Method for improving beneficiation indexes of low-grade lead-zinc-silver polymetallic ores by combining collecting agent

A technology of combining collectors and polymetallic ore, applied in flotation, solid separation and other directions, can solve the problems of poor recovery performance, poor selectivity, difficult to improve, etc., to improve recovery rate, increase content, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

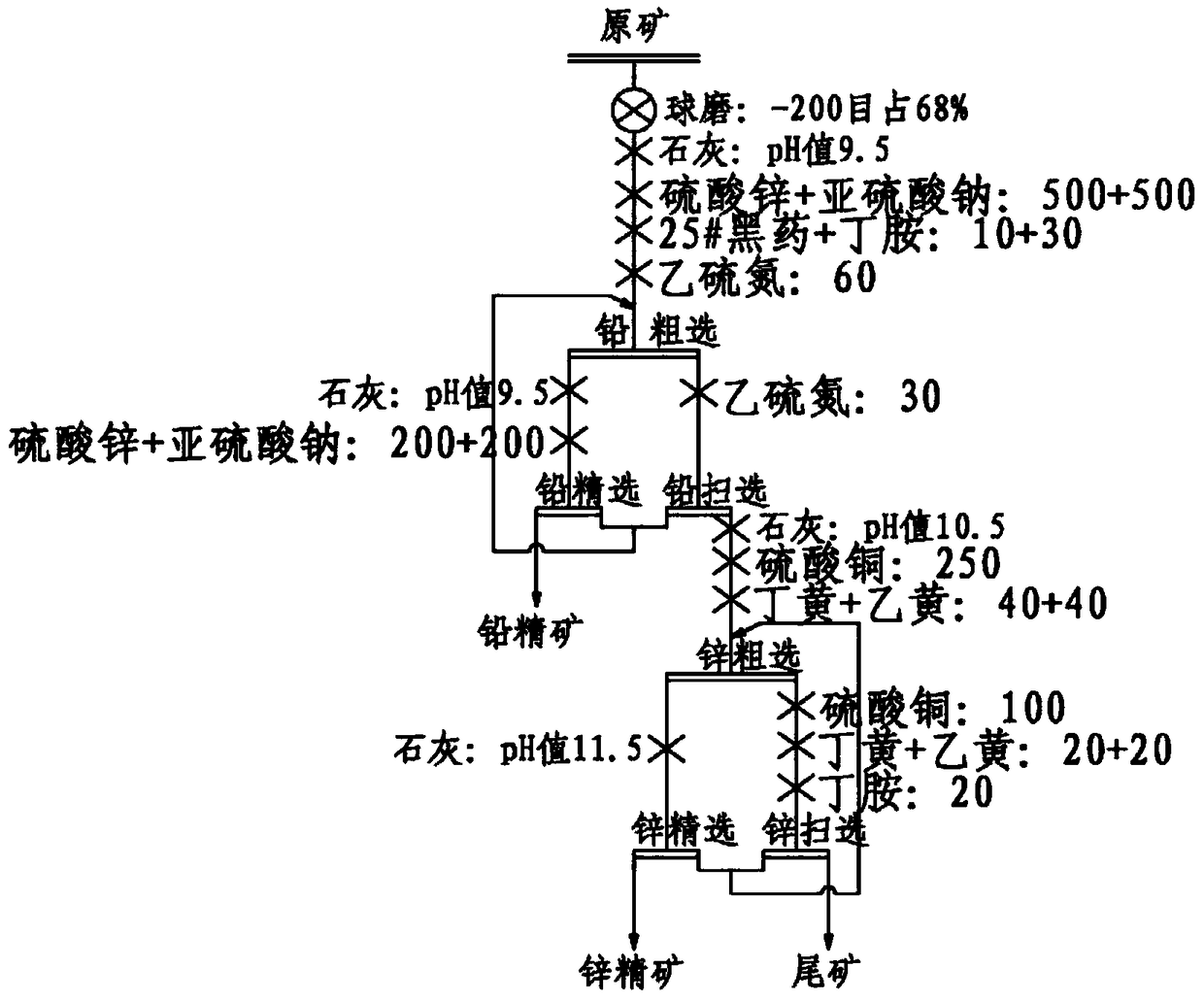

[0019] Combination collector in the present embodiment improves the method for beneficiation index of low-grade lead-zinc-silver polymetallic ore, carry out according to the following steps:

[0020] (1) Ball mill the raw ore of low-grade lead-zinc-silver polymetallic ore to -200 mesh, accounting for more than 68%, add lime to adjust the pH to 9.5, add zinc sulfate and sodium sulfite and stir, the amount of zinc sulfate added is 500g / t raw ore, and the amount of sodium sulfite added 500g / t, then add 25# black medicine and butylamine to stir, 25# xanthate is added in an amount of 10g / t raw ore, and finally add ethyl disulfide and stir, and the amount of ethyl disulfide added is 60g / t raw ore to obtain lead rough dressing Perform lead roughing flotation to obtain lead roughing concentrate and lead roughing tailings;

[0021] (2) add lime to adjust pH to 9.5 in described lead roughing concentrate, then add zinc sulfate and sodium sulfite, the add-on of zinc sulfate is 200g / t lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com