Method for increasing molybdenum ore recovery using fine-sweeping

A recovery rate, fine sweeping technology, applied in flotation, solid separation and other directions, can solve the problems of worsening tailings cycle in sweeping, not much improvement in comprehensive recovery rate, and large enrichment of fine-grained tailings in fine sweeping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

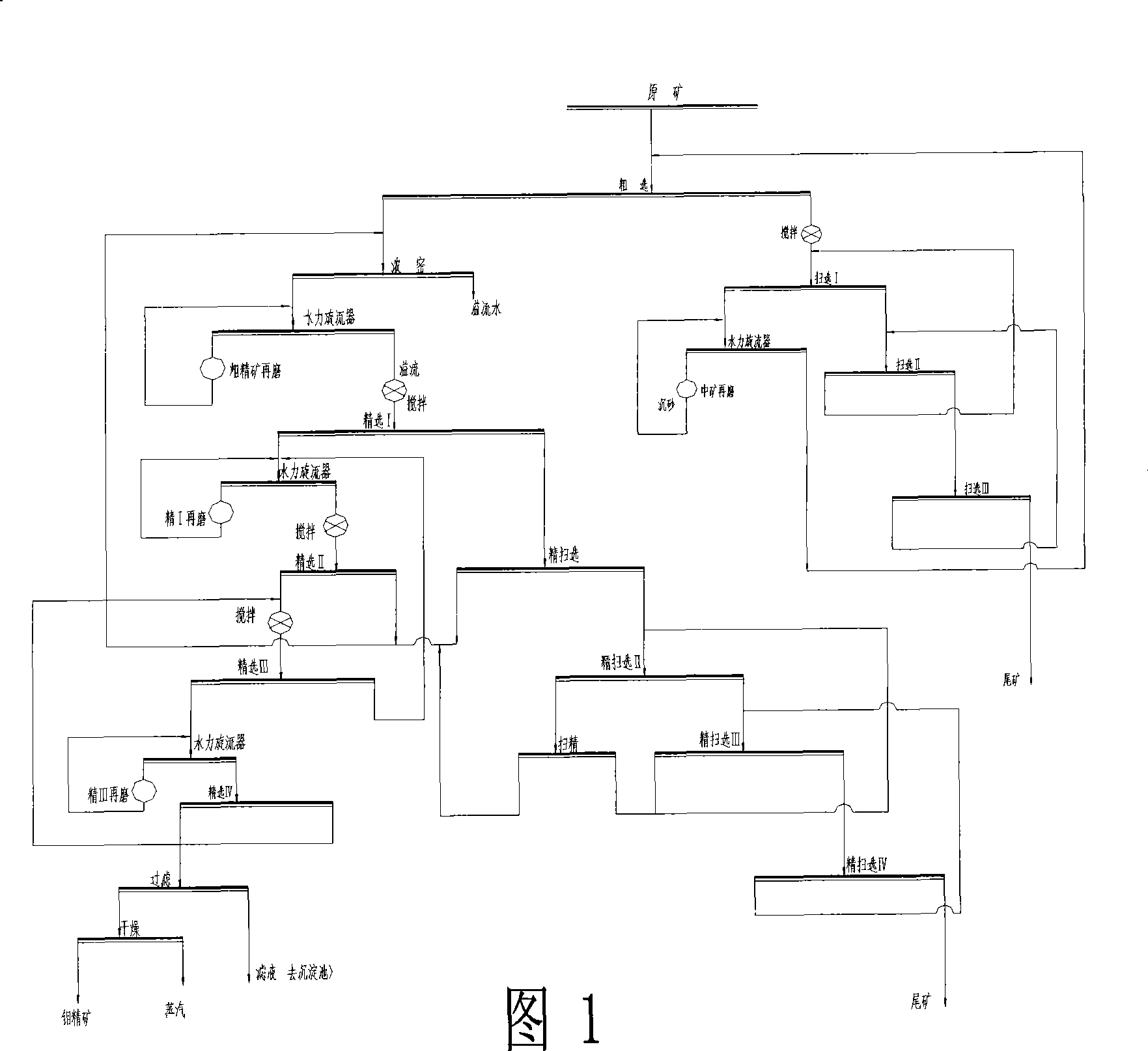

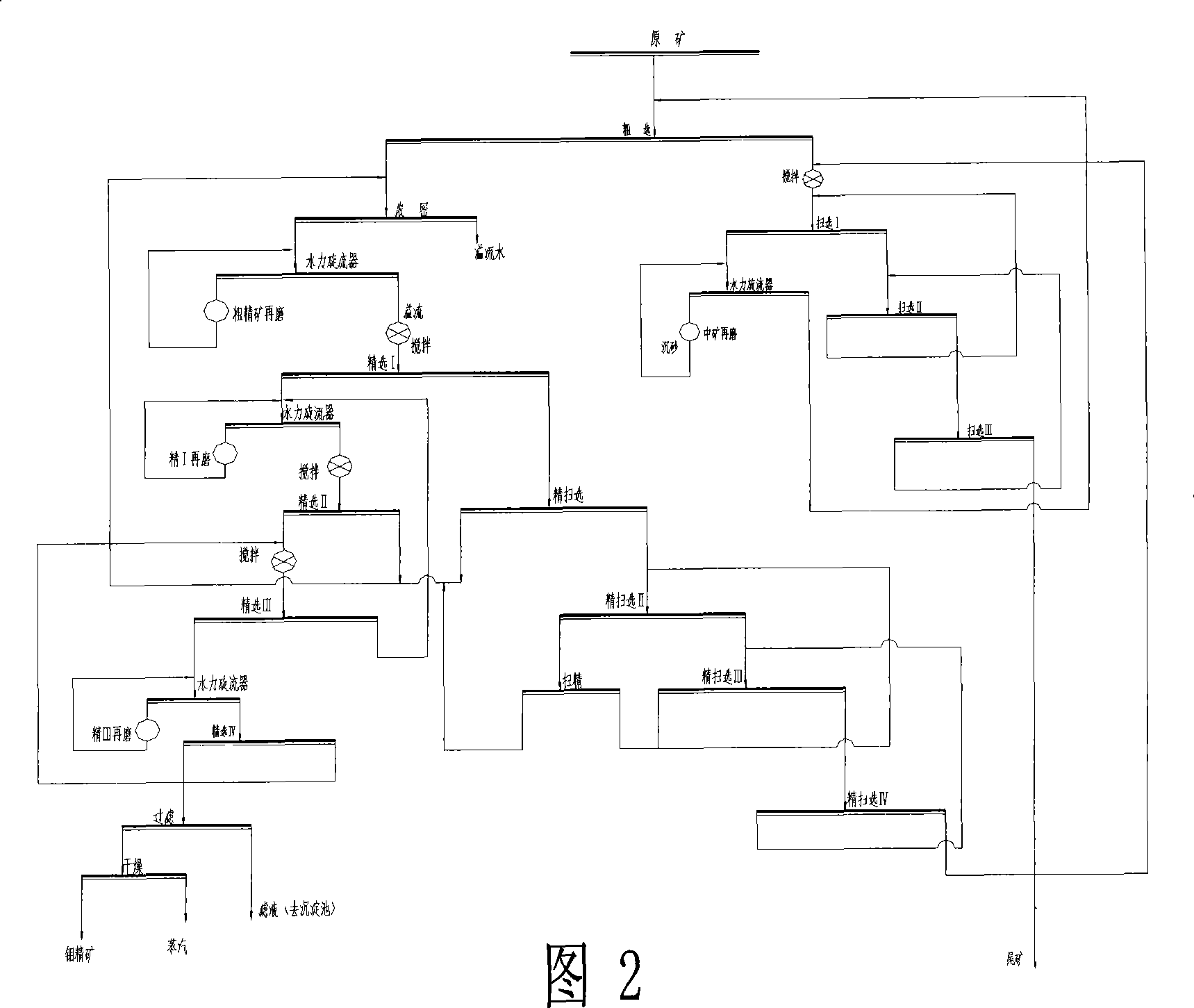

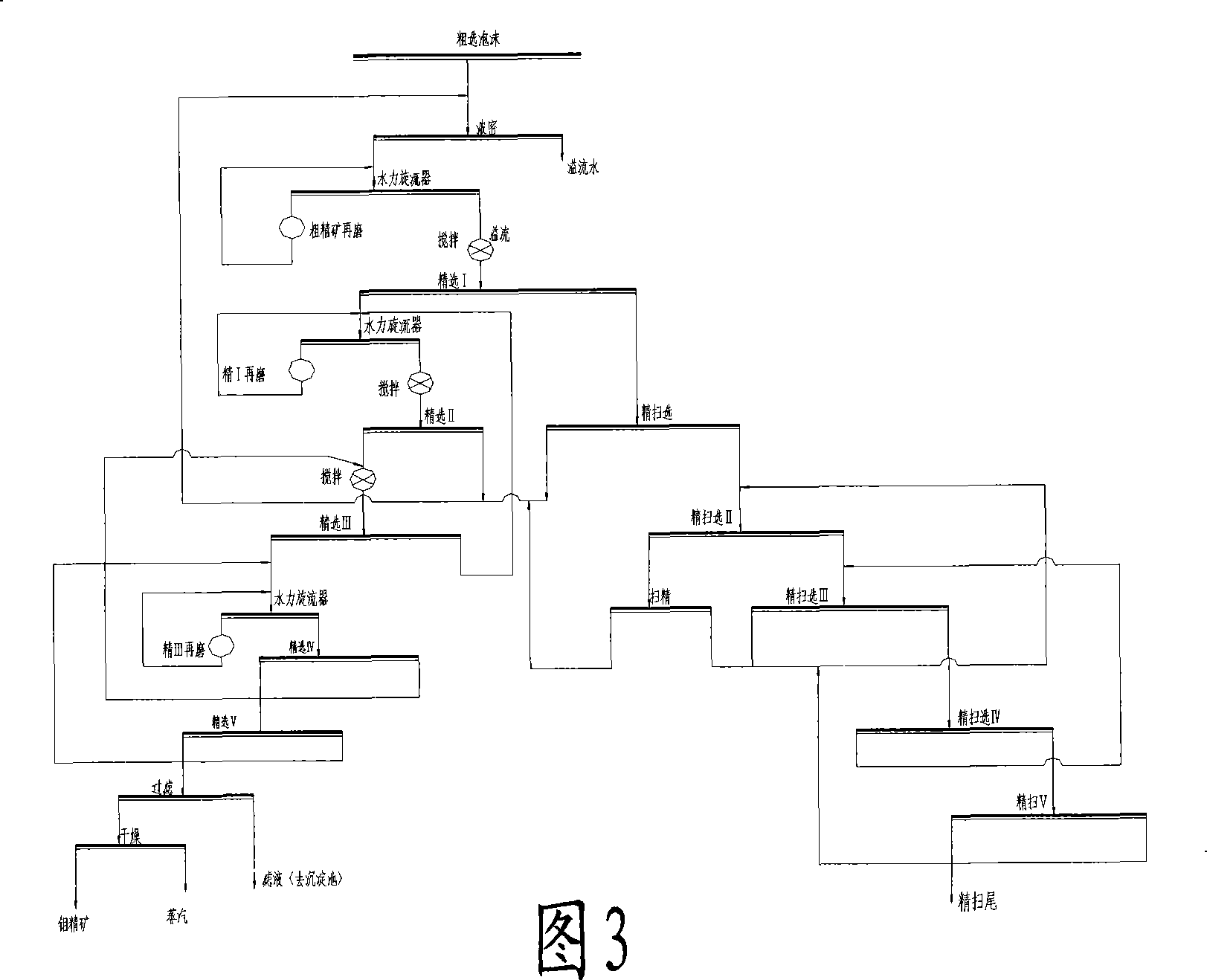

[0010] Embodiments of the present invention are further described in conjunction with the accompanying drawings.

[0011] In this embodiment, on the basis of the existing molybdenum beneficiation fine sweeping section process, a group of flotation columns with an effective volume of 30 cubic meters is added on the basis of four fine sweeping separations, so that the original fine sweeping tailings can directly enter the new stage. The flotation column is added to improve the recovery rate of ore dressing and increase the output of molybdenum concentrate under the premise of reducing the final tailings grade.

[0012] As shown in Figure 3: it includes five sorting operations: fine sweep I, fine sweep II, fine sweep, fine sweep III, and fine sweep IV. Among them, the fine sweep I foam, sweep fine foam, coarse concentrate, and fine II tailings are classified by the 2# cyclone, and the overflow is used as the ore feed for the fine sweep I, while the fine sweep I tailings enter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com