Sorting method for anshan-type lean iron ores

An iron ore, Anshan-style technology, applied in the separation of Anshan-style lean iron ore, can solve the problems of difficulty in ore development, low magnetic field strength, fluctuation of ore properties, etc., to reduce fixed investment and operating costs, improve The effect of beneficiation recovery rate and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

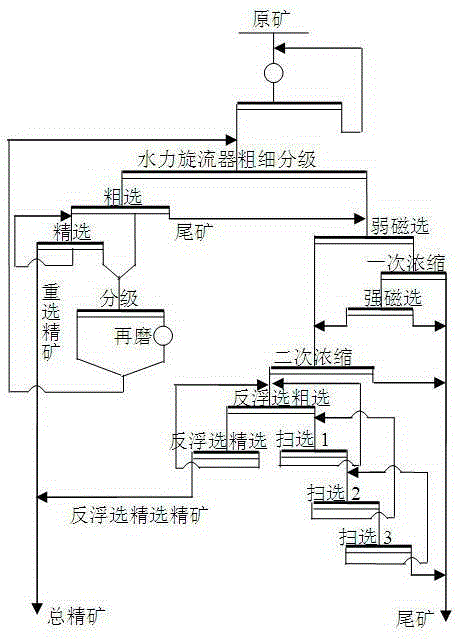

[0026] The specific flow process of the sorting method of the Anshan type lean iron ore of the present embodiment is as follows figure 1 shown, and follow these steps:

[0027] (1) Send the raw ore of Qidashan Iron Mine into a closed-circuit grinding system to obtain raw ore powder with a particle size of -0.074mm accounting for 58.17% of the total weight;

[0028] (2) Send the raw ore powder into the hydrocyclone for coarse and fine classification, the grading particle size is 36 μm, the overflow yield rate of the hydrocyclone is 41.63%, and the underflow is fed into the spiral concentrator for rough separation, and the rough separation is obtained Concentrated ore, rough ore and rough beneficiation tailings, the rough beneficiation concentrate is sent to the spiral concentrator and then be beneficiated, and the beneficiation will be the beneficiation concentrate, the beneficiation middle ore and the beneficiation tailings, the concentrate Concentrated ore is gravity-concent...

Embodiment 2

[0033] The specific flow process of the sorting method of the Anshan type lean iron ore of the present embodiment is as follows figure 1 shown, and follow these steps:

[0034] (1) Send the raw ore of Qidashan Iron Mine into a closed-circuit grinding system to obtain raw ore powder with a particle size of -0.074mm accounting for 58.17% of the total weight;

[0035] (2) Send the raw ore powder into the hydrocyclone for coarse and fine classification, the grading particle size is 25μm, the overflow yield rate of the hydrocyclone is 33.61%, and the underflow is fed into the spiral concentrator for rough separation, and the coarse separation is obtained Concentrated ore, rough ore and rough beneficiation tailings, the rough beneficiation concentrate is sent to the spiral concentrator for beneficiation, and the beneficiation is concentrated to obtain the beneficiation concentrate, the beneficiation medium ore and the beneficiation tailings, the concentrate Concentrated ore is grav...

Embodiment 3

[0040] The specific flow process of the sorting method of the Anshan type lean iron ore of the present embodiment is as follows figure 1 shown, and follow these steps:

[0041] (1) Send the raw ore of Qidashan Iron Mine into a closed-circuit grinding system to obtain raw ore powder with a particle size of -0.074mm accounting for 59.2% of the total weight;

[0042] (2) Send the raw ore powder into the hydrocyclone for coarse and fine classification, the grading particle size is 20 μm, the overflow yield rate of the hydrocyclone is 21.72%, and the underflow is fed into the spiral concentrator for rough separation, and the coarse separation is obtained Concentrated ore, rough ore and rough beneficiation tailings, the rough beneficiation concentrate is sent to the spiral concentrator and then be beneficiated, and the beneficiation will be the beneficiation concentrate, the beneficiation middle ore and the beneficiation tailings, the concentrate Concentrated ore is gravity-concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com