Triphen waste gas treatment device of porous medium material

A technology of porous media and exhaust gas, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., and can solve problems such as small headroom, large resistance, and small contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

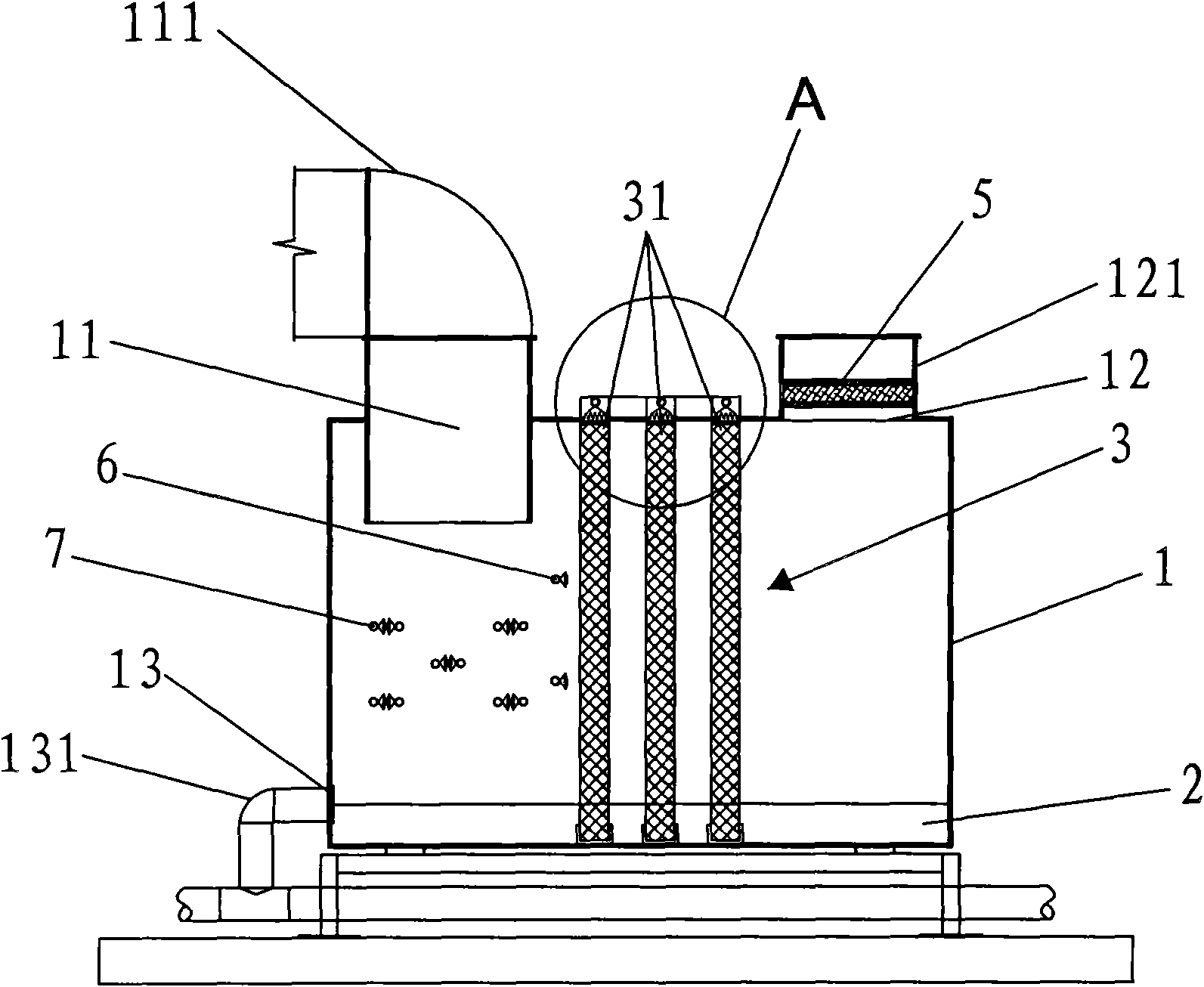

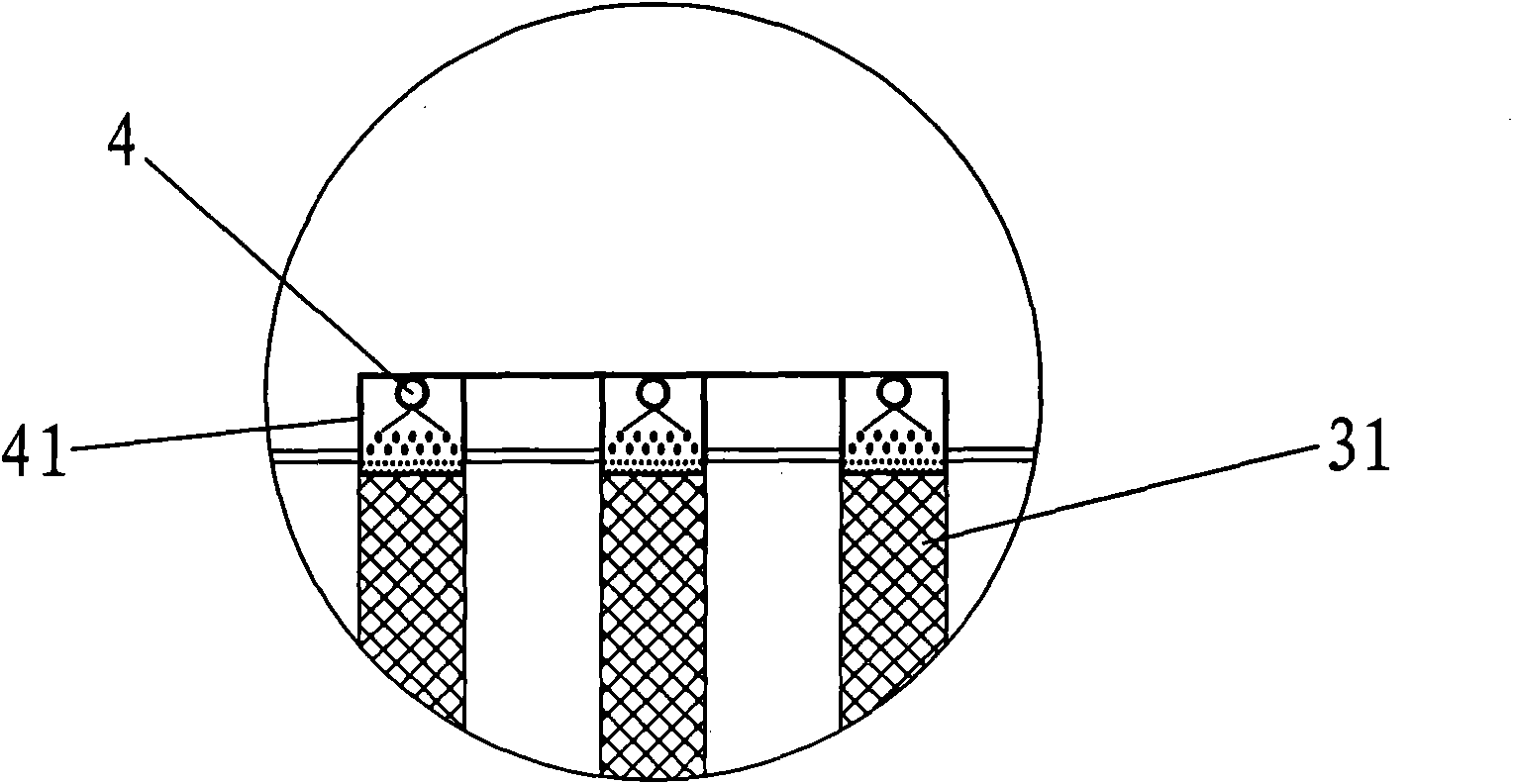

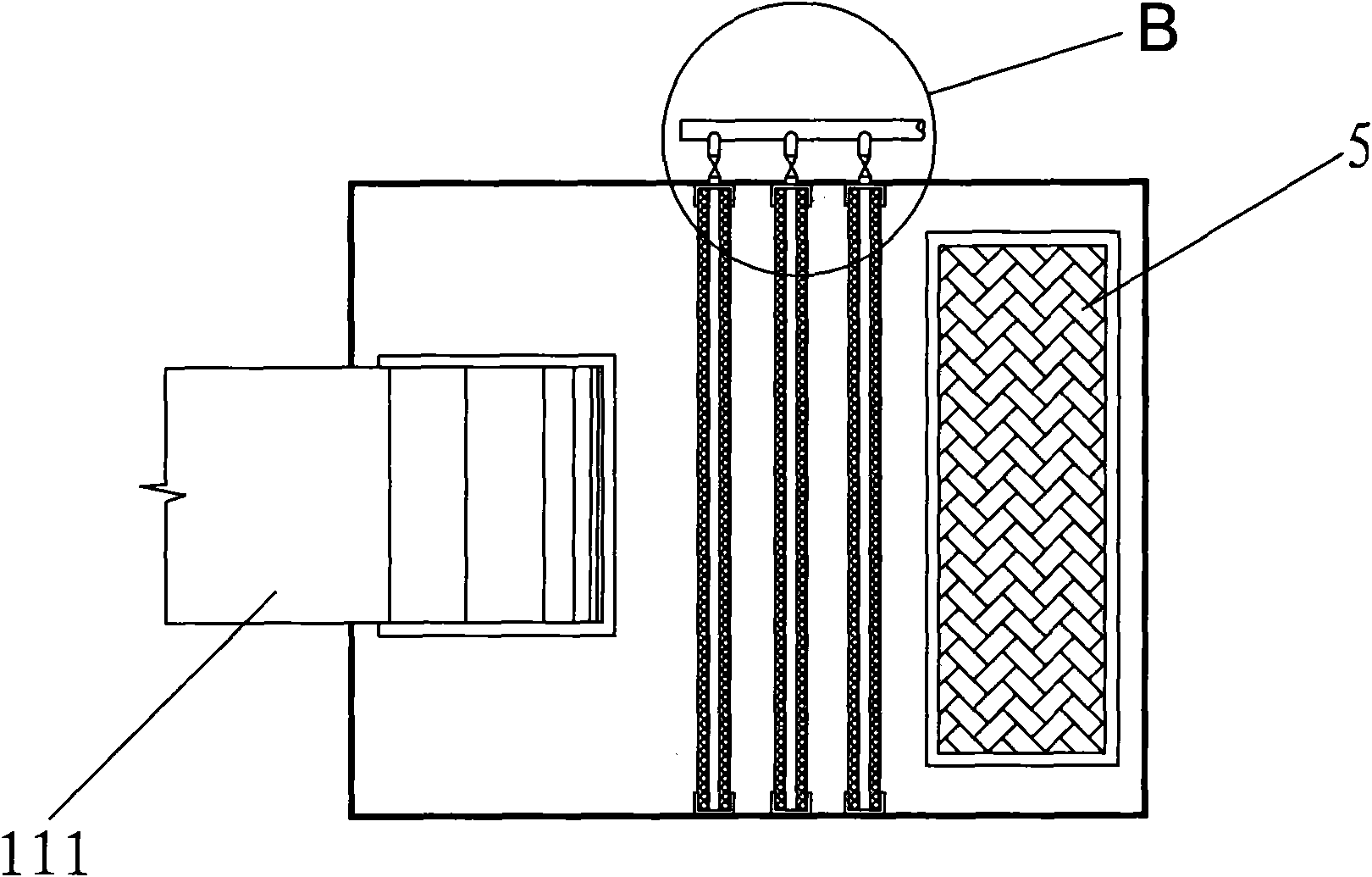

[0018] Below in conjunction with accompanying drawing, the present invention will be further described, see Figures 1 to 4 As shown, the present invention includes a box body 1, a sump 2 positioned at the bottom of the box body 1, a porous media material filter group 3 made up of at least one porous media material filter 31, and the porous media material filter group 3 is arranged in the box body 1 , the top of the porous media material filter 31 is equipped with a water spray pipe 4, and the bottom end of the porous media material filter 31 is inserted in the sump 2; and the air outlet 12 are respectively located on both sides of the porous media filter group 3, wherein an air inlet pipe 111 is installed at the air inlet 11 of the box body 1, and an air exhaust pipe 121 is installed at the air outlet 12 of the box body 1; A water outlet 13 is provided on the box body 1 on one side of the sump 2, and a water outlet pipe 131 for draining water is installed at the water outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com