Synthesis technology for N,N-diethylamino group ethanethiol

A technology of diethylaminoethane mercaptan and synthesis process, which is applied in the field of N, can solve the problems of large volatilization loss of raw materials, long reaction time and high cost, and achieves the effects of small excess molar ratio of feeding materials, few kinds of raw materials and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

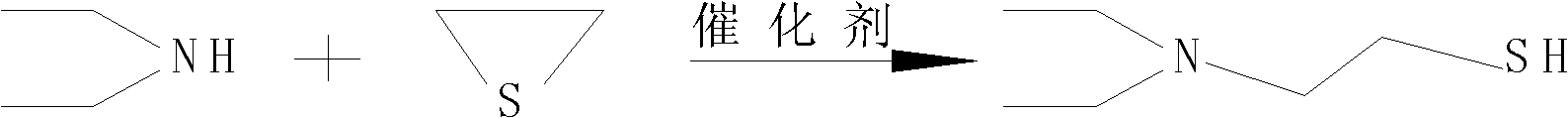

Image

Examples

Embodiment 1

[0014] Press 80 kg of sulfide and 100 kg of diethylamine into a 500L autoclave with nitrogen, heat to 80°C with stirring, and seal the reaction. During the reaction, the pressure in the kettle rose up to 0.2MPa. As the reaction progressed, the pressure in the kettle dropped from the highest point. When the pressure in the kettle dropped to 0.02MPa, the reaction ended, and the reaction time was 3 hours. After the reaction was completed, the temperature was lowered to 50° C., and the material was put into a distillation kettle. Firstly, diethylamine was recovered by distillation, and then 170.2 kg of N,N-diethylaminoethanethiol was obtained by distillation under reduced pressure.

[0015] The mass percent content of N,N-diethylaminoethanethiol in this example is 99%. The product yield is 96%.

Embodiment 2

[0017] Press 250 kg of sulfide and 330 kg of diethylamine into a 2000L autoclave with nitrogen, heat to 90°C with stirring, and seal the reaction. During the reaction process, the pressure in the kettle rose to 0.3MPa at the highest. As the reaction progressed, the pressure in the kettle dropped from the highest point. When the pressure in the kettle dropped to 0.02MPa, the reaction ended, and the reaction time was 4 hours. After the reaction is completed, the temperature is lowered to 50° C., and the material is put into a distillation still. Firstly, diethylamine is recovered by distillation, and then 534.7 kg of N,N-diethylaminoethanethiol can be obtained by distillation under reduced pressure.

[0018] The mass percent content of N,N-diethylaminoethanethiol in this embodiment is 99%. The product yield is 96.5%.

Embodiment 3

[0020] Press 250 kg of sulfide and 330 kg of diethylamine into a 2000L autoclave with nitrogen, heat to 100°C with stirring, and seal the reaction. During the reaction, the pressure in the kettle rose up to 0.5MPa. As the reaction progressed, the pressure in the kettle dropped from the highest point. When the pressure in the kettle dropped to 0.02MPa, the reaction ended, and the reaction time was 4 hours. After the reaction is completed, the temperature is lowered to 50° C., and the material is put into a distillation kettle, diethylamine is recovered by distillation, and 530 kg of N,N-diethylaminoethanethiol can be obtained by distillation under reduced pressure.

[0021] The mass percent content of N,N-diethylaminoethanethiol in this embodiment is 99%. The product yield is 95.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com