An egr water filter tank and water filter type exhaust gas recirculation system

A technology of exhaust gas recirculation and water filtration system, which is applied in exhaust gas recirculation, charging system, exhaust device, etc., can solve the problems of supercharger blade influence, cylinder pulling, damage to the lubricating oil film in the cylinder, etc., and is easy to implement. , the effect of reducing emissions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

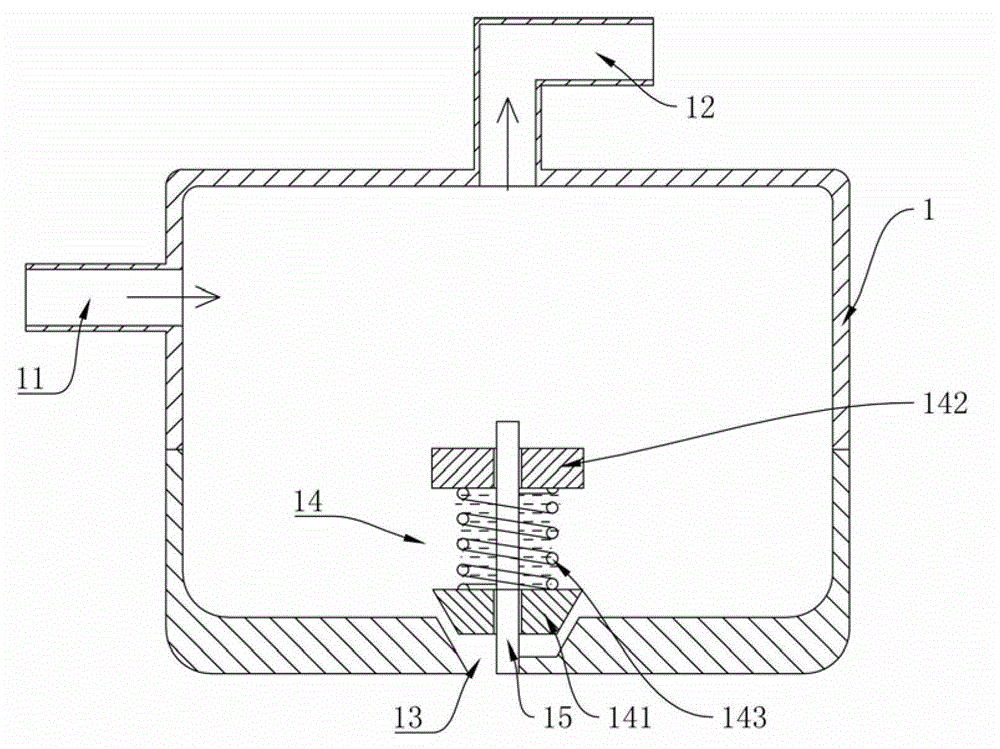

[0026] see figure 1 . The EGR filter tank described in this embodiment includes a tank body 11, which is a stainless steel tank. The top of the tank body 11 is provided with an air inlet 11 and an air outlet 12, and the bottom of the tank body 11 is provided with a drainage hole 13, and the drainage hole 13 is provided with a guide pipe 15 perpendicular to the bottom of the tank. A sealing float 14 is placed on the drainage hole 13, and a guide hole is arranged on the sealing float 14. The lower bottom surface of the sealing float 14 is attached to the drain port 13 , and the guide hole is slidingly matched with the guide pipe 15 . The shape of the inner surface of the drainage hole 13 cooperates with the shape of the bottom surface of the sealing float 14 . The lower part of the sealing float 14 is an inverted cone, an inverted pyramid or a sphere, and the sealing float 14 is composed of a sealing float 141 below, a pressure float 142 above and a supporting connector 143 b...

Embodiment 2

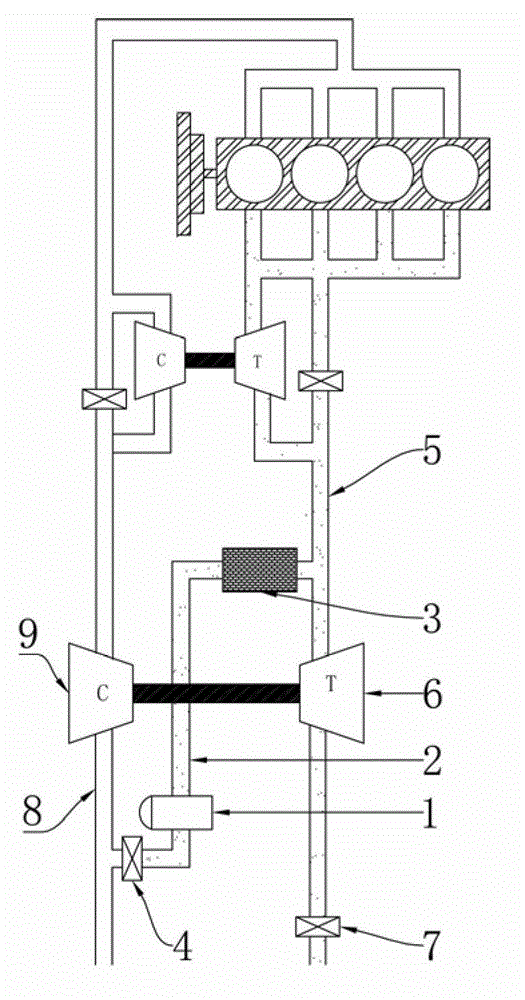

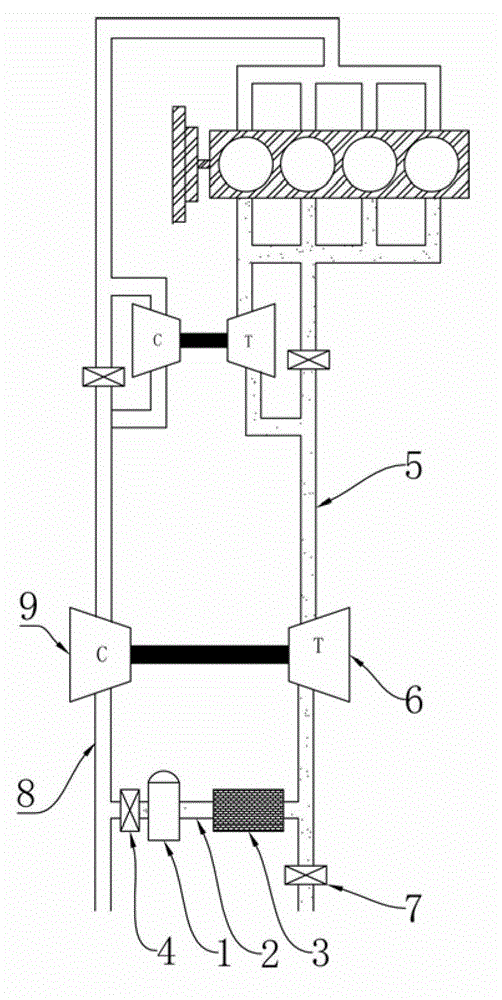

[0030] see Figure 1 to Figure 3 . The exhaust gas recirculation filter system described in this embodiment is composed of an EGR filter tank 1 , an EGR pipeline 2 , an EGR cooler 3 and an EGR valve 4 . An EGR cooler 3, an EGR filter tank 1 and an EGR valve 4 are installed in sequence on the EGR pipeline 2. The EGR filter water tank is also the EGR filter water tank described in Embodiment 1.

[0031] In the medium-pressure exhaust gas recirculation system, the intake pipe section of the EGR duct 2 is connected before the turbocharger turbine end 6 on the exhaust pipe 5 of the engine. The outlet pipe section of the EGR pipeline 2 is connected before the compressor 9 of the supercharger on the intake pipe 8 of the engine. The front and rear mentioned here are based on the direction of gas flow.

[0032] In the low-pressure exhaust gas recirculation system, the intake pipe section of the EGR pipe 2 is connected to the exhaust pipe 5 of the engine after the turbo end 6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com