Grinding while floatation process for carrying out floatation separation in grinding

A process method, side grinding technology, applied in flotation, solid separation, etc., can solve the problems of low recovery rate of buoyant minerals, covered by oil film or scale film, and reduced mineral buoyancy, etc., to achieve significant economic Benefits and social benefits, reducing wear and power consumption, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

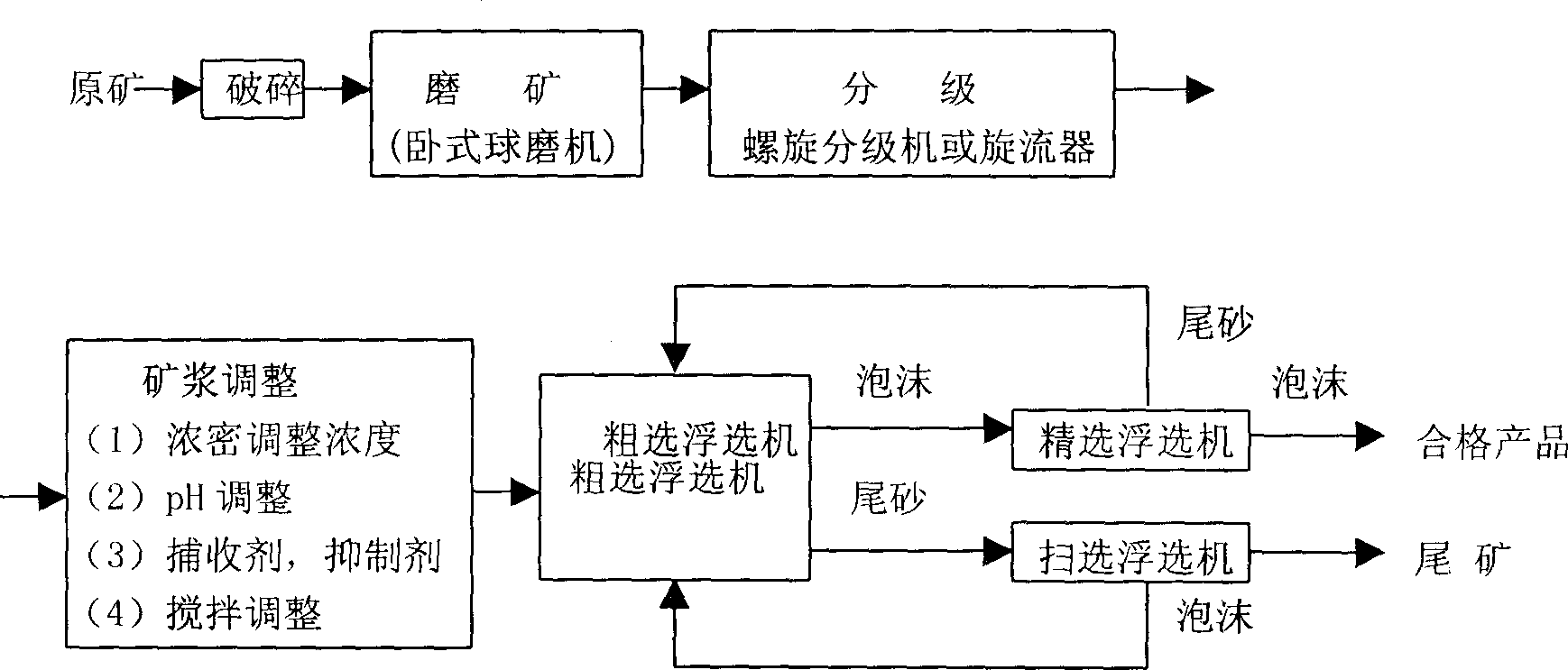

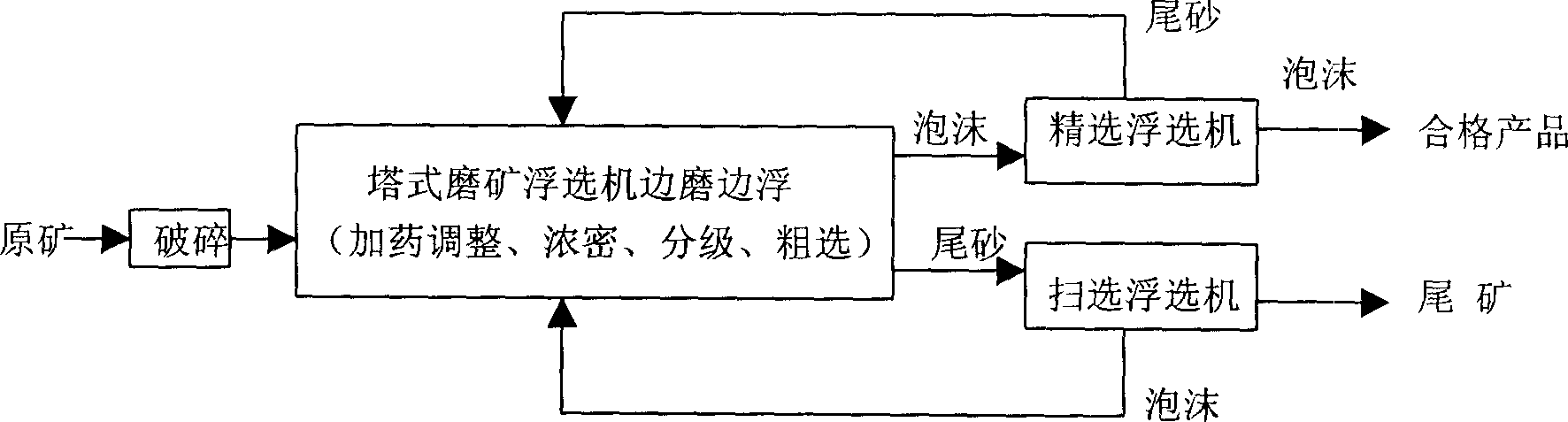

Method used

Image

Examples

Embodiment 1

[0042] The ore used is low sulfide arsenic gold ore. The main metal sulfides in the ore are pyrite and arsenopyrite. The gangue minerals are mainly quartz, followed by chlorite sericite and feldspar. The ore contains: Au11.5g / t, Ag2.3g / t, As1 .35%, S3.1%, Sb41.3g / t, Hg0.048g / t, Cu0.009%, Pb0.006%, Zn0.011%, Fe3.96%, Ca1.89%. The natural gold particle size in the ore is very fine, micro-grained gold accounts for 20.91%, submicroscopic gold accounts for 70.6%, sulfide-enclosed gold accounts for 69.23%, and gangue-enclosed gold accounts for 14.49%.

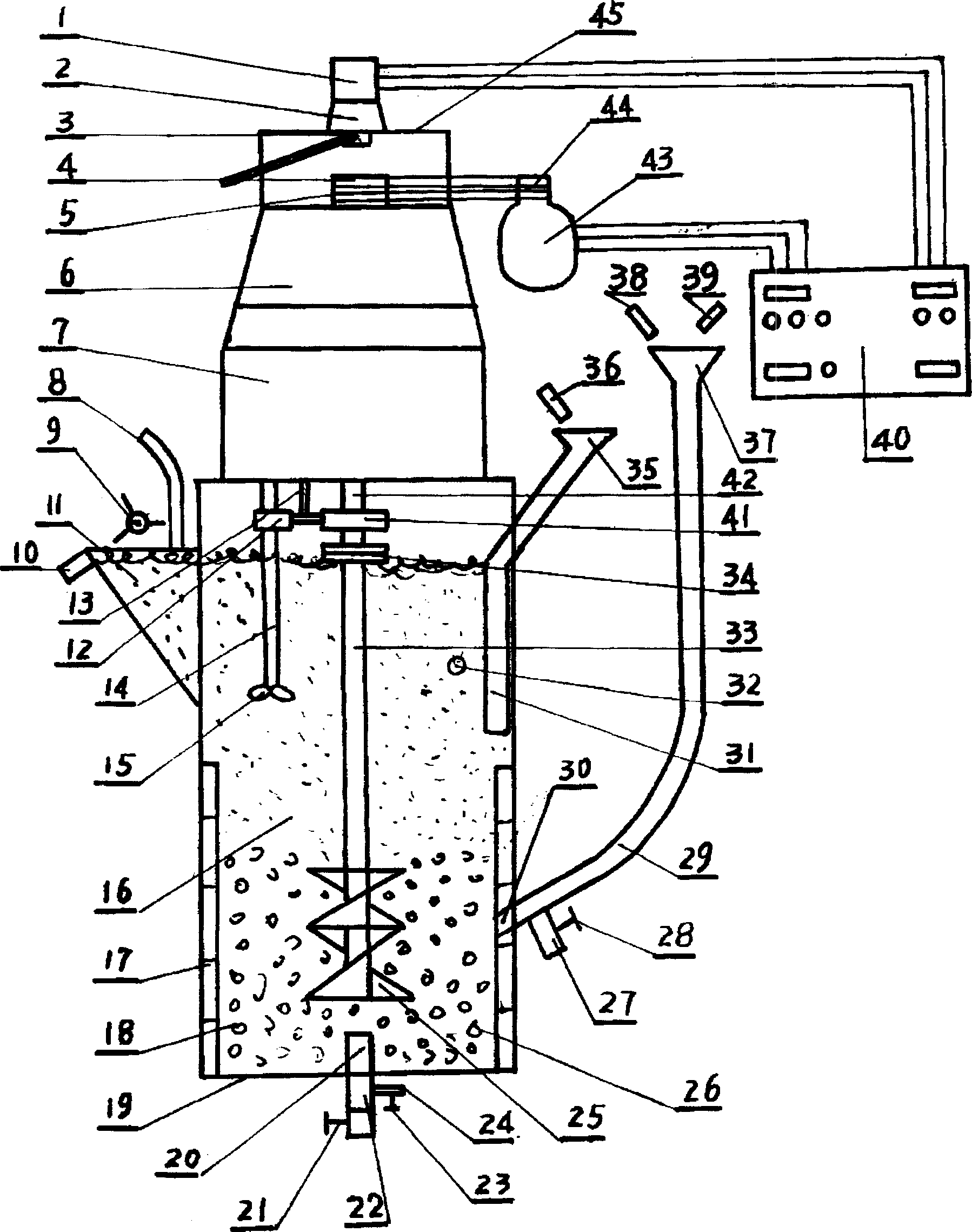

[0043] First, the 100-200mm large ore is crushed to -3mm by the jaw crusher and the roller crusher, and then fed into the tower grinding flotation machine through the ore feeder, and the ore feeding speed is 2kg / hr. At the same time, the pH adjuster Na 2 CO 3 Add in the amount of 500g / t, add butyl black drug collector at 40g / t, add butyl xanthate at 80g / t, add water at a solid-liquid ratio of 1:2, and add 40g / t of 2# oil foaming a...

Embodiment 2

[0054] The ore used is low sulfide arsenic gold ore. The ore contains: Au8.5g / t, Ag15.8g / t, C4.51%, CaO9.29%, S1.75%, Fe3.41%, Zn0.19%, Cu0.018%, Pb0.065% , As0.55%, SiO 2 : 49.31%, Al 2 o 3 7.5%, MgO5.80%. More than 80% of the gold distribution is invisible gold, the most important gold-bearing mineral is arsenopyrite, accounting for 72.8% of invisible gold, followed by pyrite and other sulfide minerals, accounting for 12.46% of invisible gold. 20% is visible gold, but its particle size is also very fine, below 10 microns, distributed in gangue, pyrite, arsenopyrite, black copper ore and galena.

[0055] First, the 100-200mm large ore is crushed to -3mm by the jaw crusher and the roller crusher, and then fed into the tower grinding flotation machine through the ore feeder, and the ore feeding speed is 2kg / hr. At the same time, the pH regulator CaO is added at 5kg / t, the collector butyl xanthate is added at 120g / t, water is added at a solid-liquid ratio of 1:2, and 2# oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com