Patents

Literature

72results about How to "Reduce mix rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

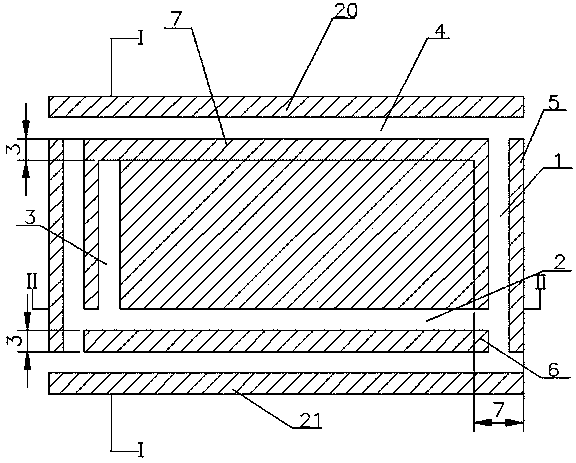

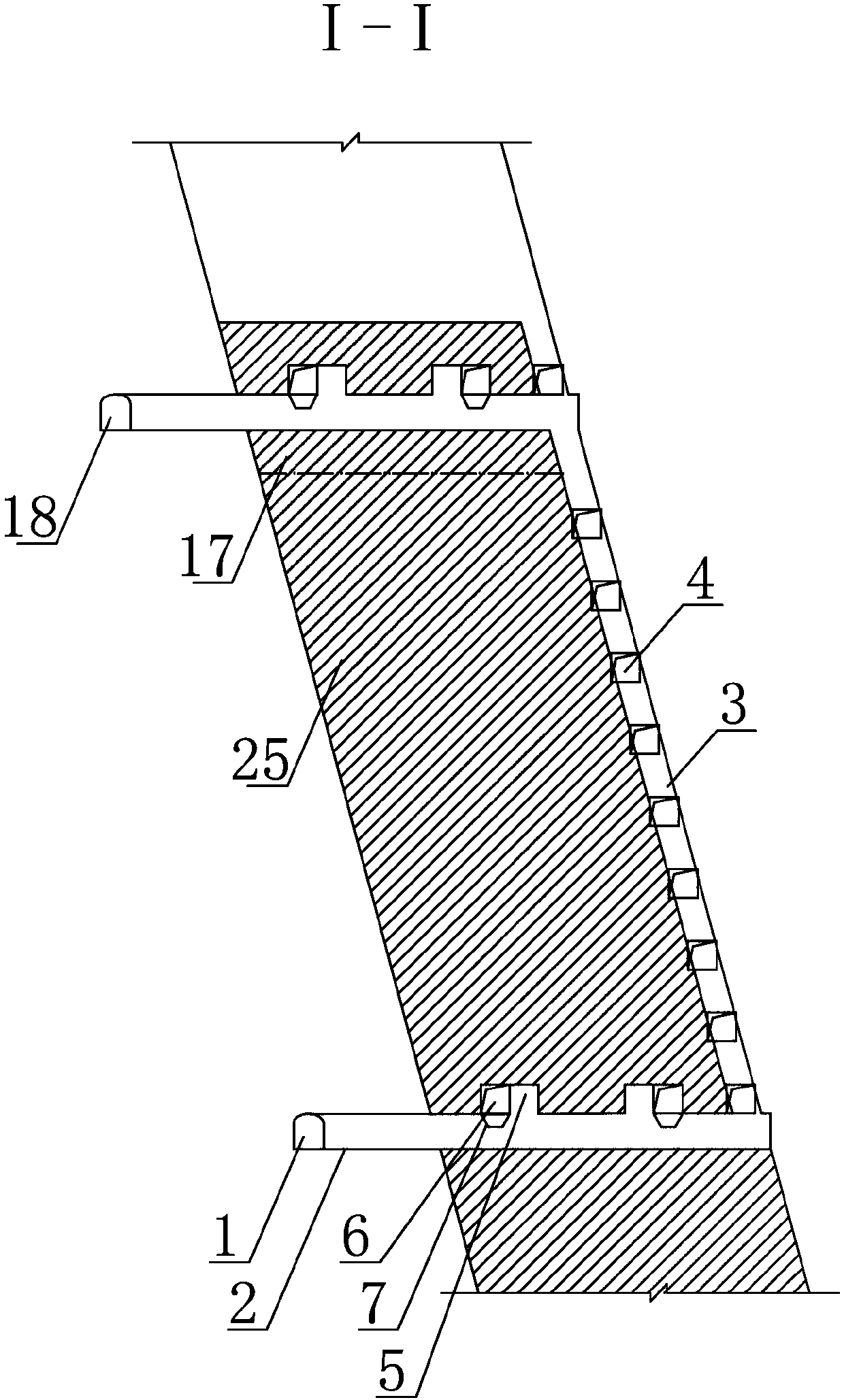

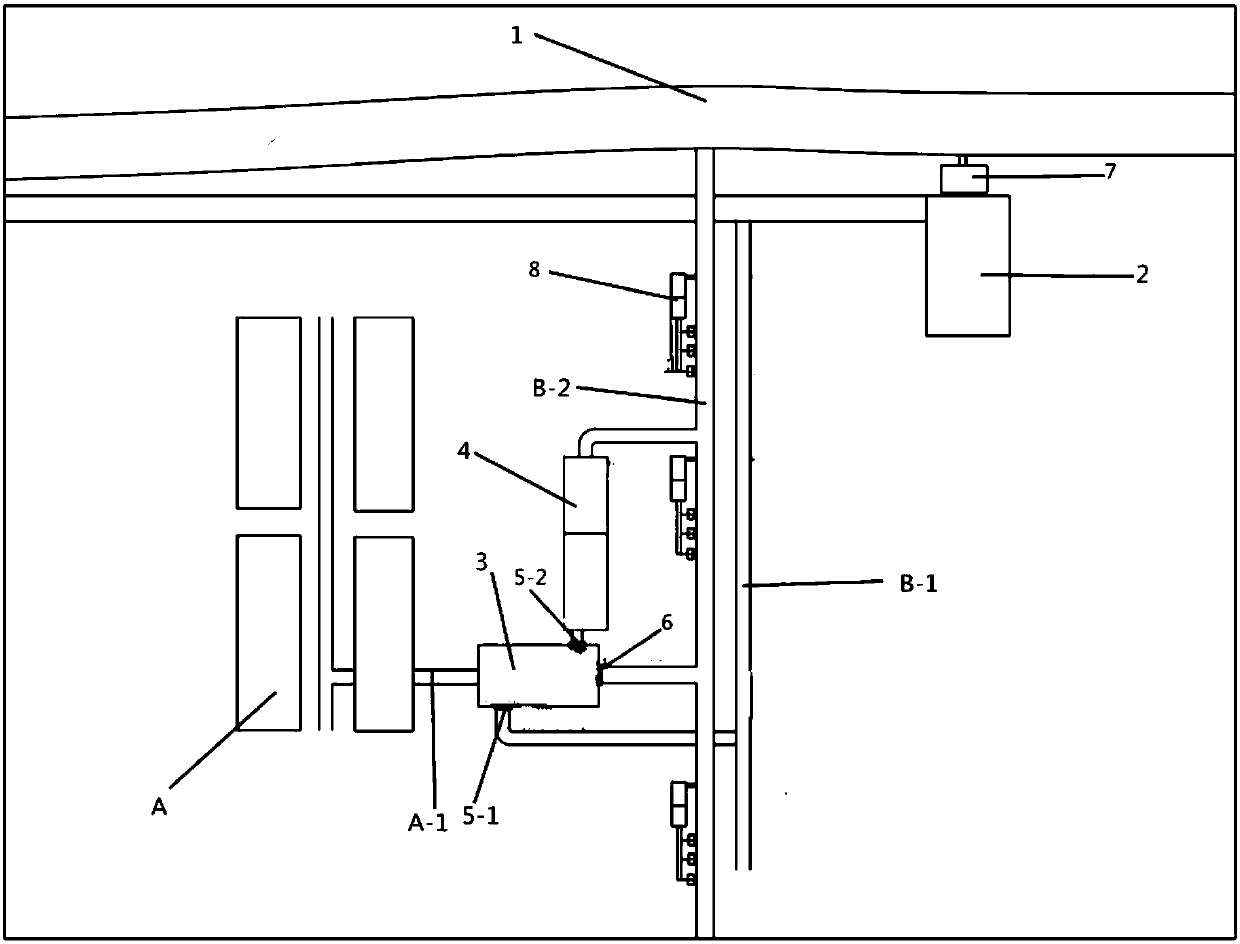

Mining method for multilayer fragile gently-inclined extra-narrow ore vein

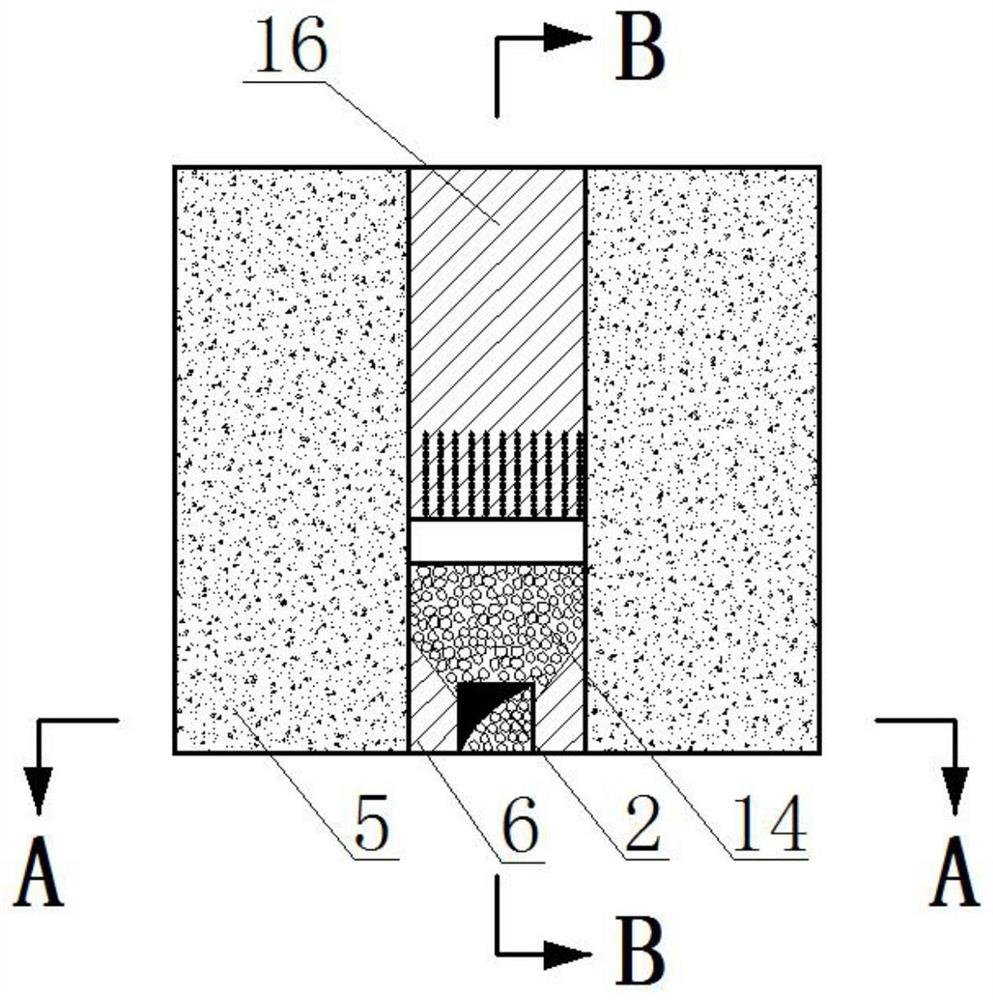

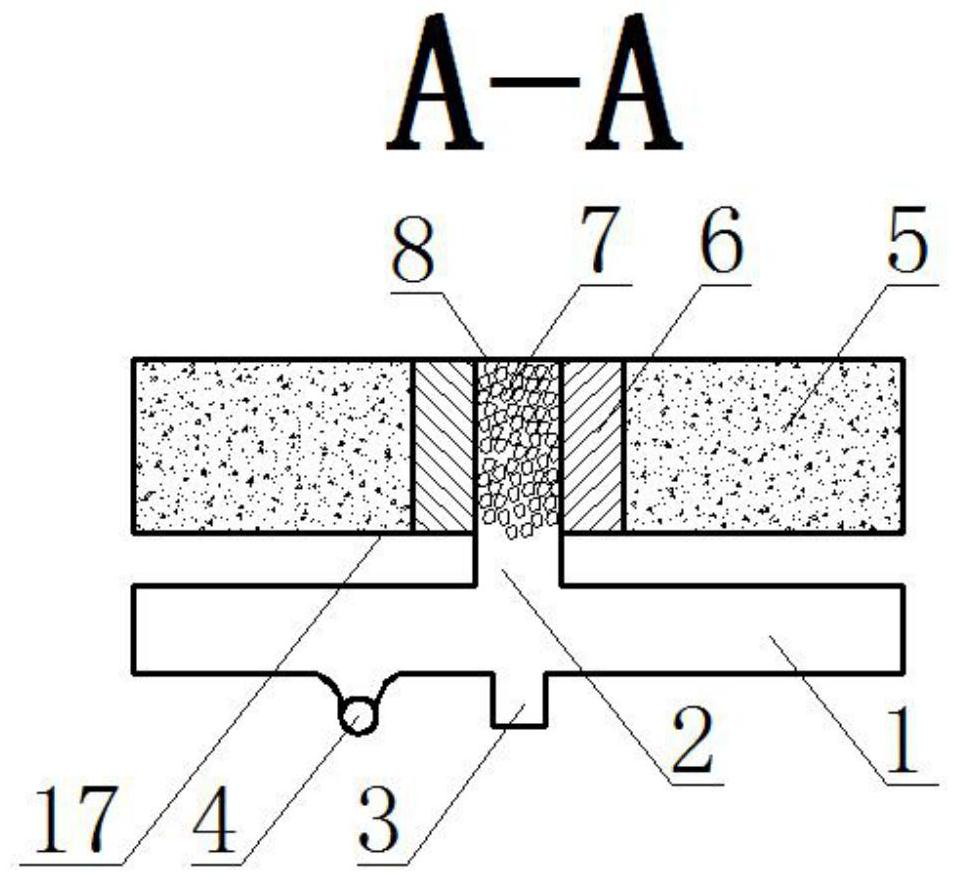

The invention discloses a mining method for a multilayer fragile gently-inclined extra-narrow ore vein. According to the method, mining areas are divided along the ore body trend; mining area columns (5) are reserved among the mining areas; a mine slope (1) is arranged in each mining area column (5); one vein following combined roadway is arranged in the inclination direction every 20m to 40m; vein following cutting roadways (2) and cutting mine slopes (3) are excavated at the end part of a chamber in the trend direction and the inclination direction; and a first layered ore vein, a rock sandwich layer and a second layered ore vein are totally excavated in one step along the vein following cutting roadways (2) and the cutting mine slopes (3). In the backstopping process, different drilling and blasting parameters are adopted at the first layered ore vein, the rock sandwich layer and the second layered ore vein, rocks among the ore veins can be removed; the problem of ore mixing into the rocks is solved; and the ore dilution is reduced. The method provided by the invention is particularly applicable to the mining of the underground metal mine multilayer fragile gently-inclined extra-narrow ore vein and the ore vein easy to crush due to blasting disturbance; the simultaneous recovery of the multilayer ore vein is realized; and the problem of personnel operation and equipment operation space limitation is solved through full thickness mining.

Owner:河南发恩德矿业有限公司

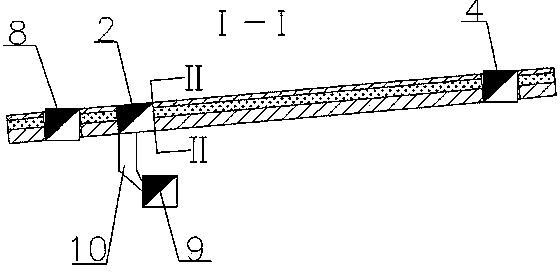

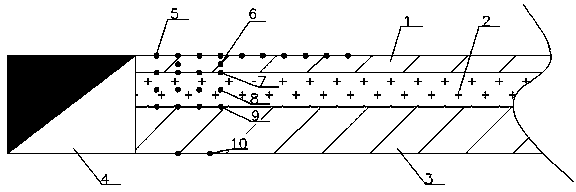

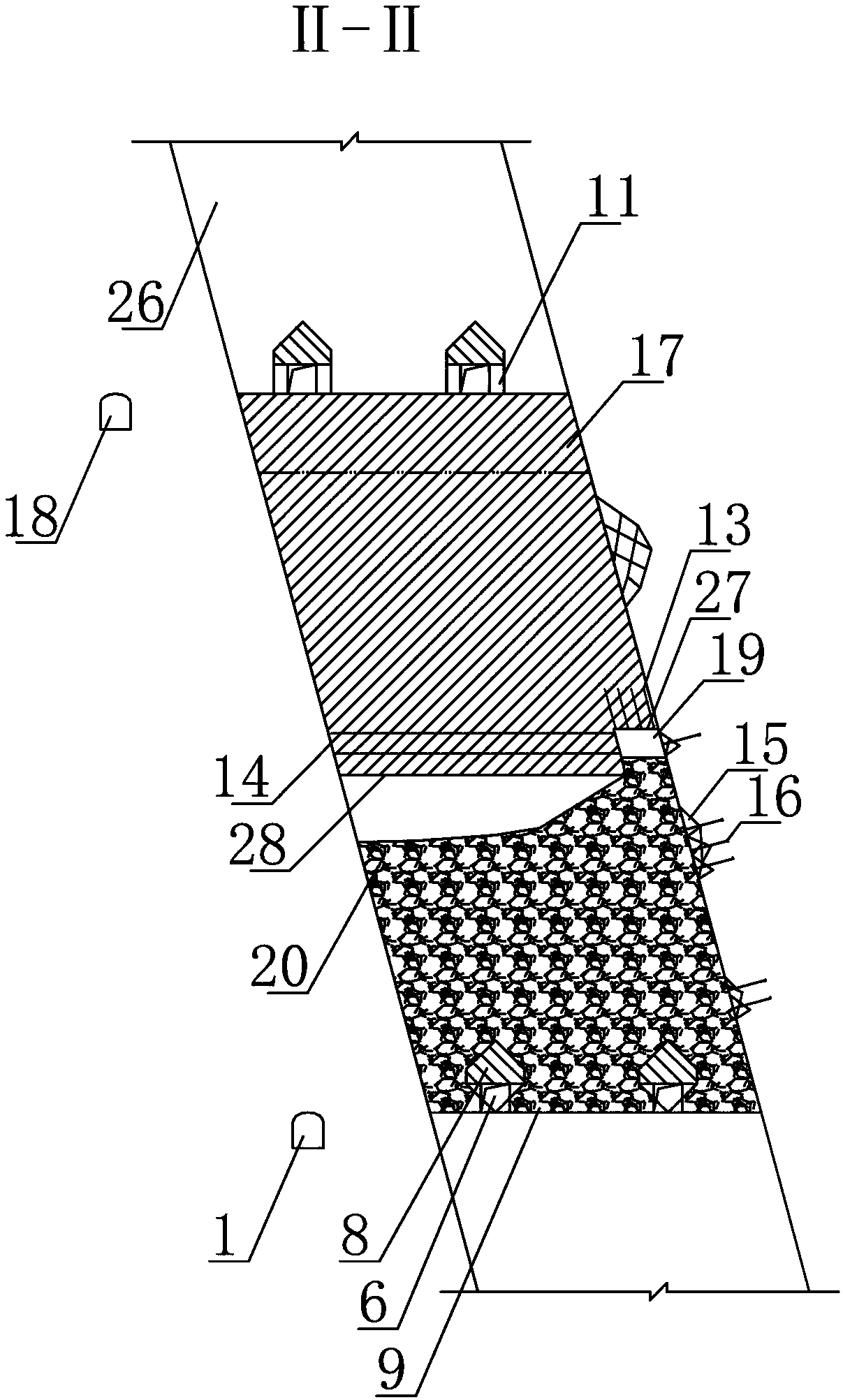

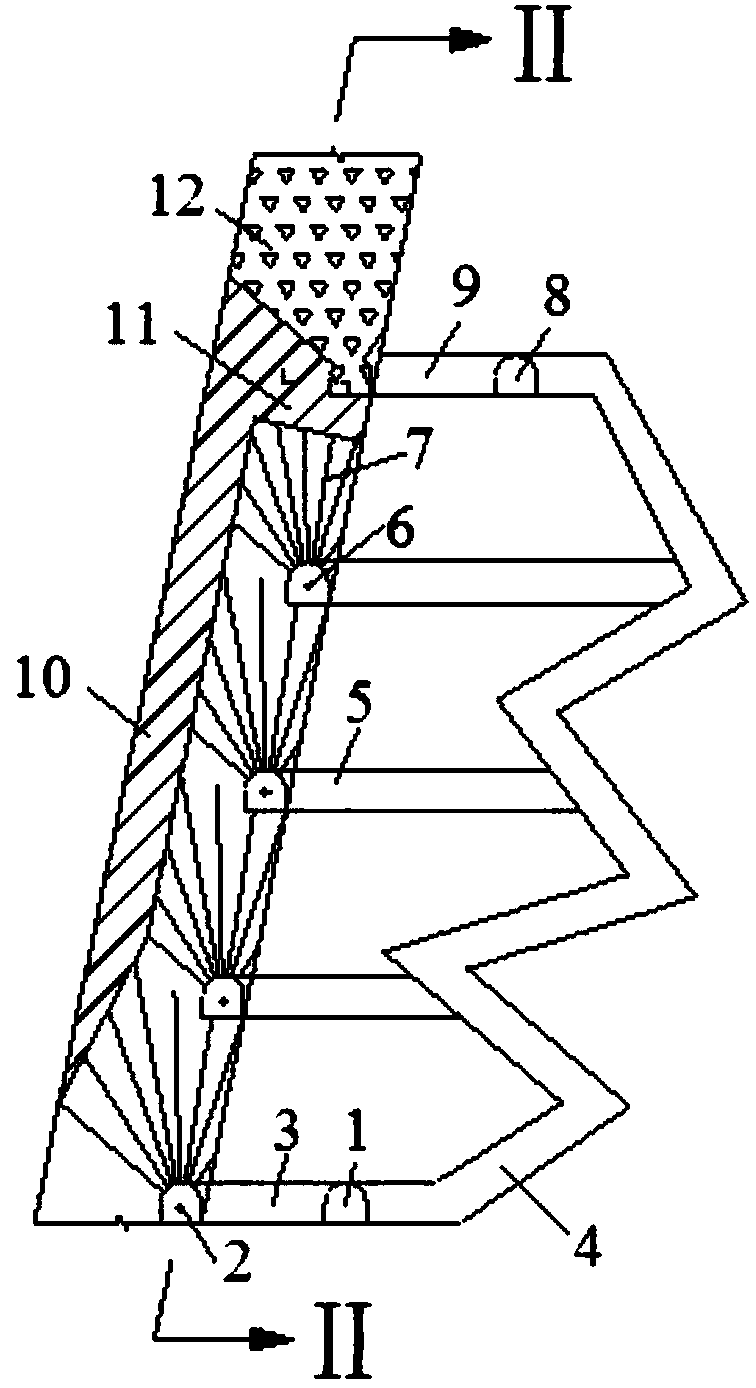

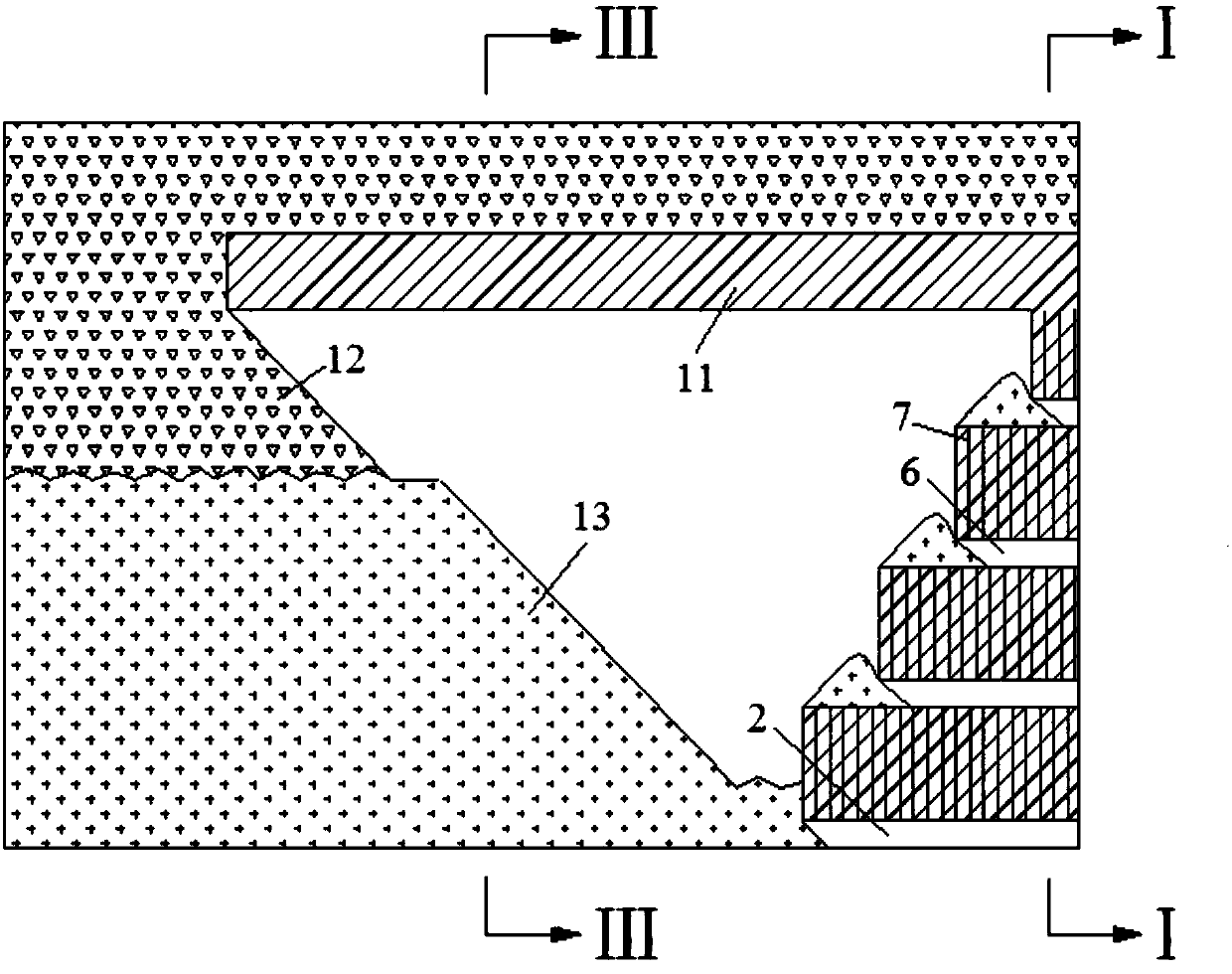

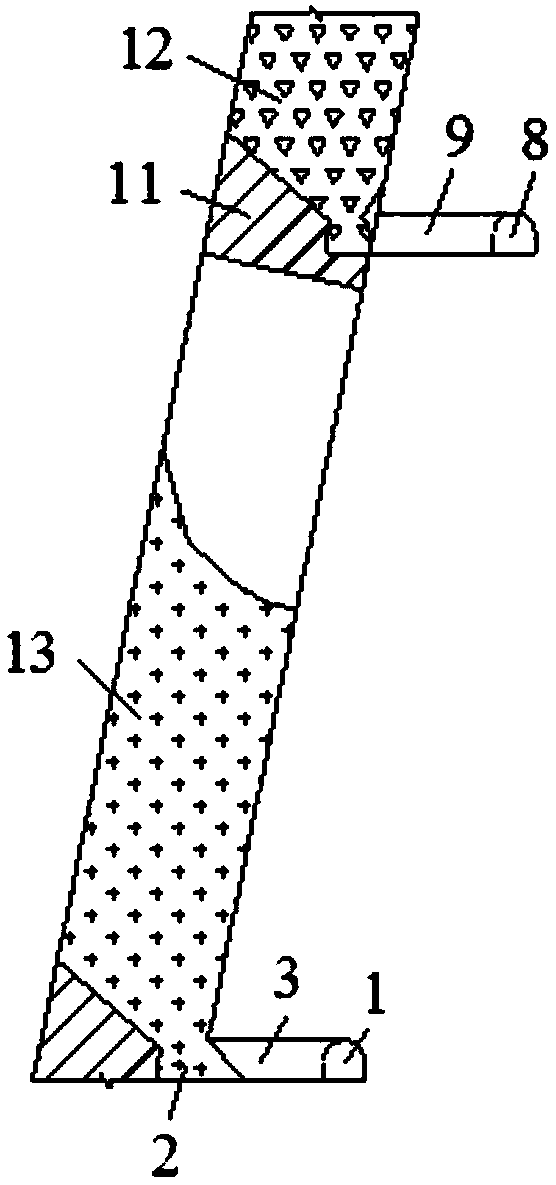

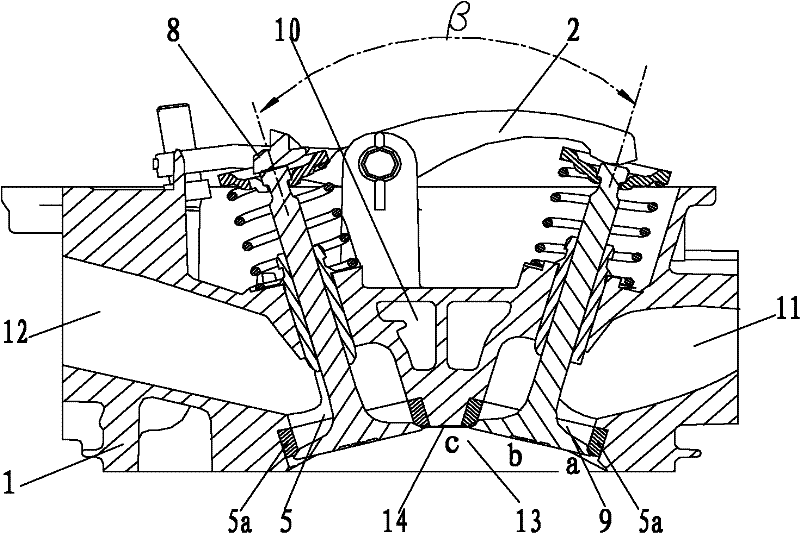

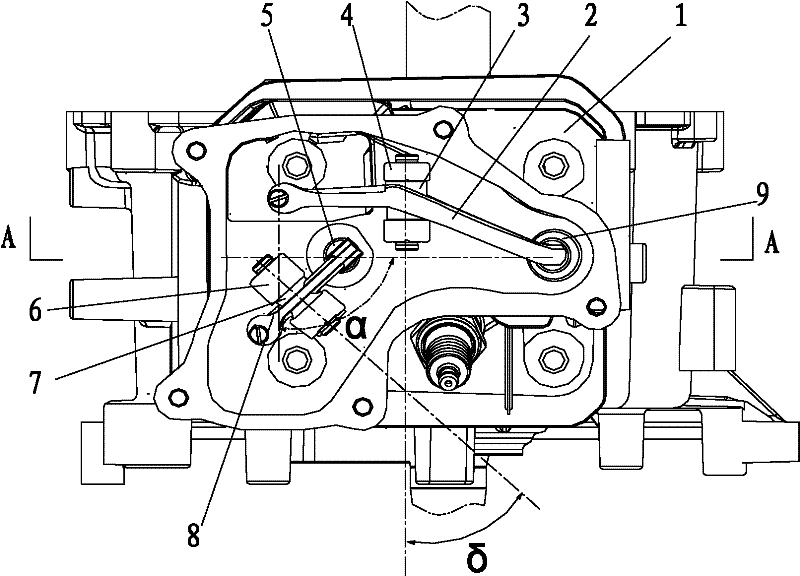

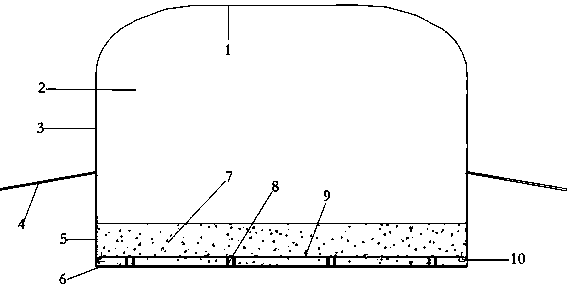

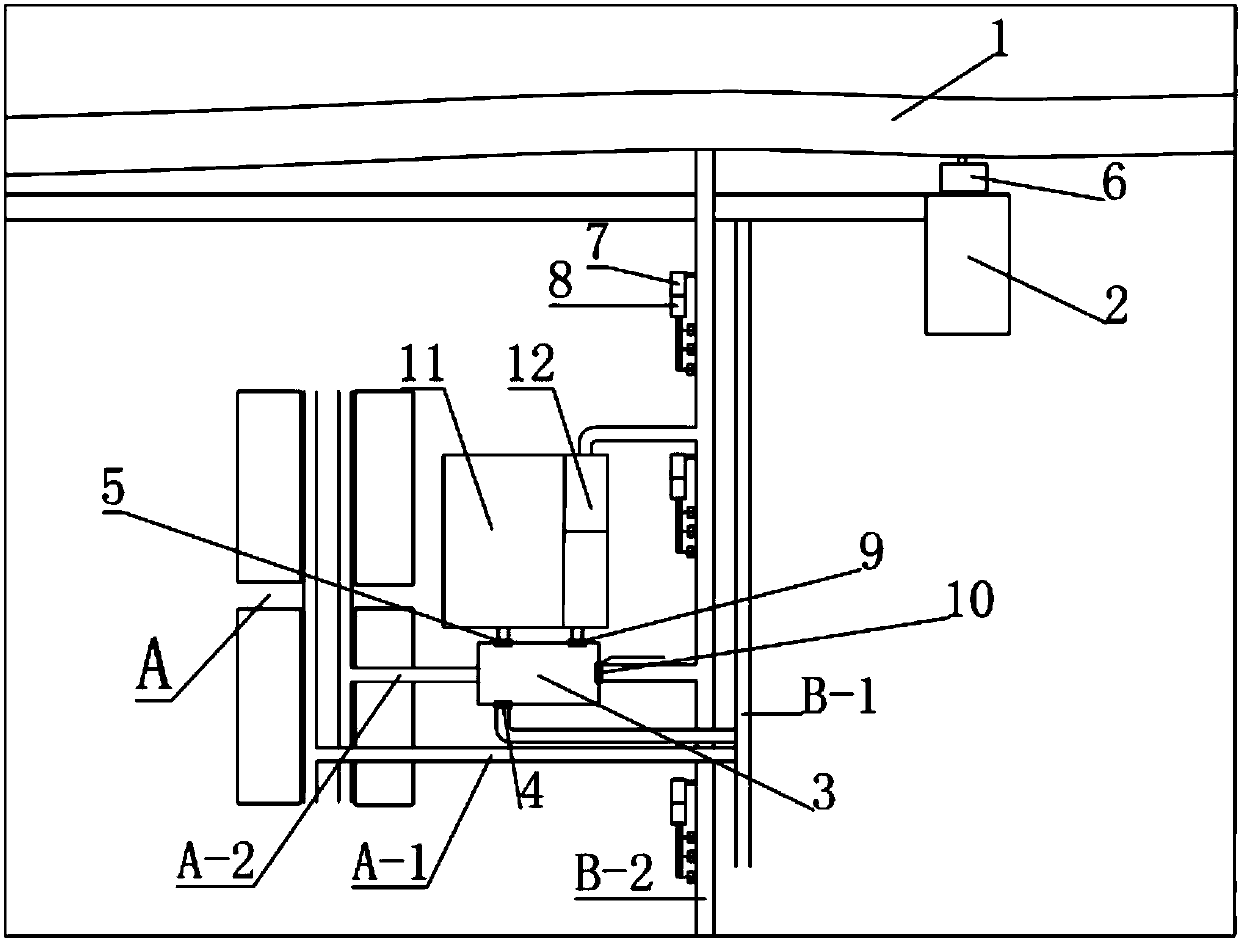

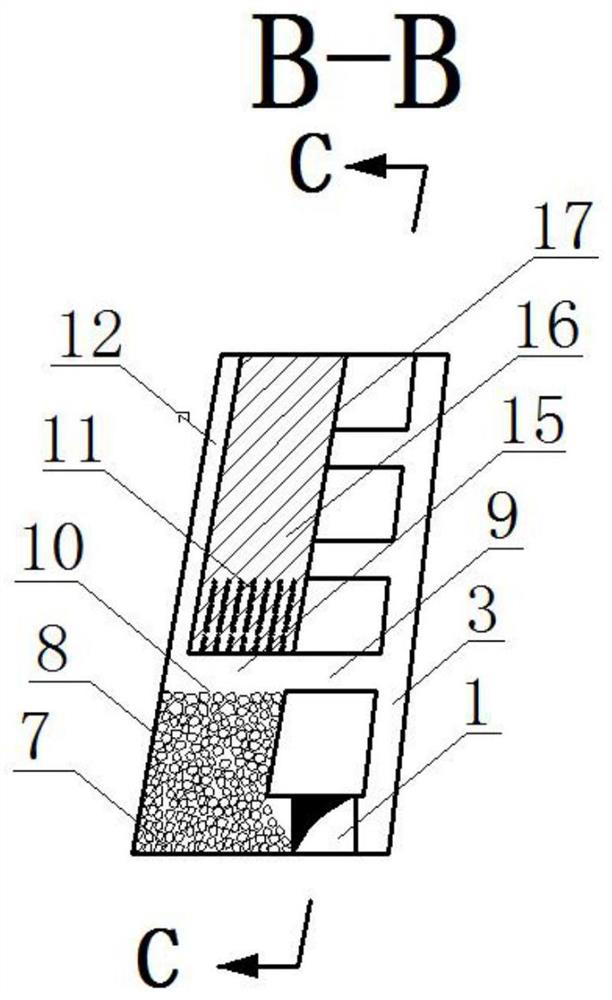

Multilayer gently-inclined extremely-narrow vein stoping blasting technology

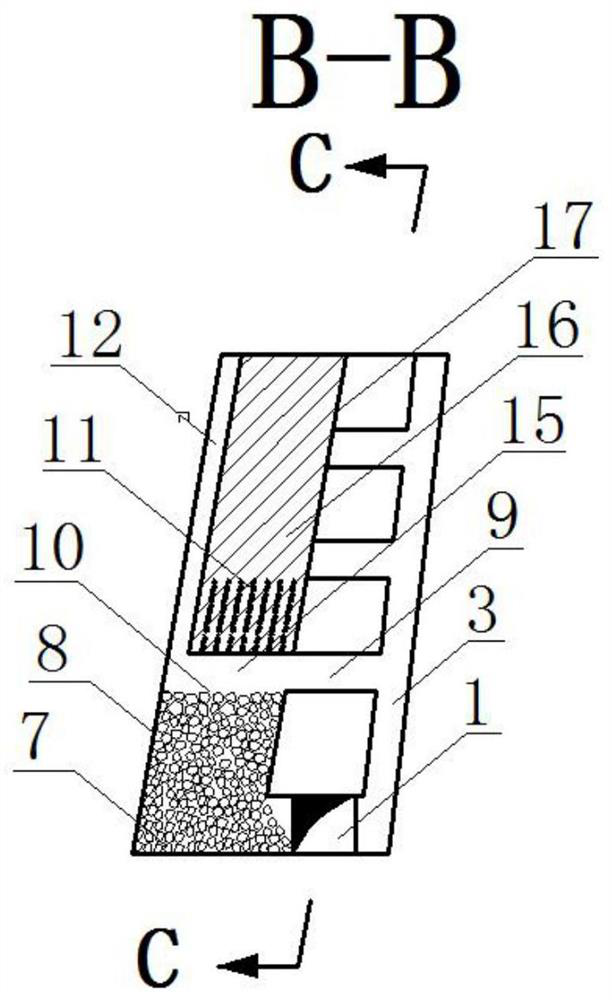

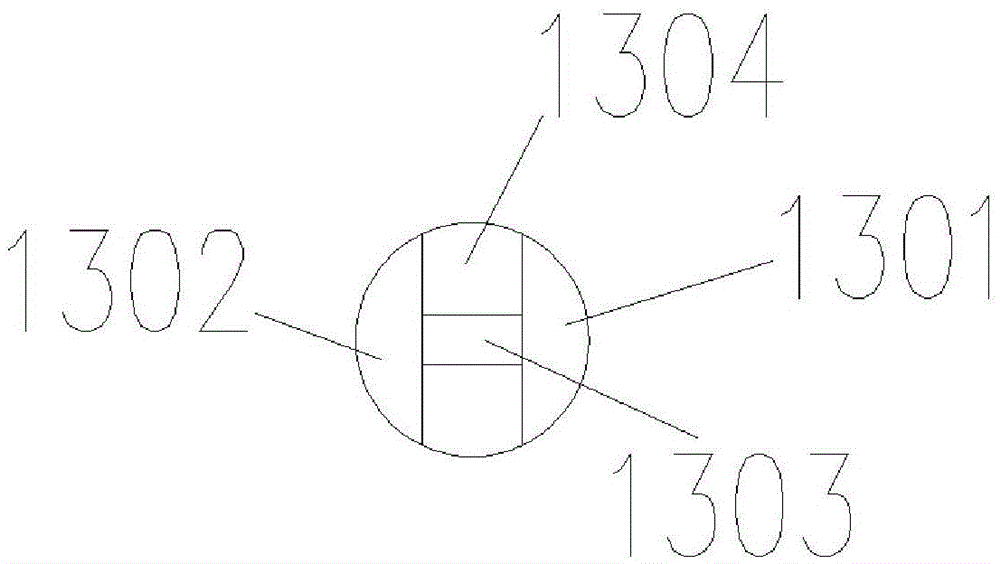

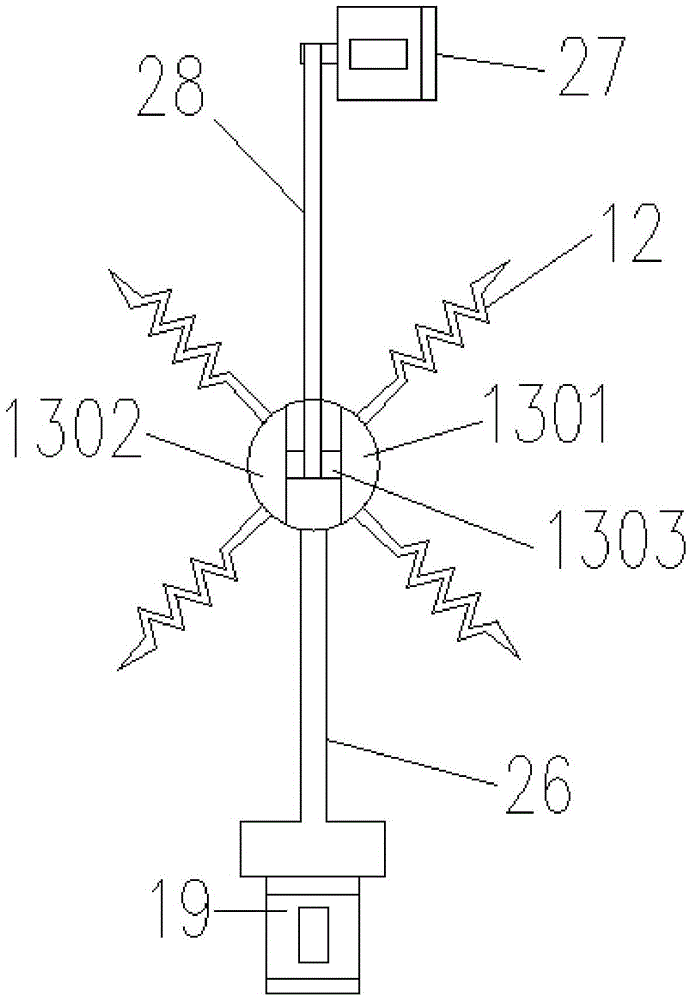

The invention discloses a multilayer gently-inclined extremely-narrow vein stoping blasting technology. In the technology, a top-to-bottom layer-by-layer blasting and layered stoping method is employed. An intensive blasthole (5) are dug in a first layered vein (1) and an upper rock layer boundary. First layered vein middle blasthole (6) are dug in the middle of the first layered vein (1). A vein and intercalated rock layer boundary blasthole (7) is dug in the boundary between the first layered vein (1) and an intercalated rock layer (2). An intercalated rock layer and vein boundary blasthole (9) is dug in the boundary between the intercalated rock layer (2) and a second layered vein (3). An intercalated rock layer middle blasthole (8) is dug in the middle of the intercalated rock layer (2). A vein and lower surrounding rock boundary blasthole (10) is dug in the boundary between the second layered vein (3) and the lower surrounding rock boundary. The technology can achieve synchronic recycle of multilayer veins. A buffer seam can weaken an effect of a blasting shock wave on surrounding rock during a stoping process and meanwhile intercalated rock can be directly removed so that a difficult problem that the intercalated rock is mixed with ores and an ore dilution rate is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

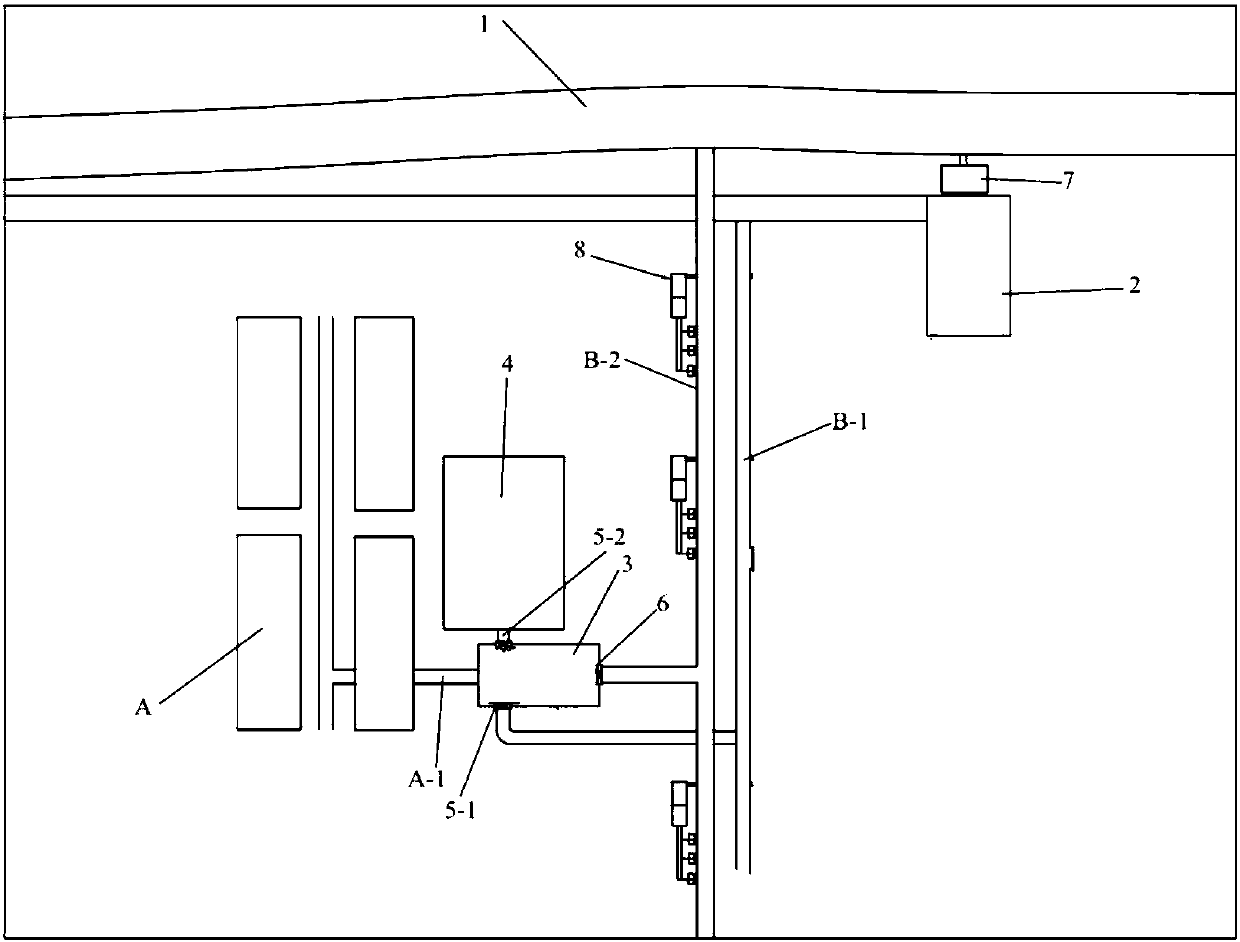

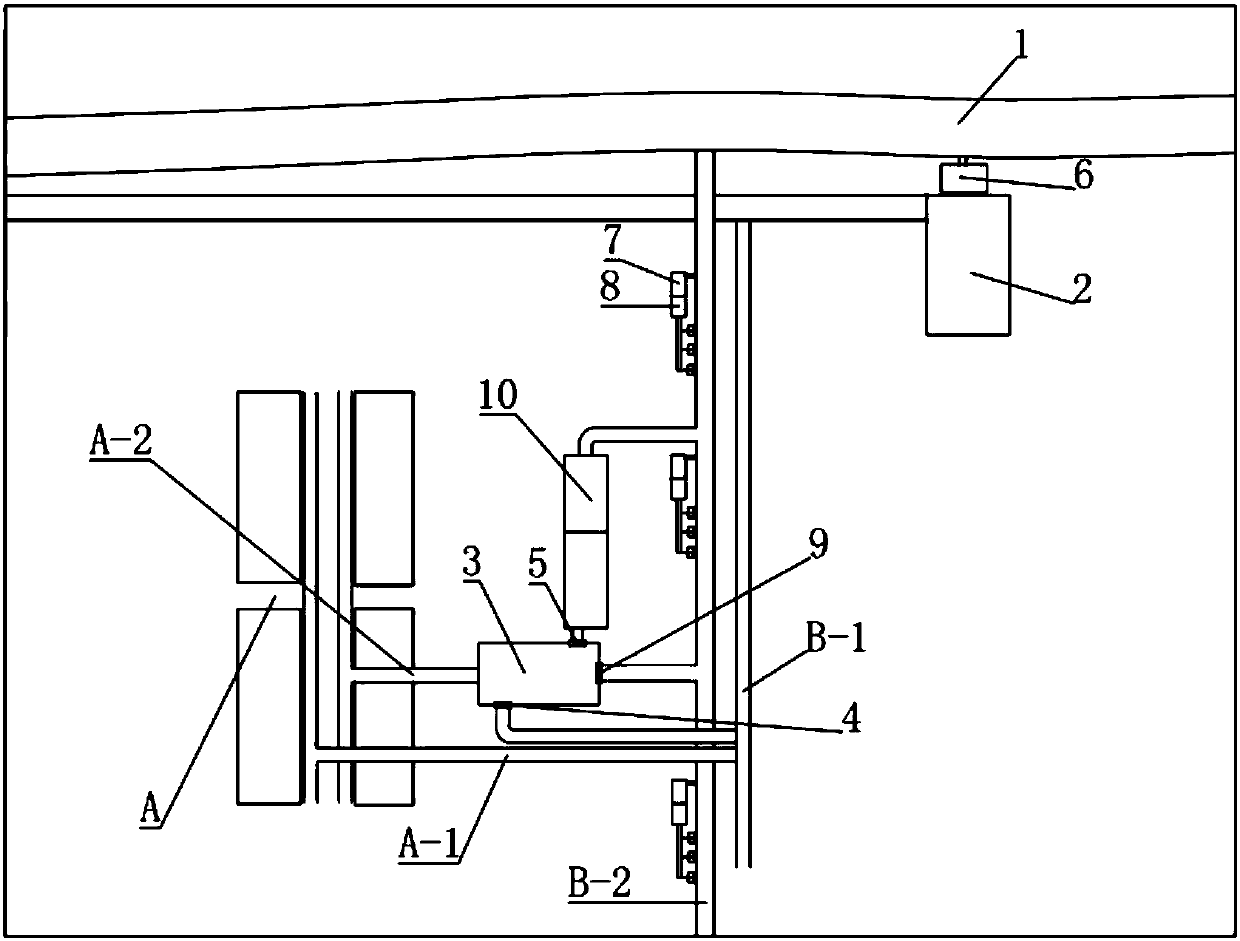

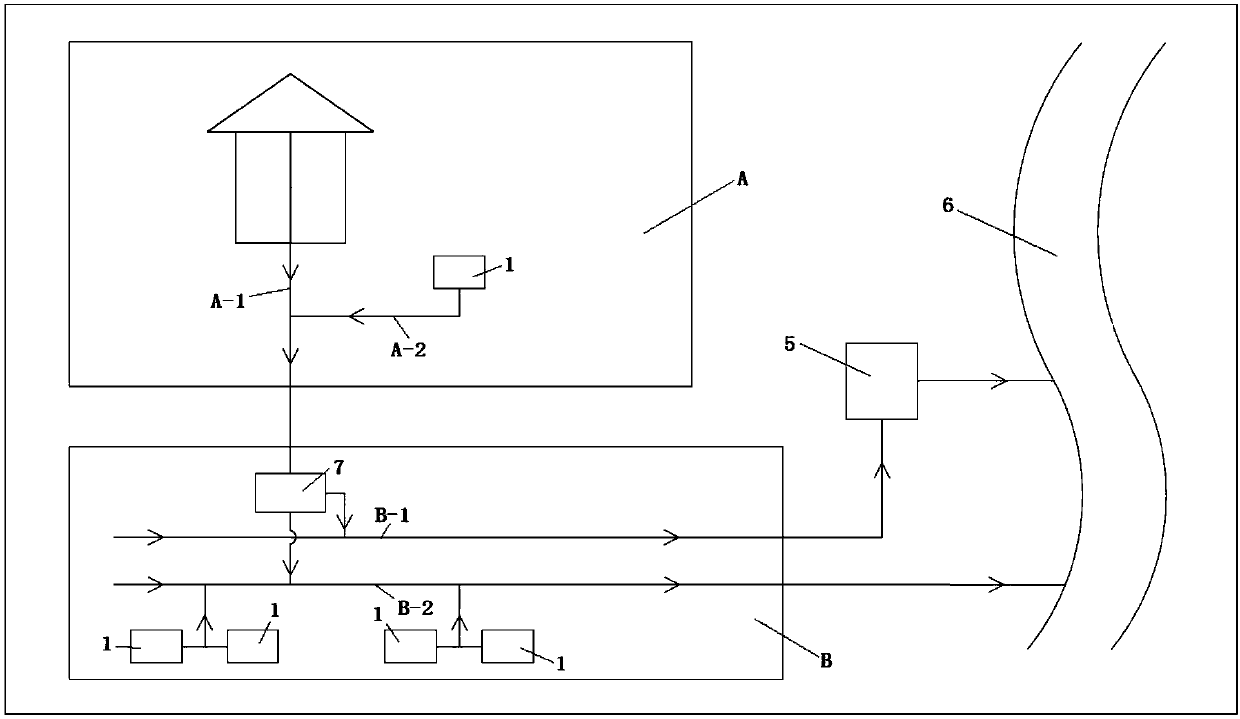

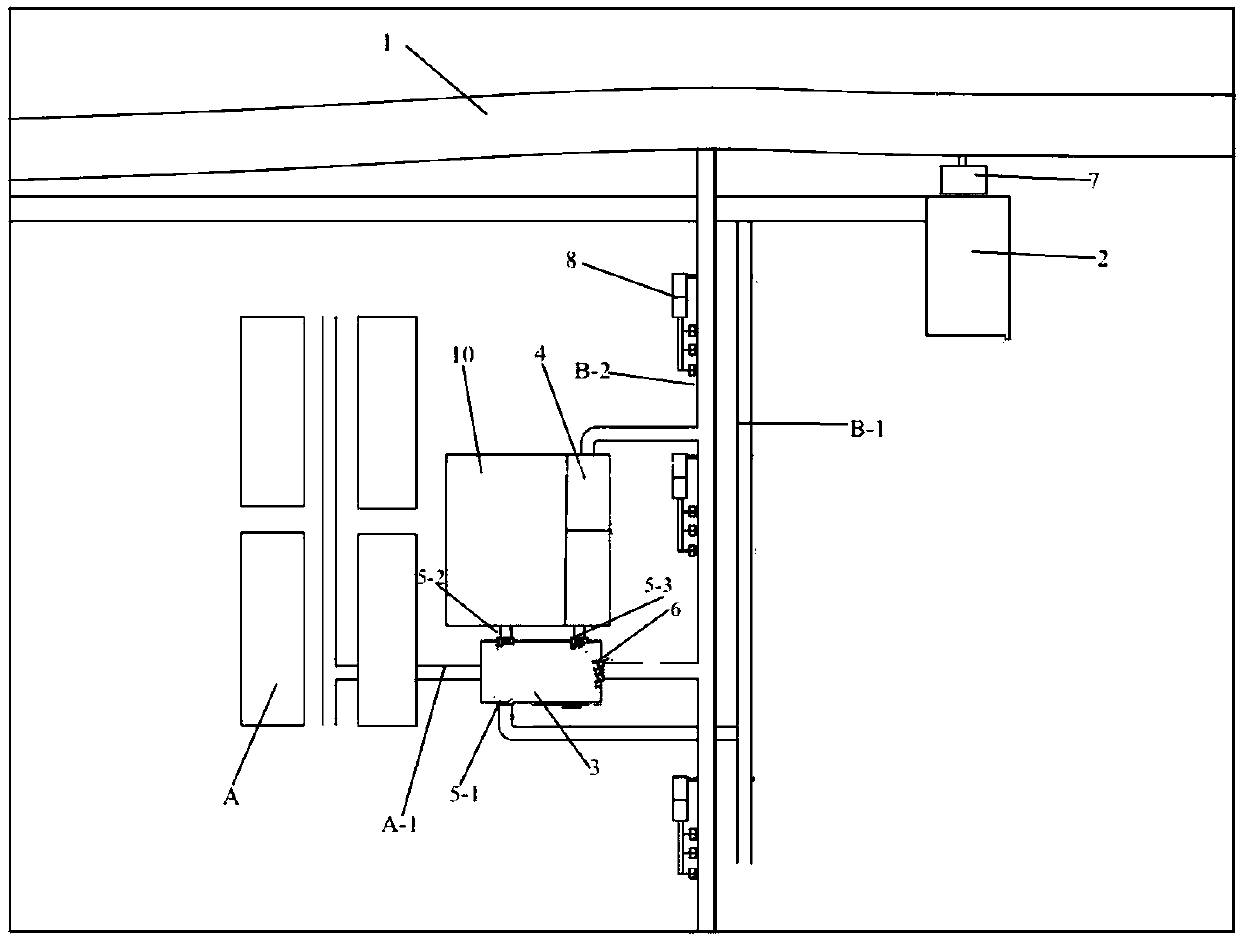

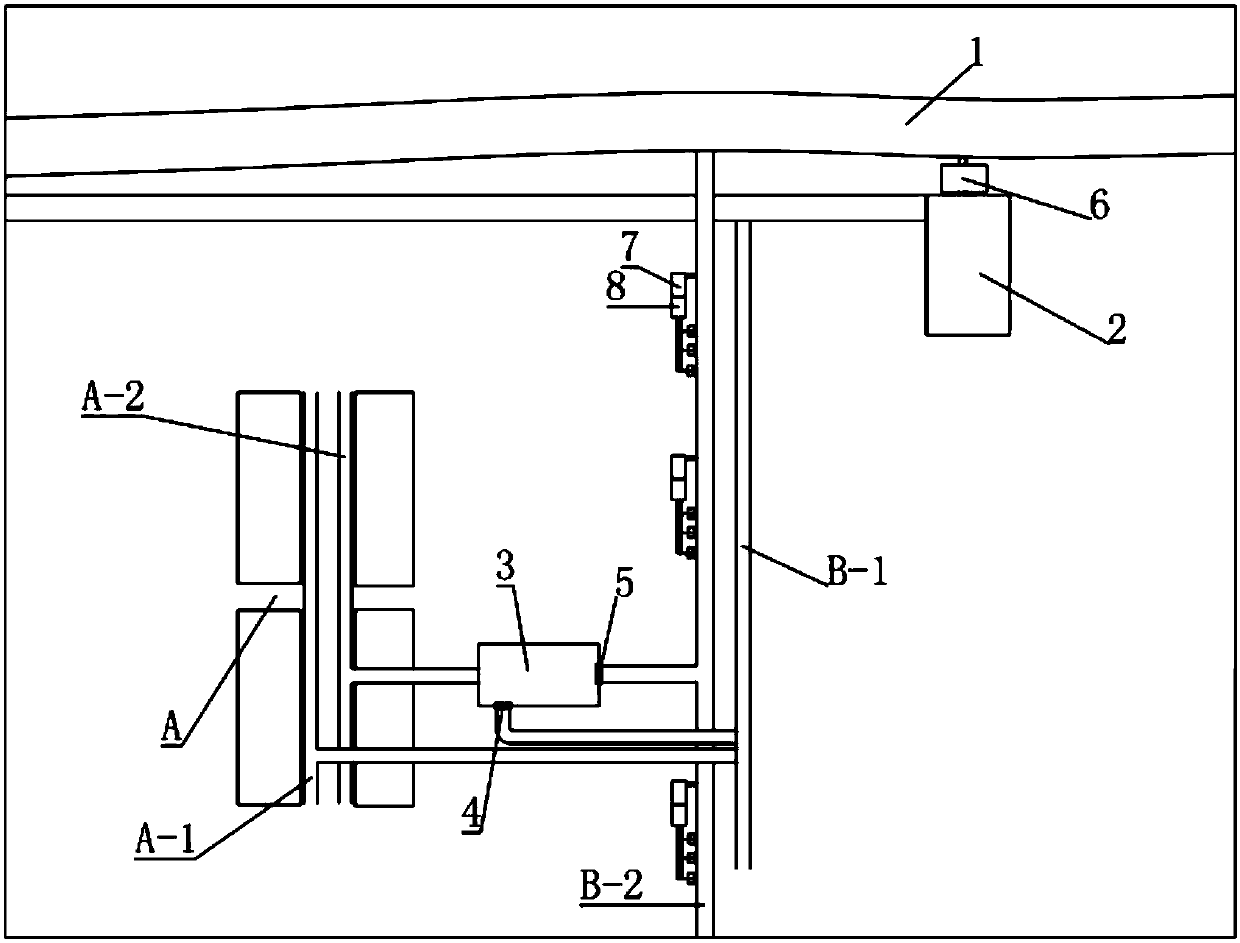

Combined water drainage system for sewage and rainwater and control method

PendingCN107806159AEasy to handleSimple structureFatty/oily/floating substances removal devicesSewerage structuresSewageEngineering

The invention relates to a combined water drainage system for sewage and rainwater. The system comprises a sewage trunk pipe arranged on a municipal road, a rainwater trunk pipe arranged on the municipal road, and a confluence header pipe for unit areas, wherein a sewage treatment plant is arranged at the outlet of the sewage trunk pipe; the tail end of the rainwater trunk pipe is connected with anatural water body; the outlet of the confluence header pipe is connected with the sewage trunk pipe; one or more flow distributing devices are arranged on the confluence header pipe, and the water inlet end of each flow distributing device communicates with the confluence header pipe; each flow distributing device is provided with three water outlets, each first water outlet is connected with the sewage trunk pipe, each second water outlet is connected with the rainwater trunk pipe, and each third water outlet is connected with a water inlet of a regulation and storage facility.

Owner:WUHAN SHENGYU DRAINING SYST

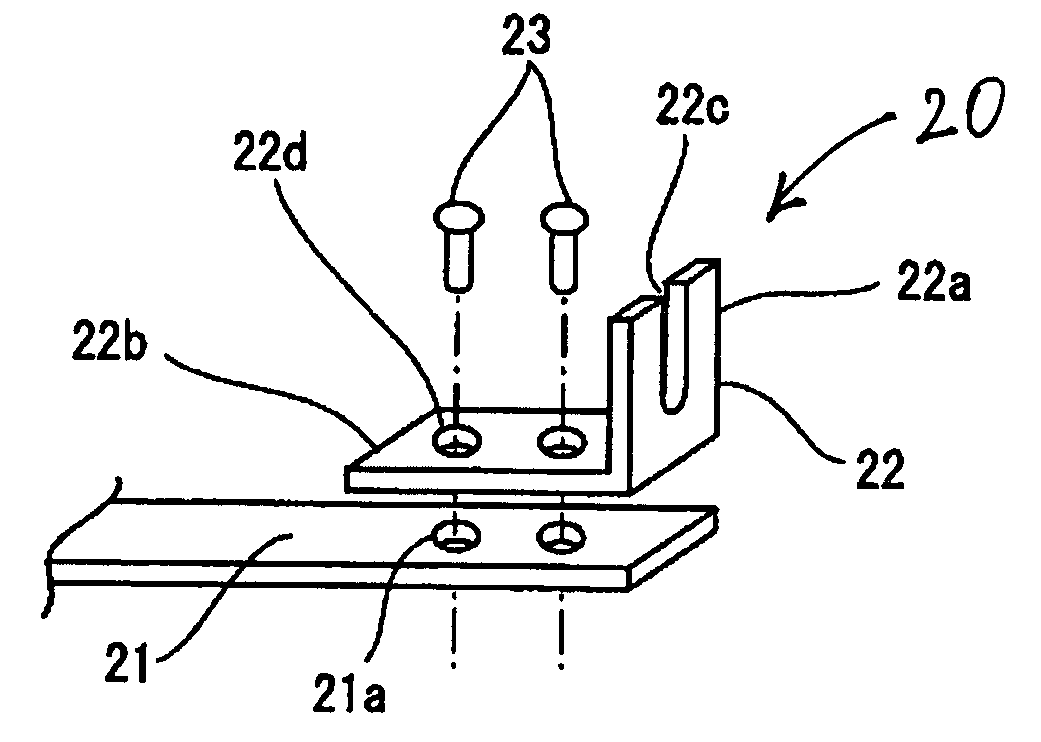

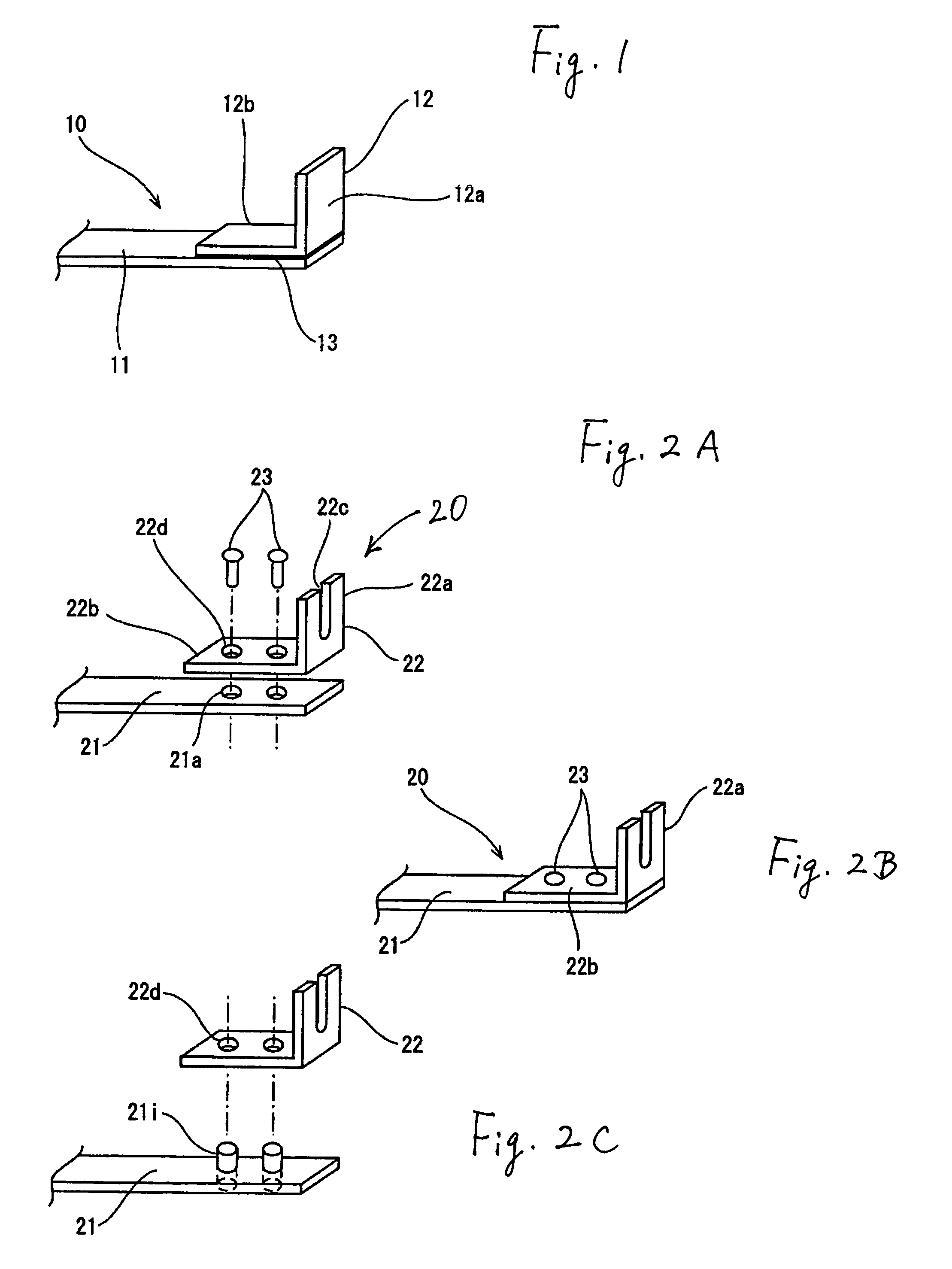

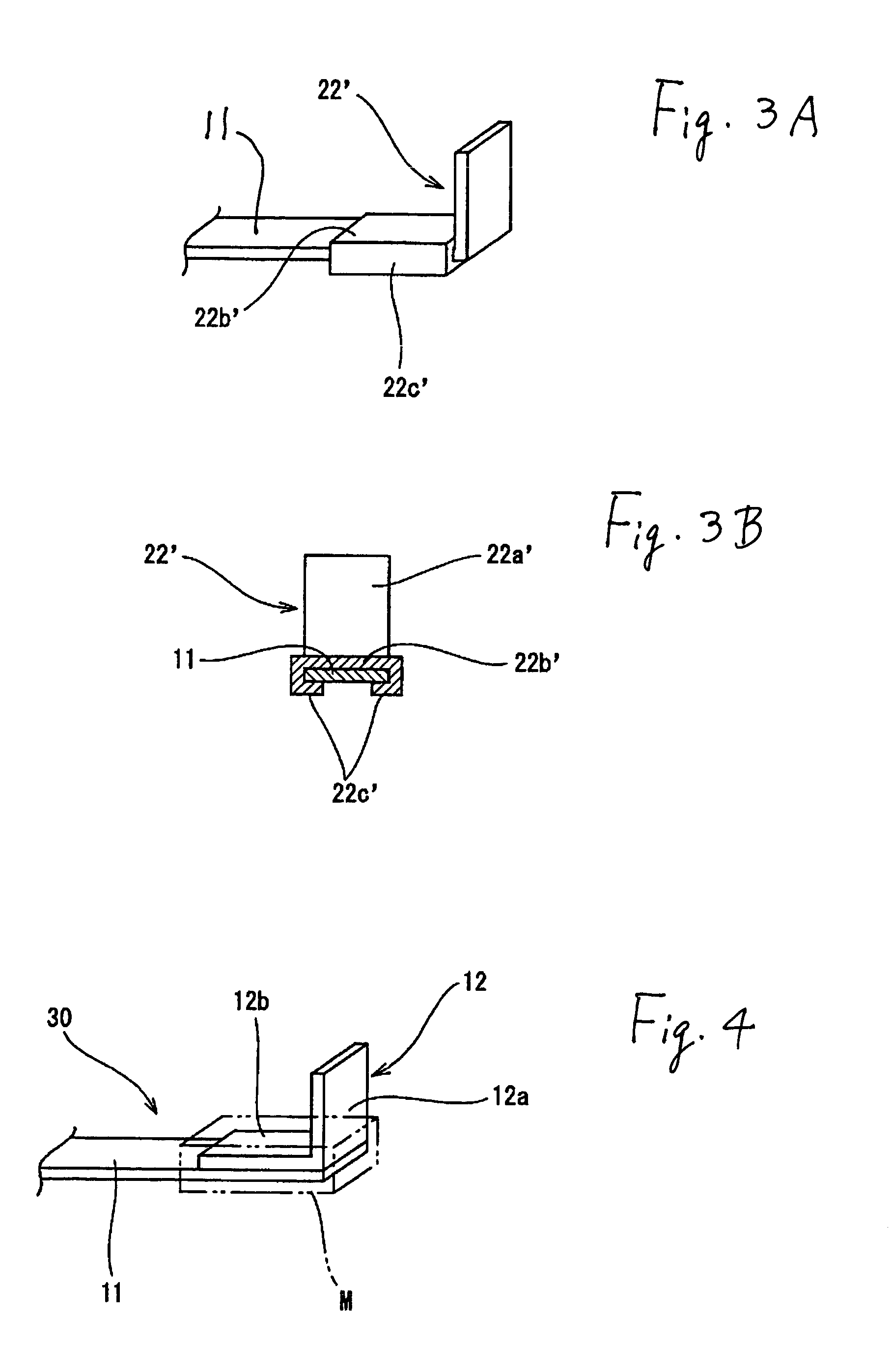

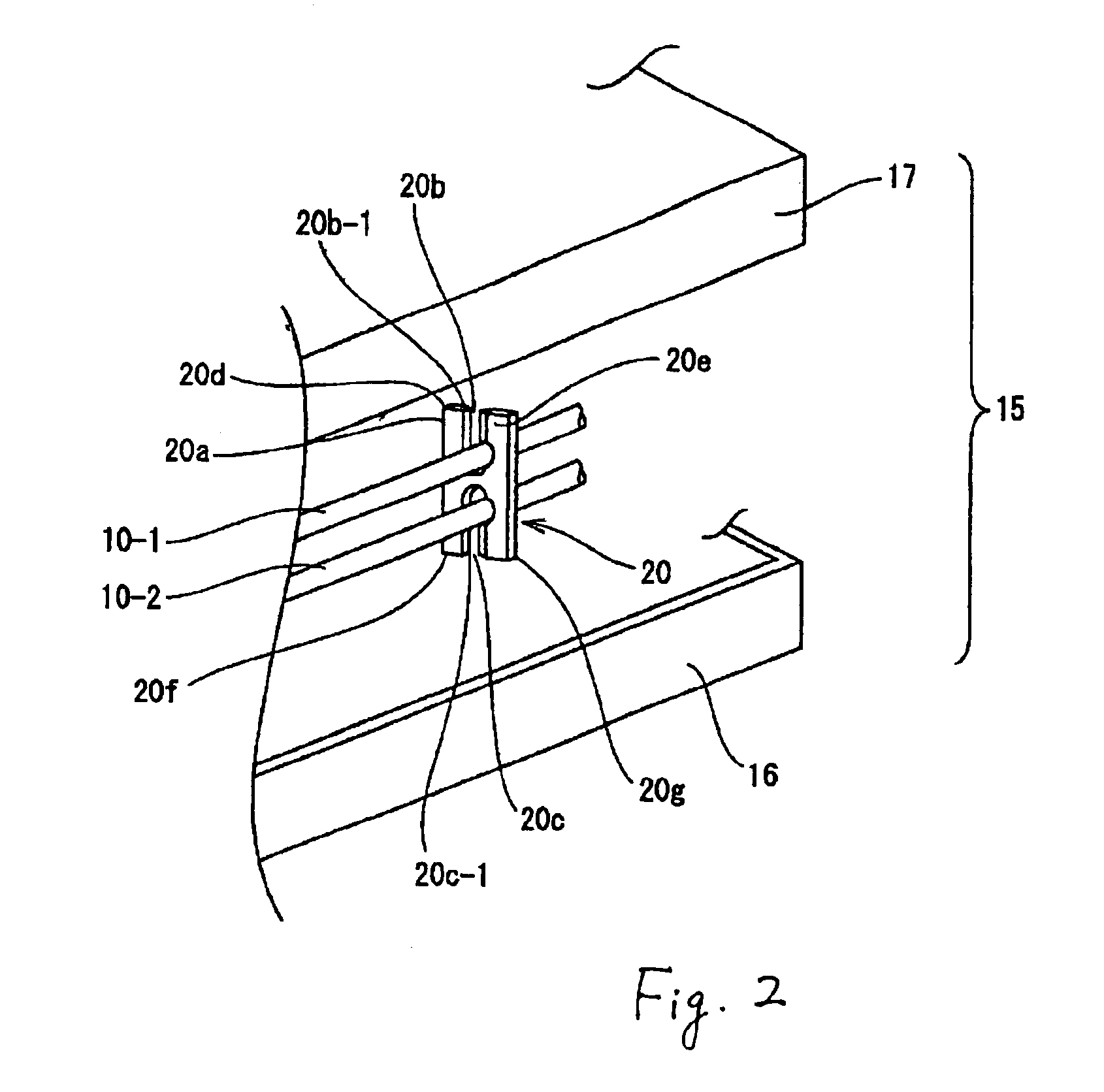

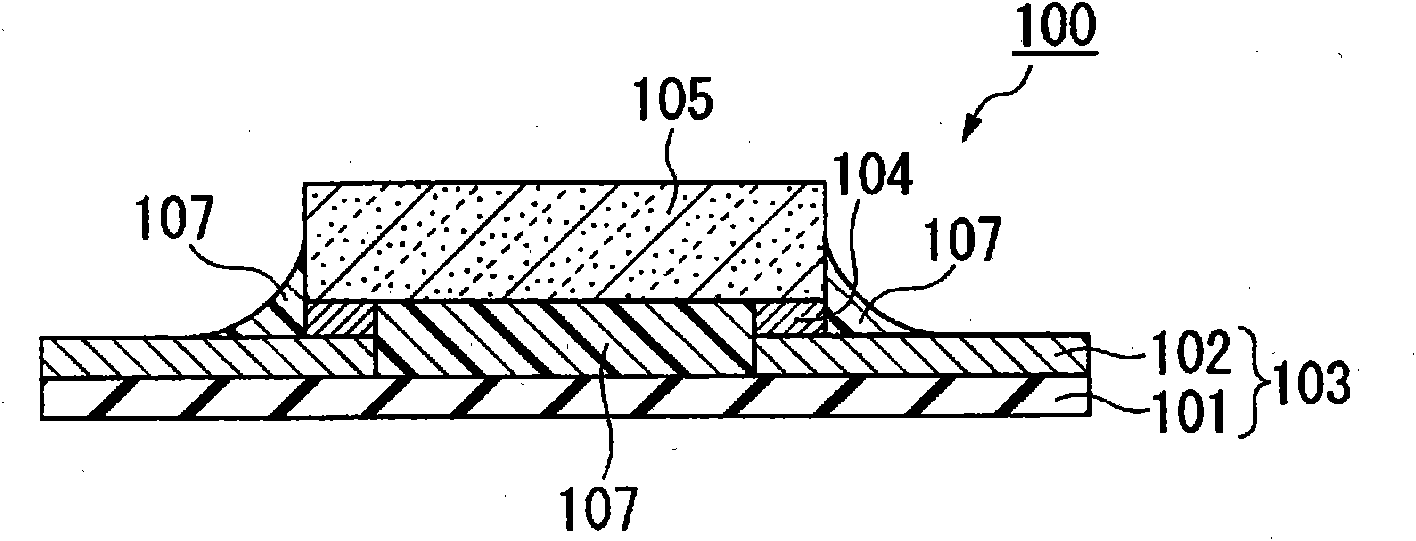

Bus bar with L-shaped terminals

InactiveUS7004798B2Reduce mixPromote recoveryPrinted circuit aspectsSoldered/welded conductive connectionsAdhesiveElectrical connection

A bus bar, with a desired circuit configuration contained in an electrical connection box to be mounted on an automobile, has an aluminum-based metal plate punched into a desired circuit configuration to form a flat plate-like circuit body. An L-shaped terminal piece is made from a copper-based metal plate. A horizontal portion of the L-shaped terminal piece is secured to the flat plate-like circuit body by welding a conductive adhesive, riveting, or caulking so that a vertical portion of the terminal piece projects from the circuit body to form a tab.

Owner:SUMITOMO WIRING SYST LTD

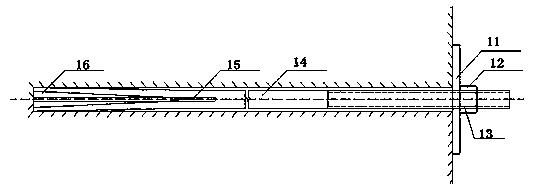

Recovery method of underground mine goaf remaining studs

ActiveCN111828007AImprove recovery rateReduce depletion rateUnderground miningBlastingMining engineeringWorking environment

The invention discloses a recovery method of underground mine goaf remaining studs. The recovery method comprises the following steps that an ore removal roadway is tunneled into a stub (16) on one side of a middle section transportation roadway (1) to reach an ore body hanging wall, and the top of the ore removal roadway is expanded by adopting a fan-shaped medium-length hole to form a horn-mouth-shaped bottom structure; a cutting raise (12) and a pedestrian ventilation raise (3) are arranged in the stud pillar hanging wall ore rock contact face and the footwall surrounding rock respectivelyand communicate with an upper middle section air return roadway, layered connection ways (9) are tunneled in the pedestrian ventilation raise (3) in the vertical direction at intervals of a certain height to reach the stud pillar footwall boundary, the operation links that upward parallel blast holes (11) are drilled layer by layer in circulating mode one by one from bottom to top, charging blasting, forced ventilation and caving ore discharging are conducted till whole interval column is completely mined, then the caved ore (7) is completely discharged through a carry-scraper and fills the goaf, the recovery rate of the stud ore is increased, the ore dilution rate is reduced, and the working environment of a working surface is improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Ming method for stoping high-dipping thick orebody with medium and above stability in ore mass

ActiveCN107939402AAvoid collapsing intoReduce mix rateUnderground miningSurface miningMineralogyDeep hole

The invention discloses a mining method for stoping a high-dipping thick orebody with the medium and above stability in an ore mass. The method comprises the steps that an inverted-stepped mining faceis arranged in the thickness direction of the orebody in an ore room, mining is advanced from bottom to top, the mining face part close to a hanging wall is ahead of the mining face part close to a lying wall by a certain height, the advanced mining height of the mining face part close to the hanging wall is utilized to provide an operation space, a shallow hole is drilled upwards in the operation space, and a horizontally parallel medium-length hole is drilled in the direction of the lying wall to blast and break ores; and an anchor rod is used for anchoring partial unstable rocks on the hanging wall in the operation space, a part of the mined ores is temporarily left in the ore room to serve as a protective bottom column and a buffer layer of the hanging wall and provide a standing platform for upward operation and temporarily bearing hanging wall rocks, and a large quantity of ores are removed after ore room exploration is completed. The mining method is beneficial for reducing mixing of waste rocks in the mining process of the high-dipping thick orebody and improving the recycling ratio of resources, the blackness of the ores is even, the stope preparation work amount is less,and rock drilling and blast working are easy to organize.

Owner:KUNMING METALLURGY COLLEGE

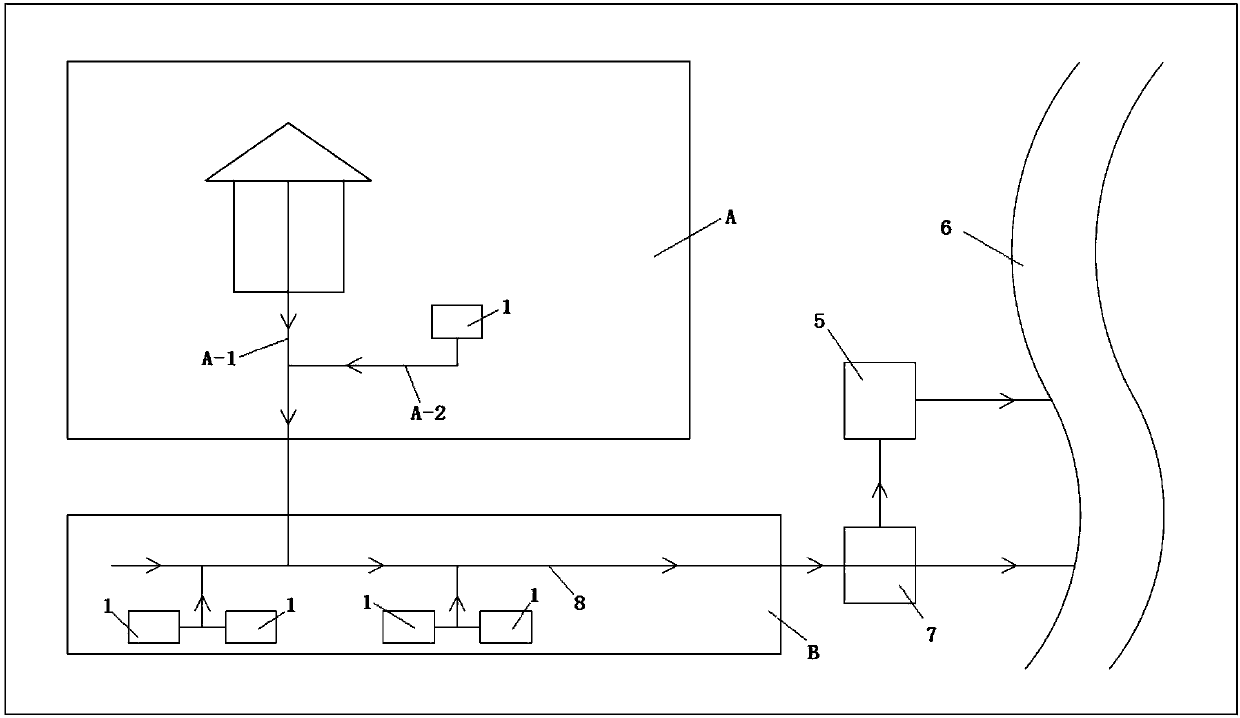

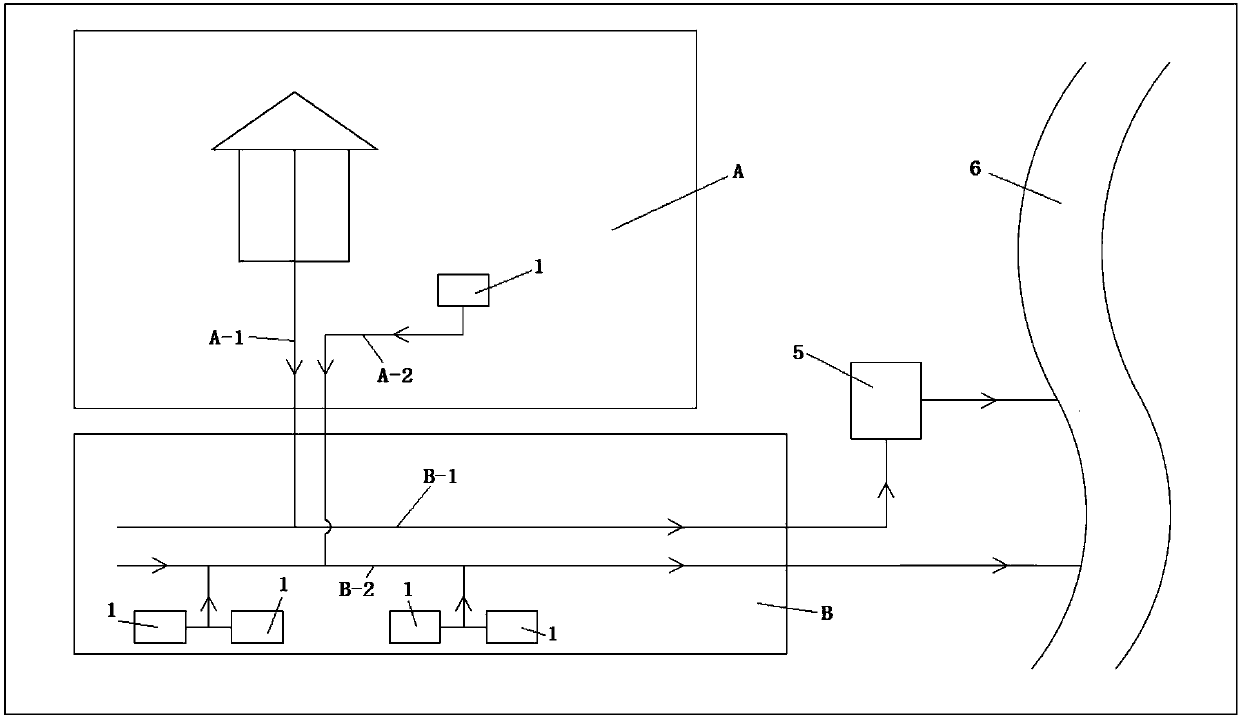

Sewage and rainwater separate drainage system and method for controlling same

InactiveCN107558567AEasy to handleSimple structureFatty/oily/floating substances removal devicesSewerage structuresShunt DeviceStormwater treatment

The invention provides a sewage and rainwater separate drainage system which comprises a sewage main pipe, a rainwater main pipe, a rainwater pipeline and a sewage pipeline. The sewage main pipe is arranged on a municipal road, and a sewage treatment plant is arranged at an outlet of the sewage main pipe; the rainwater main pipe is arranged on the municipal road, and the tail end of the rainwatermain pipe is connected with natural water; the rainwater pipeline and the sewage pipeline are arranged in a unit region, and the sewage pipeline is connected with the sewage main pipe; a rainwater treatment system is arranged at an outlet of the rainwater pipeline and comprises distribution equipment and an online treatment facility; the rainwater pipeline is connected with a water inlet of the distribution equipment, a first water outlet of the distribution equipment is connected with the sewage main pipe, a second water outlet of the distribution equipment is connected with the online treatment facility, and a third water outlet of the distribution equipment is connected with the rainwater main pipe. The sewage and rainwater separate drainage system has the advantages that the sewage andrainwater separate drainage system is simple in structure and convenient to construct, and only the distribution equipment and the online treatment facility need to be constructed in a limited regionof a residential area, so that mixed sewage in the region of the residential area can be efficiently treated.

Owner:WUHAN SHENGYU DRAINING SYST

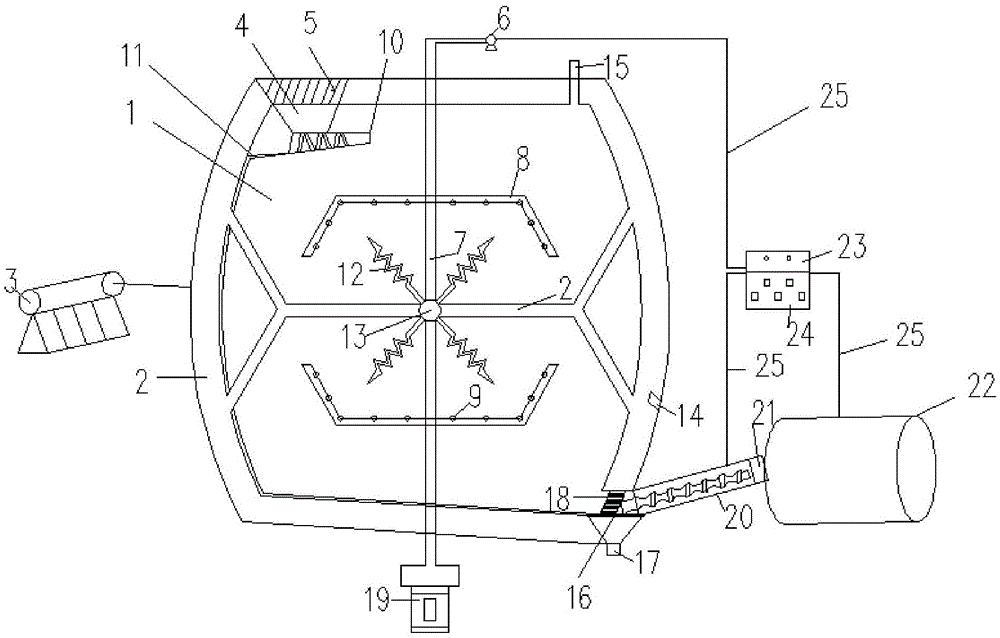

Household garbage fermentation and fertilizer making device and method

ActiveCN105461367AAvoid blockingBlocking implementationClimate change adaptationOrganic fertilisersFermentationScrew conveyor

The invention discloses a household garbage fermentation and fertilizer making device and method. A device body is a fermentation bin. A feed inlet and an air outlet are formed in the upper portion of the fermentation bin. A feeding baffle is arranged at the feed inlet. The lower portion of the fermentation bin is provided with a liquid outlet used for draining percolate and a discharge outlet used for outputting fermented materials. A breaking device is arranged in the fermentation bin and composed of a plurality of sets of breaking blades distributed in a cross shape, and has two perpendicular rotary dimensionalities. Household garbage to be treated passes through a spiral conveying machine through the feed inlet to enter the fermentation bin where a hot water pipeline is laid, is broken and fermented and then enters a dehydration pelleting and drying system from the position of a discharge baffle. According to the household garbage fermentation and fertilizer making device and method, breaking, stirring, heating, fermentation, dehydration pelleting and drying are integrated, garbage is converted into fertilizer, the energy is nature is effectively utilized, the running cost is reduced, the resources are effectively utilized while the environment problem is solved, the garbage is made profitable, and a new approach for effectively treating household garbage is provided.

Owner:ZHEJIANG UNIV

Non-point pollution control system for combined sewer system and control method thereof

PendingCN107747345ASimple structureEasy to buildSewerage structuresSewage drainingStormwater treatmentSewage

The invention discloses a non-point pollution control system for a combined sewer system and a control method thereof. The system comprises a trunk sewer, a storm-water sewer and rain and sewage pipes, and also comprises one or more unit areas, and a sewage pipe and a rainwater pipe are disposed in each unit area. Outlets of each sewage pipe and the corresponding rainwater pipe are communicated with an inlet of the corresponding rain and sewage pipe. Outlets of the rain and sewage pipes are connected with an inlet of the trunk sewer, and an outlet of the trunk sewer is provided with a sewage treatment plant. An outlet of the storm-water sewer is communicated with natural water. The non-point pollution control system is characterized in that the trunk sewer is provided with first rainwatertreatment systems, water inlets of the first rainwater treatment systems are communicated with the rain and sewage pipes, and drainage ends of the first rainwater treatment systems are respectively communicated with the trunk sewer and the storm-water sewer. The system and control method are simple in structure and convenient to construct, and efficient treatment of sewage and preliminary rainwater in regions divided by administrative functions in a city can be achieved just by building diversion treatment systems in the limited regions of municipal roads.

Owner:WUHAN SHENGYU DRAINING SYST

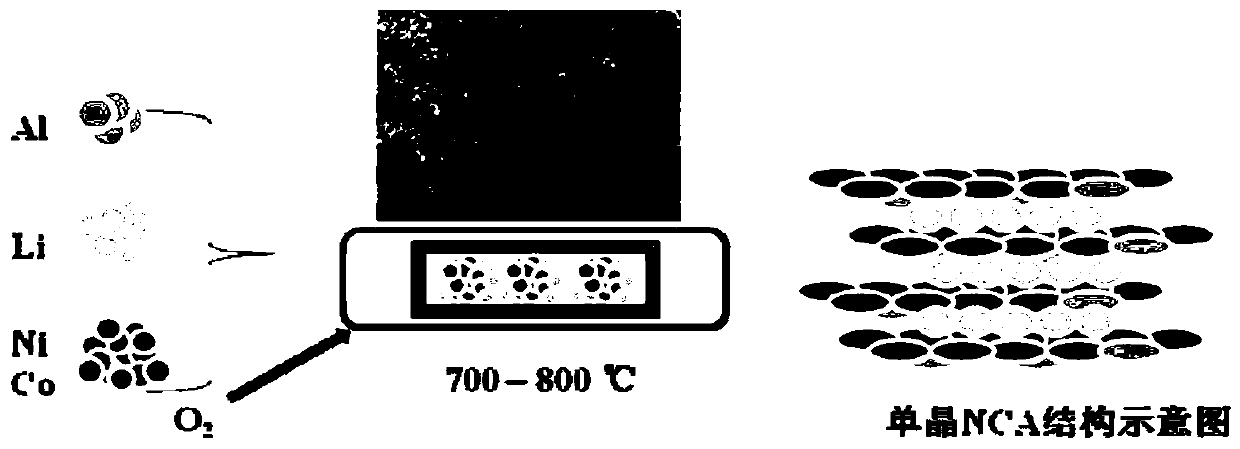

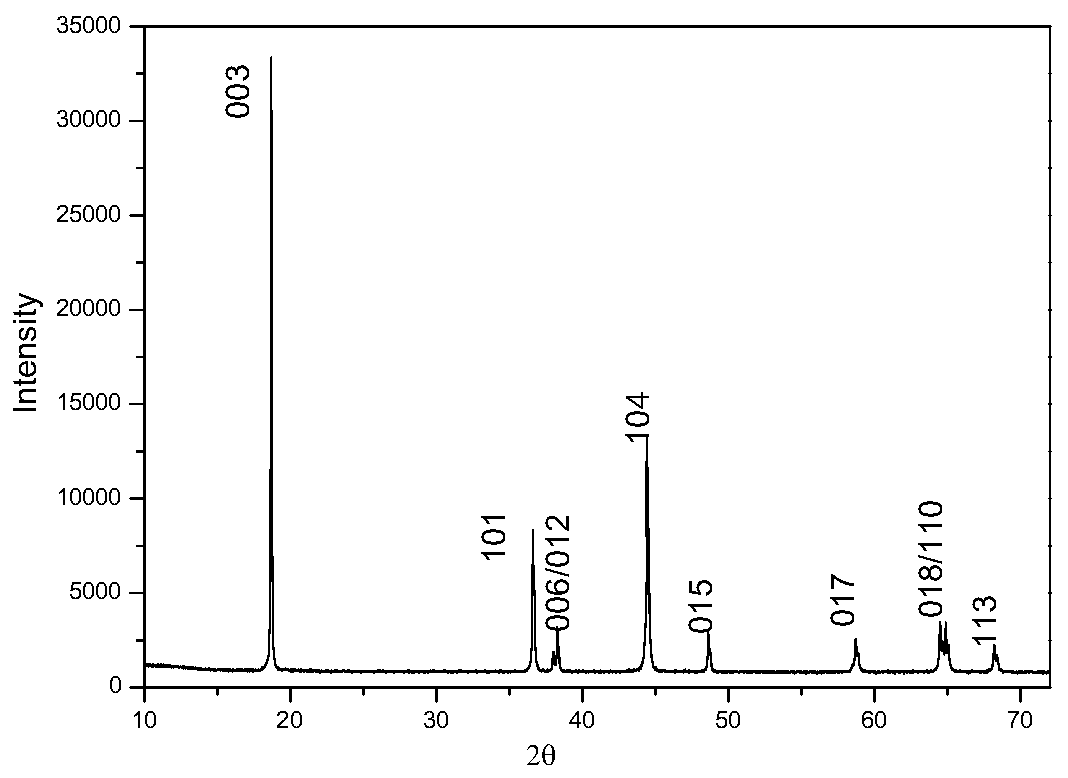

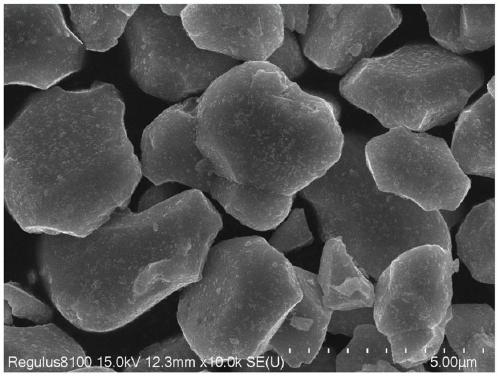

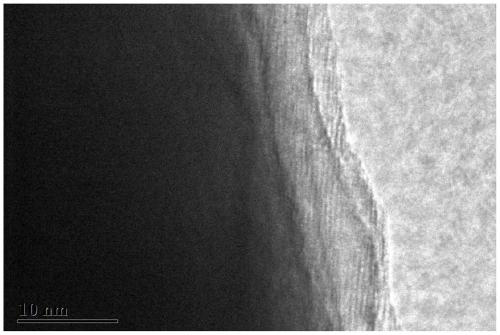

High-magnification monocrystal-like lithium nickel cobalt aluminate positive electrode material with coating layer and preparation method thereof

ActiveCN111009646AReduce usageReduce pollutionCell electrodesSecondary cellsAluminium hydroxideLithium hydroxide

The invention discloses a high-magnification monocrystal-like lithium nickel cobalt aluminate positive electrode material with a coating layer and a preparation method thereof, the preparation methodcomprises the following steps: (1) uniformly mixing a cobalt nickel hydroxide precursor and aluminum hydroxide, then adding lithium hydroxide, and continuously mixing to obtain a mixture; and (2) putting the material into a high-temperature-resistant container, sintering in an oxygen-enriched environment, cooling to room temperature, and sieving to obtain the monocrystal-like lithium nickel cobaltaluminate positive electrode material, (3) mixing the material with cold water, and controlling the washing time and the drying temperature to obtain the washed monocrystal-like lithium nickel cobaltaluminate positive electrode material; and (4) uniformly mixing the materials with a coating agent, continuously sintering under an oxygen-enriched condition, cooling to room temperature, and sievingto obtain a finished product. According to the invention, the stability of the monocrystal-like lithium nickel cobalt aluminate positive electrode material can be improved, so that the cycle performance and the rate capability of the positive electrode material are improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Combined water drainage system for sewage and rainwater and control method

InactiveCN107806160AEasy to handleSimple structureFatty/oily/floating substances removal devicesSewerage structuresEngineeringSewage treatment

The invention relates to a combined drainage system of sewage and rainwater, comprising: a main sewage pipe on a municipal road, the outlet of the main sewage pipe is provided with a sewage treatment plant; a main rainwater pipe on the municipal road, the main rainwater pipe The end of the junction is connected to the natural water body; the outlet of the confluence main pipe in the unit area is connected to the main sewage pipe; it is characterized in that: a diversion device is arranged on the confluence main pipe, and the water inlet end of the diversion device is communicated with the confluence main pipe; The diversion device has five openings, namely the water inlet, the first water outlet, the second water outlet, the third water outlet and the fourth water outlet, the first water outlet is connected to the main sewage pipe, and the second water outlet is connected to the The rainwater main pipe is connected; the third water outlet is connected with the water inlet of the regulation and storage facility; the fourth water outlet is connected with the water inlet of the online rainwater treatment facility, and the water outlet of the online rainwater treatment facility is connected with the rainwater main pipe.

Owner:WUHAN SHENGYU DRAINING SYST

Induced-falling mining method for steep medium-thickness ore with hanging side containing unstable rock stratum

The invention belongs to the technical field of mining engineering, and particularly relates to an induced-falling mining method for steep medium-thickness ore with the hanging side containing an unstable rock stratum. Ore is crushed by mining pressure, so that the falling time of unstable surrounding rock at the hanging side is prolonged, the ore stope environment is improved, ore loss and dilution is lowered, and production efficiency is improved. The induced-falling mining method is particularly suitable for steep medium-thick ore and steep thick ore which have the features that surroundingrock at the hanging side is poor in stability, ore is hard but has developed joint fissure, and surrounding rock at the heading side is moderately stable.

Owner:ANSTEEL GRP MINING CO LTD

Sewage and rainwater combined drainage system and control method

PendingCN107806156ASimple system structureEasy to buildFatty/oily/floating substances removal devicesSewerage structuresStormwaterEngineering

The invention relates to a sewage and rainwater combined drainage system, which comprises a sewage main pipe on a municipal road, a rainwater main pipe on the municipal road, and a confluence header pipe in a unit area, wherein a sewage treatment plant is arranged at the outlet of the sewage main pipe; the tail end of the rainwater main pipe is connected to a natural water body; and the outlet ofthe confluence header pipe is connected to the sewage main pipe; the drainage system is characterized in that one or more flow distributing devices are arranged on the confluence header pipe; the confluence header pipe is connected to a water inlet of each flow distributing device; the first water outlet of each flow distributing device is connected to the sewage main pipe; and the second water outlet is connected to the rainwater main pipe.

Owner:WUHAN SHENGYU DRAINING SYST

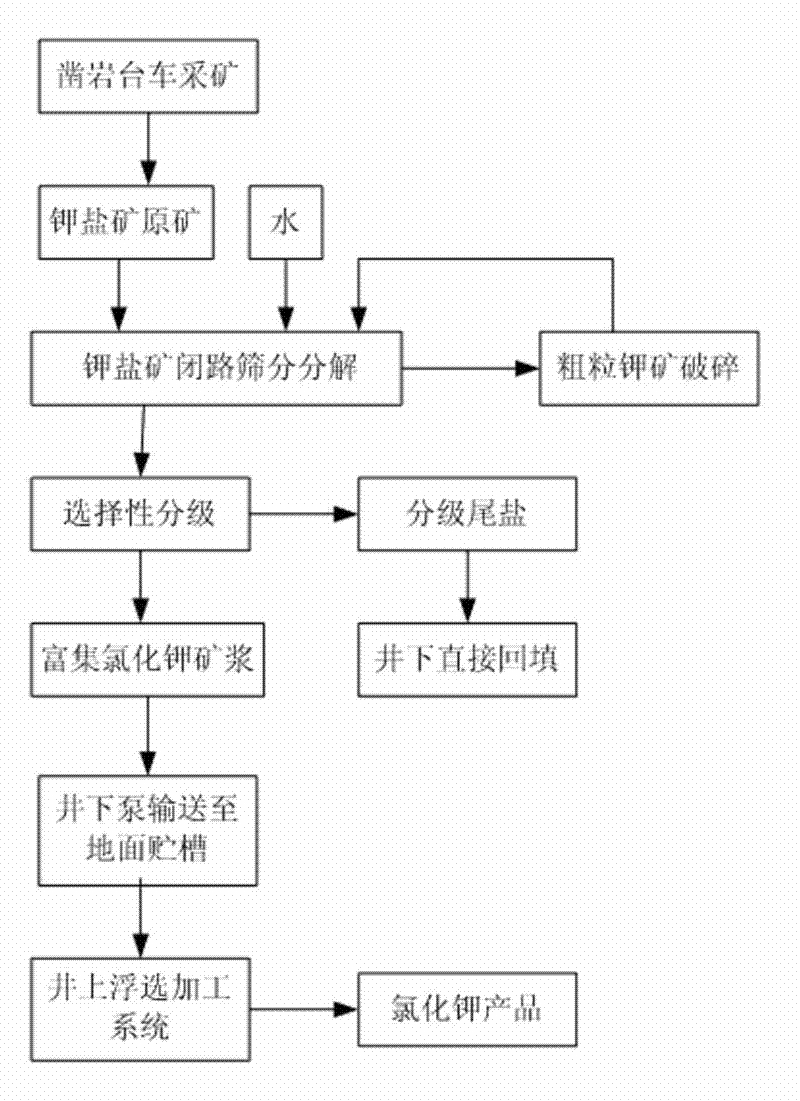

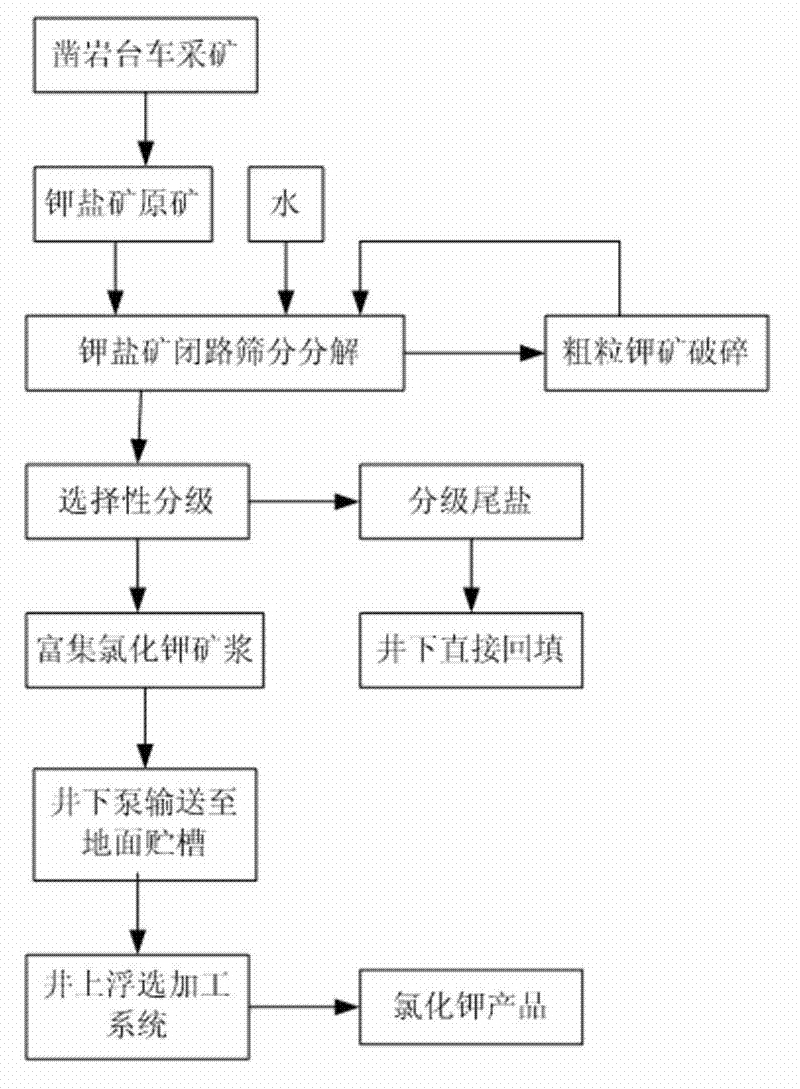

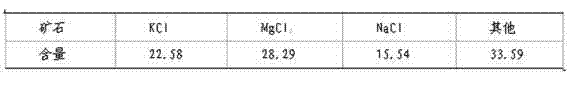

Method for producing enriched potassium chloride by downhole fractional decomposition of solid potash salt ore

The invention provides a method for producing enriched potassium chloride by downhole fractional decomposition of solid potash salt ore, belongs to the technical field of chemical mineral processing, and in particular relates to a dry mining process of land burial carnallite potash salt ore, and the dry mining process is one of technological processes for improving the mining capability of the potash salt ore and lowering the production and backfill cost of potassium chloride. The method comprises the following process flows: mining the land burial carnallite potash salt ore by a drill jumbo to obtain raw solid potash salt ore; sieving the raw potash salt ore for decomposition in a downhole closed-circuit manner; selectively grading to obtain enriched potassium chloride slurry; conveying the slurry to ground through a pump; and finally producing the potassium chloride product by a flotation system. The method provided by the invention has the remarkable beneficial effects that under the existing investment conditions of lifting the potash salt ore to the ground by a vertical shaft and then producing the potassium chloride, the potassium chloride slurry is enriched by directly adopting underground mining and vertical shaft facilities, thus greatly improving the capability of the existing solid potash salt ore for producing the potassium chloride and greatly lowering the production cost and tailings backfill investment. Therefore, the method is applicable to producing the potassium chloride fertilizer product by downhole dry mining and processing of the land burial carnallite potash salt ore, thus achieving high industrial popularization value.

Owner:YUNNAN CHEM RES INST

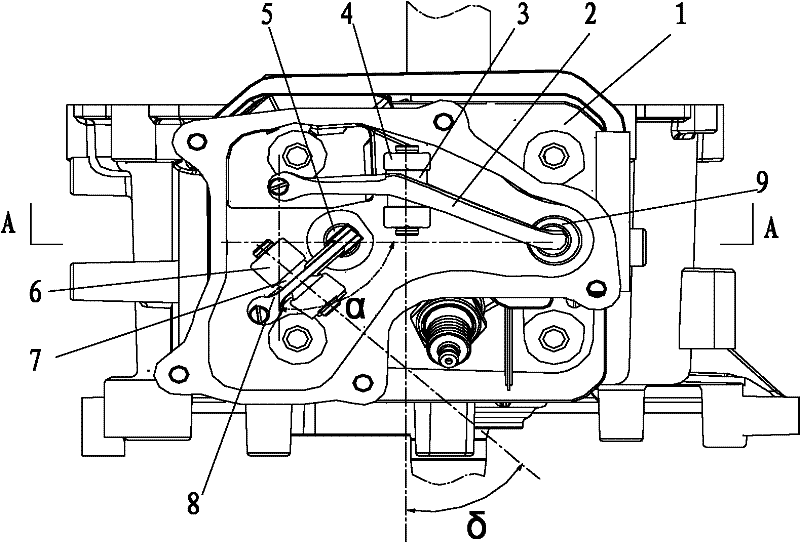

Cylinder head for arched combustion chamber and gasoline engine employing same

InactiveCN102305143AReduce consumption rateIncrease motivationInternal combustion piston enginesCylinder headsCombustion chamberCylinder head

The invention discloses a cylinder head for an arched combustion chamber and a gasoline engine employing the cylinder head. The cylinder head comprises a cylinder head body, wherein a combustion chamber face is formed on the inner side of the cylinder head body; the combustion chamber face has an arched face structure consisting of smooth curved surfaces; the surface to volume ratio of the combustion chamber can be reduced further, the working efficiency of the gasoline engine is improved, and gas flow which enters the combustion chamber is subjected to resistance in different directions, so that fuel oil mixed gas can be well formed into turbulent flow and combusted fully; therefore, the fuel oil consumption rate is reduced effectively, combustion is facilitated, and CH+NO(x) emission can be reduced, and gasoline power is increased; and the emission reaches or even exceeds the environmental protection agency (EPA) standard in America. The power of a gasoline engine with the maximum power of 3.0 kW (the rotating speed is 3,600 rpm) can be increased to 3.5 kW and the emission is reduced from 9.0 g / kW.h to 8.0 g / kW.h; the power of a gasoline engine with the maximum power of 3.5 kW can be increased to 4.0 kW and the emission is reduced from 9.0 g / kW.h to 8.0 g / kW.h; and the emission of the two gasoline engines meets the standard of 10 g / kW.h in the EPA3 stage; therefore, the power increment and the emission reduction of the gasoline engine are obvious, and environmental protection is facilitated.

Owner:LONCIN MOTOR

Multilayer limestone ore body mining method

InactiveCN108868767AReduce mix rateImprove recovery rateUnderground miningSurface miningMaterial PerforationTopography

The invention relates to a multilayer limestone ore body mining method. The method comprises the following steps: (1) according to physical properties of to-be-mined limestone ore, using blasting lumpiness analysis software to select the needed drilling aperture and blasting mesh parameters; (2) adopting a bottom sandwich layer one-step blasting method, controlling the inclination of the ore bodyin different areas, controlling a perforation depth, ensuring that the bottom rock layer is perforated, wherein after the blasting, the sandwich layer is small in deformation, and no splashing is produced; (3) determining a mining and stripping method: (1) according to the drilling data and an exposed ore body, if the ore body is arched in a certain direction, combining the topographical featuresof the orientation, advancing steps towards the direction; according to the topography of one mined region, selecting the southern part of the region as a furrowed position of each step section; and (2) successively transversely arranging blasting areas which are longitudinally limited for 25 meters until reaching the edge of the step. By adopting the multilayer limestone ore body mining method, the waste stone mixing rate can be decreased, the ore mining is facilitated, and the ore recovery rate is increased.

Owner:张春荣

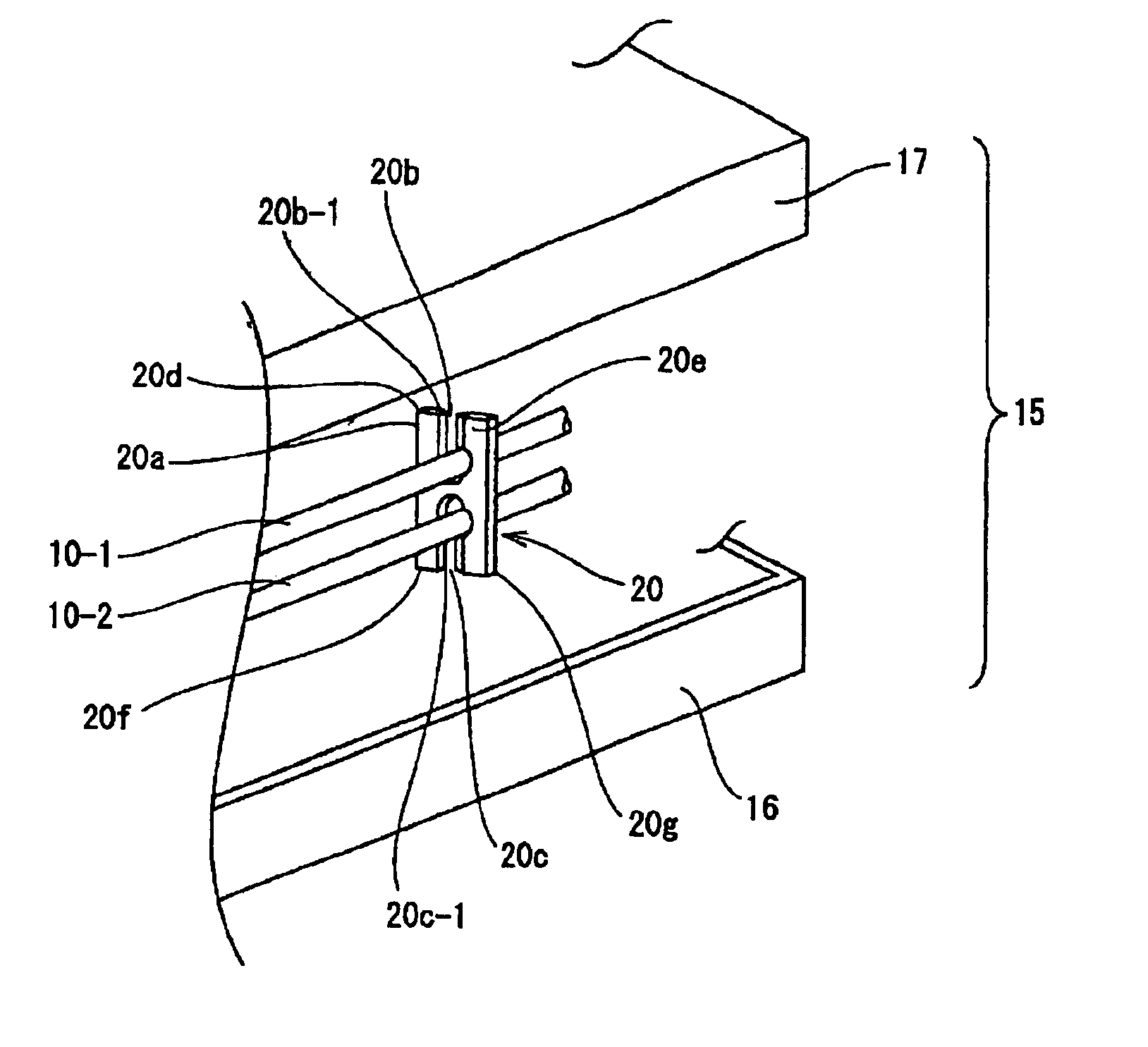

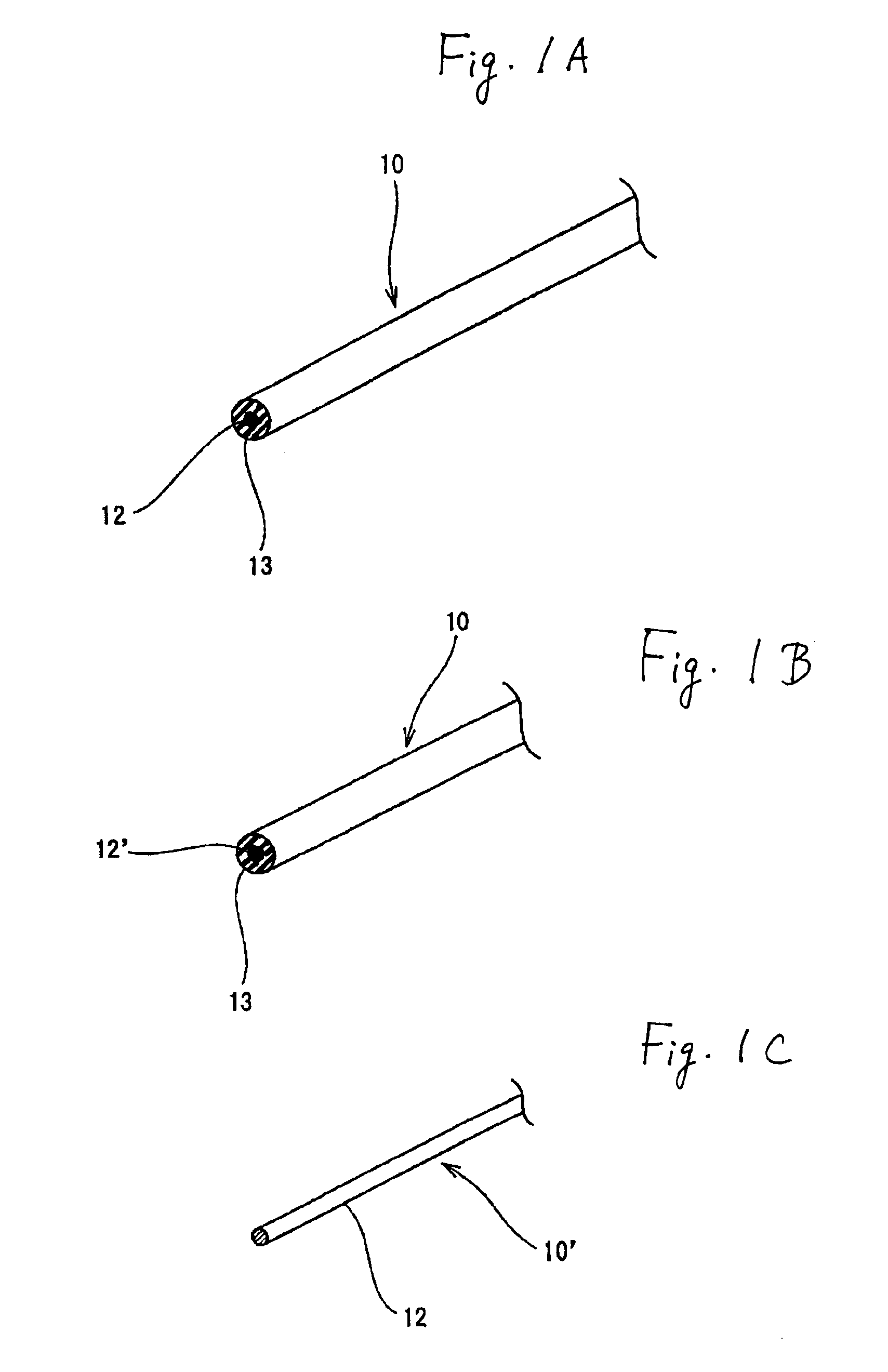

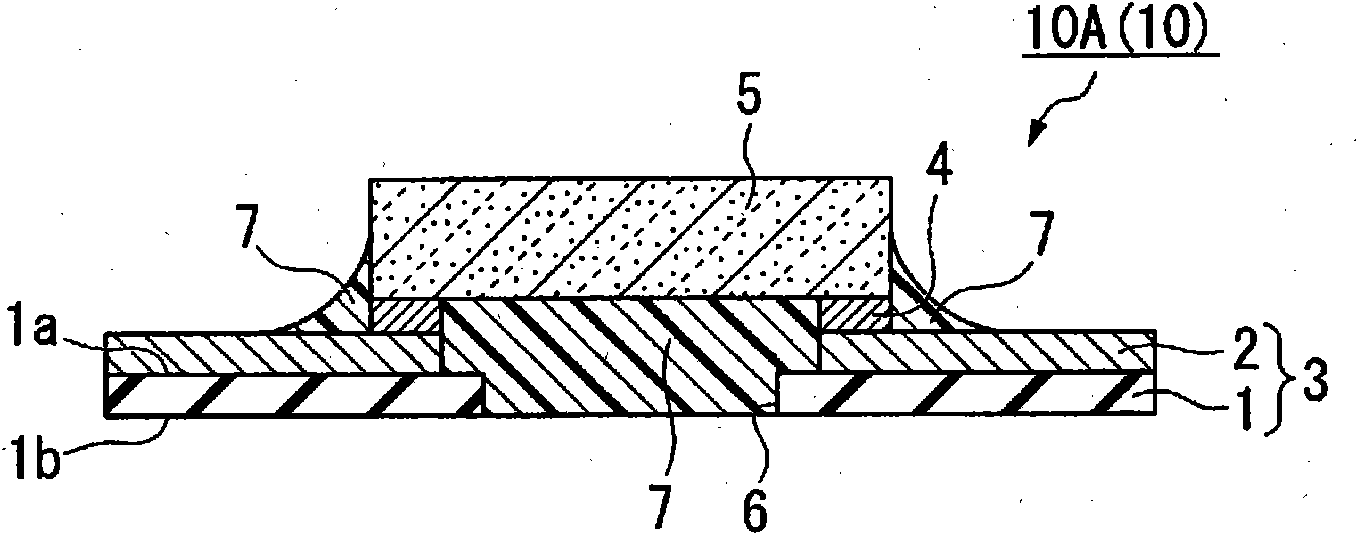

Electrical cable and connection structure between electrical cable and terminal

InactiveUS6866537B2Reduce mix rateAchieve recyclabilityElectrically conductive adhesive connectionsInsulated cablesAluminiumElectrical connection

An electrical cable is used to form an internal circuit in an electrical connection box to be mounted on an automobile. An aluminum-based metal conductor is covered with a heat-resistant resin, such as PE (polyethylene) or PBT (polybutylene terephthalate). The conductor is a single core wire or a twisted core wire, which has a plurality of element wires. The conductor is pushed into an insulation displacement slot in an insulation displacement terminal. The insulation displacement terminal is made from an aluminum-based metal or a copper-based metal. A welding material, made of an iron-based metal, welds a contact portion between the conductor and a blade section on an inner peripheral edge of the insulation displacement slot.

Owner:SUMITOMO WIRING SYST LTD

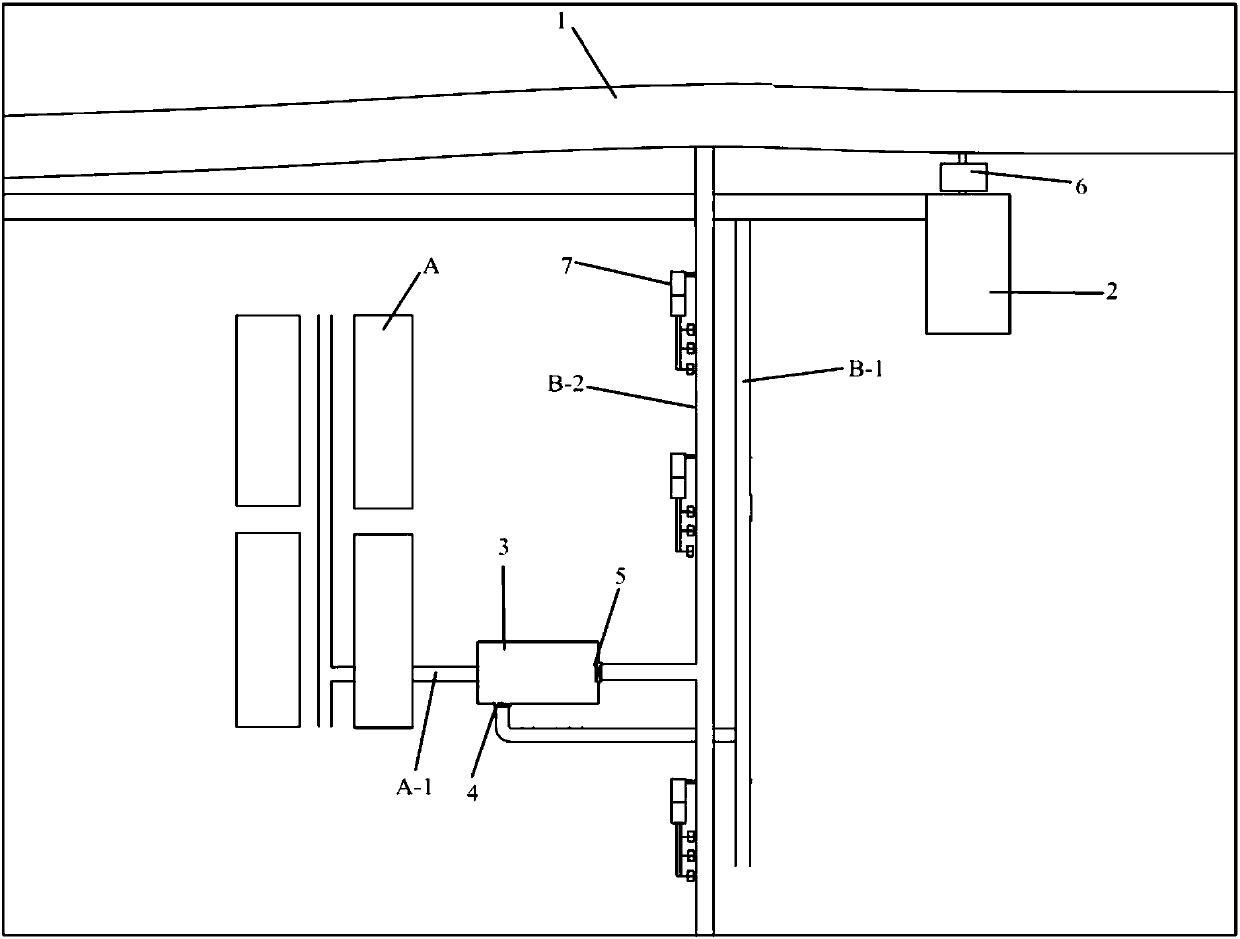

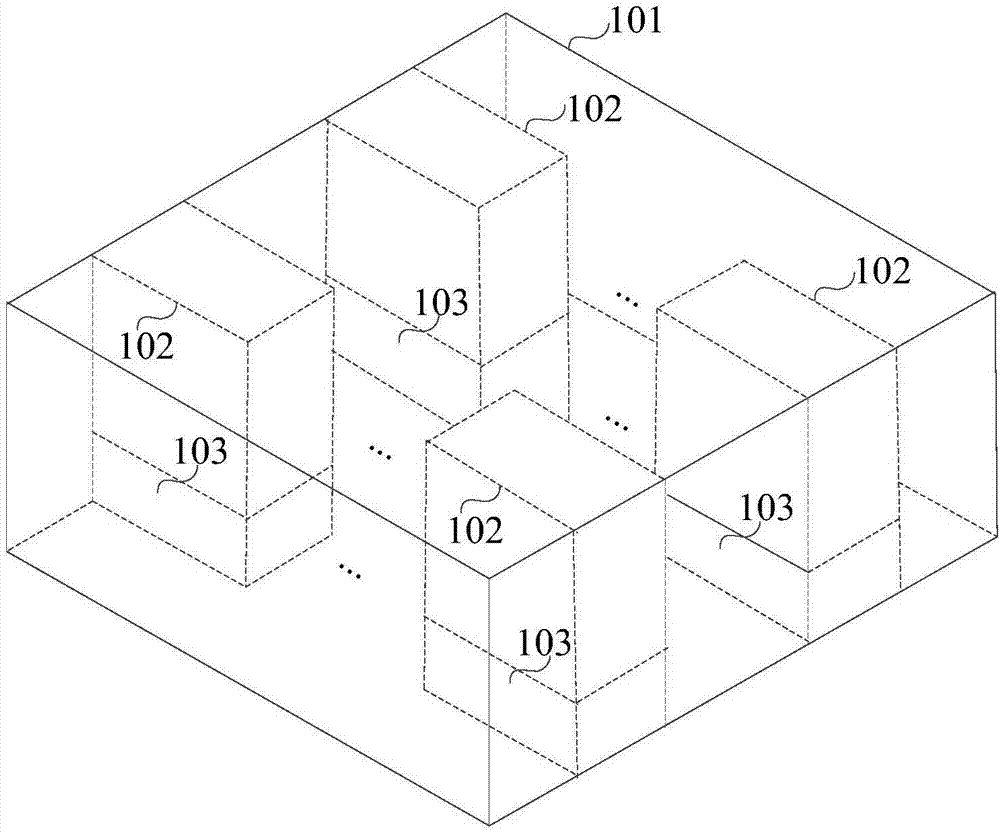

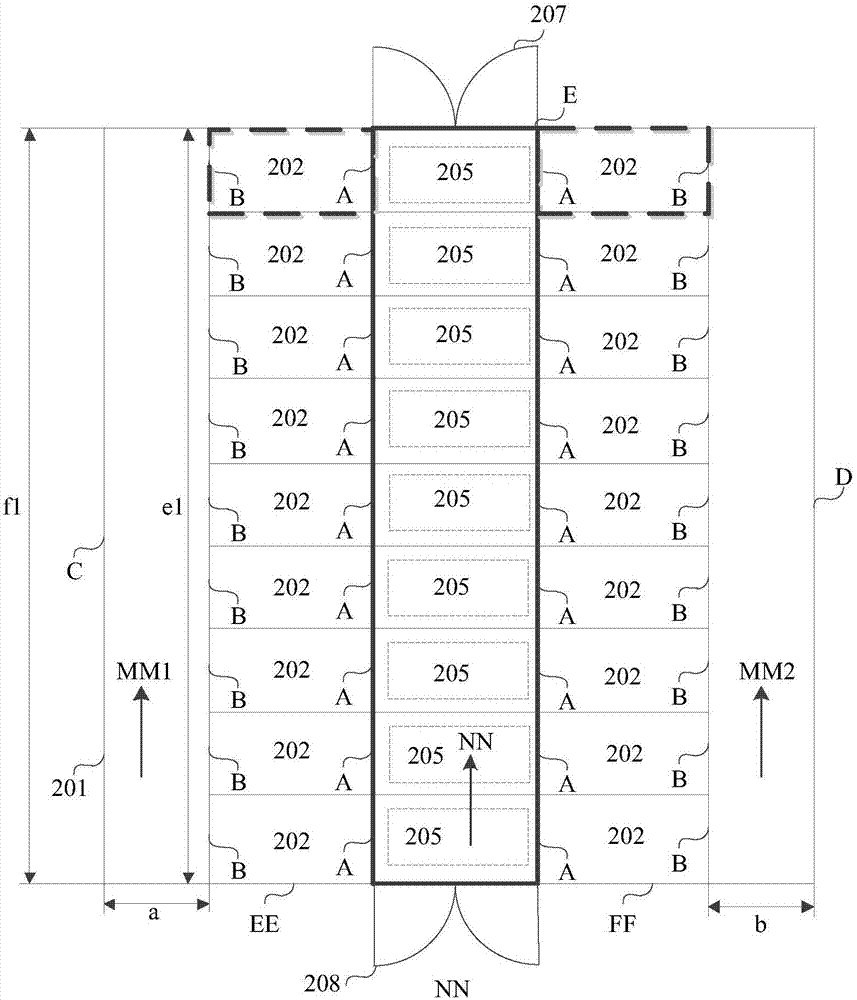

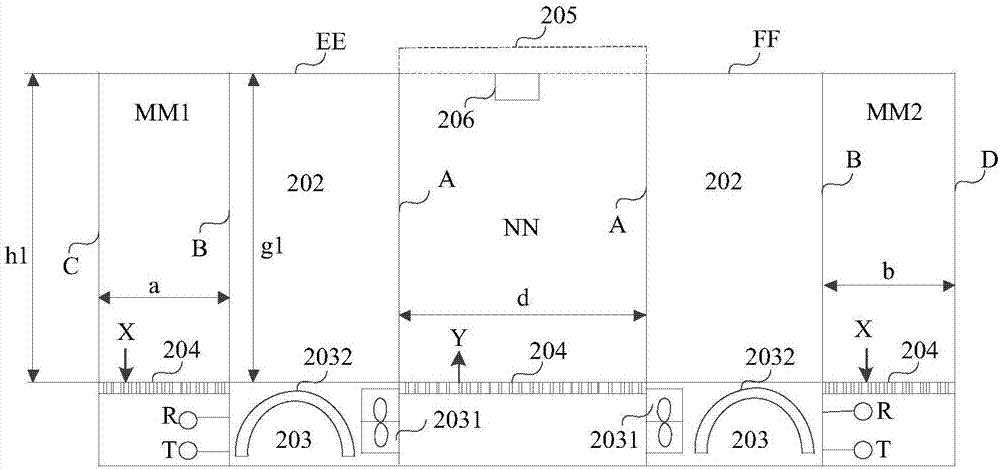

Micro module data center and business implementation method thereof

InactiveCN107278112AReduce mix rateImprove cooling efficiencyCooling/ventilation/heating modificationsCold airData center

The invention provides a micro-module data center and a service realization method thereof. The micro-module data center includes: a cabinet, at least two cabinets, and at least one air conditioner; each cabinet forms two rows of cabinets; each cabinet includes an opposite operation surface and an air outlet surface; each cabinet and each air conditioner are placed in the cabinet ;Two rows of cabinets are placed side by side at intervals to form a cold aisle between the two rows of cabinets; the operating surface of each cabinet in each row of cabinets faces the cold aisle; the air outlet surface of each cabinet in each row of cabinets is in line with the adjacent cabinet There is a set distance between the side walls to form corresponding hot aisles; each air conditioner obtains hot air in each hot aisle, converts the acquired hot air into cold air, and discharges the cold air to the cold aisle; each cabinet and the cold aisle The cold air in the heat exchange is carried out, and the hot air formed after heat exchange is discharged to the corresponding hot aisle through the corresponding air outlet surface. Therefore, the scheme provided by the present invention can improve refrigeration efficiency.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

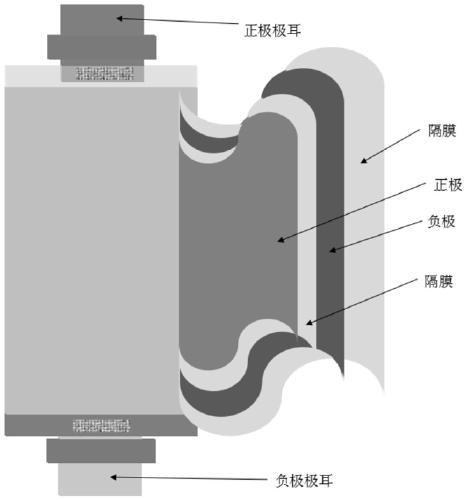

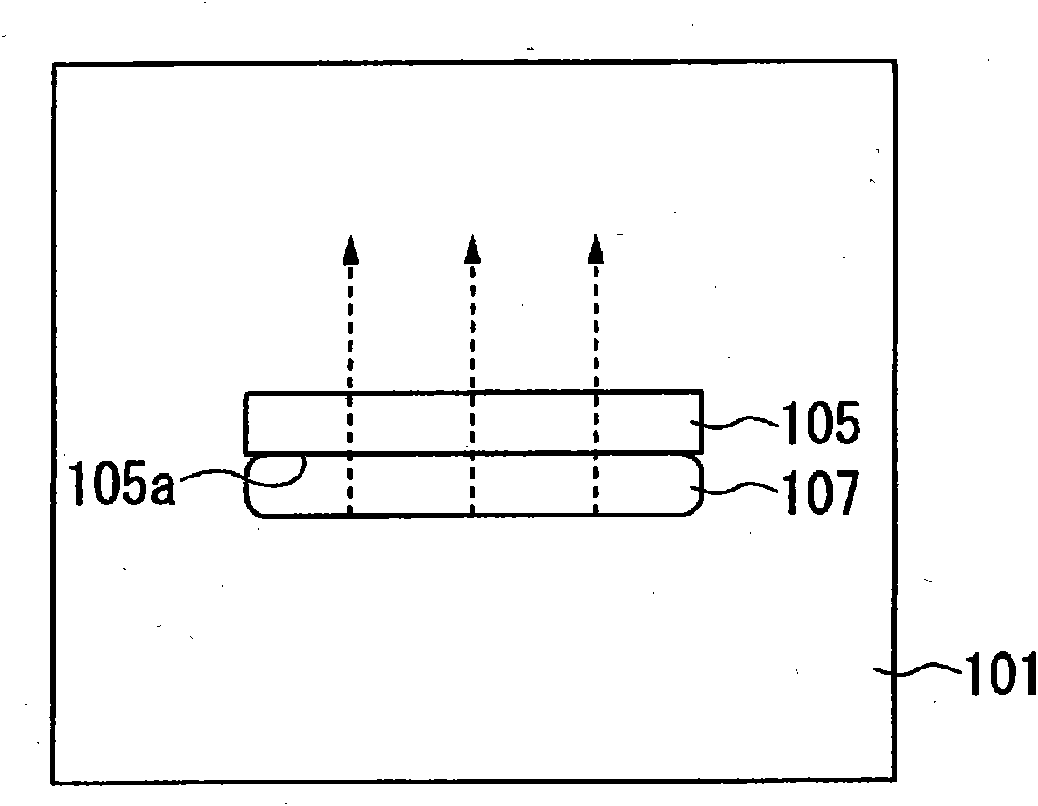

Positive electrode active material of battery core, high-voltage high-magnification battery core and manufacturing method thereof

PendingCN111403738AReduce phase changeImprove cycle performanceFinal product manufactureSecondary cellsPhysical chemistryChemistry

The invention relates to a positive electrode active material of a battery core, a high-voltage high-magnification battery core and a manufacturing method thereof. The positive electrode active material is modified nickel cobalt lithium manganate, wherein the modified nickel cobalt lithium manganate is of a single-crystal structure, and the modified nickel cobalt lithium manganate is one or more of doped nickel cobalt lithium manganate and coated nickel cobalt lithium manganate. The battery core comprises a positive electrode, a negative electrode and a diaphragm, and the battery core adopts afull-tab winding type structure in which the diaphragm, the positive electrode, the diaphragm and the negative electrode are connected; the positive electrode comprises a positive electrode binder, apositive electrode conductive agent, a positive electrode current collector and the positive electrode active material; and the negative electrode comprises a negative electrode active material, a negative electrode conductive agent, a negative electrode binder and a negative electrode current collector. According to the invention, the rate capability of the battery core can be improved, and theheating of the battery core at a high rate is reduced, so that the overall performance of the battery core is improved.

Owner:HUBEI RONGBAI LITHIUM BATTERY MATERIAL CO LTD

Module, wiring board and module manufacturing method

InactiveCN101828254AExcellent adhesionReduce mix rateFinal product manufactureSemiconductor/solid-state device detailsElectrical conductorElectrode

A module is provided with a wiring board wherein a conductor pattern is formed on an insulating layer, and a functional element mounted with its face down on the conductor pattern through an electrode. An opening section is formed in a region, which is in the functional element mounting position of the wiring board, is smaller than the projection surface of the functional element and is inside the portion where the electrode is bonded. A space between the functional element and the wiring board, and the opening section are sealed by a sealing resin.

Owner:THE FUJIKURA CABLE WORKS LTD

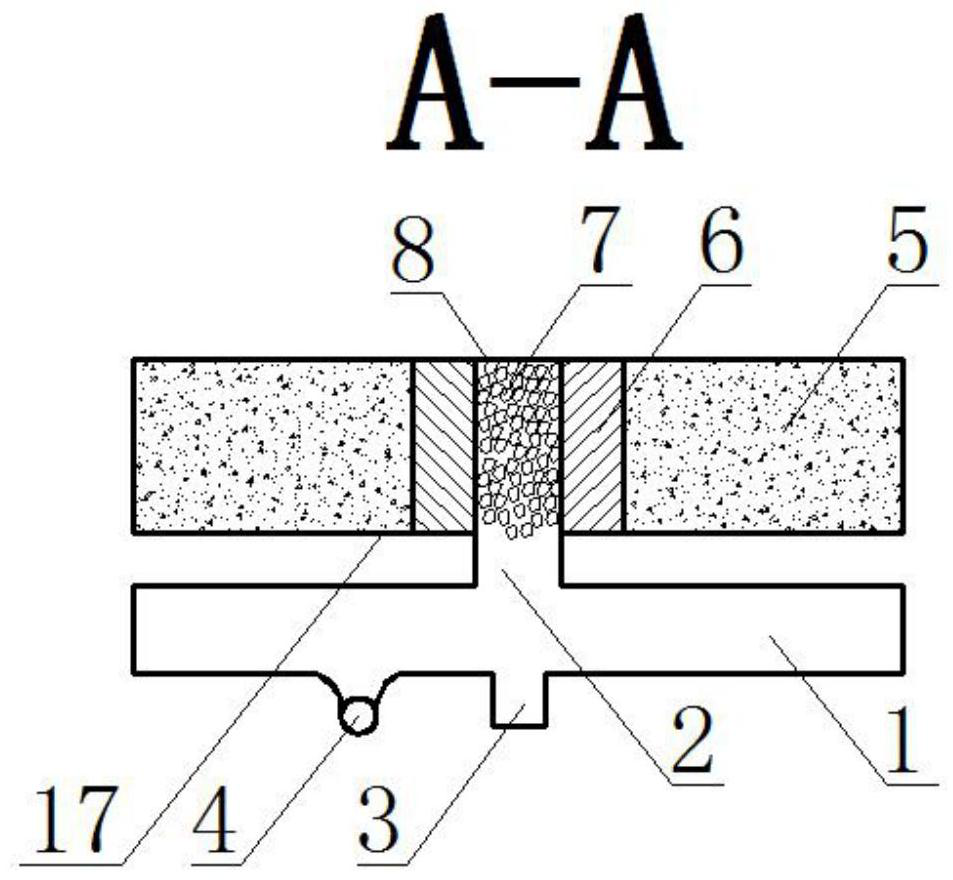

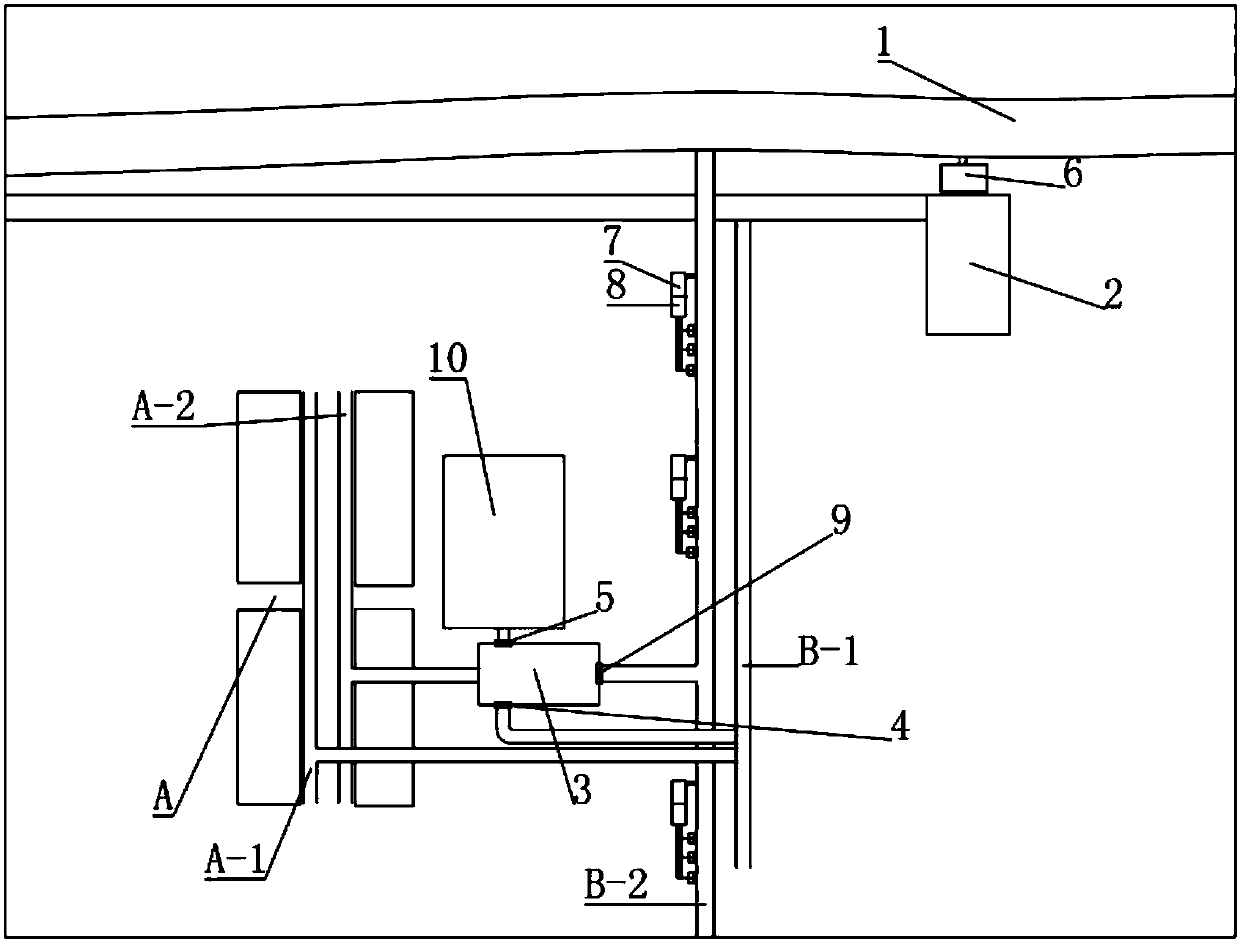

Artificial false bottom and manufacturing method

PendingCN110541729AHigh strengthReduce mix rateMaterial fill-upAnchoring boltsEconomic benefitsEngineering

The invention discloses an artificial false bottom. The artificial false bottom is built in a roadway and comprises an artificial false bottom body and a fixing part, wherein one end of the fixing part is inserted into a side plate of the roadway, and the other end of the fixing part is connected with the artificial false bottom body through a connecting piece; the artificial false bottom body ispositioned on a bottom plate of the roadway, and a reinforcing mesh is arranged in the artificial false bottom body. The artificial false bottom can replace a top-bottom ore column in the mining process, so that the top-bottom ore column does not need to be reserved in the mining process, the top-bottom ore column does not need to be recovered in the later period, and as a result, the recovery process is saved; the artificial false bottom is made of high-grade concrete, so that the strength of the artificial false bottom is high, the mixing rate of waste rocks in the process of recovering thetop-bottom ore column is low, the mineral separation recovery rate is high, and the economic benefit is good; in addition, reinforcing steel bars and anchor rods are connected with the side plate of the roadway, so that the safety is high.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Sewage and rainwater combined drainage system and control method

PendingCN107806155AEasy to handleSimple structureFatty/oily/floating substances removal devicesSewerage structuresOutfallEngineering

The invention relates to a sewage and rainwater combined drainage system, which comprises a sewage main pipe on a municipal road, a rainwater main pipe on the municipal road, and a confluence header pipe in a unit area, wherein a sewage treatment plant is arranged at the outlet of the sewage main pipe; the tail end of the rainwater main pipe is connected to a natural water body; and the outlet ofthe confluence header pipe is connected to the sewage main pipe; the drainage system is characterized in that one or more flow distributing devices are arranged on the confluence header pipe, and thewater inlet end of each flow distributing device communicates with the confluence header pipe; each flow distributing device is provided with three water outlets; each first water outlet is connectedto the sewage main pipe; each second water outlet is connected to the rainwater main pipe; each third water outlet is connected to the water inlet of an online rainwater treatment facility; and the water outlet of each online rainwater treatment facility is connected to the rainwater main pipe.

Owner:WUHAN SHENGYU DRAINING SYST

Sewage and rainwater separate drainage system and method for controlling same

PendingCN107558568AEasy to handleSimple structureFatty/oily/floating substances removal devicesSewerage structuresEngineeringStormwater treatment

The invention provides a sewage and rainwater separate drainage system which comprises a sewage main pipe, a rainwater main pipe, a rainwater pipeline and a sewage pipeline. The sewage main pipe is arranged on a municipal road, and a sewage treatment plant is arranged at an outlet of the sewage main pipe; the rainwater main pipe is arranged on the municipal road, and the tail end of the rainwatermain pipe is connected with natural water; the rainwater pipeline and the sewage pipeline are arranged in a unit region, and the sewage pipeline is connected with the sewage main pipe; a rainwater treatment system is arranged at an outlet of the rainwater pipeline and comprises distribution equipment, a regulation and storage facility and an online treatment facility; the rainwater pipeline is connected with a water inlet of the distribution equipment, a first water outlet of the distribution equipment is connected with the sewage main pipe, a second water outlet of the distribution equipmentis connected with the regulation and storage facility, a third water outlet of the distribution equipment is connected with the online treatment facility, and a fourth water outlet of the distributionequipment is connected with the rainwater main pipe. The sewage and rainwater separate drainage system has the advantages that the sewage and rainwater separate drainage system is simple in structureand convenient to construct, and only the distribution equipment, the regulation and storage facility and the online treatment facility need to be constructed in a limited region of a residential area, so that mixed sewage in the region of the residential area can be efficiently treated.

Owner:WUHAN SHENGYU DRAINING SYST

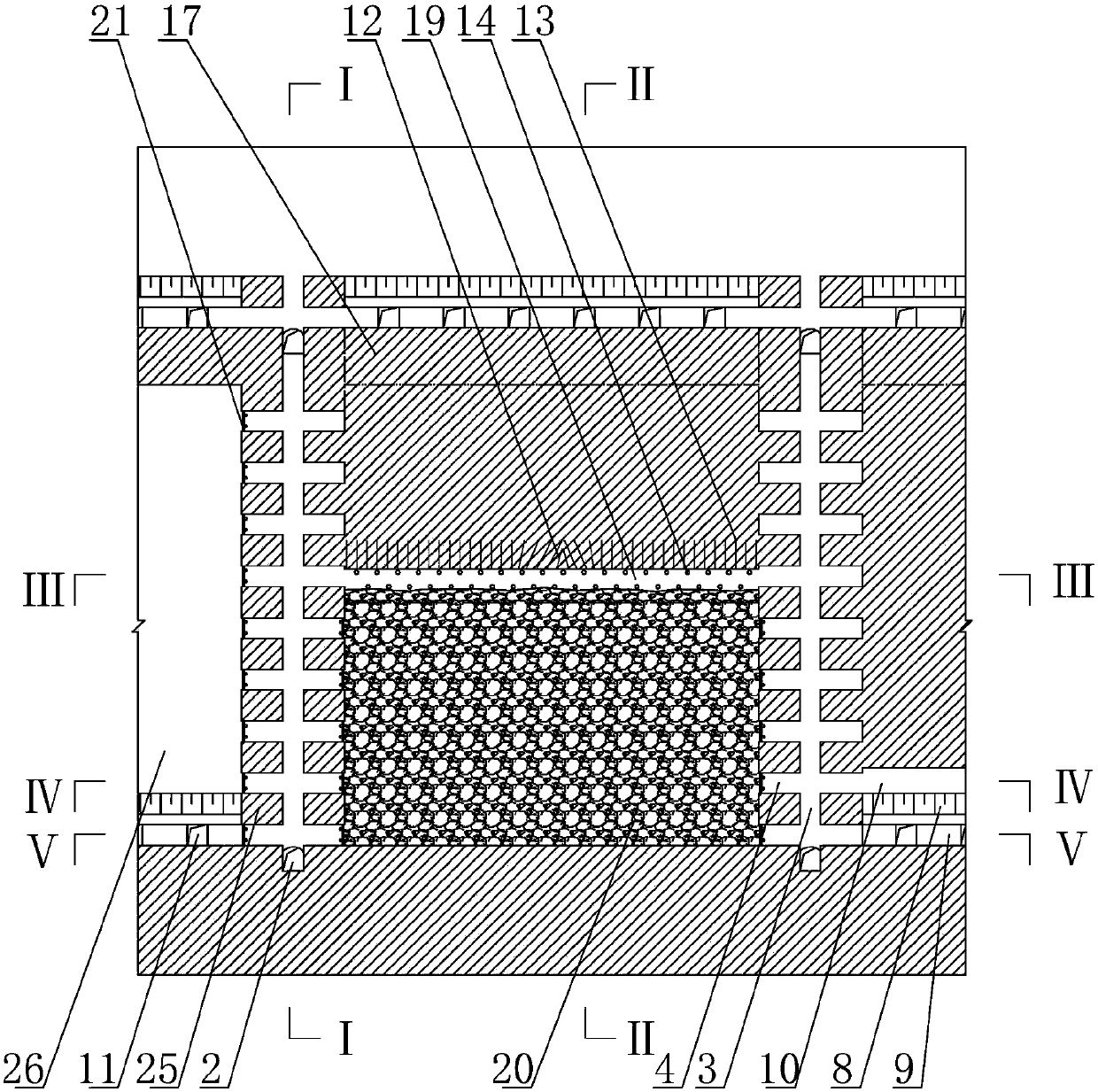

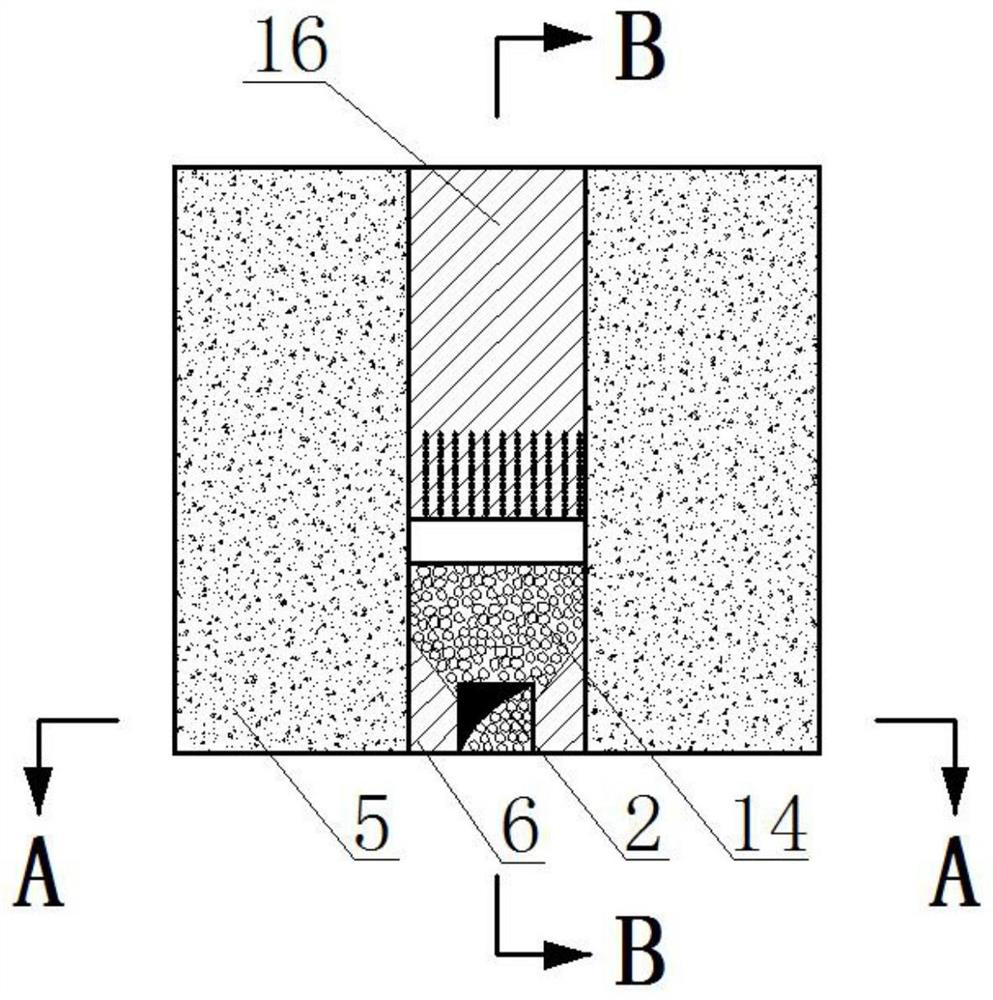

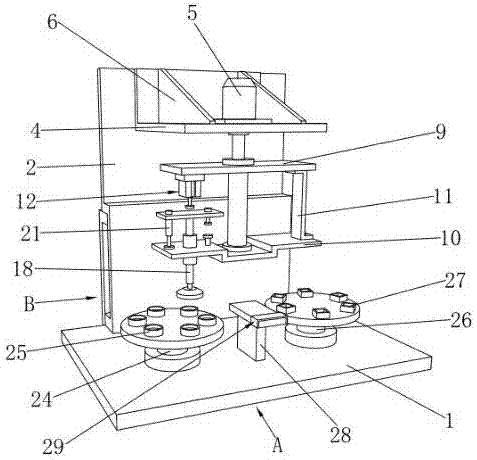

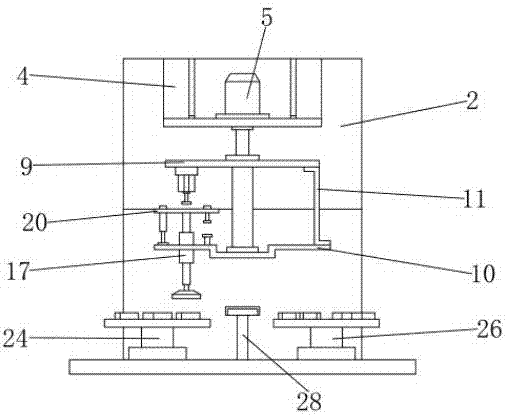

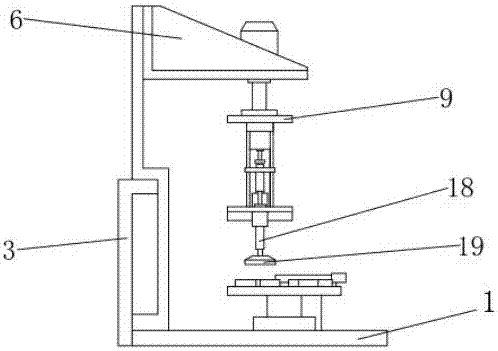

Mining method for treating goaf remaining intervening pillar by filling method

ActiveCN111706328AImprove ore recovery rateReduce ore dilution rateUnderground miningBlastingMining engineeringStructural engineering

The invention discloses a mining method for treating goaf remaining intervening pillars by a filling method. The method comprises the following steps of tunneling an ore removal roadway into an intervening pillar (16) on one side of a middle section transportation roadway (1) to reach an ore body hanging wall, and expanding the top of the ore removal roadway by adopting a fan-shaped medium-lengthhole to form a horn-mouth-shaped bottom structure; arranging a cut raise (12) and a pedestrian ventilation raise (3) in a intervening pillar hanging wall ore rock contact face and a footwall surrounding rock respectively, and enabling the cut raise (12) and the pedestrian ventilation raise (3) to communicate with the upper middle section air return roadway, and tunneling layered cross gateways (9)in the pedestrian ventilation raise (3) in the vertical direction at intervals of a certain height to reach the intervening pillar footwall boundary; and drilling upward parallel blast holes (11) layer by layer in circulating mode one by one from bottom to top, and performing the the operation links of explosive charging blasting, forced ventilation and caved ore discharging till the whole intervening pillars are completely mined; and completely discharging the caved ore (7) through a carry-scraper and filling the goaf. The recovery rate of the intervening pillar ore is increased, the ore dilution rate is reduced, and the working environment of a working surface is improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Device for machining parts

InactiveCN106925982ASynchronous rotationGuaranteed to workMetal working apparatusDrive motorEngineering

The invention discloses a device for processing parts, which comprises a mounting platform and a supporting base, a supporting plate is arranged on the supporting base, a driving motor is arranged on the supporting plate, a rotating assembly is connected to the driving motor, and a rotating assembly is arranged on the mounting platform. There is a first turntable, the first turntable is provided with a first clamping part, the installation platform is provided with a second turntable, and a second stopper is arranged on the second turntable. The invention can quickly complete the processing of a large number of mechanical parts, automatically add sealing gaskets to the mechanical parts, improve the work efficiency, reduce the cost, be automatic and efficient, and the quality of the processed mechanical parts is high, reducing the mixing of defective products The utility model has the advantages of simple structure, strong practicability, low manufacturing cost and remarkable economic benefit.

Owner:全南县韬寻机械设备开发有限公司

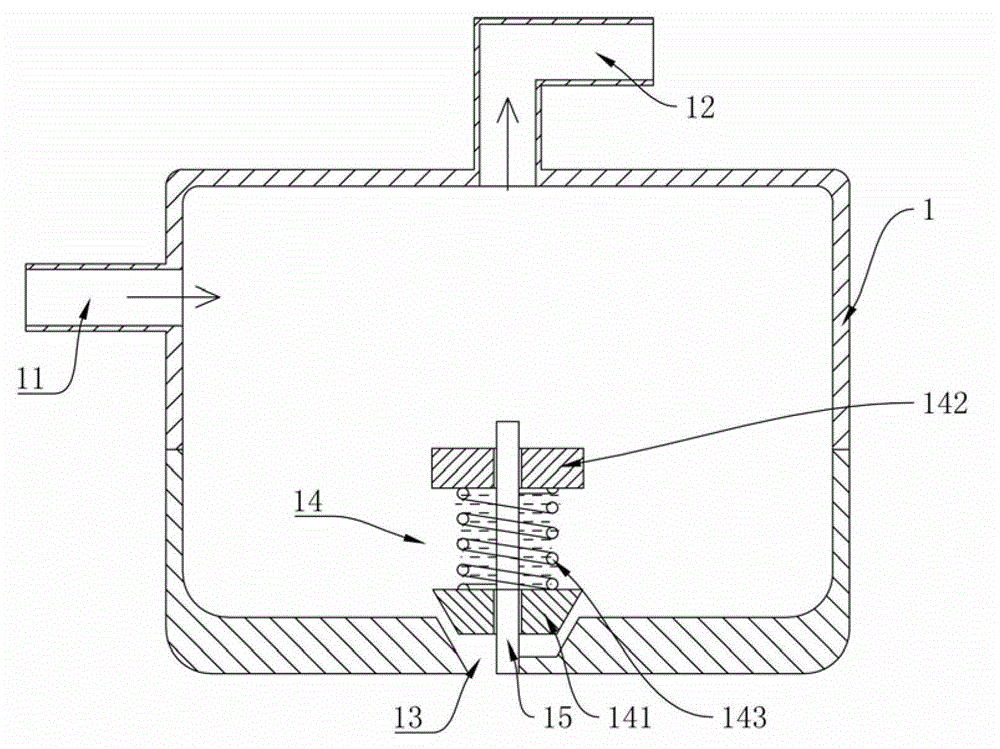

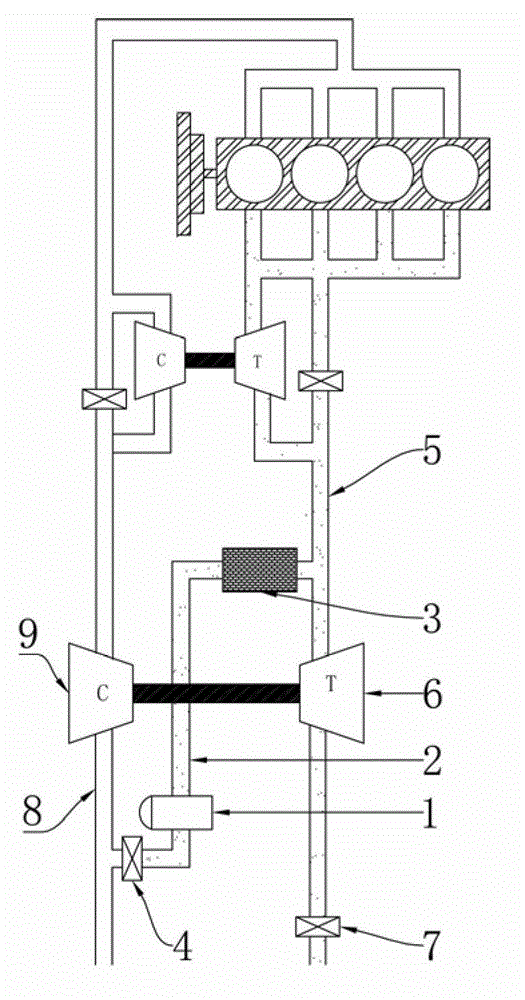

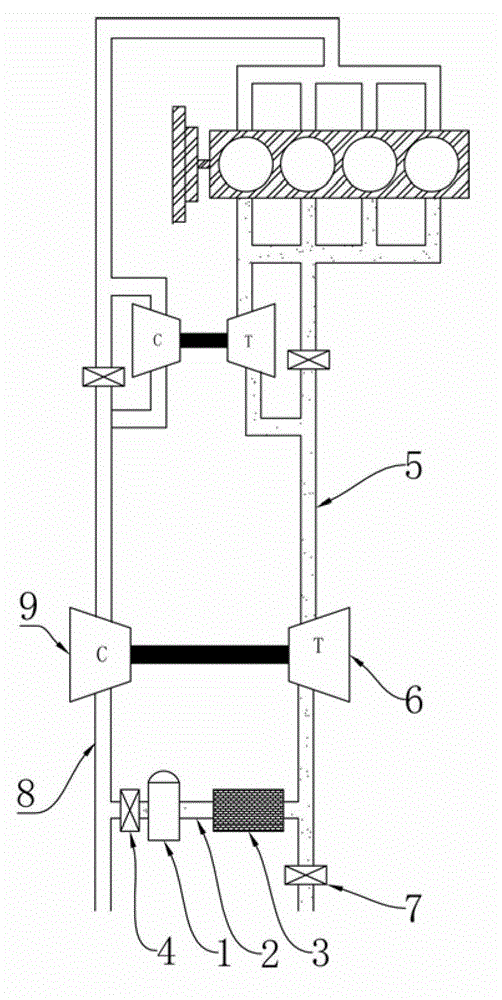

An egr water filter tank and water filter type exhaust gas recirculation system

ActiveCN102937043BImprove reliabilityHigh thermal efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelWater dischargeWater filter

The invention discloses an EGR (Exhaust Gas Recirculation) water filtering tank and a water filtering type exhaust gas recirculation system. The water filtering tank comprises a tank body; an air inlet and an air outlet are formed in the upper part of the tank body; a water discharging hole is formed in the bottom of the tank body; a sealing floater is arranged on the discharging hole; the lower bottom surface of the sealing floater is adhered to a water discharging opening. The water filtering type exhaust gas recirculation system comprises an EGR cooler, the EGR filtering tank and an EGR valve which are sequentially mounted on an EGR pipeline. Compared with the prior art, liquid-sate water in the EGR system is filtered, so that smoke and hydrocarbon in part waste gas can be dissolved, the EGR system is purified, and the emission are reduced. Furthermore, the reliability of an engine can be further improved, aggravating of the abrasion of parts can be avoided; and meanwhile, the inflating density of the engine further can be increased, so that a novel combustion mode can be realized, the emission can be reduced, and the heat efficiency of the engine can be improved.

Owner:山东格新精工有限公司

Sewage and rainwater separate drainage system and method for controlling same

InactiveCN107558566AEasy to handleSimple structureFatty/oily/floating substances removal devicesSewerage structuresSewageEngineering

The invention provides a sewage and rainwater separate drainage system which comprises a sewage main pipe, a rainwater main pipe, a rainwater pipeline and a sewage pipeline. The sewage main pipe is arranged on a municipal road, and a sewage treatment plant is arranged at an outlet of the sewage main pipe; the rainwater main pipe is arranged on the municipal road, and the tail end of the rainwatermain pipe is connected with natural water; the rainwater pipeline and the sewage pipeline are arranged in a unit region, and the sewage pipeline is connected with the sewage main pipe; a rainwater treatment system is arranged at an outlet of the rainwater pipeline and comprises distribution equipment and a regulation and storage facility; the rainwater pipeline is connected with a water inlet of the distribution equipment, a first water outlet of the distribution equipment is connected with the sewage main pipe, a second water outlet of the distribution equipment is connected with the regulation and storage facility, and a third water outlet of the distribution equipment is connected with the rainwater main pipe. The sewage and rainwater separate drainage system has the advantages that thesewage and rainwater separate drainage system is simple in structure and convenient to construct, and only the distribution equipment and the regulation and storage facility need to be constructed ina limited region of a residential area, so that mixed sewage in the region of the residential area can be efficiently treated.

Owner:WUHAN SHENGYU DRAINING SYST

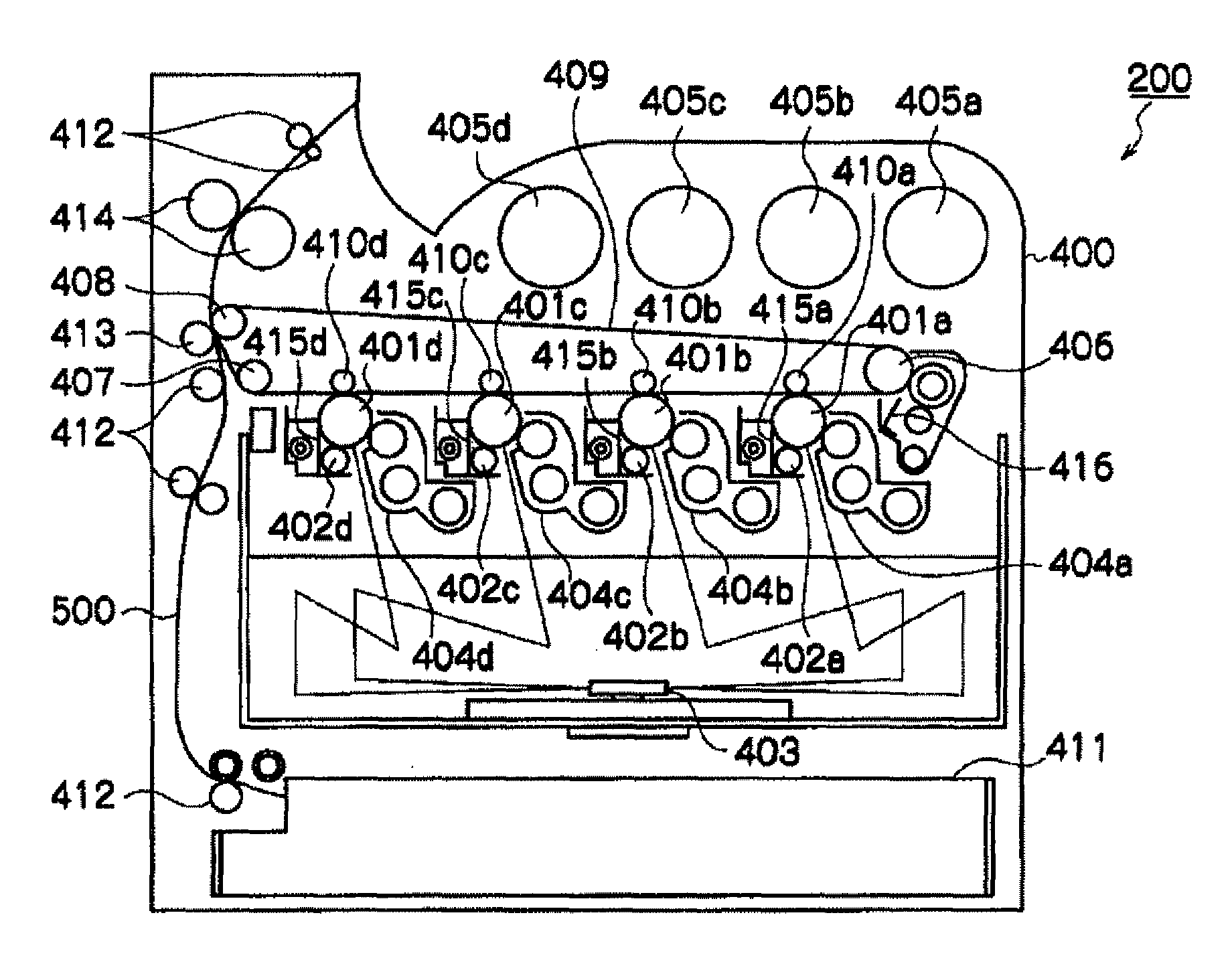

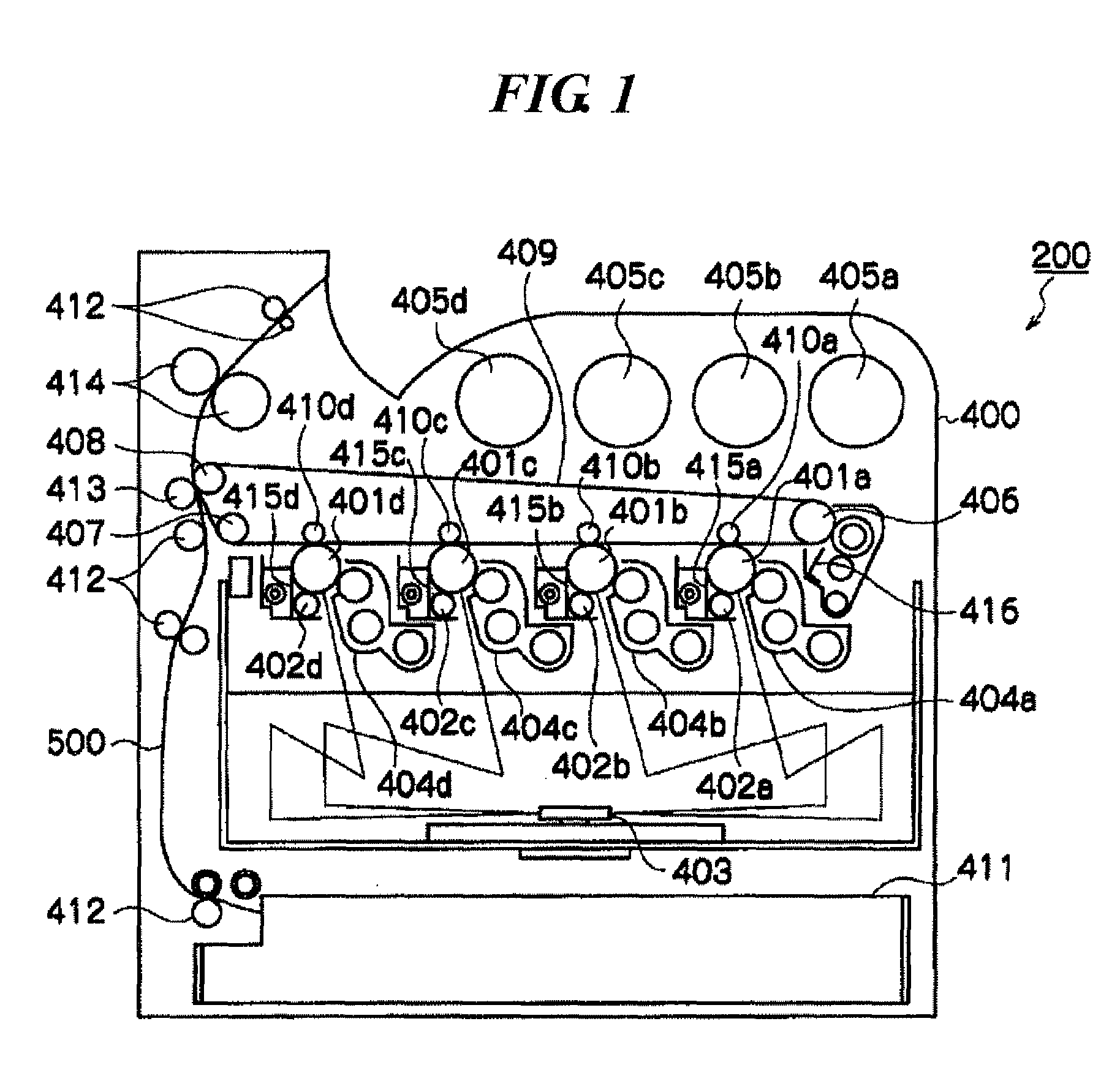

Electrostatic-image-developing toner, electrostatic image developer, method of manufacturing electrostatic-image-developing toner, toner cartridge, process cartridge, method of image formation, and image forming apparatus

ActiveUS20110045395A1Rate of mixing of hard-to-charge non-colored release agent particlesReduce releaseDevelopersElectrographic process apparatusImage formationVolume average

An electrostatic image developing toner includes toner particles that contain a binding resin, a coloring agent and a release agent and that have D50 of from about 2.0 μm to about 8.0 μm, D50 standing for a volume-average particle size of the toner particles; and non-colored release agent particles, wherein out of the non-colored release agent particles, those ranging in volume-average particle size of from about 0.8 to about 1.2 times a value of D50 are present in a proportion of about 50 or below per 5,000 of the toner particles.

Owner:FUJIFILM BUSINESS INNOVATION CORP

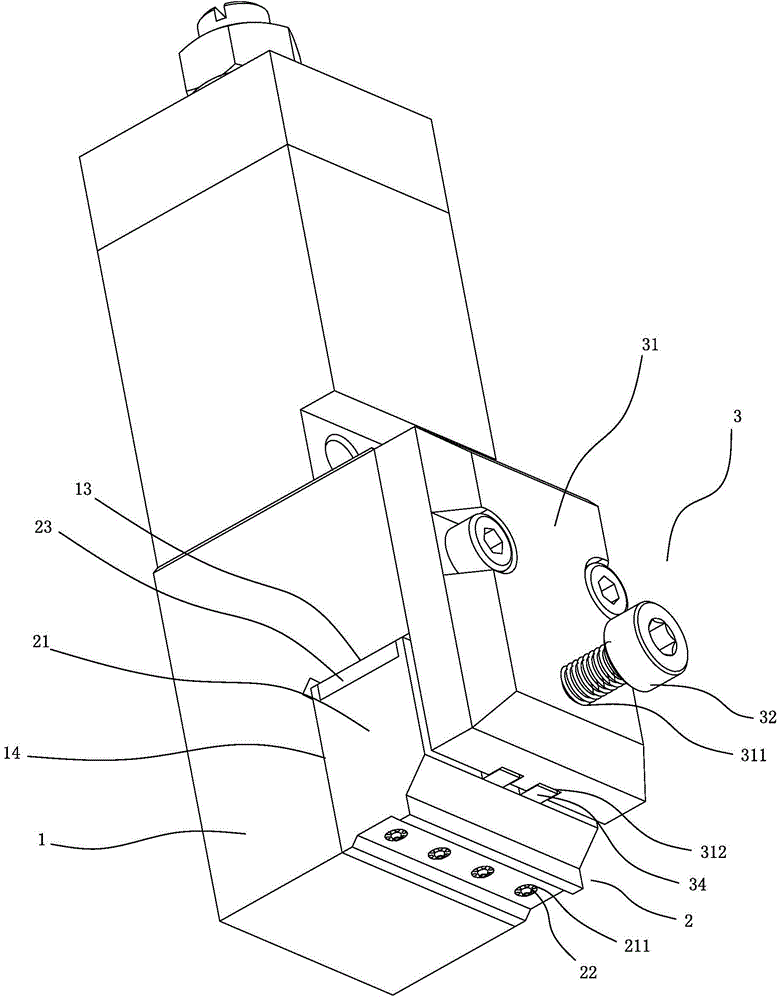

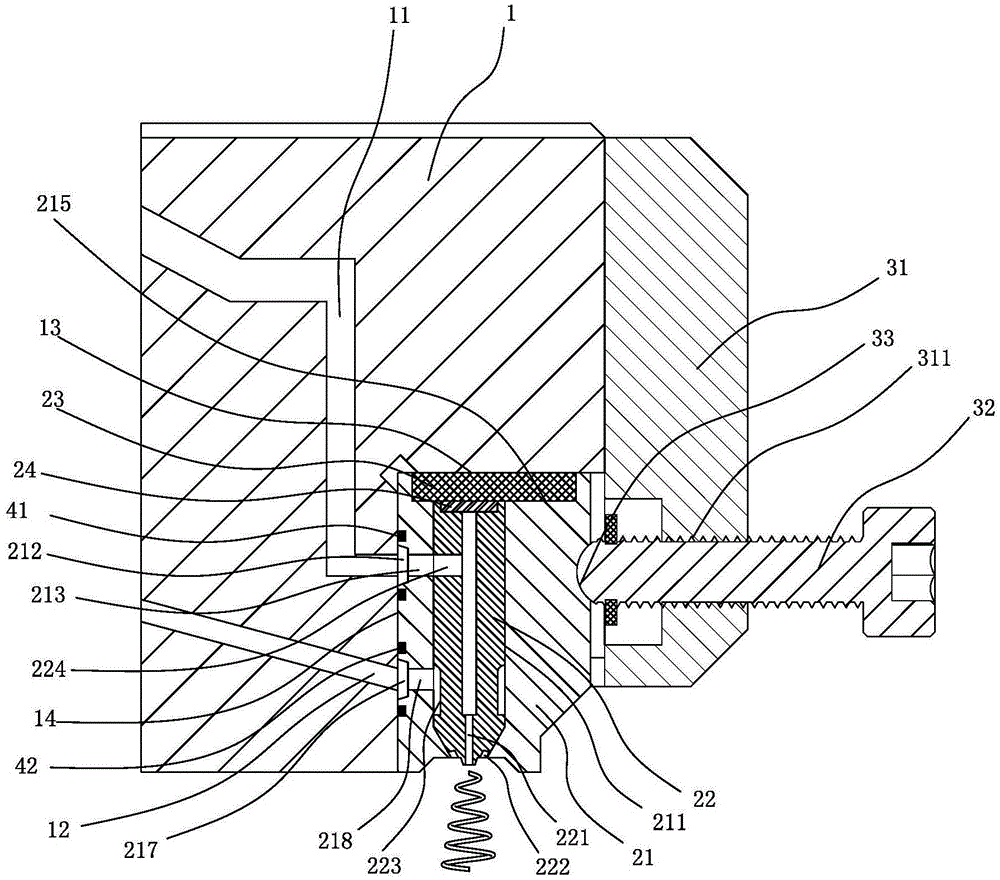

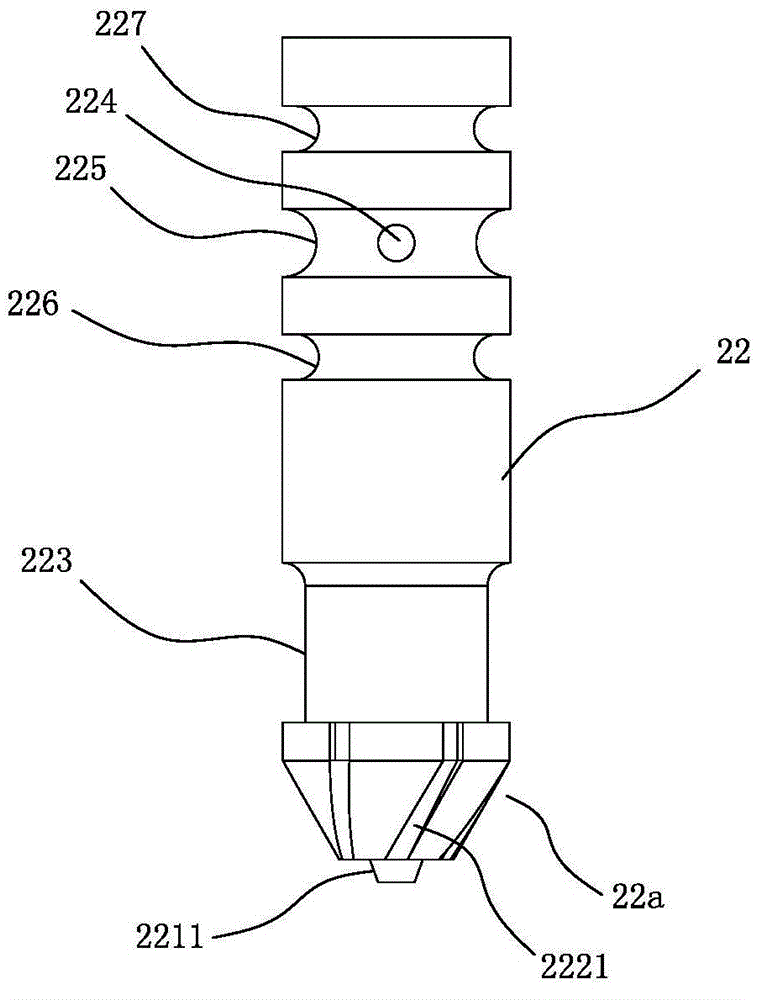

High-precision hot melt glue nozzle and hot melt glue gun

InactiveCN104399645ASimple processingHigh precisionLiquid surface applicatorsCoatingsAirflowHot-melt adhesive

The invention discloses a high-precision hot melt glue nozzle. The high-precision hot melt glue nozzle is mounted on a glue gun body; the glue gun body is provided with a solution supply channel and a gas supply channel; the high-precision hot melt glue nozzle comprises a nozzle body and a core body, wherein a containing hole penetrating the upper and lower parts of the nozzle body is formed inside the nozzle body; the core body is matched with the containing hole and is closely embedded in the containing hole; a glue solution channel with an opening in the lower end surface of the core body is formed inside the core body; at least two gas channels extending to the lower end surface of the core body are formed in the peripheral surface of the core body; a gas channel is formed between the gas channel and the wall of the containing hole. The glue solution channel and the solution supply channel are communicated for outputting an glue solution line during operation, the gas channel and the gas supply channel are communicated for outputting gas flow, the glue solution line is output in a specific shape under the action of the gas flow, and the machining of the gas channel can adopt a mode of milling a groove in the conical peripheral surface of the core body to replace the traditional drilling mode, so that the formation mode of the gas channel is more accurate and efficient than the traditional drilling technology.

Owner:QUANZHOU NDC SPRAY COATING SYST FABTING

Sewage and rainwater separate drainage system and method for controlling same

InactiveCN107558569AEasy to handleSimple structureFatty/oily/floating substances removal devicesSewerage structuresShunt DeviceEngineering

The invention provides a sewage and rainwater diversion drainage system, comprising a sewage main pipe on a municipal road, the outlet of the sewage main pipe is provided with a sewage treatment plant; a rainwater main pipe on the municipal road, the rainwater main pipe The end is connected with the natural water body; the rainwater pipeline and sewage pipeline in the unit area, the sewage pipeline is connected with the sewage main pipe; the outlet of the rainwater pipeline is provided with a rainwater treatment system, and the rainwater treatment system includes a diversion device; the rainwater pipeline and the diversion The water inlet of the device is connected, the first water outlet of the diversion device is connected with the sewage main pipe, and the second water outlet of the diversion device is connected with the rainwater main pipe. The system of the present invention is simple in structure and convenient in construction, and only needs to build diversion equipment in the limited area of the community to realize efficient treatment of mixed sewage in the area of the community.

Owner:WUHAN SHENGYU DRAINING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com