Patents

Literature

85results about How to "Improve mineral processing recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

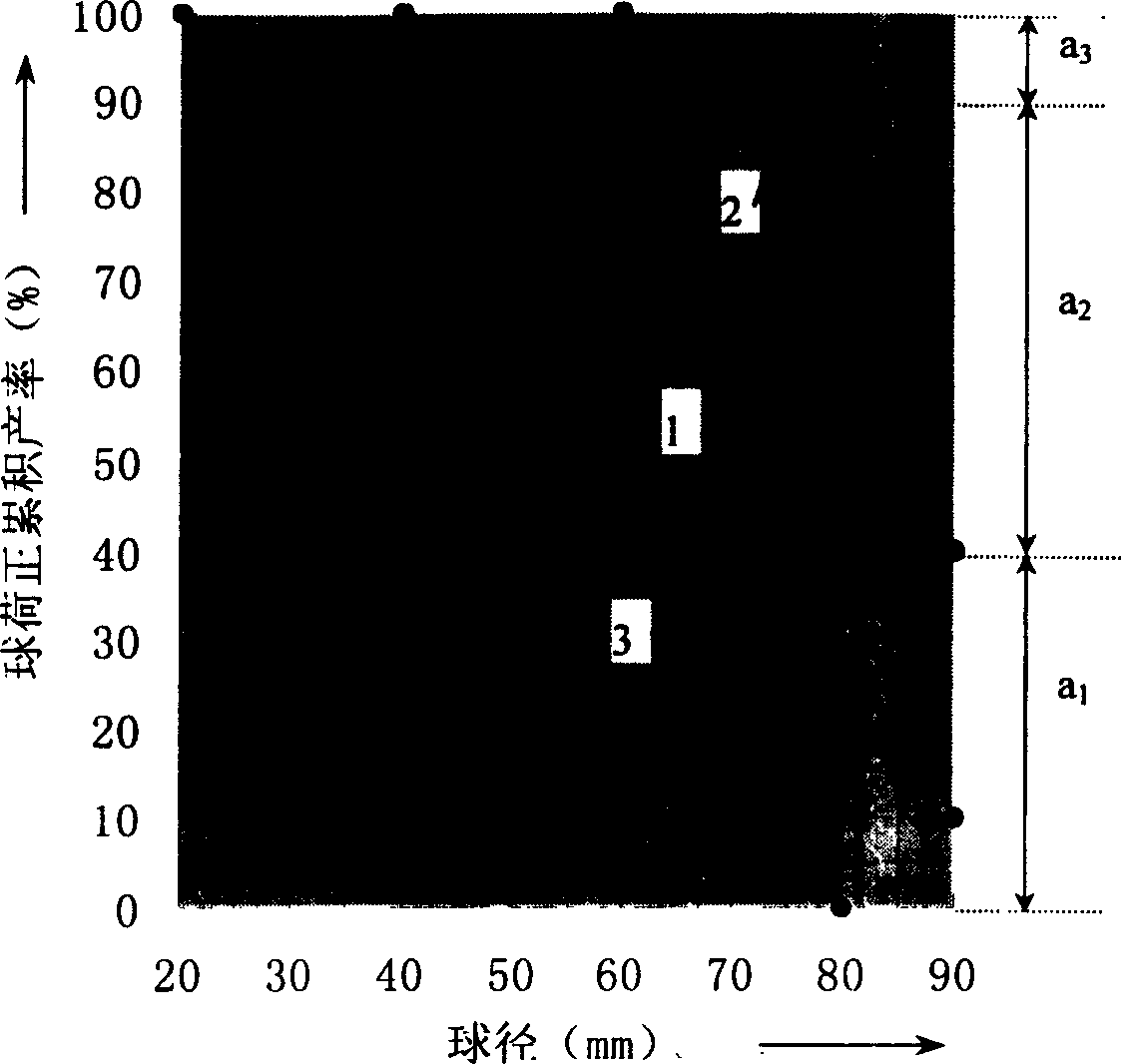

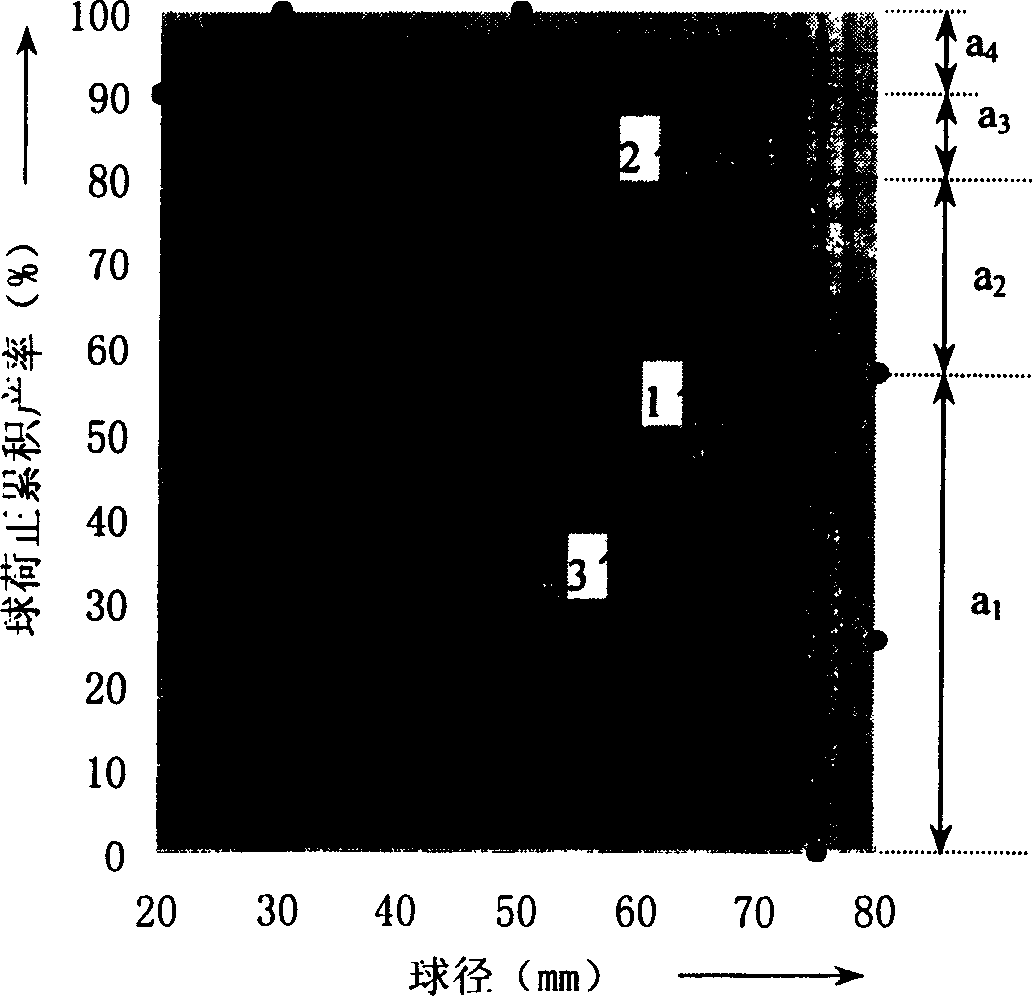

Ball grinder accurate ball loading method

The invention is a method for ball mill to recuperate balls precisely, which belongs to ore pulverizing, grinding technology field. The method includes: measures the mechanical parameter of ore; sifts and analyzes the mill ore and back sands, calculates the ore particle components and groups them; calculates the particle radius value according to ball radius haft theory formula; determines the ball ratio of the mill according to the ore particle and the needed ball radius; paints the ball particle accumulating curve, thus acquires the radius and recuperating ratio precisely. The proportion is reasonable, the method is simple, the productivity is upgraded greatly, and the quality is improved.

Owner:KUNMING UNIV OF SCI & TECH +2

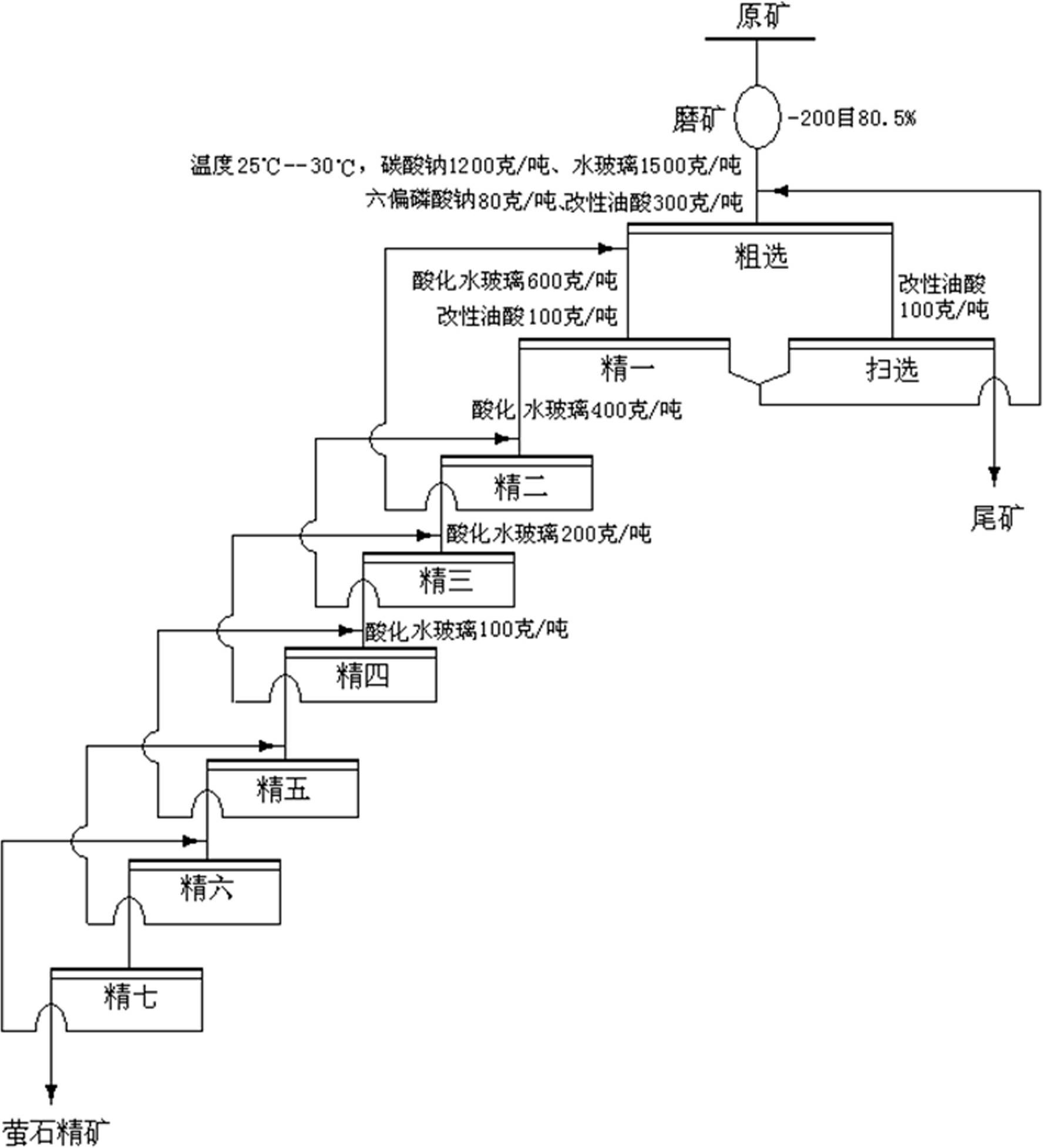

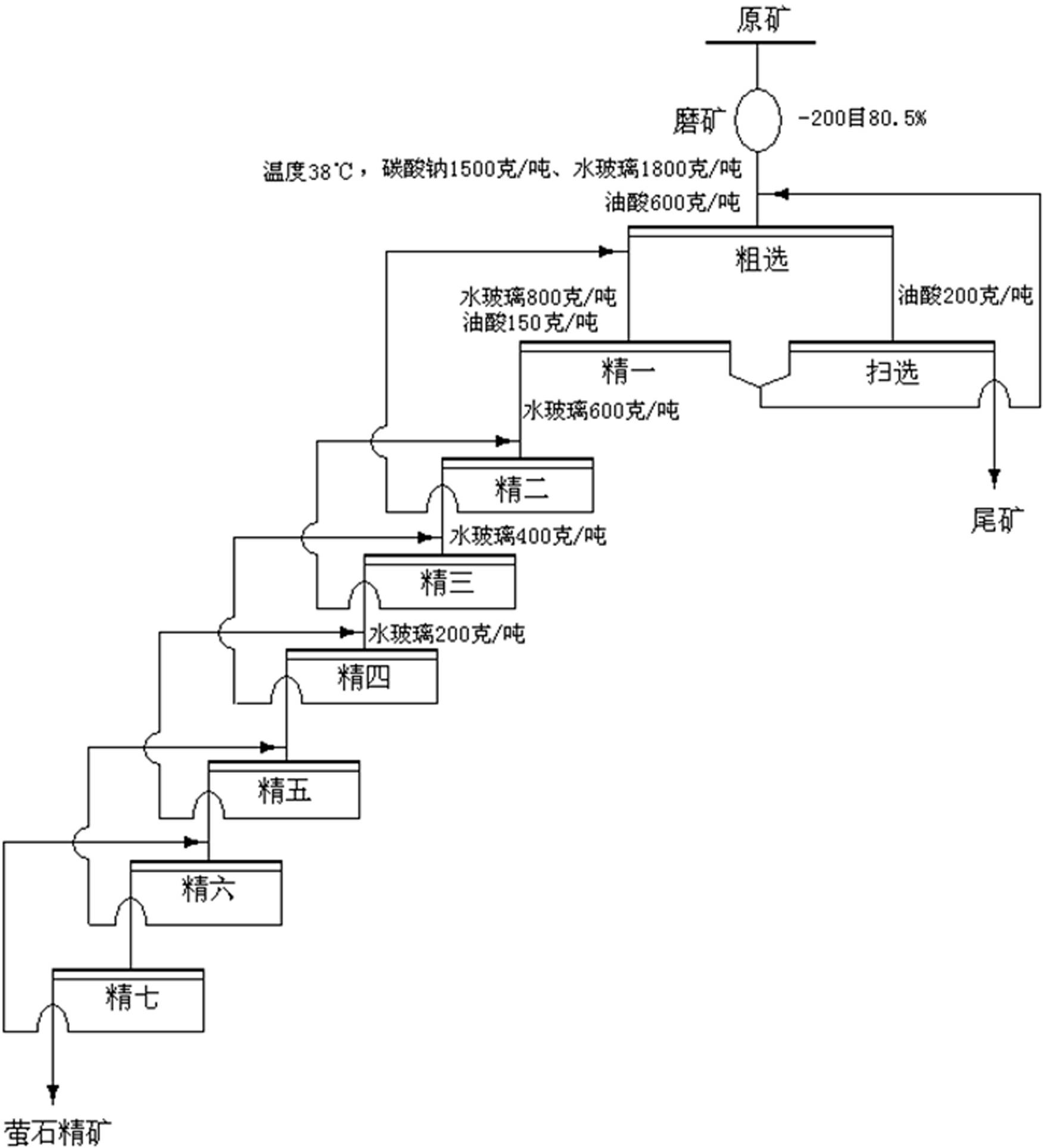

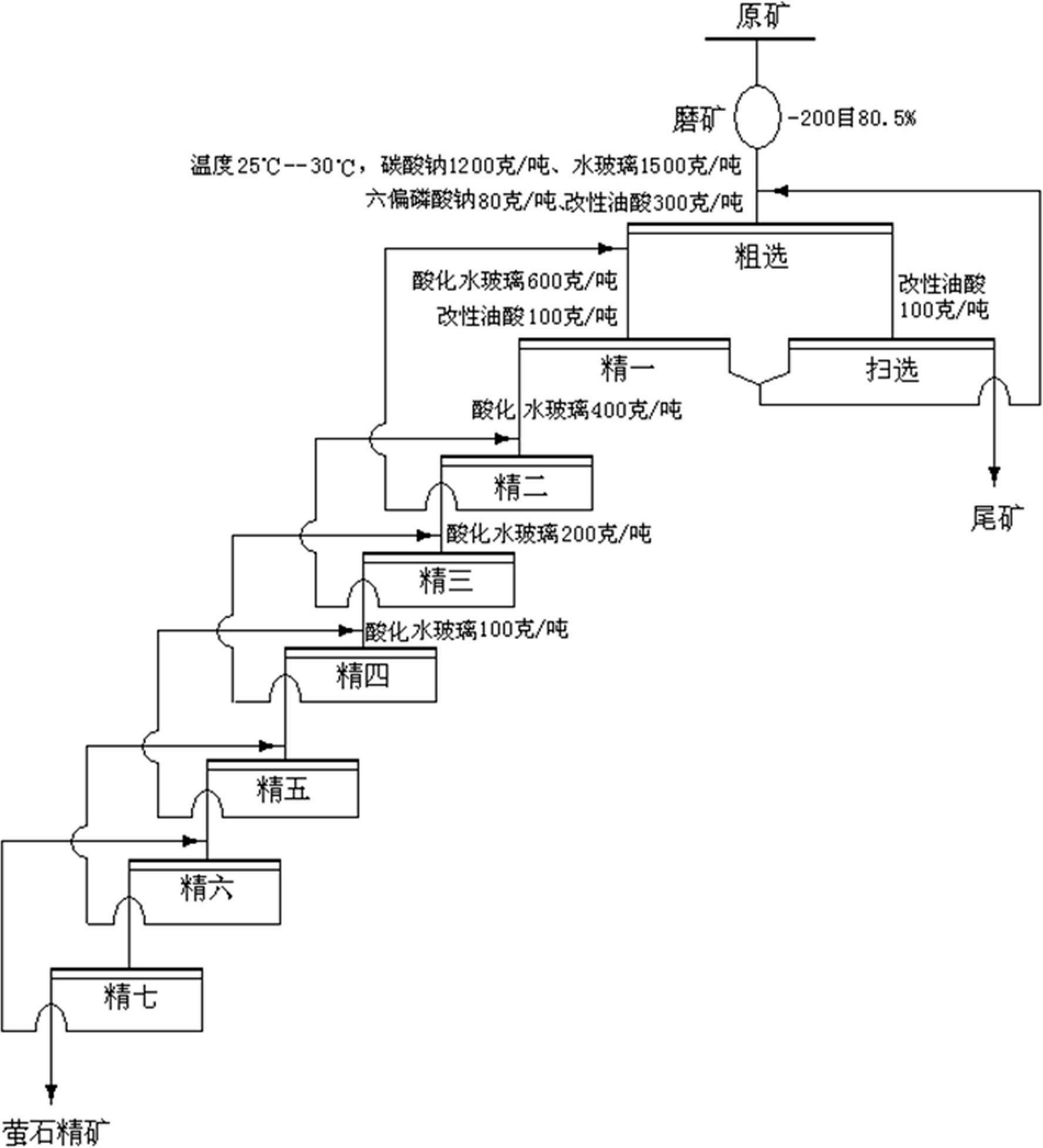

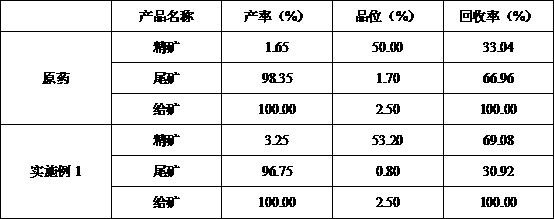

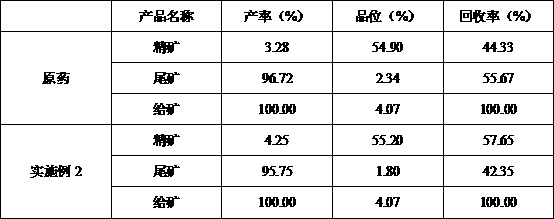

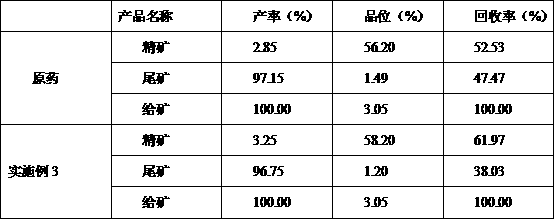

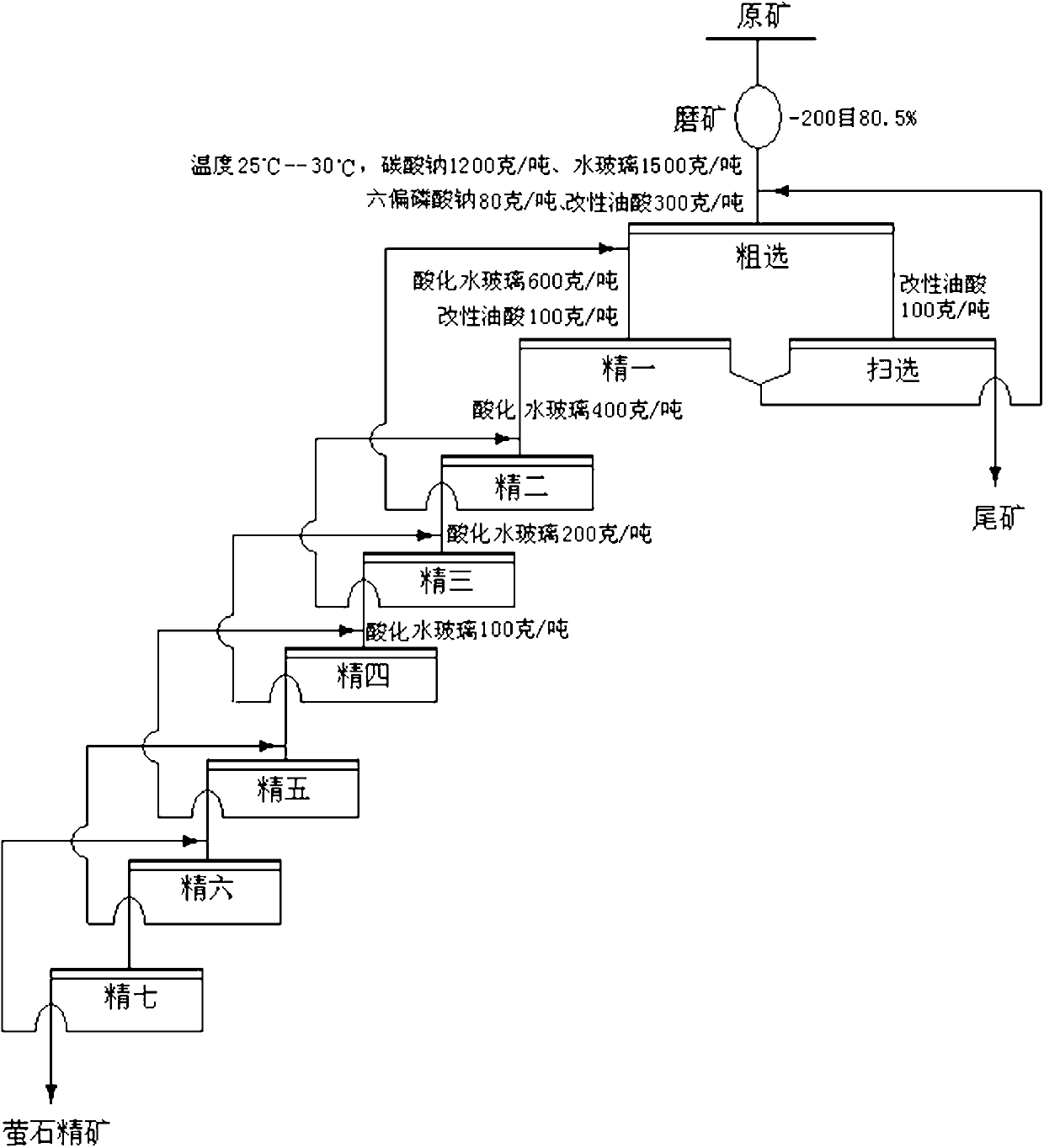

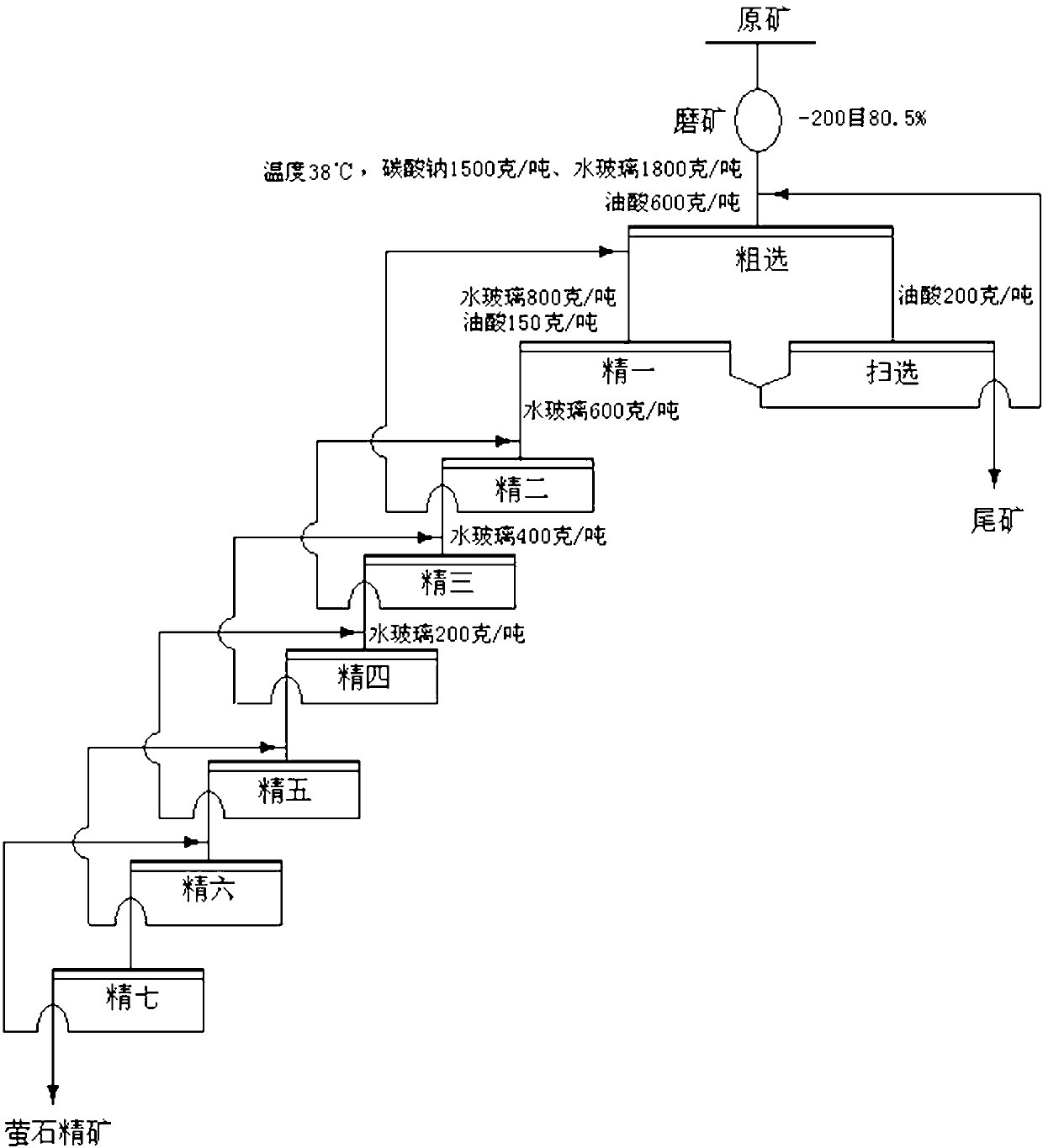

Mineral separation process of complex fluorite difficult to separate

The invention relates to a mineral separation process, in particular to a mineral separation process of complex fluorite difficult to separate. The process includes utilizing sodium hydroxide to treat oleic acid to obtain modified oleic acid, utilizing concentrated sulfuric acid to treat water glass and obtain acidized water glass, conducting ore grinding on fluorite ores according to the prior art, conducting coarse separation under the temperature of 25-30 DEG C, then conducting seven times fine separation on coarse separation foams and adding the acidized water glass into the foams in the first four times of fine separation to prepare fluorite concentrate. The process can improve separation efficiency of calcium fluoride, silica and calcite, improves quality and recycle rate of the fluorite ores, obtains high quality acid grade fluorite ores and resolves the problem of difficulty in separation of complex fluorite flotation, is remarkable in application effect in separation of the complex fluorite difficult to separate, has repeatability, simultaneously reduces requirements of fluorite mineral flotation for ore temperature, reduces energy consumption, reduces usage of collectingagent oleic acid, reduces environment pollution caused by exhaust of a large amount of waste water containing oleic acid and has better economical and social benefits.

Owner:BAIYIN NONFERROUS GROUP

Beneficiation method for separating fluorite and tungsten through flotation

ActiveCN104084315AAvoid the problem of poor floatability and difficult flotation recoveryAvoid lostFlotationSulfidationTungsten

The invention discloses a beneficiation method for separating fluorite, white tungsten (black tungsten) and gangue minerals in complex polymetallic ore through flotation. Non-magnetic products of tailings subjected to sulphide ore flotation or tailings subjected to sulphide ore flotation and then subjected to strong magnetic separation for recycling black tungsten serve as two kinds of samples. The pH value is controlled by adding regulators, white tungsten, black tungsten, other gangue combined inhibitors and collectors are added, fluorite is subjected to differential flotation, then, tungsten minerals are subjected to flotation, and therefore fluorite and tungsten can be efficiently recycled. Loss of fluorite in tungsten flotation concentrate is avoided when tungsten minerals are subjected to differential flotation, and the defect that when tungsten flotation is performed, fluorite is difficult to recycle through flotation because the inhibitors have strong inhibition on fluorite, and beneficiation efficiency is low is avoided. Compared with a current beneficiation situation, the fluorite recycling rates of tests on the two different samples are increased by 39% to 48 % and 9% respectively, and the tungsten recycling efficiency is improved by 3%.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

Reverse flotation iron increase and silicon removing method for refractory limonite

InactiveCN101234366AImprove mineral processing recovery rateReduce typesFlotationIron increasedRefractory

The invention discloses an reverse flotation iron extracting and desiliconizing method of rebellious limonite. The procedure of the invention is as following: finely grinding, dispersing and desliming ore; adding sulphuric acid to stir the ore power into paste; adding a certain amount of starch or modified starch, lignosulfonate sulphonic acid and their salt and polyacrylamide with the molecular weight about 10,000 or polyacrylamide inhibitory iron-bearing mineral; adopting cation collector quaternary ammonium salt to reverse flotation and separate ore with silicon range or iron ore in a method of adding a little amount of medicine for many times. The reverse flotation iron extracting and desiliconizing method has the advantages of simple process, few medicine agent varieties, able to obtain high grade iron ore concentrate and good effect of raising ore dressing recovery percentage of limonite.

Owner:CENT SOUTH UNIV

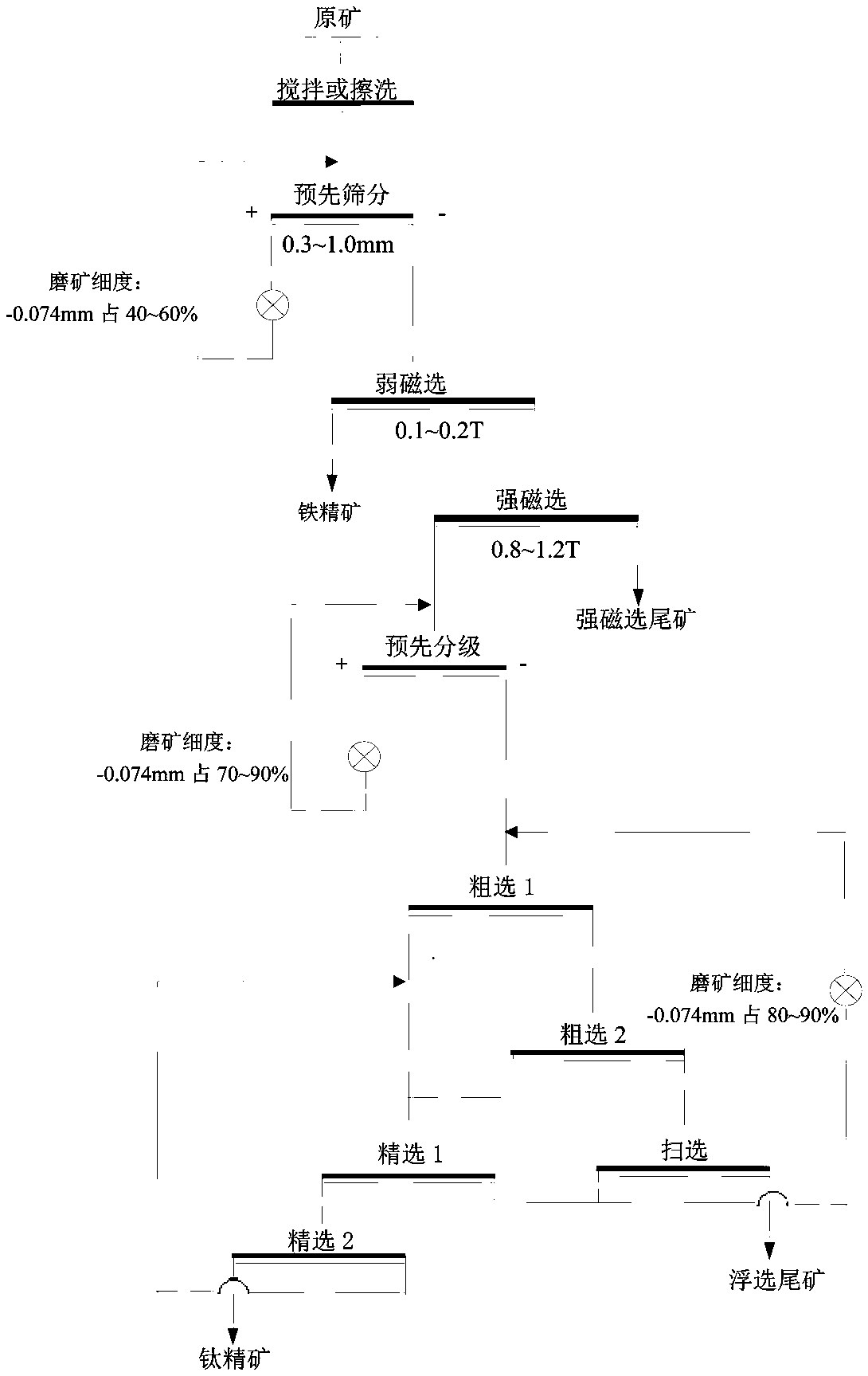

Weathering type ilmenite beneficiation treatment method

The invention discloses a weathering type ilmenite beneficiation treatment method. The beneficiation treatment method comprises the following steps that A prescreening is carried out; B, low intensitymagnetic separation is carried out; C, high intensity magnetic separation is carried out; D, preliminary classification is carried out; and E, flotation is carried out. According to the weathering type ilmenite beneficiation treatment method, the titanium recovery rate is effectively improved, titanium concentrate and iron ore concentrate are obtained at the same time, the technology is simple, the technological process is easily operated, and popularization is facilitated. Beneficiation according to the technical scheme is adopted, the particle size of monomer separation fine-fraction ilmenite in raw ore is protected, and excessive abrasion is avoided; the high intensity magnetic separation technology is used for discarding tailings, the follow-up handling quantity is greatly reduced, and the ore grinding cost and the beneficiation cost are reduced; and an environment-friendly collecting agent KM221 which is good in selectivity, low in cost, non-poisonous and harmless is adopted forflotation recovering of ilmenite ore, fine fraction titanium resources which are difficult to recover through the traditional technological process are effectively recovered, and the weathering type ilmenite resource using rate is improved.

Owner:KUNMING METALLURGY INST

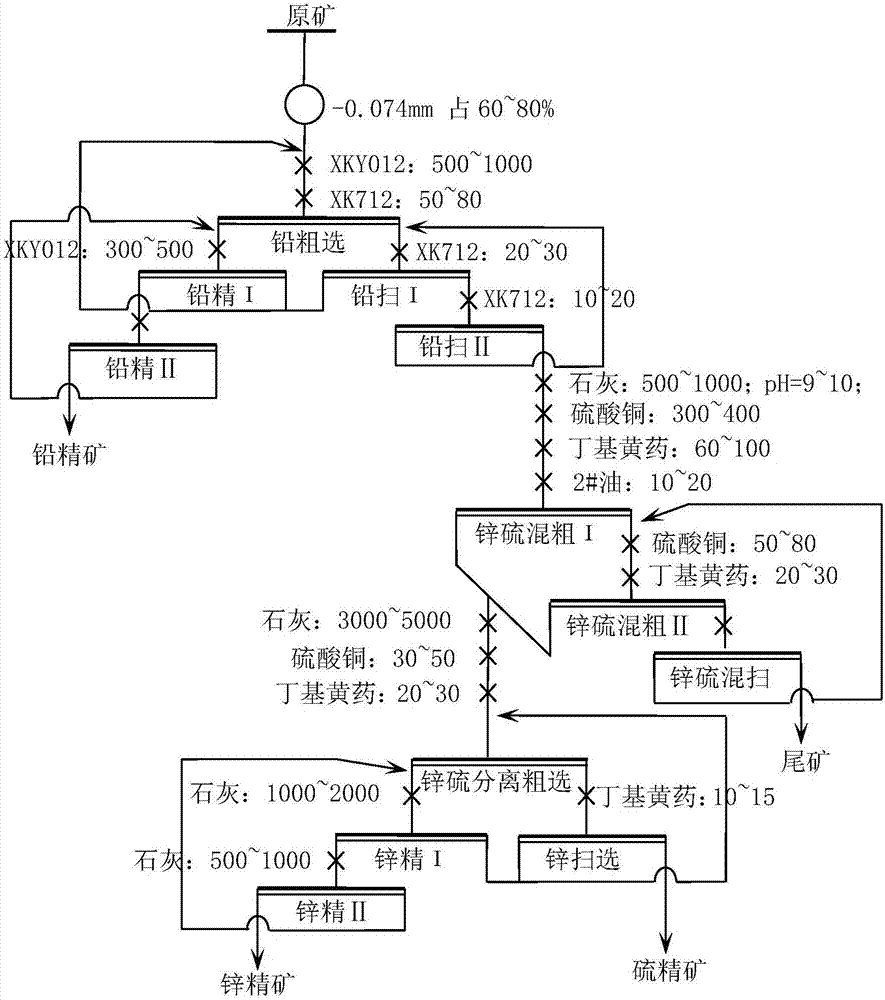

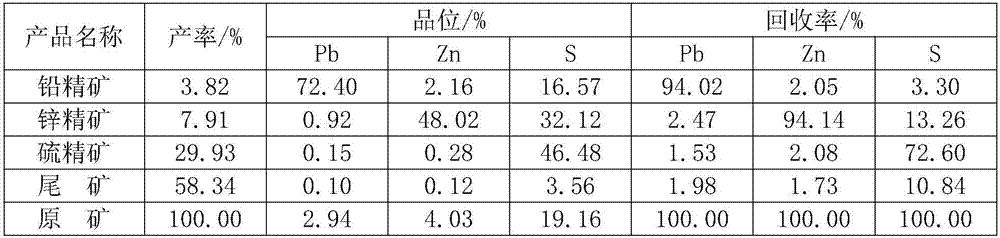

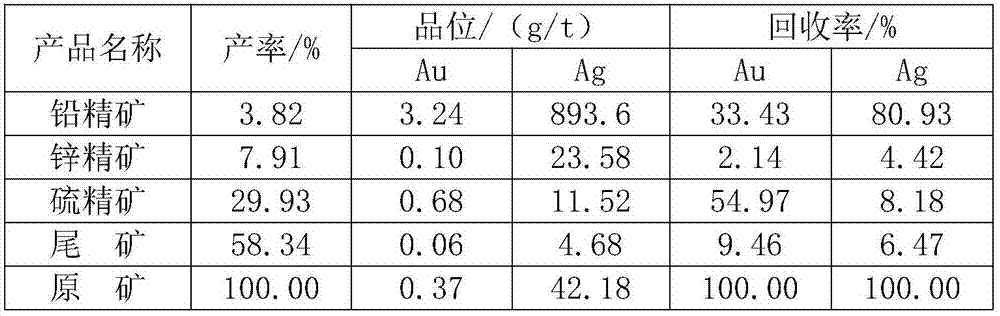

Flotation separation technology for high-sulfur lead-zinc ore in high-concentration environment

ActiveCN107999267AImprove acceleration performanceStrengthen the arching effectFlotationWet separationHigh concentrationSeparation technology

The invention discloses a flotation separation technology for high-sulfur lead-zinc ore in a high-concentration environment. The flotation separation technology aims at high-sulfur lead-zinc sulfide ore containing associated gold and silver, and flotation of lead and associated gold and silver minerals is preferentially carried out in a high-concentration and neutral natural pH flotation environment; and lead-flotation tailings are subjected to two-stage rough flotation so as to realize bulk flotation of zinc-sulfur minerals, the pH value and the potential of ore pulp are regulated and controlled by adopting lime in the zinc-sulfur separation flotation process so as to realize zinc-sulfur separation, and a small amount of activating agents and collecting agents are added to strengthen flotation of zinc minerals difficult to float. According to the flotation separation technology, the defects that in the lead flotation process of high-alkali mediums, the recovery rate of lead, gold andsilver is low, the usage amount of agents is large, the floatation process is not stable, and the like can be overcome; and meanwhile, a zinc-sulfur mineral inhibitor XKK012 and a lead-gold-silver collecting and frothing agent XKY712 are invented, so that the problems that the lead-zinc-sulfur separation efficiency is low, the separation precision is poor, and the hydrophobic capacity of part of lead-gold-silver minerals is weak can be solved, and the technology has the advantages of being energy-saving, environment-friendly, non-toxic, harmless, low in beneficiation cost, high in recovery efficiency and suitable for comprehensive recovery of valuable metal minerals in the high-sulfur silver-lead-zinc-contained ore.

Owner:WESTERN MINING CO LTD +2

Rare earth ore collector, preparation method and ore dressing process of low-grade hard-selection rare earth ore

ActiveCN103240184AGood light transmissionCompatibility is simpleFlotationMagnetic separationMining engineeringMethyl salicylate

The invention relates to a rare earth ore collector which is characterized in that the rare earth ore collector is obtained through reaction of 4-7 parts by weight of -naphthalene hydroxyl oxime acid, 2-4 parts by weight of methyl salicylate and a water solution containing 1-2 parts by weight of solid sodium hydroxide. The rear earth ore collector is simple in medicine compatibility, easy to prepare, low in cost, capable of being applied to flotation of complicated hard-selection low-grade rare earth ore and good in selection performance and collecting performance and simultaneously has no rigorous requirements on temperature and pH values of a flotation system. The invention further provides a preparation method of the collector, and the preparation method is simple to operate, easy in condition control and easy to implement. The invention simultaneously provides an ore dressing process of low-grade hard-selection rare earth ore, a flotation pre-enrichment - wet strong magnetic separation purification ore dressing method is adopted to obtain high-grade rear earth ore concentrate with high recovery rate. In the process, flotation pulp temperature is wide in application range, no warming is needed in a whole process, technological process is short, and recovery rate of low-grade complicated rear earth ore is improved remarkably.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Foaming agent for rare earth ore dressing and normal temperature mineral separation processing for low grate refractory rare earth ore

The invention provides a foaming agent for rare earth ore dressing and normal temperature mineral separation processing for low grate refractory rare earth ore, and particularly relates to a low grade normal temperature mineral separation processing with large slurry containing, fine mineral disseminated extent, complex mineral constitute, and 3% REO grade. The processing provided by the invention is characterized in that the 3% REO grade low grade rare earth ore is taken as the raw material, the mineral pulp temperature ranges from 10 DEG C to 25 DEG C, the flotation pre-enrichment-wet magnetic separation purification beneficiation method is adopted, so as to obtain rare earth ore concentrate with high grade and high recovery. The invention has the marked advantages that the flotation pulp temperature has a wide range of application, needs no warming, is short in processing process, and can remarkably improve the recovery of low grade complex rare earth ore.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Processing method of powdered carbon in extraction of gold by CIP (carbon-in-pulp) process

InactiveCN104928487AReduce gold gradeLow costProcess efficiency improvementActivated carbonEconomic benefits

The invention discloses a processing method of powdered carbon in extraction of gold by the CIP (carbon-in-pulp) process. The processing method comprises the steps of collecting powdered carbon, grinding powdered carbon, chalking powdered carbon, leaching ash, adsorbing with activated carbon, desorbing with gold-loaded carbon and electrolyzing and smelting gold slurry. The processing method of powdered carbon in extraction of gold by CIP (carbon-in-pulp) process, provided by the invention, reduces the gold-containing grade of tailings, improves the ore dressing recovery percentage, saves resources, reduces the cost and improves the economic benefits.

Owner:CHANGCHUN GOLD RES INST

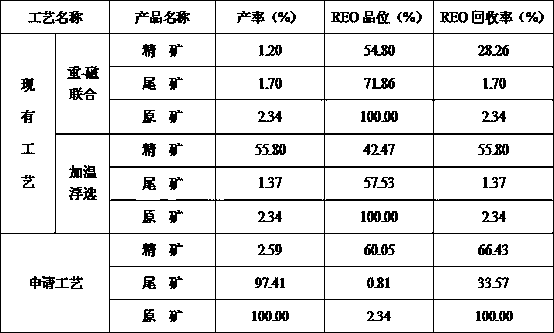

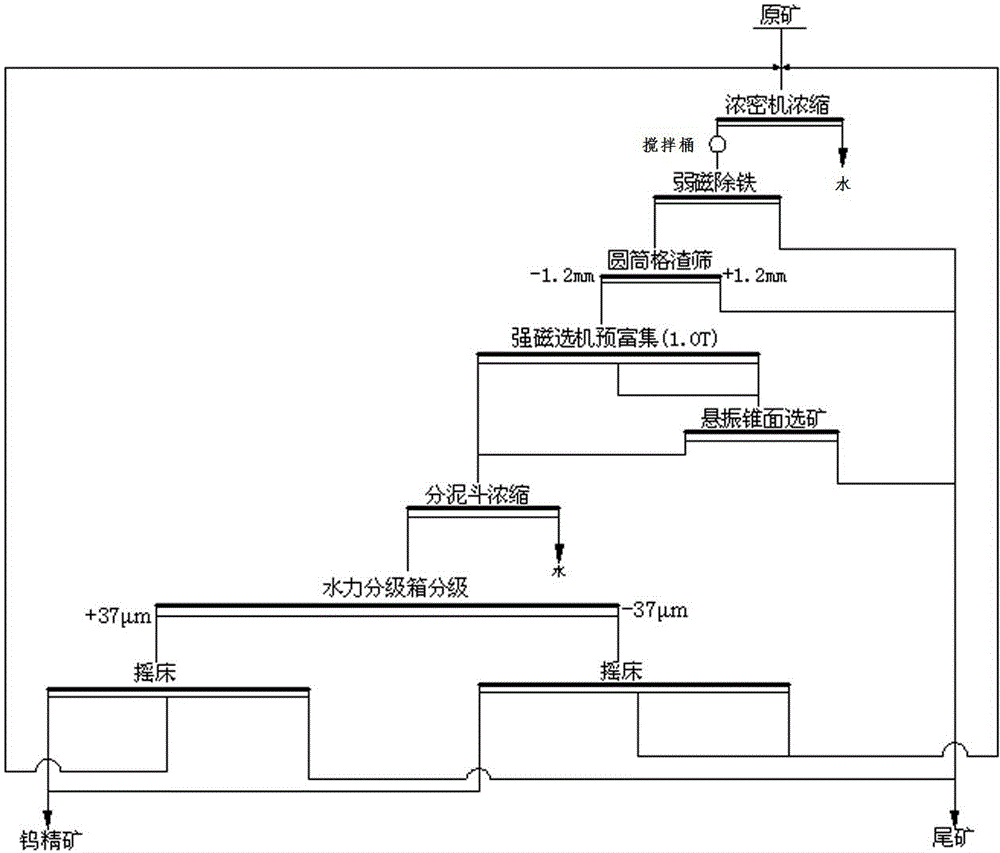

Method for increasing fine-grained wolframite ore dressing recovery ratio

ActiveCN104475340AImprove mineral processing recovery rateNot with the lossGas current separationHigh intensityMaterials science

The invention relates to a method for increasing the fine-grained wolframite ore dressing recovery ratio and belongs to the field of tungsten ore dressing. The method comprises the steps that (1) fine-grained wolframite raw ore is concentrated by a thickener and subjected to low-intensity magnetic separation to remove ferromagnetic mineral aggregate such as iron, and then low-intensity magnetic tailings are obtained; (2) the low-intensity magnetic tailings are screened to remove the mineral aggregate at plus 1.2-mm size fraction and then subjected to high-intensity magnetic separation to obtain first rough concentrate and high-intensity magnetic tailings; (3) the high-intensity magnetic tailings are fed into a suspended vibration taper-face ore separator for roughing to obtain second rough concentrate; (4) the first rough concentrate and the second rough concentrate are combined and then concentrated, dewatered and classified to obtain coarse-grained mineral aggregate and fine-grained mineral aggregate; (5) the coarse-grained mineral aggregate and the fine-grained mineral aggregate pass through a coarse-grained shaking table and a fine-grained shaking table respectively, and concentrate produced by the coarse-grained shaking table and concentrate produced by the fine-grained shaking table are combined to obtain tungsten concentrate. When the technological method is adopted to treat wolframite slime with the WO3 content being 0.4-0.8%, the tungsten concentrate with the grade being 30% or so can be obtained, and the WO3 recovery ratio can reach more than 90%.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Step recycling method for metallic aluminum in aluminum ash

ActiveCN108325738AHigh metal recovery rateHigh recovery rateSolid separationProcess efficiency improvementBall millMetal recycling

The invention discloses a step recycling method for metallic aluminum in aluminum ash. The step recycling method includes steps of 1), sieving the aluminum ash to obtain oversize aluminum ash and undersize aluminum ash; 2), smashing the oversize aluminum ash obtained at the step 1), and then sieving the oversize aluminum ash to obtain metallic aluminum particles and undersize aluminum ash; 3), carrying out wet ball-milling on the undersize aluminum ash obtained at the steps 1) and 2) to obtain ball-milled slurry; 4), carrying out wet classification on the ball-milled slurry to obtain large-particle metallic aluminum sheets and fine-particle slurry; 5), sorting the fine-particle slurry to obtain fine-particle metallic aluminum powder and tailings; 6), dehydrating the tailings to obtain filter liquor and filter residues; 7), carrying out circulation enrichment the filter liquor and then evaporating the filter liquor to recycle industrial salt; 8), mounting ammonia gas collecting and absorbing devices above all materials exposed in the air in aluminum ash treatment procedures. The step recycling method has the advantages that step recycling is carried out on the metallic aluminum, accordingly, the metal recycling rate can be greatly increased, the purity of products can be greatly improved, and a novel way can be developed for harmlessly utilizing the aluminum ash as a resource.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

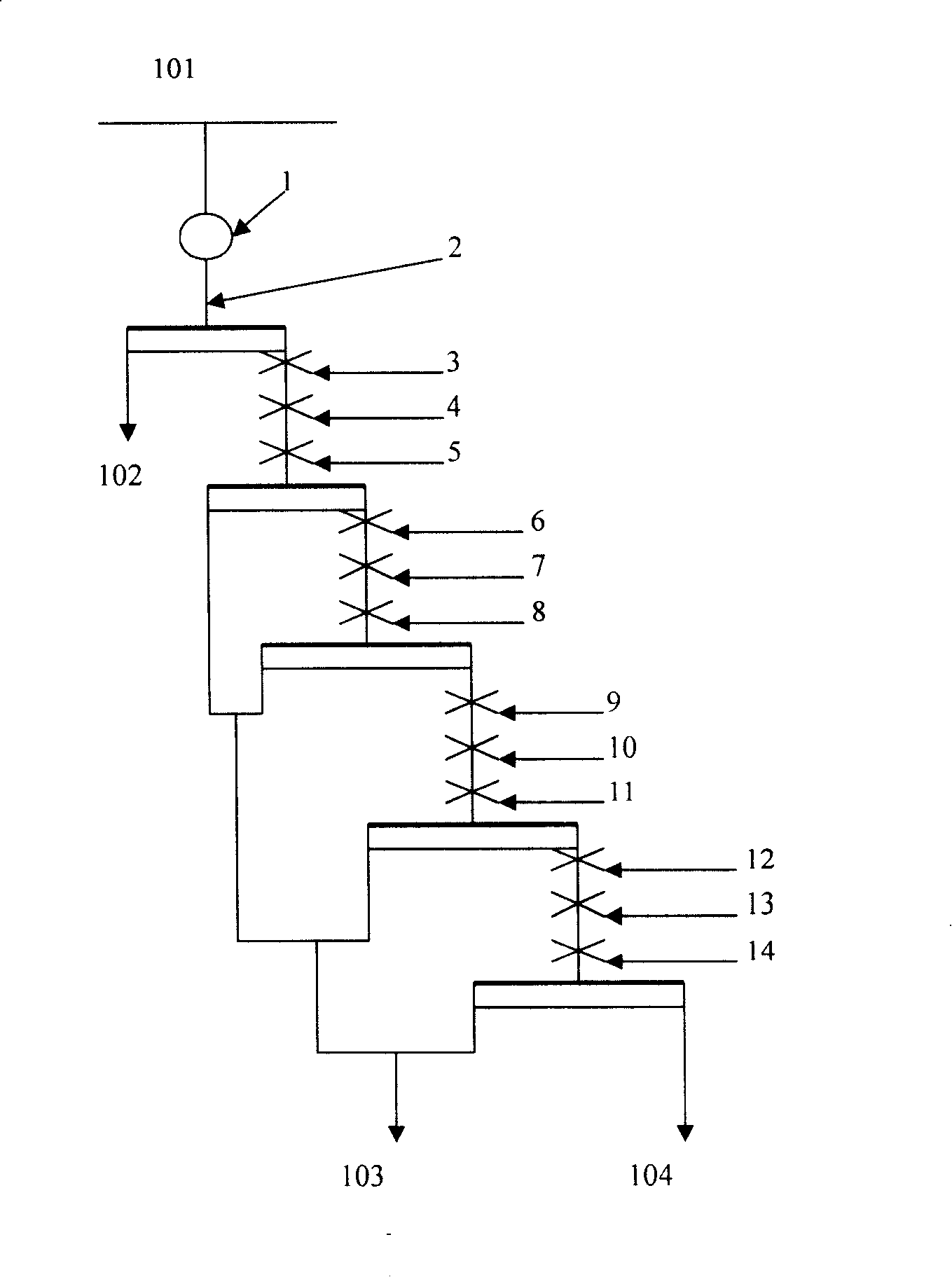

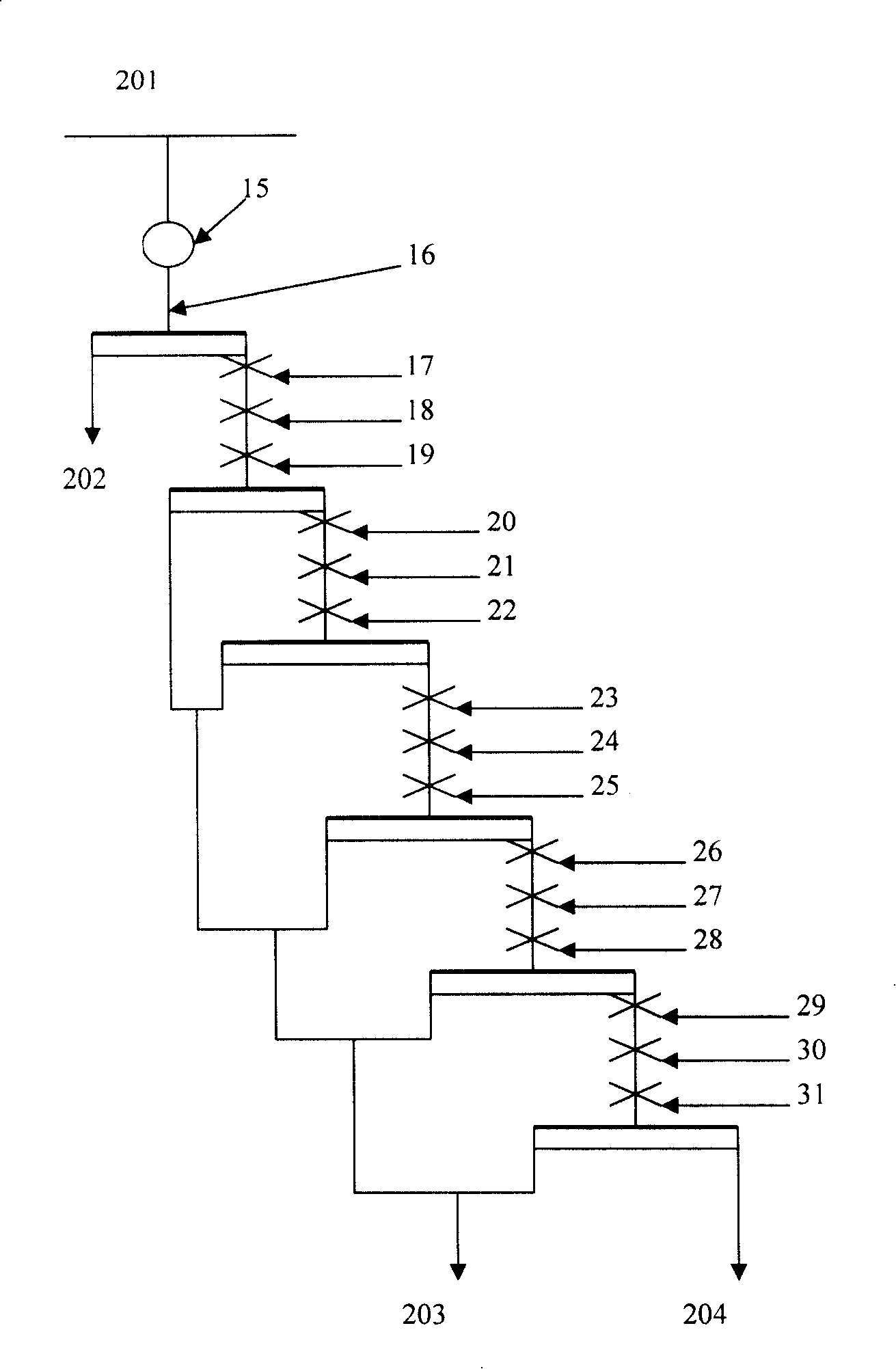

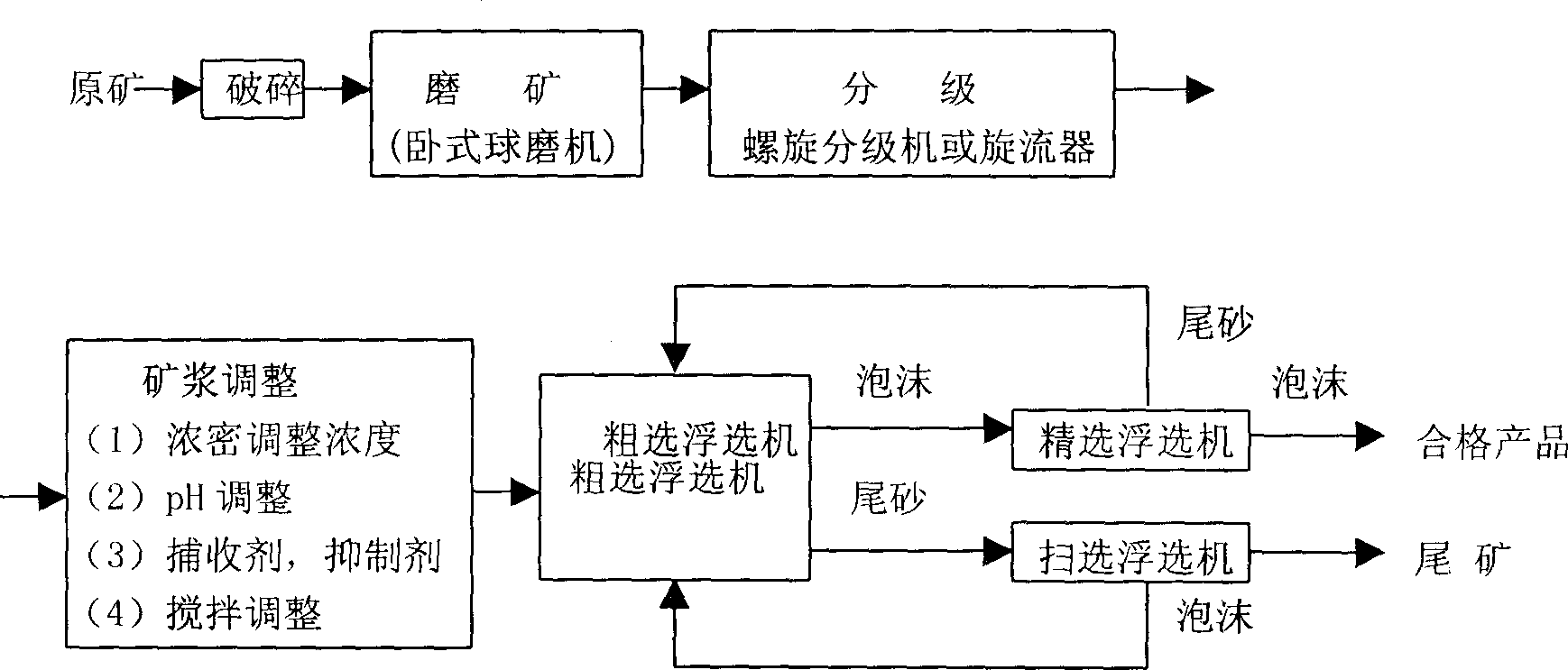

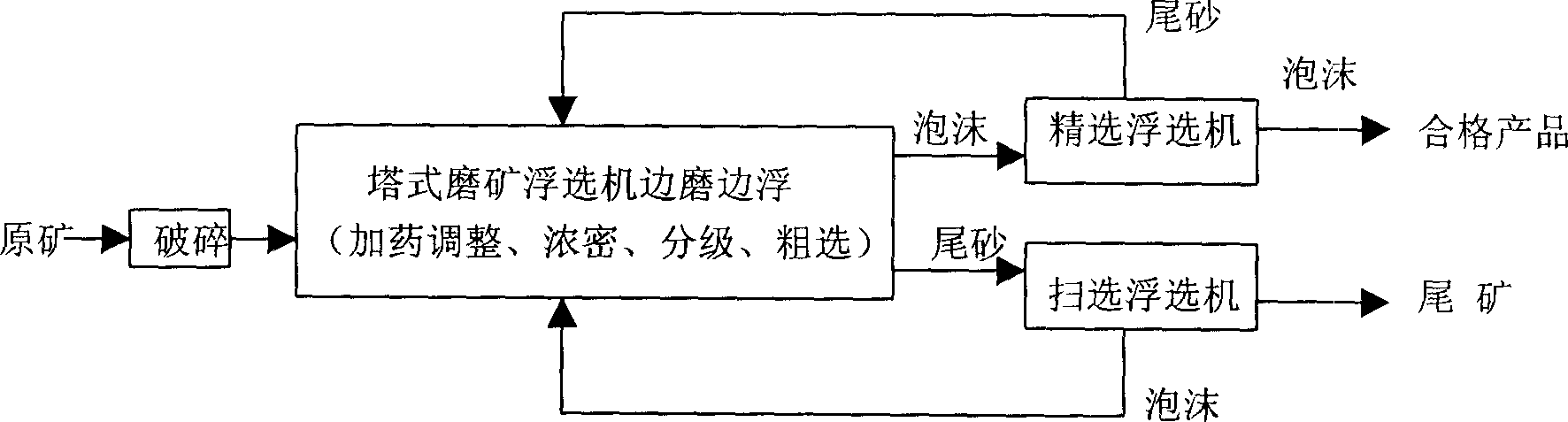

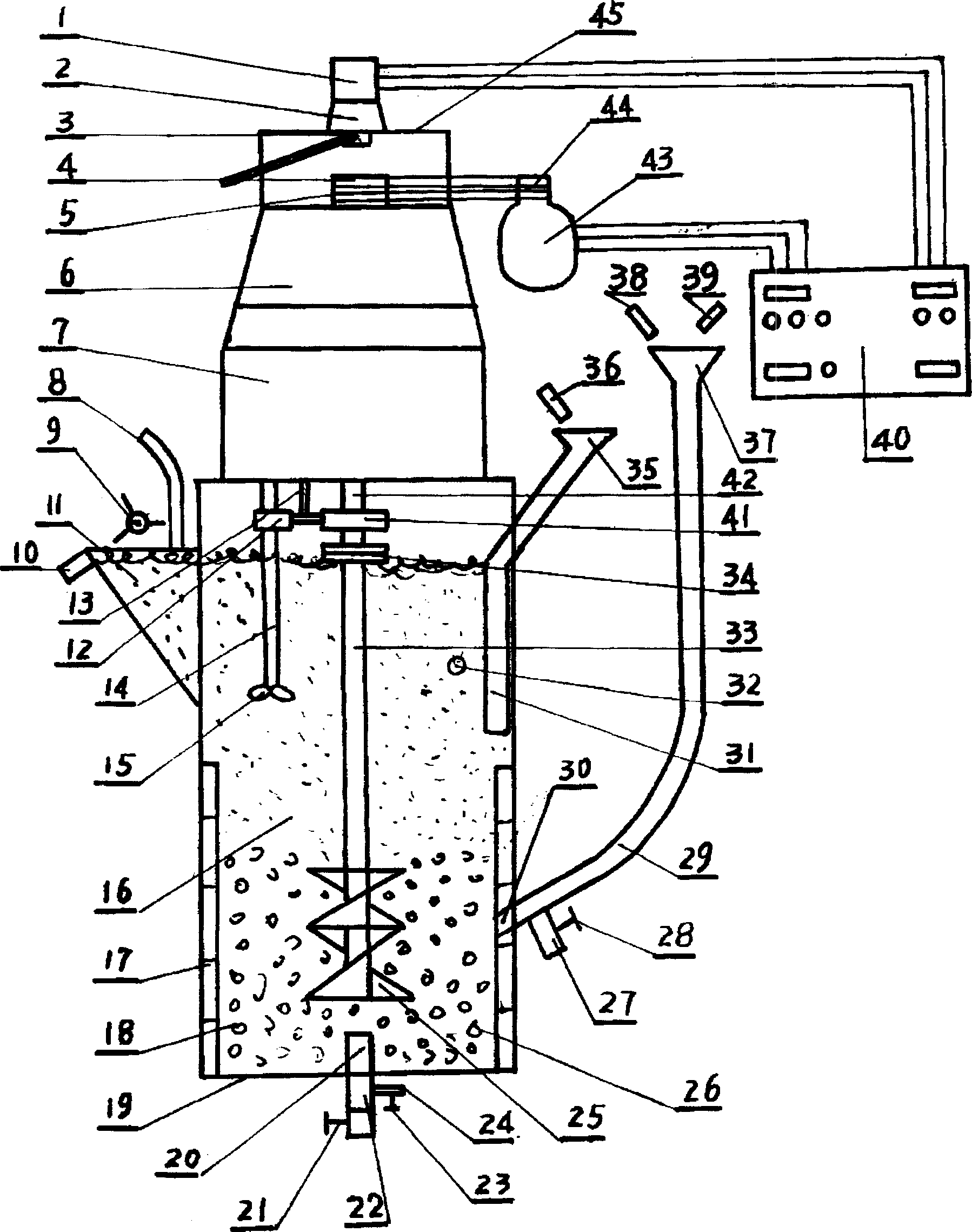

Grinding while floatation process for carrying out floatation separation in grinding

InactiveCN1401433APrevent secondary muddying and other phenomenaReduce wearFlotationEngineeringTower

A process for grinding and hydrosizing ore at same time includes crushing raw ore, feeding it into tower-type grinding floatation machine while adding pH regulator, supprssor and collector, grinding while hydrosizing, collecting froth, refining in fine floatation machine, returning tail sand back to grinding floatation machine, collecting the tail sand of grinding floatation machine, scavenging in the scavenging floatation machine, and returning the scavenged froth back to the grinding floatation machine. Its advantages are short process flow and high recovery yield.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

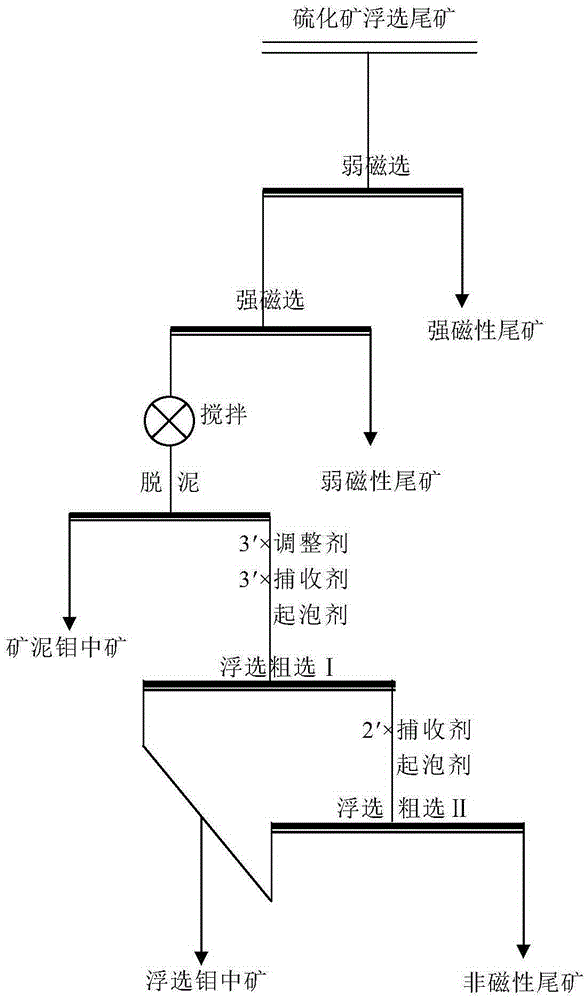

Mineral separation and enrichment method for molybdenum oxide ores

InactiveCN105381870AReduce processingImprove sorting efficiencySolid separationMechanical material recoveryEnrichment methodsHydrometallurgy

The invention provides a mineral separation and enrichment method for molybdenum oxide ores. The method includes the several steps of low intensity magnetic separation and high intensity magnetic separation for sulphide ore flotation tailing ore pulp, non-magnetic ore pulp material desliming, flotation and the like, and finally molybdenum middlings with high grade are obtained. The molybdenum middlings can serve as raw materials for extraction of ammonium molybdate products through hydrometallurgy, and low-grade hard-to-separate molybdenum oxide ore resources in copper and molybdenum polymetallic mixed associated ores are effectively and comprehensively recycled. The mineral separation and enrichment method for the molybdenum oxide ores can be widely applied to the field of recycling of the low-grade hard-to-separate molybdenum oxide ore resources in similar tailings.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

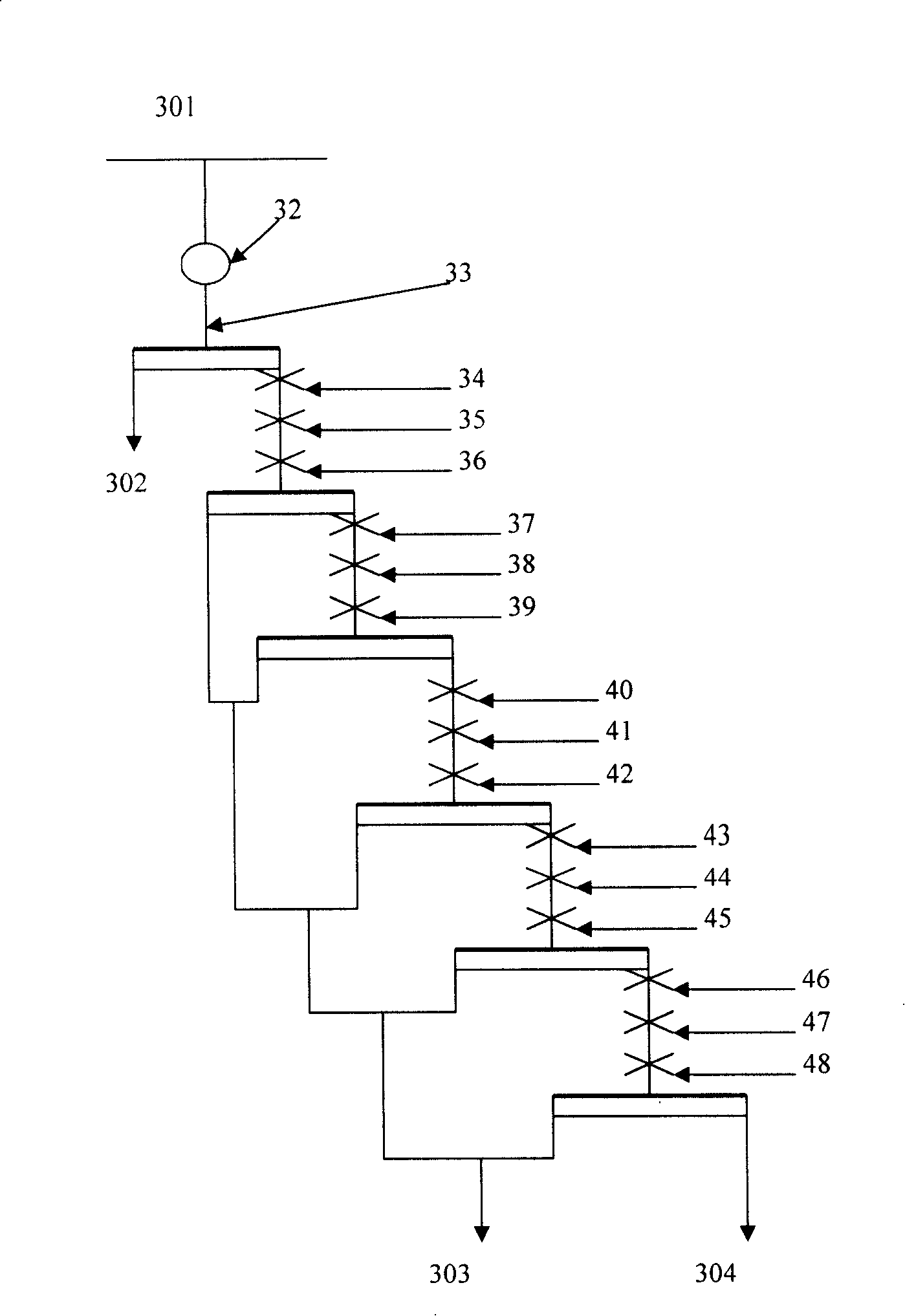

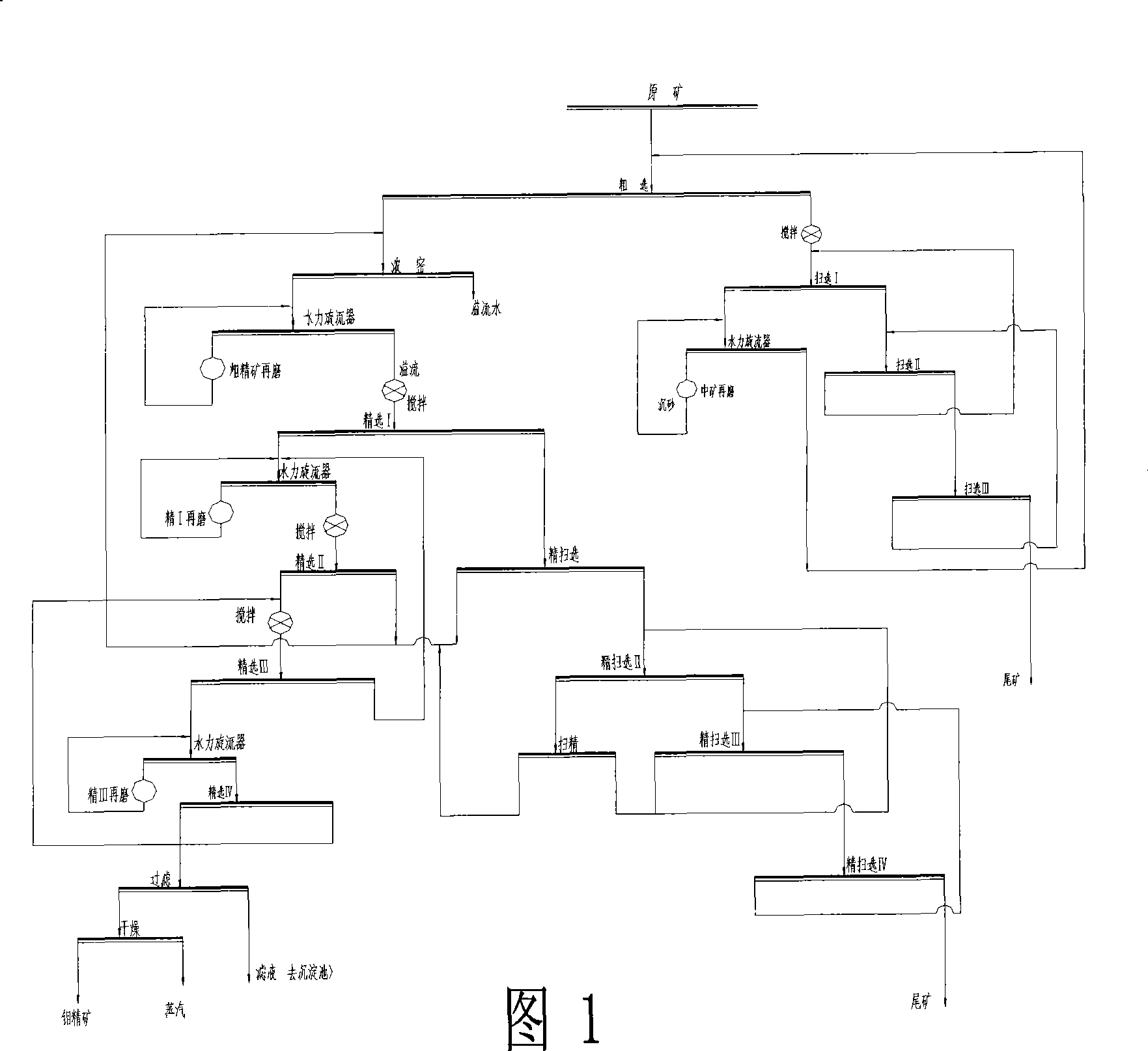

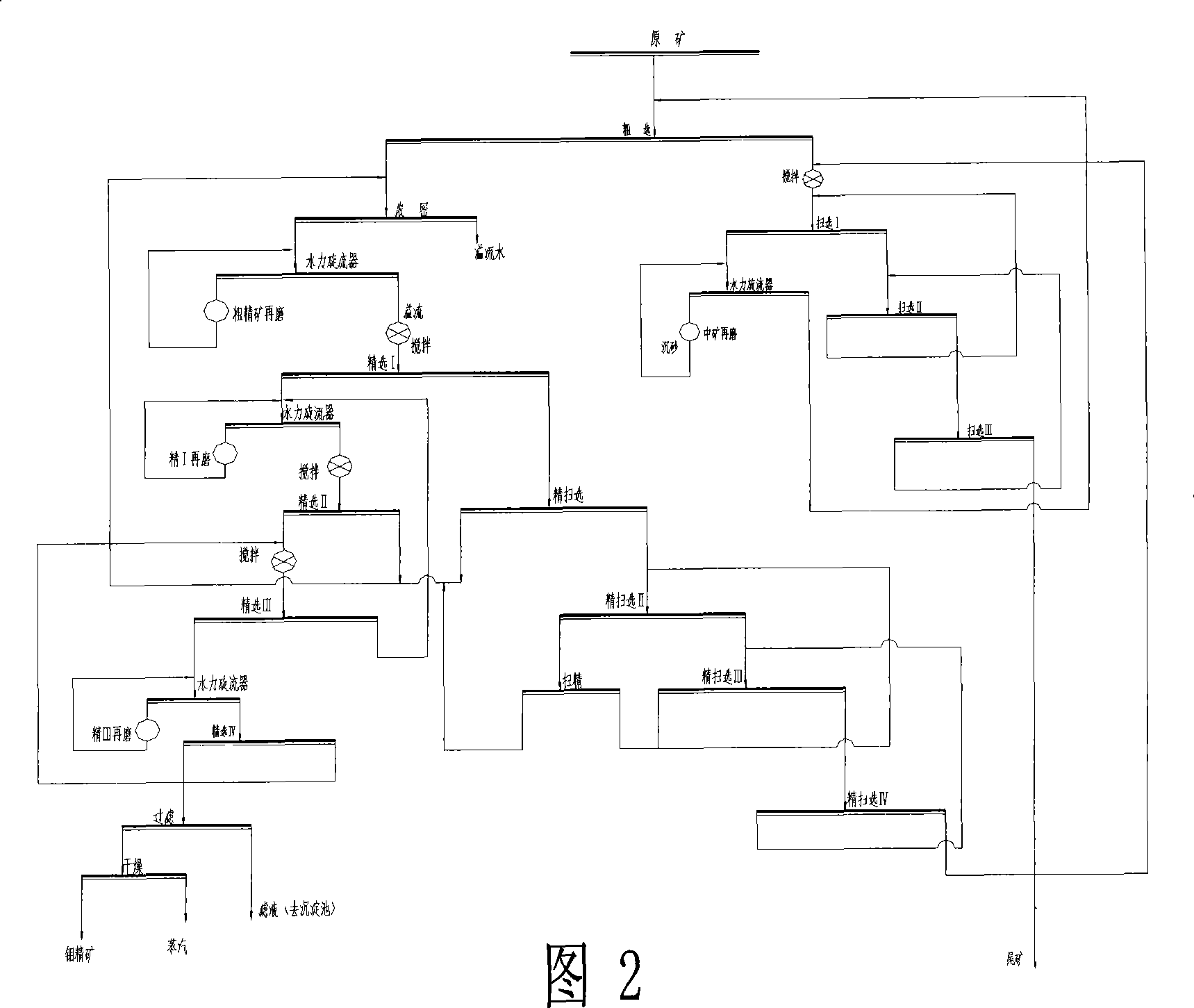

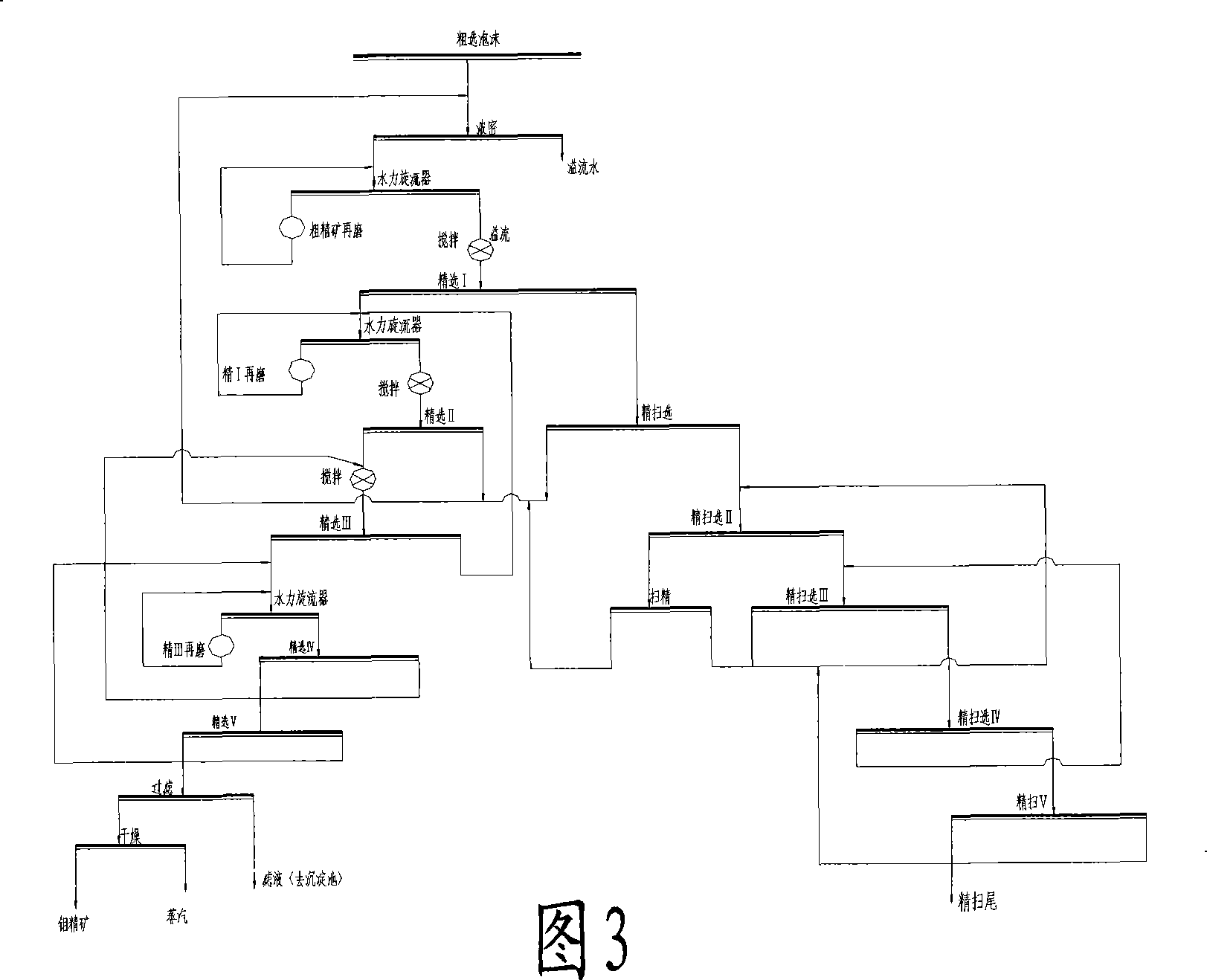

Method for increasing molybdenum ore recovery using fine-sweeping

The invention discloses a method used for improving the recovery of the molybdenum processing by fine sweeping section; the method comprises five selection operations such as fine sweeping I, II, III, IV and V; wherein, fine sweeping I foam and fine sweeping foam are returned to a slurry pond 2 together; fine sweeping II gangue is classified by a hydrocyclone and the overflow thereof is used as fine I given ore; fine sweeping I gangue enters a fine sweeping II flotation machine; the fine sweeping II flotation machine foam enters fine sweeping; fine sweeping II gangue enters a fine sweeping III flotation machine and is classified; the fine sweeping III gangue is re-classified by fine sweeping IV and used as final fine sweeping gangue; the foam thereof is re-returned to the fine sweeping III flotation machine to be classified; after the selection operation of the fine sweeping IV, a floatation column is provided so as to lead the fine sweeping IV gangue to directly enter a newly increased flotation column (fine sweeping V) and to be classified; subsequently, the gangue is directly used as final fine sweeping gangue tail and the foam as well as the fine sweeping III foam and fine sweeping gangue is returned to the fine sweeping II flotation machine and re-classified. The method leads the original fine gangue to be re-classified, reduces the grade of the final gangue and improves the recovery at the same time, and increases the yield of molybdenum concentrates.

Owner:CHINA MOLYBDENUM

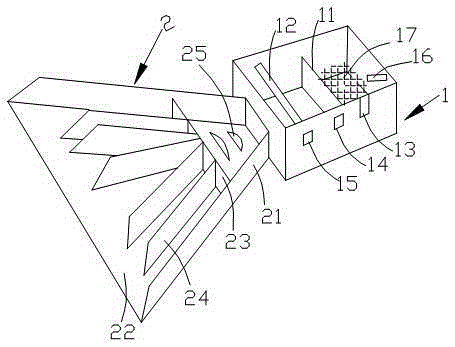

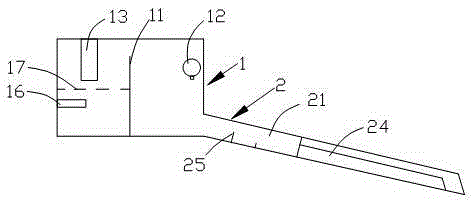

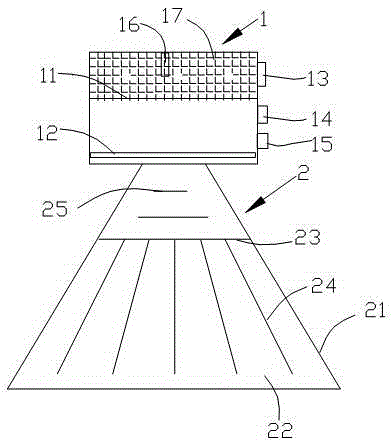

Fan-shaped material distributor

ActiveCN105381872AEliminate turbulenceUniform overflowMagnetic separationMagnetic separatorPulp and paper industry

The invention relates to the technical field of mineral separation equipment and discloses a fan-shaped material distributor. The fan-shaped material distributor comprises a box body and a material distribution chute, wherein the box body is divided into pulp inlet trough and a pulp outlet trough by an overflow plate; a valve and a plurality of on-line ore pulp concentration meters are arranged on the inner wall of the pulp inlet trough; a diluting water pipe is arranged at the upper part, parallel to a pulp outlet, of the pulp outlet trough; a controller and a pump for supplying water to the diluting water pipe are arranged on the outer wall of the box body; the controller is connected with the on-line ore pulp concentration meters, the valve and the pump respectively; the material distribution chute is shaped like a fan and comprises side plates, a bottom plate, a baffle plate, flow guiding plates and a plurality of buffer plates; and a flow stabilizing grate is arranged in the pulp inlet trough. The controller of the fan-shaped material distributor can carry out adjustment through the valve and the pump according to the treatment capacity of a downstream magnetic separator to obtain appropriate ore pulp. The ore pulp is mixed and guided by the material distribution chute to uniformly flow to a bottom box along a cylinder of the magnetic separator.

Owner:江苏紫润建设有限公司

Floating method of tungsten tin minerals

ActiveCN105057114AImprove mineral processing recovery rateStrong harvesting abilityFlotationCarboxylic acidTungsten

A floating method of tungsten tin minerals comprises the following steps that (1), after raw materials are evenly mixed, the pH is adjusted to be 9-10 through sodium carbonate; (2) lead nitrate is added for activating tungsten tin hard to float; (3), water glass and sodium hexametaphosphate are added for restraining floating of gangue impurity minerals; and (4), new collector benzyl hydroxyl oxime acid is added, and a mechanical stirring type floating machine is used for floating the tungsten tin. By the adoption of the method, tungsten concentrate and tin concentrate with the recycling rate higher than that of a common floating and gravity concentration technique of fatty acid and carboxylic acid collectors.

Owner:CNMC GUANGXI PGMA +1

Sorting method for anshan-type lean iron ores

ActiveCN105233972ALow investment costReduce operating costsWet separationHigh intensityReverse flotation

The invention belongs to the technical field of mineral processing engineering, and particularly relates to a sorting method for anshan-type lean iron ores. The sorting method comprises the following steps: concentrating and roughing to obtain concentrated concentrate which is gravity concentrate; carrying out low-intensity magnetic separation and high-intensity magnetic separation on rougher tailings and effusion with coarse and fine particle fractions; then, carrying out reverse flotation roughing on the concentrate which is respectively subjected to low-intensity magnetic separation and high-intensity magnetic separation; and then, carrying out reverse flotation concentration on the reverse flotation rougher concentrate which is obtained by reverse flotation roughing, wherein the obtained reverse flotation concentrated concentrate and the gravity concentrate are used as total concentrate; the iron grade of the total concentrate is 68-69%, and the iron recovery rate is 83-86%. The sorting method is used for sorting iron minerals in the anshan-type lean iron ores with low cost and a high recovery rate.

Owner:ANSTEEL GRP MINING CO LTD

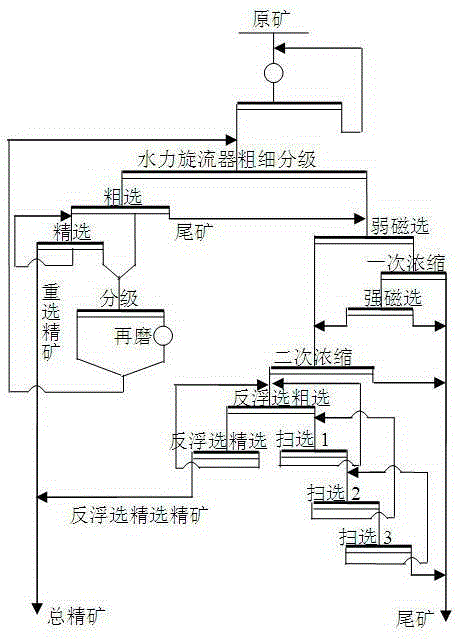

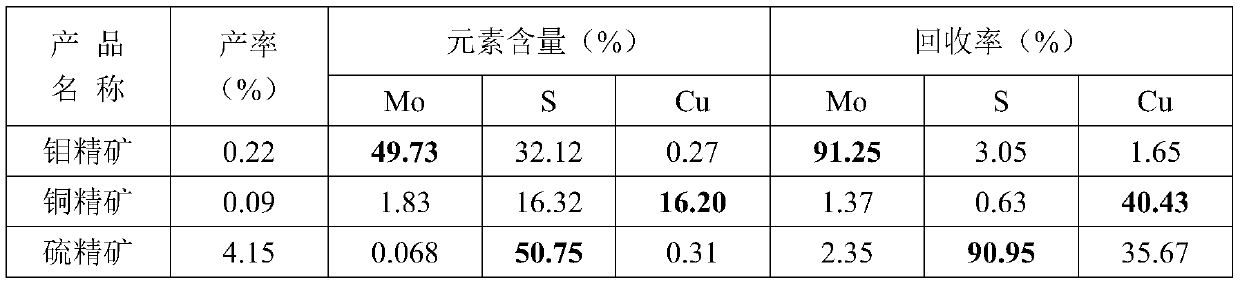

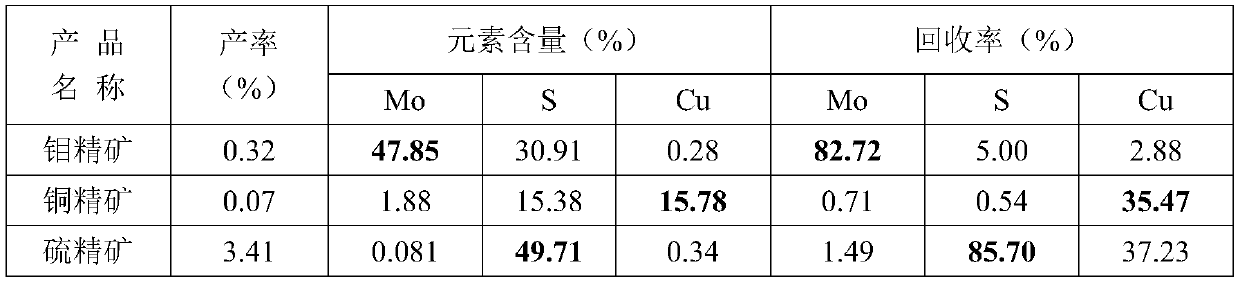

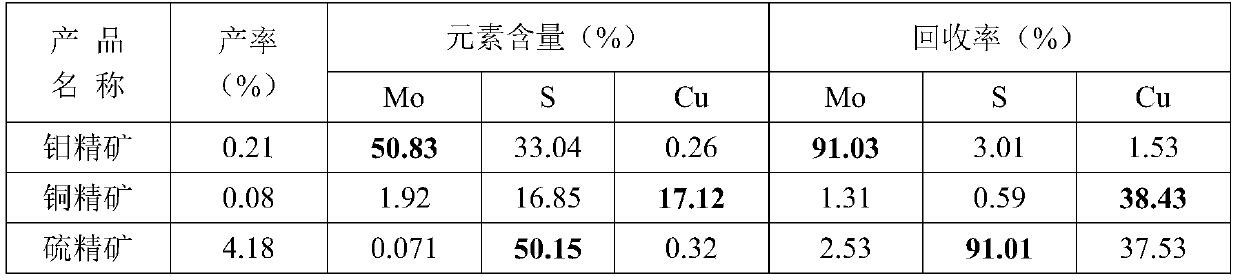

Beneficiation method for improving comprehensive recovery indexes of complex low-grade molybdenum polymetallic ores

ActiveCN110548592AImprove qualityExcellent comprehensive recovery indexFlotationWet separationChalcopyriteLower grade

The invention discloses a beneficiation method for improving comprehensive recovery indexes of complex low-grade molybdenum polymetallic ores, and particularly relates to comprehensive recovery of valuable elements such as molybdenum, copper and sulfur in low-grade molybdenum ores. According to the method, the effective flotation separation of molybdenite, chalcopyrite and pyrite can be realized,and the comprehensive recovery indexes of the low-grade molybdenum ores are improved. The method comprises the following steps of primary ore grinding, molybdenum (molybdenite) flotation, secondary ore grinding (rough molybdenum copper concentrate regrinding), copper (chalcopyrite) flotation, and sulfur (pyrite) flotation. The method is stable and effective in reagent regime and beneficiation process flow and high in adaptability. By using the beneficiation method, high-quality molybdenite, chalcopyrite and pyrite are obtained from the complex, difficult-to-select and low-grade molybdenum polymetallic ore with associated copper / sulfur, and the comprehensive recovery indexes of sulfide minerals are excellent. The adopted reagent is non-toxic and harmless, has little influence on the environment, and is an excellent beneficiation method.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

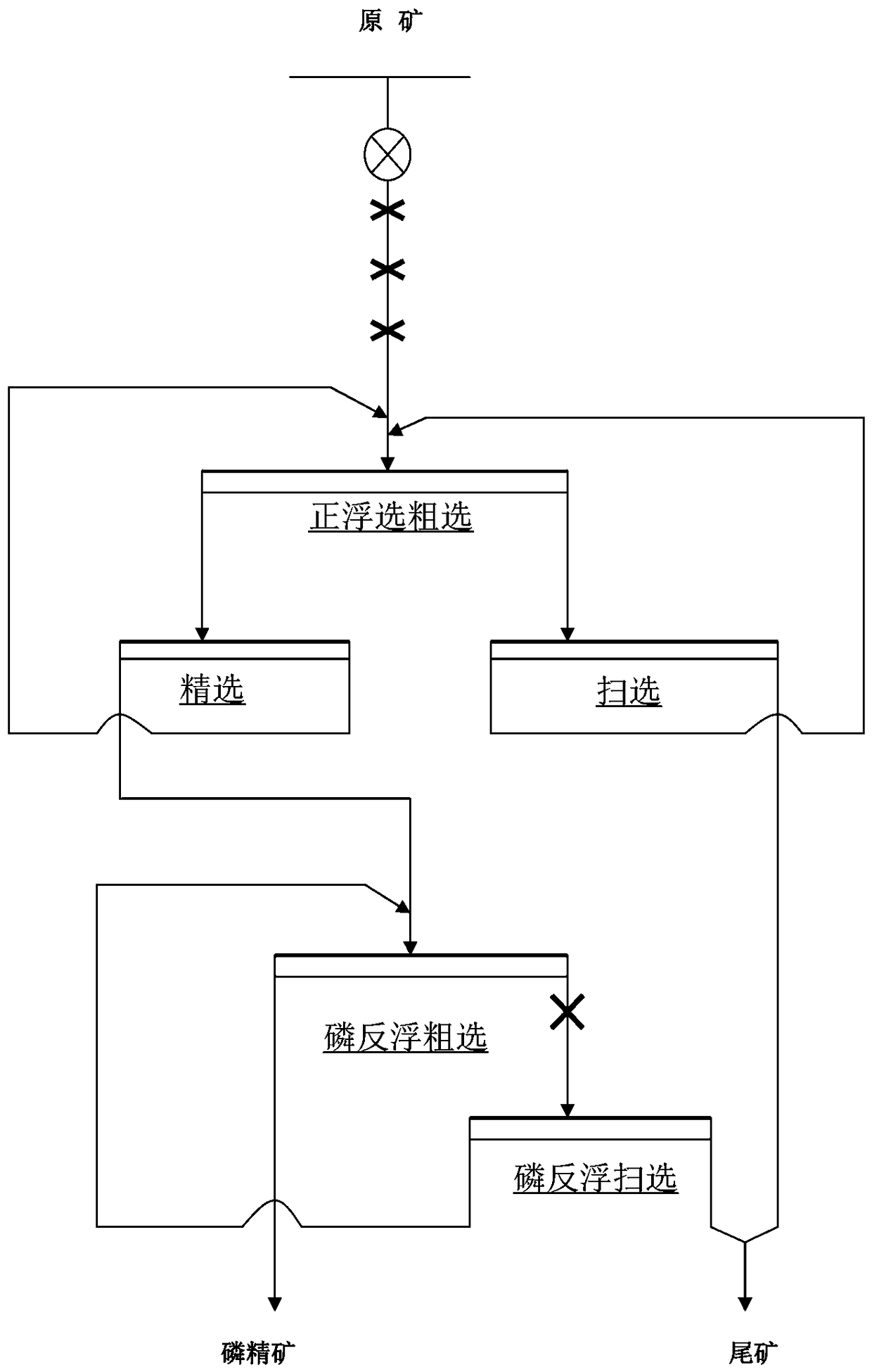

Demagging and manganese reducing phosphorus direct-reverse flotation technology of low-grade manganic phosphorite ore

InactiveCN108993779AImprove mineral processing recovery rateQuality assuranceFlotationManganesePhosphoric acid

The invention provides a demagging and manganese reducing phosphorus direct-reverse flotation technology of low-grade manganic phosphorite ore. The technology comprises the steps that the low-grade manganic phosphorite ore is crushed and ground to obtain ore pulp, sodium carbonate is added into a direct flotation ore pulp tank, the pH value of the ore pulp is adjusted, then water glass, a phosphorus direct flotation collecting agent and a foaming agent are added into the tank and mixed, air flotation is performed, an obtained froth product is phosphorus rough concentrate, the phosphorus roughconcentrate is transferred into a concentrating tank for concentrating, an obtained froth product is direct flotation phosphorus concentrate, and a product in the tank is direct flotation tailings; and the direct flotation phosphorus concentrate is placed in a reverse flotation ore pulp stirring tank, sulfuric acid and phosphoric acid are added, the pH value of the ore pulp is adjusted, then a phosphorus reverse flotation collecting agent is added, stirring and pulp adjusting are performed, air flotation is performed, an obtained froth product is tailings containing magnesium and manganese, and a product in the tank is phosphorus concentrate. In alkalescent medium ore pulp, the phosphorus ore has the good floatability. In weakly acidic ore pulp, dolomite carbonate minerals have the good floatability while the floatability of phosphorus minerals is poor, and the phosphorus minerals and the dolomite carbonate minerals are effectively separated.

Owner:湖北省黄麦岭磷化工有限责任公司

Collecting agent for increasing beneficiation indicator of associated gold and silver

The invention provides a collecting agent for increasing the beneficiation indicator of associated gold and silver. The collecting agent consists of 15-20 parts by weight of alkyl propiontrile xanthate ester, 25-35 parts of dianilinodithiophosphoric acid, 30-45 parts of 25# dithiophosphate and 5-15 parts of dithiophosphate acid. The collecting agent has collecting and foaming properties and is high in selectivity and collecting capability, effective enrichment of nonferrous metal associated gold and silver can be realized in the pH value of 7-10, and the beneficiation recovery rate of the nonferrous metal associated gold and silver can be increased by 2-5 percent; meanwhile, the collecting agent has a better floatation effect on carrier minerals of the associated gold and silver, and is an efficient collecting agent with a wider application range for increasing the nonferrous metal associated gold and silver.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

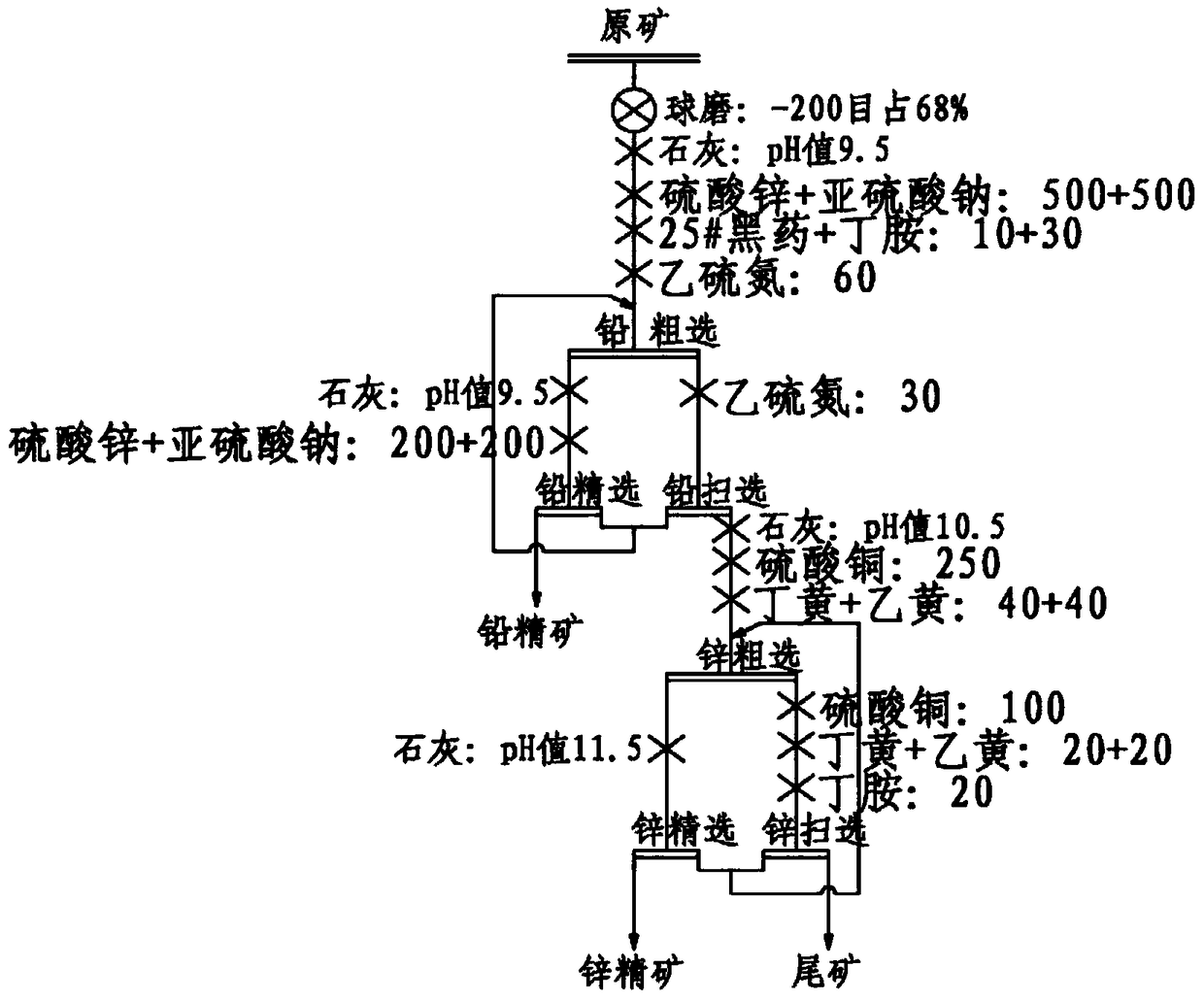

Method for improving beneficiation indexes of low-grade lead-zinc-silver polymetallic ores by combining collecting agent

The invention belongs to the technical field of beneficiation, particularly relates to a method for improving beneficiation indexes of low-grade lead-zinc-silver polymetallic ores by combining a collecting agent. According to the method, ethanethiol is adopted as a main collecting agent in the lead process, a butylamine black medicine, the 25 # black medicine is an auxiliary collecting agent, thezinc flow ethyl xanthate and the butyl xanthate are added according to a ratio of 1:1 to serve as a main collecting agent, and the butyl amine black medicine is used as an auxiliary collecting agent.By utilizing the use of the combined collecting agent, the concentrate grade is stable and even the small amplitude is improved, the recovery rate of the three kinds of metal of the lead and zinc silver is greatly improved, the content of the silver in the lead concentrate is improved, and the economic benefit is obviously improved.

Owner:云南中金共和资源有限公司

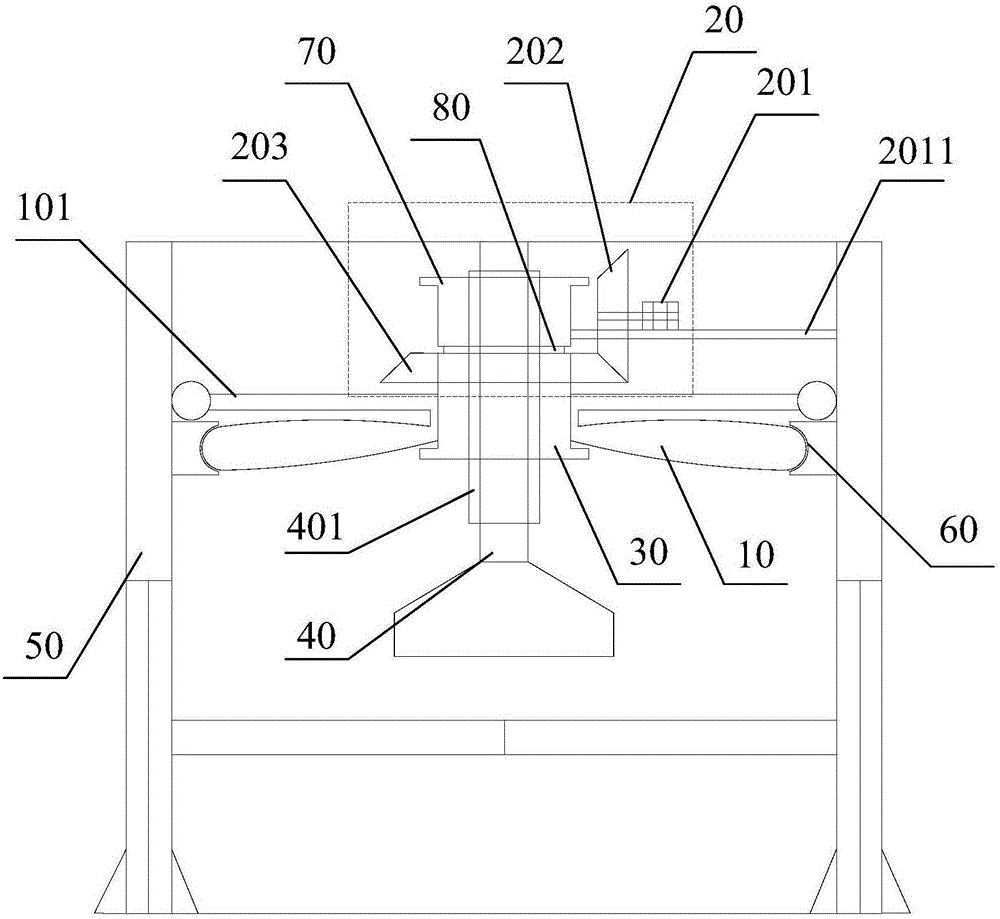

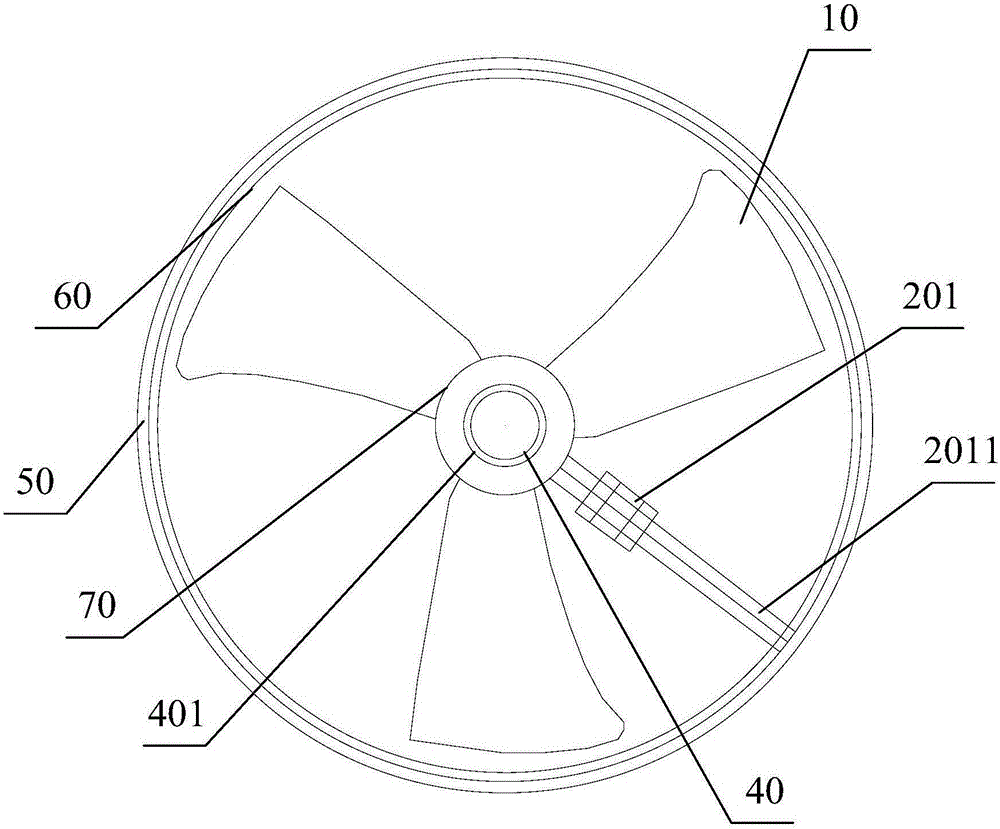

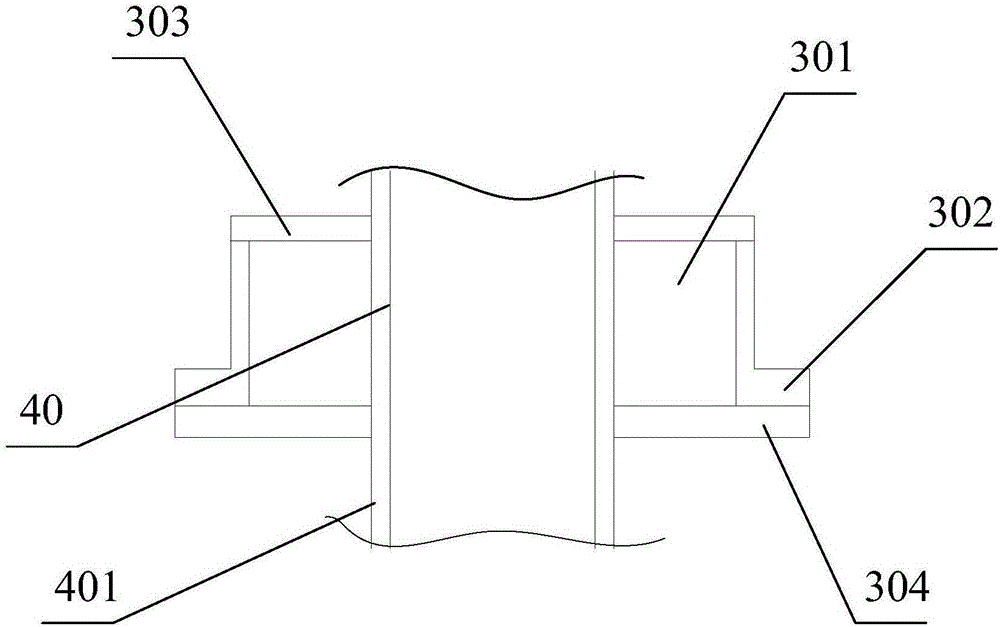

Center drive type foam scraper

The invention relates to the technical field of equipment for the coal mining industry and provides a center drive type foam scraper. The center drive type foam scraper comprises a scraping plate, a driving device and a rotating sleeve. The driving device comprises a variable-frequency motor, a driving bevel gear and a driven bevel gear, the variable-frequency motor is connected with the driving bevel gear to drive the driving bevel gear to rotate, and the driving bevel gear is meshed with the driven bevel gear to realize motion transmission. The rotating sleeve externally sleeves a central rotating shaft of a flotation machine, the driven bevel gear externally sleeves the rotating sleeve to drive the rotating sleeve to move circularly around own axis, and the rotating sleeve is connected with the scraping plate which rotates along with the rotating sleeve. The center drive type foam scraper is integrally stable in operation, foam viscosity is reduced, the foam discharge rate is increased, normality in next operation is guaranteed, flotation effects are guaranteed, and the ore dressing recovery rate is increased.

Owner:TIBET HUATAILONG MINING DEV

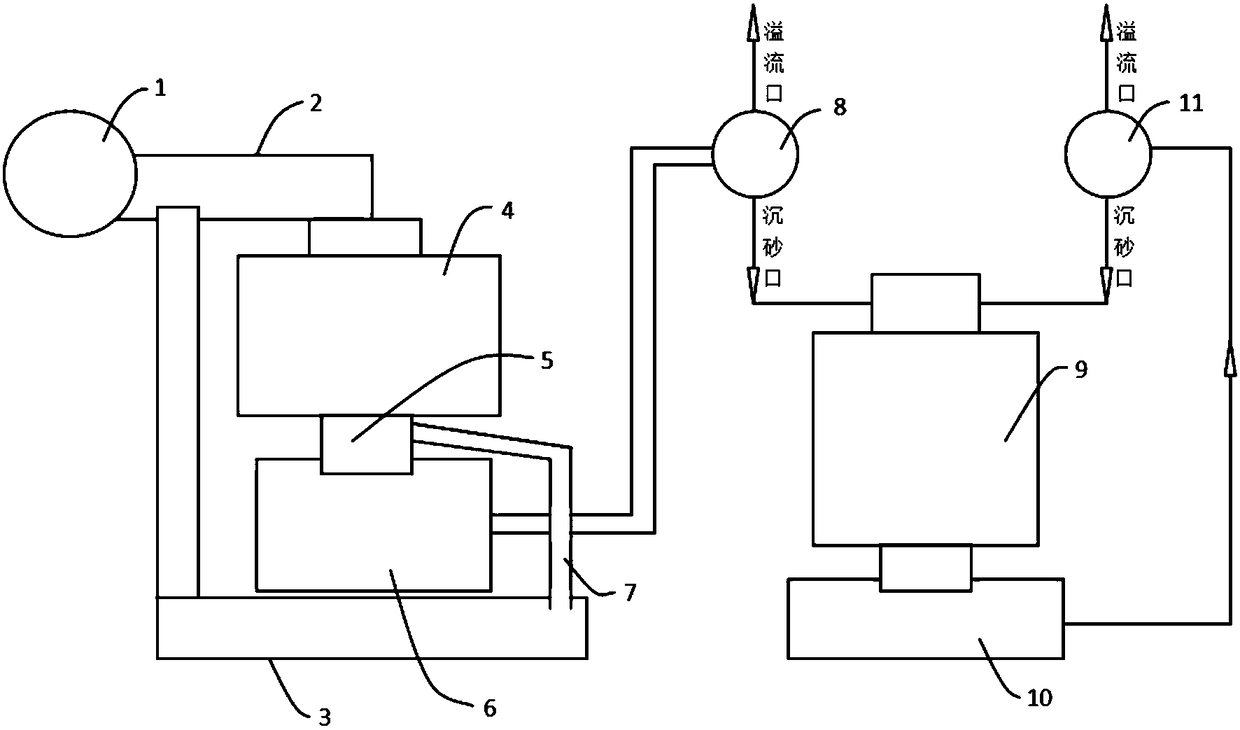

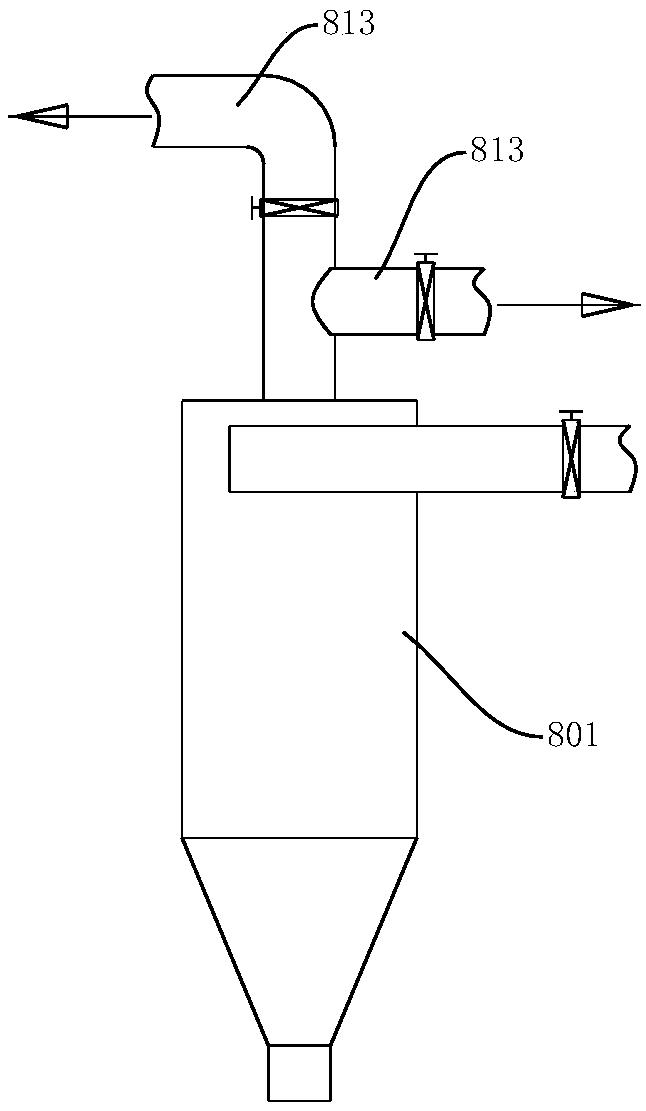

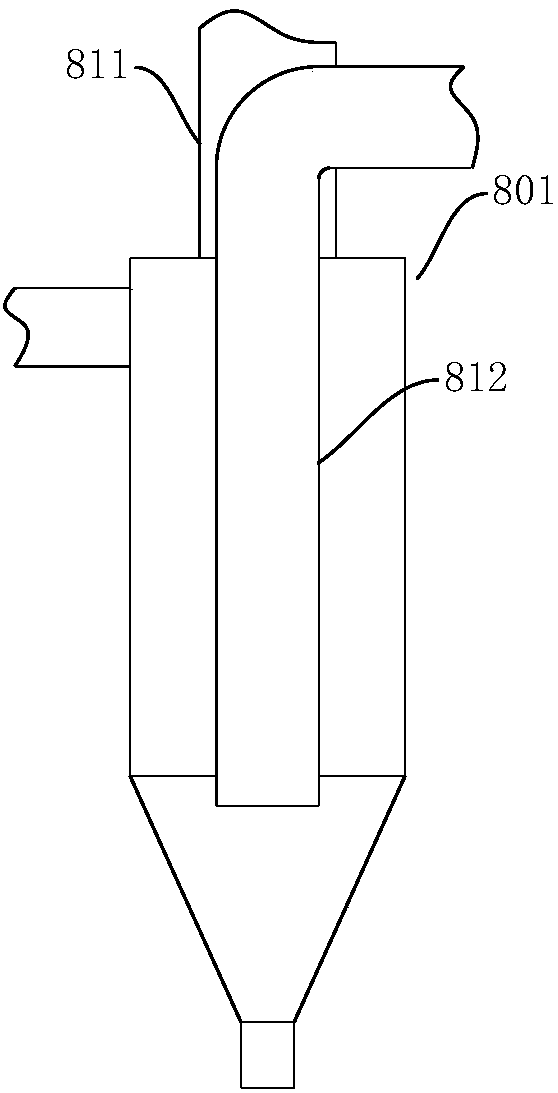

Gold ore grinding classification system and grinding classification processing technology

PendingCN108927281AOptimize structure layoutEasy to handleGrain treatmentsWet separationReturn ratioEngineering

The invention discloses a gold ore grinding classification system and grinding classification processing technology. The grinding classification system includes a first section grinding classificationsystem and a second section grinding classification system. The first section grinding classification system comprises a semi-autogenous mill, a cylinder screen, a first classification pump pool andan inspection classification hydrocyclone group, and the second section grinding classification system comprises a ball grinding mill, a second classification pump pool and a control classification hydrocyclone group. Compared with original one-time screening processing, the gold ore grinding classification system reduces the sand-returning ratio of the semi-autogenous mill and improves the sand-returning ratio of the ball grinding mill, part of qualified materials in ore discharge of the semi-autogenous mill performs flotation operation in advance, the load of the two-stage ore grinding millsis optimized, the particle size composition of grinding products is optimized, the argillation problem caused by over-grinding is avoided, and the recovery rate of the ore dressing is improved.

Owner:DULAN JINHUI MINE CO LTD

Gravity separation method with defoaming agent for non-ferrous metal ore capable of being treated with gravity method

InactiveCN101486011AFull performance of natural specific gravity characteristicsImprove mineral processing recovery rateFoam dispersion/preventionWet separationGramMaceral

The invention relates to a defoaming reselection method for reselectable non-ferrous metal ores, which belongs to the technical field of ore dressing of the non-ferrous metal ores. The method can add a defoaming agent in the process of performing water power shaking table reselection or chute reselection on the reselectable non-ferrous metal ores, wherein the total dose of the defoaming agent added to each ton of the selected ores is between 50 and 800 grams, and the rest operating conditions are the same as that of the common water power shaking table reselection or chute reselection. The method can add the defoaming agent which is not corrosive to a used device in the ore grinding and classifying processes, and the total dose of the defoaming agent added to the each ton of the processed ores is between 20 and 900 grams. Because of the addition of the defoaming agent, in the process of performing the water power shaking table reselection or chute reselection on the non-ferrous metal ores, ore grains are not attached to steam bubbles, the natural specific gravity characteristics are presented sufficiently, and the ore dressing recovery efficiency can be improved.

Owner:兰坪县矿产三废回收厂

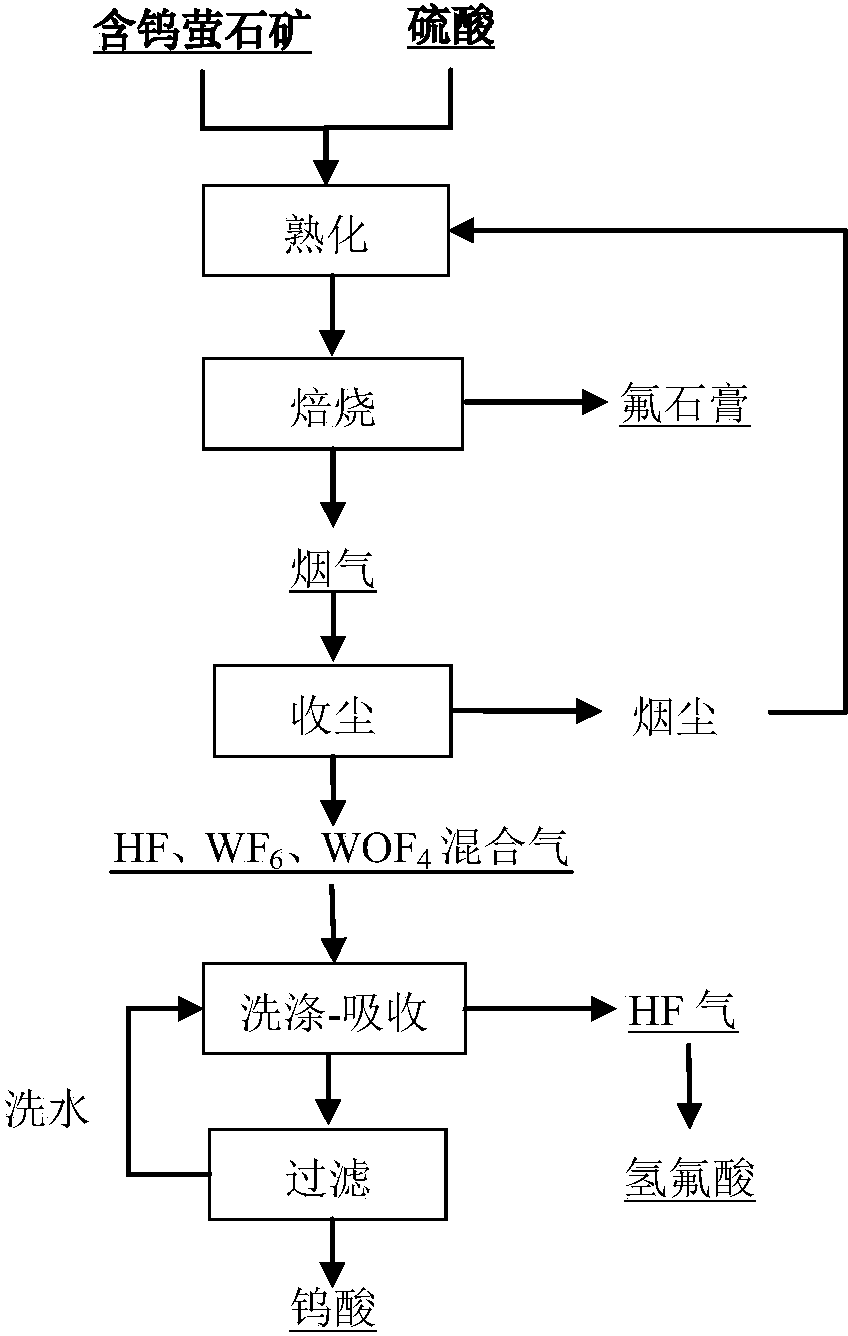

Method for recovering tungsten from tungsten-containing fluorite mine

ActiveCN103526052ALess investmentImprove mineral processing recovery rateProcess efficiency improvementFluorine/hydrogen-fluorideTungstic acidMaceral

The invention relates to a method for recovering tungsten from tungsten-containing fluorite mine. Sulfuric acid and tungsten-containing fluorite mine are mixed at a mass ratio of 0.8:1 to 1.5:1, cured, and then roasted at 200-500 DEG C, a fluorite mineral is subjected to acidolysis by sulphuric acid to release hydrogen fluoride (HF), a tungsten mineral is subjected to acidolysis by sulphuric acid to become tungsten trioxide, and the HF and the tungsten trioxide continue to react to generate tungsten hexafluoride (WF6) or tungsten oxytetrafluoride (WOF4); the HF, the WF6 and the WOF4 are all volatile matters and enter roasted flue gas, the flue gas is washed, absorbed and hydrolyzed to obtain tungstic acid, the washed gas is used for producing hydrofluoric acid, and the volatilization rate of fluorine can be higher than 95% while the volatilization rate of tungsten can be higher than 90%. The method for recovering tungsten from tungsten-containing fluorite mine has the advantages that when hydrogen fluoride is prepared, tungsten is fluorated and volatilized and then enters flue gas to achieve high-efficiency extraction of tungsten; the method can be used to treat mixed concentrate produced by bulk flotation of tungsten and fluorite, a flotation-metallurgical process is greatly simplified, and a comprehensive recovery rate is increased.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for decreasing magnesium oxide in nickel sulfide concentrate

InactiveCN102965500AImprove mineral processing recovery rateEfficient removalProcess efficiency improvementChemical structureNickel sulfide

The invention discloses a method for decreasing magnesium oxide in nickel sulfide concentrate, and relates to a method for treating nickel sulfide concentrate in flash furnace smelting production process. The method is characterized by comprising the following steps of: adding sulfuric acid in the nickel sulfide concentrate to ensure that the magnesium oxide in the concentrate reacts with the sulfuric acid to generate magnesium sulfate, and carrying out solid-liquid separation to detain the magnesium sulfate in the solution so as to be separated and removed from the concentrate. According to the method for decreasing magnesium oxide in the nickel sulfide concentrate, the sulfuric acid is added in the concentrate, the NiS and CuS in the concentrate do not change in the aspect of chemical structure and exist in a solid form, the MgO in the concentrate reacts with the sulfuric acid to generate the magnesium sulfate which is dissolved in water, and during the solid-liquid separation process of the ore pulp, the magnesium sulfate is mostly retained in the solution, so that the separation of the NiS and the CuS from the MgO in copper-nickel sulfide ore is realized and thus the effect of decreasing the magnesium oxide in the nickel sulfide concentrate. According to the method, the magnesium oxide in the concentrate is effectively removed and the ore dressing recovery percentage of the nickel is improved.

Owner:JINCHUAN GROUP LIMITED

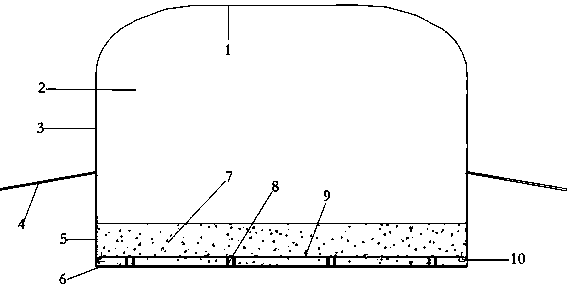

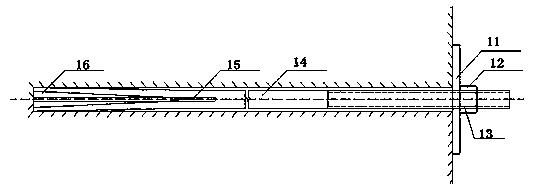

Artificial false bottom and manufacturing method

PendingCN110541729AHigh strengthReduce mix rateMaterial fill-upAnchoring boltsEconomic benefitsEngineering

The invention discloses an artificial false bottom. The artificial false bottom is built in a roadway and comprises an artificial false bottom body and a fixing part, wherein one end of the fixing part is inserted into a side plate of the roadway, and the other end of the fixing part is connected with the artificial false bottom body through a connecting piece; the artificial false bottom body ispositioned on a bottom plate of the roadway, and a reinforcing mesh is arranged in the artificial false bottom body. The artificial false bottom can replace a top-bottom ore column in the mining process, so that the top-bottom ore column does not need to be reserved in the mining process, the top-bottom ore column does not need to be recovered in the later period, and as a result, the recovery process is saved; the artificial false bottom is made of high-grade concrete, so that the strength of the artificial false bottom is high, the mixing rate of waste rocks in the process of recovering thetop-bottom ore column is low, the mineral separation recovery rate is high, and the economic benefit is good; in addition, reinforcing steel bars and anchor rods are connected with the side plate of the roadway, so that the safety is high.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Mineral separation process of complex fluorite difficult to separate

Owner:BAIYIN NONFERROUS GROUP

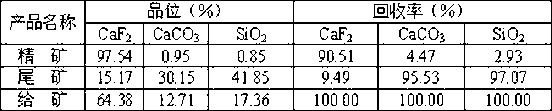

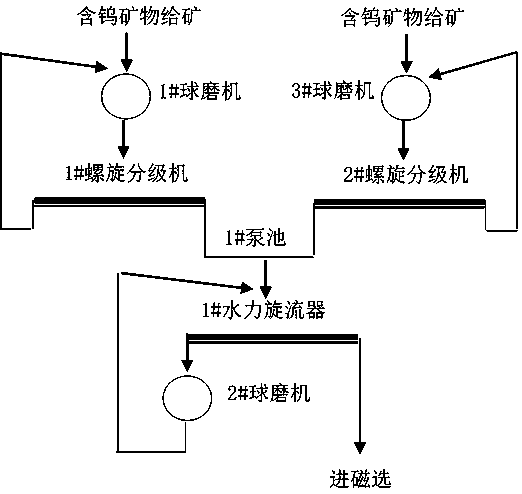

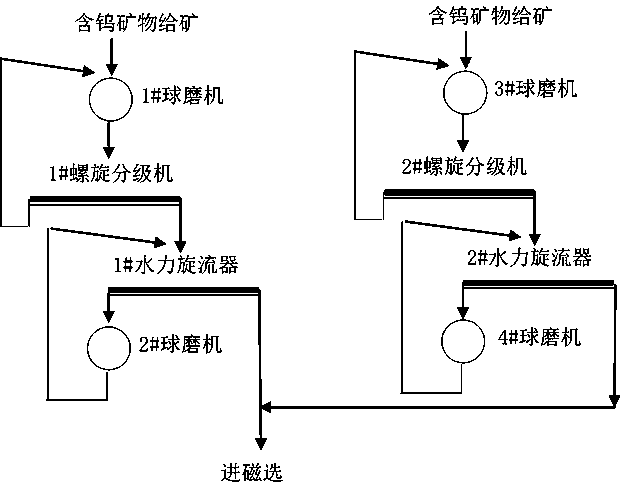

Non-standard-configured two-stage continuous ore grinding and grading process

InactiveCN110052321AUniform particle size distributionLow total grinding energy consumptionGrain treatmentsEngineeringBall mill

The invention discloses a non-standard-configured two-stage continuous ore grinding and grading process. Tungsten-containing raw ore is fed into two ball mills at the same time, ground products of each ball mill are fed into a corresponding spiral classifier for grading, graded returned sand returns to the corresponding ball mill for grinding again, each ball mill and the corresponding spiral classifier form closed-circuit grinding, graded overflow of the two spiral classifiers is fed into a same pump tank, ore pulp in the pump tank is fed into a hydrocyclone for grading, a graded overflow sample is obtained as a final product after grinding and grading, obtained grading grit is fed into a third ball mill for regrinding, and reground ore pulp is discharged into the pump tank to form closed-circuit grinding. The process has the advantages that for brittle and fragile tungsten-containing substances, not only total grinding energy consumption is low, the operation cost is low, process improvement is convenient, but also the graded overflow product has uniform particle size distribution, and the grade of tungsten-containing flotation tailings can be continuously reduced based on the prior art. The process is suitable for popularization and application of metallic mineral rich in tungsten.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

Method for gravity separation of fine antimony oxide ore

ActiveCN106391296AImprove mineral processing recovery rateIncrease productivityWet separationGravity separationAntimony oxide

The invention provides a method for gravity separation of fine antimony oxide ore. The method comprises the following steps: first, coarse materials are screened out of antimony separation tailings or grinded crude ore of antimony oxide by utilizing a vibrating screen; then, slime is removed by utilizing a hydrocyclone; and finally, a slime-free material automatically flows into a suspension vibration cone concentrator for one-time separation, thereby obtaining antimony concentrate and final tailings. By adoption of the method provided by the invention, the separation recovery rate and the grade of the finally obtained antimony concentrate can reach up to 49.25% and 20.0% respectively; and the separation recovery rate is high, the production efficiency is high, the operation is simple and convenient, the labor intensity, the energy consumption and the cost are low, and the operation environment is friendly.

Owner:锡矿山闪星锑业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com