Patents

Literature

144 results about "Ethanethiol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethanethiol, commonly known as ethyl mercaptan, is a clear liquid with a distinct odor. It is an organosulfur compound with the formula CH₃CH₂SH. Abbreviated EtSH, it consists of an ethyl group (Et), CH₃CH₂, attached to a thiol group, SH. Its structure parallels that of ethanol, but with sulfur in place of oxygen. The odor of EtSH is infamous. Ethanethiol is more volatile than ethanol due to a diminished ability to engage in hydrogen bonding. Ethanethiol is toxic. It occurs naturally as a minor component of petroleum, and may be added to otherwise odorless gaseous products such as liquefied petroleum gas (LPG) to help warn of gas leaks. At these concentrations, ethanethiol is not harmful.

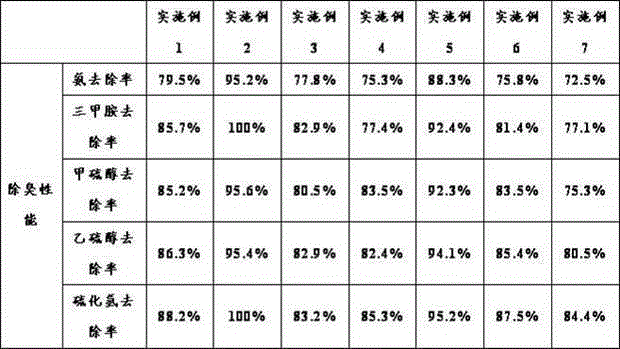

Antibacterial and environment-friendly deodorant of microorganism strains

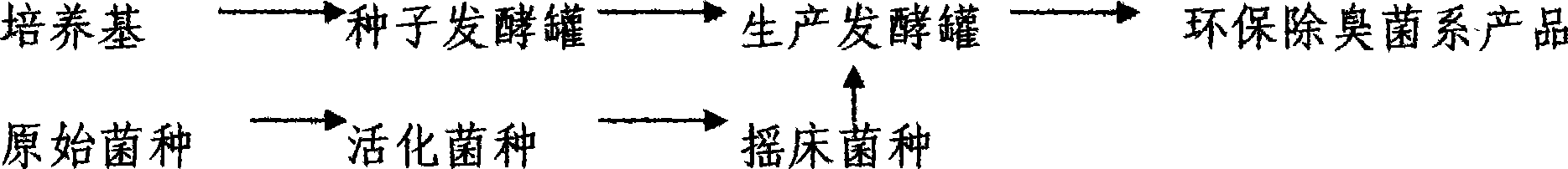

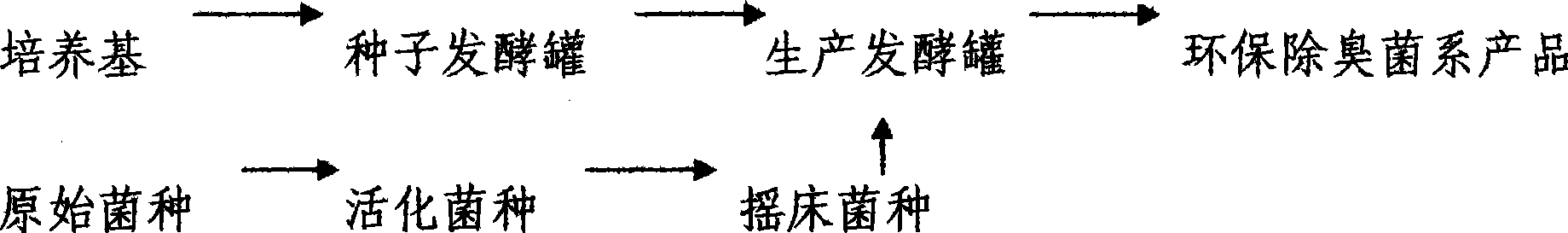

The invention relates to an antibacterial and environment-friendly deodorant of microorganism strains and a preparation method thereof. The traditional method for removing odor generally uses essence to cover up the odor or pumping odor physically or uses ozone to oxidize and degrade the odor or uses a chemical method. The methods also can alleviate the odor to a certain extent, but finally the problem can not be solved really and fundamentally and the essence and chemical deodorization also have secondary pollution. The microbial deodorization technology utilizes the effects of high-efficient absorption, absorption and metabolism of particular microorganism strains which can convert or degrade odorant, to purify the odorous gases of amyl mercaptan, benzene methanethiol, methyl sulfide, ethanethiol, hydrogen sulfide, sulfur dioxide, p-benzyl mercaptan, ammonia, dimethylamine, trimethylamine and carbon disulfide and the like which are emitted from human life areas, domestic sewage and domestic garbage and the like and to convert the odorous components of amyl mercaptan, benzene methanethiol, methyl sulfide, ethanethiol, hydrogen sulfide, sulfur dioxide, p-benzyl mercaptan, ammonia, dimethylamine, trimethylamine and carbon disulfide and the like into matters without harm and odor, thus achieving the purpose of thoroughly improving air quality and protecting health of people. The preparation method utilizes a fermentation method of microorganism strains to prepare deodorant products.

Owner:王峰

Method for preparing valnemulin

The invention discloses a method for preparing valnemulin. The method comprises the following steps of: preparation of chloridized pleuromutilin, preparation of N-allyloxycarbonyl-valine; preparation of 1, 1-dimethyl-2-(N-allyloxycarbonyl valyl amino) ethanethiol and preparation of the valnemulin. The method can effectively improve the product quality and the yield.

Owner:江苏赛奥生化有限公司

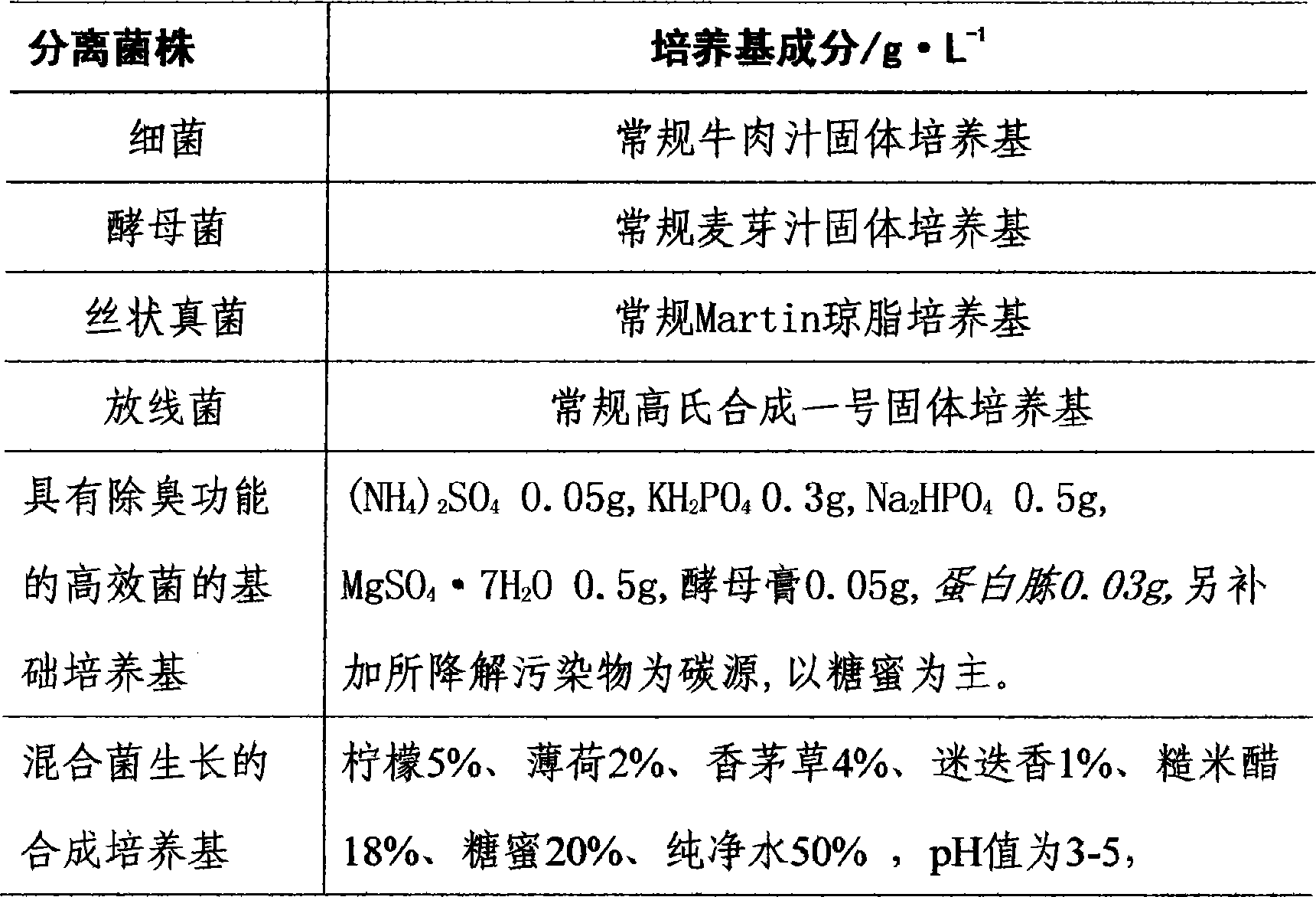

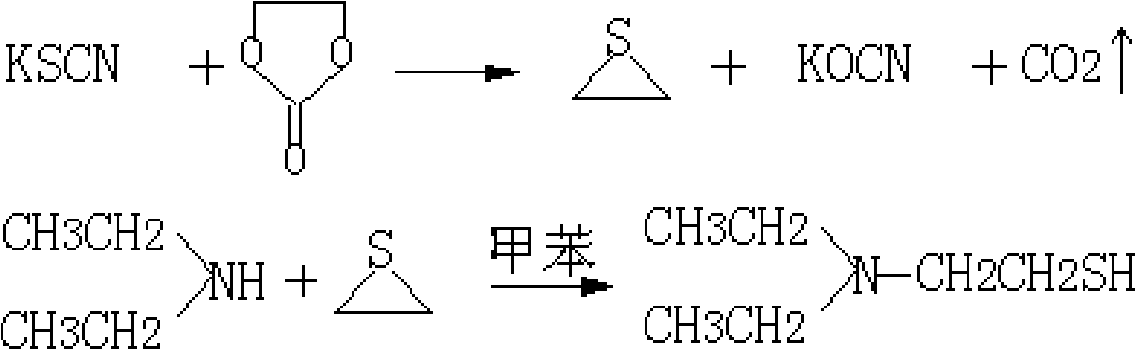

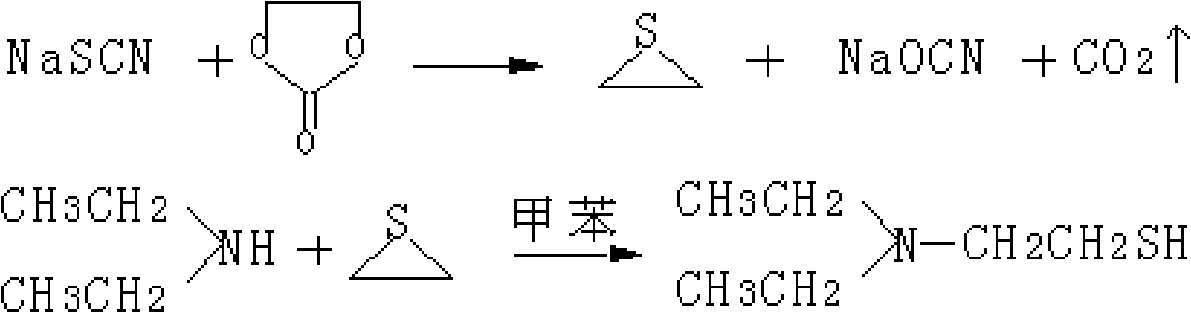

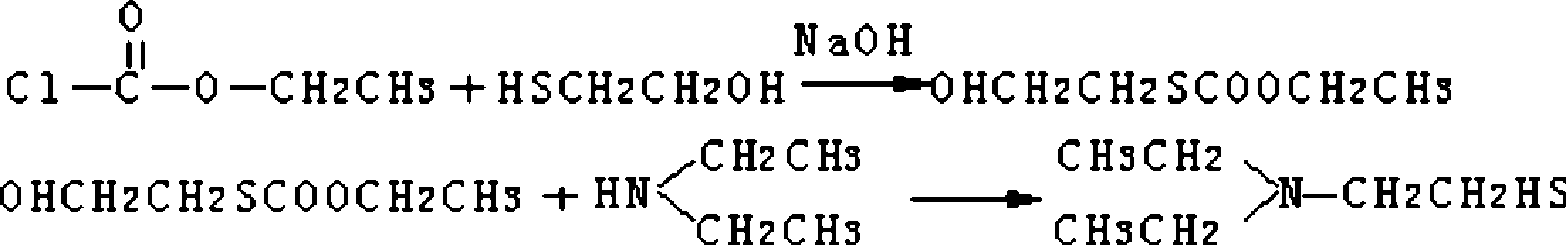

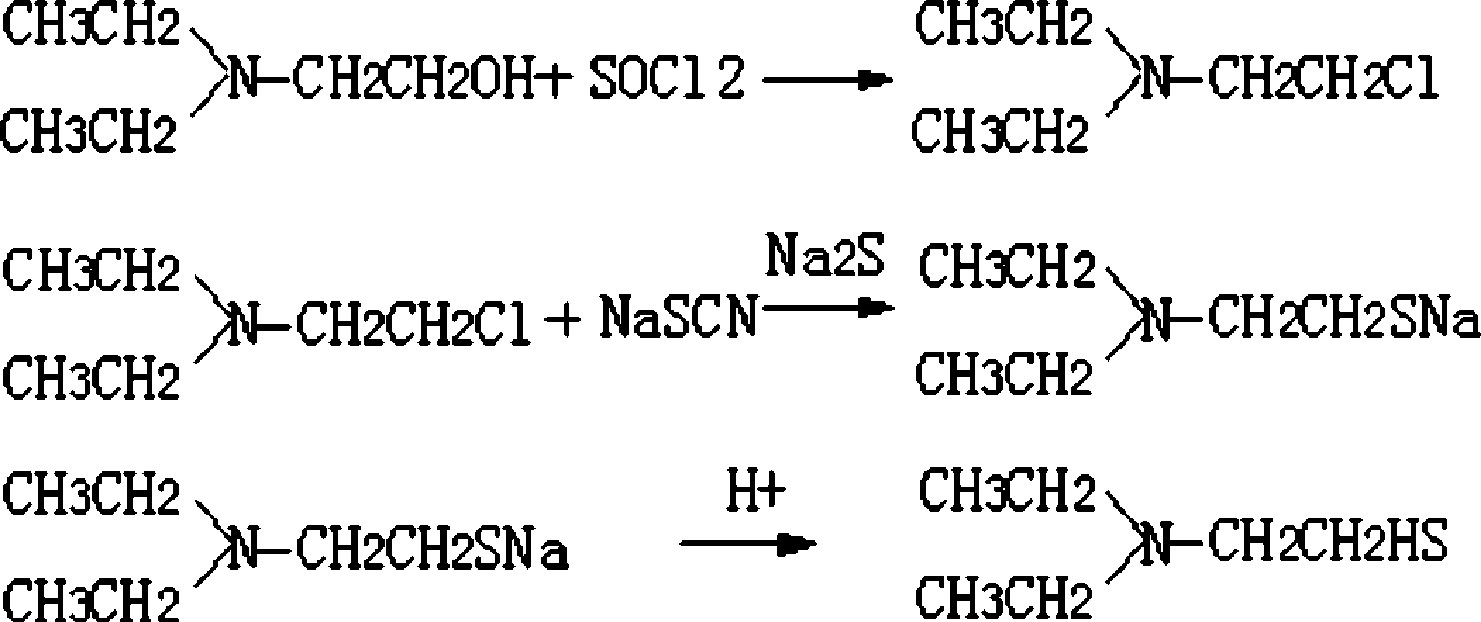

Method for preparing N, N-diethylamino ethanethiol

The present invention relates to a method for preparing N, N-diethylamino ethanethiol, belonging to a chemical technical field. The method includes steps of a. heating rhodanides and ethylene carbonate to react under ordinary pressure, distilling to obtain Thiirane after the reaction, the general formula of the rhodanides is M-SCN, wherein M is alkali metal of Na or K; b. mixing and stirring the Thiirane and diethylamine in a toluene dissolvant, heating under an ordinary pressure to implement a backflow reaction and distilling to obtain the N, N-diethylamino ethanethiol after the backflow reaction. The method has a short synthesis technical process, the kind of the raw materials is few and source is wide, the used toluene dissolvant may be recovered, and there will generate little waste water, waste gas and waste which may reduce environmental pollution.

Owner:赵云现

Synthesis technology for N,N-diethylamino group ethanethiol

ActiveCN102153494ANothing producedFeeding molar ratio is too smallThiol preparationMaterial typeNitrogen

The invention discloses a synthesis technology for N,N-diethylamino group ethanethiol. The synthesis technology includes the steps of pressing ethane episulfide and diethylamine into a pressure reaction kettle by nitrogen, heating to the temperature of 80-100 DEG C in a closed state under the condition of stirring, and reacting for 3-5 hours to obtain the N,N-diethylamino group ethanethiol. The synthesis technology is finished in the closed reaction kettle by adopting the technical conditions as above, does not use any dissolvent or catalyst, does not generate by-product, and has the advantages of short technology flow, few material types, short reaction time and small excess of feed mole ratio of diethylamine to ethane episulfide; the mass percent of the prepared product can achieve 99%; and the whole production technology has the characteristics of low production cost, high yield, no exhaust of three wastes (waste gas, waste water, industrial residual), and the synthesis technology belongs to an environment-friendly chemical-industrial synthesis technology.

Owner:保定加合精细化工有限公司

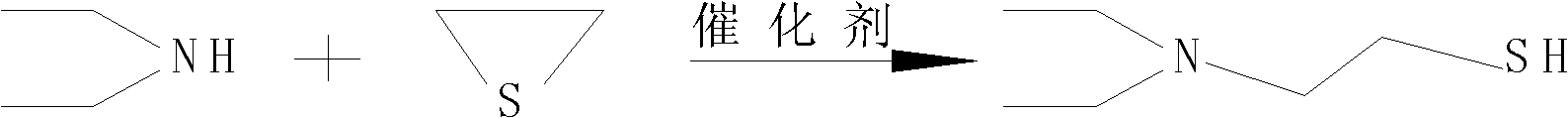

Method for synthesizing N,N-diethylamino ethanethiol

ActiveCN101481343AThorough responseEffective protectionThiol preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystEthanethiol

The invention relates to a synthetic method for N, N-diethylaminoethanethiol, comprising the following step: the N, N-diethylaminoethanethiol is prepared after mixing ethylene sulfide and diethylamine under the condition of adding catalyst and heating the mixture to 50-80 DEG C for reaction. In the method, under the condition of presence of the catalyst, the raw materials can fully react without using any solvent and the ethylene sulfide can be effectively prevented from self polymerization, thus obtaining the products with high yield and quality. Meanwhile, without producing the three wastes, the method effectively protects the environment.

Owner:河北远大九孚生物科技有限公司

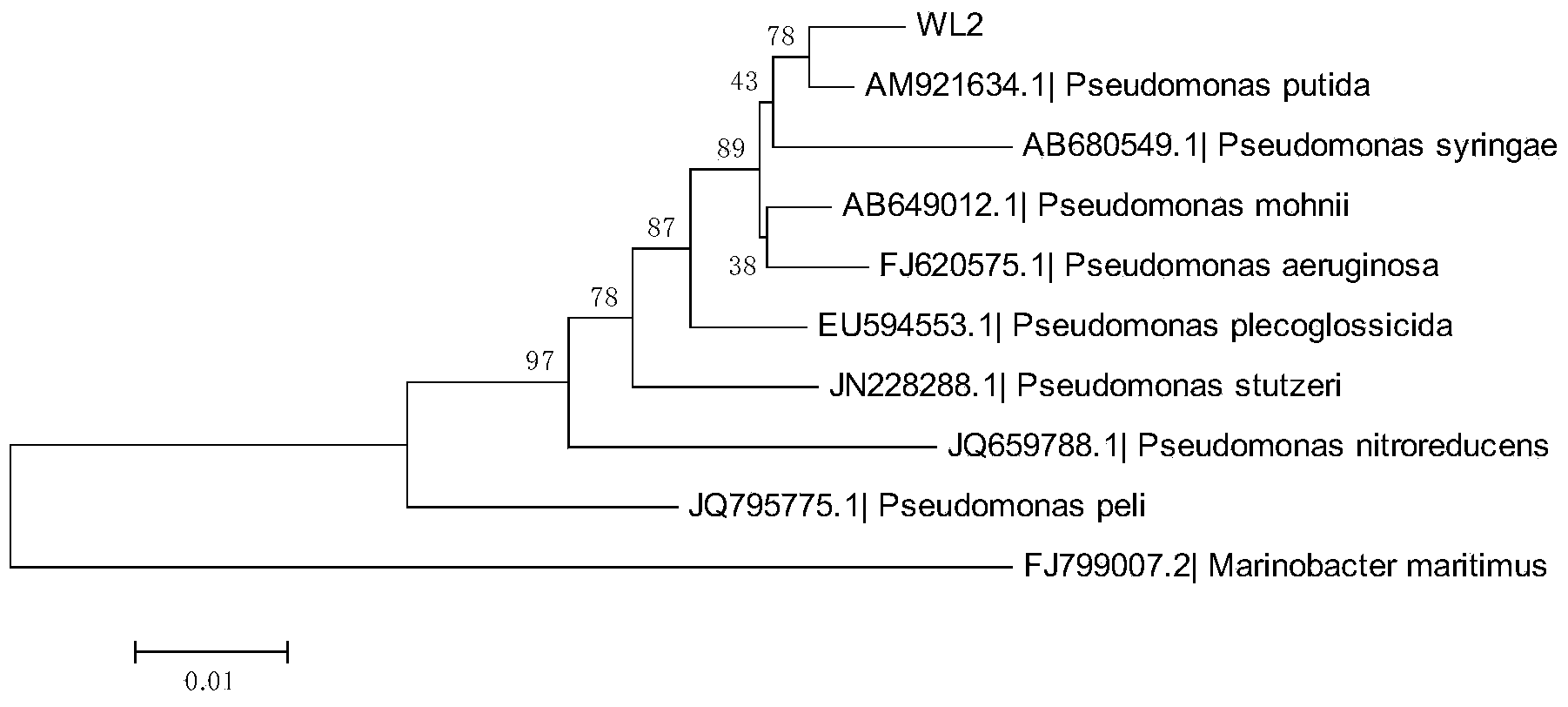

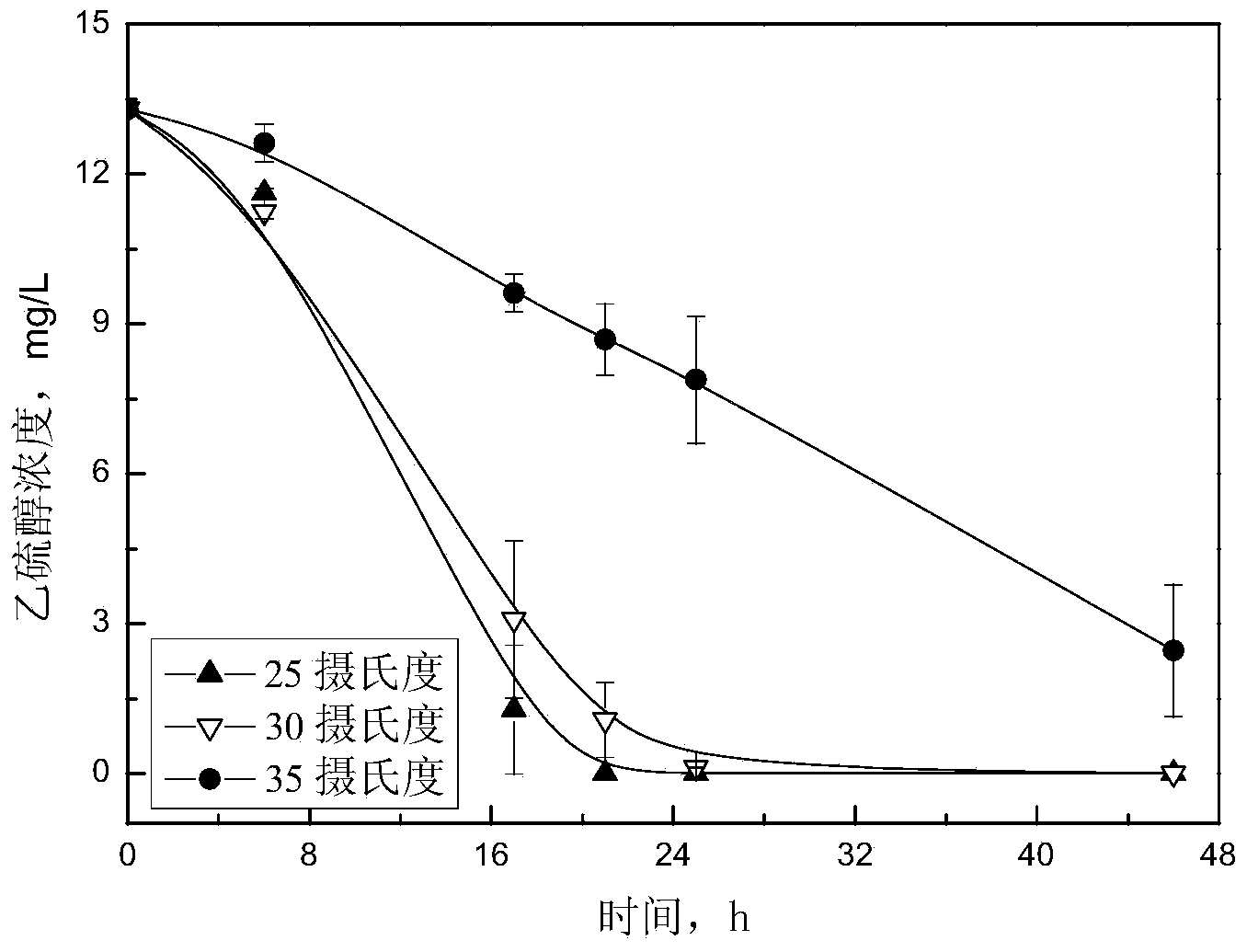

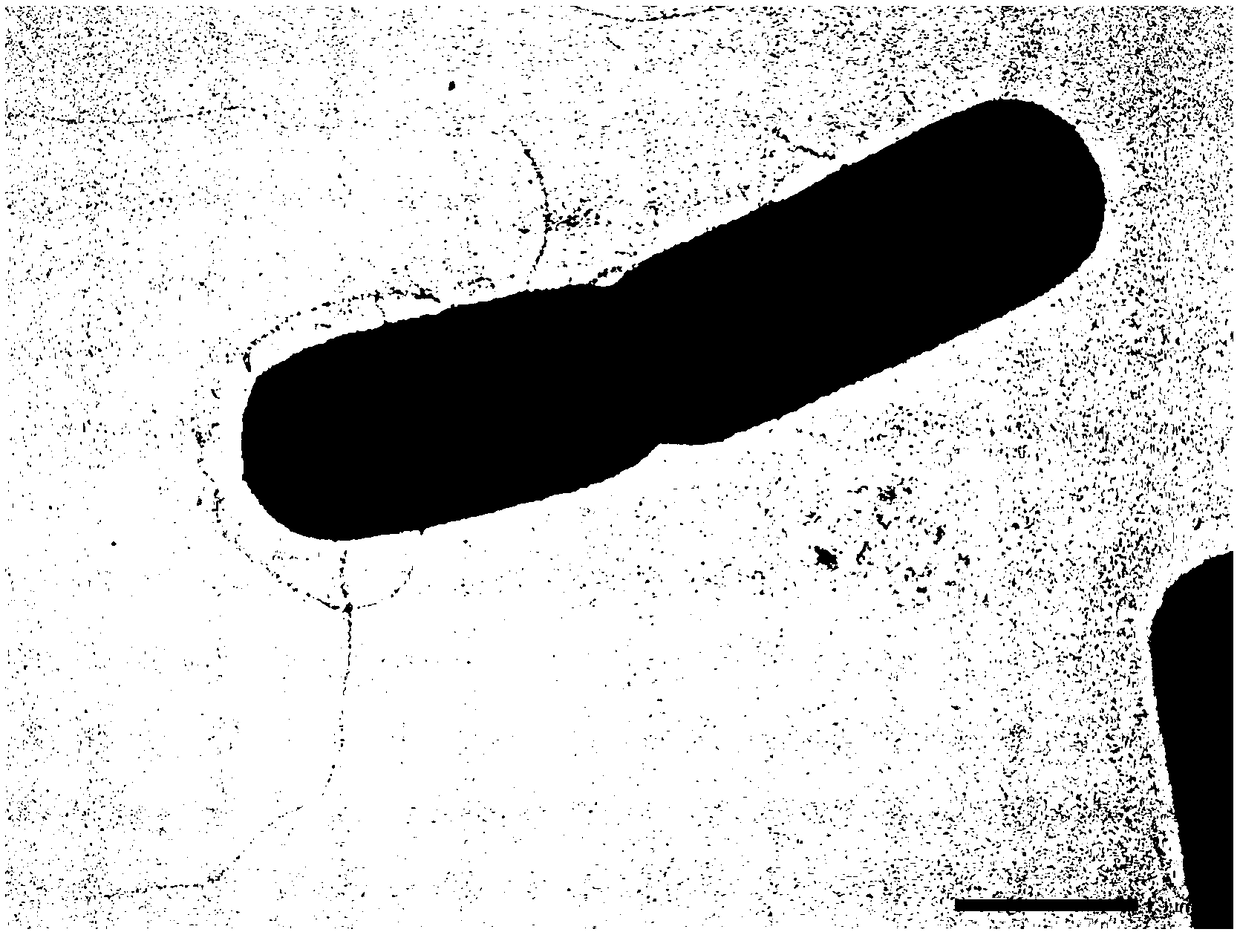

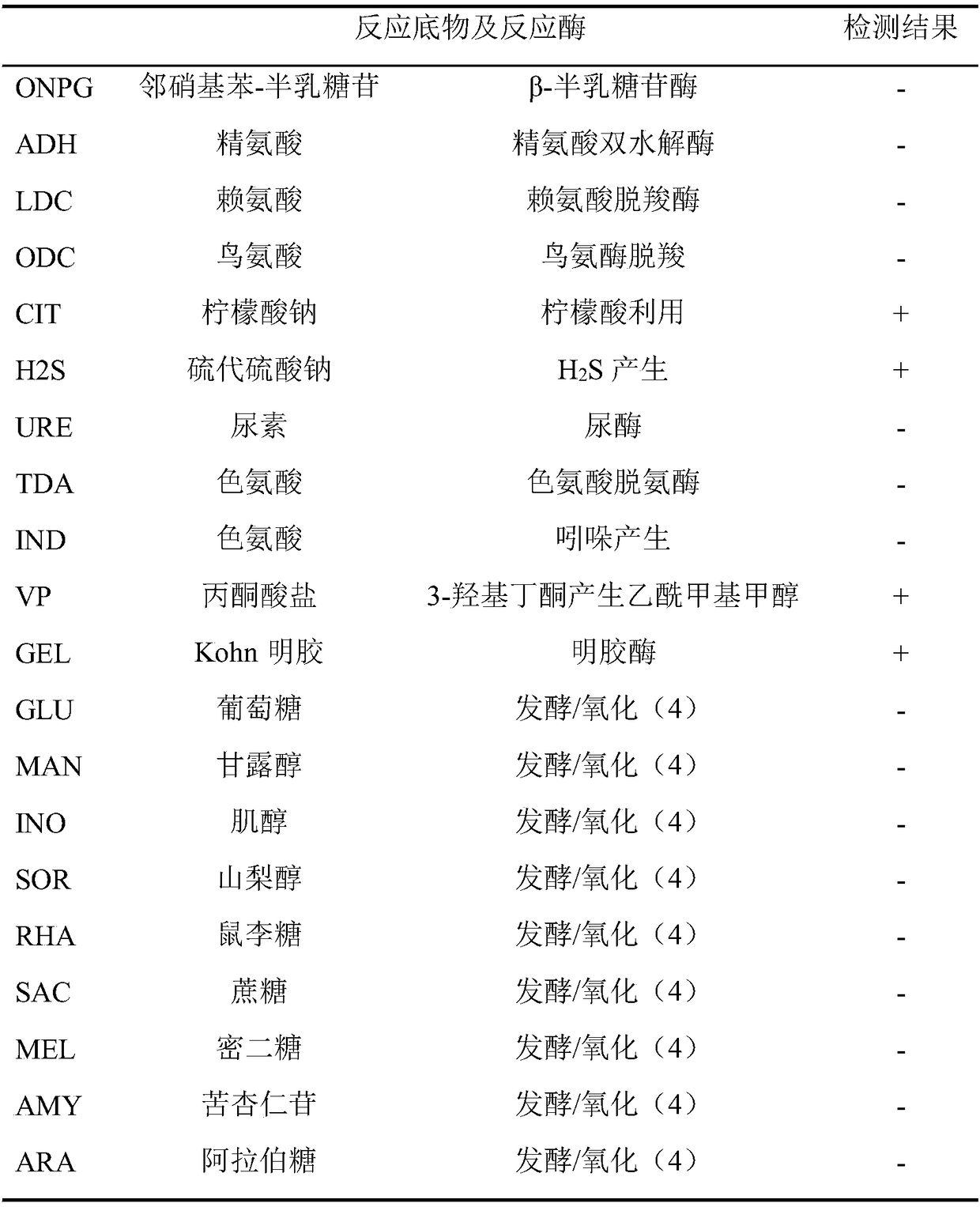

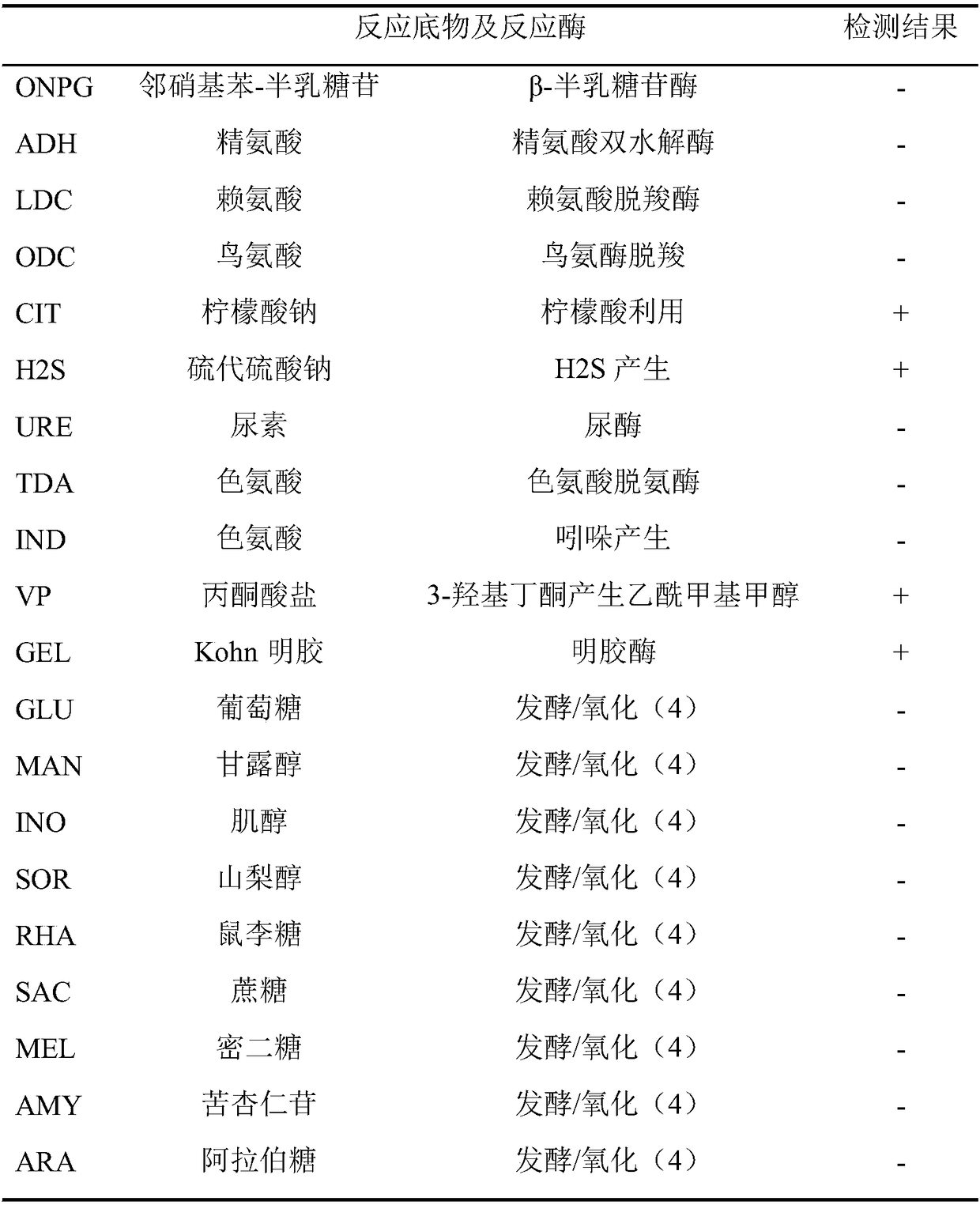

Stain for degrading ethanethiol, as well as culture method and application of strain

The invention discloses a strain for degrading ethanethiol as well as a culture method and application of the strain. The strain is named as Pseudomonas sp. WL2; the preservation number is CGMCC NO. 7898; the strain is preserved in the Common Microorganism Center of the Chinese Microorganism Strain Preservation Administration Committee(CGMCC), and the preservation date is 8th June, 2013. The strain for degrading ethanethiol is an aerobiotic Gram-negative bacterium, which can be grown by taking ethanethiol as a sole carbon source and energy, and can be thoroughly mineralized into CO2 and H2O. Under a pure culture condition, the strain is capable of degrading ethanethiol under the conditions that the temperature is 25-30 DEG C and the pH is 6-8. The strain has good substrate adaptive capacity and substrate extensiveness, and is capable of degrading propanethiol and methanol. The strain establishes the basis for industrial application in treating sulfur-containing stink organic waste gases by using a biologic method.

Owner:ZHEJIANG UNIV

Lychee brandy and production method thereof

InactiveCN101914423AReduce characteristic odor substancesIncrease irritationAlcoholic beverage preparationAlcoholCITRATE ESTER

The invention discloses lychee brandy and a production method thereof. The production method comprises the following steps of: preparing brandy base wine from fresh lychee, wherein the base wine can be wine brewed by fermenting fresh lychee juice, and also can be mixed liquor by soaking flesh, dregs and juice of the lychee in edible alcohol or lychee distilled brandy; distilling by controlling temperature in a tower mode first and then in a kettle mode, controlling the distillation temperature to between 65 and 72 DEG C, performing calcium citrate desulfurization and volatile acid reduction of basic anion resin on the wine body, debitterizing casein and polyvinylpyrrolidone, performing low-temperature vacuum re-distillation at the temperature of between 62 and 68 DEG C; and putting the qualified wine after re-distillation into an oak bucket, storing for at least two years, and blending into a finished product. The production method has low requirements on the base wine and raw materials, can obviously reduce the characteristic odor substances of the lychee brandy, such as ipomeamarone and ethanethiol, and makes the wine have thick and elegant aroma. The posttreatment method is relatively mild, has strong specificity, does not generate unpleasant taste such as metal taste and alkali taste, and has little secondary precipitate. The production method has the advantages of simple process and low cost.

Owner:GUANGDONG ZHENZHOU GRP

Deodorizing material of refrigerator and preparing method of deodorizing material

ActiveCN104998289AGood hydrogen sulfide removal effectLow priceDispersed particle separationDeodrantsIceboxChemical adsorption

The invention discloses a deodorizing material of a refrigerator and a preparing method of the deodorizing material. Manganese sulfate, potassium permanganate, a copper-bearing precursor and a magnesium-bearing precursor are configured into a solution, after a mixing reaction is carried out, a molecular sieve is added for dipping, the molecular sieve is dried and roasted after being dipped, active carbon and the roasted molecular sieve are formed together in an extruding mode, and the deodorizing material of the refrigerator is prepared. The deodorizing material of the refrigerator has a good effect of removing methyl mercaptan, ethyl mercaptan, trimethylamine, ammonia and hydrogen sulfide and is combined with the active carbon so that the peculiar smells in the refrigerator can be removed through chemical adsorption and physical adsorption, and the defects of chemical adsorption and the defects of physical adsorption compensate for each other.

Owner:SUZHOU IND PARK ANZEWEN ENVIRONMENTAL PROTECTION TECH

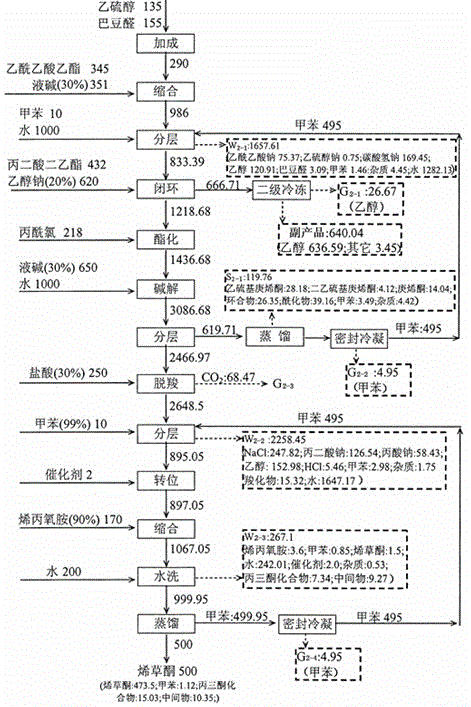

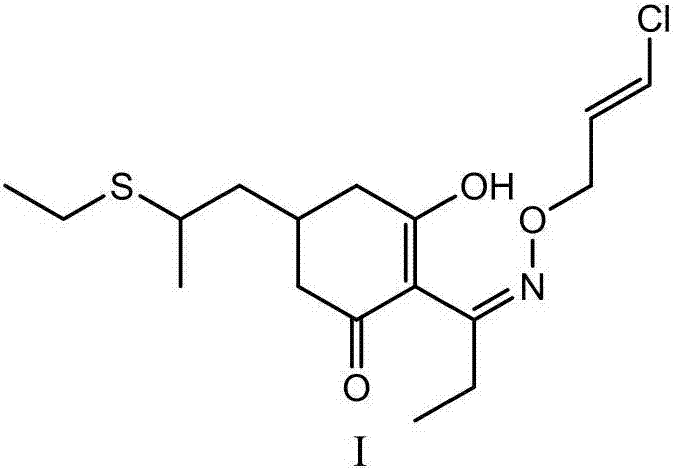

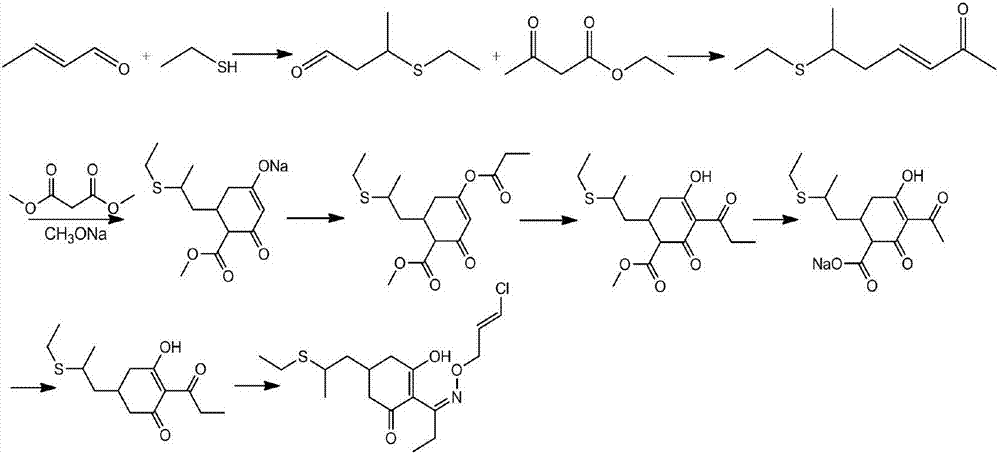

Synthetic method of clethodim

ActiveCN105418470AEasy to operateLess solventSulfide preparationPropionyl chloride2 cyclohexene 1 one

Provided is a synthetic method of clethodim. The invention relates to cyclohexenone herbicide clethodim, namely, 2-(1-(((3-chloro-2-propenyl)oxy)imino)propyl)-5-(2-(ethylthio)propyl)-3-hydroxy-2-cyclohexene-1-one. A chain reaction is conducted on ethanethiol, crotonaldehyde, ethyl acetoacetate, ethylsuleenyl heptenone and propionyl chloride which serve as main raw materials and a trace catalyst to generate the clethodim. The synthetic method of the clethodim is green, environmentally friendly and high in economic benefit.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

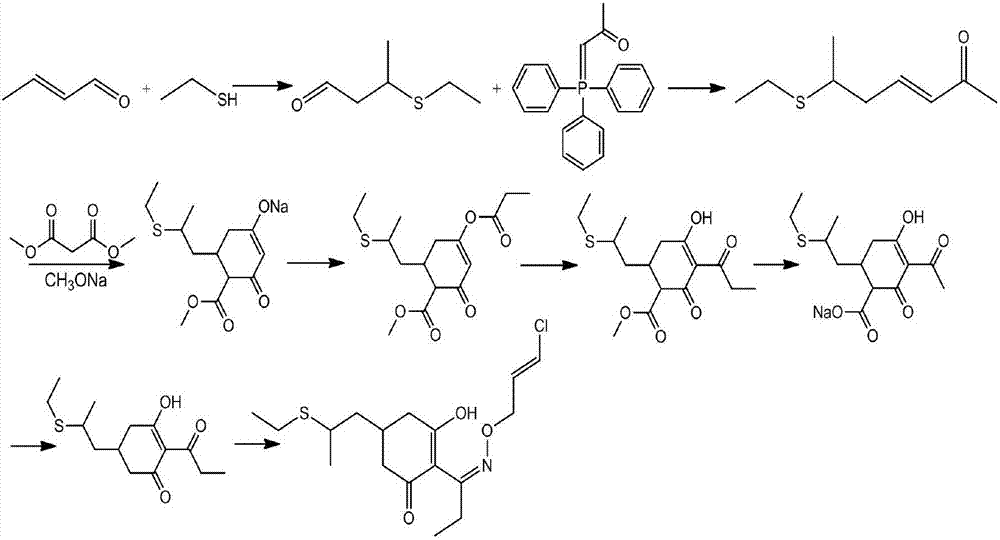

Method for synthesizing clethodim

InactiveCN107162945AHigh yieldImprove product qualitySulfide preparationPropionyl chlorideEthanethiol

The present invention proposes a method for synthesizing clethodim, comprising 3,5-heptadiene-2-one (formula II) and ethanethiol for nucleophilic addition to prepare clethodim intermediate 6-ethylthio ‑3‑heptene‑2‑ketone (formula III); formula III reacts with dimethyl malonate and propionyl chloride to prepare (±)‑3‑[propionyloxy]‑5‑[ 2-(Ethylthio)propyl]-6-[methoxyformyl]cyclohex-2-enone (Formula V); Formula V is then rearranged, hydrolyzed and decarboxylated to obtain (±)-2- [Propionyl]-3-[hydroxyl]-5-[2-(ethylthio) propyl]cyclohex-2-enone (formula VIII); formula VIII reacts with chloroallyloxyamine to obtain alkene Clethodim (formula I), the method for preparing clethodim by using intermediate 3,5-heptadiene-2-one (formula II) in the present invention is proposed for the first time, and the clethodim (formula I) prepared by this method is generally The yield is high, the product quality is good, and the method has low production cost and little environmental pollution, and is suitable for large-scale production.

Owner:江苏威格瑞斯化工有限公司

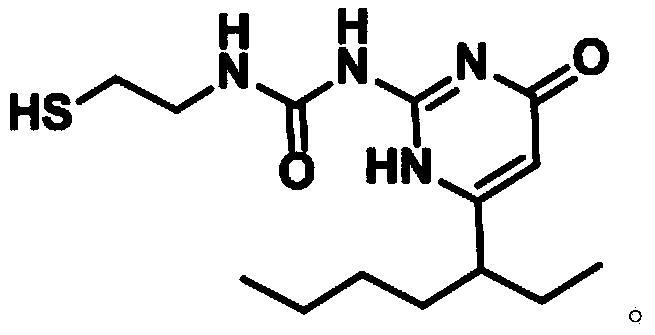

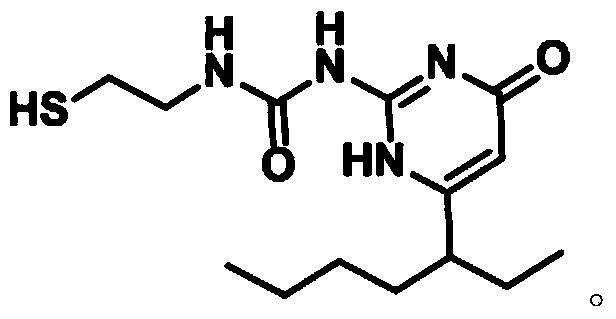

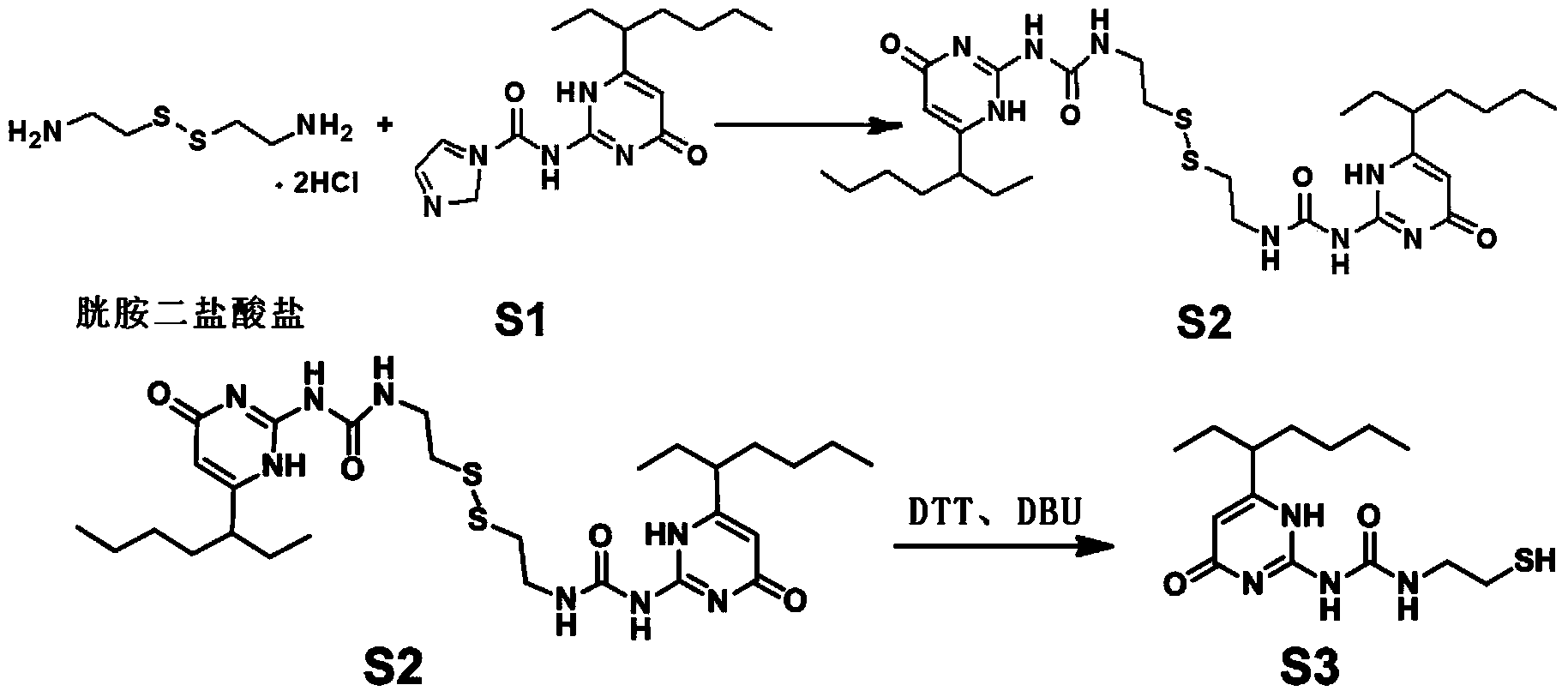

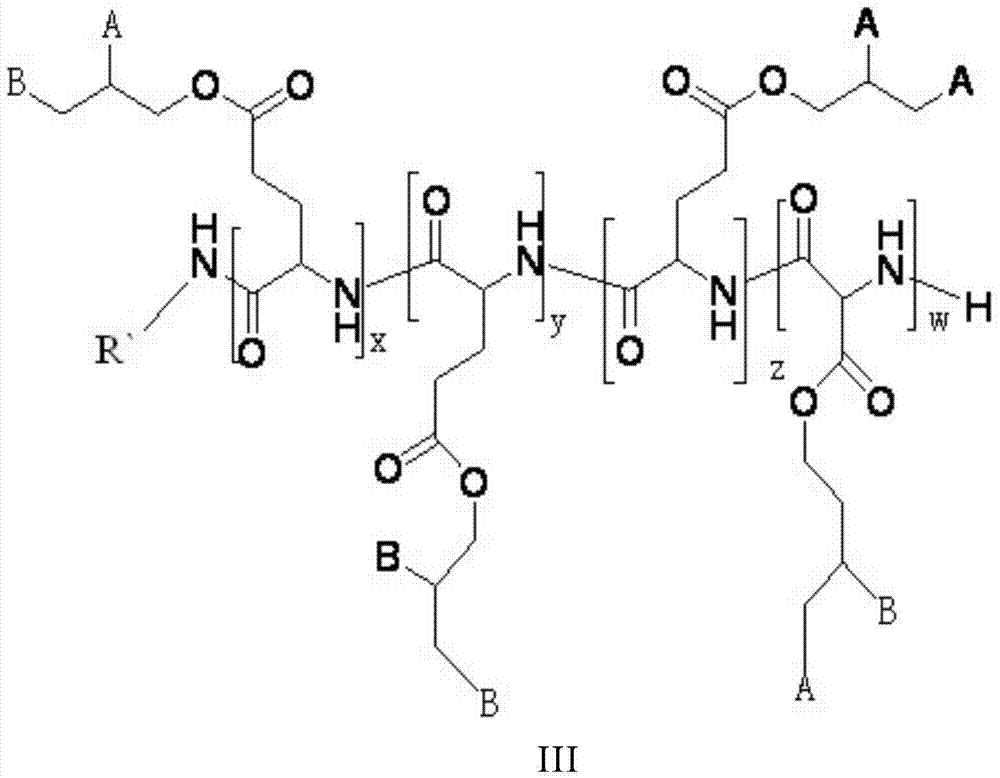

Compound as well as synthesis thereof and method for synthesizing double-UPy substituted compound by using same

InactiveCN103755644ARaw materials are easy to getHigh isolation yieldOrganic chemistryAlkaneChemical reaction

The invention discloses a compound which is 2[2-(1-ethanethiol)] urea-4 [1H]-pyrimidone. The invention also discloses a synthesis method of the compound, which comprises the steps: enabling cystamine dihydrochloride to react with activated ureido pyrimidine S1 to obtain a 2-urea-4[1H]-pyrimidine disubstituted sulfur-sulfur compound S2; and reducing the sulfur-sulfur compound S2 by using DTT (Dithiothreitol) to obtain the compound. The invention also discloses a method for synthesizing a double-UPy substituted compound by using the compound disclosed by the invention. According to the method, the compound has a free radical thiol-alkynyl click chemical reaction with an alkane alkynyl-terminated compound CHR to obtain the double-UPy substituted compound. According to the method disclosed by the invention, the thiol-alkynyl click chemical reaction is utilized to synthesize the double-UPy substituted compound for the first time; raw materials are easy to obtain, the application range is wide, the separation yield is high, and the synthesis method is scientific and reasonable; therefore a general method is provided for synthesizing the double-UPy substituted compound.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for recovering diethylamino ethanethiol from taimulin production waste water

ActiveCN101417965AHigh purityReasonable designOrganic chemistryOrganic compound preparationChemical industryOrganic solvent

The invention discloses a method for reclaiming diethylaminoethanethiol from tiamulin production wastewater, which belongs to the technical field of medical and chemical industries. The method comprises the following steps: the tiamulin production wastewater is subjected to pressure reduction concentration and the pH value of the wastewater is adjusted; then the extraction is performed; then the heating concentration is performed; and finally the rectification is performed, and fractions obtained at a temperature of between 70 and 100 DEG C are taken. The method ensures that the diethylaminoethanethiol in wastewater is dissociated out from the wastewater by adjusting the pH value, then uses an organic solvent with good intermiscibility for extraction and layering, and then performs heating concentration and rectification to obtain the diethylaminoethanethiol with higher purity. The reclaiming method has reasonable design and simple operation; and the obtained product has higher purity and good reclaiming effect.

Owner:浙江拜克生物科技有限公司

Spindle-shaped lysine bacillus with degradation ability of ethanethiol and dimethyl disulfide and application thereof

ActiveCN109234191AEfficient degradationImprove degradation rateBacteriaWater contaminantsGramEthanethiol

The invention discloses a spindle-shaped lysine bacillus with the degradation ability of ethanethiol and dimethyl disulfide and the application thereof. The strain was named Lysinibacillus fusiformisGDUTAN6, Deposited at China Typical Culture Collection, Wuhan University, Wuhan City, Hubei Province, CCTCC NO: M 2018416, dated 2 July 2018. GDUTAN6 is gram-positive, rod-shaped, round, white, transparent, and 1-2mm in diameter, and that bacterial colony of the spindle-shaped lysine bacillus GDUTAN6 is round and transparent. The degradation rate of ethanethiol and dimethyl disulfide was 93.17% and 100%, respectively. The biodegradation of ethanethiol and dimethyl disulfide by Bacillus spindle GDUTAN6 could be used in environmental remediation.

Owner:GUANGDONG UNIV OF TECH

Wear-resistant organic glass and preparing method thereof

The invention discloses wear-resistant organic glass. The wear-resistant organic glass comprises, by weight, 60-80 parts of methyl methacrylate, 20-40 parts of isobornyl methacrylate, 50-60 parts of toluene-2,4-diisocyanate, 70-80 parts of polyethylene glycol, 3-5 parts of pentaerythritol tetraacrylate, 3-5 parts of modified diatomite, 12-14 parts of wear-resistant agent, 8-12 parts of fire retardant, 4-6 parts of dibutyl phthalate, 10-12 parts of rubber particles, 3-5 parts of maleic anhydride grating compatilizer, 0.48-0.64 part of azodiisobutyronitrile, 0.3-0.5 part of dibutyltin dilaurate, and 6-8 parts of ethanethiol. The invention further discloses a preparing method of the wear-resistant organic glass. The wear-resistant organic glass is good in wear-resistant performance, high in rigidity and good in mechanical properties.

Owner:安徽亚克力实业有限公司

Method for preparing 1-cyclohexenylethylamine through catalytic selective hydrogenation of modified Pd/C catalyst

ActiveCN107011178AImprove conversion rateHigh selectivityOrganic compound preparationAmino compound preparationHydrogen pressureAcetonitrile

The invention discloses a method for preparing 1-cyclohexenylethylamine through catalytic selective hydrogenation of a modified Pd / C catalyst. The method comprises the steps of (1) modifying a Pd / C catalyst, namely modifying the Pd / C catalyst through one or more of dimethyl disulfide, ethanethiol, dimethyl sulfide, thiophene, hydrogen sulfide and sulfur dioxide, adjusting the pH to be 7-11 by using an alkaline substance, filtering and washing to obtain a modified Pd / C catalyst; and (2) putting the modified Pd / C catalyst and 1-cyclohexenylacetonitrile into a reaction kettle of an ethanol solvent and reacting under the conditions that hydrogen pressure is 1-10MPa, the rate is 200-800r / min and the temperature is 50-140 DEG C to obtain the 1-cyclohexenylethylamine. According to the method for preparing the 1-cyclohexenylethylamine through catalytic selective hydrogenation of the modified Pd / C catalyst, the raw material conversion rate is greater than 80%, the selectivity is greater than 85% and the method can be used for industrial production.

Owner:JIANGSU UNIV OF TECH

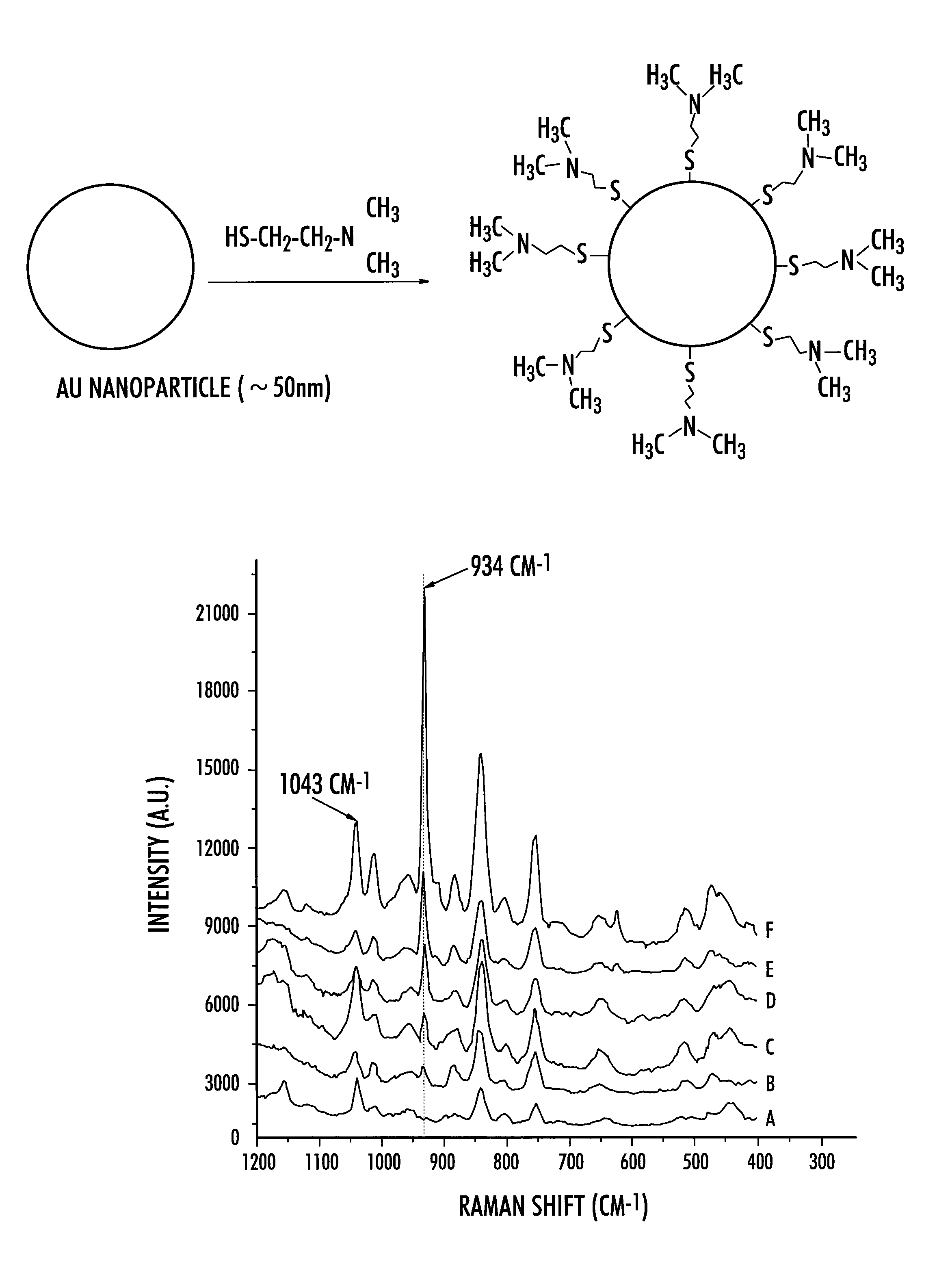

Functionalized gold surface-enhanced raman scattering substrate for rapid and ultra-sensitive detection of anionic species in the environment

InactiveUS7989211B1Reduced analytical timeLow costChemiluminescene/bioluminescenceRaman scatteringVibrational bandsUltra sensitive

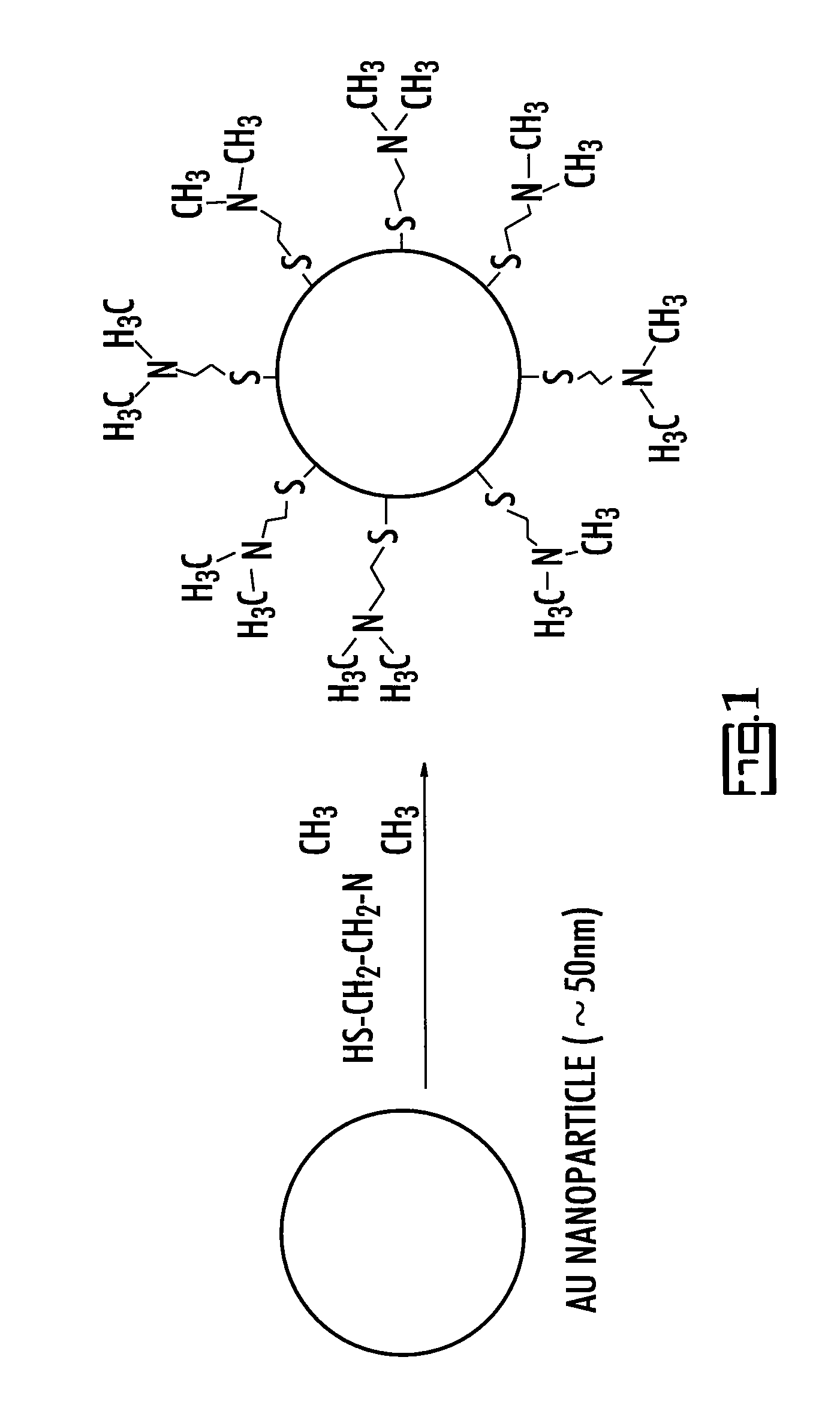

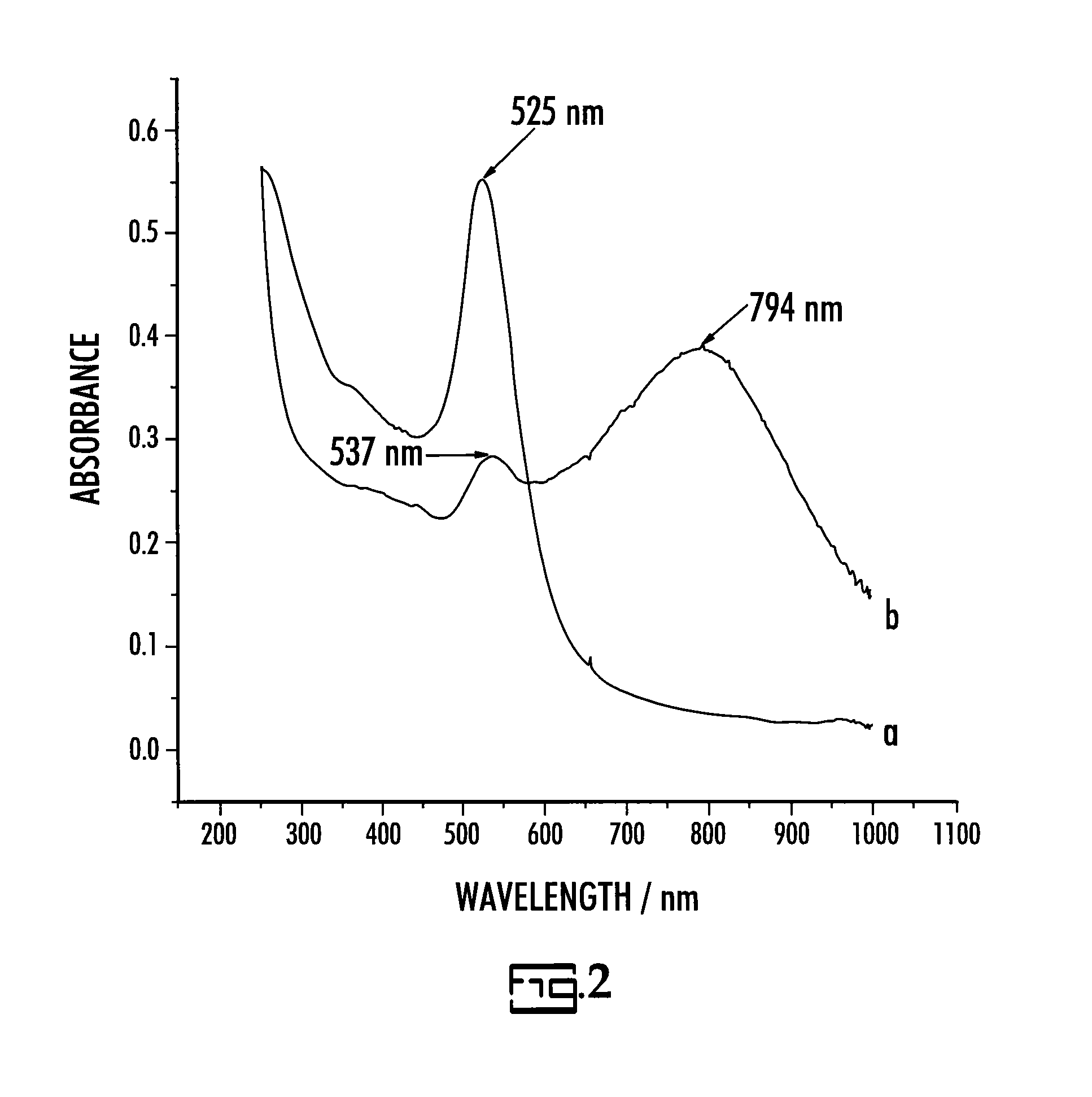

This invention relates to the development of a new Raman enhancing reagent and a surface-enhanced Raman scattering (SERS) method for rapid and ultra-sensitive detection and identification of perchlorate (ClO4−) and other anions such as technetium (TcO4−), uranium and nitrate in environmental samples. The method involves the synthesis of controlled gold nanoparticles which are modified with amine functional groups such as 2-(dimethylamino)ethanethiol and N,N,N-trimethylaminethiol. These functionalized Au nanoparticles were found to be reactive with perchlorate and other anions and can be used to detect these anions by Raman spectroscopy at ultra low concentrations in complex environmental matrices. This invention overcomes the limitations of currently-available analytical techniques by offering an inexpensive, rapid, ultra-sensitive, and real-time identification and detection of perchlorate and other anions. The technique is not only sensitive but also highly specific because of the unique Raman vibrational bands of perchlorate and other anions.

Owner:UT BATTELLE LLC

Genetic vector system and preparation method thereof

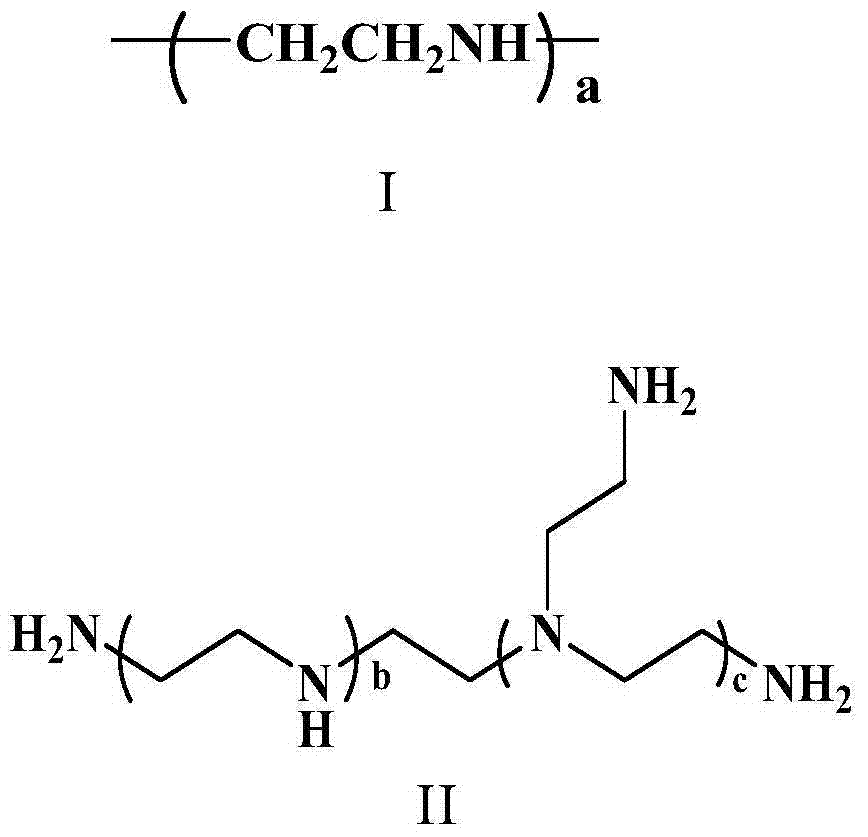

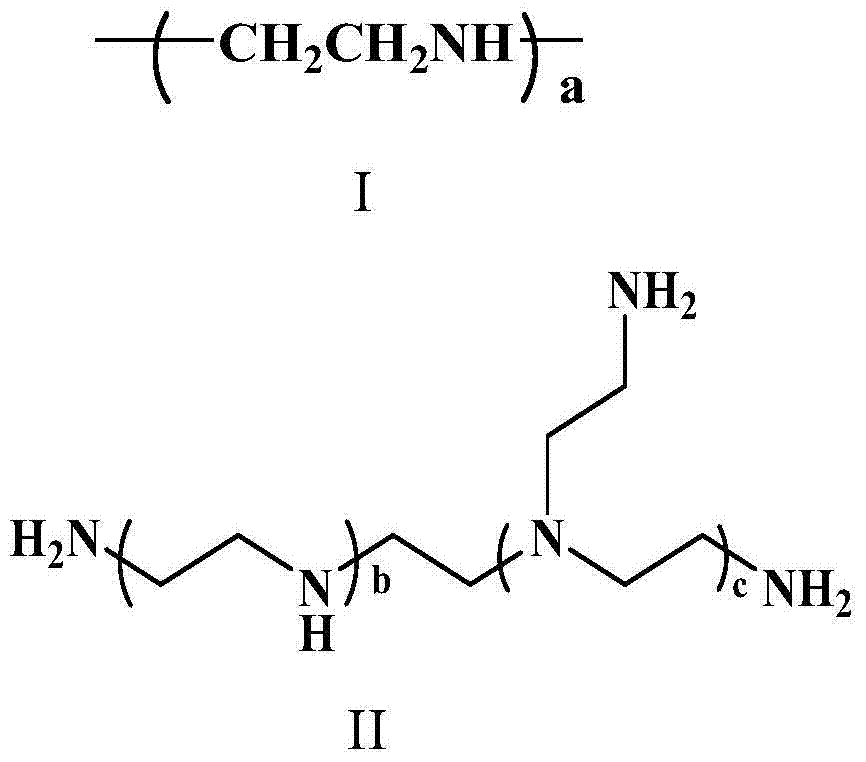

ActiveCN103497961ALow toxicityImprove binding efficiencyOther foreign material introduction processesVector-based foreign material introductionTert-Butyloxycarbonyl protecting groupCytotoxicity

The invention provides a genetic vector system. The genetic vector system comprises a pH sensitive masking system, a cation carrier and a genetic material, wherein the pH sensitive masking system is a polymer obtained by reaction of polyglutamate, 2-(Boc-amino)ethanethiol and mercaptoacetic acid and with removal of t-butyloxycarboryl protection, the polyglutamate is obtained by gamma-propinyl-L-glutamic acid-N-carboxyanhydride initiated by polyethyleneimine or micromolecule alkyl amine through ring opening polymerization, the mass ratio of the pH sensitive masking system and the cation carrier is (2-100):1, the mass ratio of the pH sensitive masking system and the genetic material is (5-80):1, and the genetic material is plasmid DNAs or siRNAs. The invention also provides a preparation method of the genetic vector system and an amino acid polymer. The genetic vector can introduce relatively multiple electrified groups, the using amount of the masking system is reduced, and the cytotoxicity generated by the masking system can be reduced when the genetic vector system is used.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

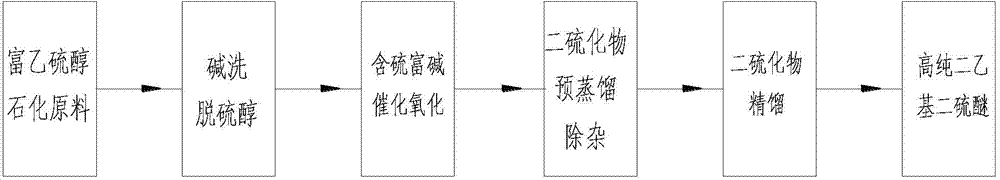

Method for preparing high-purity diethyl disulfide

ActiveCN103880722AReduce manufacturing costReduce the discharge of three wastesHydropoly/poly sulfide preparationBisulfideCatalytic oxidation

The invention relates to a method for preparing high-purity diethyl disulfide. The method comprises the following steps: mixing an ethanethiol-enriched petrochemical raw material with NaOH solution in a volume ratio of (1:1)-(5:1), and reacting for 1-30 minutes at 25-45 DEG C to prepare a sodium mercaptide-containing alkaline solution; adding cobalt phthalocyanine catalysts and an oxidant in the sodium mercaptide-containing alkaline solution, carrying out catalytic oxidation at 35-40 DEG C, and reacting for 1-8 hours to obtain a disulphide mixture; primarily distilling the disulphide mixture to obtain a disulphide crude product; rectifying and purifying the disulphide crude product to obtain the high-purity diethyl disulfide finished product. The method disclosed by the invention has the following beneficial effects that the production cost of diethyl disulfide is reduced, the production process is simplified, and the three-waste discharge and environmental pollution during the preparation process for the diethyl disulfide are reduced.

Owner:NINGBO ZHONGYI PETROCHEM TECH

Process for preparing hydrogen sulfide

The invention discloses a process for preparing hydrogen sulfide through the reaction between sulfuric-acid-containing exhausted liquid (by product of the production process for preparing chemical product and intermediate product by means of chemical reactions) and barium sulphide water soluble liquid phase (prepared from barium sulphide calcined member through water leaching), the produced hydrogen sulfide can be further used in preparing other chemical products, such as sodium hydroxide, sodium hydrogen sulfide, ammonium sulfide, ammonium hydrosulfide, sulfourea, methyl hydrosulfide, ethyl mercaptan and dimethyl sulfur ether.

Owner:唐培堃

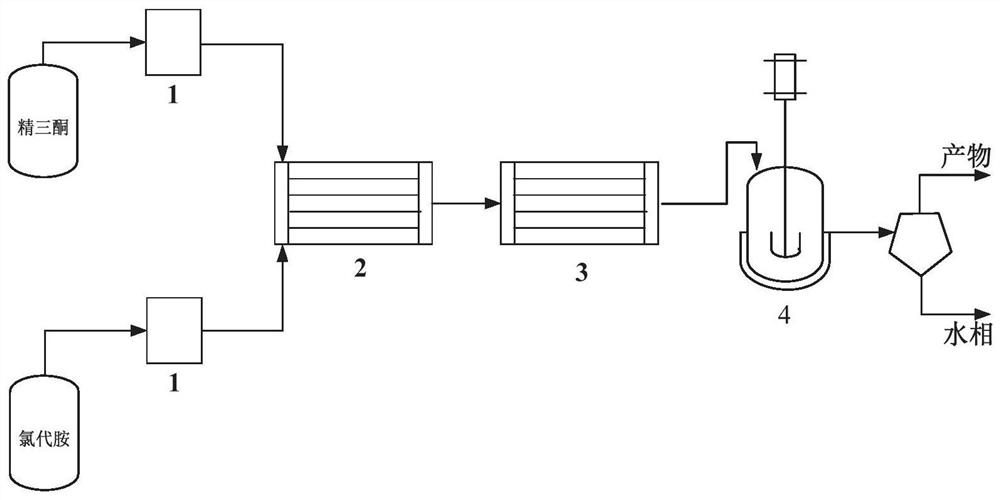

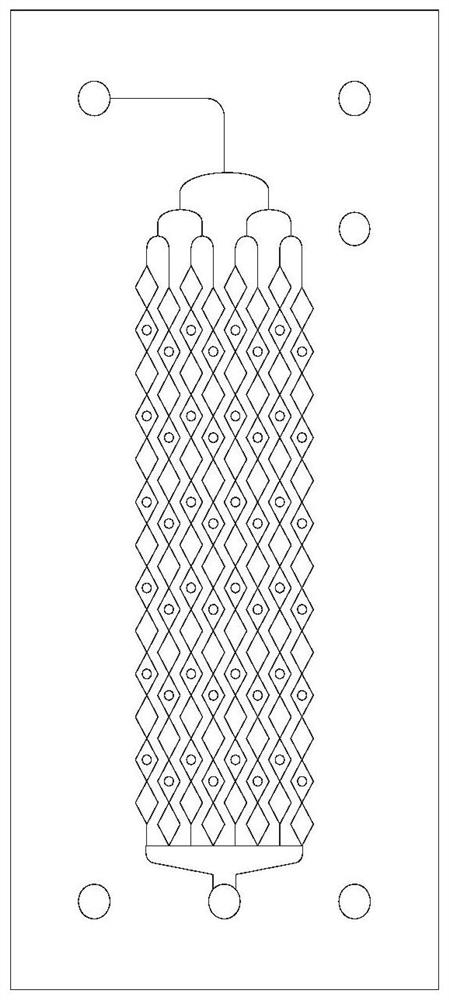

System and method for continuously synthesizing clethodim

ActiveCN112221444AWell mixedEnhanced mass transferSequential/parallel process reactionsChemical/physical/physico-chemical microreactorsAcyl groupChemical products

The invention belongs to the technical field of chemical product synthesis, and relates to a micro-reaction system and method for synthesizing herbicide clethodim. The system is formed by sequentiallyconnecting a micro-channel reactor I, a micro-channel reactor II and a collector in series. The synthesis method comprises the following steps of: by taking an ethanol solution of 5-[2-(ethanethiol)propyl]- 2-propionyl-1, 3-cyclohexanedione (referred to as refined triketone) and chloroallyloxyamine (referred to as chloroamine) as raw materials, respectively and continuously conveying the raw materials into the micro-channel reactor I through a metering pump to realize strong mixing and reaction; and continuing to mix and react the reacted materials in the micro-channel reactor II, controlling the temperature of the system through a heat exchanger, enabling the reaction product to enter the collector, and carrying out acid washing separation to obtain the product clethodim. According to the system and the method, low-energy-consumption, safe and continuous production of clethodim can be realized, the conversion rate of refined triketone is higher than 99% under the condition that themolar ratio of chloramine to refined triketone is 1.20, and the yield of the product clethodim is higher than 95%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

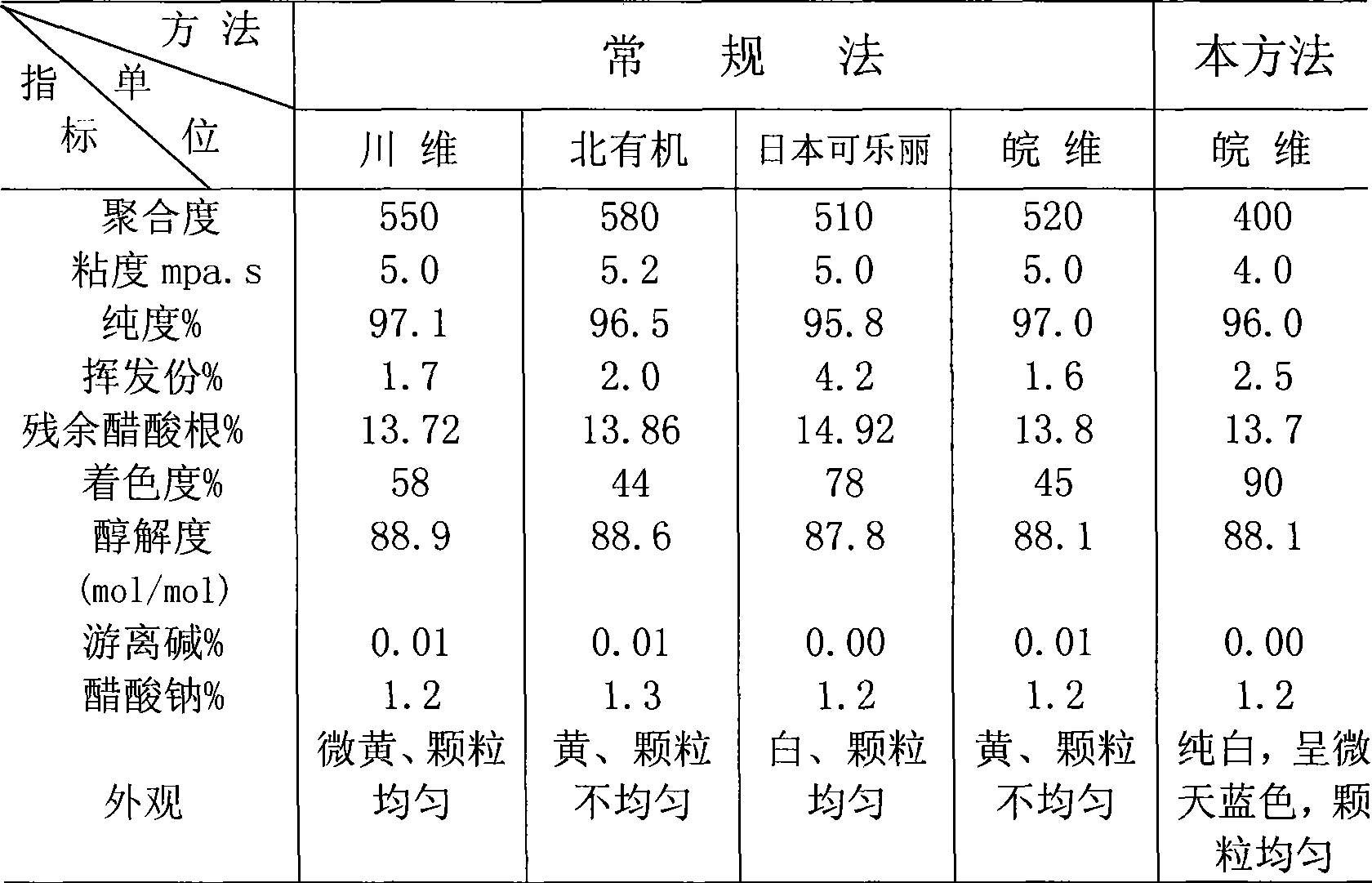

Polyvinyl acetate with low polymerization degree and polymerization method thereof

Polyvinyl acetate with low polymerization degree has a polymerization degree which is equal to or more than 200 and less than 500. The polymerization method is that monomer vinyl acetate polymerizes by the initiation of a free radical with the existence of initiating agent AIBN and chain transfer agent mercaptan. The mercaptan is selected from methyl hydrosulfide and / or ethanethiol, the addition amount is 0.2-0.6% of the monomer weight. The polyvinyl acetate resin of the invention has narrow molecular weight distribution, and the ratio of a height homo-polymerization degree and a number homo-polymerization degree is from 2.0 to 2.5.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

Fly ash chelating agent and preparation method thereof

InactiveCN108014444AHigh molecular weightStrong flocculation functionChemical protectionSulfurEthanethiol

The invention provides a fly ash chelating agent and a preparation method thereof. The fly ash chelating agent includes, by weight, 10% to 20% of trithione triazine trisodium salt, 3% to 8% of sodiumtrithiocarbonate, 2% to 6% of 2, 6-diamido pyridineethanethiol, 0.5% to 1.5% of 1, 3-bisbenzamido ethanethiol, 0.2% to 0.8% of an additive and 60% to 80% of water. The preparation method of the fly ash chelating agent comprises adding trithione triazine trisodium salt, sodium trithiocarbonate, 2, 6-diamido pyridineethanethiol and 1, 3-bisbenzamido ethanethiol into water, carrying out stirring to obtain a mixed solution, and adding the additive into the mixed solution. The preparation method has simple processes. The fly ash chelating agent is an organic sulfur compound chelating agent, has large molecular weight, a strong flocculating function and a strong heavy metal chelating capacity. The additive is soluble starch, improves the chelating ability of the chelating agent and reduces the toxicity of the macromolecular heavy metal chelating agent. The modified product is easily biodegrade.

Owner:东莞市升佳净水材料有限公司

Predominating Population for removing ethanethiol and introduction domestication method thereof

The invention relates to preponderant strains for removing ethanethiol and an introduction domestication method thereof. Quantitative mixing strains from different resources of mud samples in live mud, industrial mud, and the like, which contain sulfur or sulphide, are obtained. The mixing strains are domesticated and cultured in a culture medium with ethanethiol, after a definite time, bacteria in the culture medium have the characteristic of definite ethanethiol removal. Bacterial strains are separated many times by using a continuous dilution separation method and a plate streaking method so as to obtain preponderant strains with ethanethiol removal. The strain is CTB138-1 AY345539.1 through DNA determination and the scanning and observation of an electron microscope, and the bacteria are in a short rod shape. The ethanethiol removal rate can reach more than 85 percent through determination result indication.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

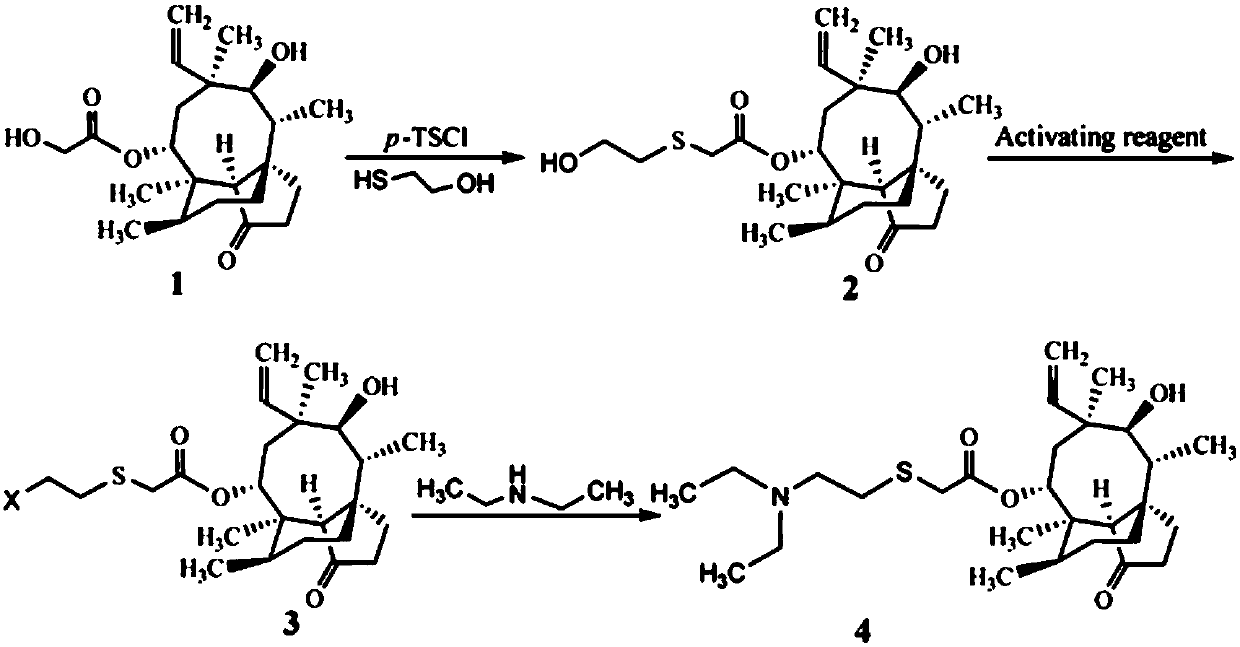

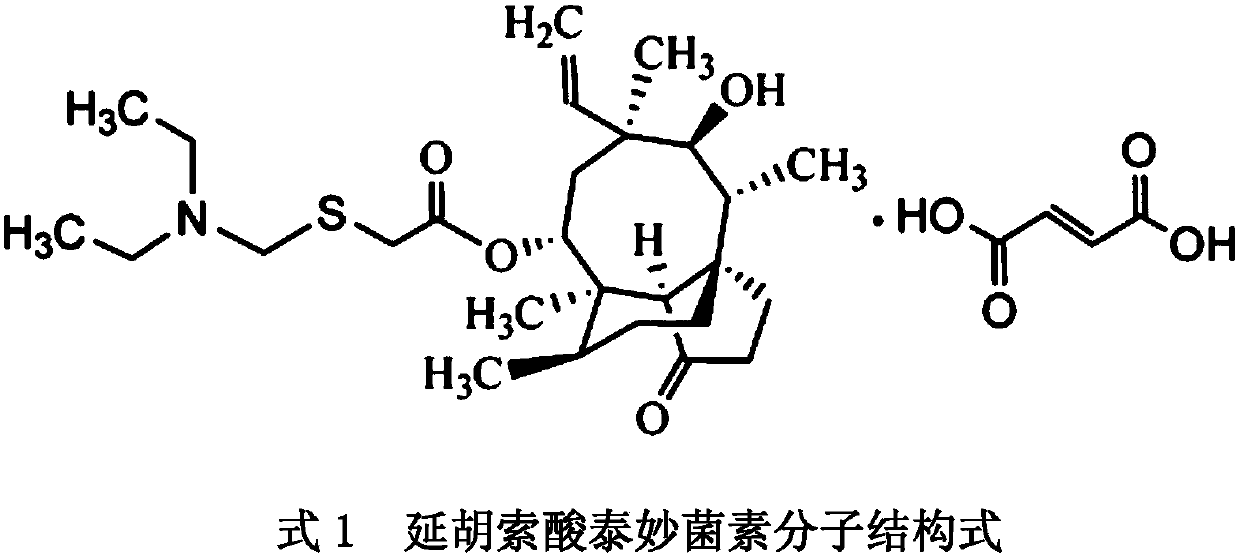

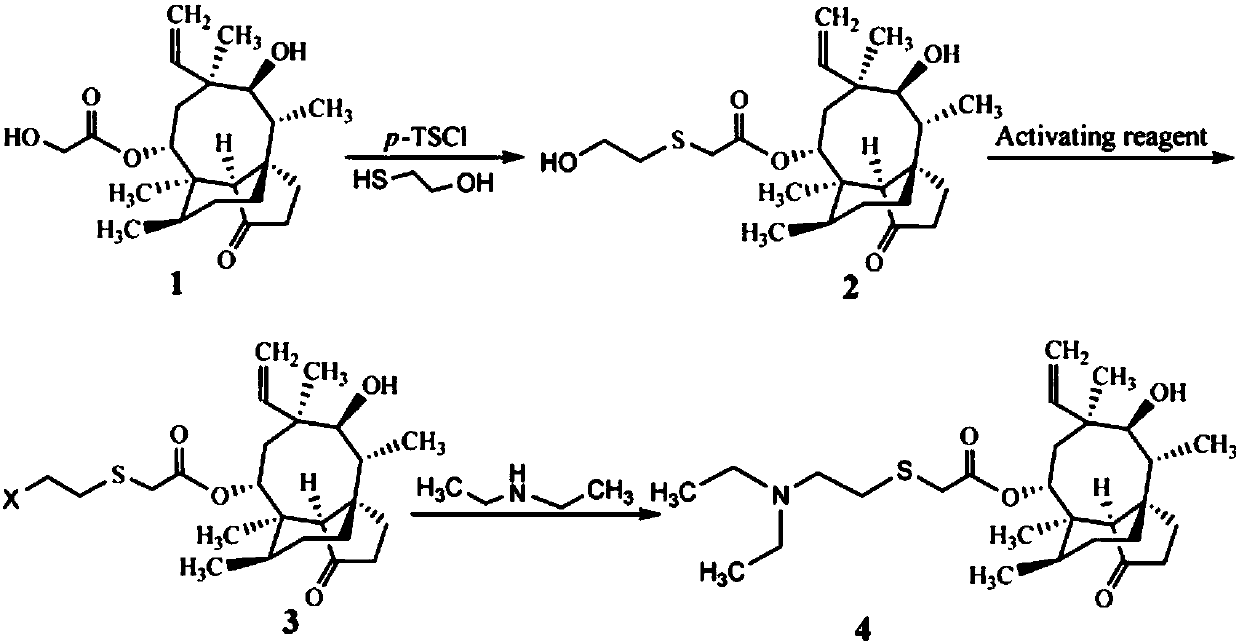

Method for preparing tiamulin

ActiveCN107759502AAddressing major headwinds to yieldLow costSulfide preparationPleuromutilinHydroxy compound

The invention discloses a method for preparing tiamulin. The method comprises the following synthesis routes: by taking a compound of formula 1, namely pleuromutilin, as a raw material, performing p-tosylation; synthesizing an intermittent, namely tosylate; performing a direct nucleophilic substitution reaction with beta-mercaptoethanol without separation so as to obtain an intermittent of formula2, namely 14-O-[(1-hydroxyl propane-2-yl) sulfur acetyl] tiamulin; activating the intermittent of the formula 2 by using a halogenation reagent or a sulfonylation reagent so as to form an intermittent of formula 3; enabling the intermittent to react with diethylamine directly without separation, thereby synthesizing a compound of formula 4, namely tiamulin. By adopting the method, 2-lignocaine ethanethiol which is supervised is not used, current main adverse factors which restrict the yield of tiamulin are solved, and tiamulin is prepared through synthesis routes which are low in cost, gentlein condition, environmental-friendly and applicable to industrial production.

Owner:山东德信生物科技有限公司

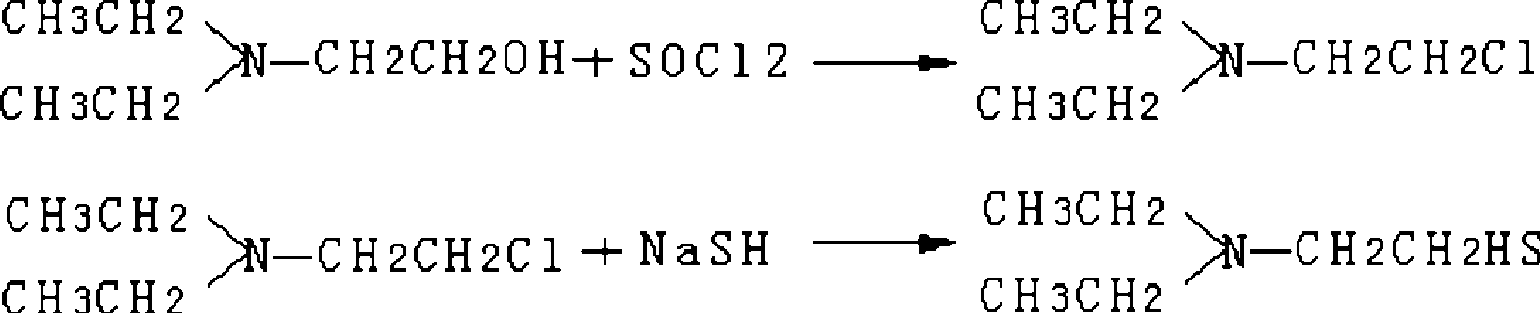

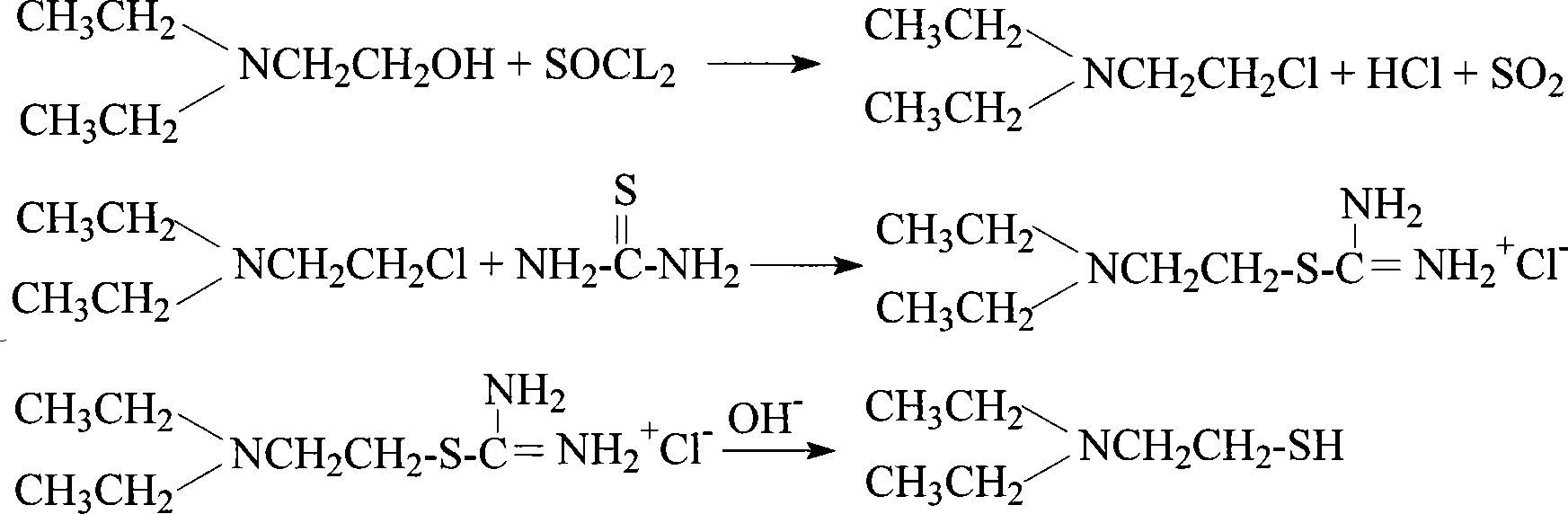

Method for preparing diethylamino ethanethiol

A preparation method of diethylamino ethanethiol comprises chlorinating diethylamino alcohol via chlorinating agent to generate diethylamino chloroethane or relative hydrochloride, reacting the diethylamino chloroethane or relative hydrochloride with thiourea to generate S-substituted isothiourea salt, and processing alkaline hydrolysis on the S-substituted isothiourea salt via strong alkali to prepare diethylamino ethanethiol. The preparation method has simple process, low cost, reduced water consumption, reduced environment pollution, high reaction activity, better directionality, high product purity and high yield (at least 80%). The invention has wide application in medicine industry.

Owner:保定加合精细化工有限公司

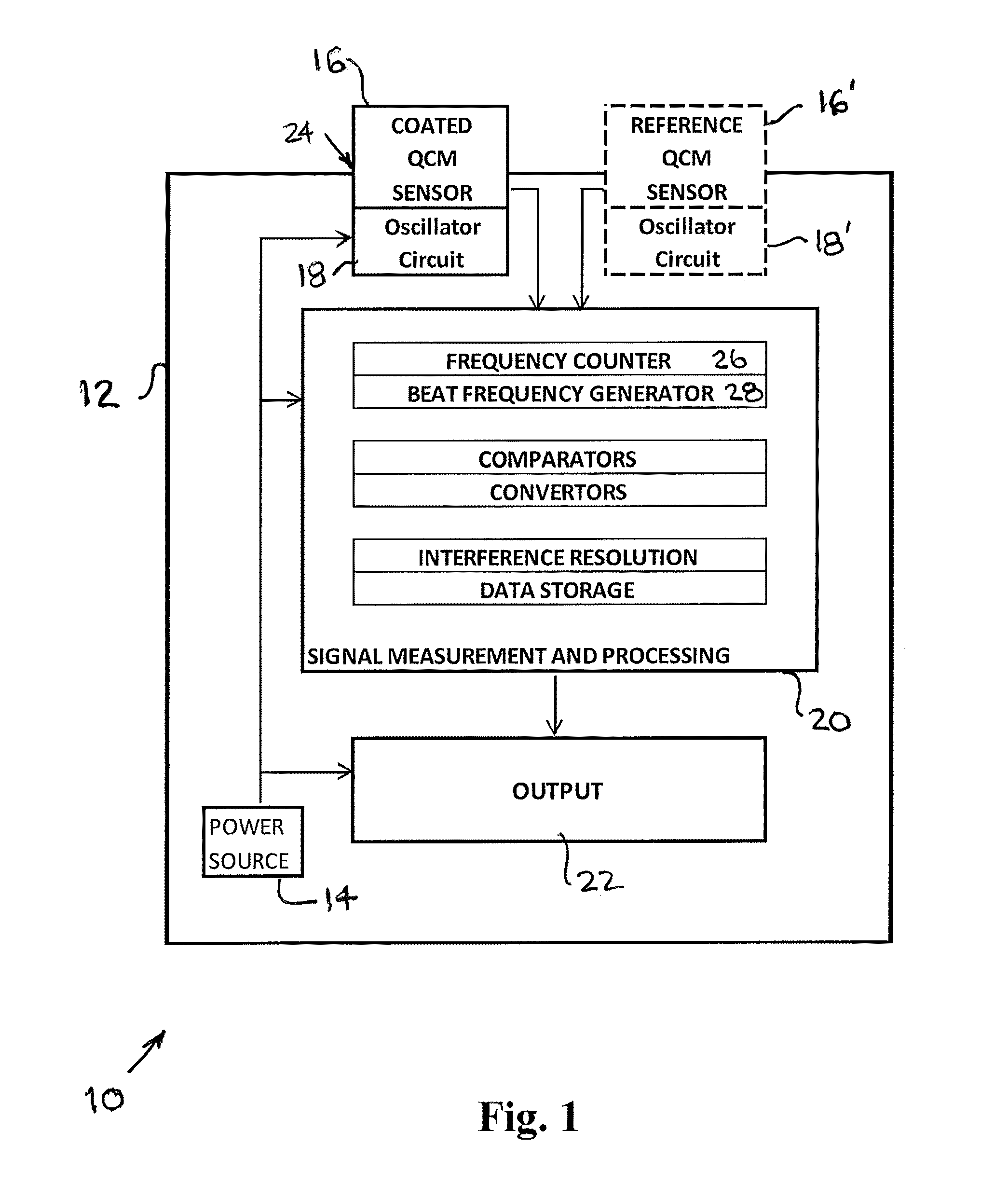

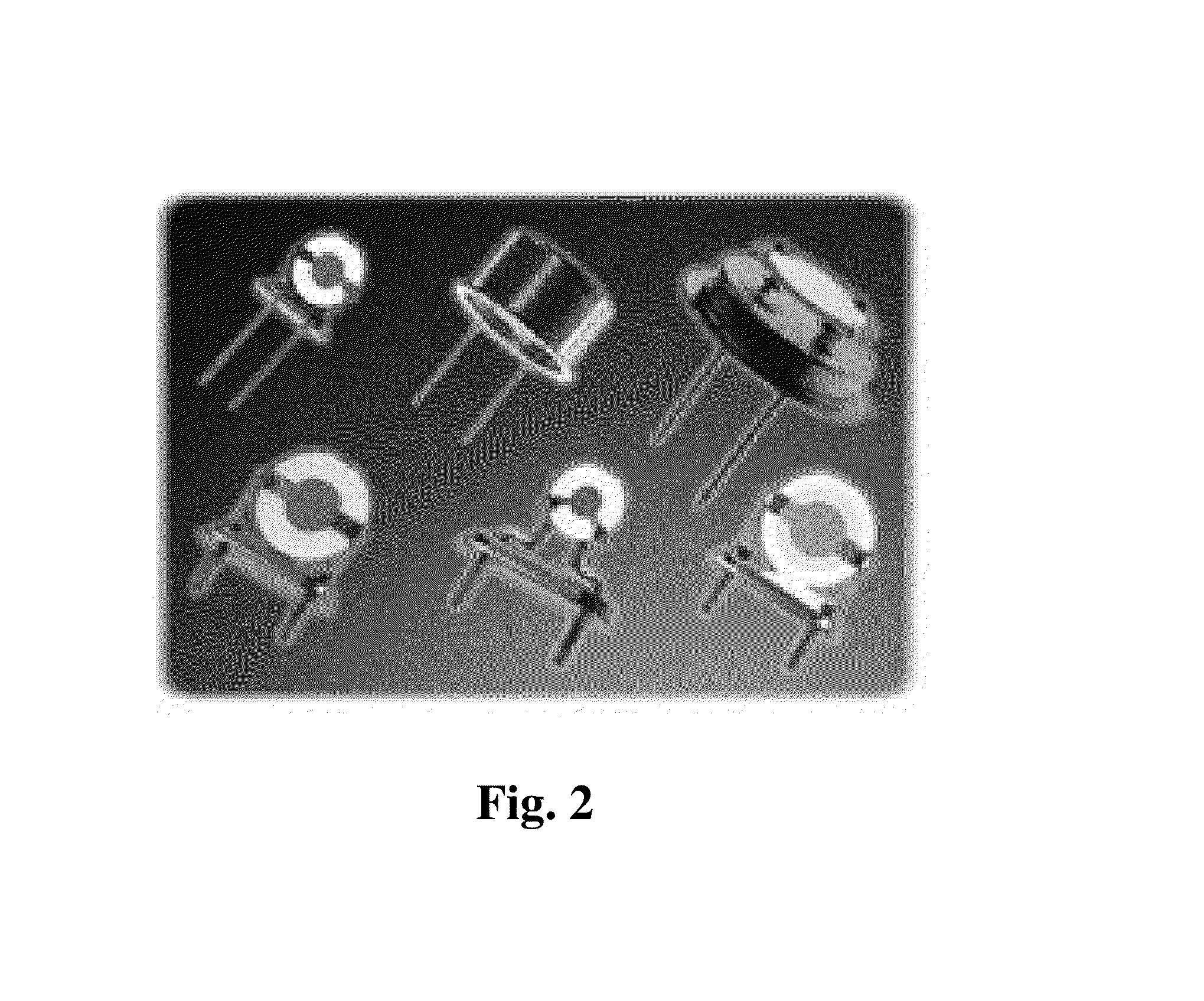

Method and Device for Detecting Odorants in Hydrocarbon Gases

ActiveUS20150160165A1Analysing fluids using sonic/ultrasonic/infrasonic wavesThiolQuartz crystal microbalance

A quartz crystal microbalance (QCM) is disclosed for use in a hand-held detection device for detecting the presence of an odorant in hydrocarbon gaseous fuels. The odorant is a thiol-based compound, such as ethanethiol. The QCM is coated with a coating typically containing a reagent that specifically reacts with the thiol of the odorant and alters its oscillation frequency as a result of mass gained in the reaction. Signal measurement and processing circuitry is provided for monitoring the change in oscillation frequency, for nulling out the effect of interfering compounds, and for reporting out the result.

Owner:BATTELLE MEMORIAL INST

Scratch-resistant organic glass

The invention discloses a scratch-resistant organic glass which is composed of organic glass, an anti-wear agent, a lubricant, a plasticizer, a molecular weight regulator and an initiator, wherein the anti-wear agent is silicon carbide, the lubricant is talcum powder, the plasticizer is dibutyl phthalate, the molecular weight regulator is ethanethiol, and the initiator is diisopropyl peroxydicarbonate. By adding the anti-wear agent, lubricant, plasticizer, molecular weight regulator and initiator into the organic glass, the organic glass has the characteristics of high wear resistance, scratch resistance, high strength, high quality and high working efficiency.

Owner:ZHANGJIAGANG DELITE NEW MATERIAL

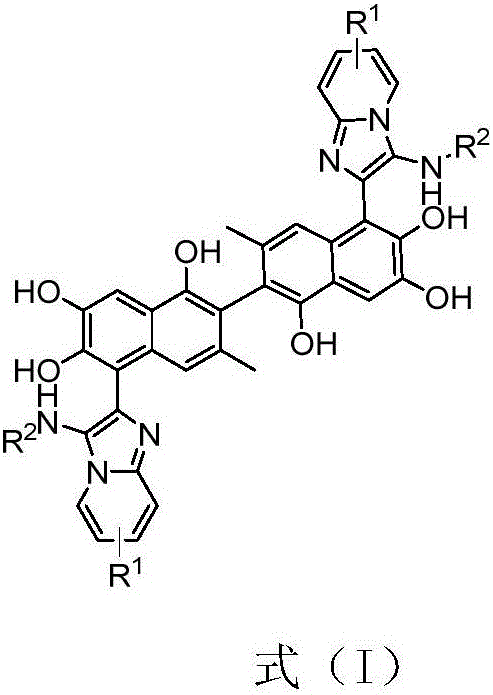

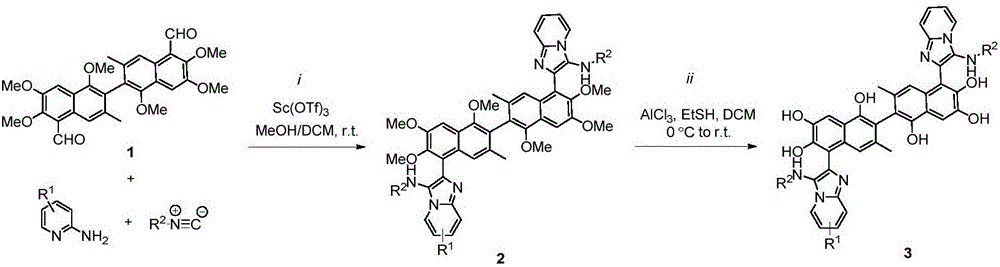

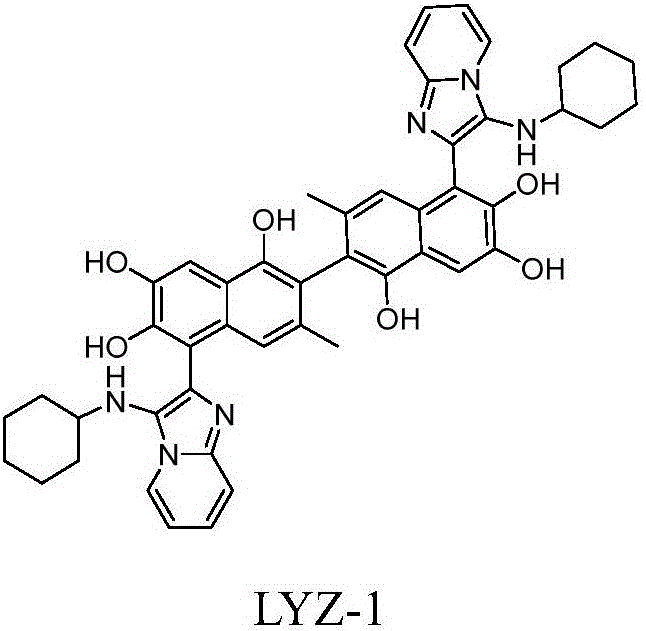

Apogossypol derivatives and preparation method thereof, and application of apogossypol derivatives in antitumor and immunoregulation

ActiveCN106632409AEnhanced inhibitory effectOrganic active ingredientsOrganic chemistryFiltrationOrganic synthesis

The invention belongs to the technical field of organic synthesis, particularly discloses a preparation method and application of apogossypol derivatives. The preparation method comprises the following steps: stirring apogossypol and isonitrile used as raw materials in a polar solvent at room temperature, and carrying out column chromatography separation to obtain a reaction product which is used as the raw material for the next reaction; under waterless oxygen-free conditions, adding ethanethiol into anhydrous aluminum chloride, cooling to 0 DEG C, dissolving the reaction product in the first step in anhydrous dichloromethane, and dropwisely adding into the solution; and after the reaction finishes, adding water to quench the reaction, regulating the pH value to 3-5, standing, carrying out vacuum filtration, washing the filter residue with dichloromethane, and carrying out vacuum drying, thereby obtaining the solid which is the target product. The multicomponent synthesis process centrally modifies the isopropyl of the apogossypol, thereby constructing series derivatives of apogossypol. The derivatives have favorable antitumor activity, have favorable inhibiting actions on IL-17A, and have wide application prospects.

Owner:江苏度未生物工程科技有限公司

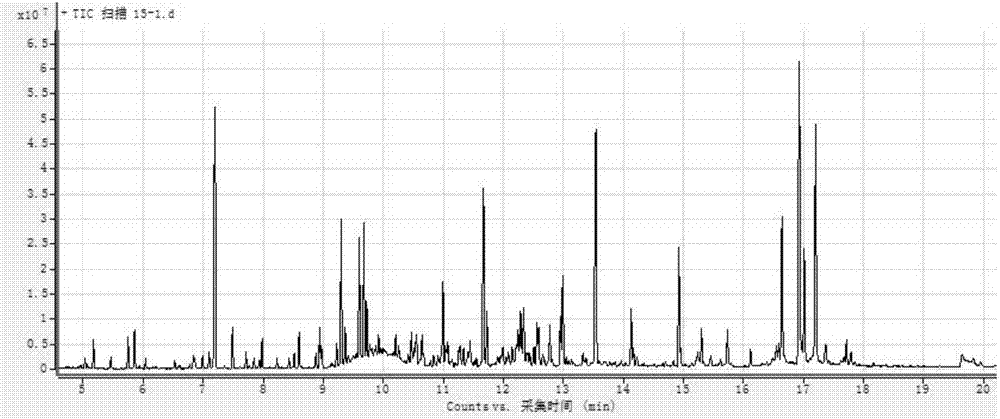

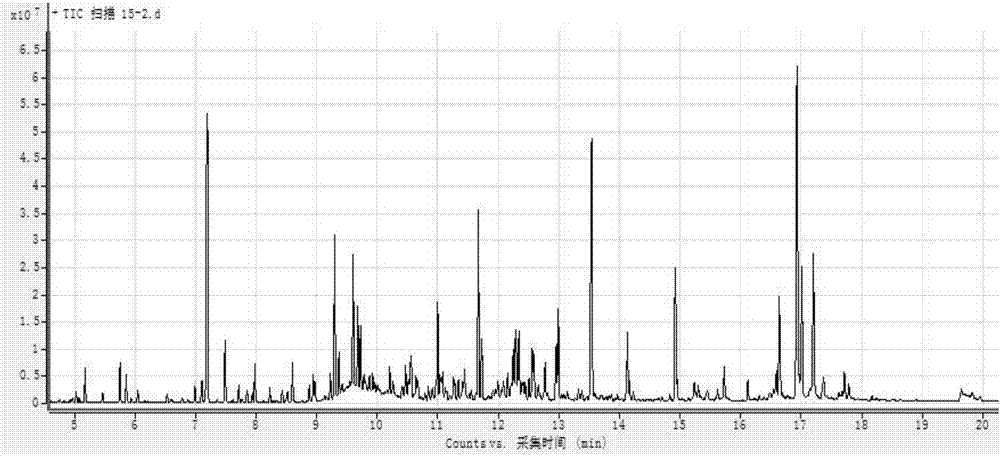

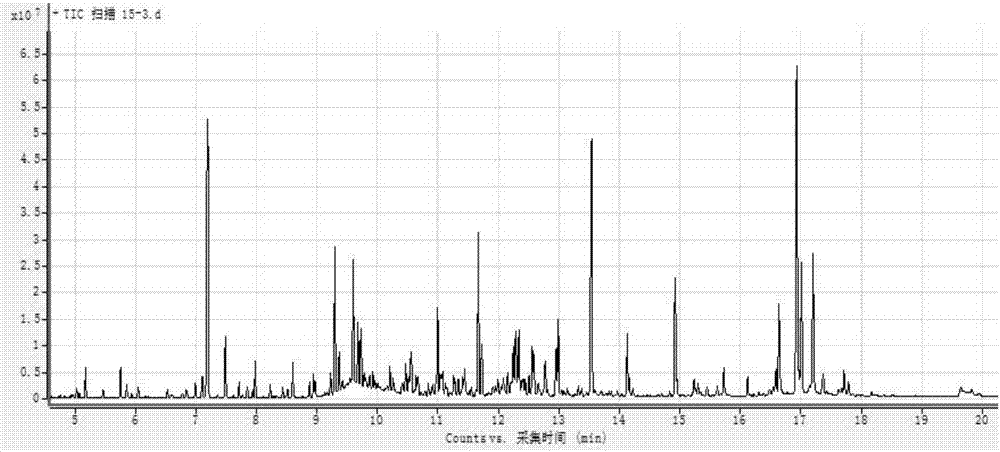

A detection method for metabolites in urine and a kit

ActiveCN107340337AThermally unstableGood thermal instabilityComponent separationMetaboliteDerivatization

The invention relates to a detection method for metabolites in urine. The method includes (1) a step of removing impurities from a urine sample, namely a step of removing urea, sulfur and phosphorus and precipitating protein to obtain urine C; (2) a drying step, namely a step of drying the urine C to obtain urine residues D; (3) a step of oximation, namely a step of subjecting beta-carbonyl in acid or alcohol metabolites in the urine residues D to oximation by utilizing an oximation agent to obtain urine E; (4) a step of derivatization, namely a step of subjecting the urine E to derivatization with an derivatization agent to obtain a urine sample F to be detected, with the derivatization agent being an agent mixture comprising a silanization agent, a catalyst and a catalyst stabilizer, and with the catalyst stabilizer being selected from dithioerythritol, dithiothreitol, 1-propanethiol, ethanethiol and 2-mercaptoethanol; and (5) a step of detection, namely a step of detecting the urine sample F to be detected by adopting a gas chromatography-mass spectrography process. The method has advantages of a low sample using amount, simple pretreatment, short time, capability of detecting a plurality of varieties of compounds, rapid and accurate result analysis, and the like.

Owner:GUANGZHOU RIBOBIO

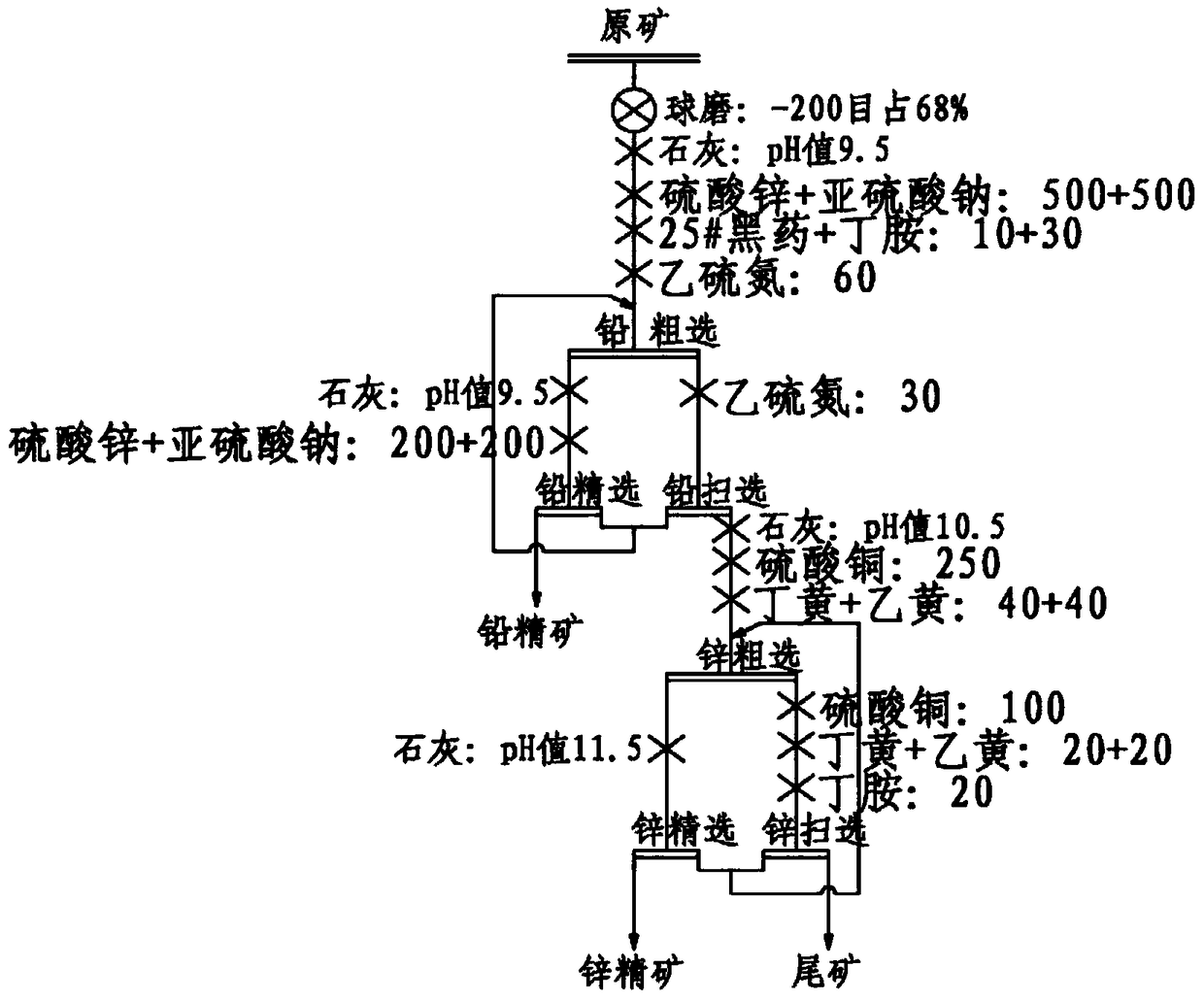

Method for improving beneficiation indexes of low-grade lead-zinc-silver polymetallic ores by combining collecting agent

The invention belongs to the technical field of beneficiation, particularly relates to a method for improving beneficiation indexes of low-grade lead-zinc-silver polymetallic ores by combining a collecting agent. According to the method, ethanethiol is adopted as a main collecting agent in the lead process, a butylamine black medicine, the 25 # black medicine is an auxiliary collecting agent, thezinc flow ethyl xanthate and the butyl xanthate are added according to a ratio of 1:1 to serve as a main collecting agent, and the butyl amine black medicine is used as an auxiliary collecting agent.By utilizing the use of the combined collecting agent, the concentrate grade is stable and even the small amplitude is improved, the recovery rate of the three kinds of metal of the lead and zinc silver is greatly improved, the content of the silver in the lead concentrate is improved, and the economic benefit is obviously improved.

Owner:云南中金共和资源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com