Method and apparatus for processing effluvial tail gas of heavy slop tank

A tail gas treatment and oil tank technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve the problems that the odor treatment device cannot be directly transported, the design scale of the deodorization device is difficult to determine, and the purge volume is uncertain. Elimination of odor pollution, good treatment effect, and the effect of reducing harmful gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

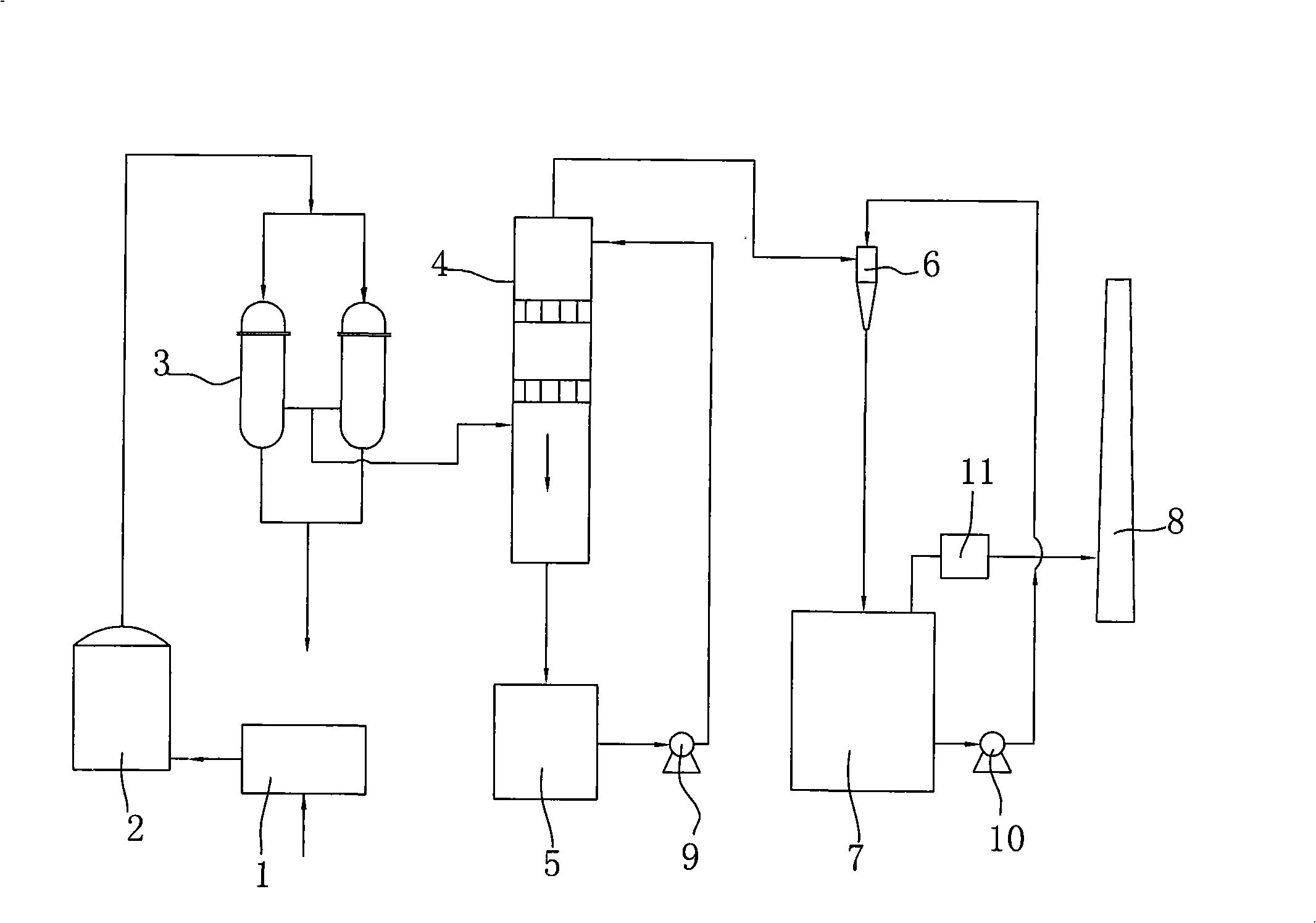

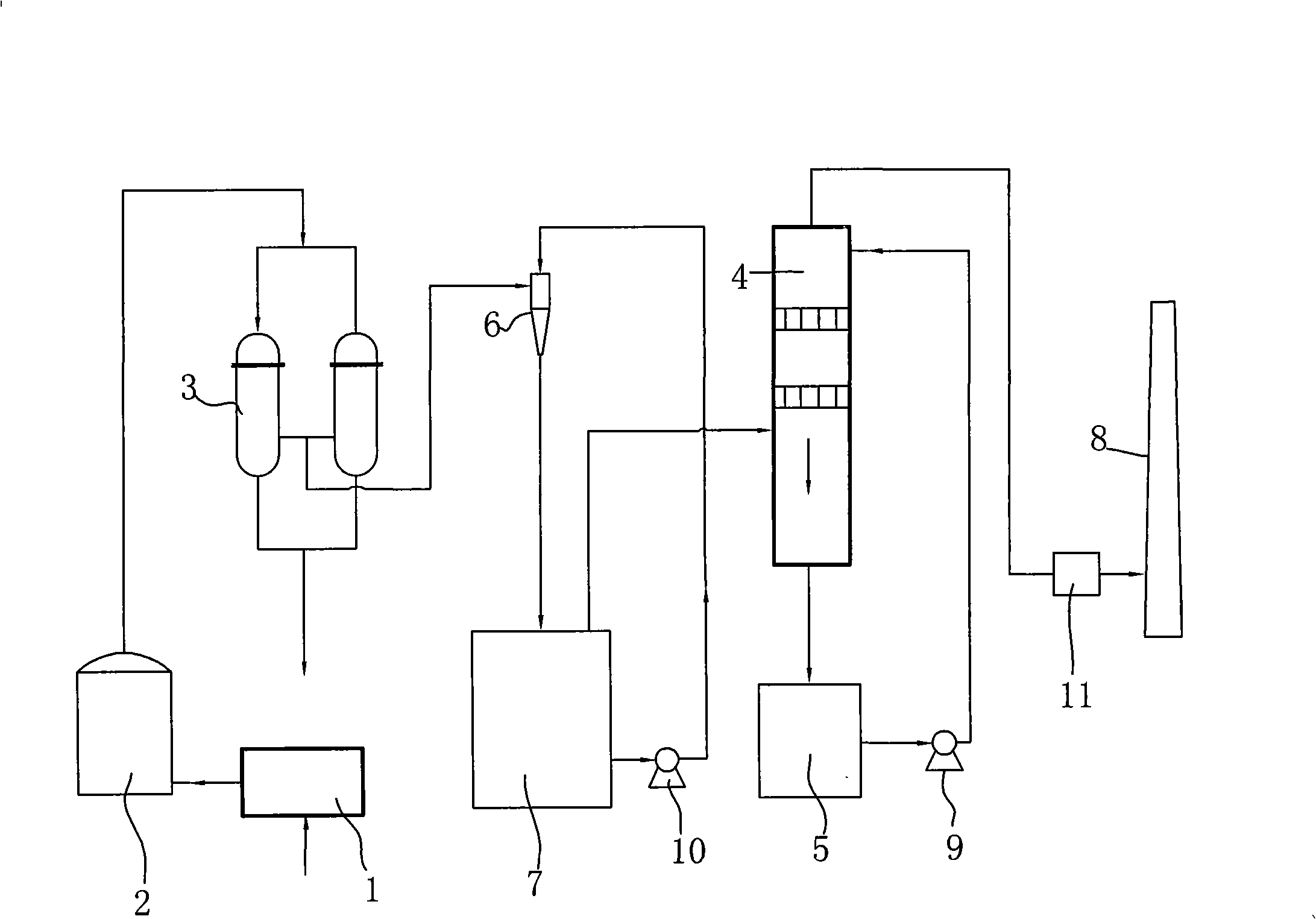

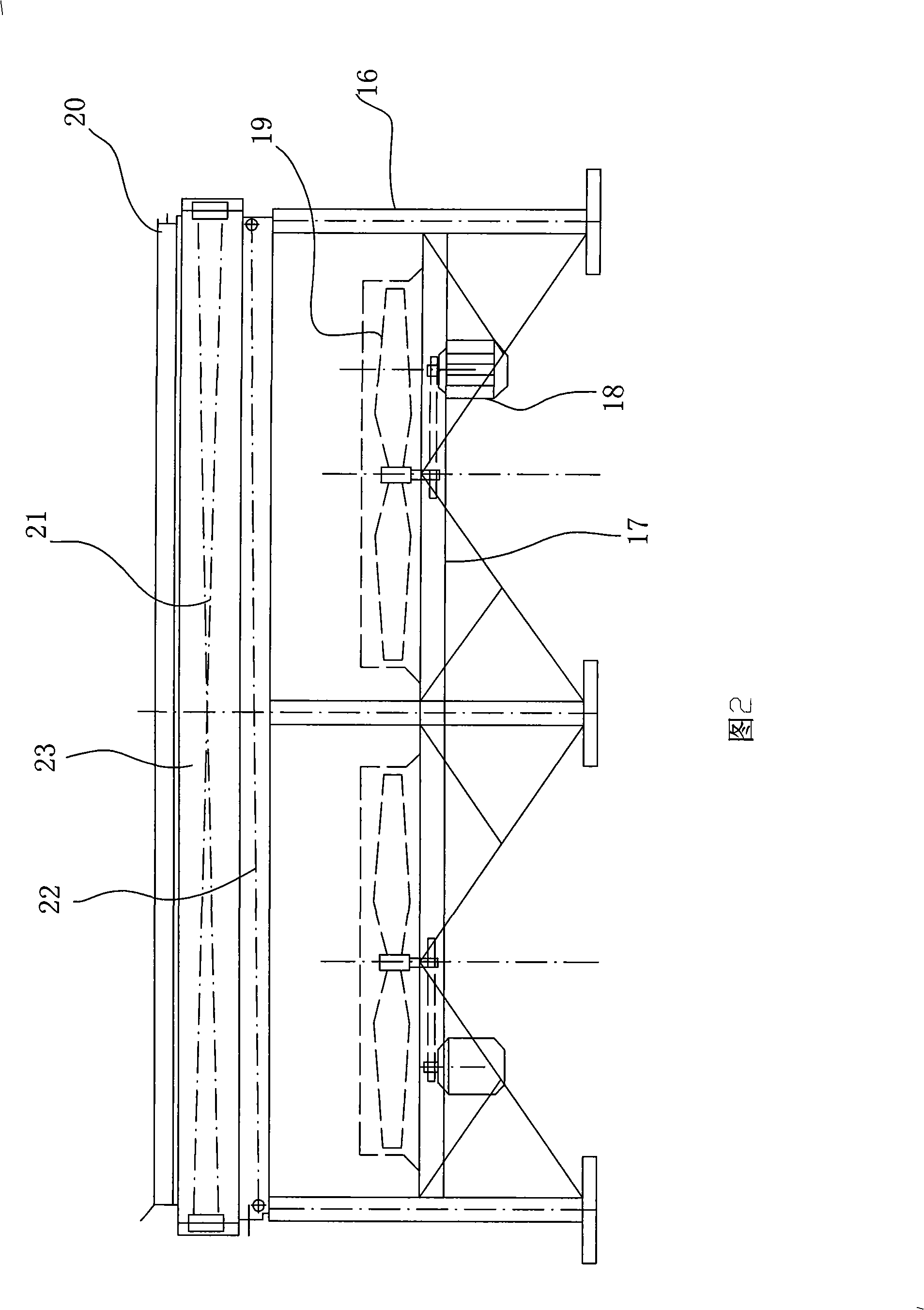

[0028] Such as Figure 1aAs shown, a heavy dirty oil tank malodorous tail gas treatment device includes a heavy dirty oil tank 2, an air cooler 1, a condenser 3, an absorption tower 4, an injector 6, a circulation tank 5, 7, etc., wherein the heavy dirty oil Tank 2 is equipped with a breathing valve and an explosion-proof membrane to avoid the phenomenon of deflated tanks and leaking tanks caused by the intermittent operation of the purging device. The heavy dirty oil tank 2 is connected to the purge gas device through the pipeline and the air cooler 1. The air cooler with cooling and heating functions that can be controlled by frequency conversion is convenient for heating or cooling the exhaust gas, as shown in Figures 2 and 3, the specific structure of the air cooler is a base frame 16, which is installed under the fixed plate 17 in the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com