Mining method for multilayer fragile gently-inclined extra-narrow ore vein

A mining method and gently inclined technology, which is applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of unresolved rock inclusions and ore piles, so as to ensure the stability of empty areas, reduce stacking, and improve operating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further describe the present invention, a kind of mining method of multi-layer friable gently inclined extremely thin vein of the present invention will be described in further detail below in conjunction with accompanying drawing.

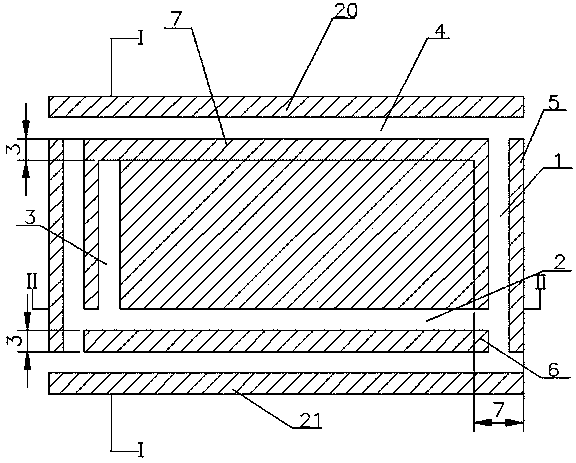

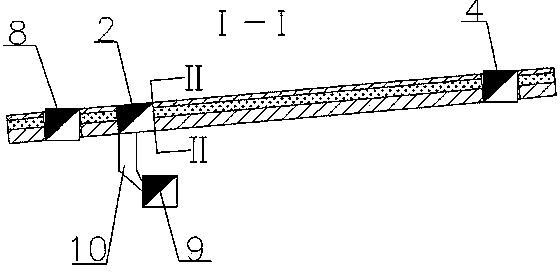

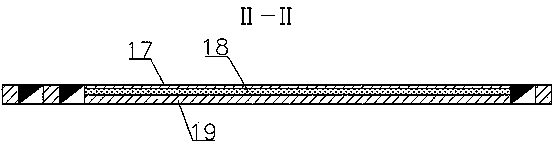

[0028] Depend on figure 1 The panel schematic diagram of the division of the mining method of a kind of multi-layer friable gently inclined extremely thin vein of the present invention is shown and combined with figure 2 , image 3 , Figure 4 It can be seen that the panel area is divided along the ore body trend, the panel area is 60m long, and the panel interval column 5 is reserved in the panel interval, and the uphill 1 is arranged in the panel interval column 5, and a roadway 8 along the vein is arranged every 30m in the direction of the inclination. Column 5 is 7m wide, panel bottom column 6 is 3m wide, and panel top column 7 is 3m wide; at the end of the mine house, excavate along the trend and inclination respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com