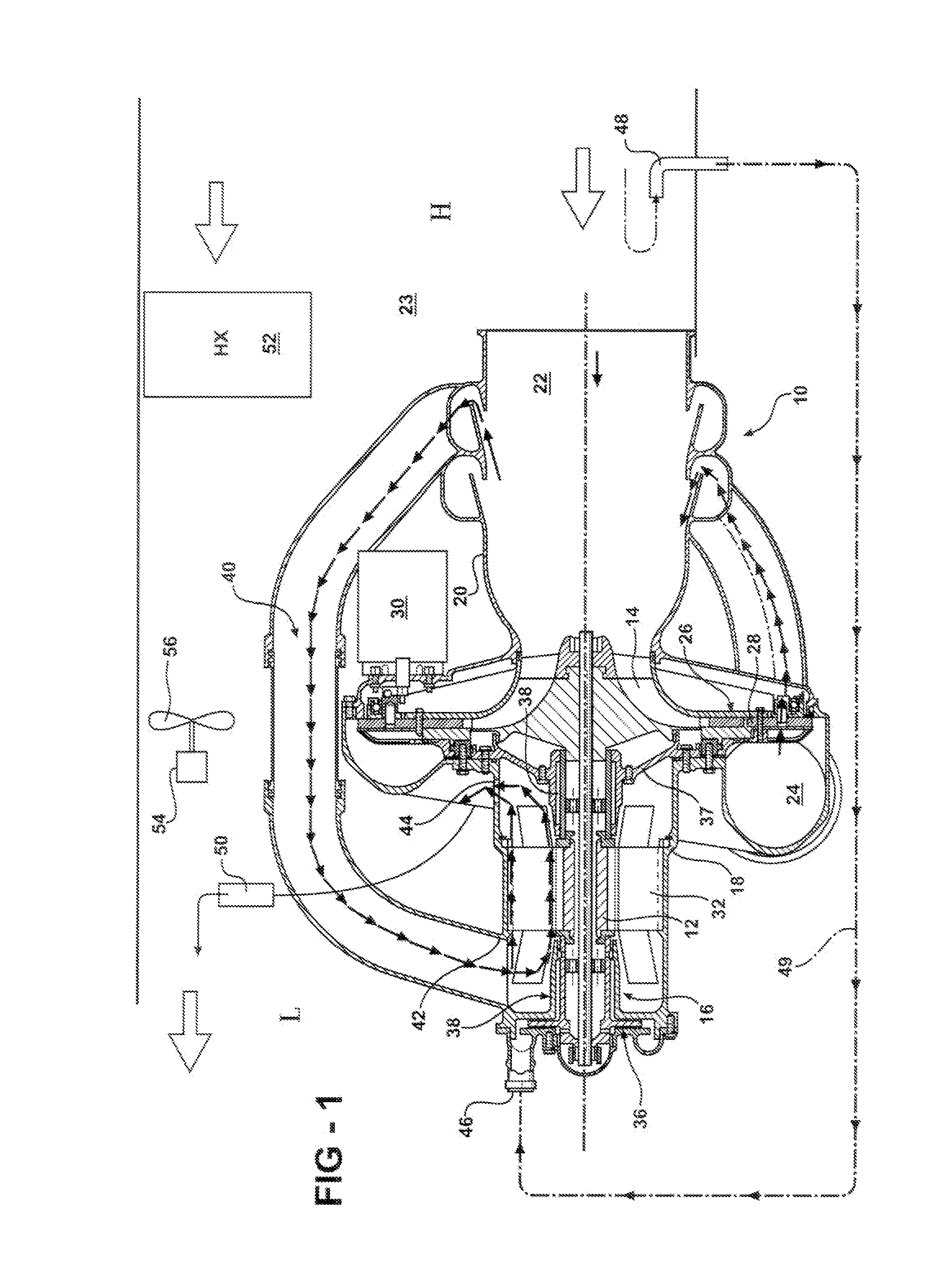

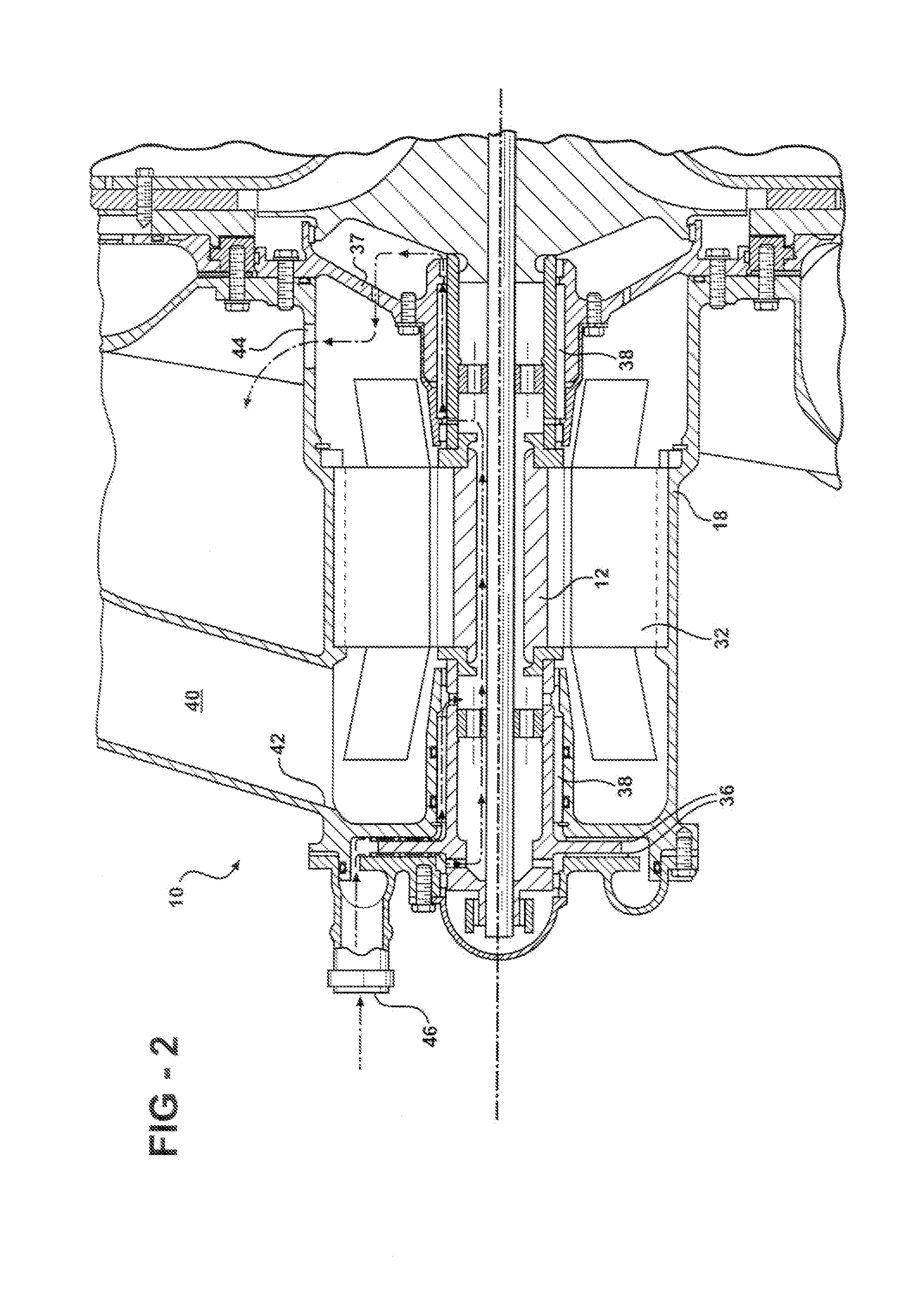

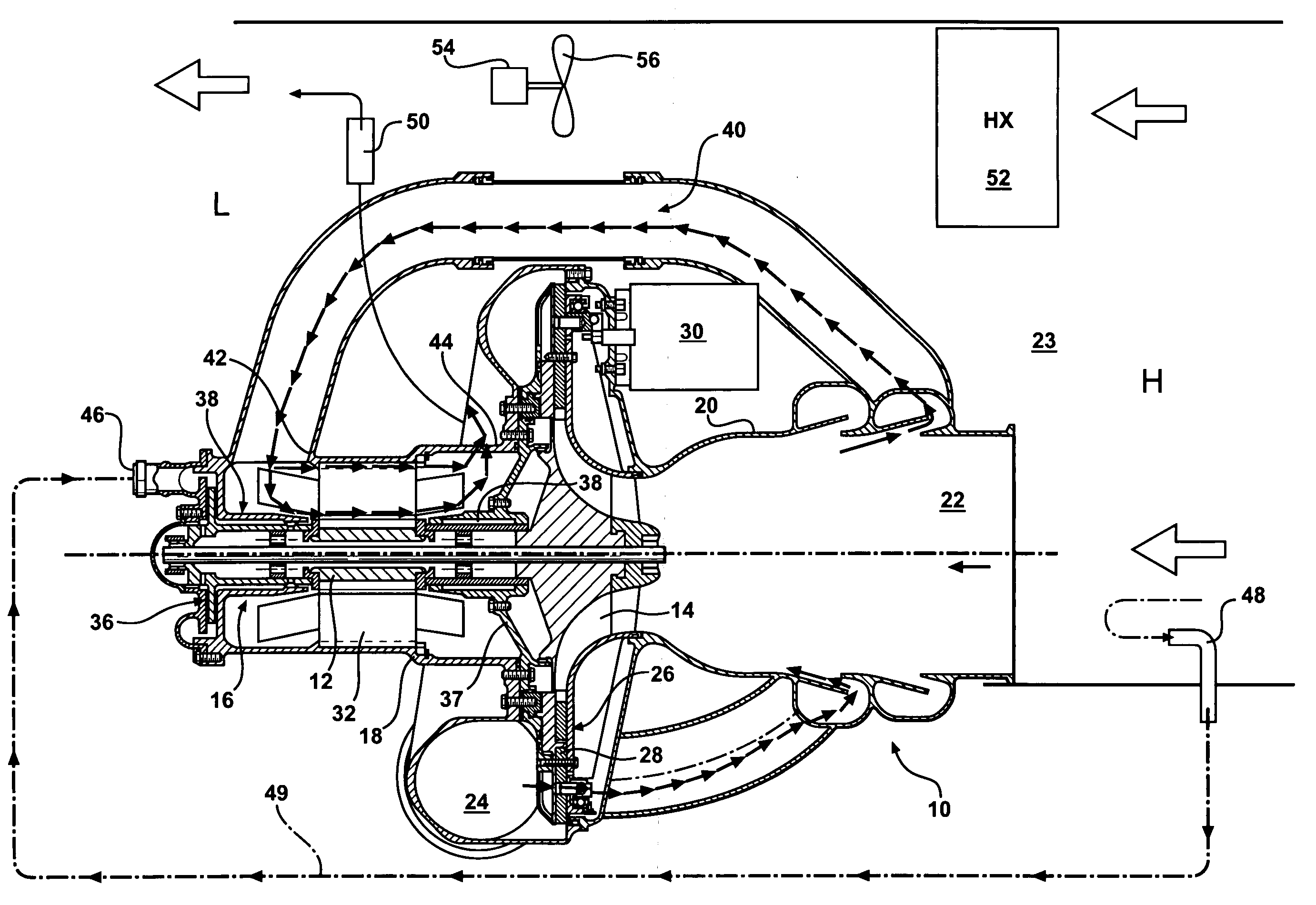

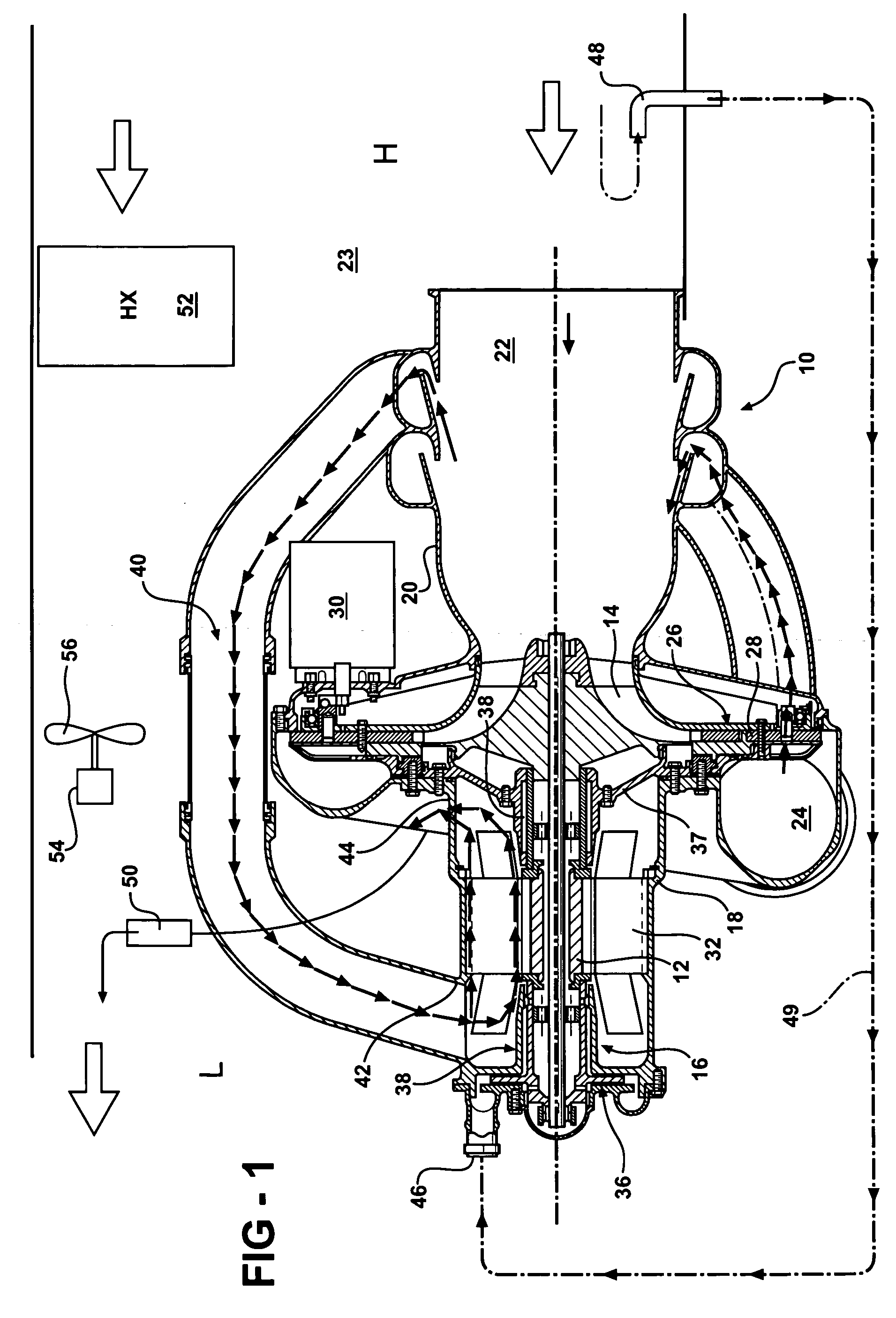

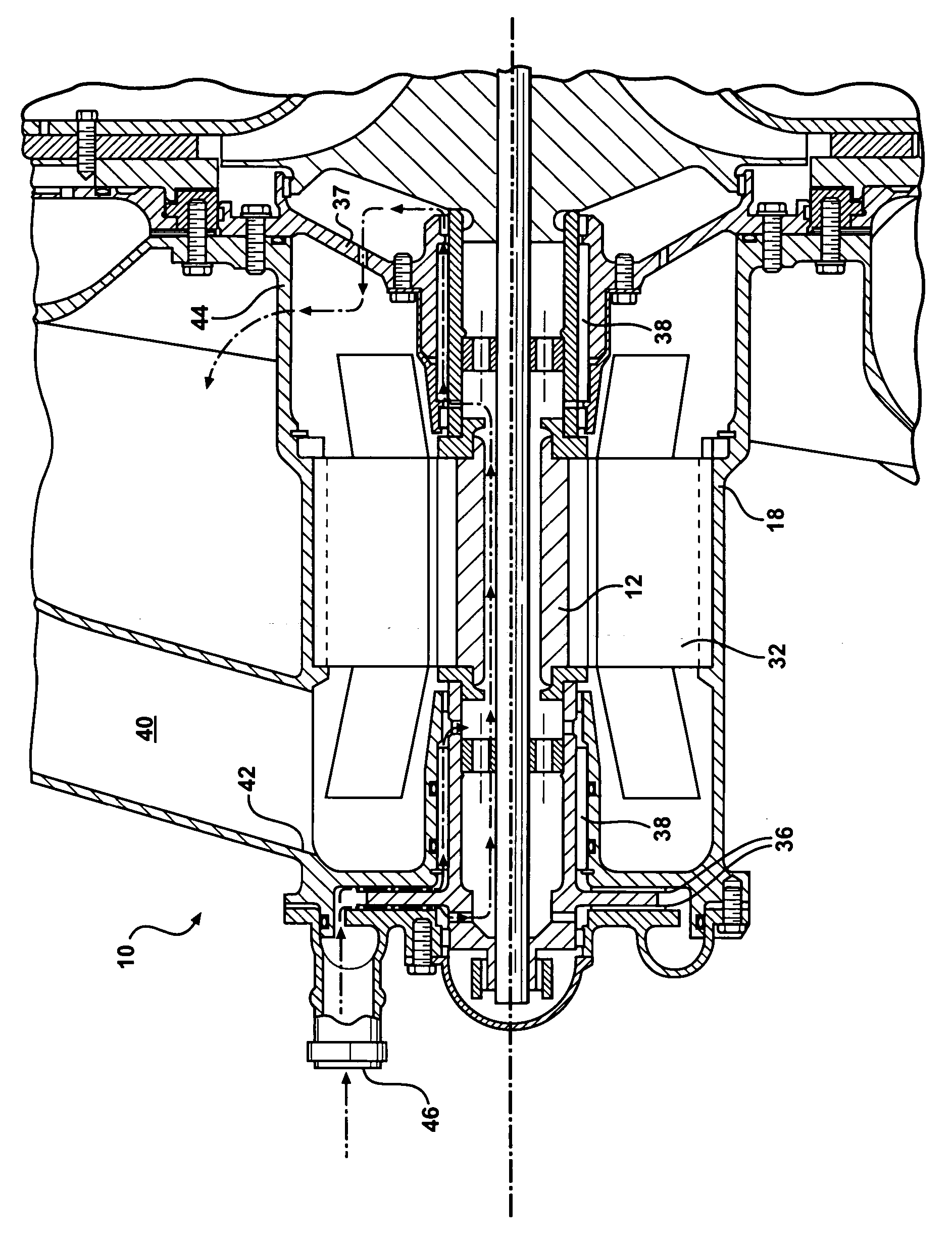

Air bearing and motor cooling

ActiveUS7342332B2Extend the flow pathEfficiently providePositive displacement pump componentsPiston pumpsAir bearingDifferential pressure

Owner:HAMILTON SUNDSTRAND CORP

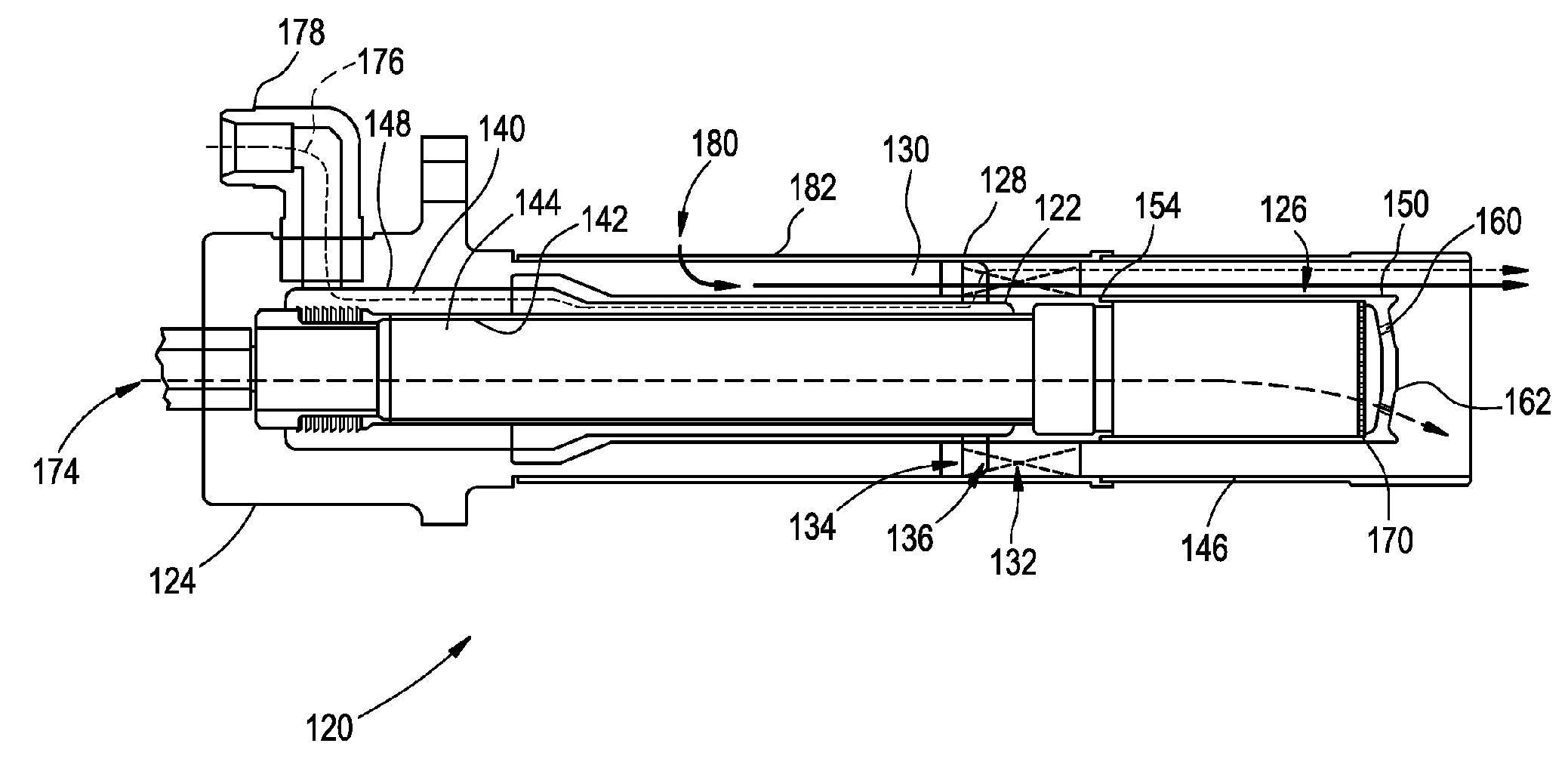

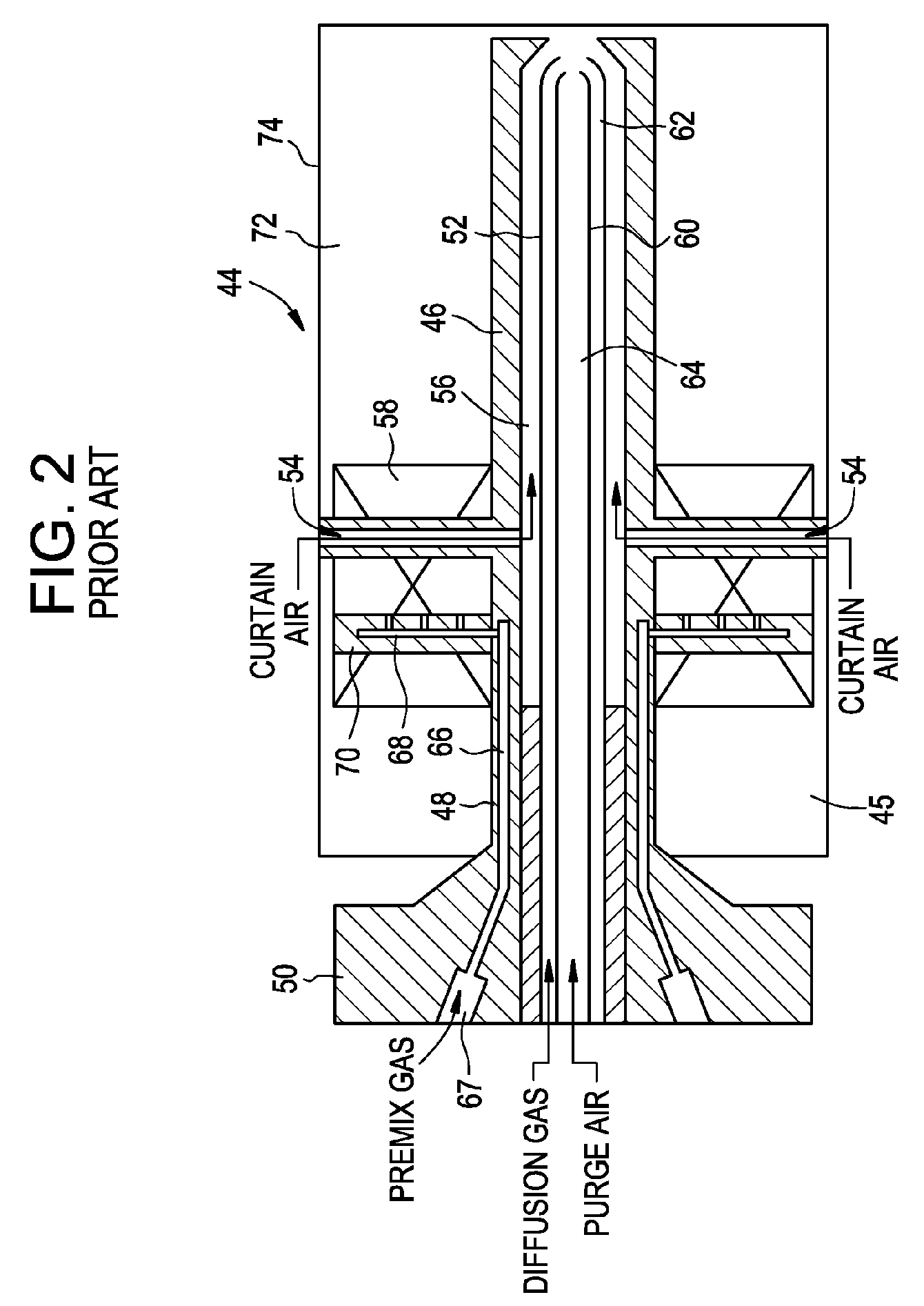

Method and apparatus for cooling gas turbine fuel nozzles

InactiveUS20060191268A1Preventing thermal distressExtend the flow pathTurbine/propulsion fuel supply systemsContinuous combustion chamberGas turbinesFuel gas

A method and apparatus for a nozzle of a gas turbine engine is disclosed that facilitates extending a useful life of the nozzle. The method and apparatus include an impingement baffle plate disposed at a back side of a diffusion tip of the nozzle. The method and apparatus includes the impingement baffle plate formed with an array of orifices creating jets for fuel or purge air to impinge on the diffusion tip. In this manner, cooling via convection through diffusion orifices in the diffusion tip is preserved, and cooling is made more robust.

Owner:GENERAL ELECTRIC CO

Air bearing and motor cooling

ActiveUS20060061222A1Improved cooling flow pathEfficiently providePositive displacement pump componentsPiston pumpsAir bearingDifferential pressure

A motor includes a housing including separate motor and bearing cooling inlets. A motor is arranged within the housing and includes a stator and rotor assembly that is supported on air bearings. The motor cooling inlet is in fluid communication with the stator, and the bearing cooling inlet is in fluid communication with the air bearings. A vent is arranged in the housing and is common to the motor and bearing cooling inlets. The vent is in fluid communication with a low pressure side of a ram air duct. The bearing cooling duct is in fluid communication with a high pressure side of a ram air duct, such as through a reverse J-tube. A differential pressure between the high and low pressure sides moves cooling fluid from the bearing cooling inlet to the vent to cool the bearings.

Owner:HAMILTON SUNDSTRAND CORP

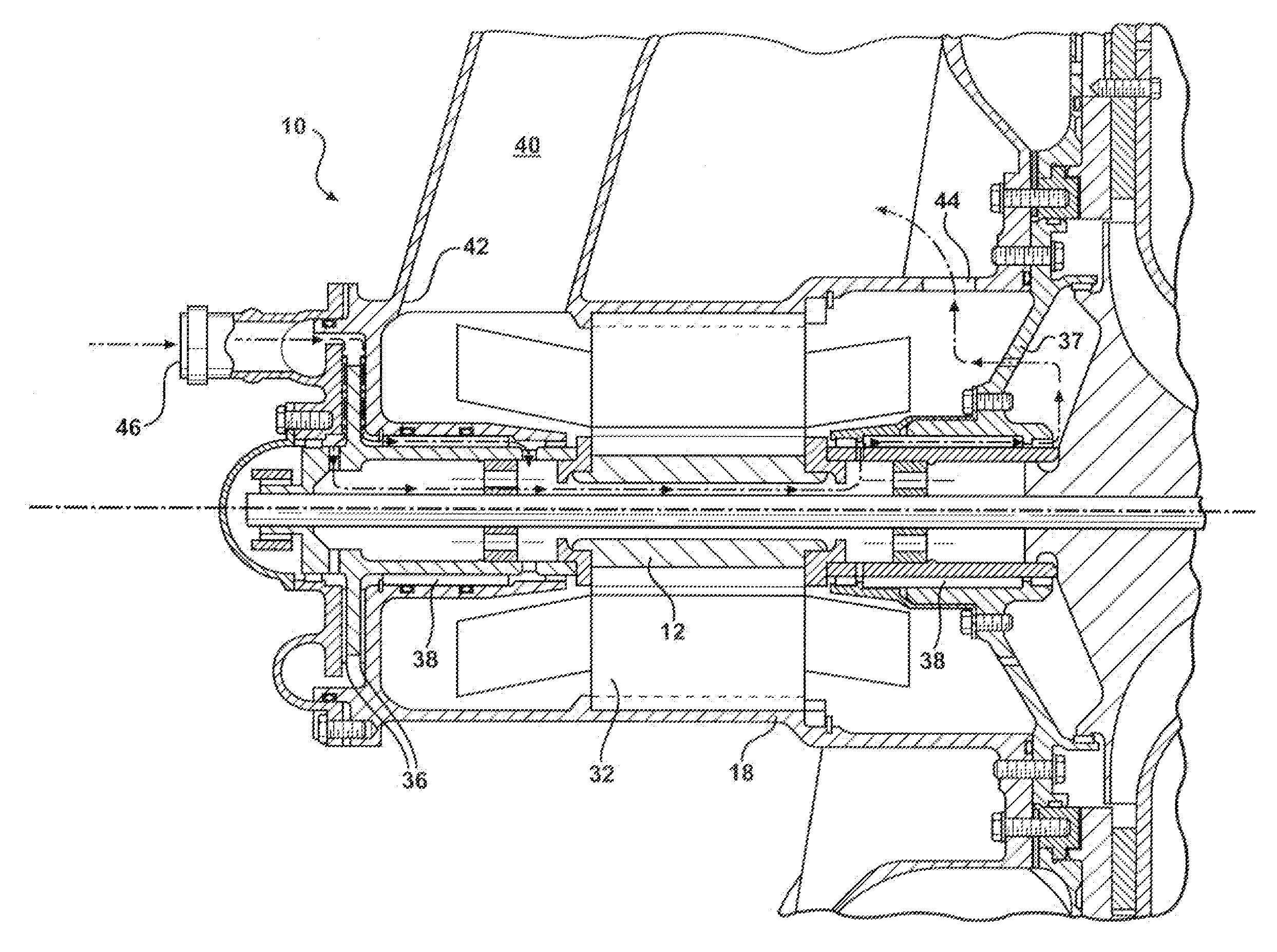

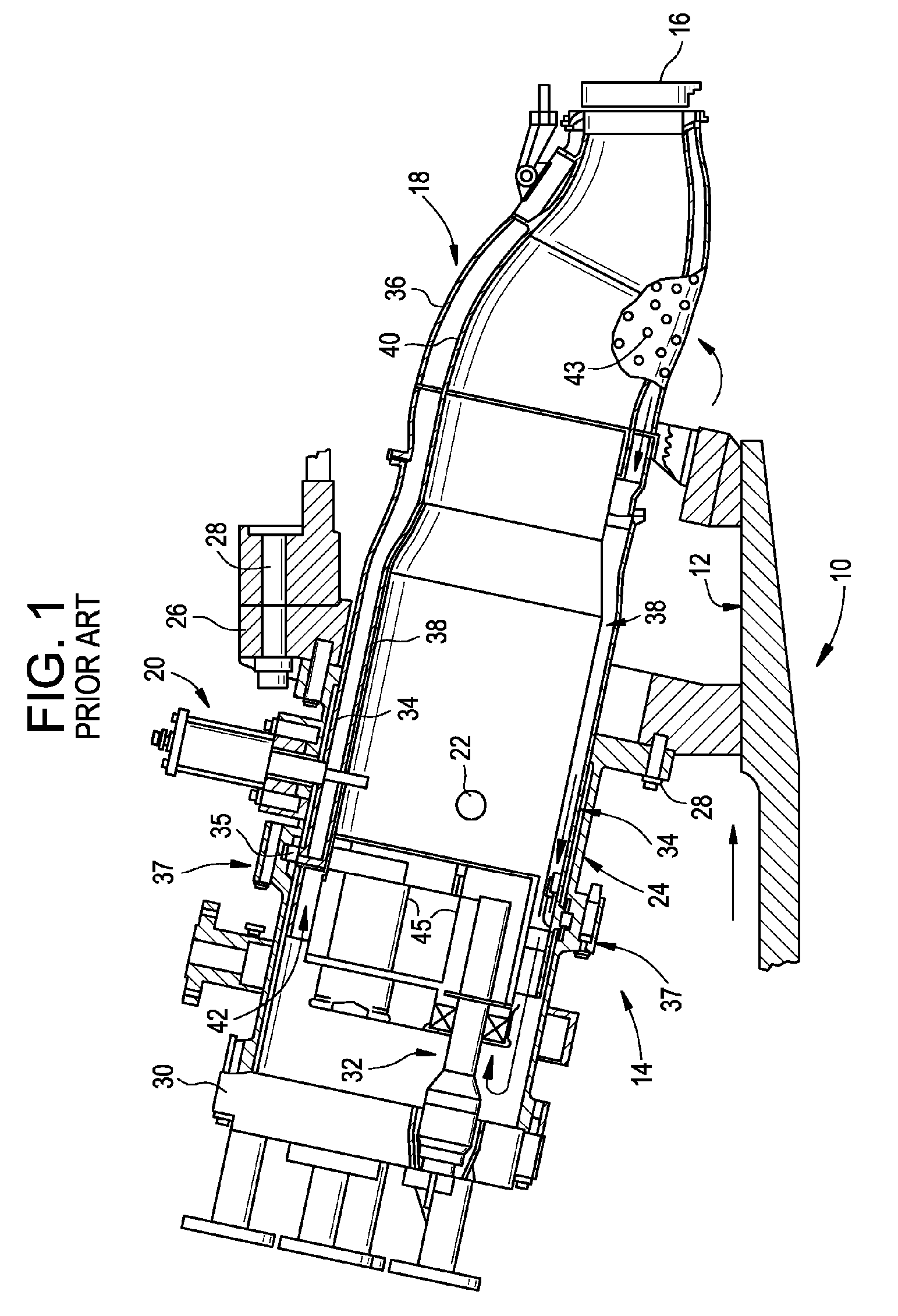

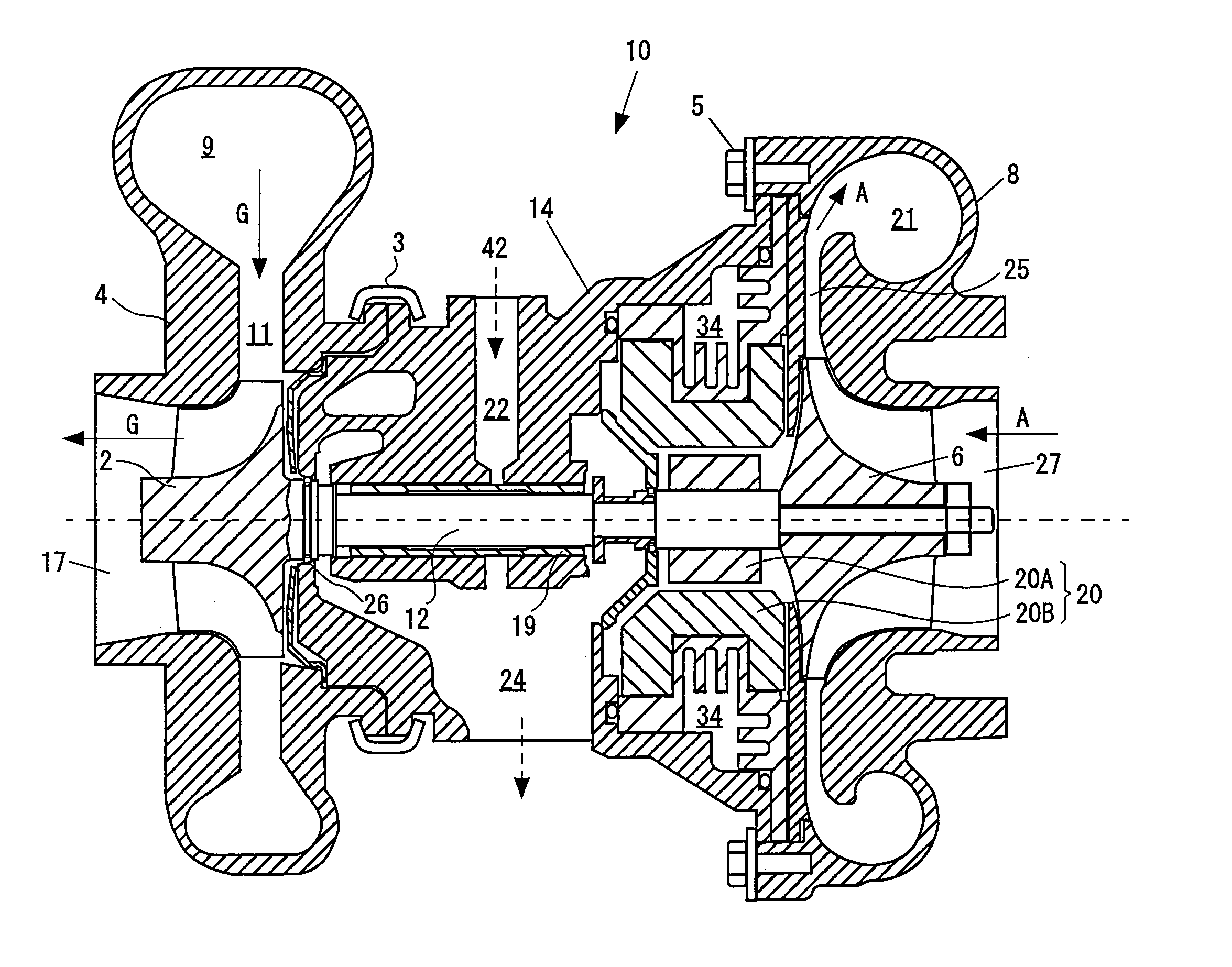

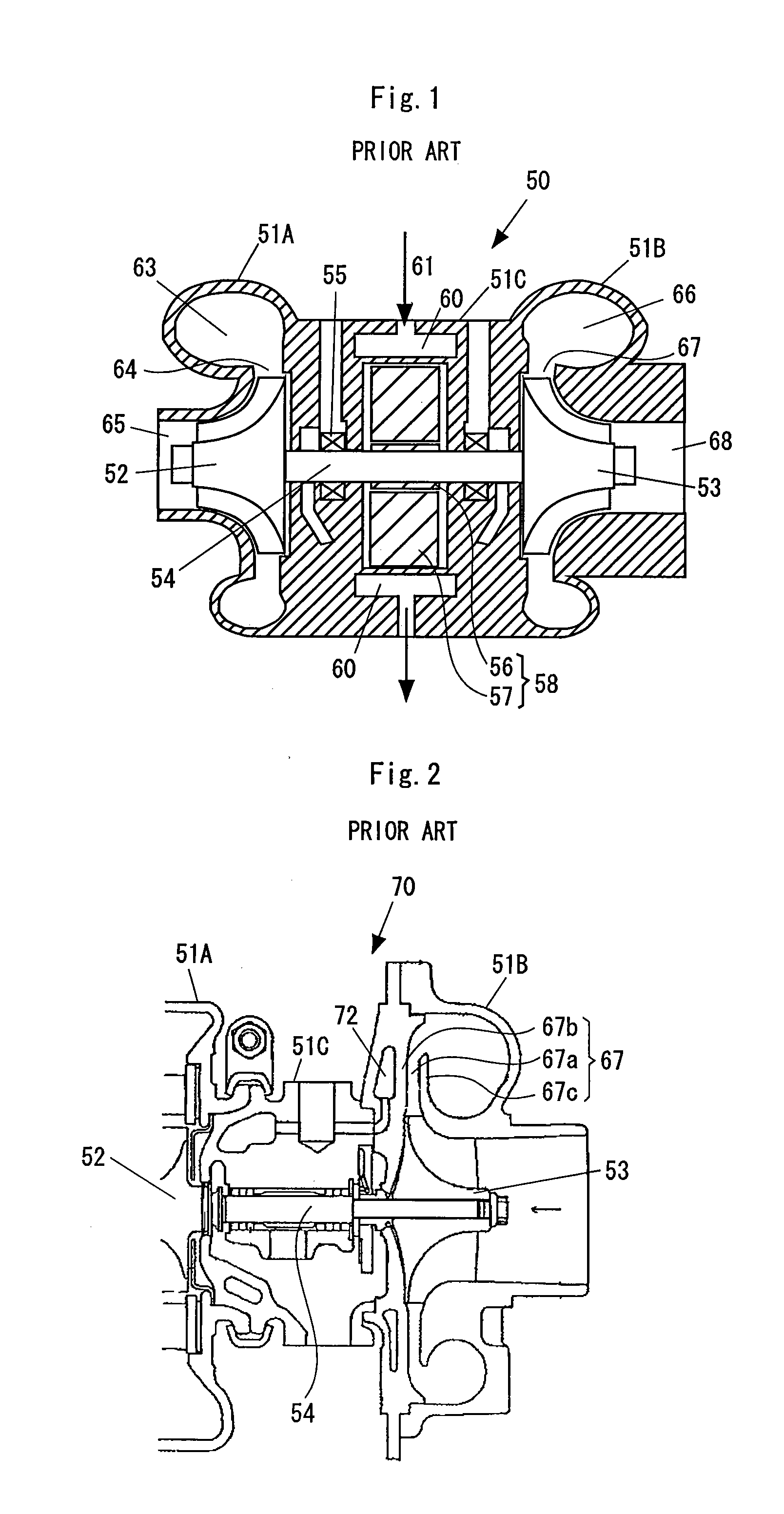

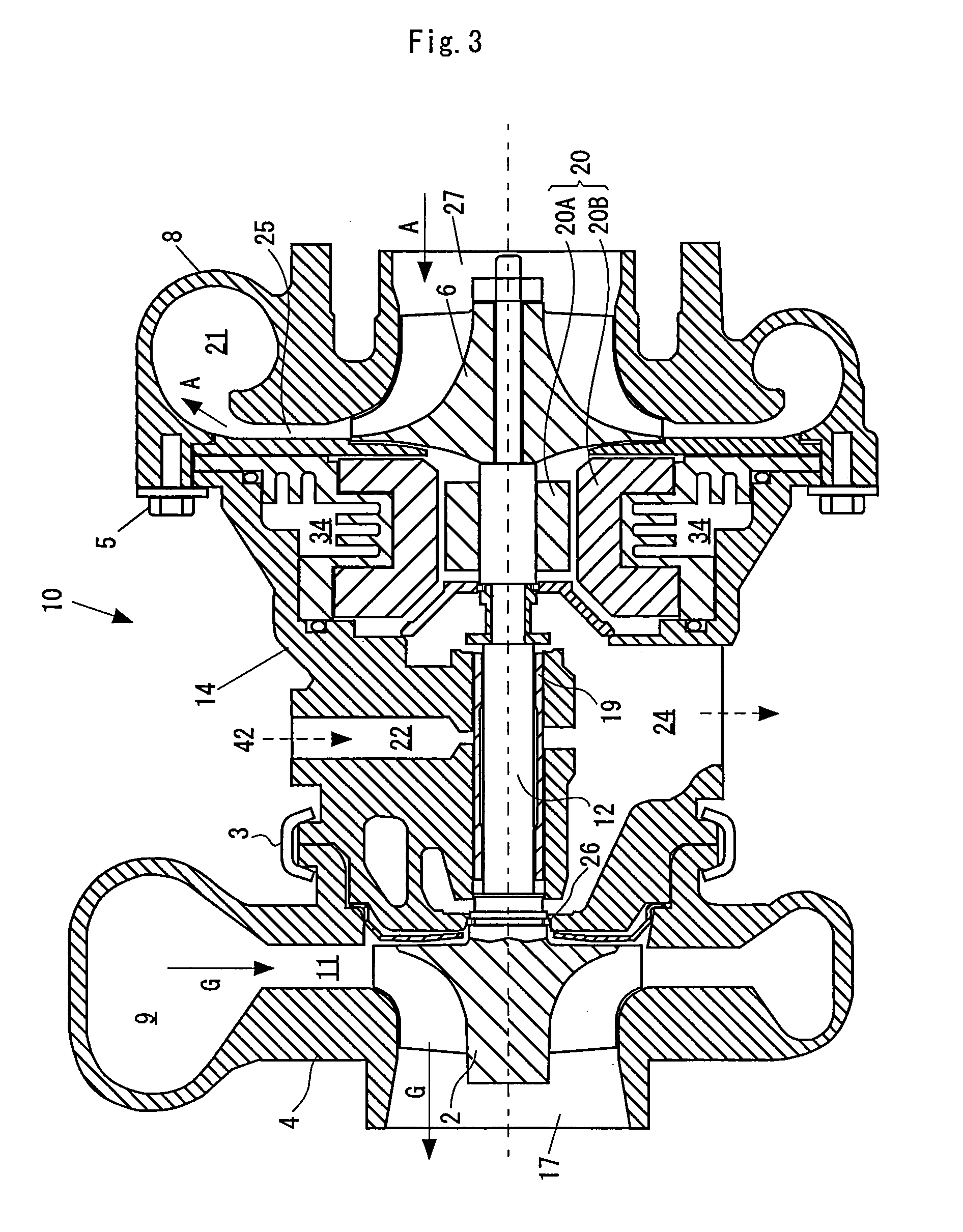

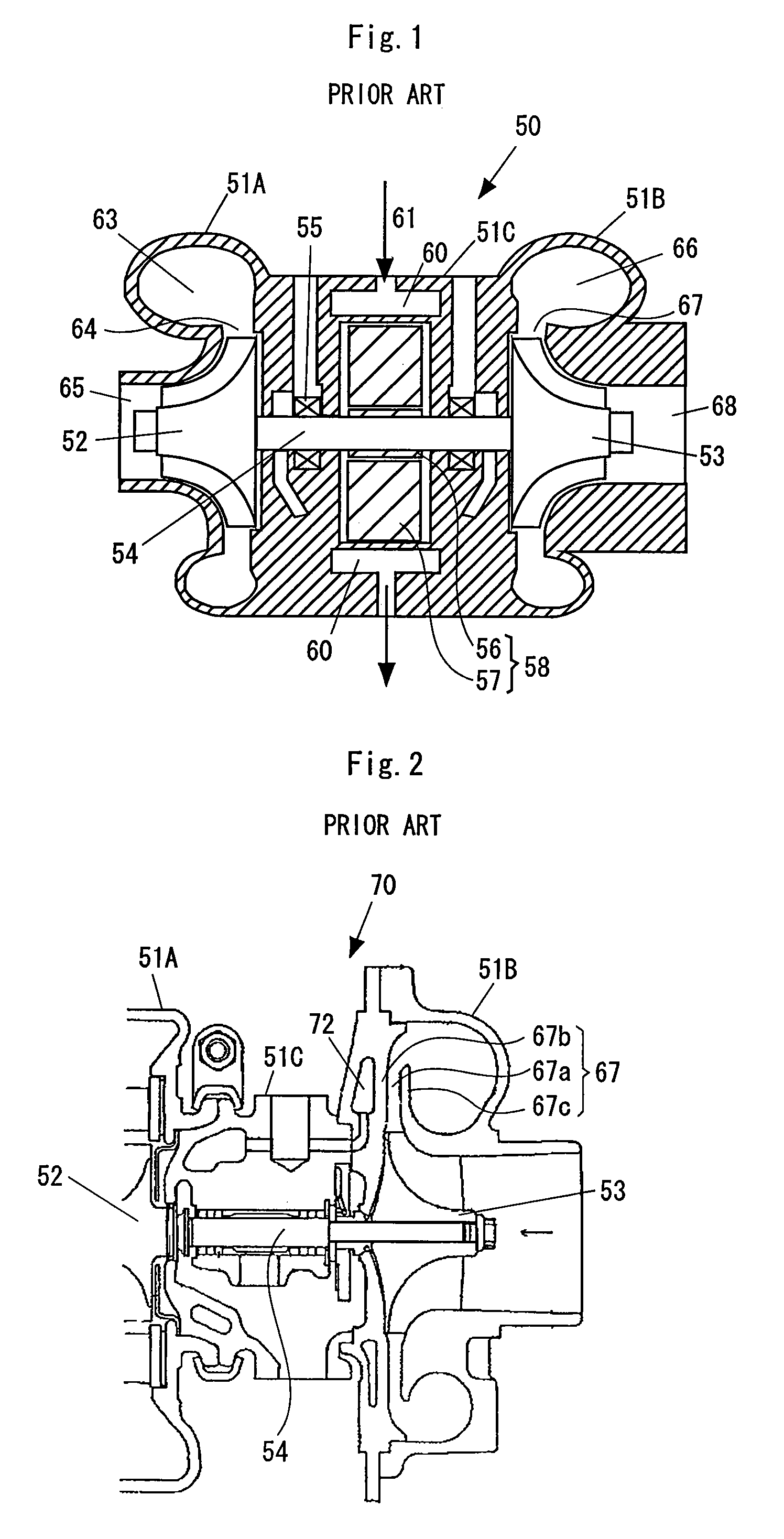

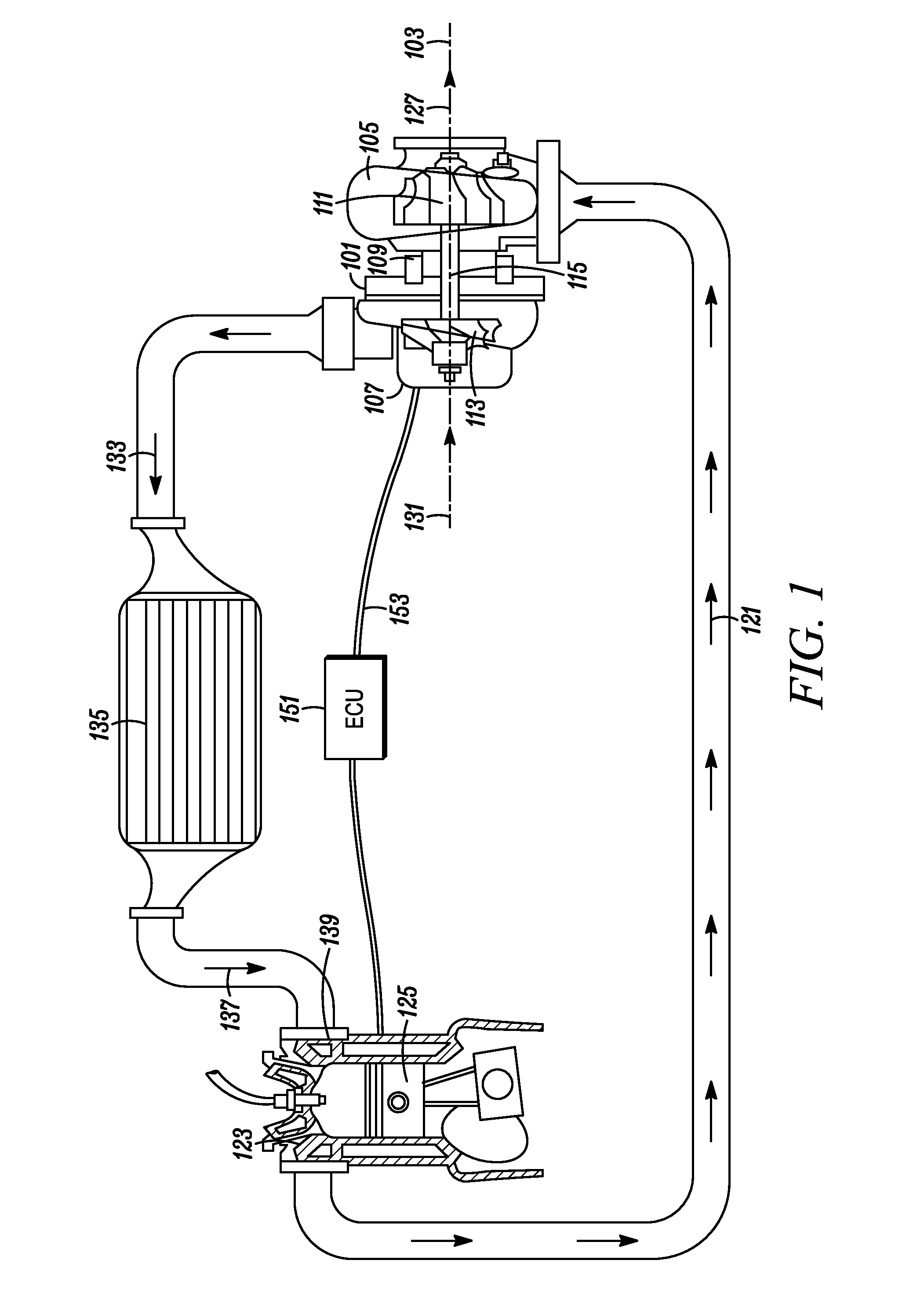

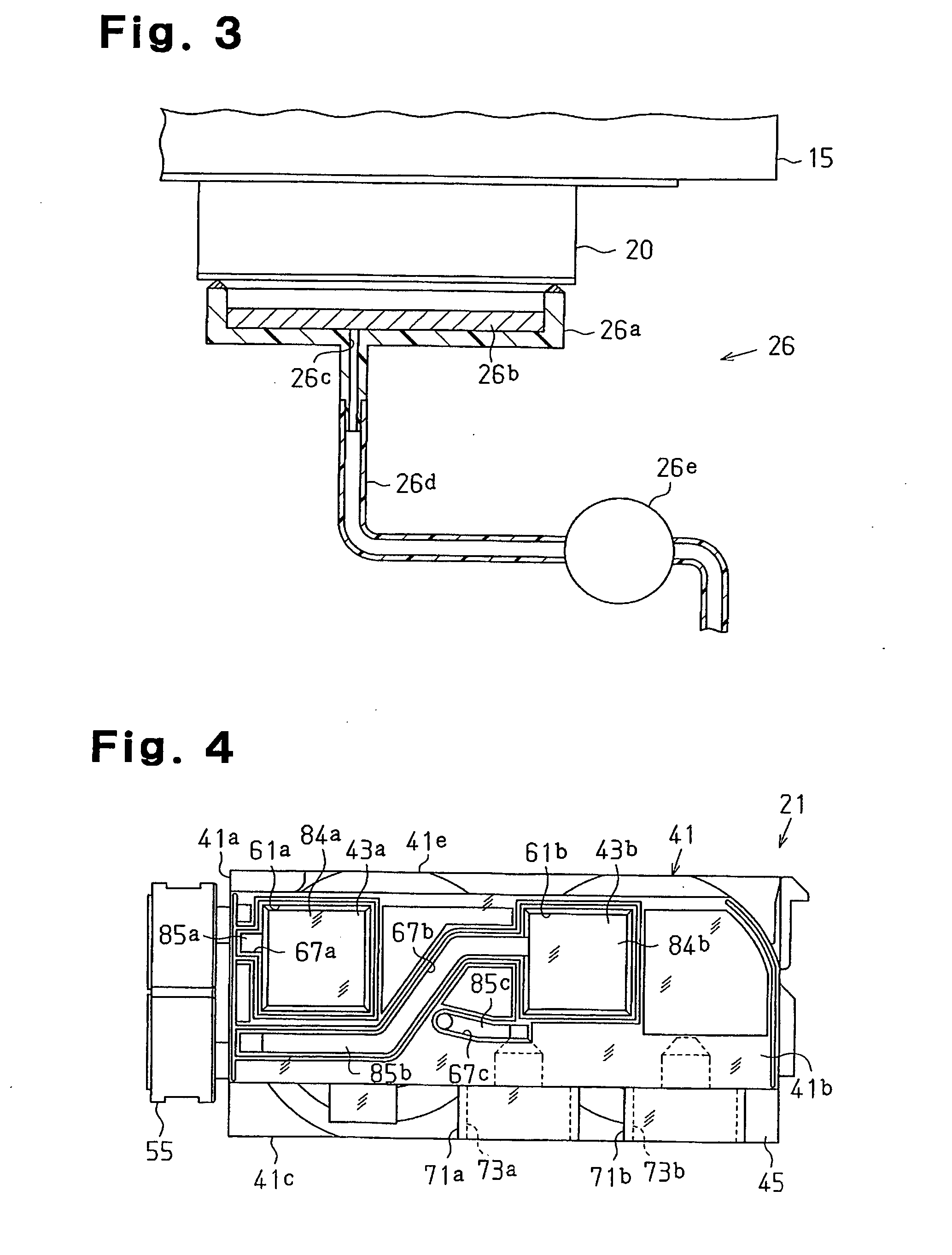

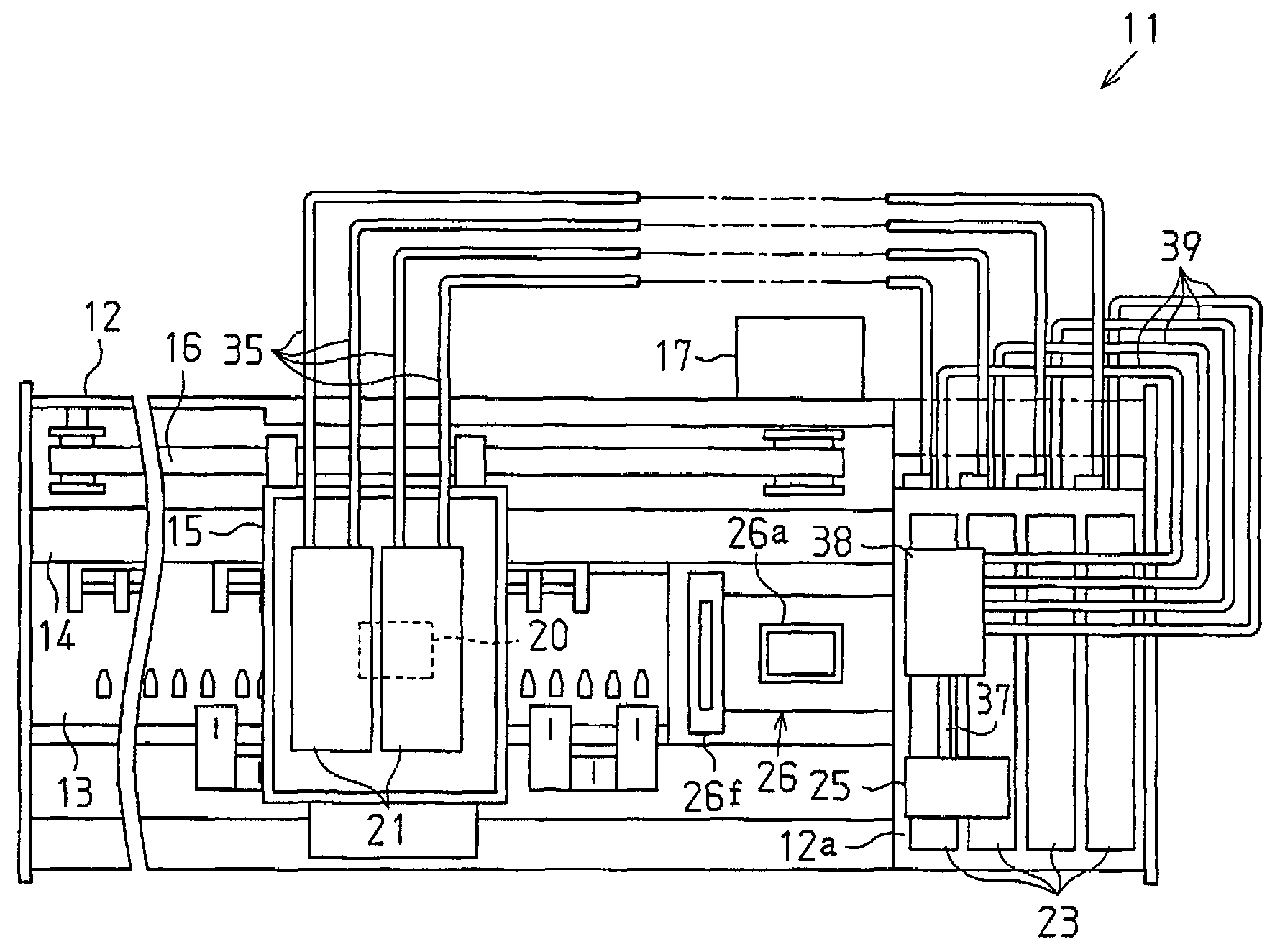

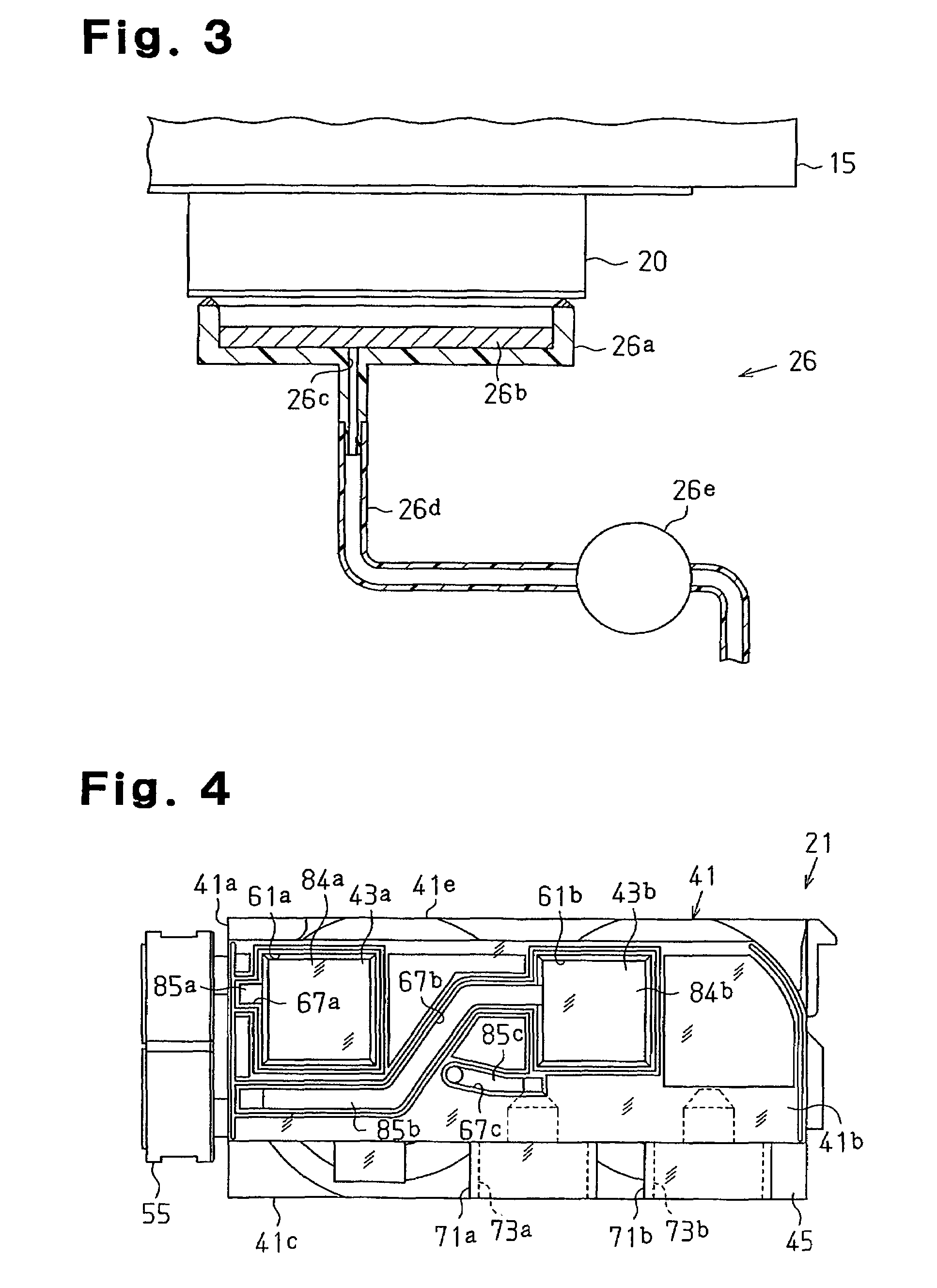

Supercharger with electric motor

ActiveUS20070036664A1Simplify cooling systemSimplify cooing systemInternal combustion piston enginesCircumferential flow pumpsImpellerEngineering

In a supercharger (10) with an electric motor in accordance with the present invention, the electric motor (20) is arranged at a position adjacent to a compressor impeller (6), a center housing (14) has a cooling fluid flow path (34) formed in such a manner as to surround the electric motor (20) and be adjacent to a diffuser portion (25). A first cooling structure portion (38) is formed at a position in the electric motor (20) side in the cooling fluid flow path (34), a second cooling structure portion (39) is formed at a position in the diffuser portion (25) side in the cooling fluid flow path (34). The electric motor (20) is cooled by the first cooling structure portion (38). The diffuser portion (25) is cooled by the second cooling structure portion (39).

Owner:IHI CORP

Polymide molding compositions containing prepolymeric polyamides, a method for the preparation thereof and the use thereof

Owner:EMS CHEM AG

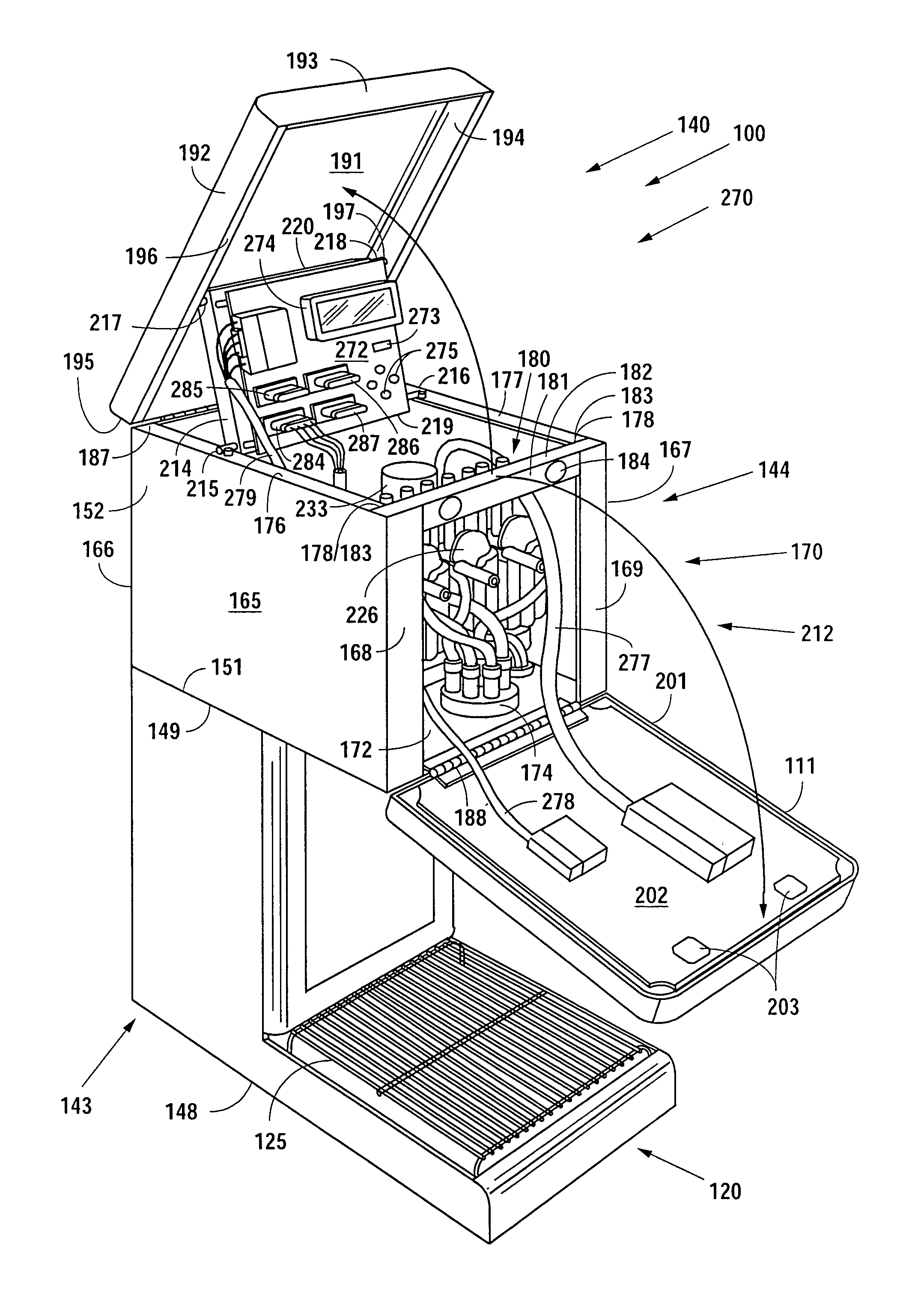

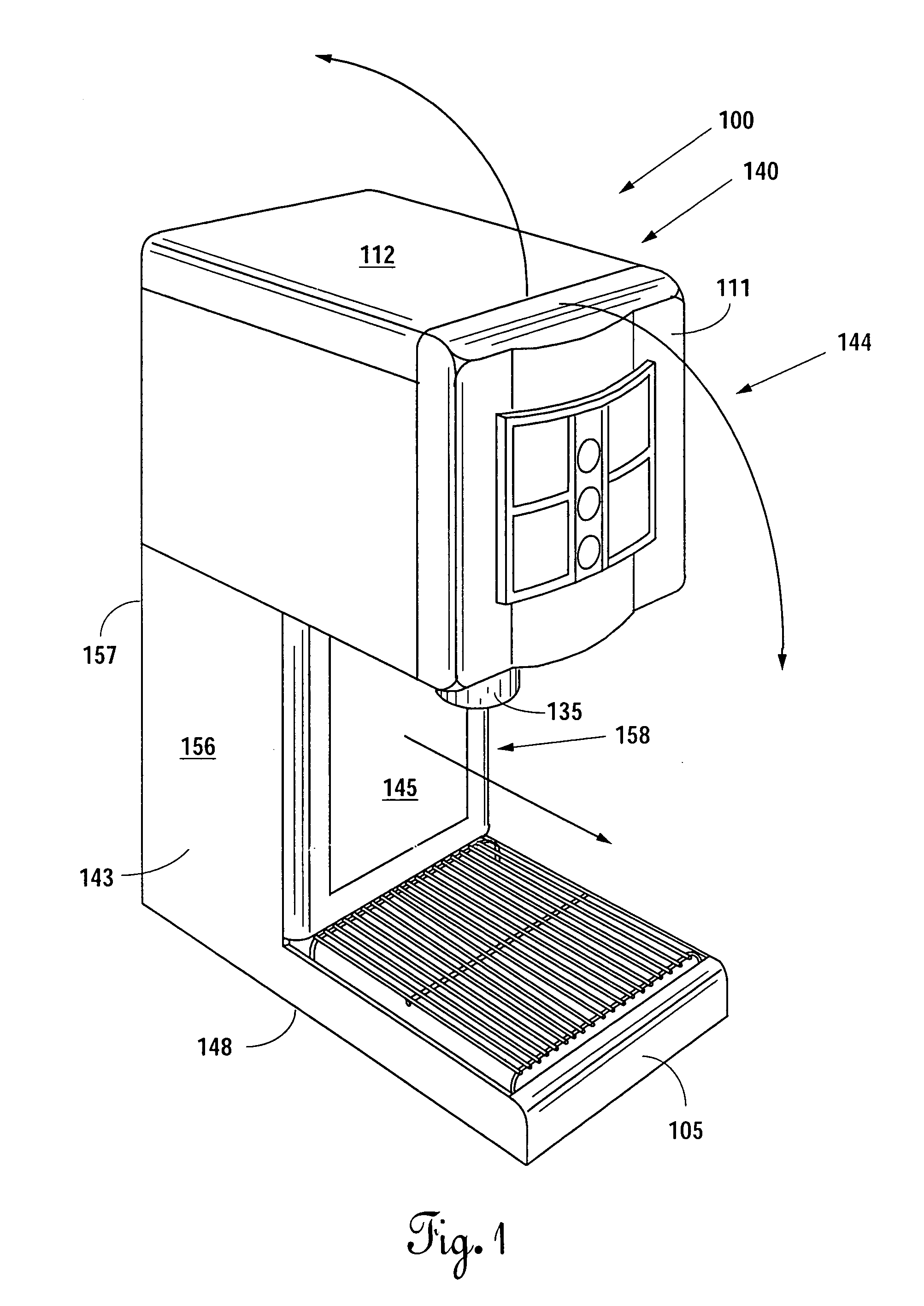

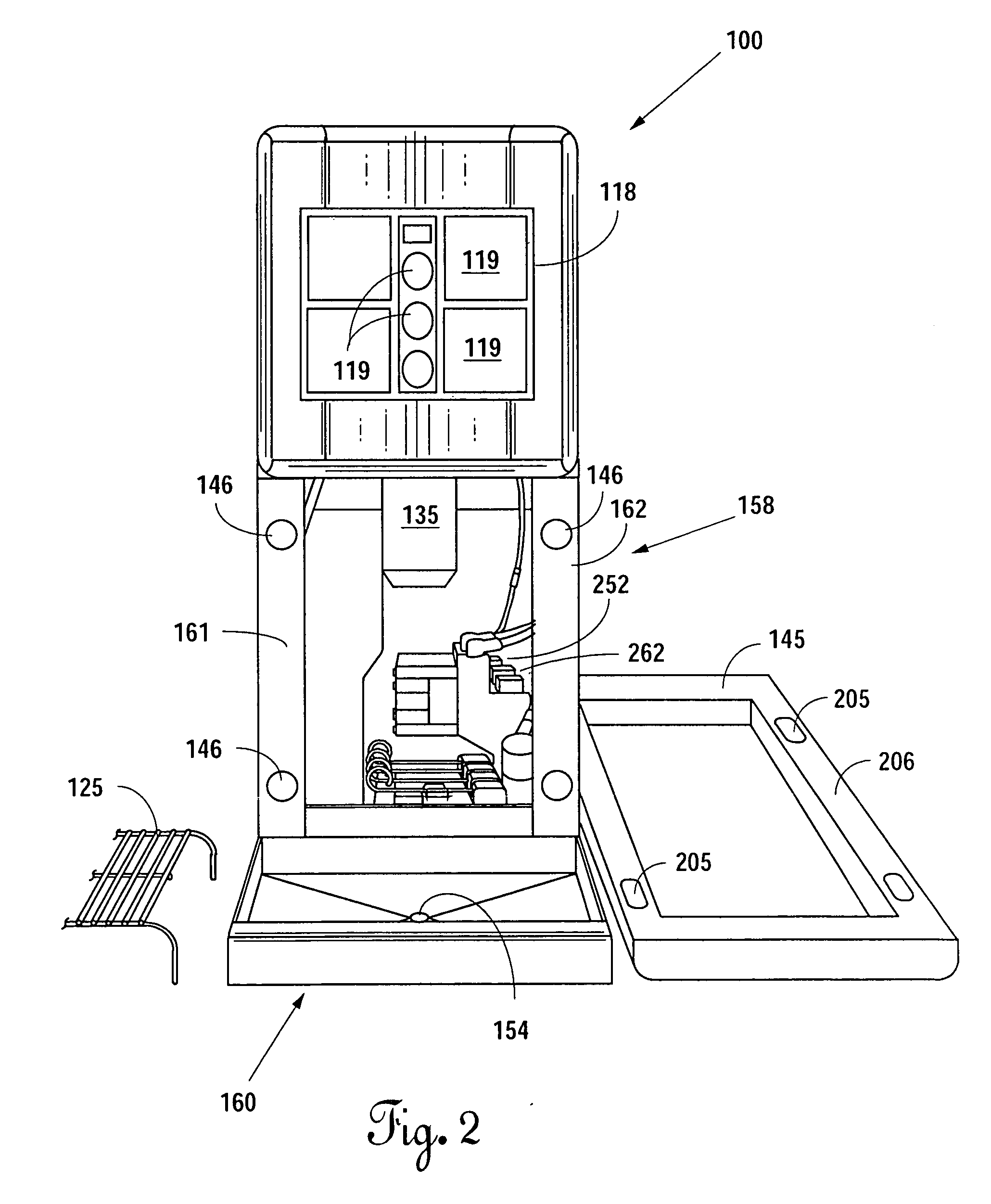

Tower dispenser

ActiveUS7624895B2Reduce envelopeMinimization requirementsLiquid flow controllersLiquid transferring devicesEngineeringOutput device

Owner:LANCER PARTNERSHIP

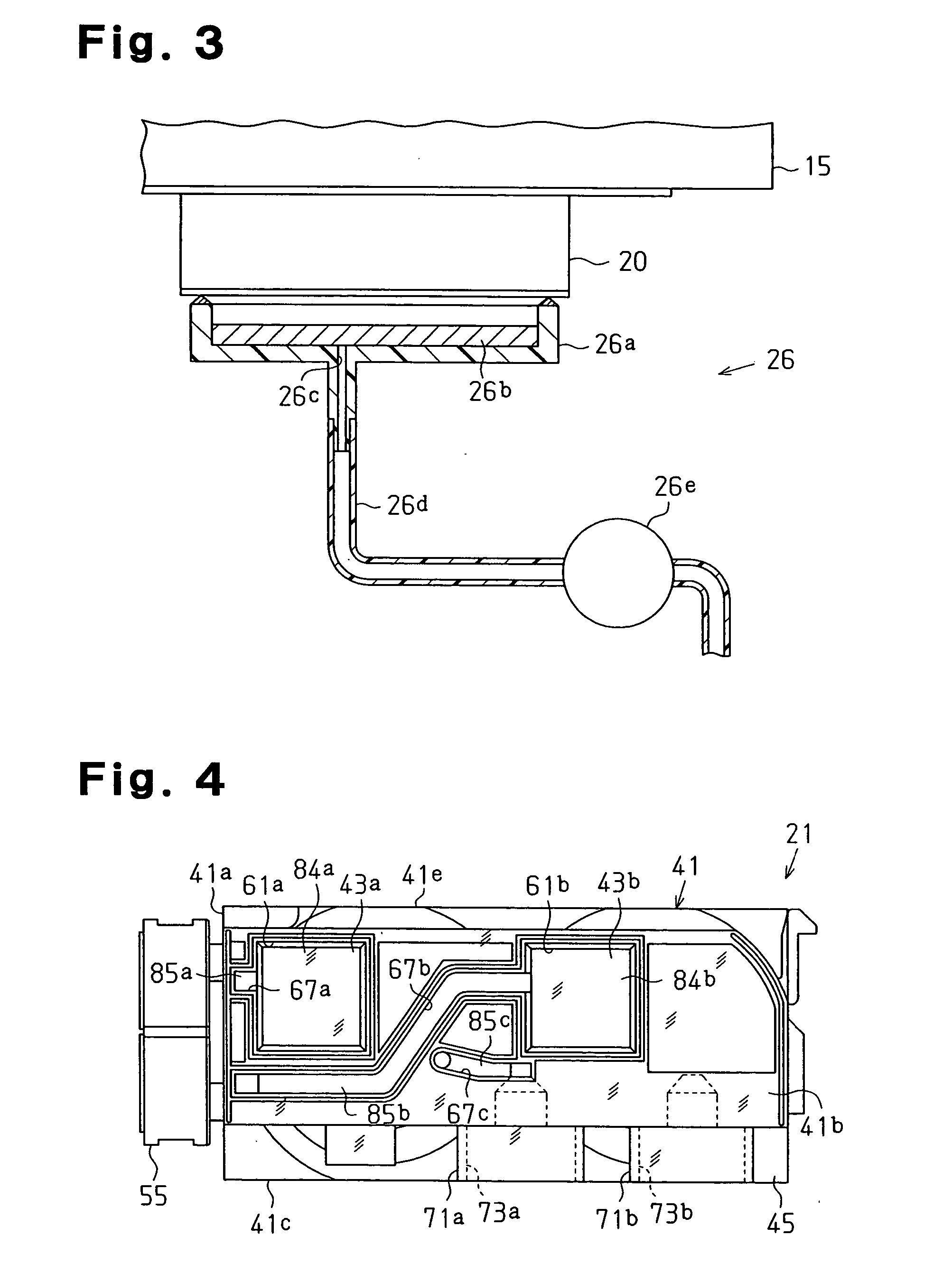

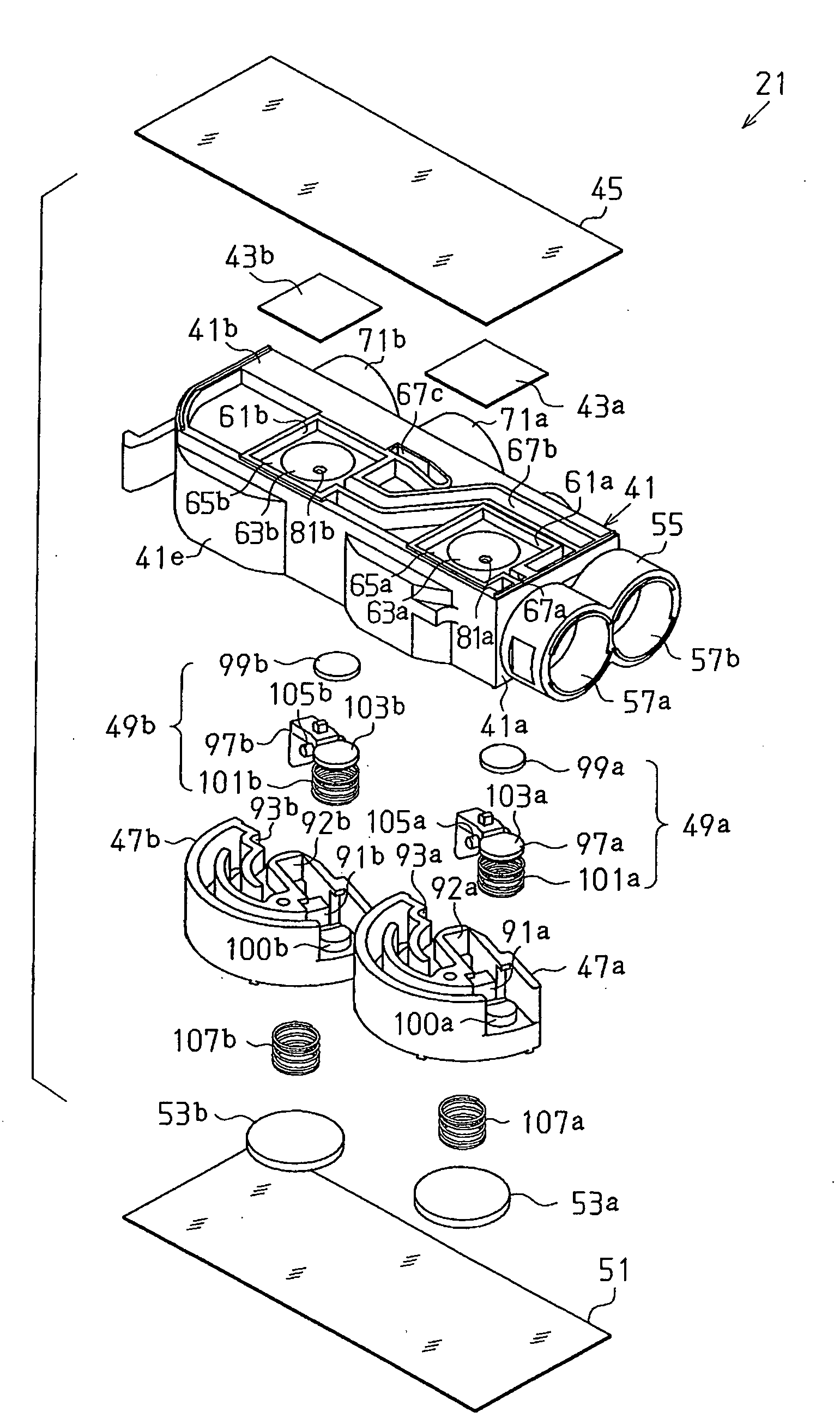

Liquid injection apparatus and method for driving the same

InactiveUS20050285913A1High viscosityEasy dischargeOther printing apparatusEngineeringFluid pressure

A liquid ejection apparatus comprises a liquid cartridge for storing a liquid, a liquid ejection head for ejecting the liquid toward a target, a liquid supply path for guiding the liquid to the liquid ejection head from the liquid cartridge, and a capping device for drawing the liquid from the liquid ejection head. The liquid supply path comprises a plurality of wall surfaces, and a part of the wall surface is formed of a flexible member that is flexed by the inside-and-outside pressure difference of the liquid supply path. A pressure pump for adjusting the pressure of a fluid within the liquid supply path in the upstream side of the flexible member is provided.

Owner:SEIKO EPSON CORP

Background of the invention and prior art

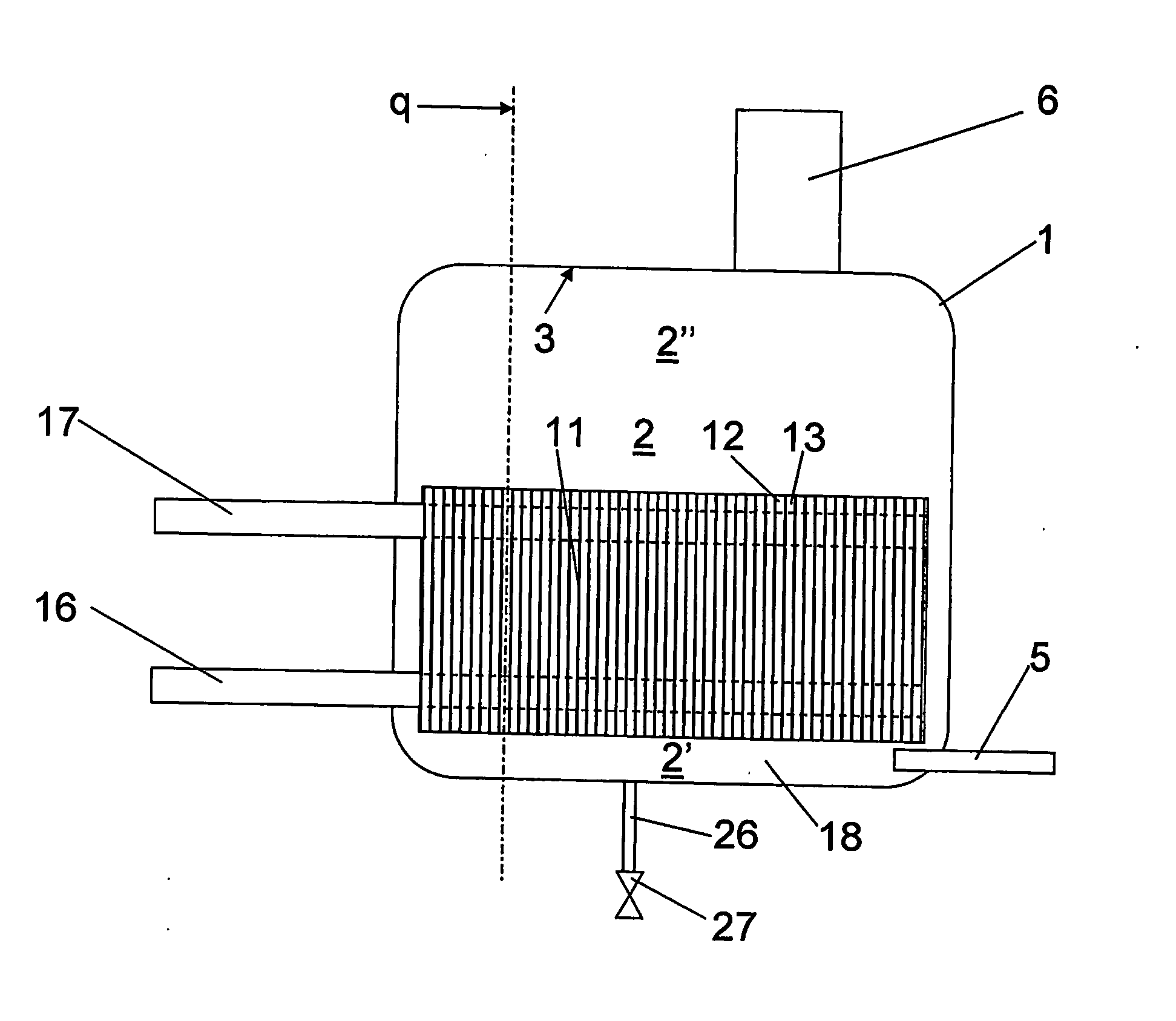

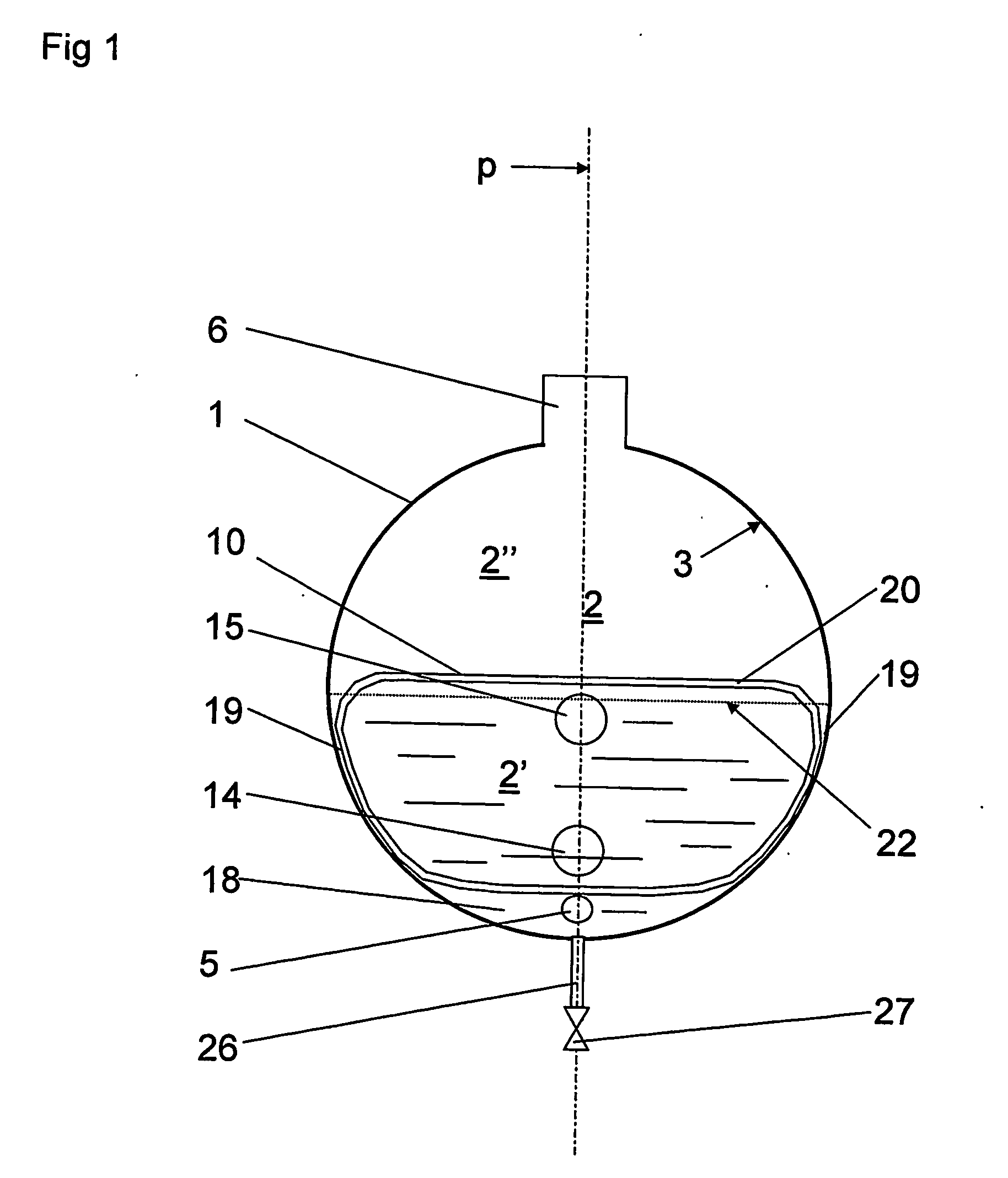

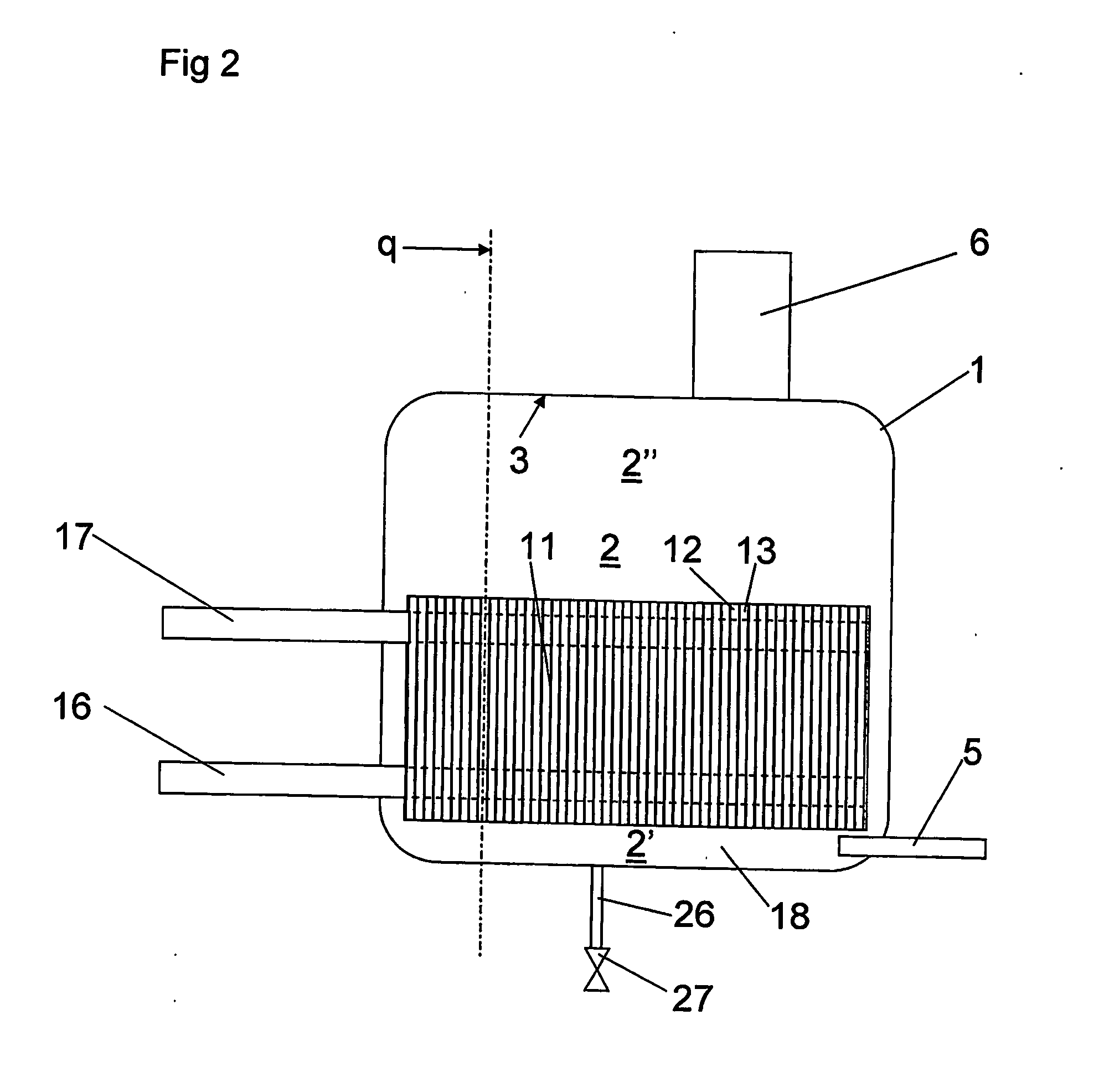

ActiveUS20060191672A1Efficient heat transferSimple and compact structureHeat exchanger casingsStationary tubular conduit assembliesInterior spaceLiquid medium

The invention refers to a plate package for a heat exchanger device including a tank with an inner space and an inner wall surface. A sectional plane (p) extends vertically through the inner space. The tank has an inlet for the supply of a liquid medium and an outlet for discharging the medium in a gaseous state. The inner space defines a lower part space and an upper part space. The plate package (10) with heat exchanger plates (11) is provided in the inner space. Each heat exchanger plate has an extension plane perpendicular to the sectional plane. The heat exchanger plates form first plate interspaces, that are open towards the inner space for recirculation of the medium, and second plate interspaces, which are closed towards the inner space for the recirculation of a fluid for evaporating the medium. Each heat exchanger plate includes a first porthole (14) and a second porthole (15). Furthermore, each heat exchanger plate includes an elongated distribution element (25) which extends into the adjacent second plate interspace and substantially transversally to the sectional plane (p).

Owner:ALFA LAVAL CORP AB

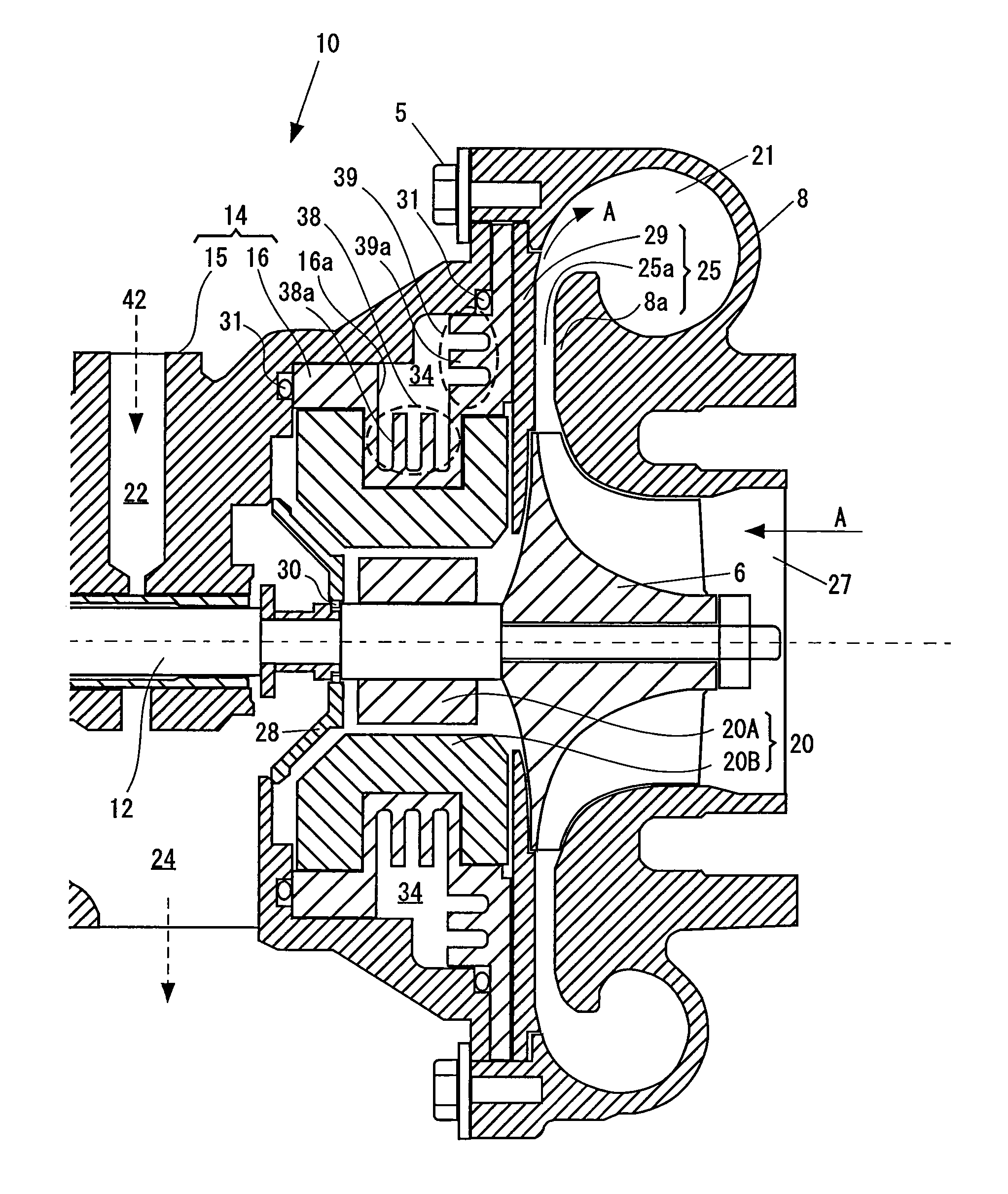

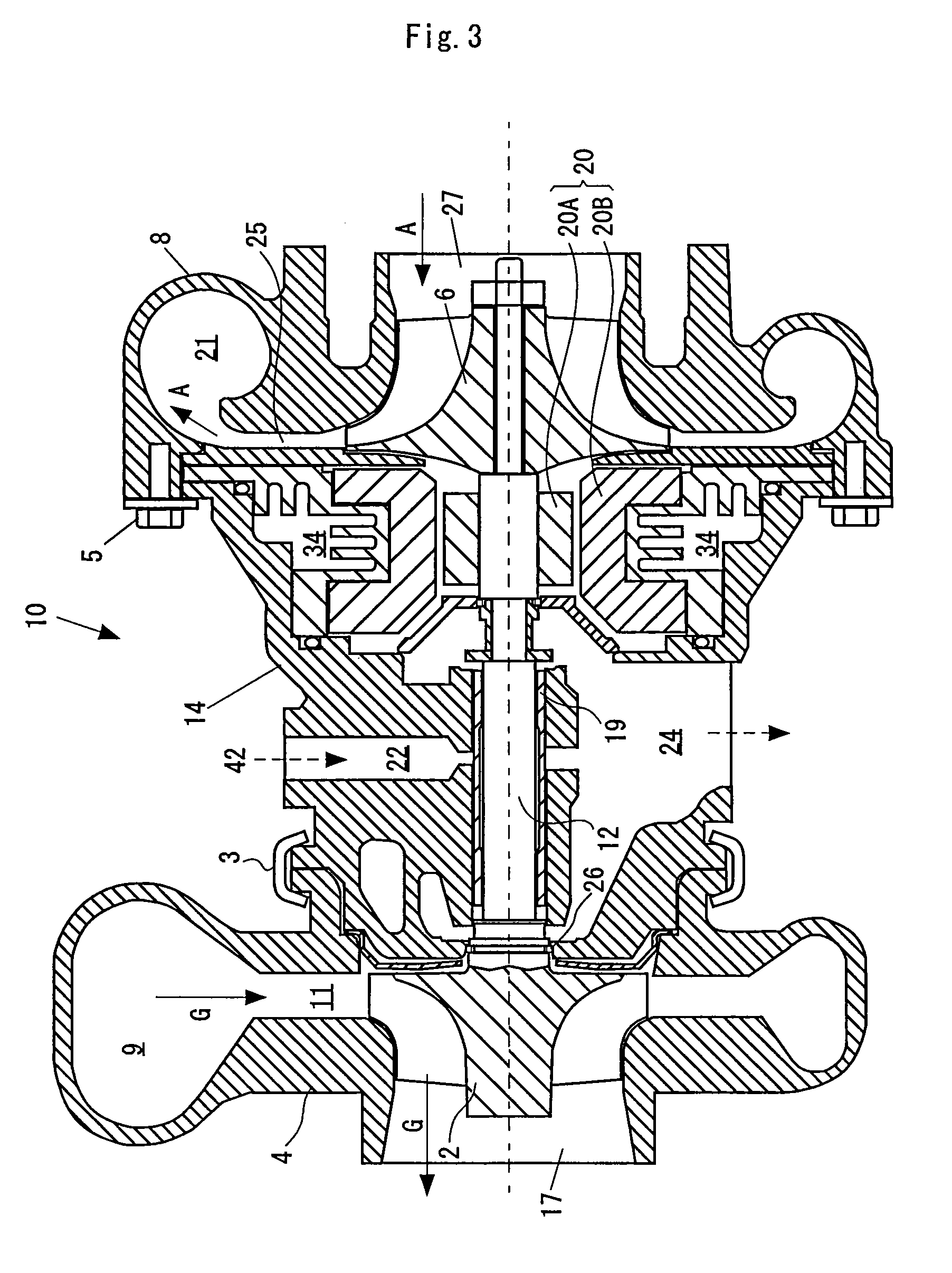

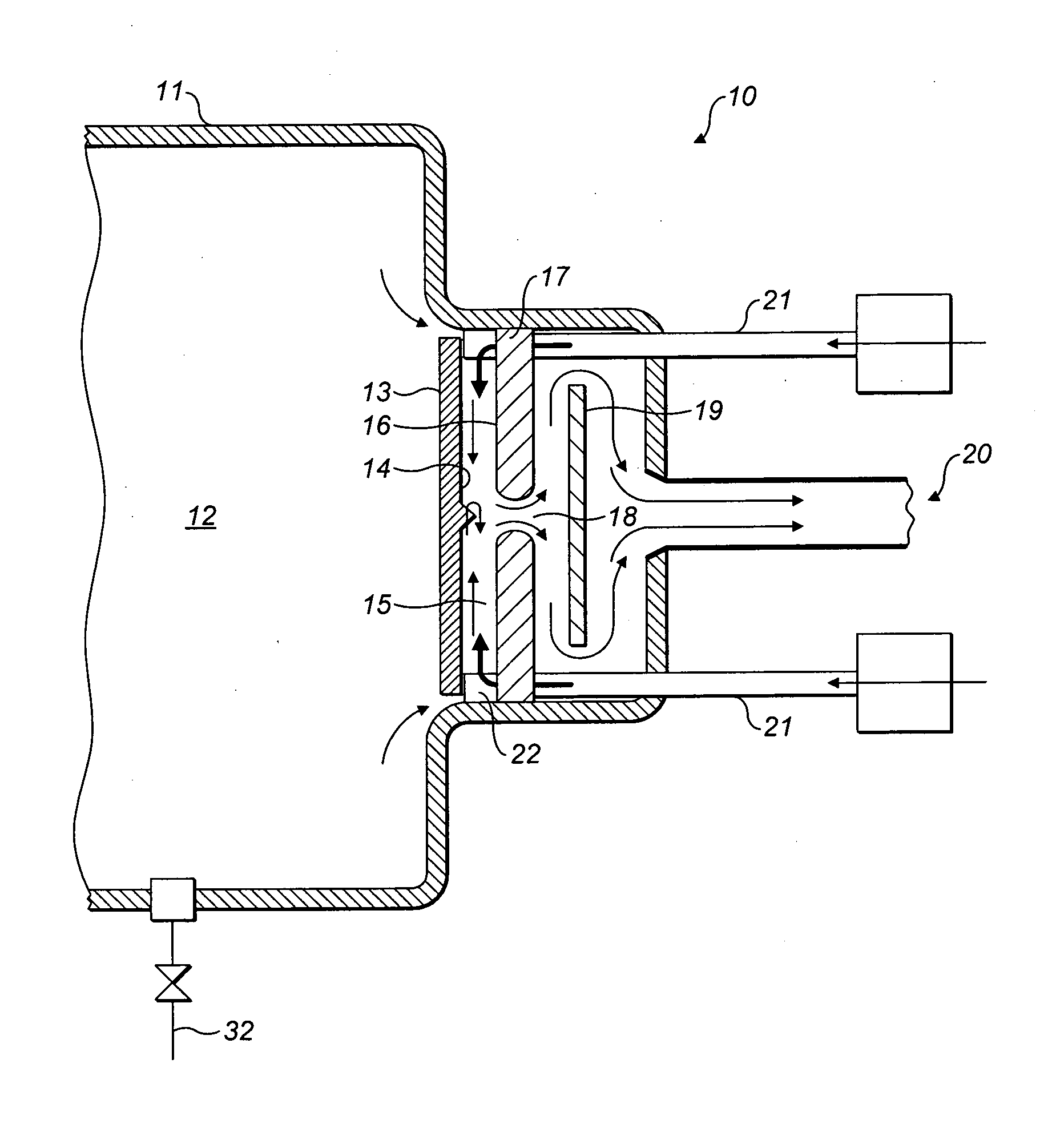

Supercharger with electric motor

ActiveUS7367190B2Improve compression efficiency and reliabilityExtend the flow pathInternal combustion piston enginesCircumferential flow pumpsImpellerEngineering

In a supercharger (10) with an electric motor in accordance with the present invention, the electric motor (20) is arranged at a position adjacent to a compressor impeller (6), a center housing (14) has a cooling fluid flow path (34) formed in such a manner as to surround the electric motor (20) and be adjacent to a diffuser portion (25). A first cooling structure portion (38) is formed at a position in the electric motor (20) side in the cooling fluid flow path (34), a second cooling structure portion (39) is formed at a position in the diffuser portion (25) side in the cooling fluid flow path (34). The electric motor (20) is cooled by the first cooling structure portion (38). The diffuser portion (25) is cooled by the second cooling structure portion (39).

Owner:IHI CORP

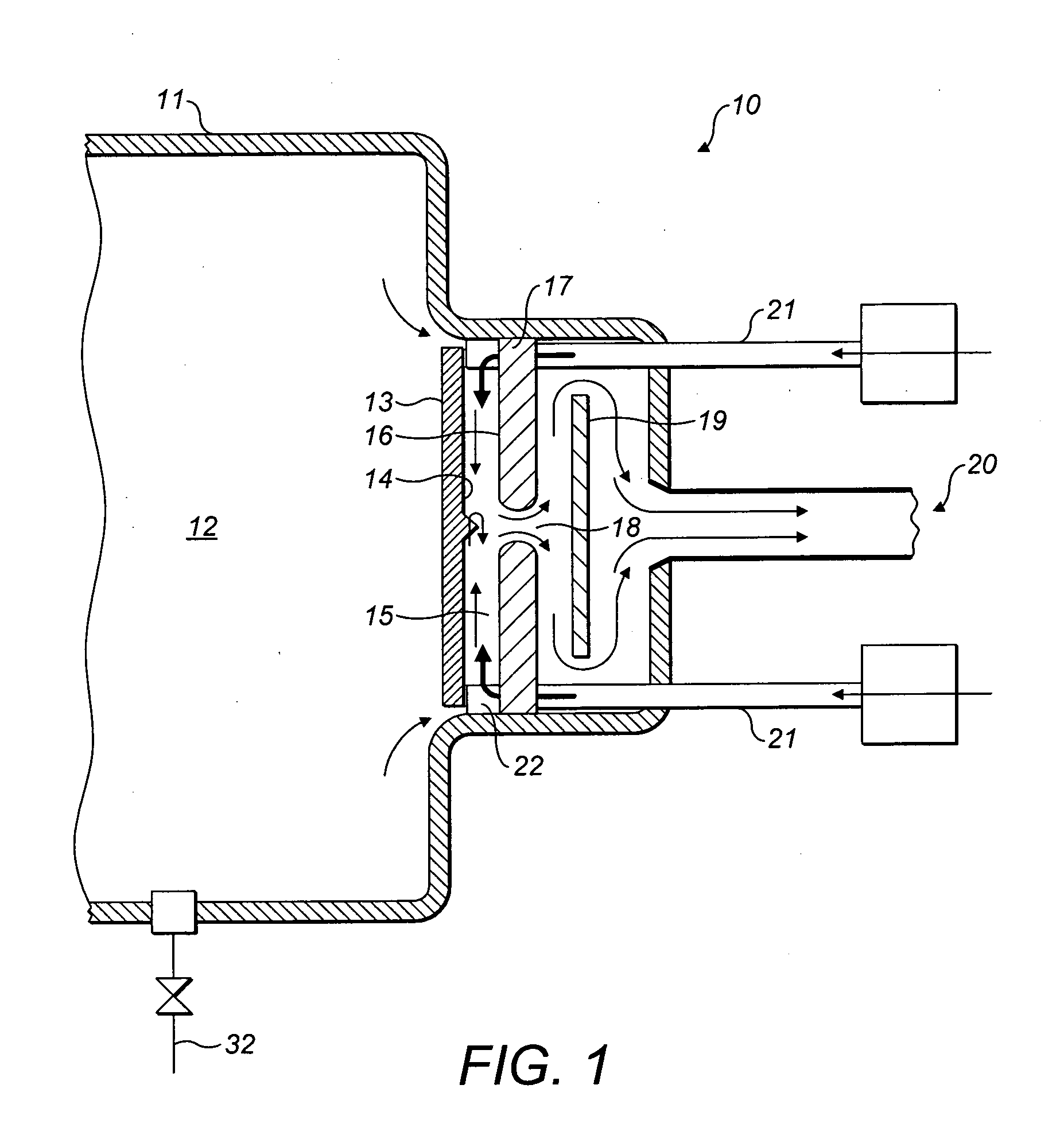

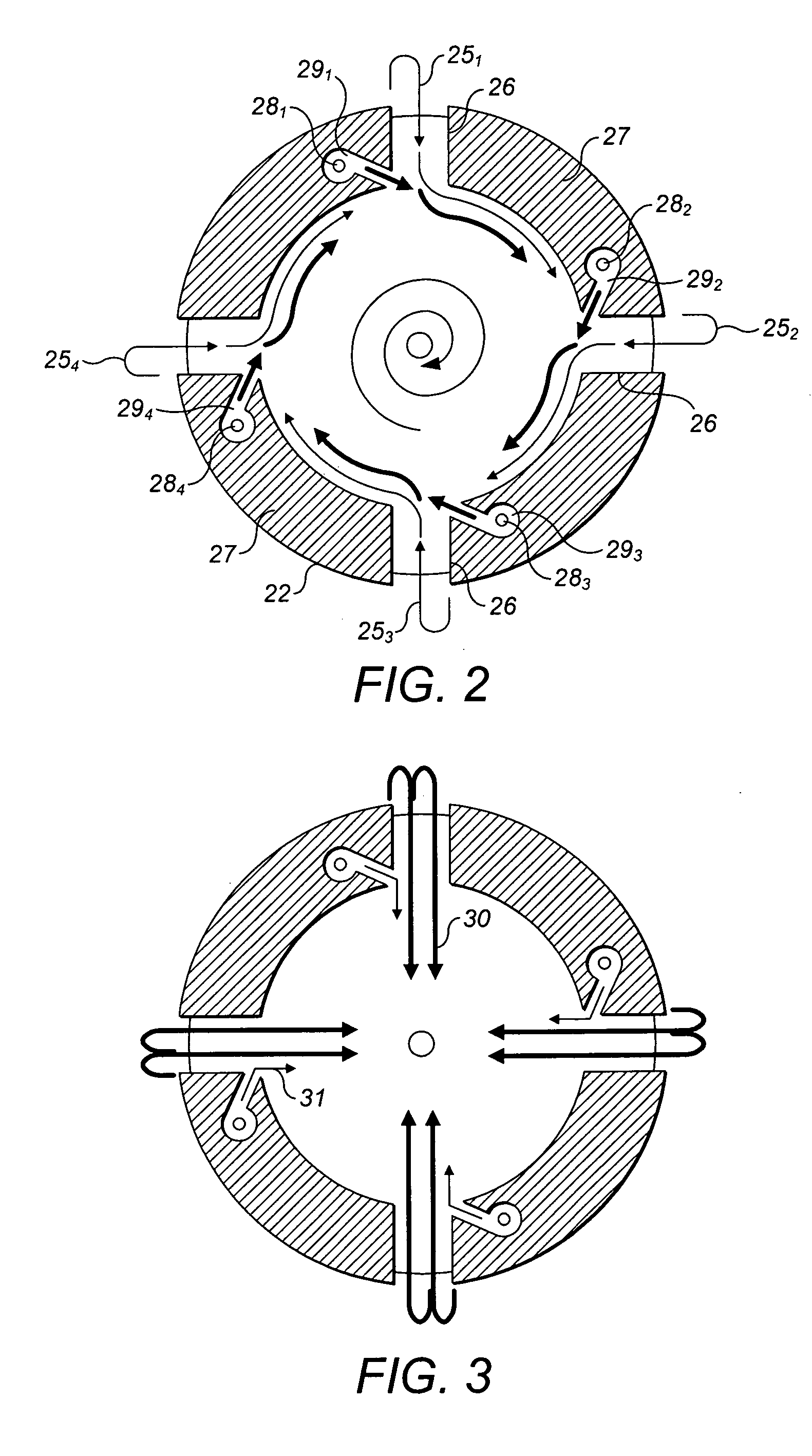

Apparatus and method for controlling the flow of fluid in a vortex amplifier

InactiveUS20110203671A1Reduce refluxIncrease pressureNuclear energy generationCircuit elementsEngineeringAmplifier

Owner:NUCLEAR DECOMMISSIONING AUTHORITY

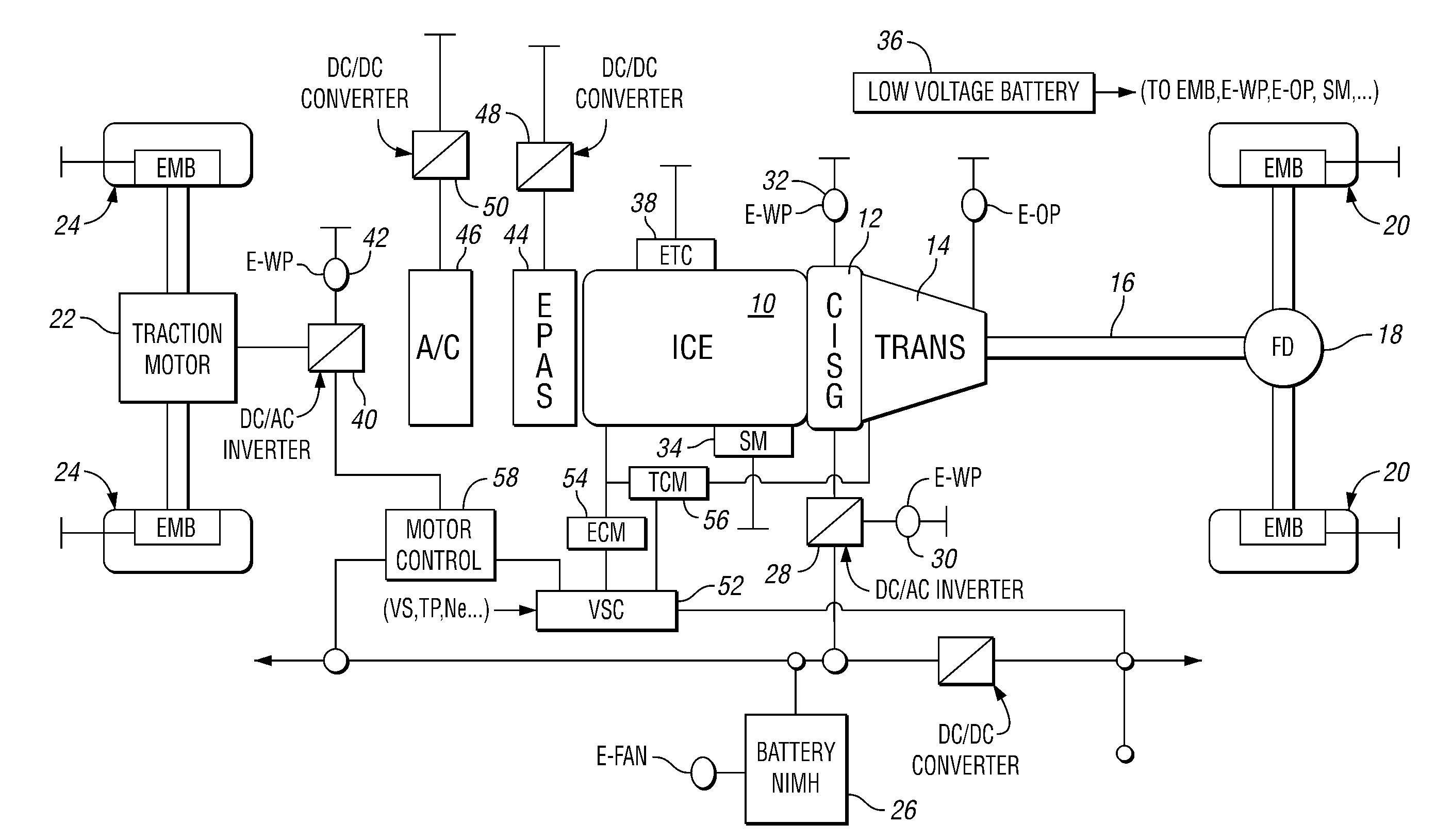

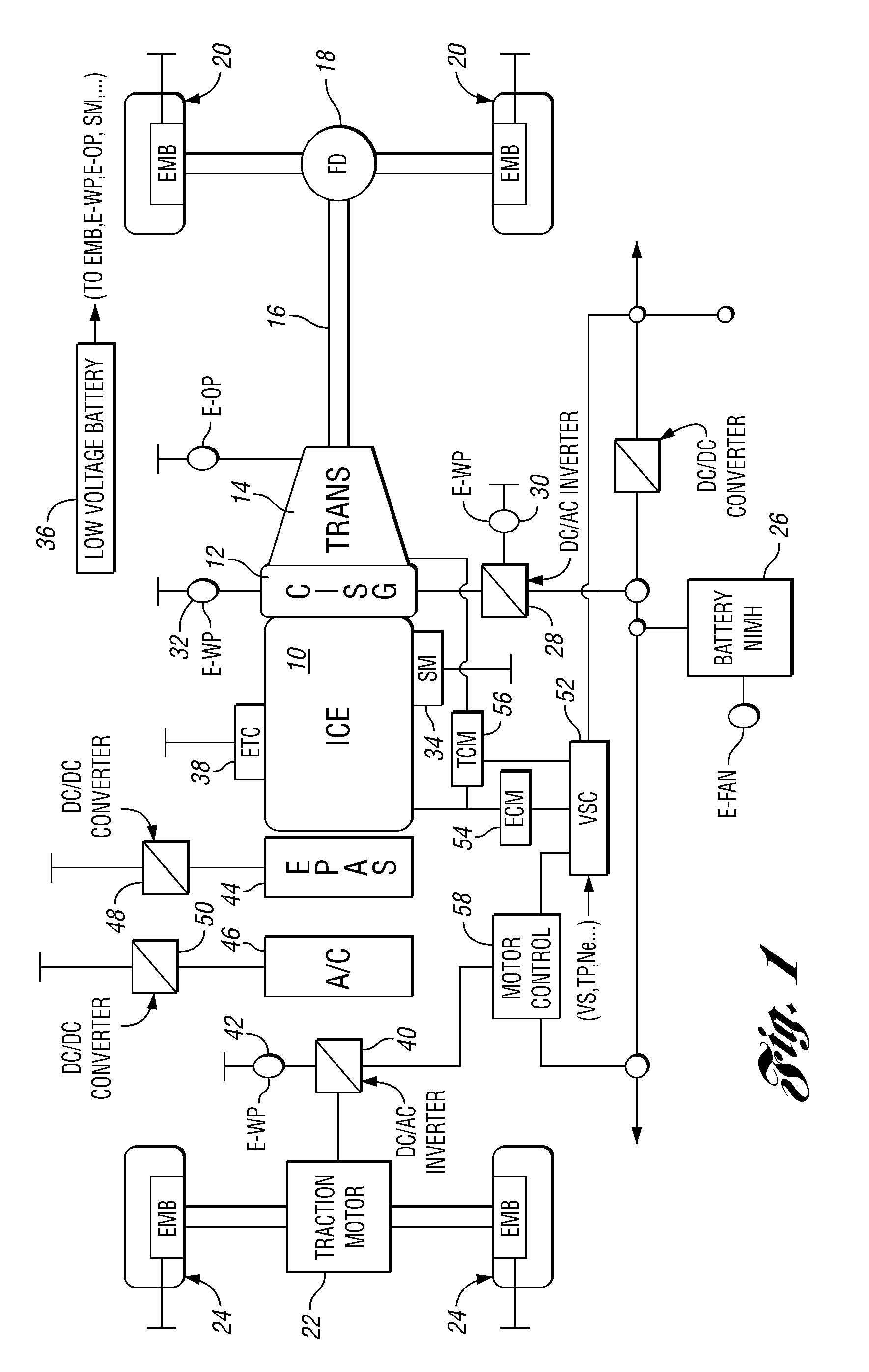

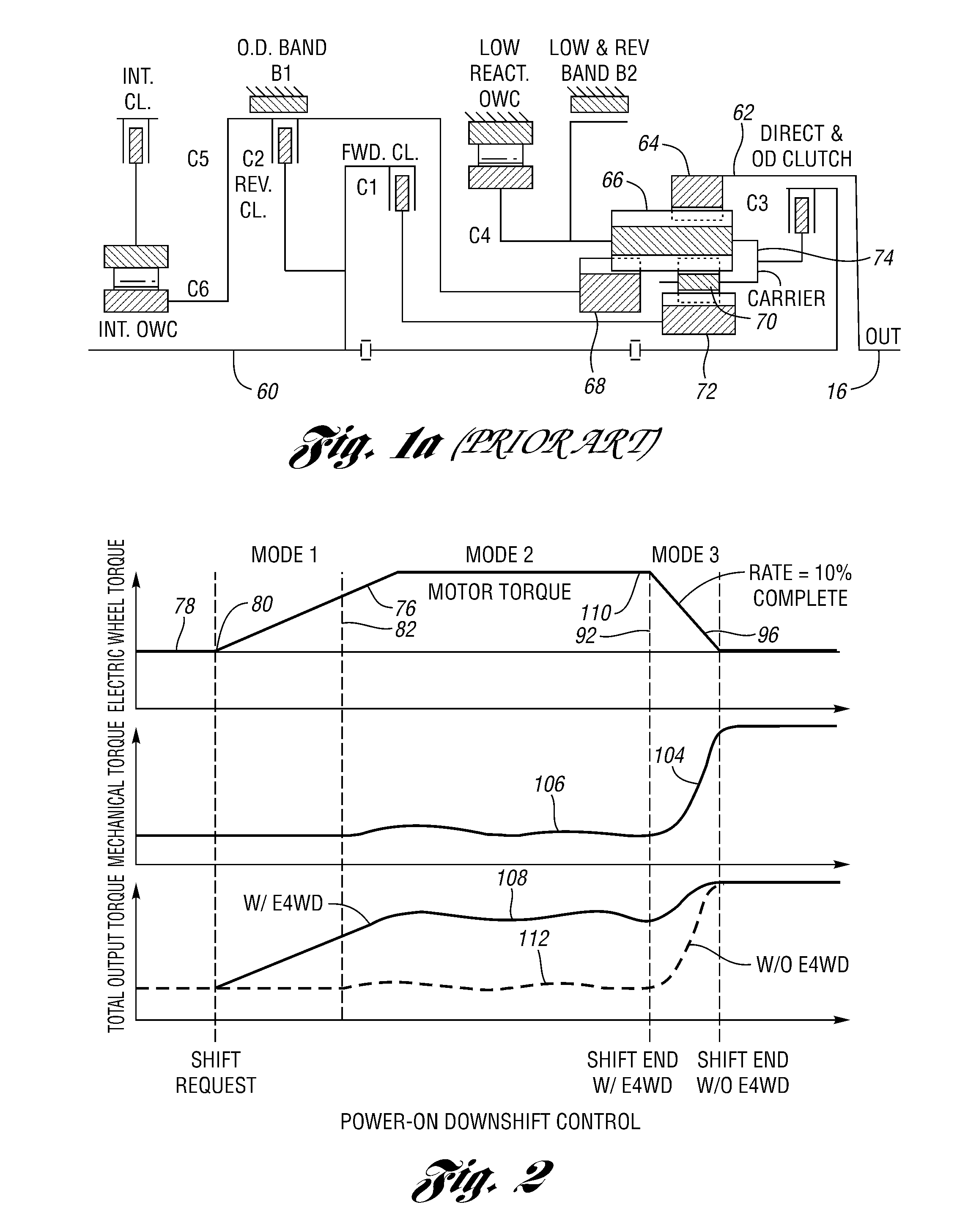

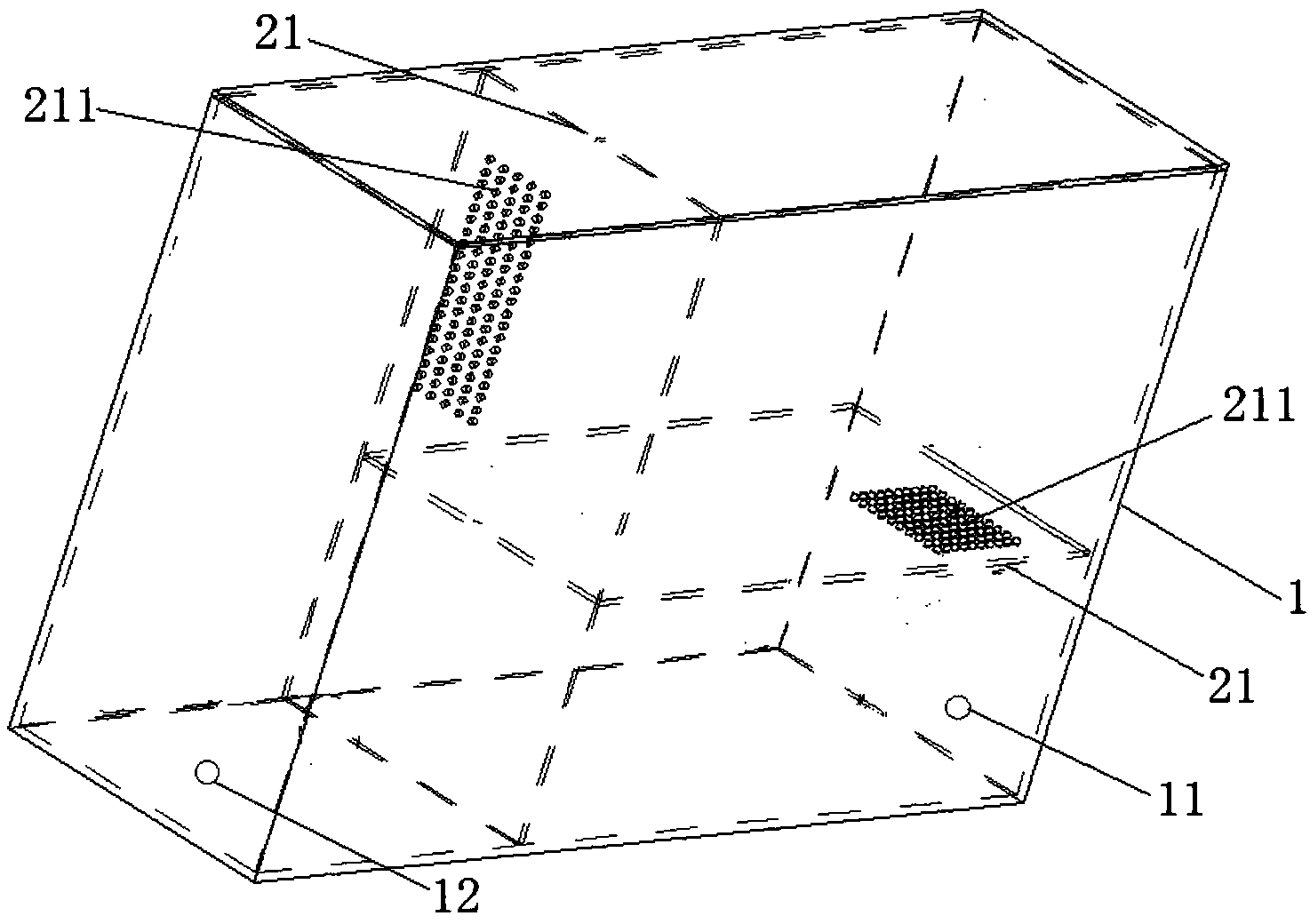

Power-on downshift control for a hybrid electric vehicle powertrain

InactiveUS20080058152A1Quality improvementImprove the level ofElectric propulsion mountingToothed gearingsElectric vehiclePowertrain

A method is disclosed for controlling a hybrid electric vehicle powertrain having a multiple-ratio transmission. On a power-on transmission downshift, electric wheel torque is used to compensate for a slow response of an engine to a request for increased traction wheel torque.

Owner:FORD GLOBAL TECH LLC

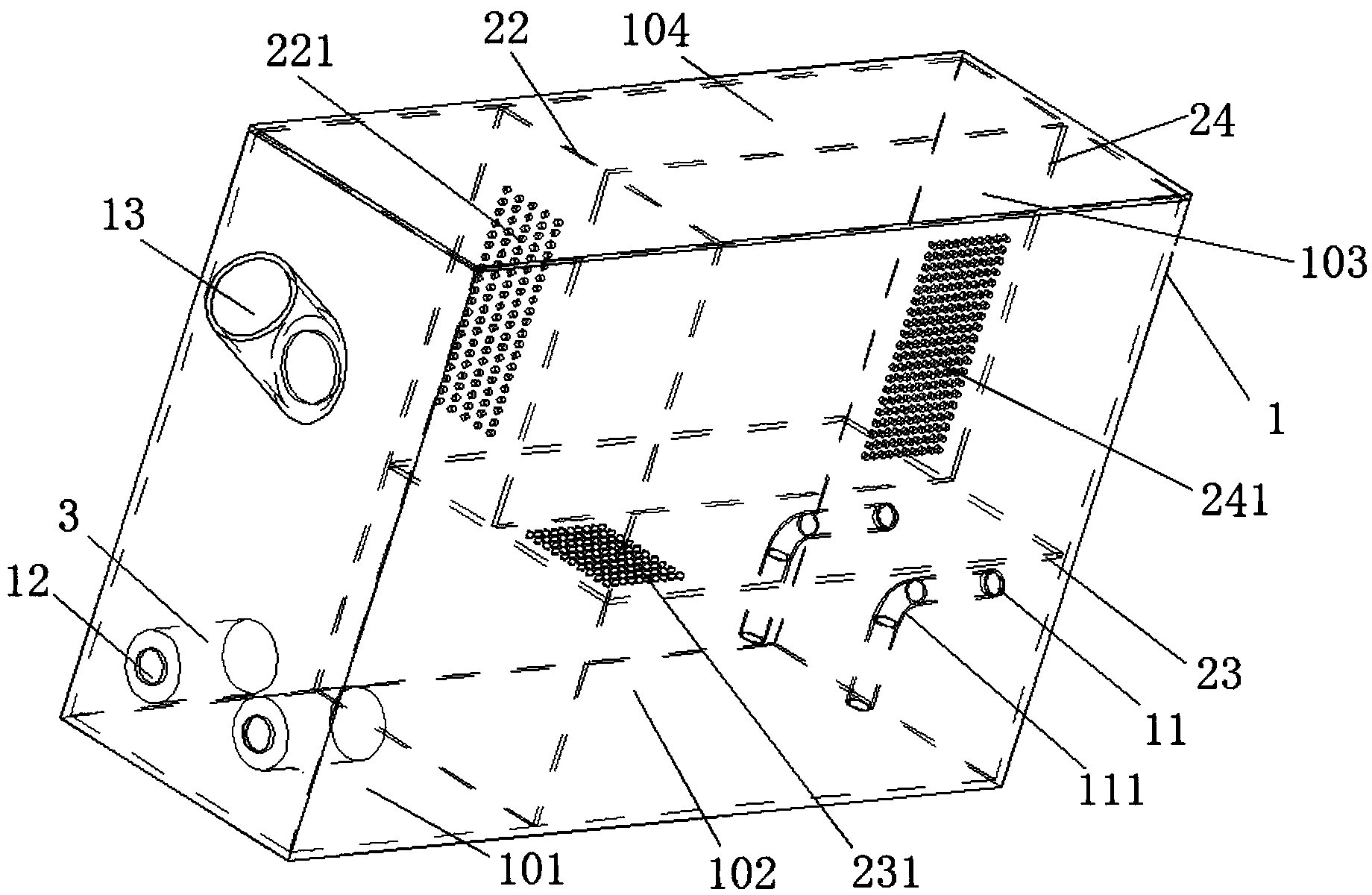

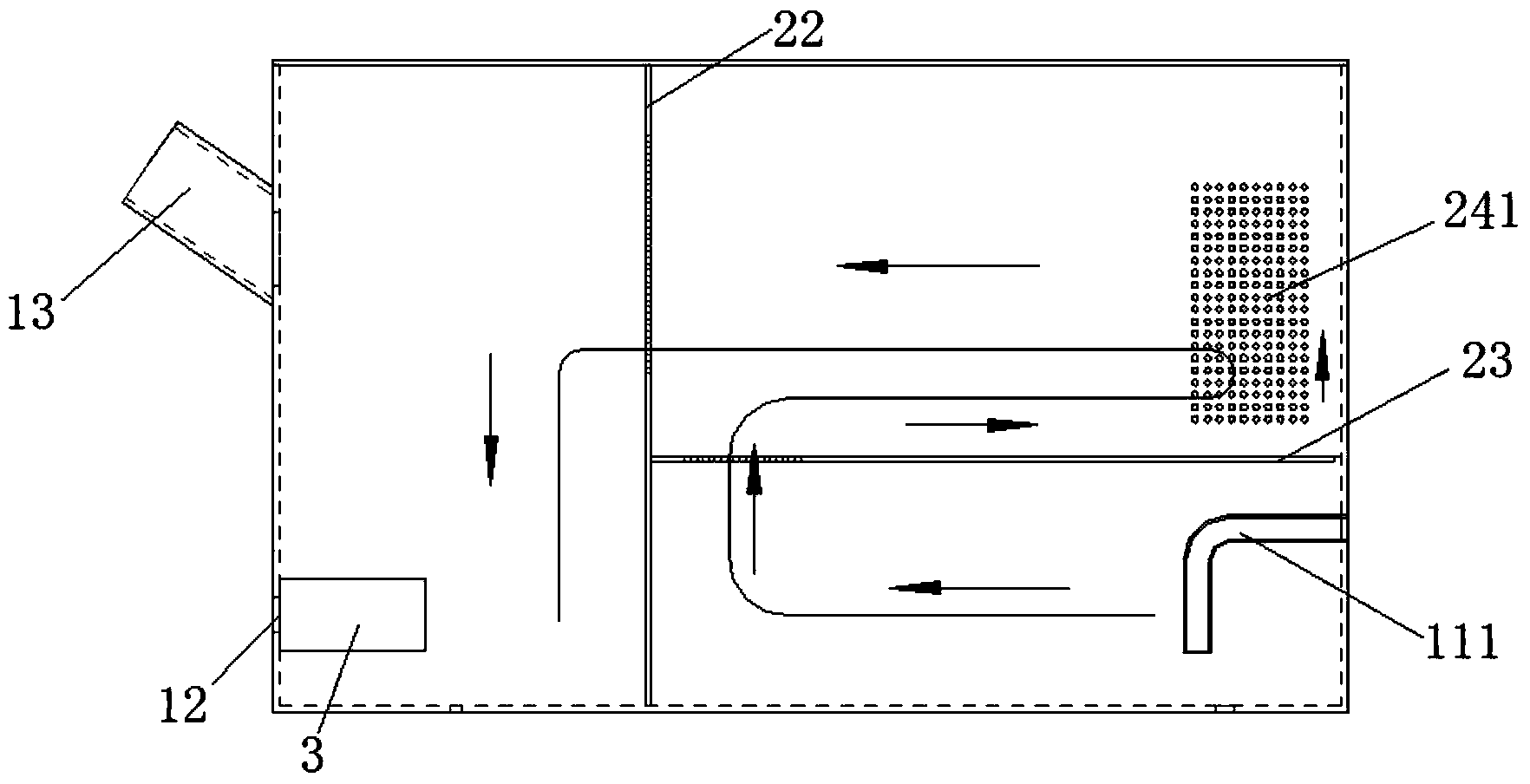

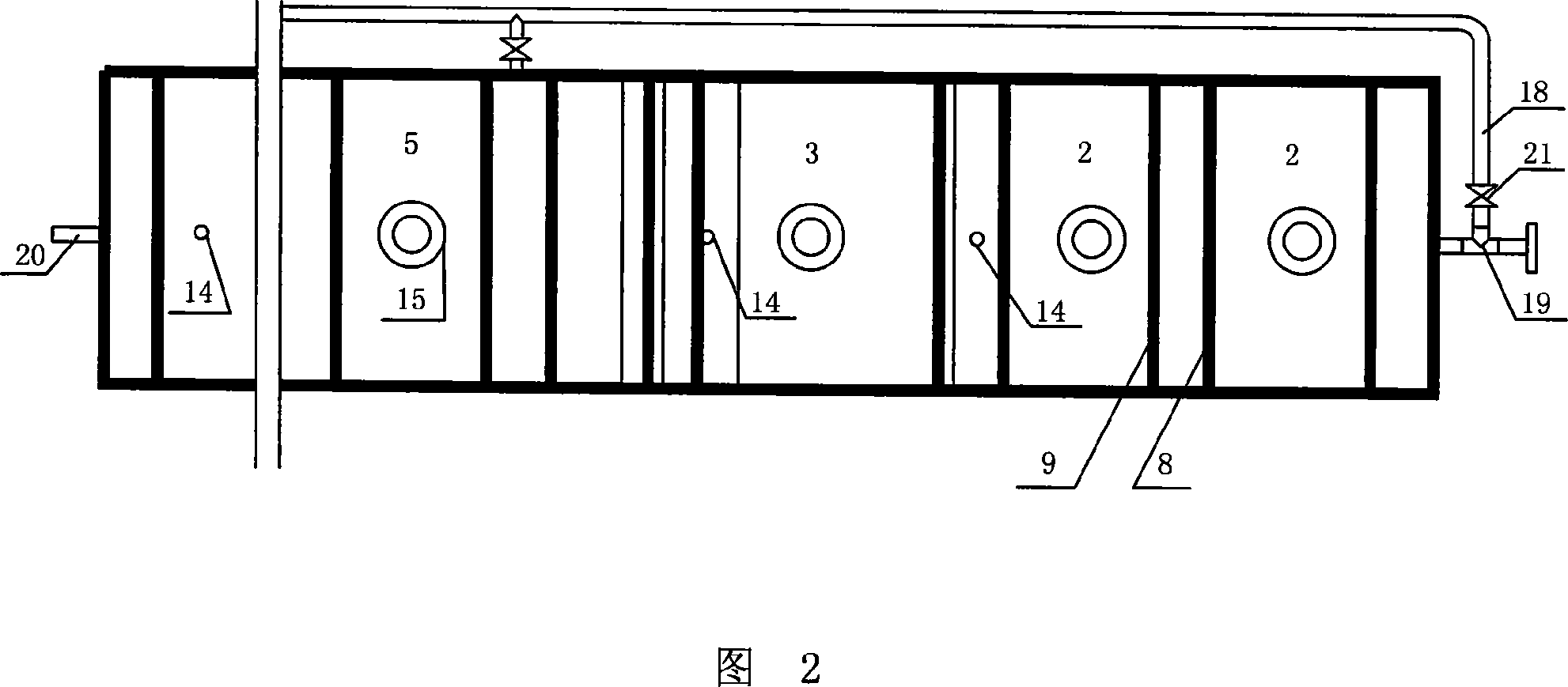

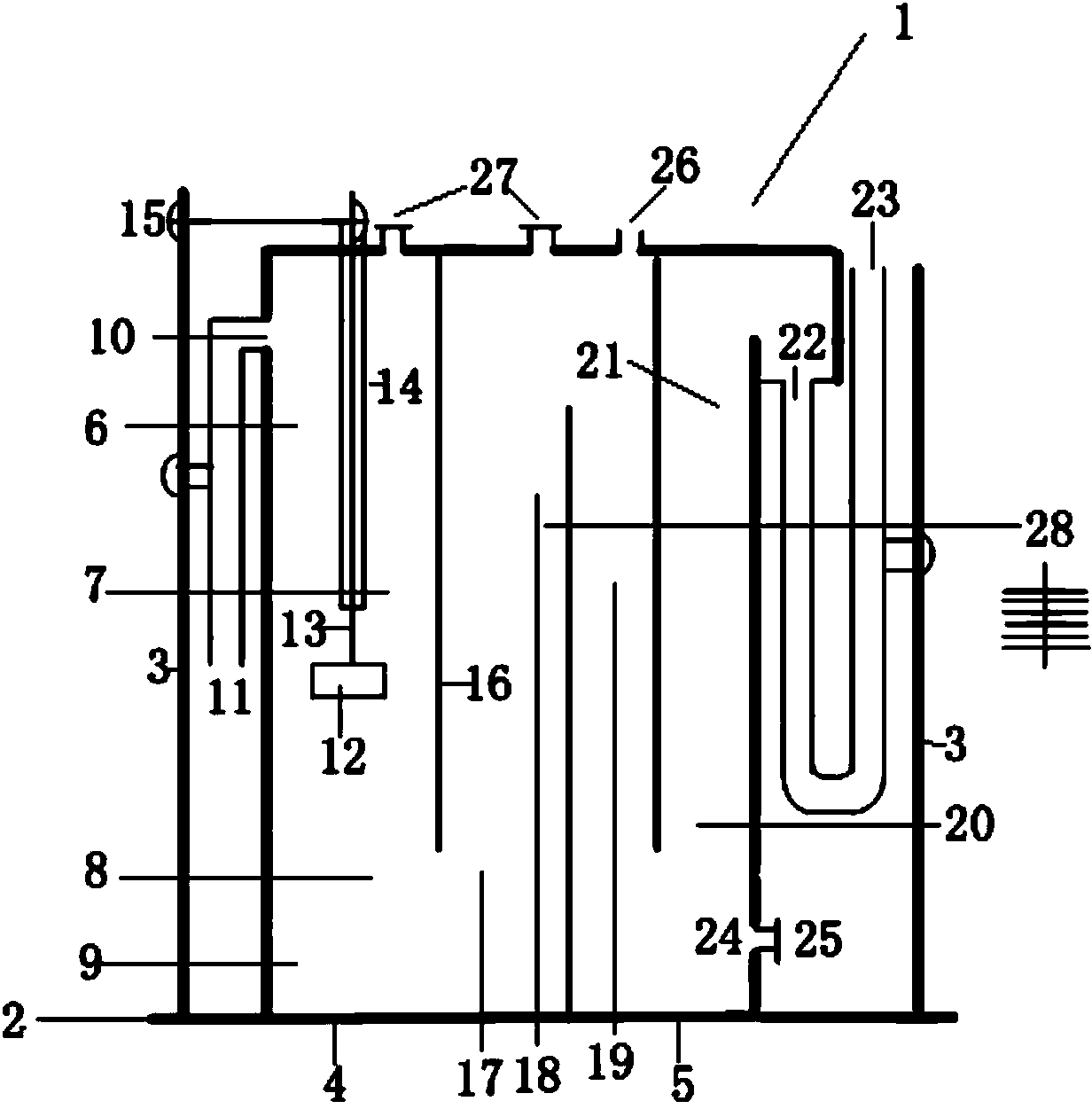

Hydraulic oil tank

ActiveCN103821780AExtend the flow pathExtended flow pathPump assembliesFluid-pressure actuator componentsOil canAir separation

The invention relates to a hydraulic oil tank, which comprises an oil tank body and an isolating component arranged in the oil tank body, wherein the oil tank body is provided with an oil return opening and an oil suction opening; the isolating component comprises at least two clapboards which divide the cavity of the oil tank body into three or more than three oil chambers; the oil return opening and the oil suction opening are positioned in two different oil chambers; all the clapboards are provided with meshes for allowing oil to pass through, so that the oil which enters the oil tank body by way of the oil return opening can pass through all the oil chambers in the oil tank body and then enters the oil suction opening; the size of each through hole which forms the mesh is big enough for the effect that air in the oil can be removed when the oil passes through the through holes. According to the hydraulic oil tank provided by the invention, effects of heat radiation, air separation and impurity precipitation are good, and bubbles in the hydraulic oil can be well removed.

Owner:LIUZHOU SHUANGJI MACHINERY

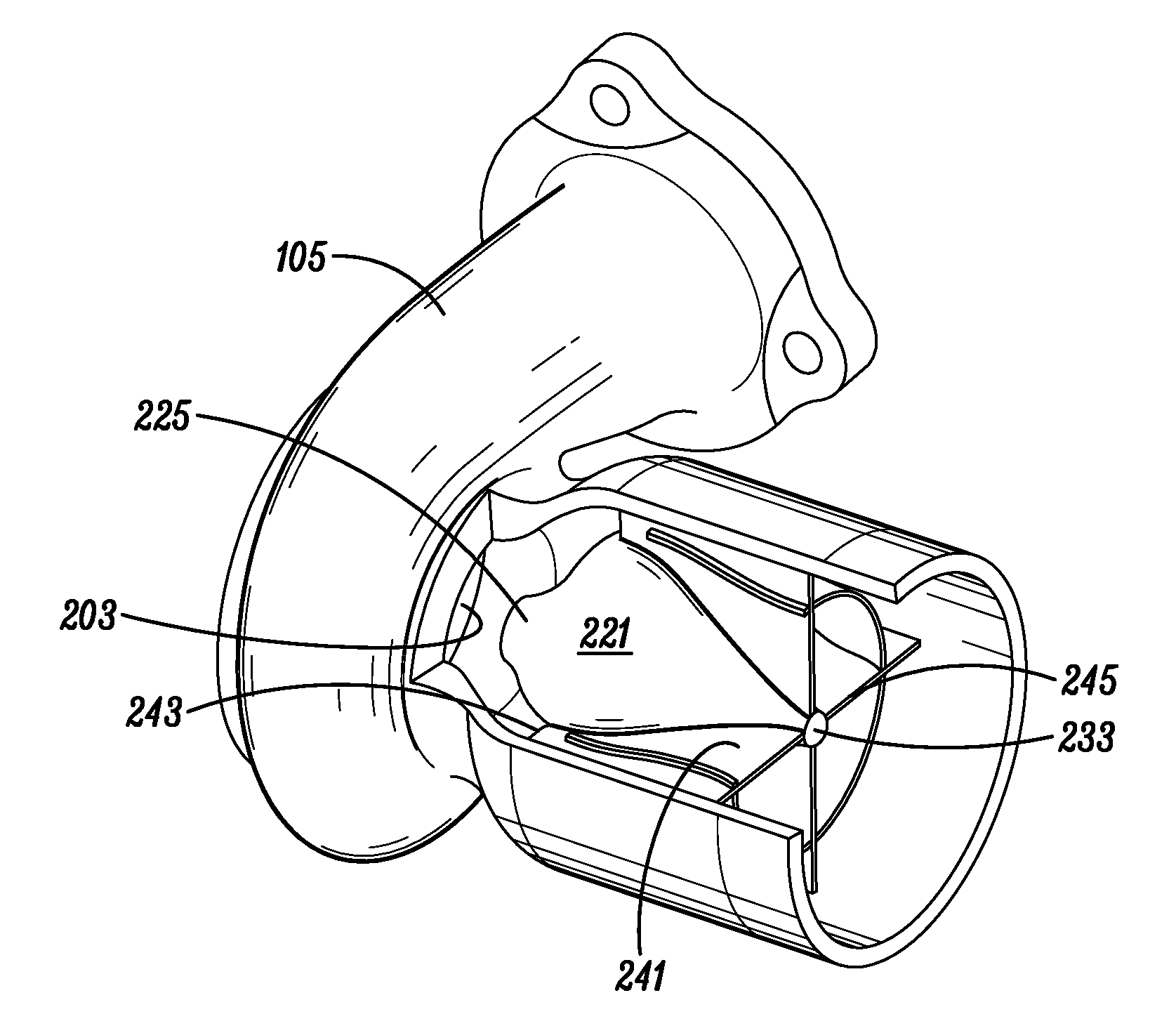

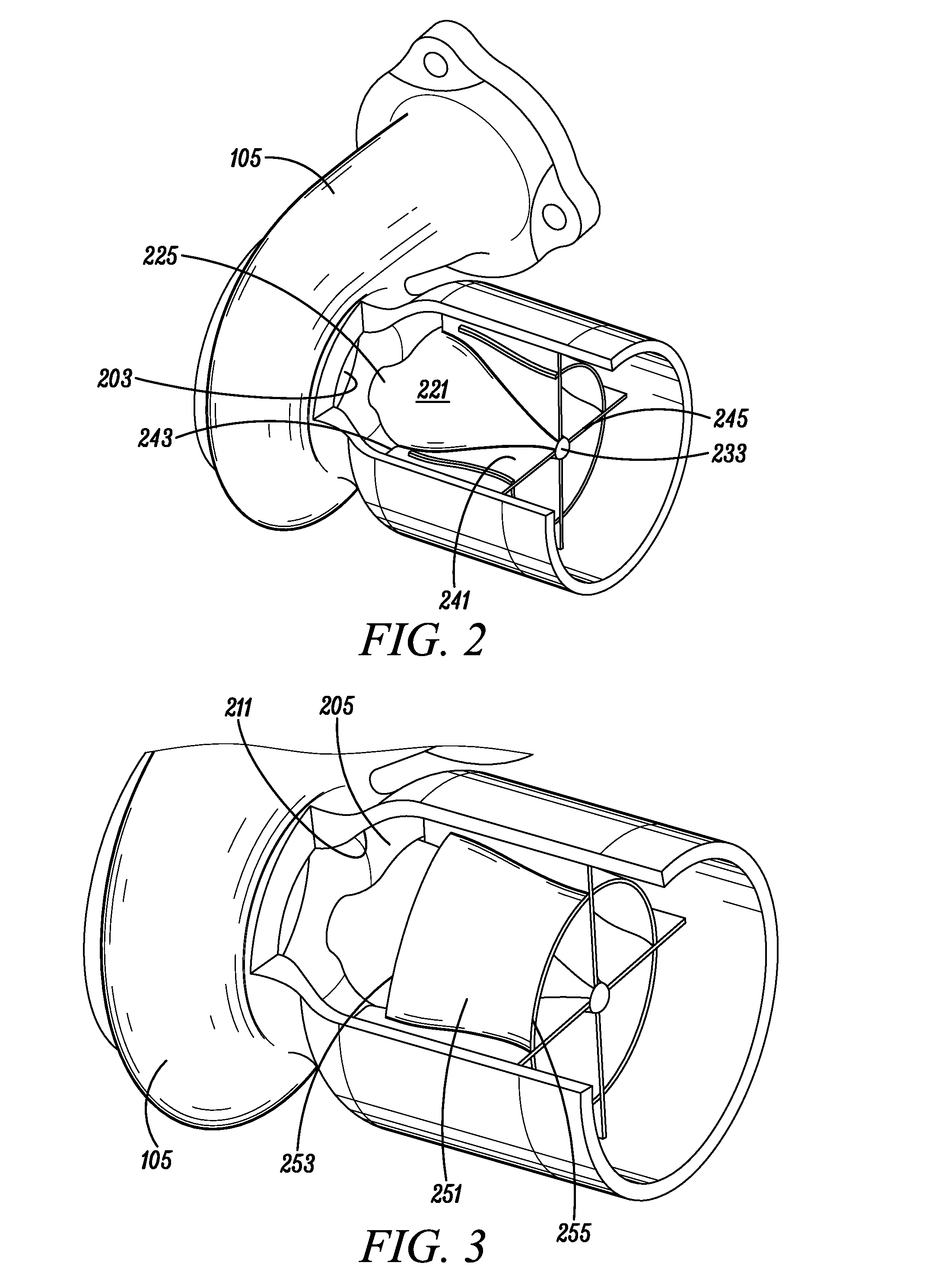

Turbocharger diffuser center body

ActiveUS20160245119A1Decrease tangential velocityIncrease mean diameterInternal combustion piston enginesEngine manufactureTrailing edgeEngineering

A turbocharger turbine having housing walls defining a diffuser. Within the diffuser, a center body within the diffuser is supported by de-swirl vanes extending from the diffuser wall. The center body forms a de-swirl passageway having an increasing mean diameter of flow from an upstream end of the center body to a leading edge of the de-swirl vanes. A trailing edge of the de-swirl vanes is near the downstream end of the center body. Annular-type guide vanes surround the center body within the de-swirl passageway. A wastegate system is configured to vent wastegate flow into the diffuser through injection ports on the de-swirl vanes, annular guide vanes and / or center body.

Owner:GARRETT TRANSPORATION I INC

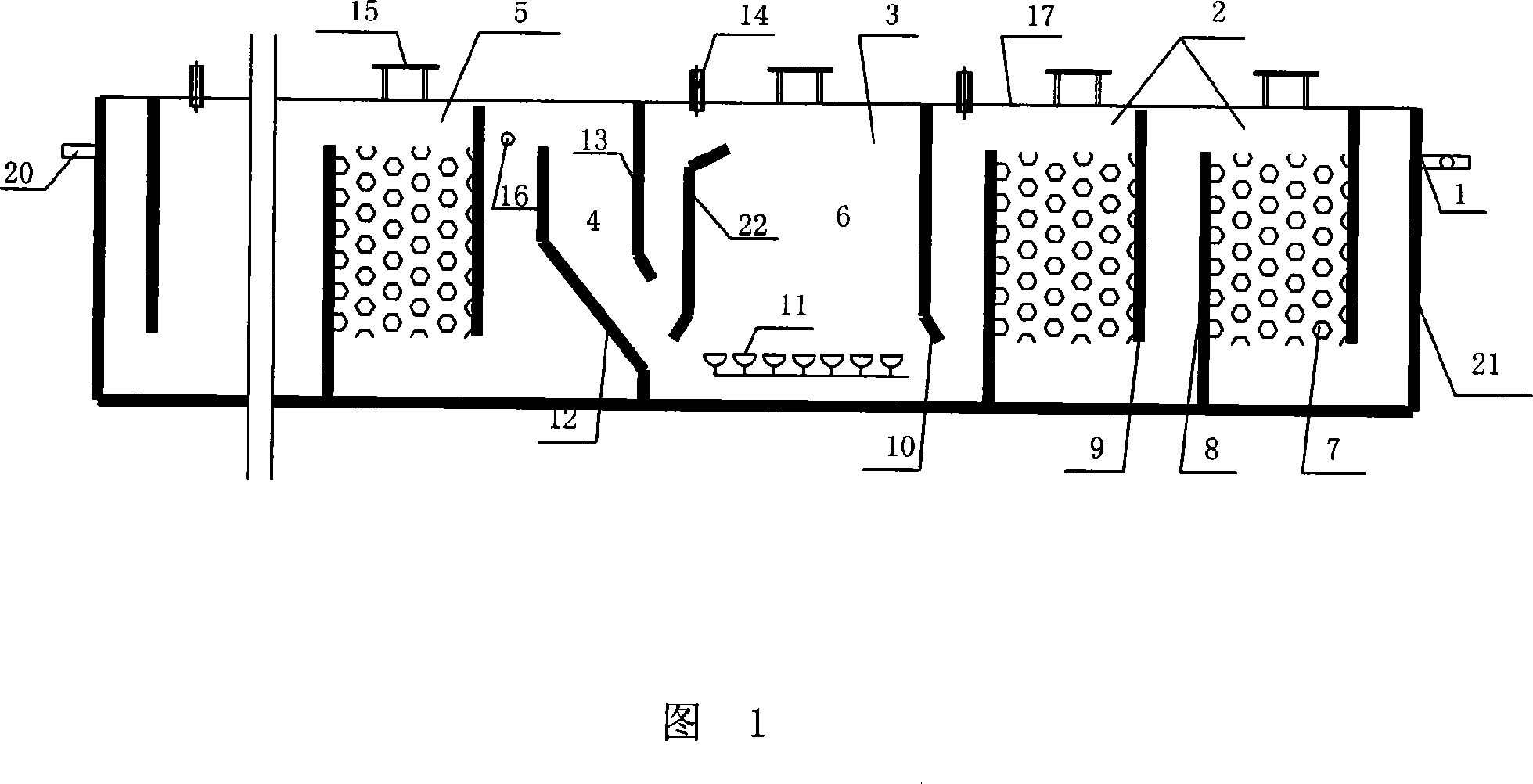

Sewage treatment device with denitrification function

InactiveCN101045583AReduce outputImprove processing efficiencyWater contaminantsTreatment with aerobic and anaerobic processesSludgeWater quality

A sewage treating apparatus with denitrifying function is composed of a pool body and a covering plate with several inoculating holes and exhausting hole. Said pool with water inlet and outlet is divided into an anaerobic decarbonizing region consisting of isolated flow-up chambers containing fixed filler and flow-down chamber, an aerobic nitrifying region consisting of the aerating chamber with internal aerating unit communicated with external air compressor and the precipitating chamber, and an anaerobic denitrifying region consisting several flow-up chambers containing fixed filler and several flow-down chambers.

Owner:ZHEJIANG UNIV

Apparatus and method for continuous separation of magnetic particles from non-magnetic fluids

InactiveUS20100200511A1Avoid stickingMinimize impactSettling tanks feed/dischargeWater/sewage treatment by magnetic/electric fieldsNon magneticMolecular physics

Owner:RES USA LLC

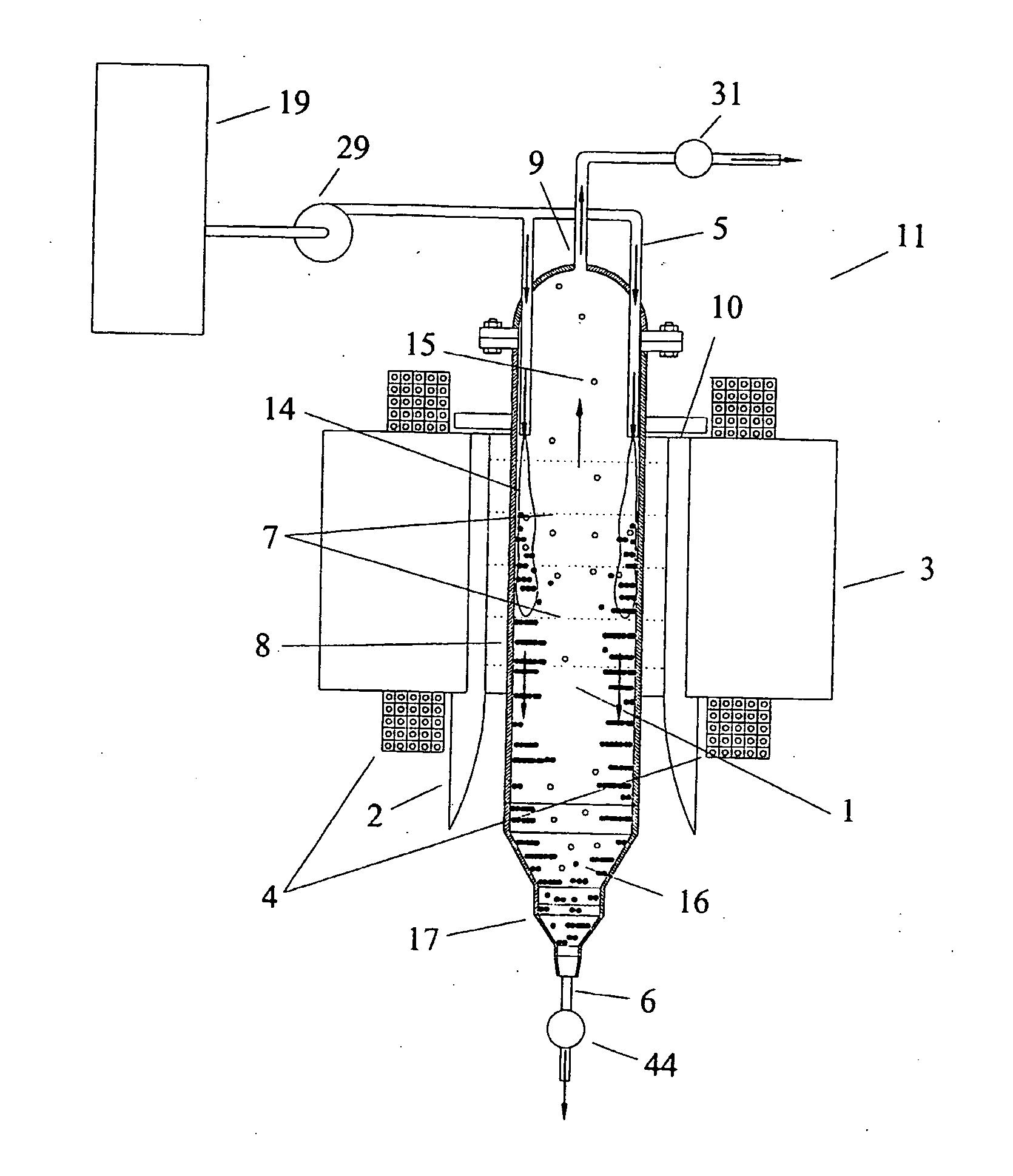

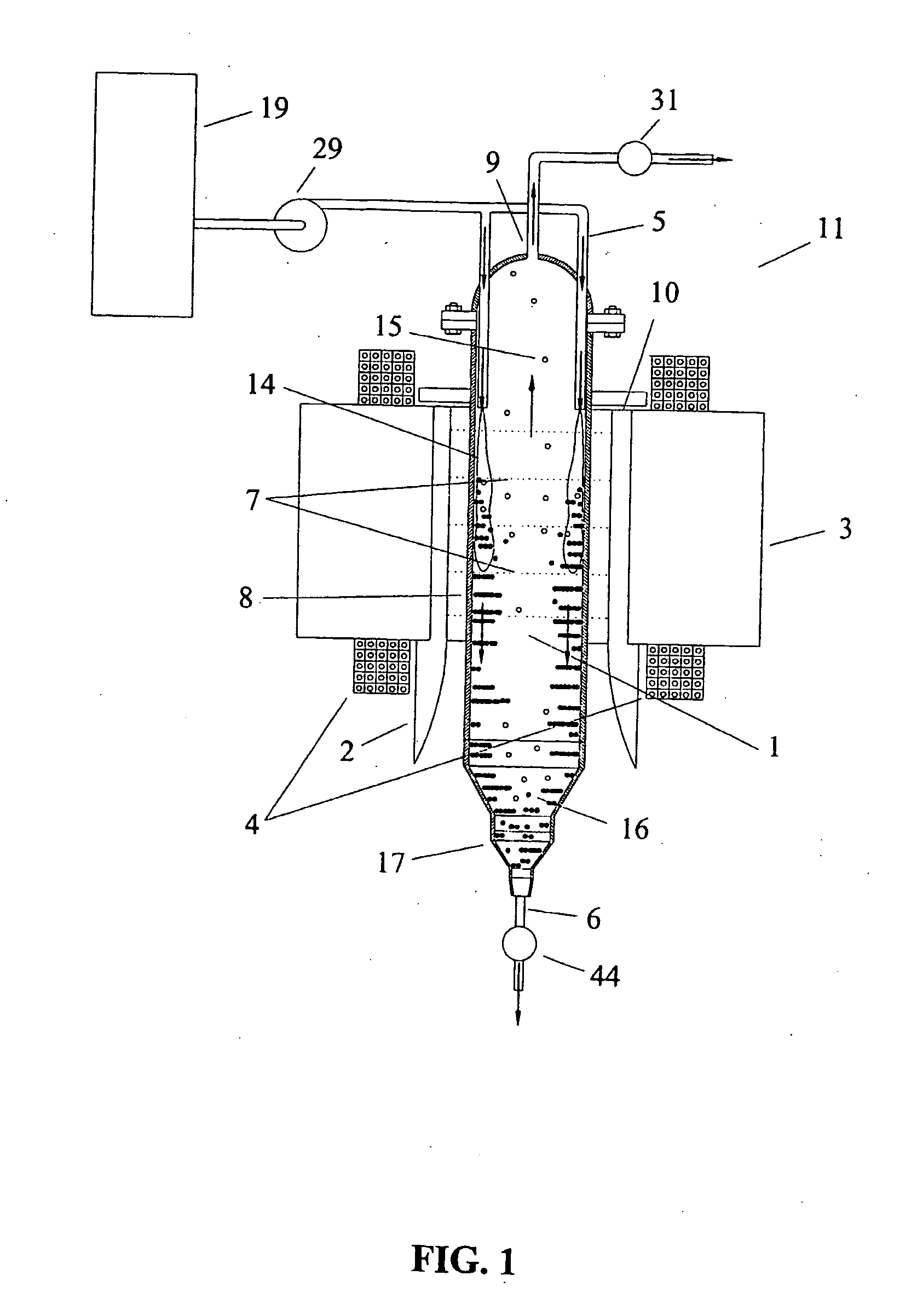

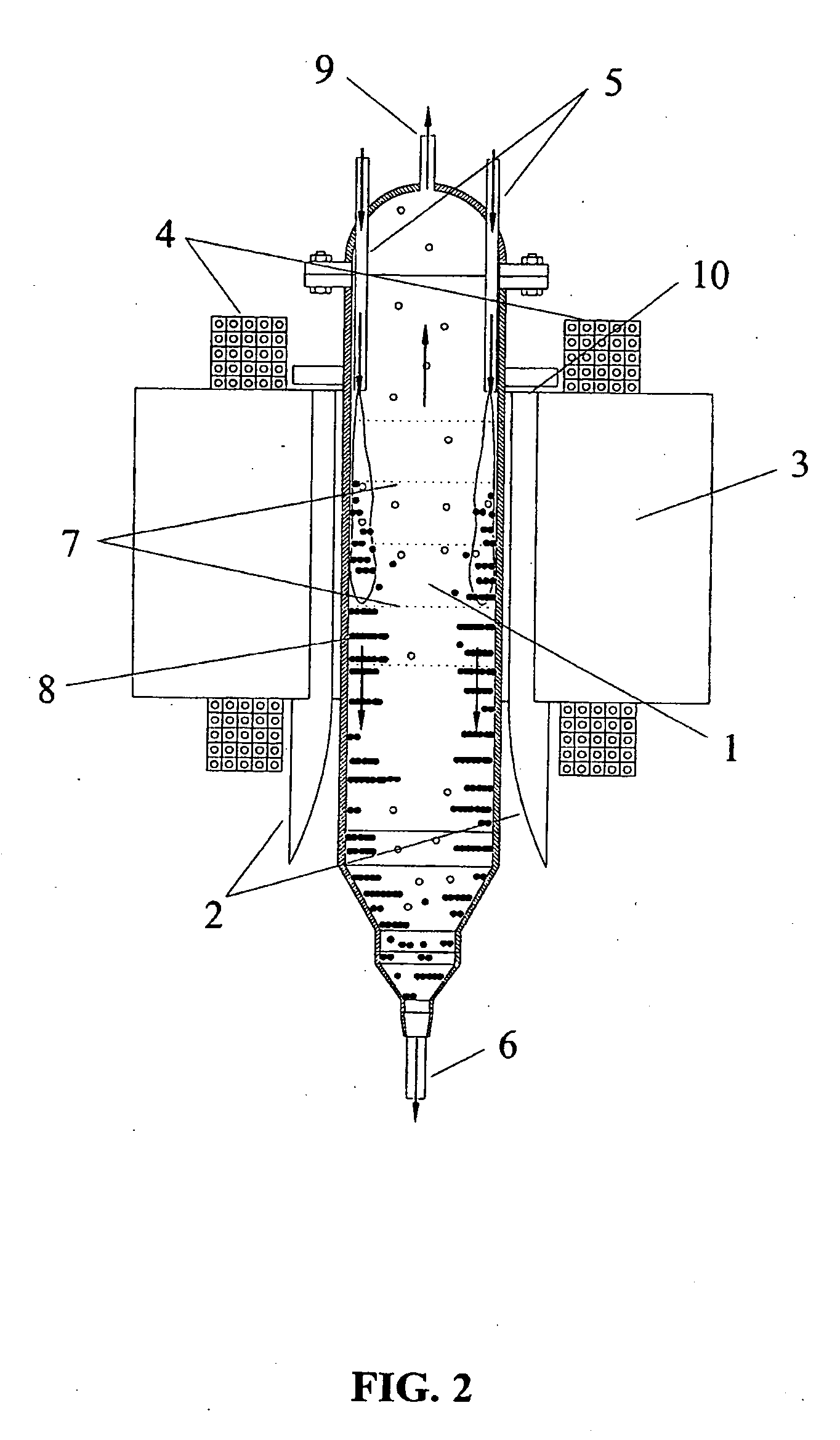

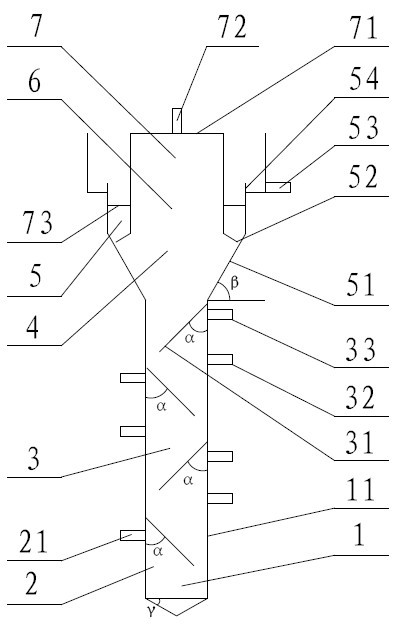

Upflow subregion anammox bioreactor

ActiveCN102153194AEfficient separationReduce churnTreatment with anaerobic digestion processesCouplingSludge

The invention relates to an upflow subregion anammox bioreactor, comprising a reactor body, wherein the reactor body is divided into a water inlet buffer region, an upflow reaction chamber and a three-phase separation region from bottom to top; the water inlet buffer region comprises a water inlet pipe arranged at one side of the bottom of the reactor body, the upflow reaction chamber is connected with a settling chamber of the three-phase separation region by virtue of an increasing coupling, an outer barrel of the settling chamber is internally provided with a three-phase separation chamber, a gas collecting chamber is arranged above the three-phase separation chamber, a gas collecting hood separated from the settling chamber is arranged at the top of the gas collecting chamber, an air outlet is arranged at the top end of the gas collecting hood, the upflow reaction chamber comprises a plurality of subregion reaction chambers which are separated by semi-opened baffles, the openings of the baffles are downward, and the baffles are connected to the wall of the reactor body in a left-right cross connecting way, the subregion reaction chambers are communicated by virtue of the baffles, and the side of the reactor body at the upper part of each subregion reaction chamber is provided with an exhaust port used for escaping part of nitrogen. By adopting the bioreactor provided by the invention, effective separation of water, gas and mud is realized, sludge loss is reduced, short circuit is avoided, and effective working space of the bioreactor is increased.

Owner:江苏清材智能制造有限公司

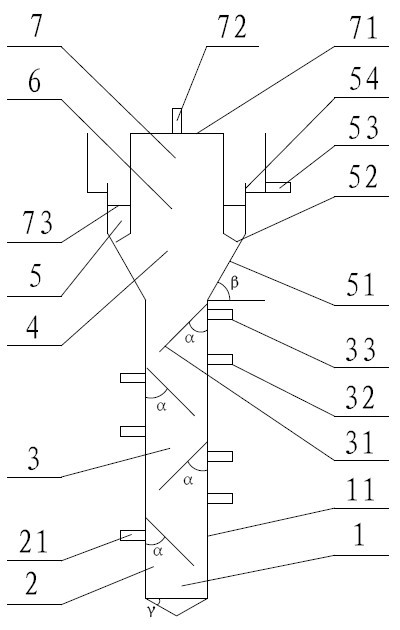

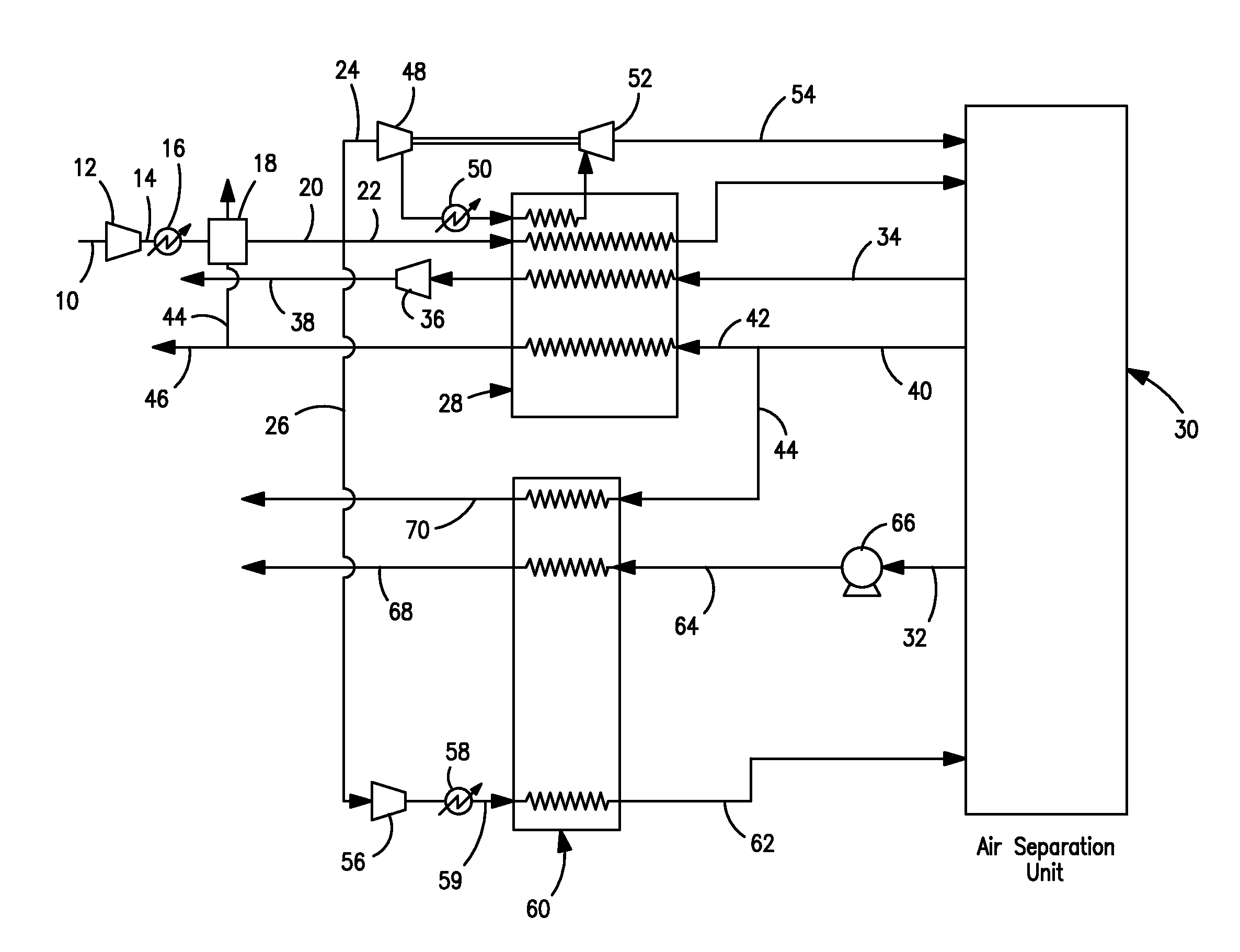

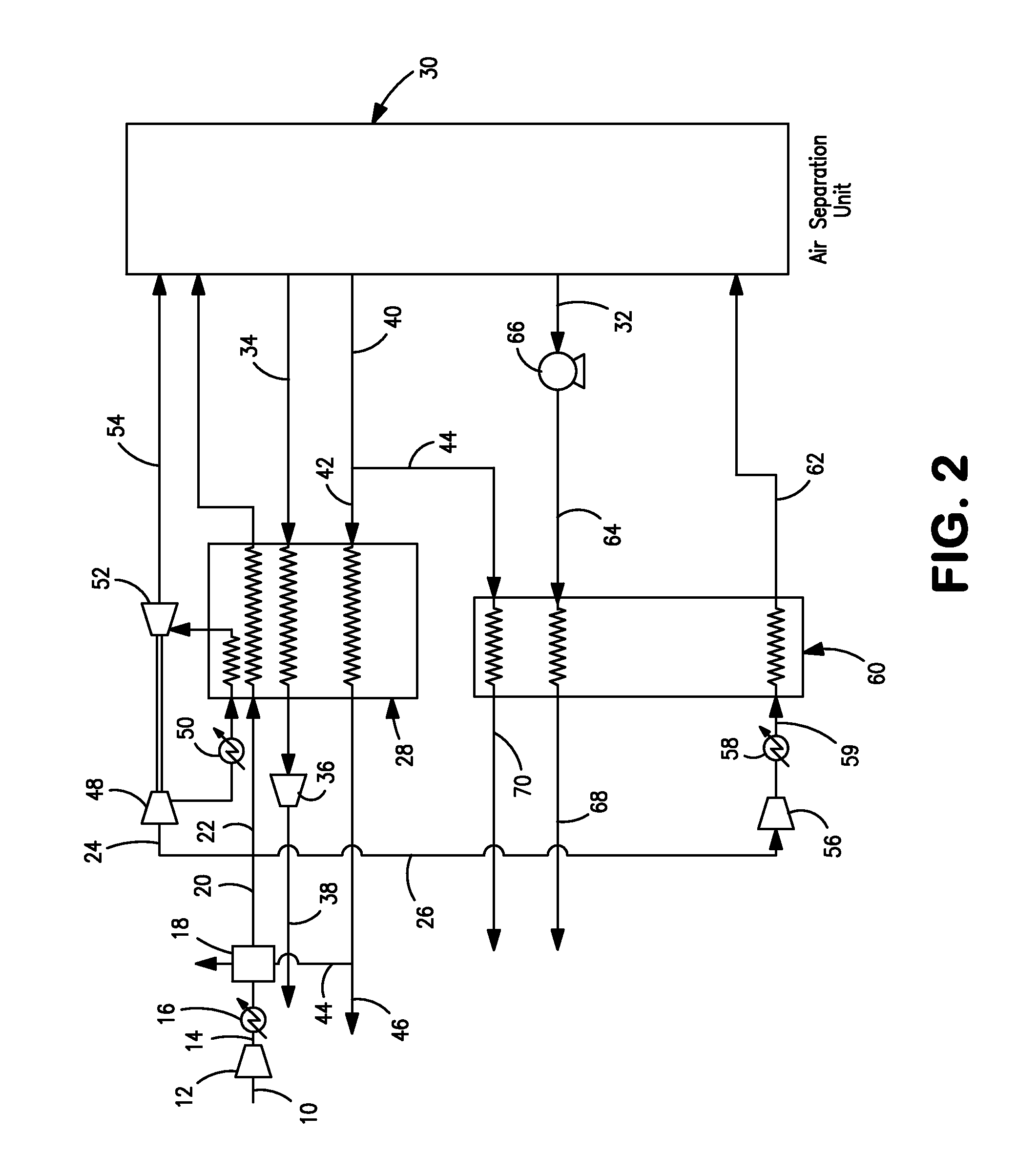

Air separation apparatus and method

InactiveUS20100287986A1Increase powerIncreased power consumptionSolidificationLiquefactionAir compressionPath length

The present invention relates to an air separation apparatus and method in which a pumped liquid oxygen stream is heated within a heat exchanger through indirect heat exchange with compressed air to produce an oxygen product. The liquid oxygen stream is pressurized in a range above about 55 bar(a) and no greater than about 150 bar(a) and is a supercritical fluid after having been heated within the heat exchanger. The air is compressed to an air pressure that is a function of the oxygen pressure that will result in a minimum power being expended in the compression of the air. The heat exchanger can be a brazed fin heat exchanger fabricated from aluminum in which the fins located in heat exchange passages have an undulating configuration to increase the flow path length and induce flow separation and thereby increase the heat transfer coefficient within the heat exchanger.

Owner:PRAXAIR TECH INC

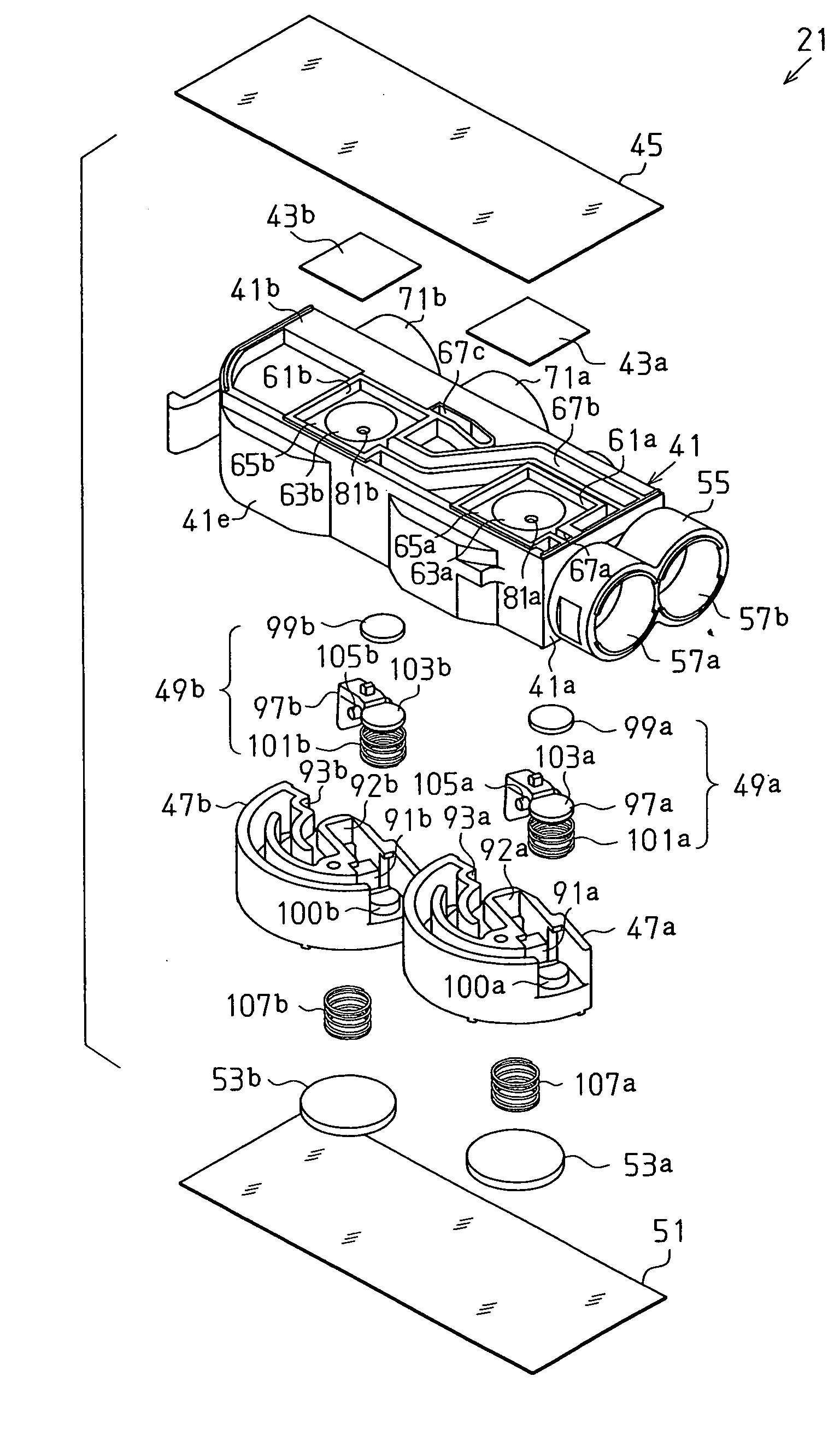

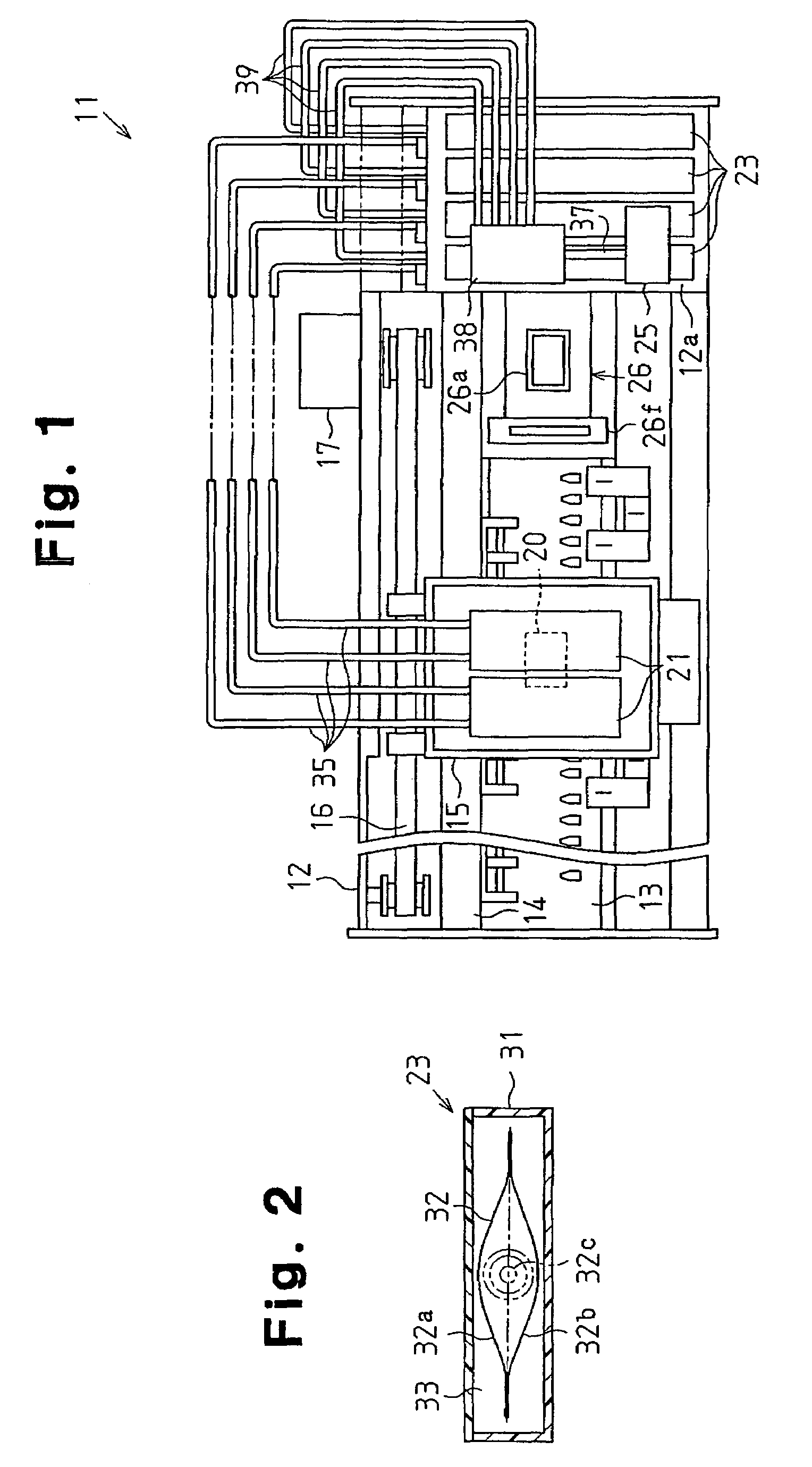

Liquid ejection apparatus and method for driving the same

InactiveUS20060061639A1Prevent ejection performanceReduced cross-sectional area of the flow pathPrintingEngineeringPressure difference

A liquid ejection apparatus comprises a liquid cartridge for storing a liquid, a liquid ejection head for ejecting the liquid toward a target, a liquid supply path for guiding the liquid to the liquid ejection head from the liquid cartridge, and a capping device for drawing the liquid from the liquid ejection head. The liquid supply path comprises a plurality of wall surfaces, and a part of the wall surface is formed of a flexible member that is flexed by the inside-and-outside pressure difference of the liquid supply path. A pressure pump for adjusting the pressure of a fluid within the liquid supply path in the upstream side of the flexible member is provided.

Owner:SEIKO EPSON CORP

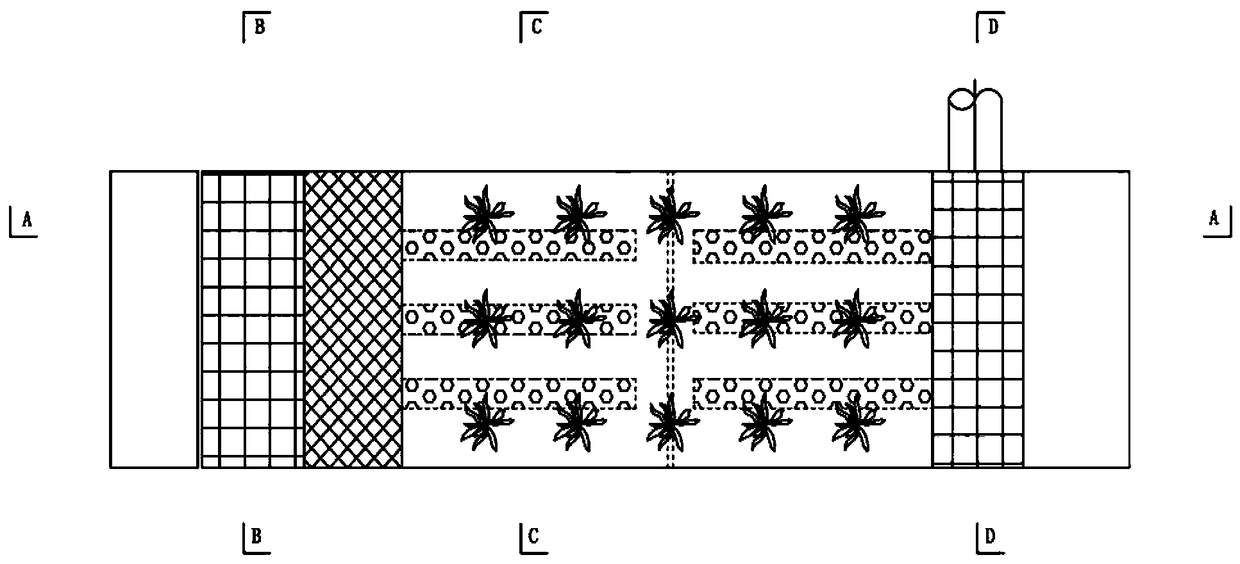

Integrated baffle-type autotrophic biological denitrification reactor

ActiveCN103523910ASmall footprintSimple structureTreatment with anaerobic digestion processesSludgeCoupling

The invention discloses an integrated baffle-type autotrophic biological denitrification reactor which comprises a reactor body, wherein the reactor body is provided with a first baffle plate; the first baffle plate divides the reactor body into a partial nitrification unit and an anaerobic ammoxidation unit; the upper end of the first baffle plate is connected with the top of the reactor body, and a gap is reserved between the lower end and the bottom of the reactor body; the anaerobic ammoxidation unit is divided into a biofilm area I, a biofilm area II, a particle sludge area, a second precipitation area and a second water outlet area from left to right; a second baffle plate is arranged between the biofilm area II and the particle sludge area; and a third baffle plate is arranged between the particle sludge area and the second precipitation area. According to the reactor disclosed by the invention, the coupling of a partial nitrification process and an anaerobic ammoxidation process is realized in a single reactor; and with the multi-level baffle plates, the flow path of the wastewater is prolonged, the effective reaction time is increased, and the biological withholding ability is enhanced.

Owner:HANGZHOU NORMAL UNIVERSITY

Liquid ejection apparatus and method for driving the same

InactiveUS7387377B2Reduced cross-sectional area of the flow pathReduce trafficPrintingLiquid jetEngineering

A liquid ejection apparatus comprises a liquid cartridge for storing a liquid, a liquid ejection head for ejecting the liquid toward a target, a liquid supply path for guiding the liquid to the liquid ejection head from the liquid cartridge, and a capping device for drawing the liquid from the liquid ejection head. The liquid supply path comprises a plurality of wall surfaces, and a part of the wall surface is formed of a flexible member that is flexed by the inside-and-outside pressure difference of the liquid supply path. A pressure pump for adjusting the pressure of a fluid within the liquid supply path in the upstream side of the flexible member is provided.

Owner:SEIKO EPSON CORP

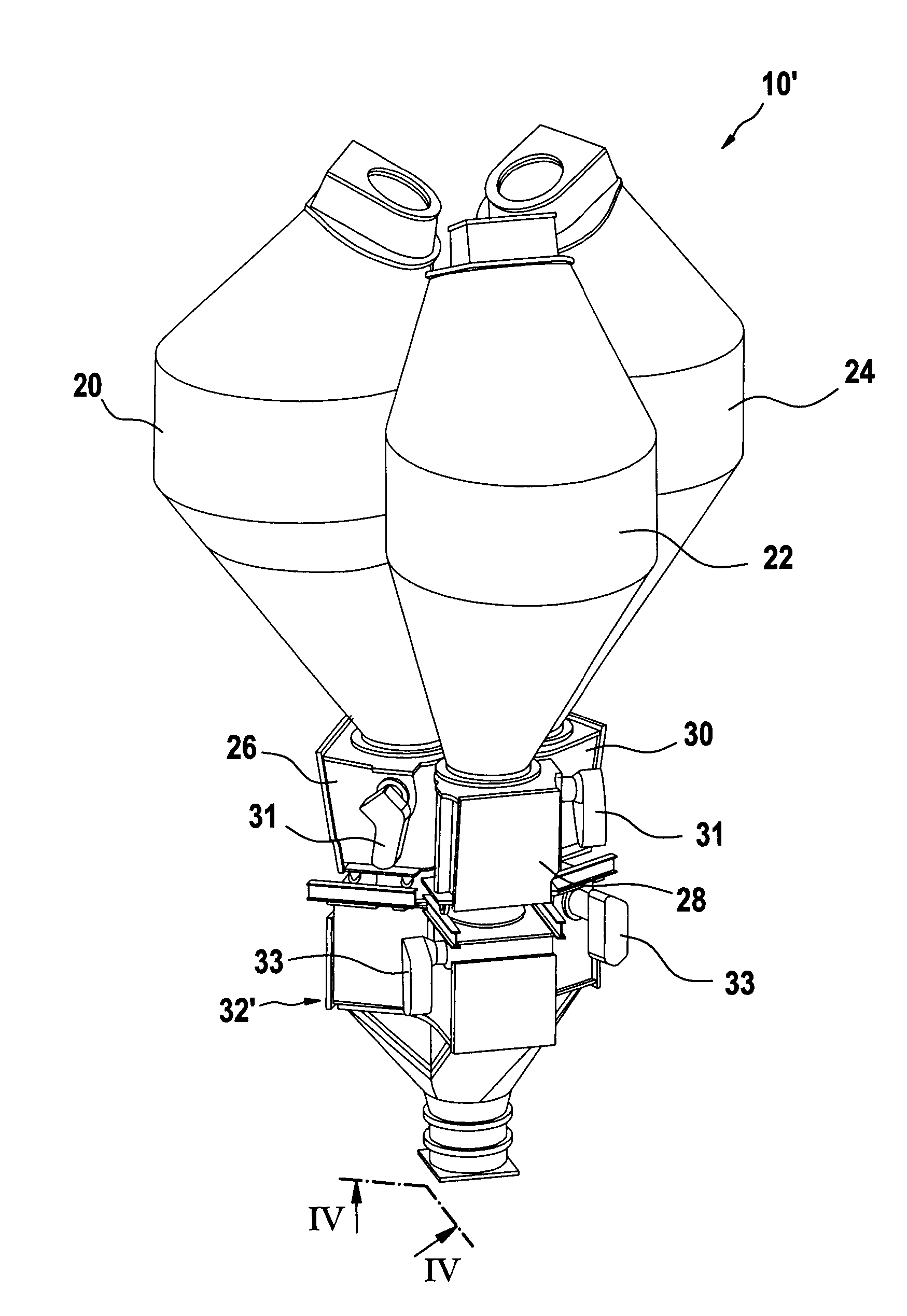

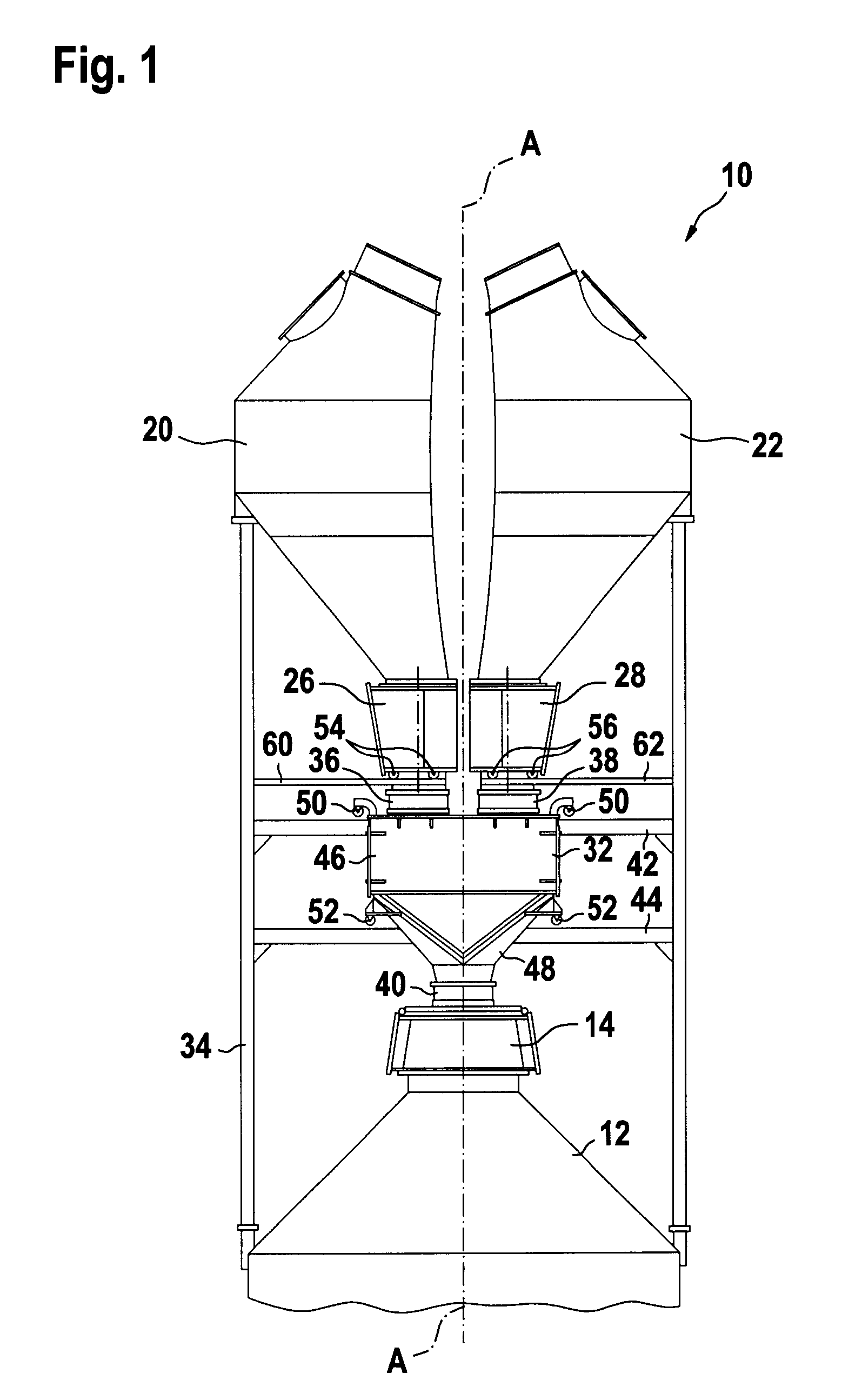

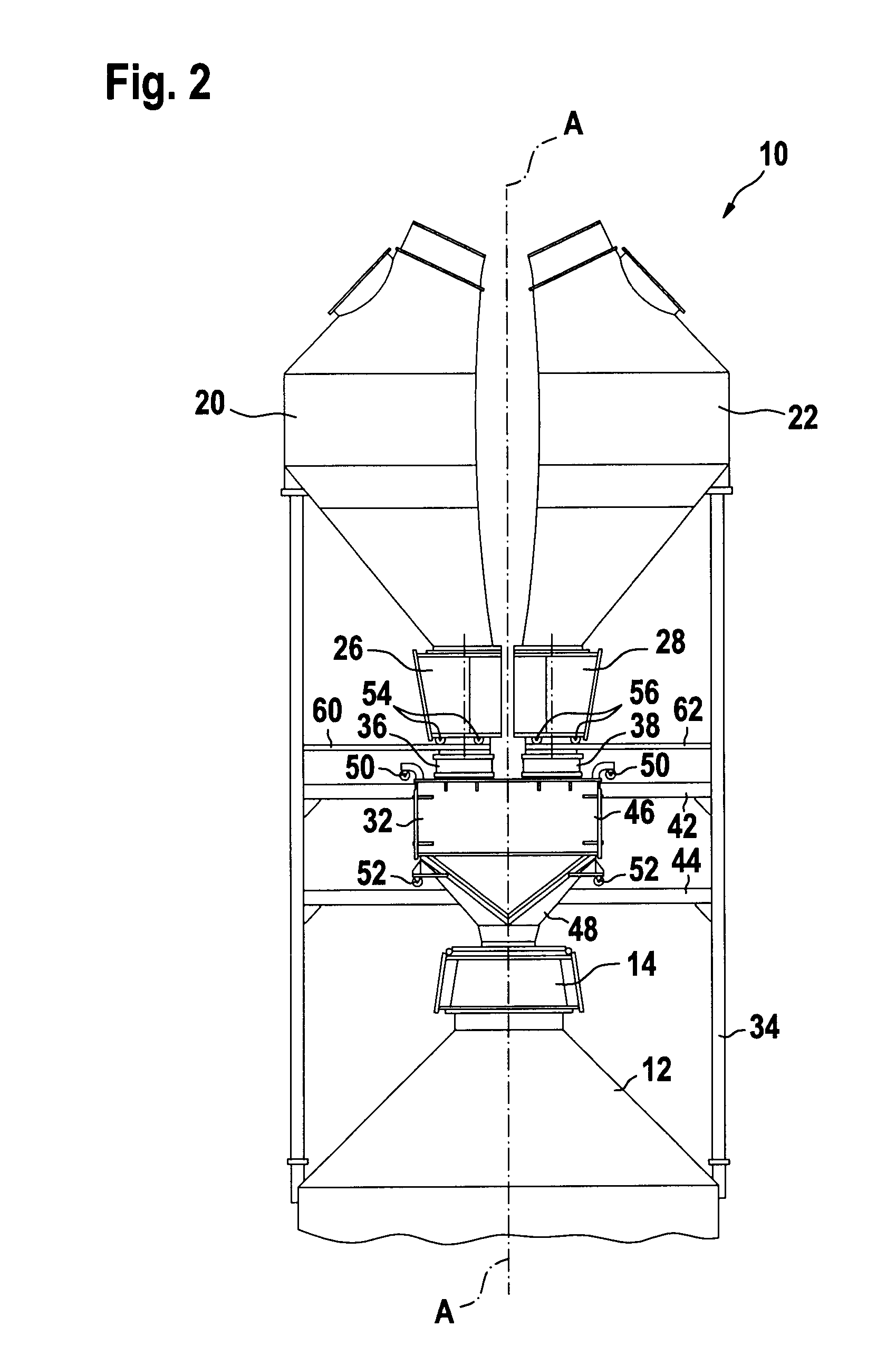

Three hopper charging installation for a shaft furnace

InactiveUS20090087284A1Smooth connectionExtend the flow pathConveyorsLarge containersEngineeringShaft furnace

A three hopper charging installation for a shaft furnace includes a rotary distribution device for distributing bulk material in the furnace by rotating a distribution member about the furnace central axis and a first, a second and a third hopper arranged in parallel above the rotary distribution device and offset from the central axis. A sealing valve housing is arranged between the hoppers and the distribution device. It has a top part with a first, a second and a third inlet respectively communicating with the first, the second and the third hopper. A first, a second and a third sealing valve are provided in the top part. Each sealing valve includes a flap which is pivotable between a closed sealing position and an open parking position. The sealing valve housing also has a funnel shaped bottom part with an outlet communicating with the distribution device. According to the invention, the top part of the sealing valve housing has a tripartite stellate configuration in horizontal section with a central portion, in which the inlets are arranged adjacently in triangular relationship about the central axis, and with a first, a second and a third extension portion, each sealing valve being adapted such that its flap opens outwardly with respect to the central axis by pivoting into a parking position located in the first, second or third extension portion respectively.

Owner:PAUL WURTH SA

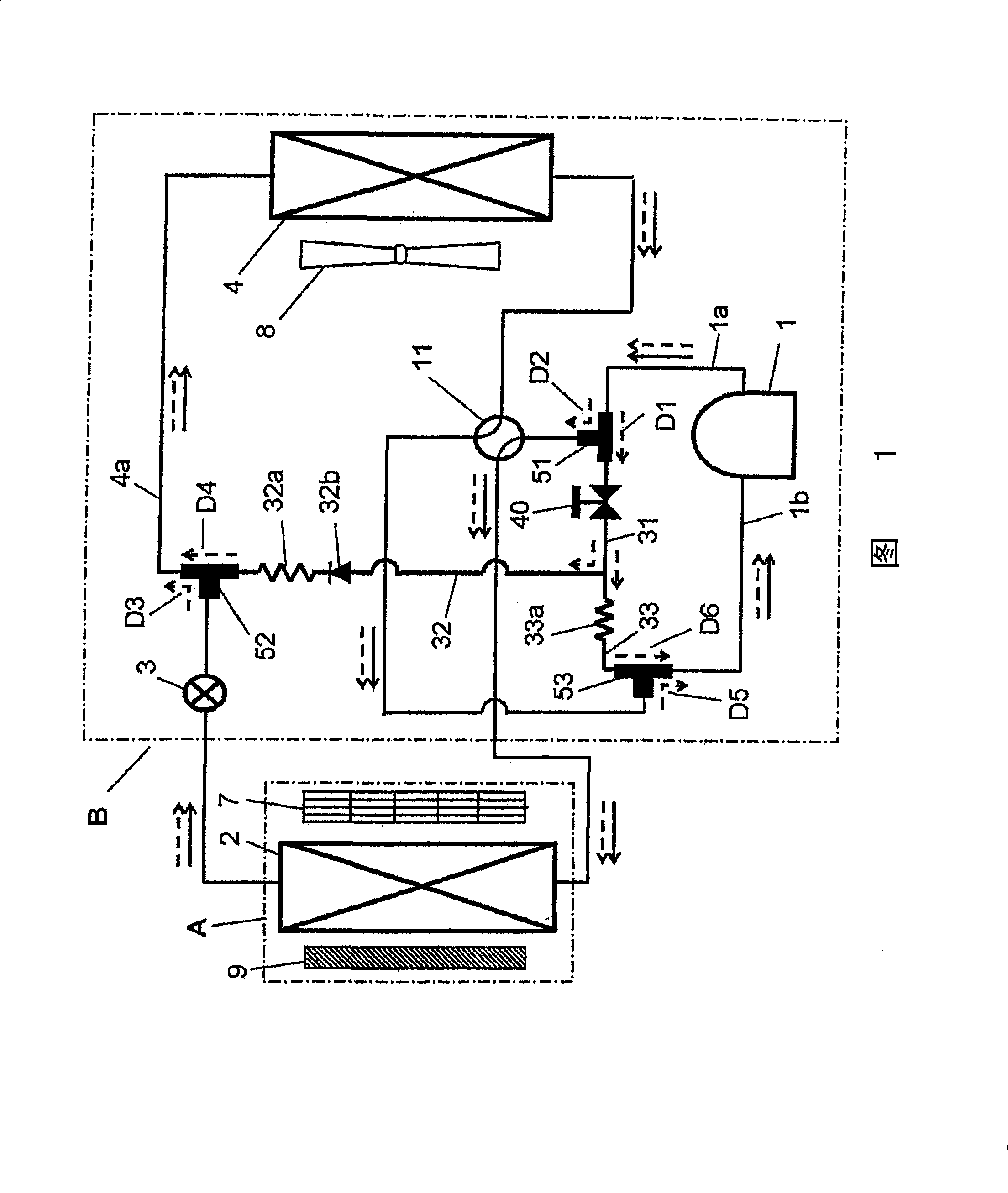

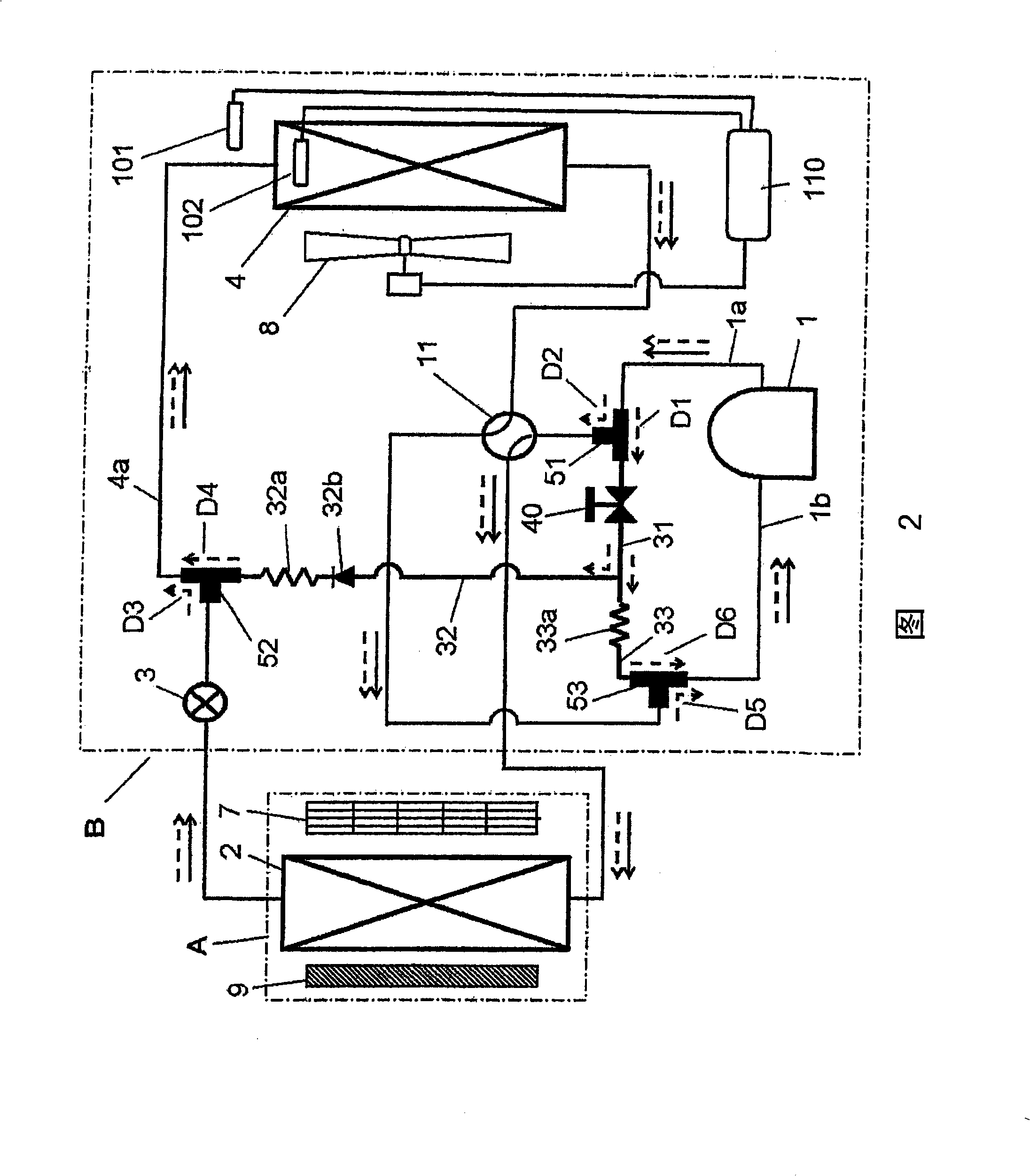

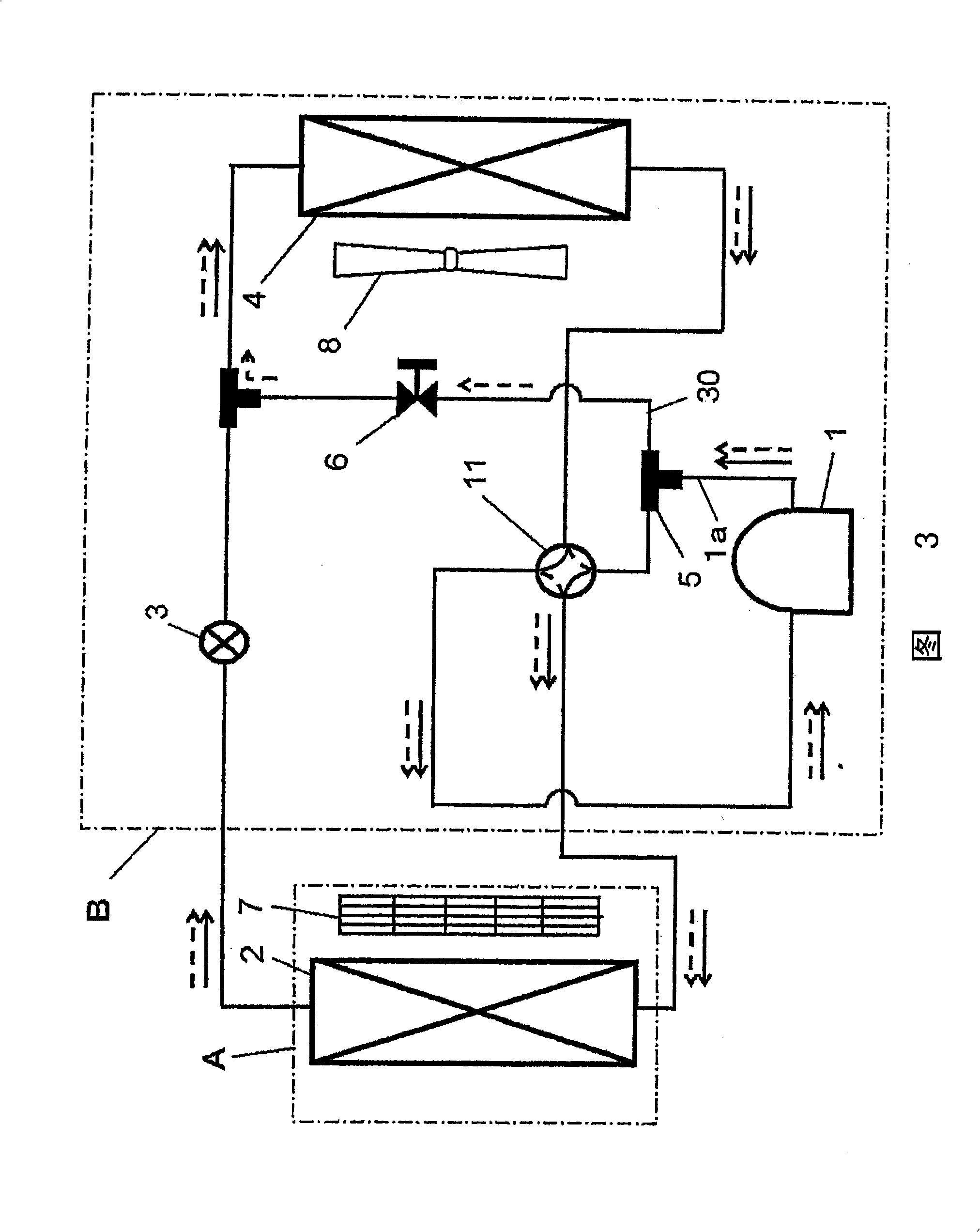

Refrigeration cycle apparatus

InactiveCN101307964AReduce flow path resistanceReduce the impactCorrosion preventionCompression machines with reversible cycleRefrigerantEvaporator

A refrigeration cycle apparatus for effectively performing defrosting, in which a compressor (1), a four-way valve (11), a condenser (2), a throttling device (3), and an evaporator (4) are connected via pipes, including: discharge gas bypasses (31, 32, 33) for flowing a discharge refrigerant to at least one of a suction pipe (1b) of the compressor and an evaporator pipe (4a) for connecting the throttling device and the evaporator, from a discharge pipe (1a) for connecting the compressor and the four-way valve; and a refrigerant controller (40) capable of optionally flowing the discharge refrigerant to the discharge gas bypasses, wherein the discharge refrigerant of the compressor is partially passed through the discharge gas bypasses during defrosting in a heating operation, and a flow rate to the discharge gas bypasses is larger than a flow rate to the four-way valve.

Owner:PANASONIC CORP

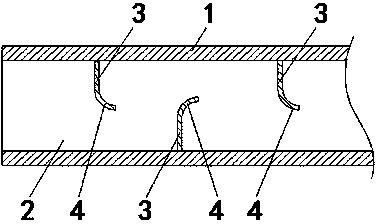

Speed reducing pipe

InactiveCN103470903AExtend the flow pathShorten speedFluid dynamicsPipe elementsEngineeringMechanical engineering

The invention discloses a speed reducing pipe, which comprises a speed reducing pipe body, wherein a flow channel is formed in the speed reducing pipe body; speed reducing plates are arranged at intervals on the upper and lower parts of an inner wall of the flow channel respectively. According to the speed reducing pipe, the speed reducing plates are arranged on the upper and lower parts of the inner wall of the flow channel in the speed reducing pipe body respectively, so that the velocity of fluid in the flow channel can be reduced under the blockage of the speed reducing plates when the fluid passes through the flow channel; in addition, the flow direction of the fluid can be changed between the adjacent speed reducing plates on the upper and lower parts of the inner wall of the flow channel, so that the flow path of the fluid can be prolonged, and a better speed reducing effect is achieved; the speed reducing pipe is simple in structure; the use of additional equipment for reducing the flow velocity of the fluid is avoided, so that the speed reducing pipe is low in using cost.

Owner:苏州市吴中区曙光铜管厂

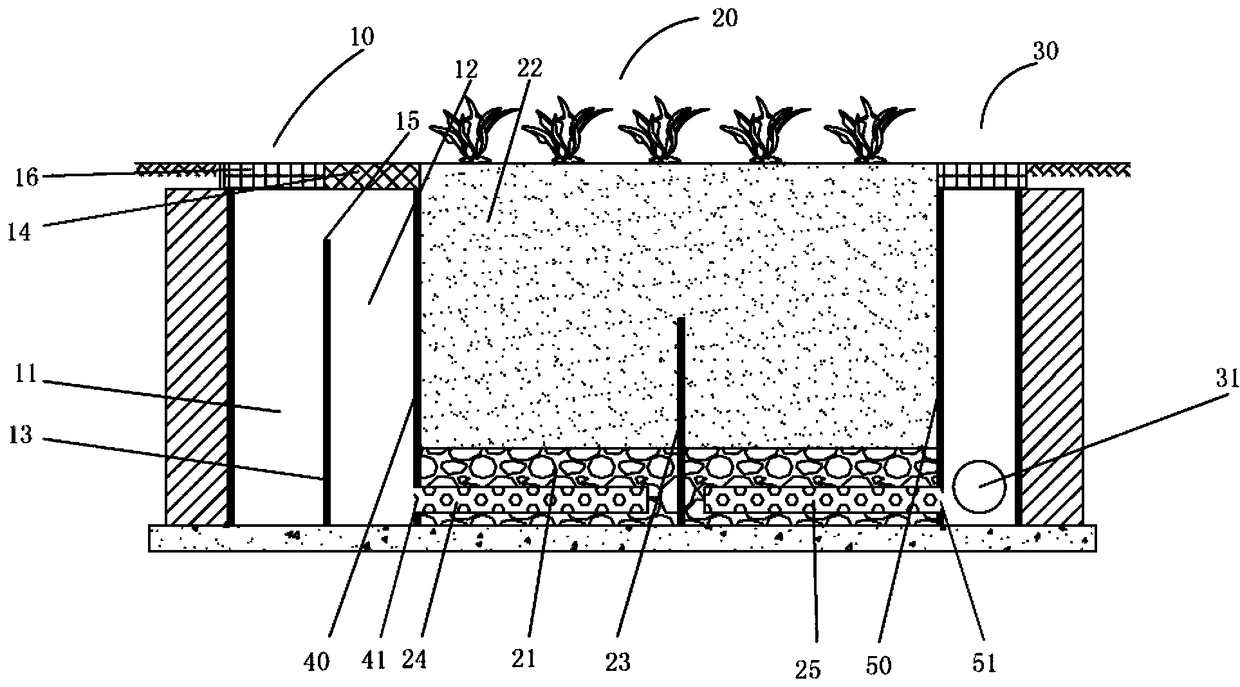

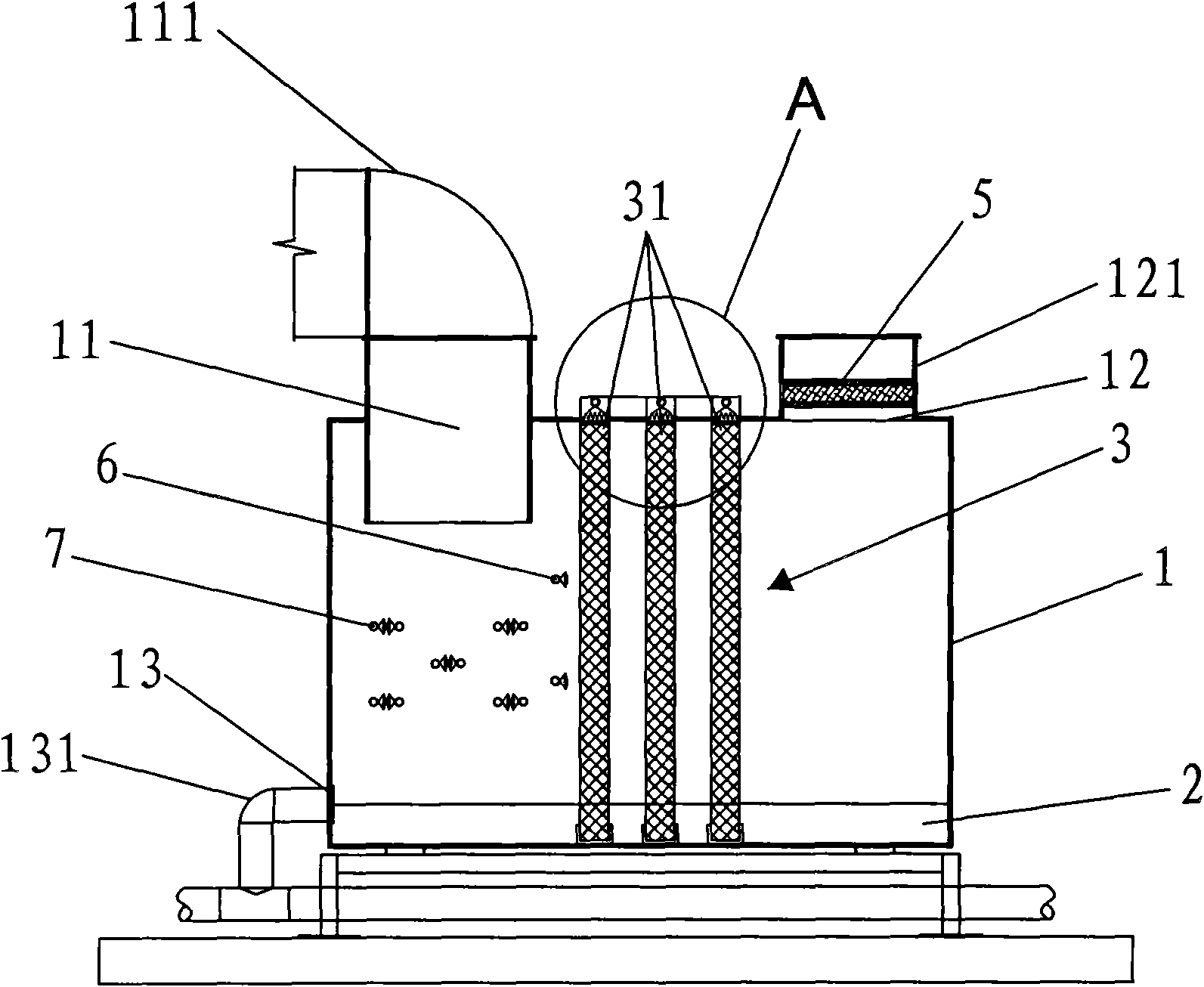

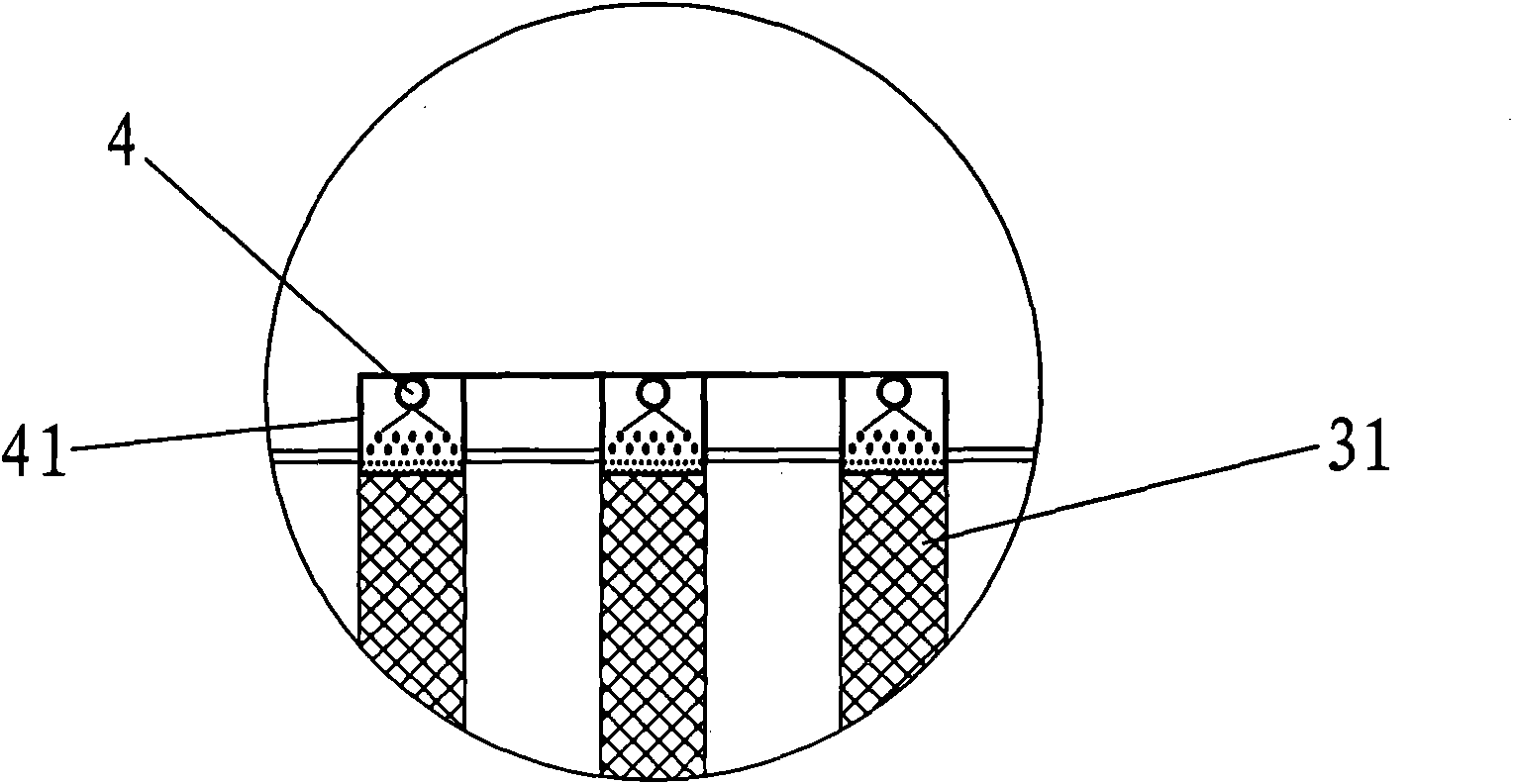

Mixed flow non-sunken bioretention pond having initial rainwater discarding function

ActiveCN108104247AReduce the likelihood of cloggingReduction of Particulate PollutantsFatty/oily/floating substances removal devicesSewerage structuresEngineeringBioretention

The invention discloses a mixed flow non-sunken bioretention pond having an initial rainwater discarding function. The retention pond comprises a bottom and sidewalls, and the retention pond is composed of three parts, namely an initial rainwater discarding and distributing well (10), a retention pond main body (20) and overflow and outflow water collecting well (30). Effective discarding and separating of initial rainwater can be achieved, and runoff pollution can be effectively controlled; a requirement on sinking downwards can be avoided, particulate pollutants in runoff entering facilitiescan be effectively relieved, the possibility that the bioretention pond gets blocked can be obviously reduced and efficient running of the facilities for a long term can be guaranteed; and through amixed flow mode combining 'upwards flowing and downwards flowing', overflowing paths of the runoff in the facilities are increased, and a control effect of the facilities over runoff pollution is obviously improved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

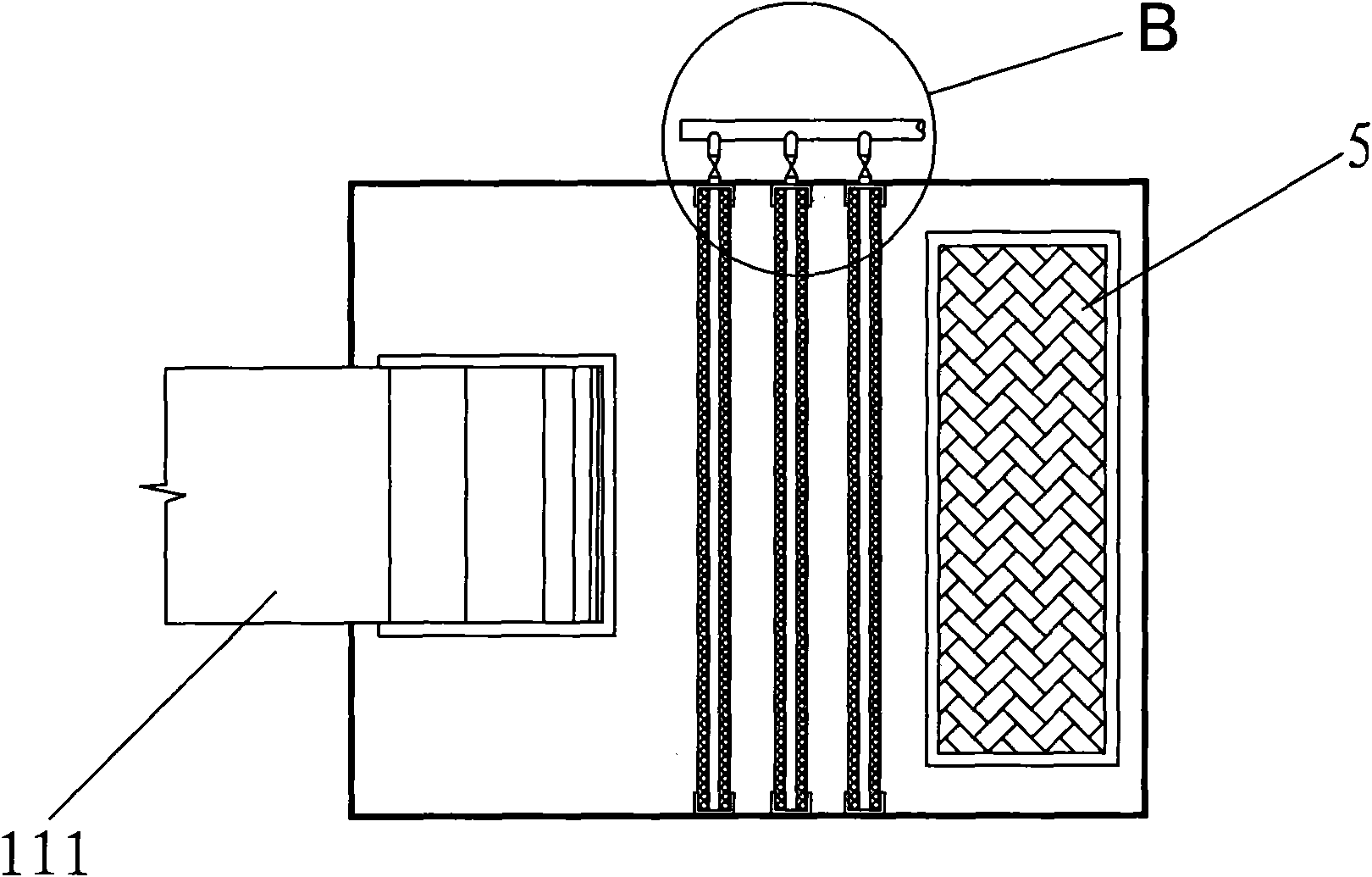

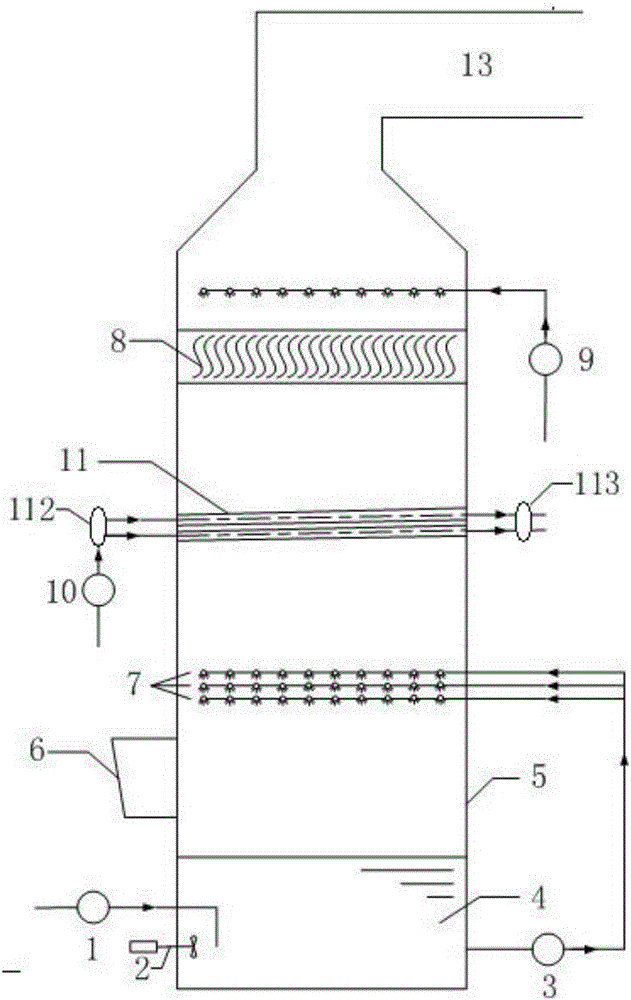

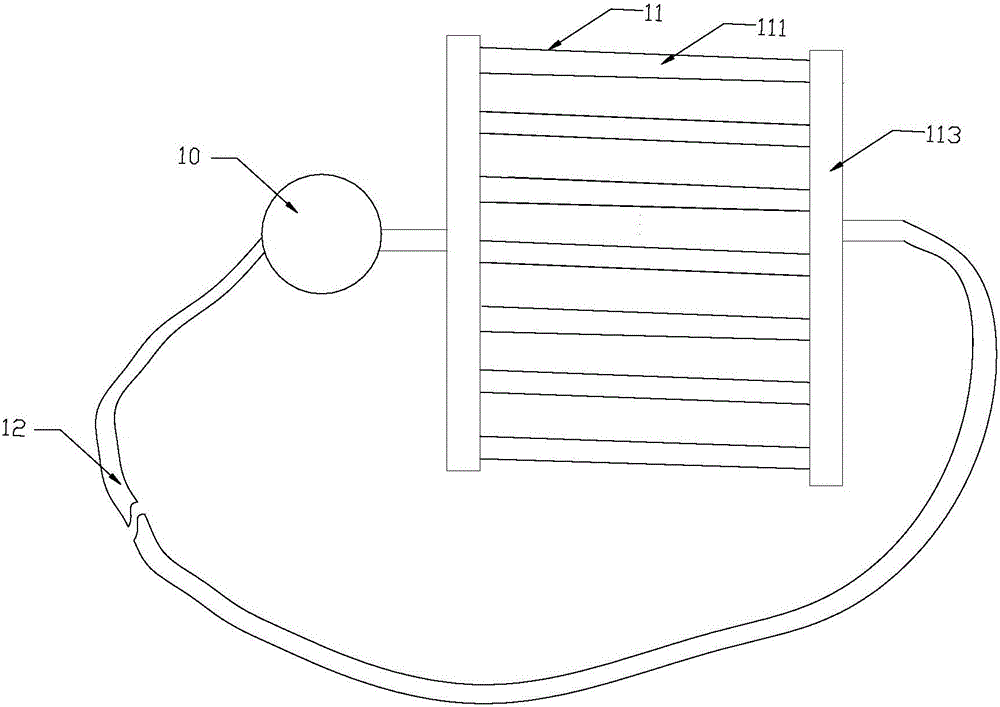

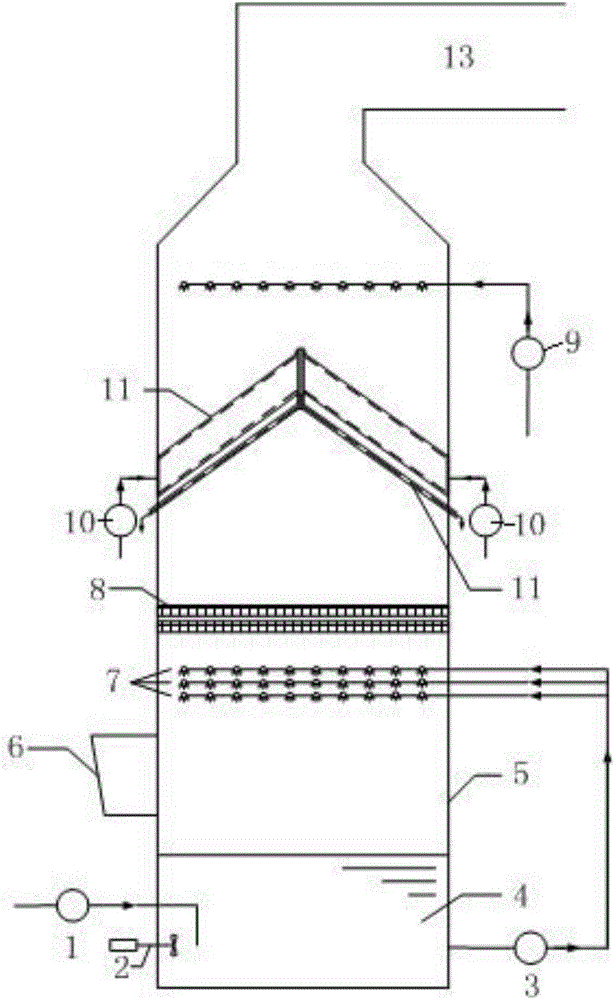

Triphen waste gas treatment device of porous medium material

The invention relates to the technical field of waste gas treatment devices, in particular to a triphen waste gas treatment device of a porous medium material, comprising a box body, a collecting tank arranged at the bottom of the box body and a porous medium material filter group comprising at least one porous medium material filter. A water certain is formed in the porous medium material filter when water is sprayed in the porous medium material filter by a spraying pipe at the top end of the porous medium material filter; and most harmful substances in triphen waste gas, such as fog drops, solid particles, and the like, can be mixed with water flows of the water curtain and emitted into a collecting tank when the triphen waste gas entering from an air inlet pipe passes by the water curtain so as to achieve the aim of treating the triphen waste gas. Compared with the traditional triphen waste gas treatment device, a triphen waste gas treatment device in the structure has remarkable treatment effect.

Owner:东莞市名航环保技术有限公司

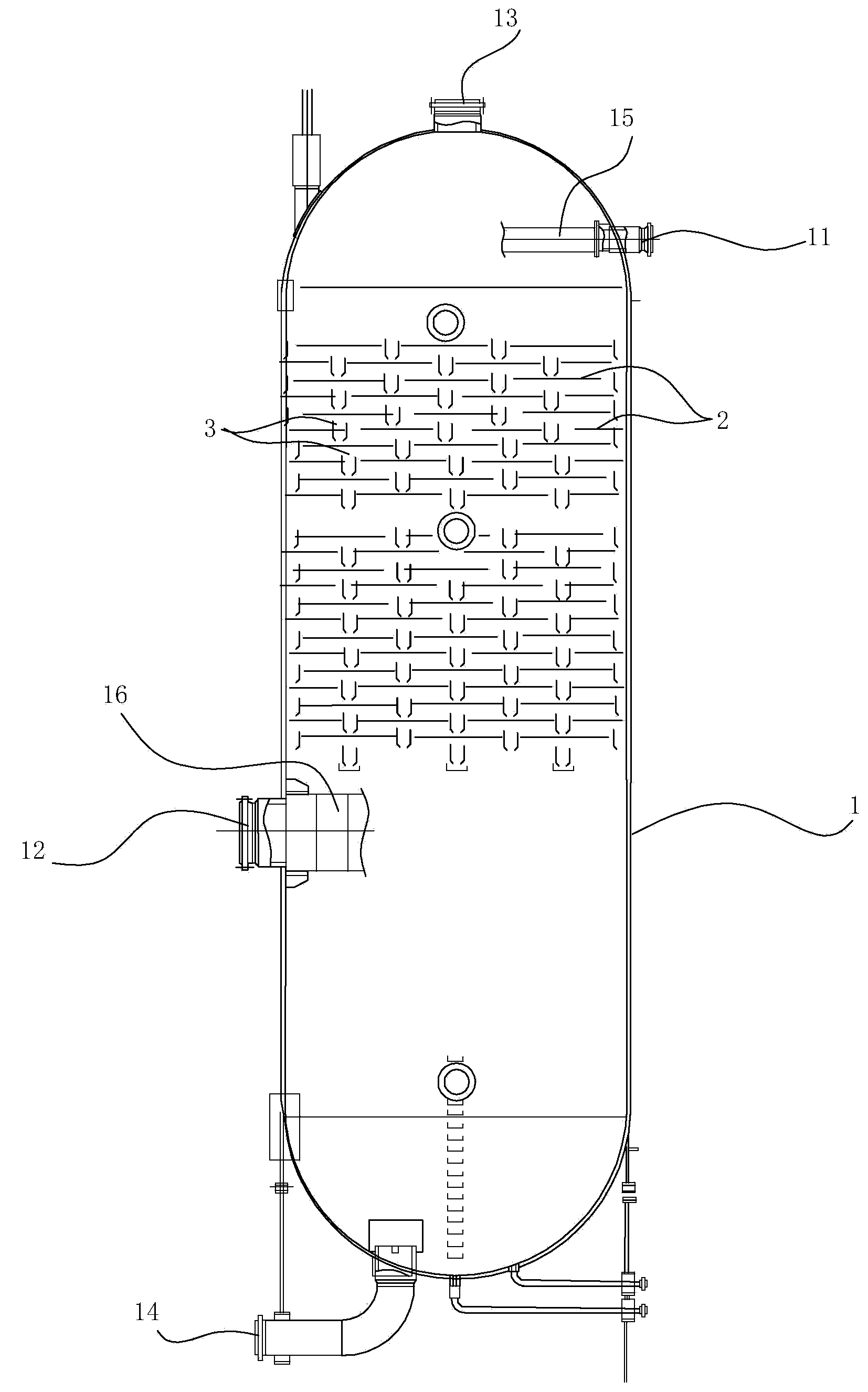

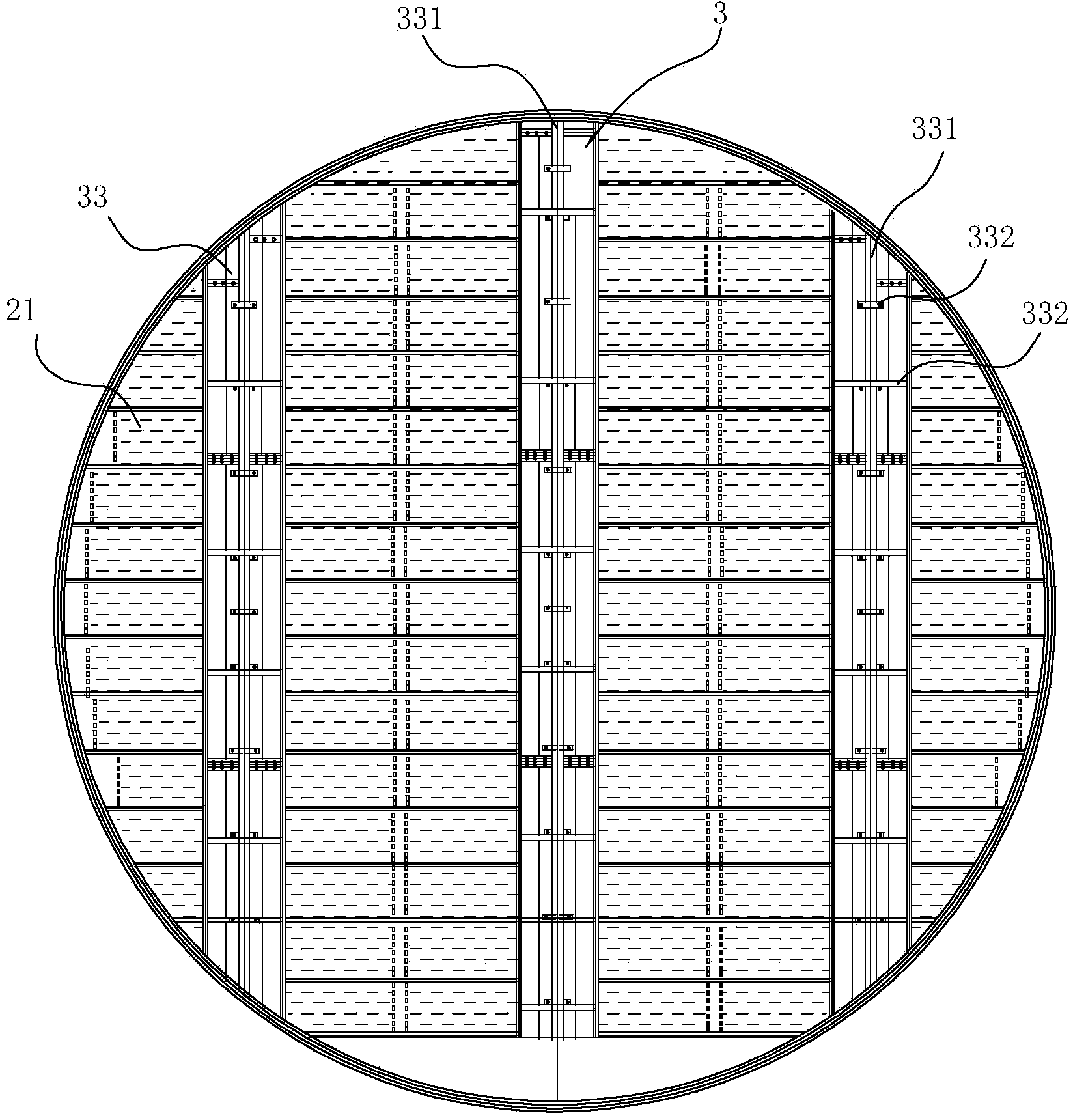

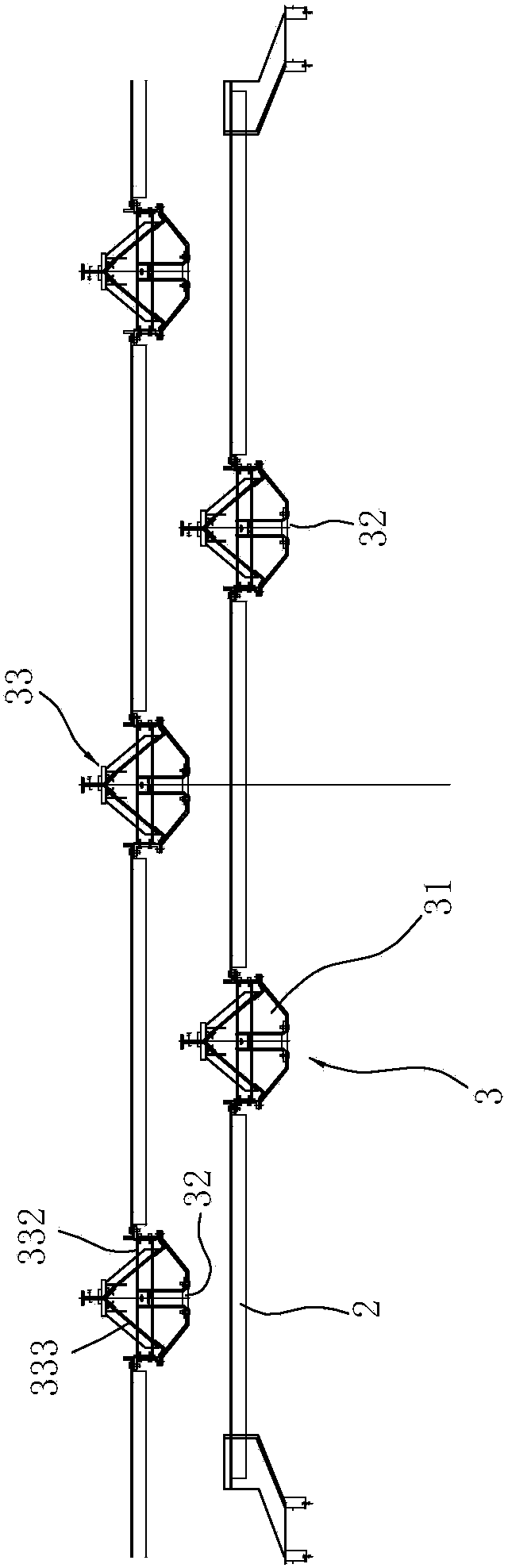

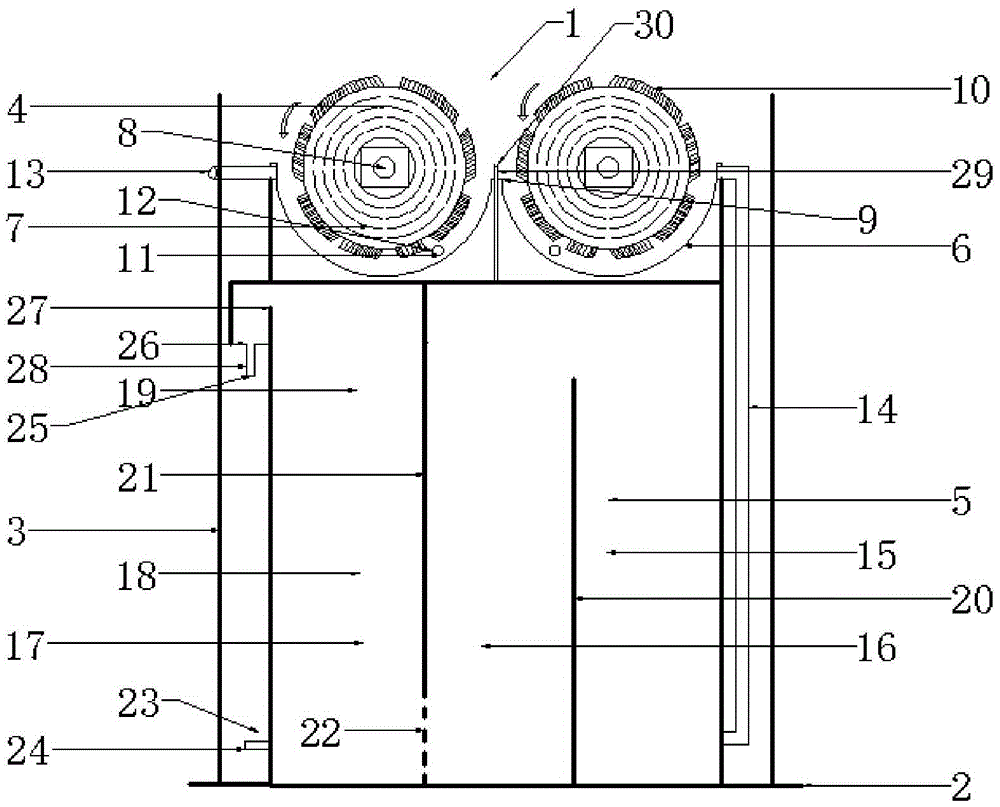

Extraction tower and process for removing methanol from residual C4 of etherification reaction

ActiveCN104225955ALower the altitudeReduce board spacingLiquid solutions solvent extractionExtraction purification/separationPtru catalystFluid phase

The invention relates to an extraction tower and a process for removing methanol from residual C4 of an etherification reaction. The extraction tower comprises a tower body which is internally provided with a plurality of supporting beams; each group of supporting beams corresponds to one layer of tower plate in parallel; a plurality of grooves are formed in each supporting beam at intervals; liquid flow holes communicated with the adjacent lower layer of tower plate are formed in the bottom surfaces of the grooves; each layer of tower plate is formed by splicing a plurality of secondary tower plate pieces; the supporting beams in each two adjacent groups are arranged in a staggered manner; a washing liquid inlet is formed in the upper part of the tower body and a C4 inlet is formed in the lower part of the tower body; a gas-phase outlet is formed in the tower top, and a liquid-phase outlet is formed in the tower bottom. Desalted water which is taken from the outside and has the temperature of 35-45 DEG C enters the tower body from the washing liquid inlet through a desalted water pump, residual C4 of the etherification reaction, which has the temperature of 35-45 DEG C, enters the tower body from the C4 inlet, and the flow ratio of the washing liquid to residual C4 of the etherification reaction is 1 to (20-25). Methanol in mixed C4 with the low methanol content can be removed and the content of methanol in processed mixed C4 is not more than 50ppm so that the consumption amount of a sulfuric acid catalyst in an isooctane device, the energy consumption of the device and the amount of waste acids can be reduced.

Owner:NINGBO HAIYUE NEW MATERIAL

Liquid film dedusting device and desulfurizer dedusting rectification system with same

InactiveCN105688581AExtend the flow pathReduce emission concentrationCombination devicesUsing liquid separation agentWater vaporFlue gas

The invention relates to a liquid film dedusting device which is used in a desulfurizer, has a simple structure, can be used for effectively removing smoke dust and liquid drops in flue gas, and is free of secondary pollution. The liquid film dedusting device comprises a dedusting assembly formed by multiple layers of dedusting units, a water inlet header, a water return header, a circulating water pump and a circulating waterway, wherein each layer of dedusting units comprises a plurality of diversion pieces in parallel, a gap is formed between each two adjacent diversion pieces, the diversion pieces of each two adjacent layers of dedusting units are staggered in parallel to rectify flue gas, a water inlet of each diversion piece is communicated with the water inlet header, a water outlet of each diversion piece is communicated with the water return header, the water return header is communicated with the water inlet header via the circulating waterway and the circulating water pump in sequence to form a continuous path, the continuous path is filled with a cooling liquid, and the cooling liquid is used for cooling via air cooling when flowing in a pipeline outside the desulfurizer and is driven by the circulating pump to flow in a continuous circulating manner to precool vapor and liquid drops in flue gas in the desulfurizer to form liquid films on the outer walls of the diversion pieces.

Owner:中国大唐集团科学技术研究总院有限公司

Integrated autotrophic denitrification reactor

ActiveCN105540843AExtend the flow pathExtended pathWater contaminantsTreatment with aerobic and anaerobic processesAeration rateLoad resistance

The invention discloses an integrated autotrophic denitrification reactor. The reactor comprises a reactor main body, a base and a support installed on the base. The reactor main body and the support are installed on the base. The reactor main body comprises an upper biological rotating disc and a lower anaerobic ammonia oxidation unit. The biological rotating disc comprises a water tank, a rotating disc, a rotation center shaft and an aeration device. The inner cavity of the anaerobic ammonia oxidation unit is orderly divided into a first reaction zone, a second reaction zone and a third reaction zone. The third reaction zone is orderly divided into a granular sludge zone, a settling zone and an outlet water zone from top to bottom. The bottom of the granular sludge zone is provided with a sludge discharge outlet with a valve. The upper part of the outlet water zone is provided with a downflow weir. The outer part of the downflow weir is provided with an outlet water groove. The bottom of the outlet water groove is provided with an outlet water pipe. According to the biological rotating disc-anaerobic ammonia oxidation combined reactor, in the air-driven biological rotating disc, through rotating disc rotation, high-nitrogen content waste water and oxygen fully contact so that shortcut nitrification is realized. Through adjustment of an aeration rate, a rotating disk rotating rate can be controlled. The reactor has good impact load resistance.

Owner:浙江国泉生态环境有限公司

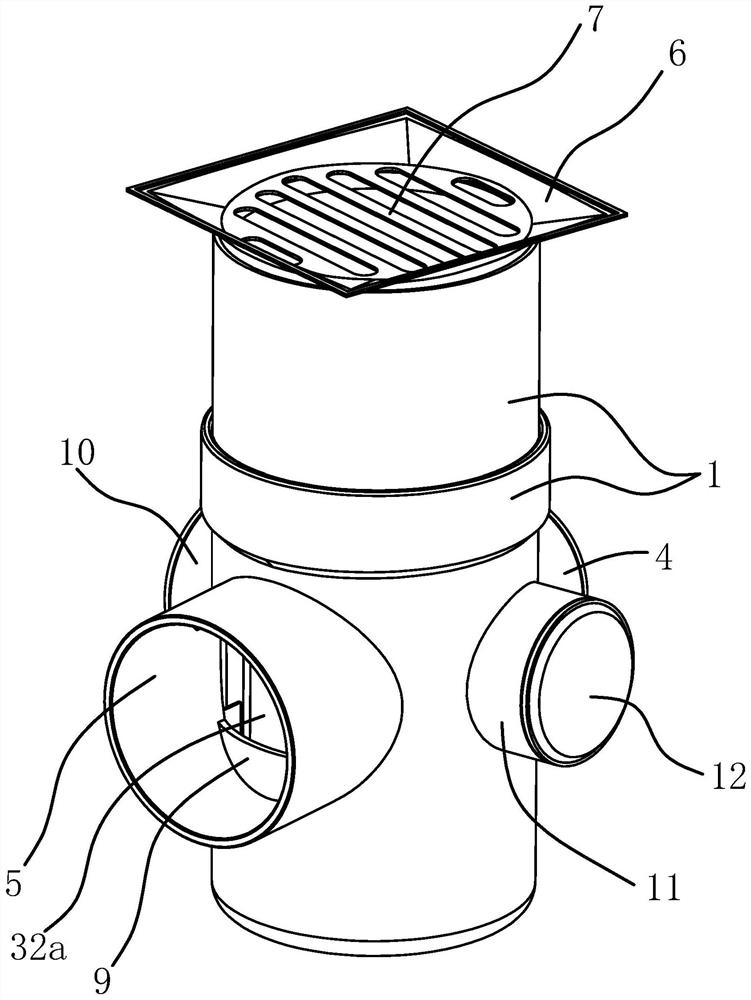

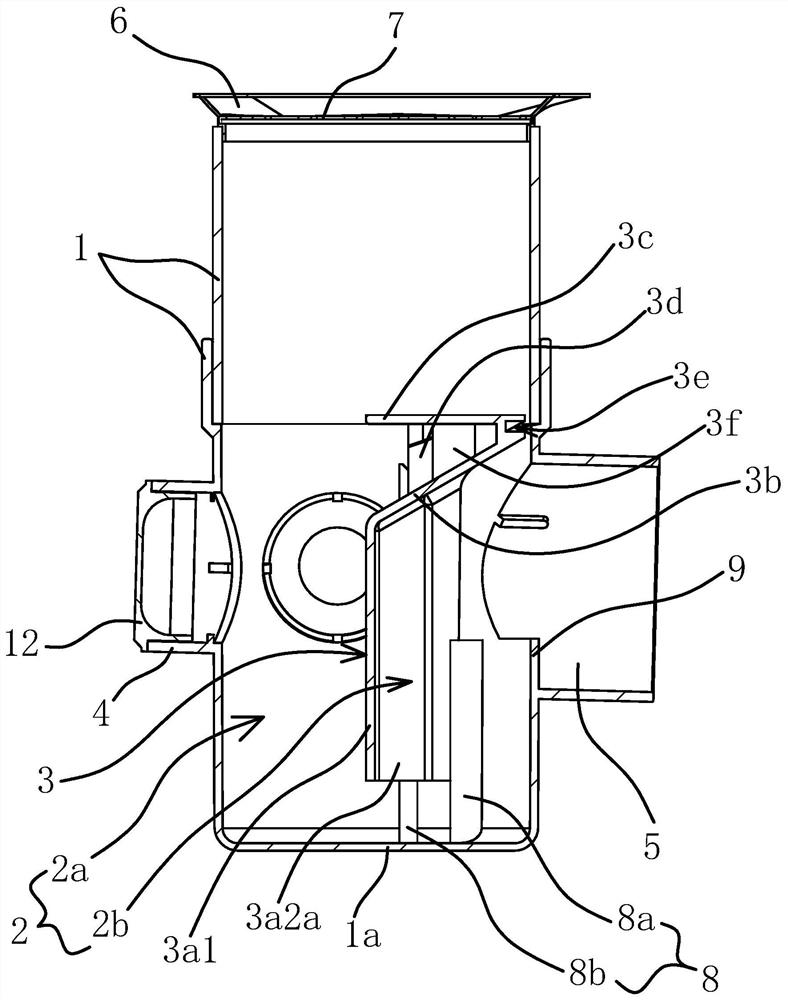

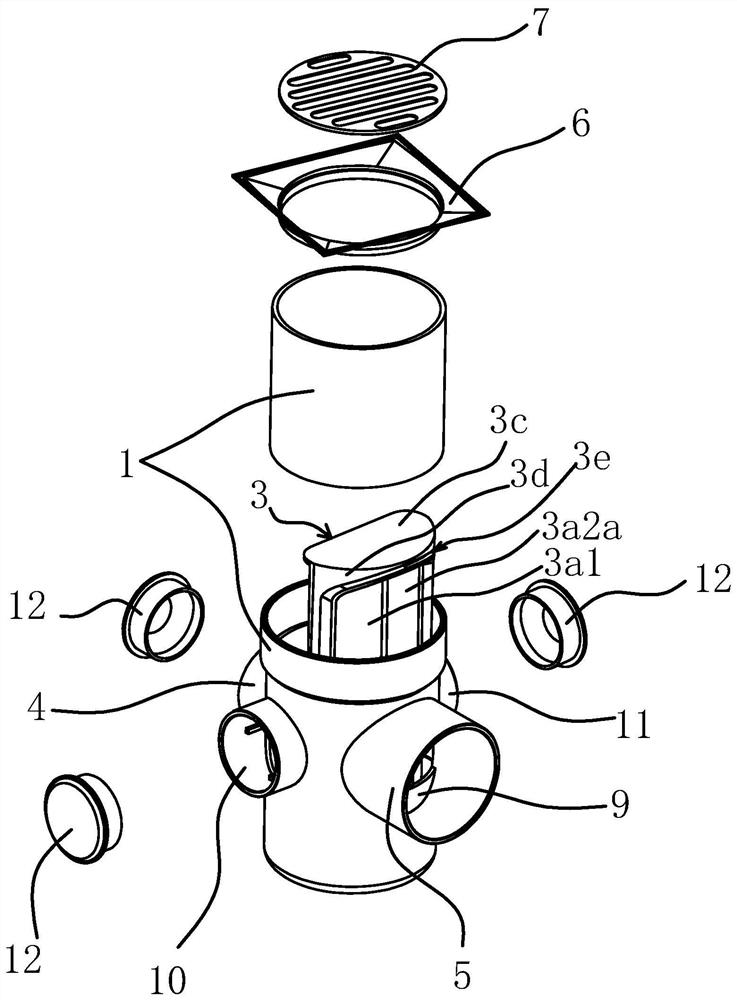

Multi-channel floor drain

PendingCN111636545AIncrease water outputExtend the flow pathSewerage structuresClimate change adaptationEnvironmental engineeringWater cut

The invention belongs to the technical field of bathrooms, and particularly relates to a multi-channel floor drain. The multi-channel floor drain solves the problems that an existing floor drain is insufficient in water outlet amount and low in water seal reliability. The multi-channel floor drain comprises a main pipe body with a containing cavity, and a flow guide cover and a floor drain cover are arranged at the top of the main pipe body; and the multi-channel floor drain is further characterized in that a bottom plate is arranged at the bottom end of the main pipe body in a closed mode, aseparator is arranged in the main pipe body and divides the containing cavity into a water inlet cavity and a water seal cavity, a channel for communicating the water inlet cavity with the water sealcavity is formed between the separator and the bottom plate, a first water inlet pipe communicating with the water inlet cavity and a water outlet pipe communicating with the water seal cavity are arranged on the peripheral wall of the main pipe body, the first water inlet pipe and the water outlet pipe are located above the channel and can form water seal between the water outlet pipe and the bottom plate, a guide plate positioned at the top of the water seal cavity is arranged on the separator, and the guide plate is obliquely arranged towards the water outlet pipe. According to the multi-channel floor drain, the water outlet amount of the floor drain and the reliability of water seal are improved.

Owner:YONGGAO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com