Method for enrichment of platinum in fluorine-containing spent platinum catalyst

A platinum catalyst and enrichment technology, applied in the field of platinum enrichment, achieves the effects of high yield, easy industrialization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

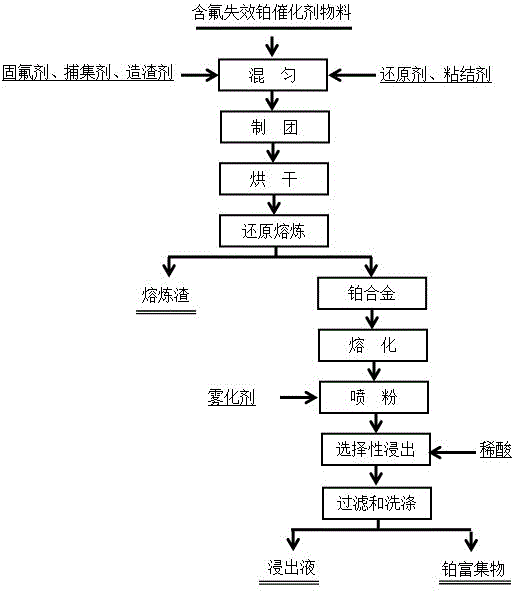

[0026] See the accompanying drawings, conditions: 1000g of fluorine-containing spent platinum catalyst, the amount of fluorine-fixing agent added is 0.4 times the weight ratio of fluorine-containing spent platinum catalyst, the amount of platinum trapping agent iron red is 0.5 times the weight ratio of fluorinated spent platinum catalyst, slagging The agent is lime and quartz, the addition amount is 10% and 15% of the weight ratio of the fluorine-containing spent platinum catalyst, the addition amount of the reducing agent is 10% of the weight ratio of the fluorine-containing spent platinum catalyst, and the addition amount of the binder water glass is 10% of the weight ratio of the fluorine-containing spent platinum catalyst. 0.5% by weight of the catalyst, mixed evenly, made into 5cm pellets with a ball forming machine, dried, and smelted at 1350°C for 1.5h in an electric arc furnace to obtain platinum alloy and smelting slag. During the smelting process, fluorine entered into...

Embodiment 2

[0028]See the accompanying drawings, conditions: 5000g of fluorine-containing spent platinum catalyst, the amount of fluorine-fixing agent added is 0.6 times the weight ratio of fluorine-containing spent platinum catalyst, the amount of platinum trapping agent iron black is 0.8 times the weight ratio of fluorine-containing spent platinum catalyst, and slagging The additives are lime and quartz, the addition amount of which is 15% and 10% by weight of the fluorine-containing spent platinum catalyst, the addition of the reducing agent is 8% of the weight ratio of the fluorine-containing spent platinum catalyst, and the addition of binder starch is 10% by weight of the fluorine-containing spent platinum catalyst. 0.5% of the weight ratio, mixed evenly, made into 5cm pellets with a ball forming machine, dried, and smelted at 1300°C for 2.0h in an electric arc furnace to obtain platinum alloy and smelting slag. During the smelting process, fluorine entered the slag; the obtained plat...

Embodiment 3

[0030] Refer to the accompanying drawings, conditions: 10000g of fluorine-containing spent platinum catalyst, the amount of fluorine-fixing agent added is 0.8 times the weight ratio of fluorine-containing spent platinum catalyst, and the amount of platinum trapping agent hematite concentrate added is 1.0 times the weight ratio of fluorine-containing spent platinum catalyst, The slagging agent is lime and quartz, the addition amount is 20% and 15% by weight of the fluorine-containing spent platinum catalyst, the added amount of the reducing agent is 6% by weight of the fluorine-containing spent platinum catalyst, and the addition amount of the binder starch is fluorine-containing spent platinum catalyst. 0.7% by weight of the platinum catalyst, mixed evenly, made into 5cm pellets with a pelletizing machine, dried, and smelted at 1350°C for 2.0h in an electric arc furnace to obtain platinum alloy and smelting slag. Fluorine entered the slag during the smelting process; the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com