Patents

Literature

81results about How to "Synchronous rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

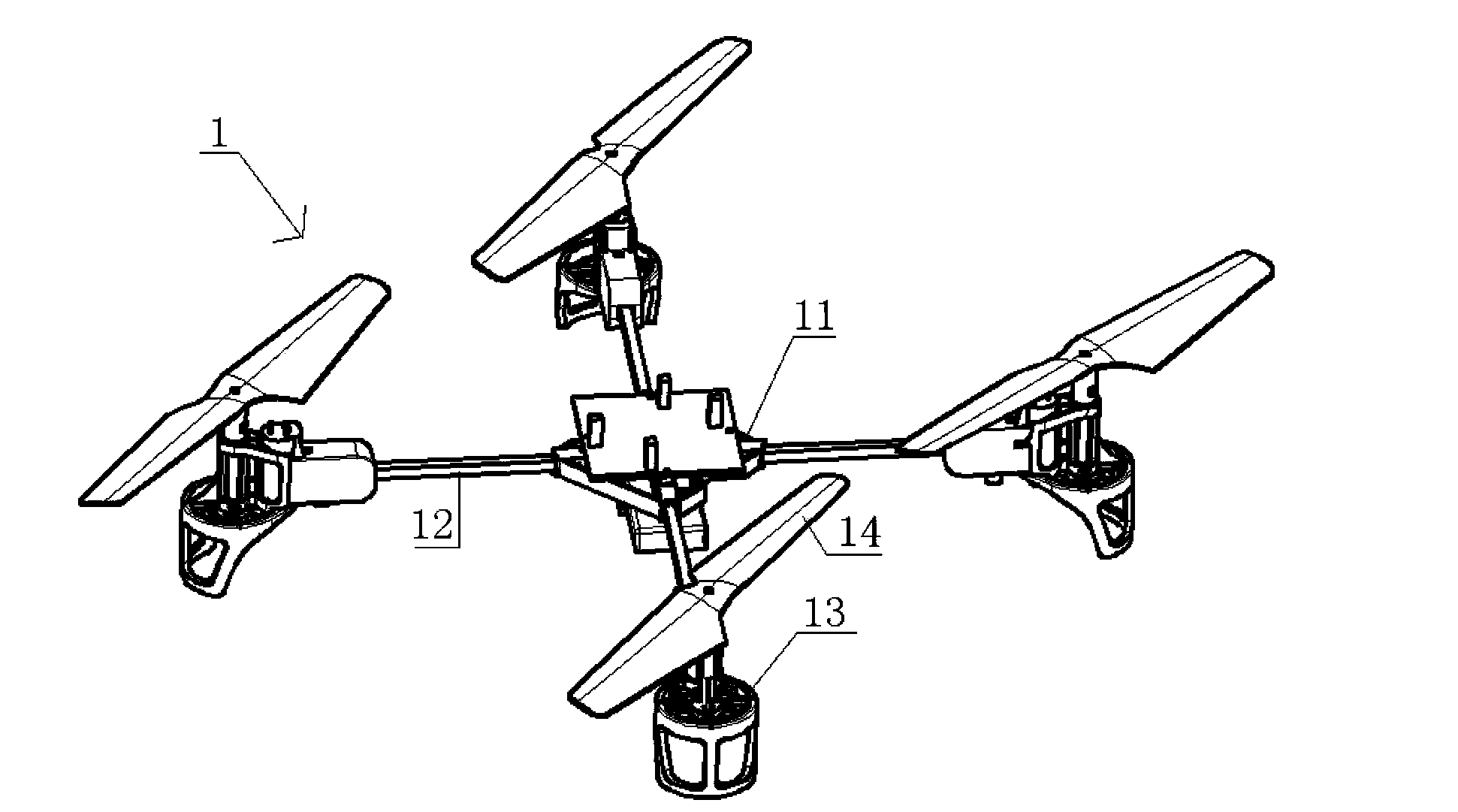

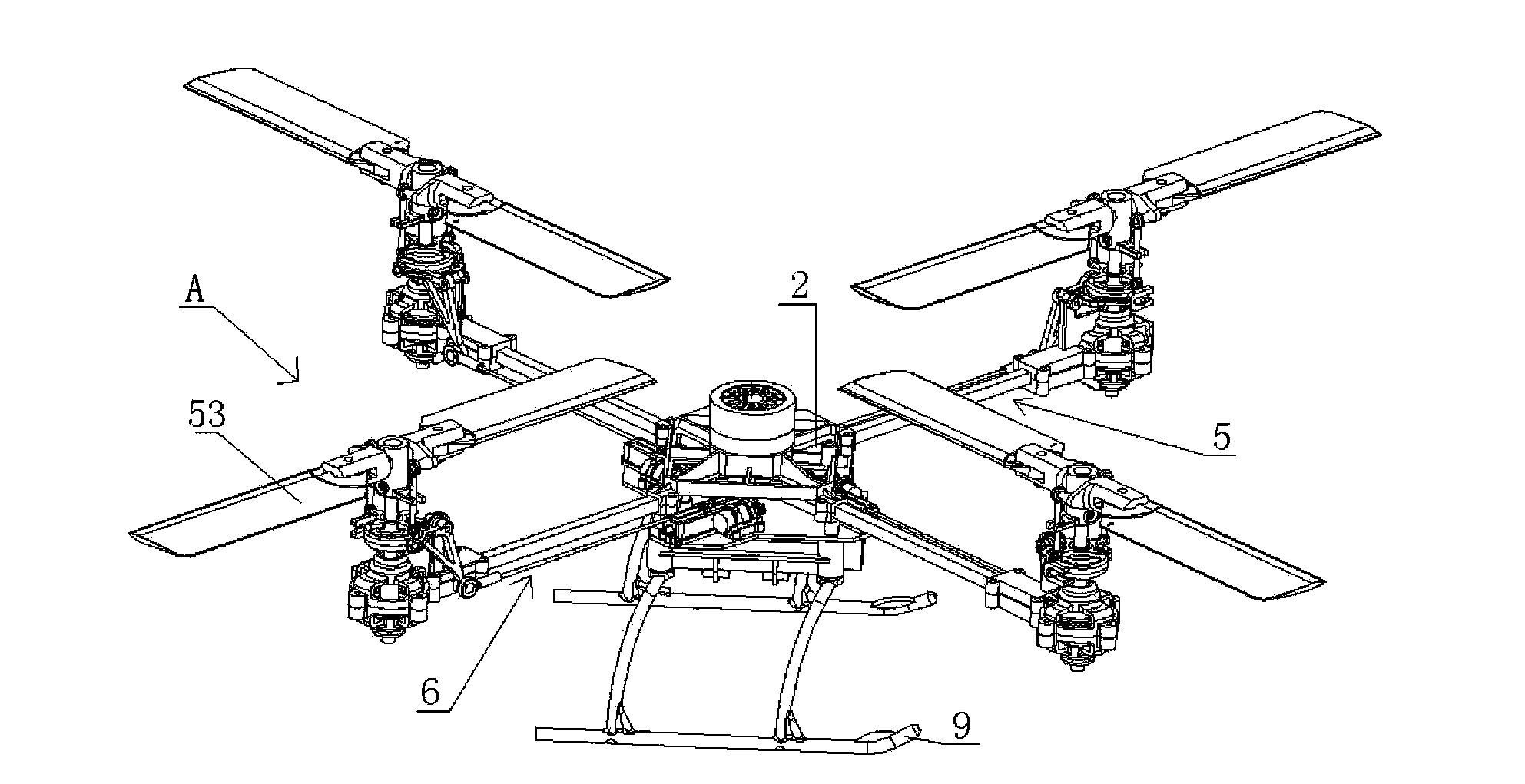

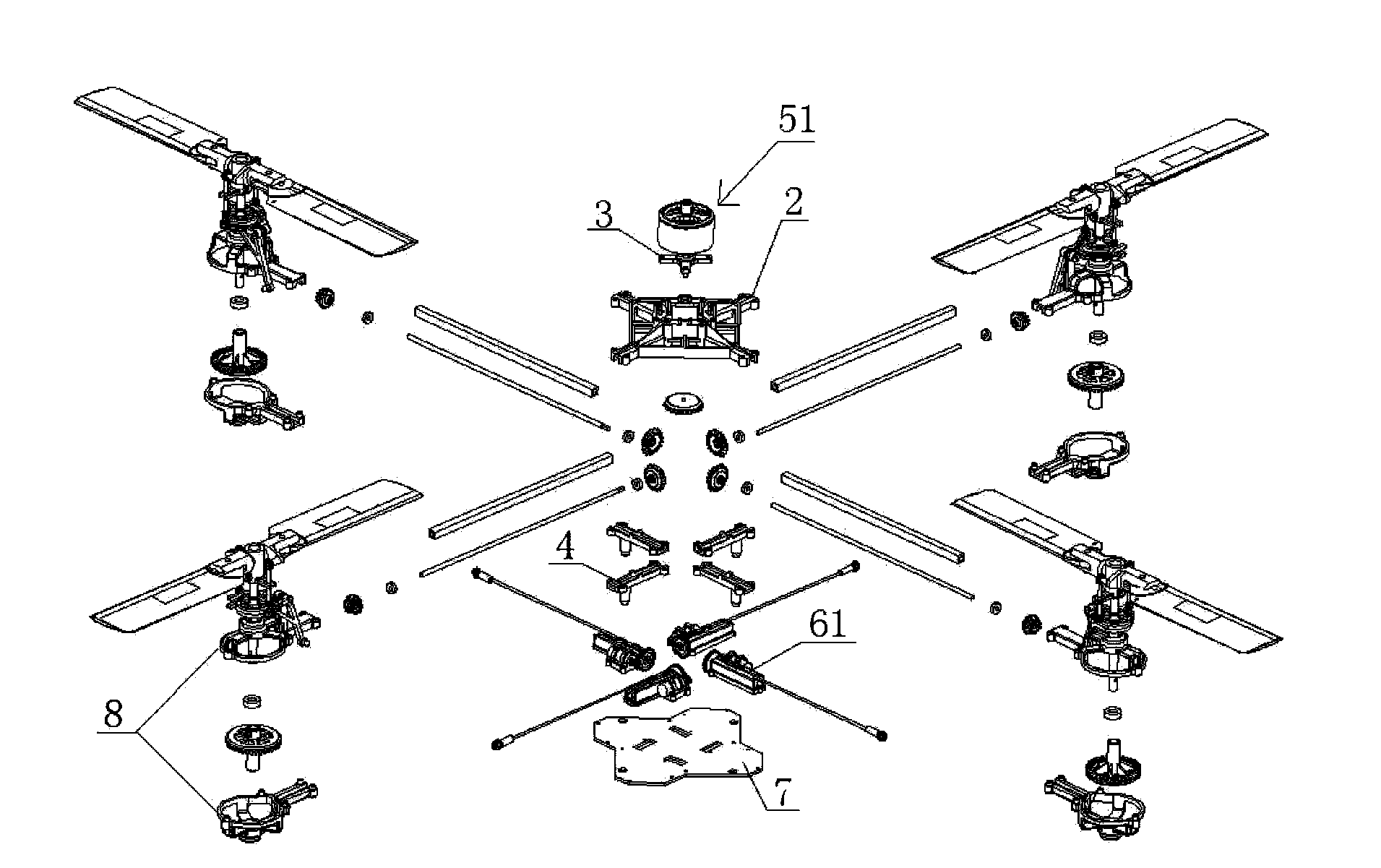

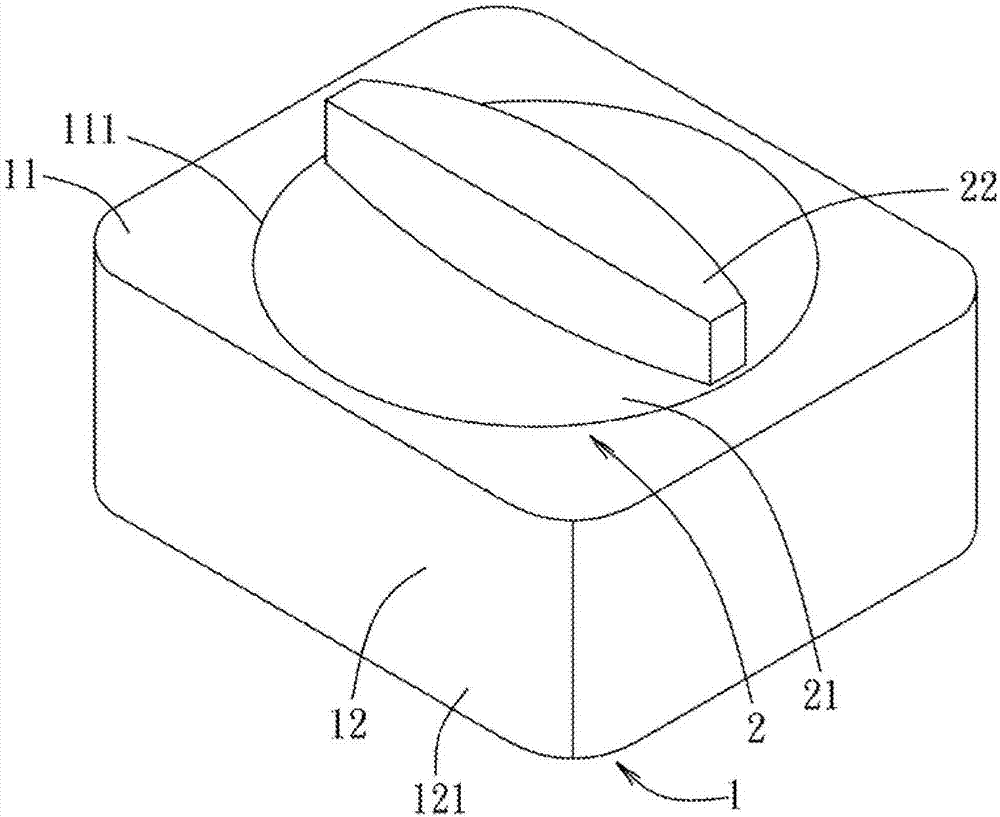

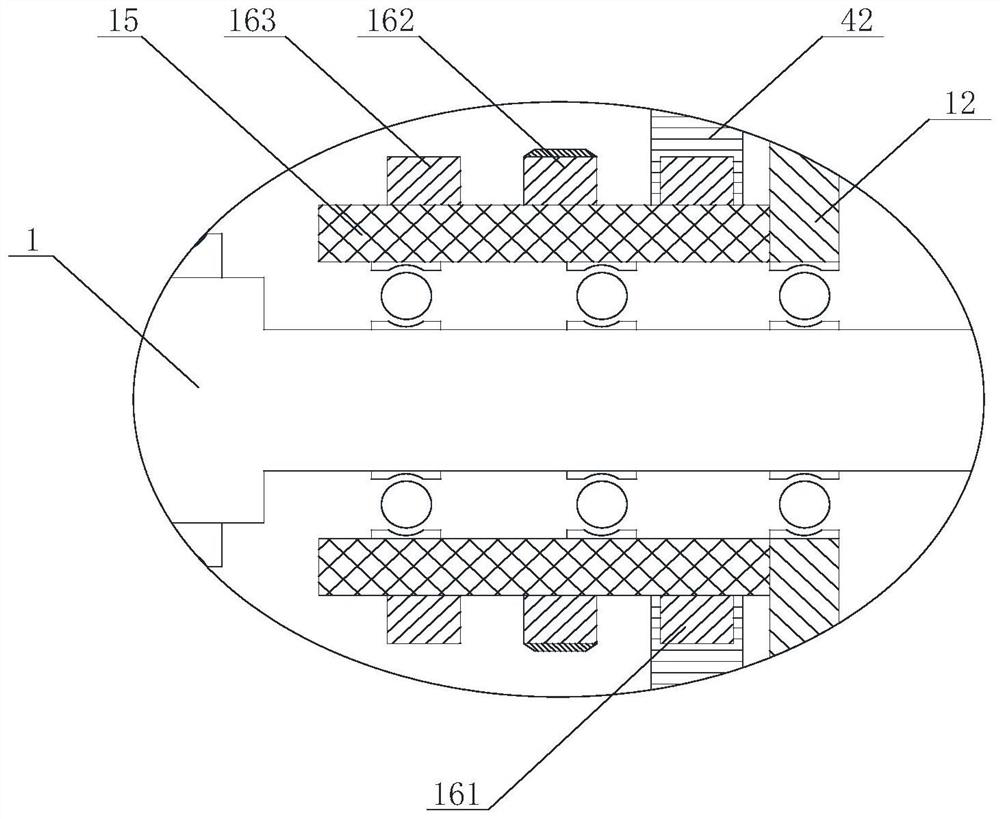

Multi-rotor wing aircraft

The invention discloses a multi-rotor wing aircraft. The multi-rotor wing aircraft comprises a power system and a distance change system. The power system comprises a main rotatable part, multiple driving parts and rotor wings connected respectively to the driving parts. The main rotatable part is provided with a rotatable end. The driving parts are driven by the rotatable end and transmit rotation to the rotor wings so that the rotor wings rotate synchronously. The distance change system comprises multiple distance change units. The distance change units are used respectively for changing incidence angles of the rotor wings. The driving parts are driven by the same rotatable end and the driving parts transmit rotation to the rotor wings so that the rotor wings rotate synchronously. Through distance change of the rotor wings, the multi-rotor wing aircraft can turn over, fly reversely or swing.

Owner:YUNEEC INT (CHINA) CO LTD

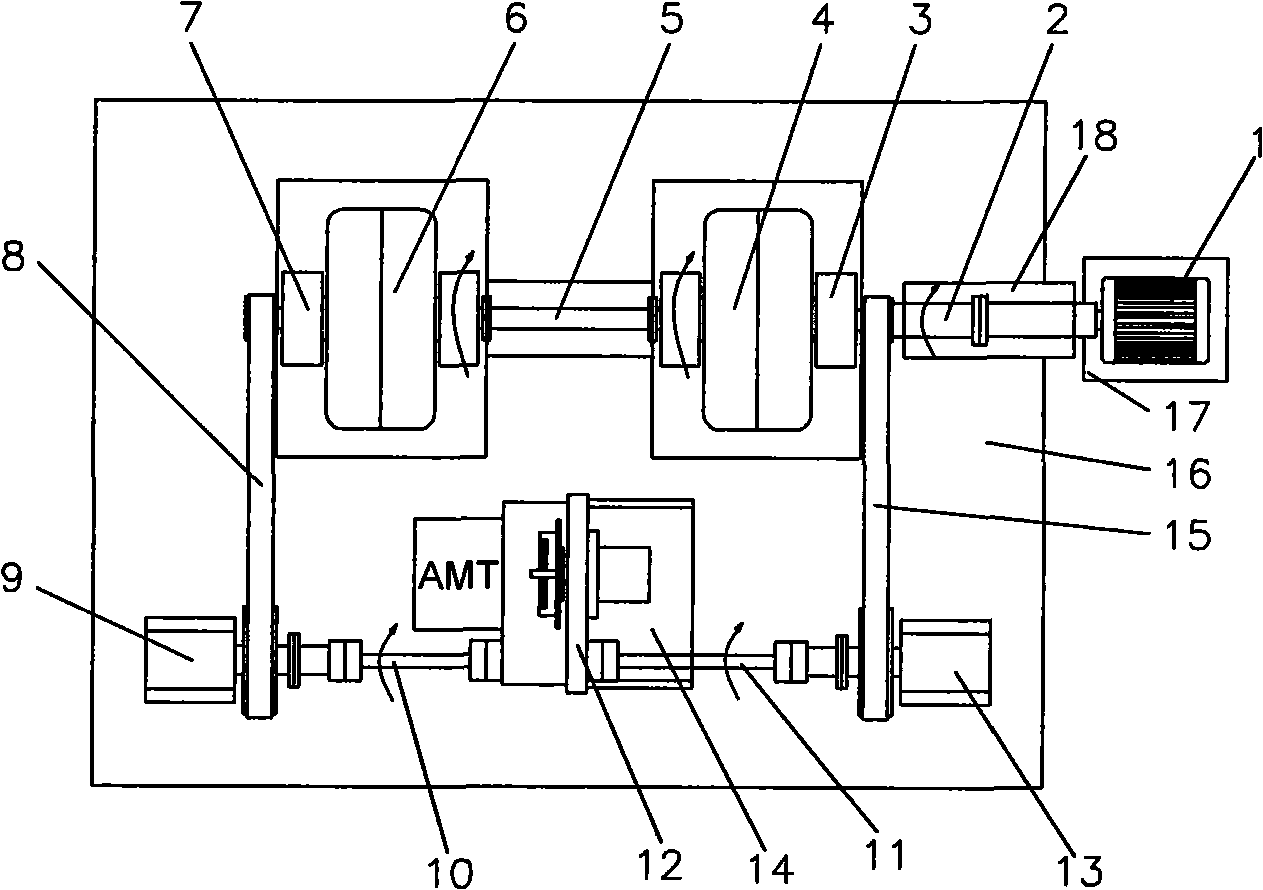

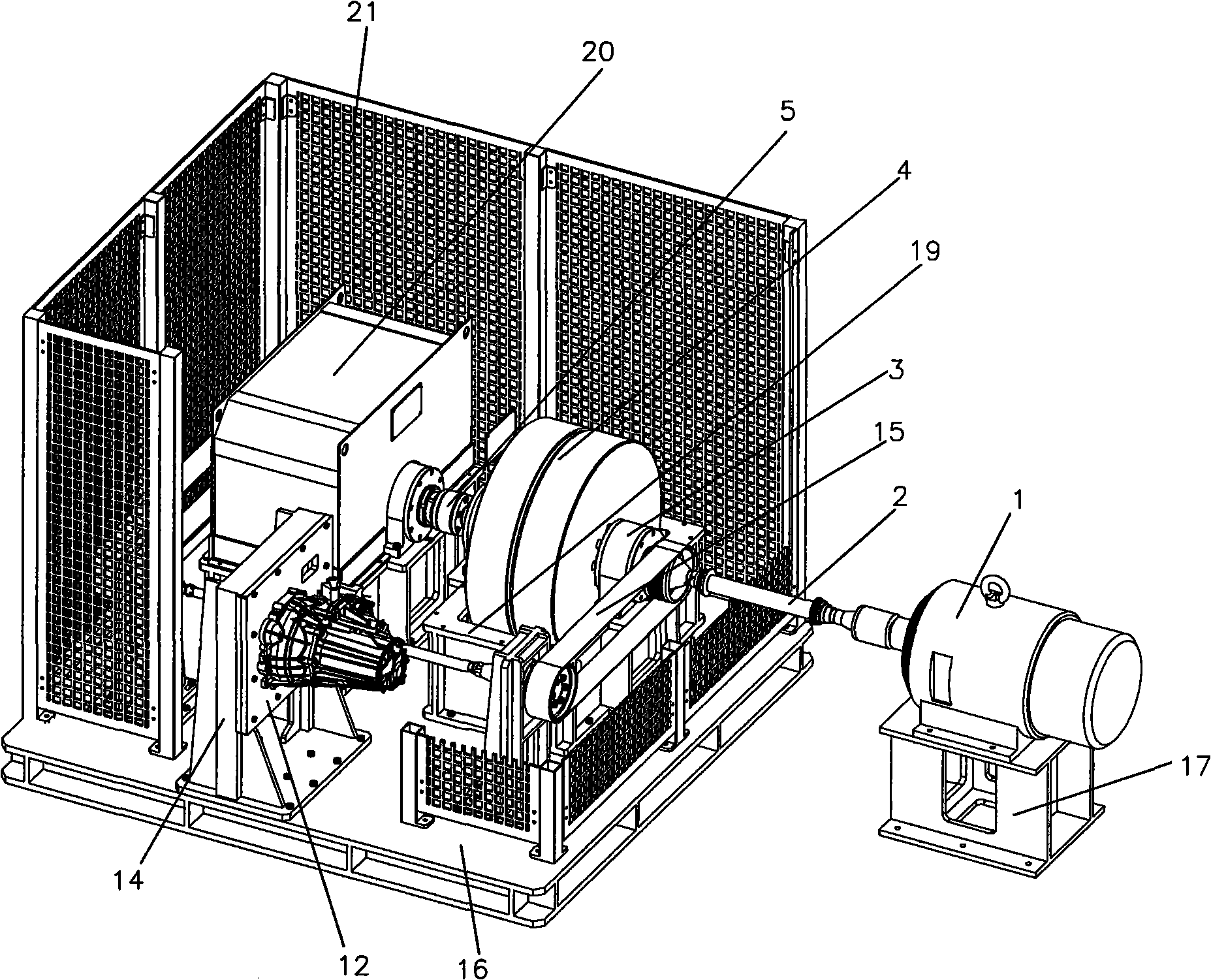

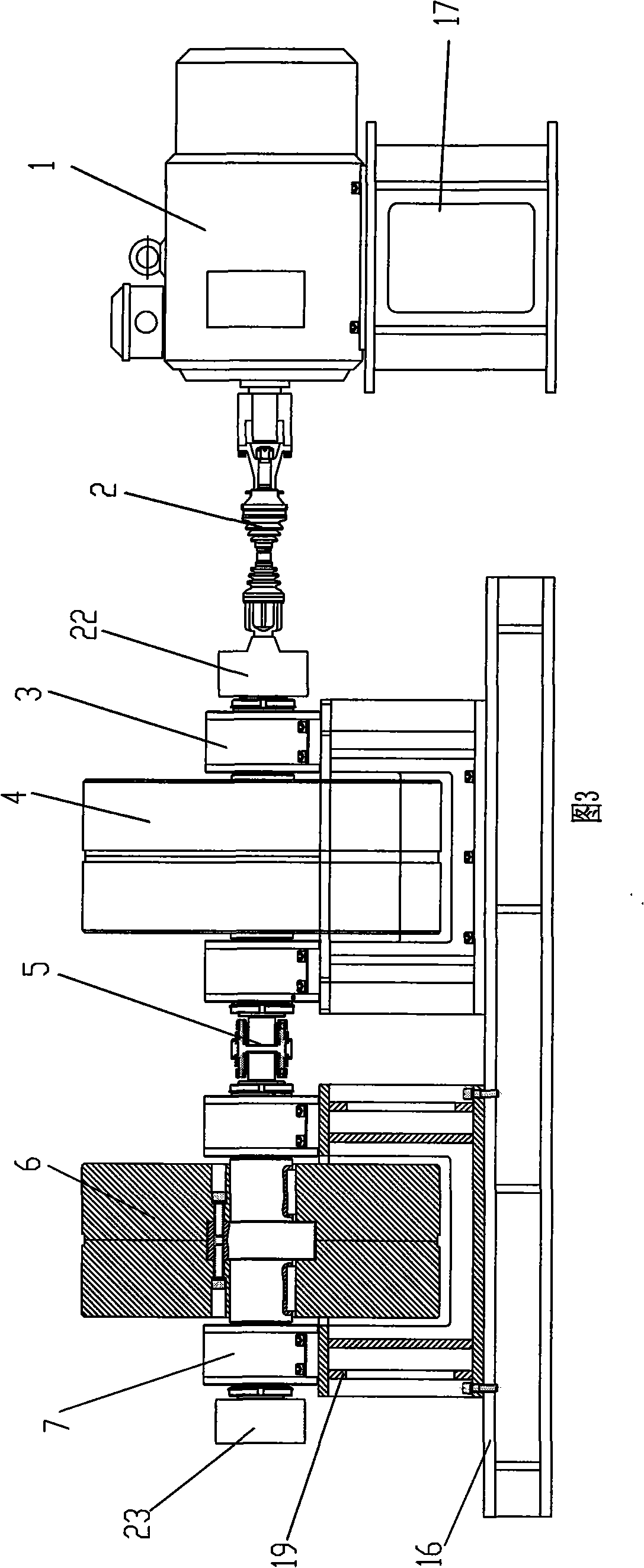

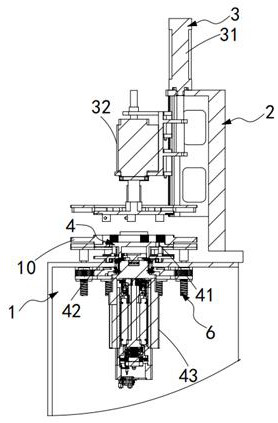

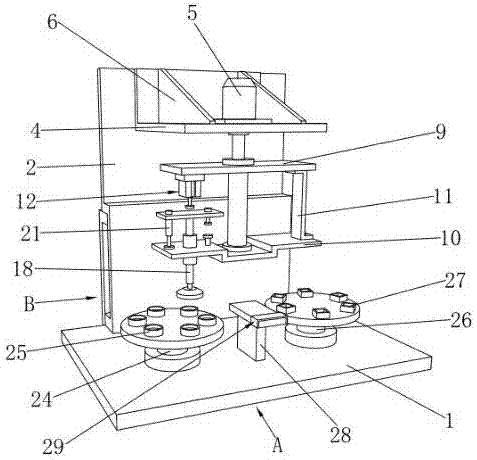

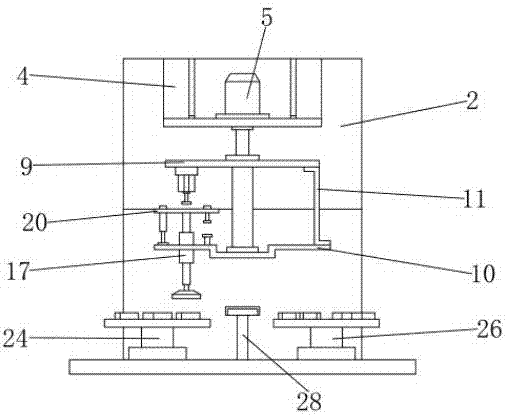

AMT shift endurance quality testing bench

ActiveCN101344456AIncrease line speedReduce noiseVehicle testingMachine gearing/transmission testingElectric machineryVariator

The invention discloses a test bed of AMT shifting durability and is characterized in that a left flywheel and a right flywheel are connected into a double-inertia flywheel group with united and synchronous rotation by an elastic shaft joint, a left transmission belt and a left driven belt wheel between a left half shaft and a right half shaft of a gear box as well as a right transmission belt and a right driven belt wheel between the ends of a left shaft and a right shaft of the double-inertia flywheel group respectively form a power transmission mechanism, and the power source of the double-inertia flywheel group is provided by an electric variable-frequency motor. The test bed of AMT shifting durability not only can satisfy functional requirements and truly simulate the AMT shifting process of a whole car, but also has simple mechanical structure, easy assembly and disassembly, easy adjustment, low production and maintenance cost, safety and reliability, and can satisfy the longtime frequent testing requirement of the gear box.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

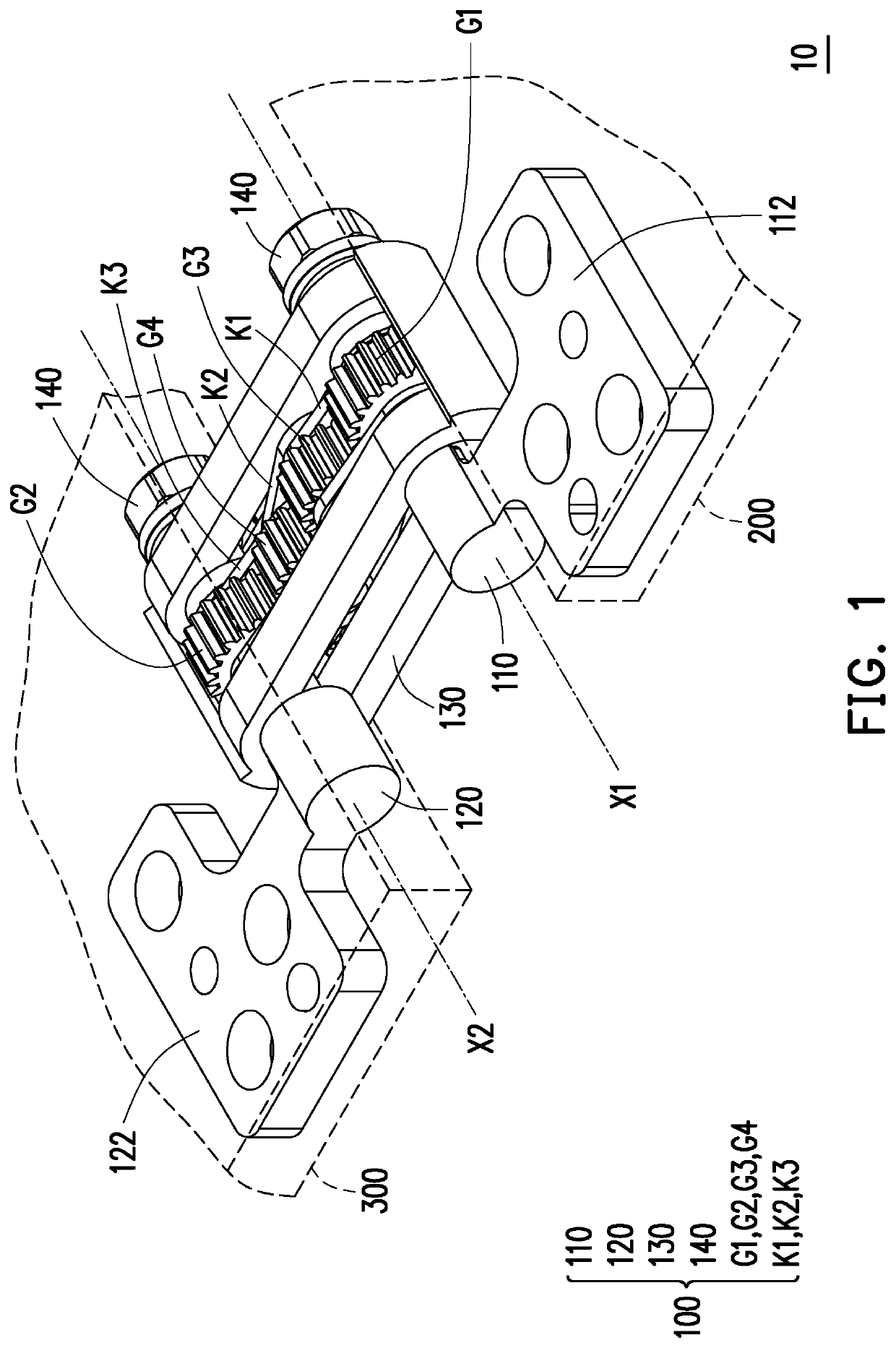

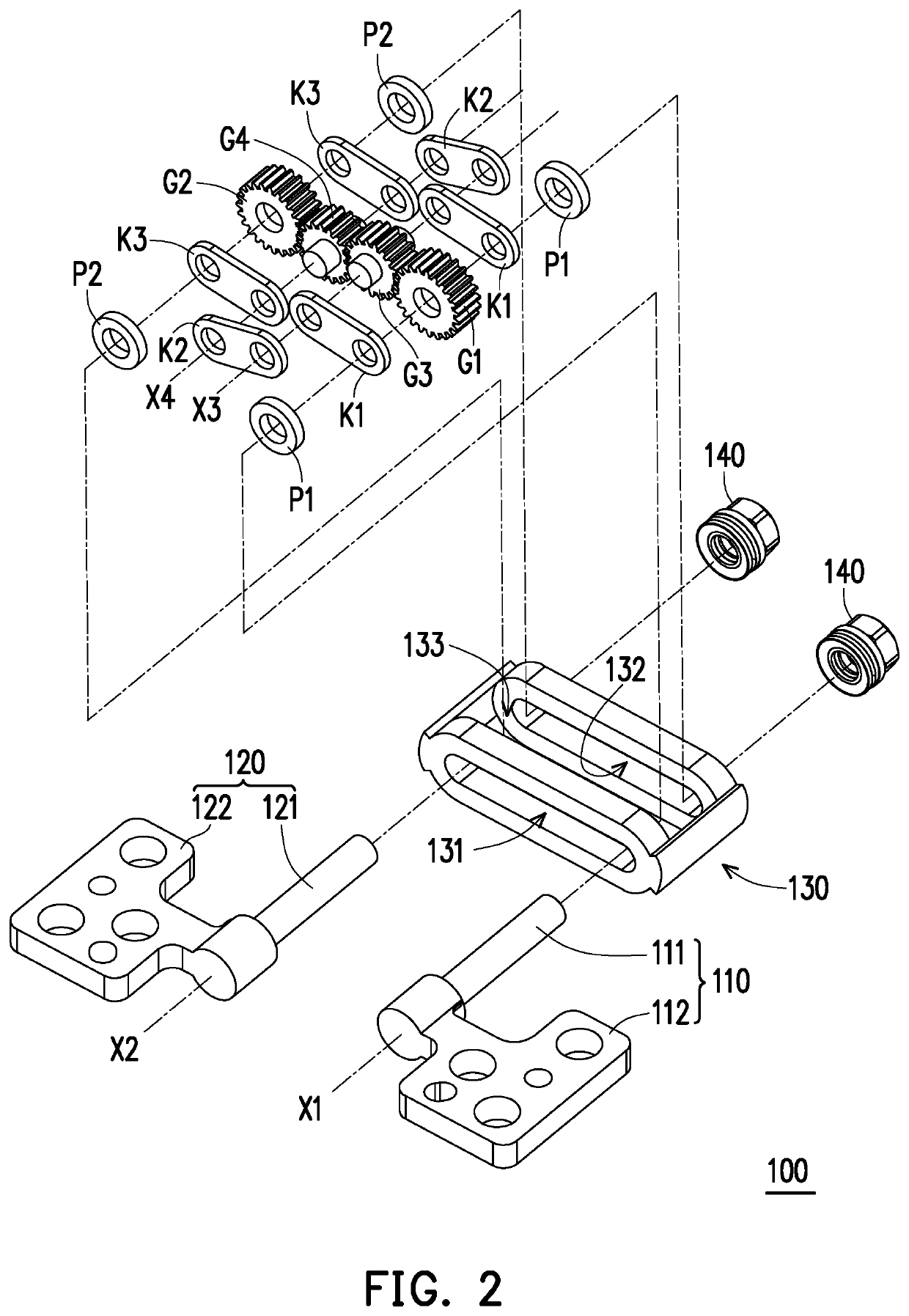

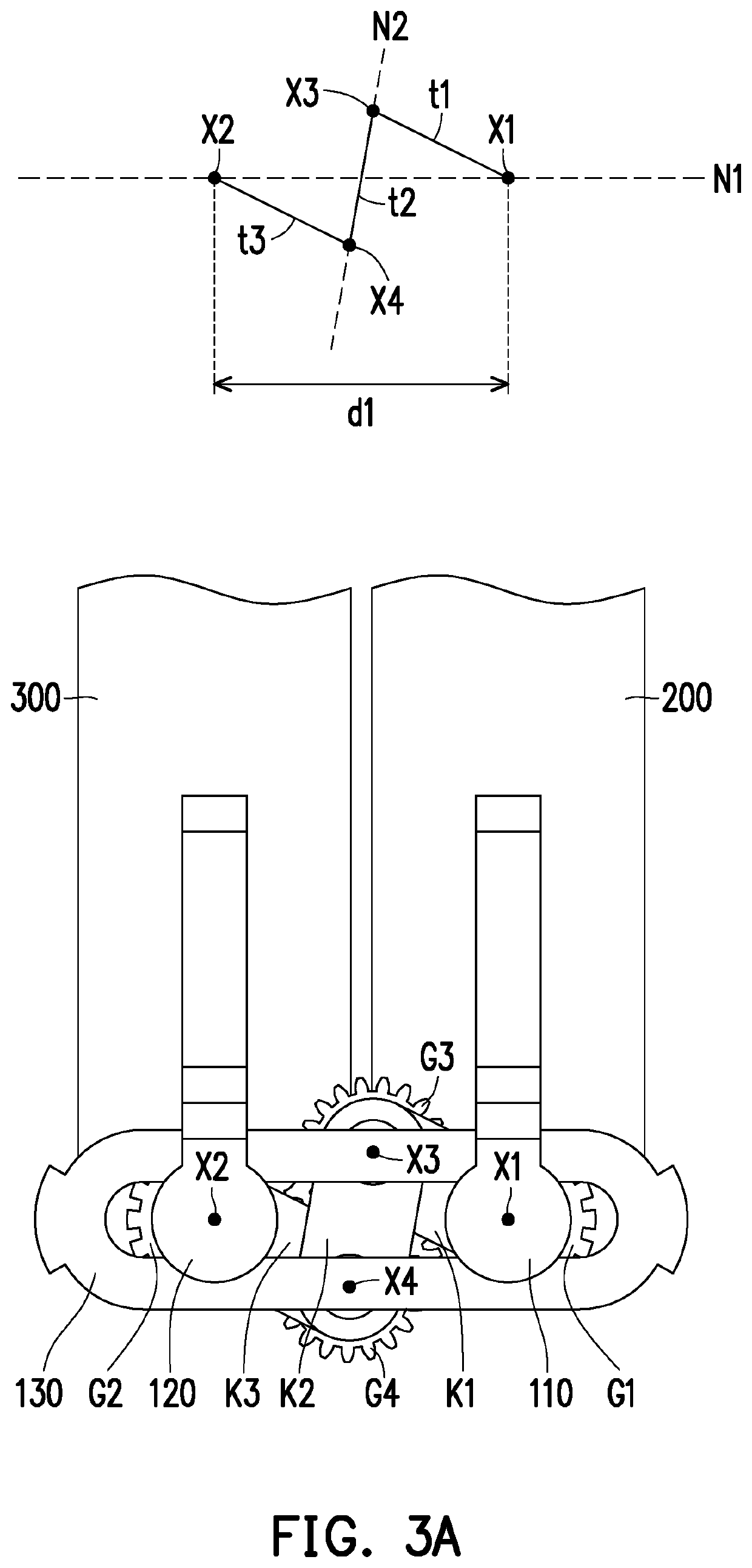

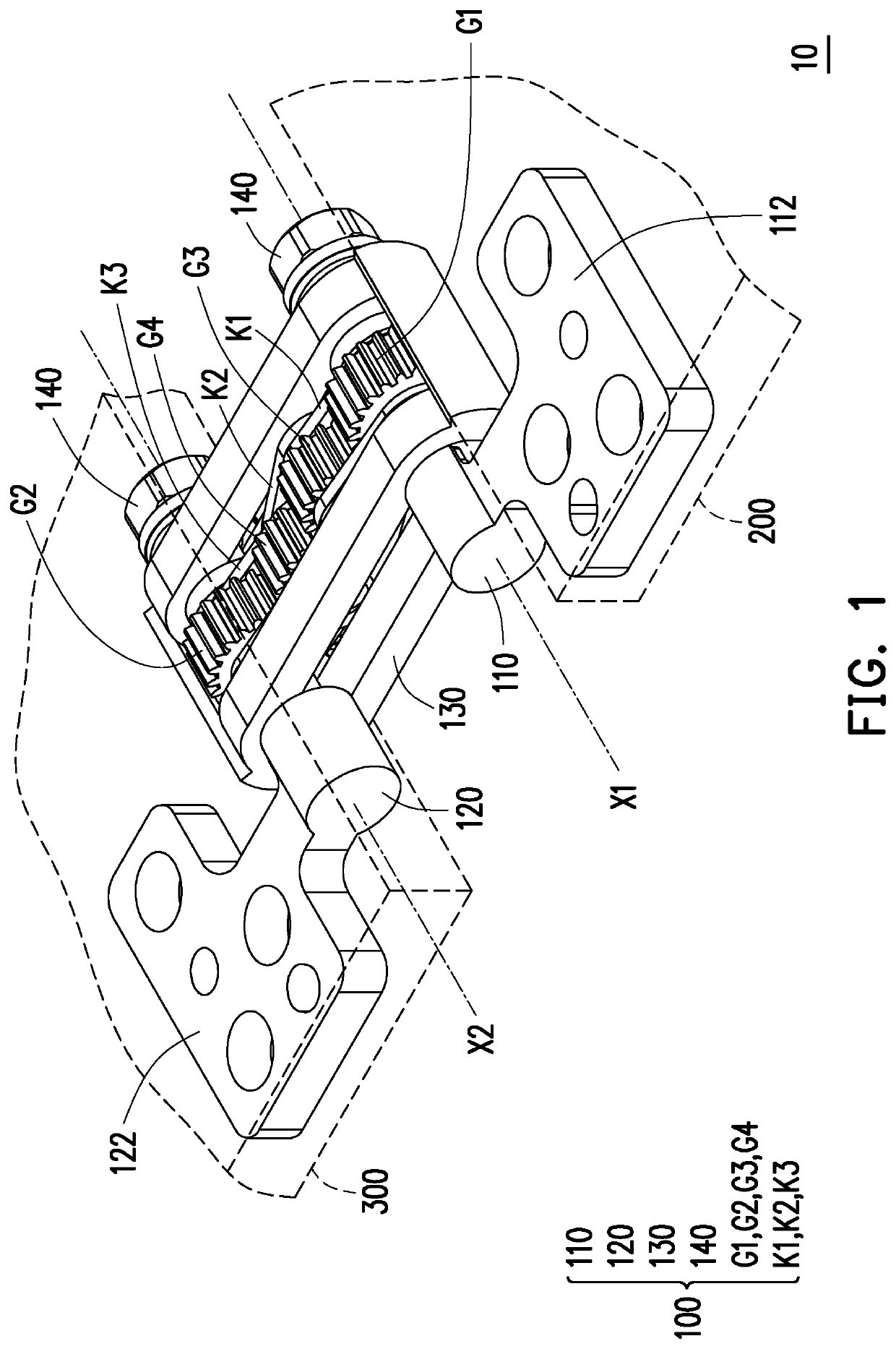

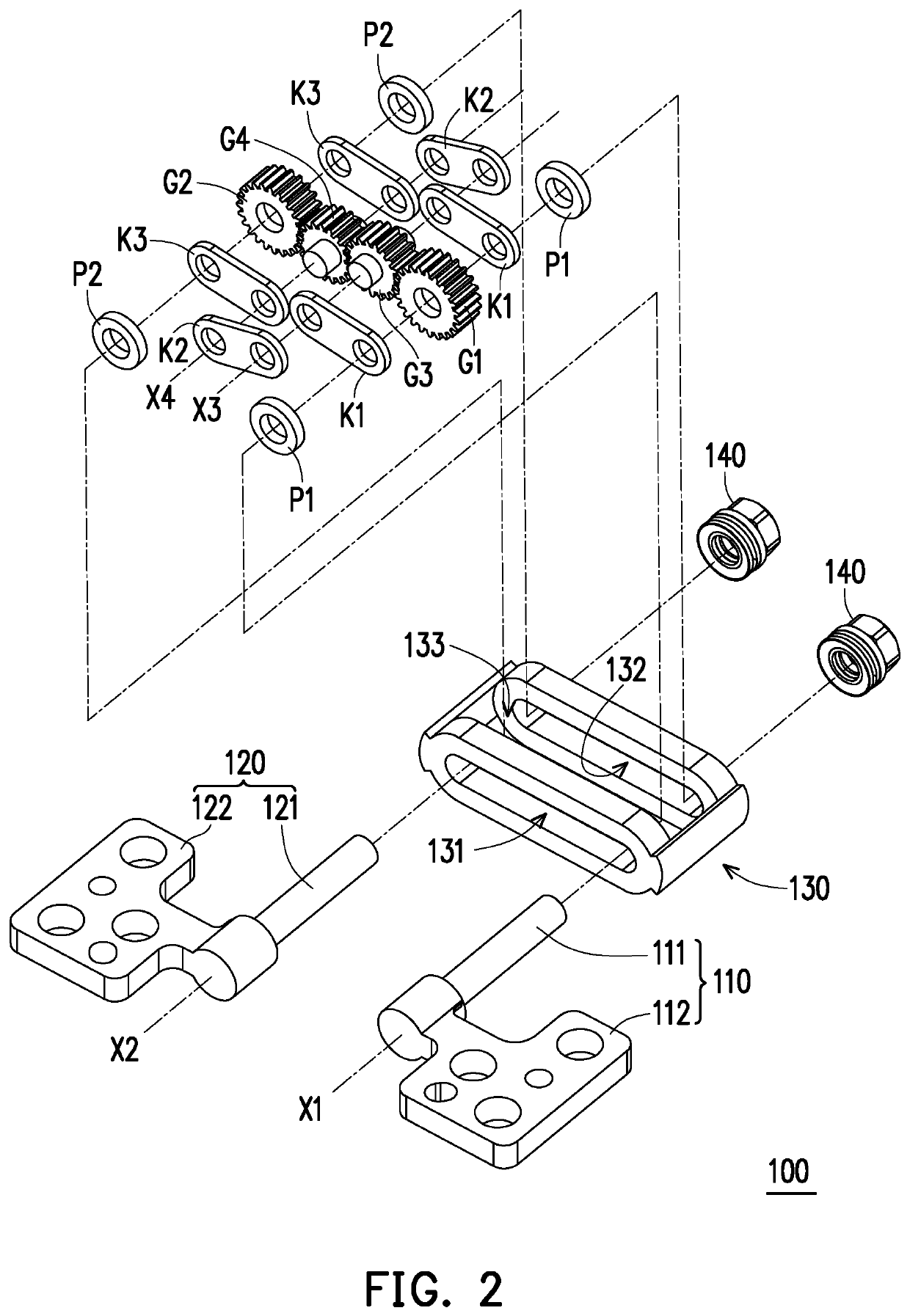

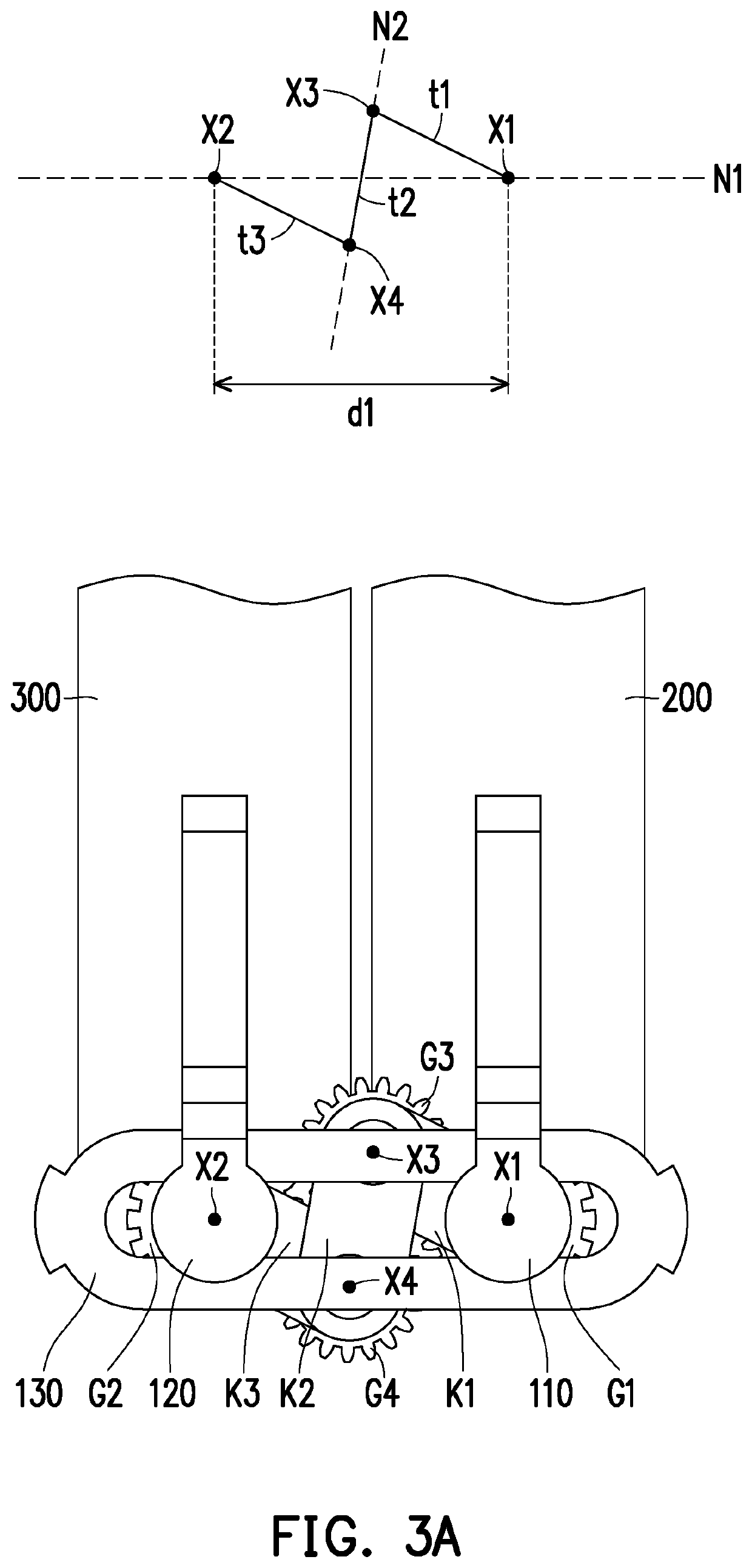

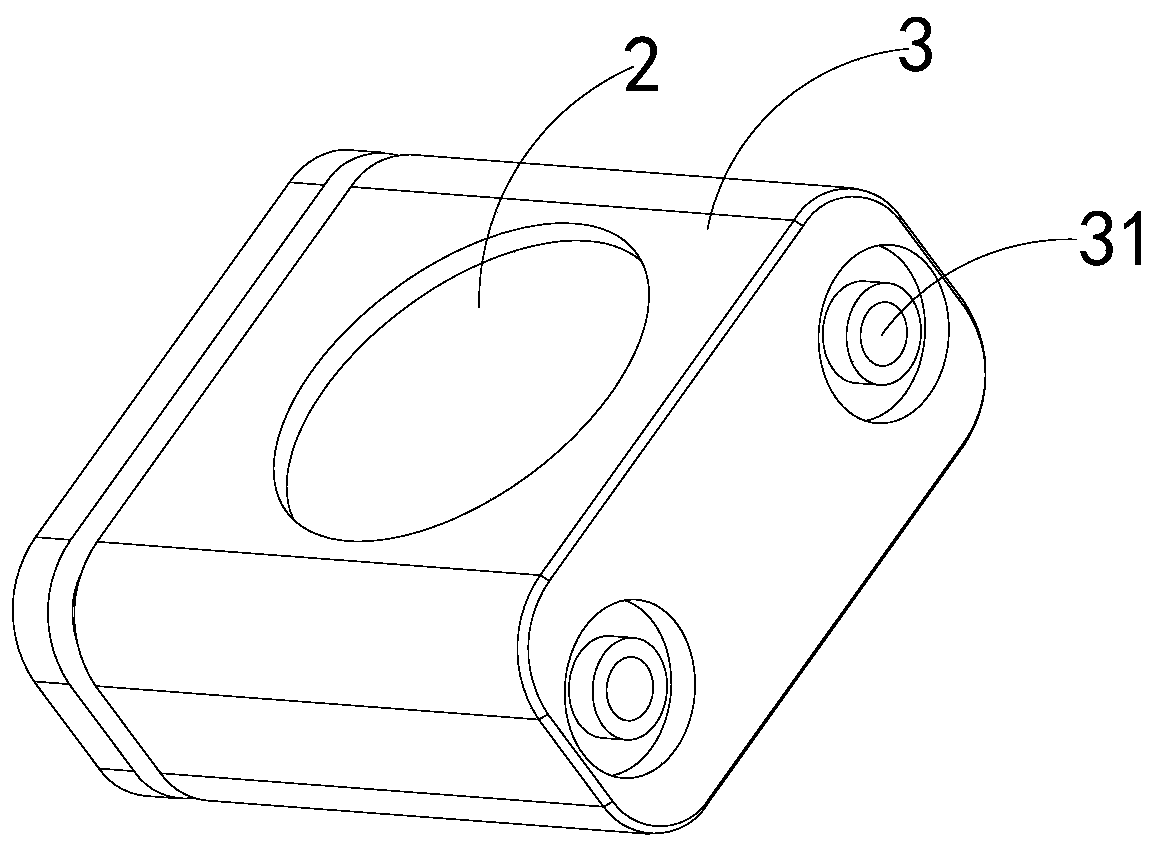

Dual-shaft hinge module and portable electronic device

ActiveUS20200291702A1Rotate synchronouslySynchronous rotationDigital data processing detailsWing accessoriesElectronic equipmentGear wheel

Owner:COMPAL ELECTRONICS INC

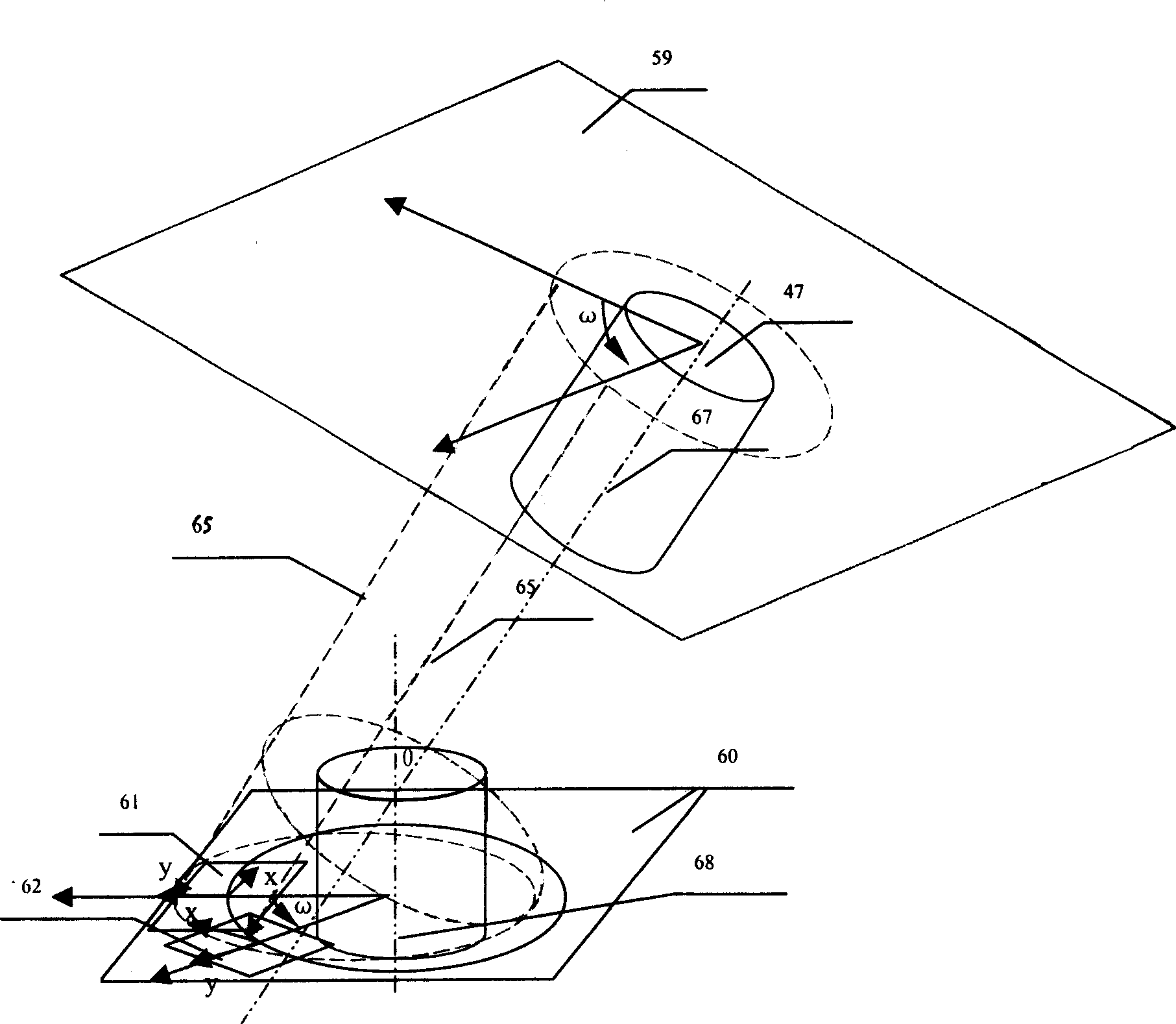

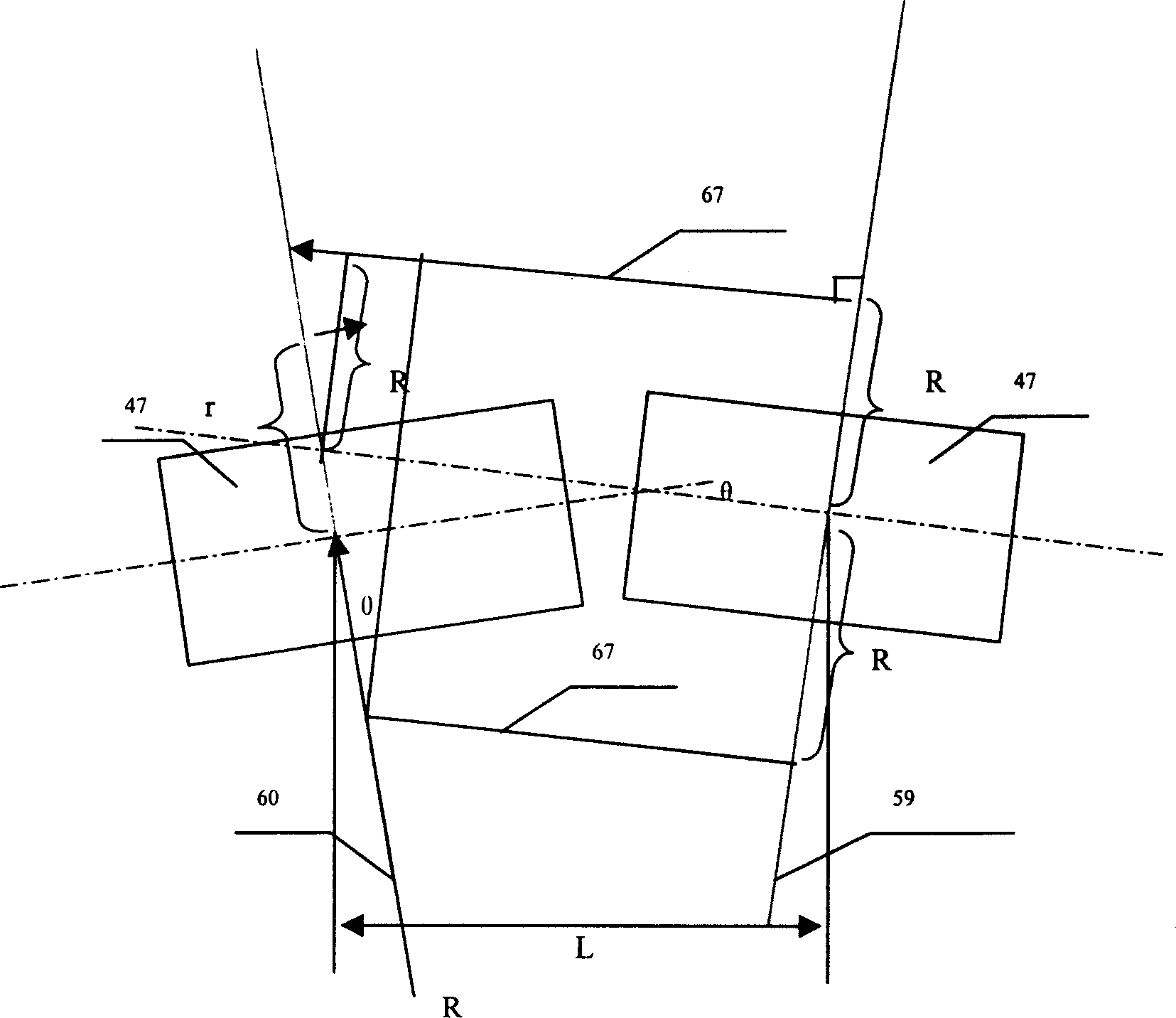

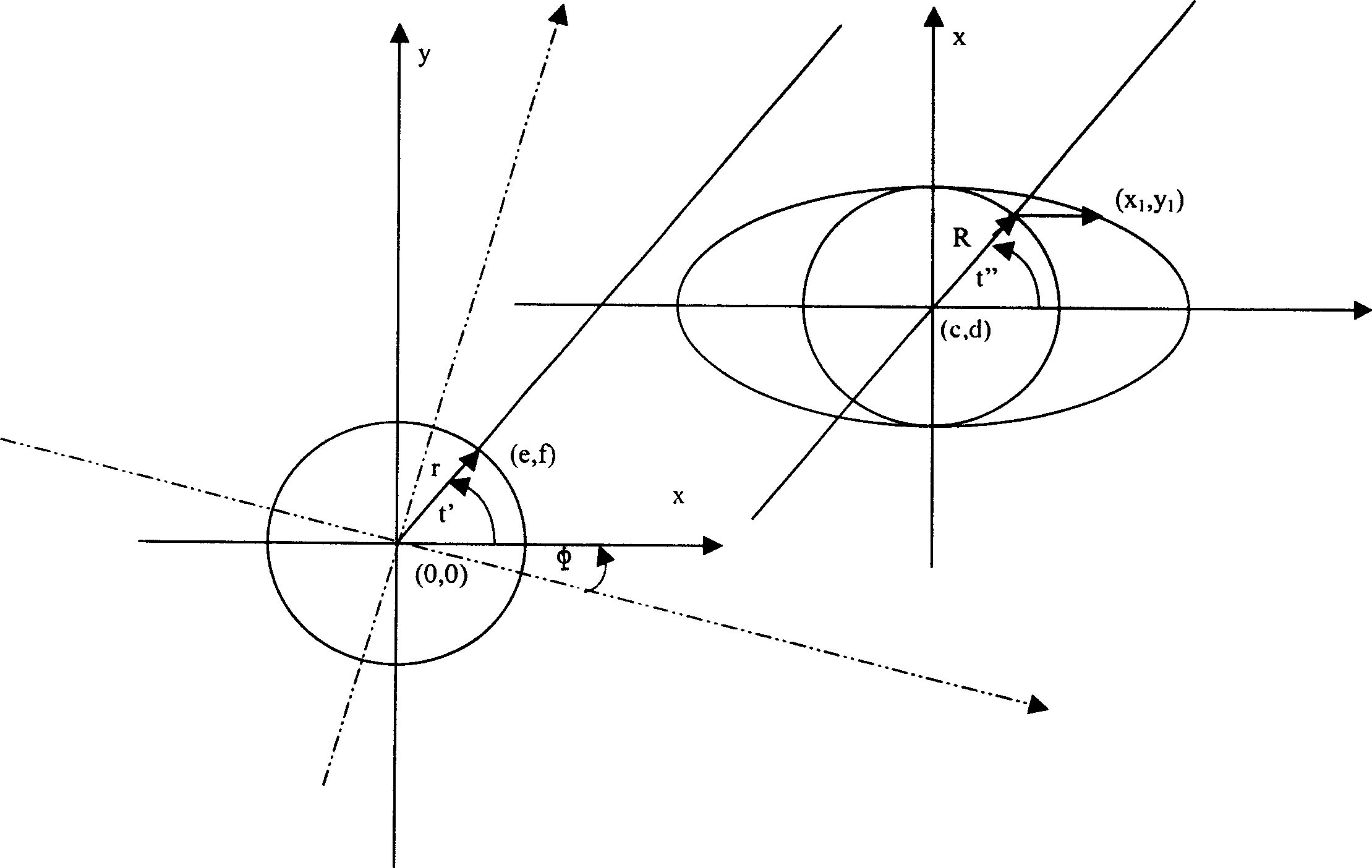

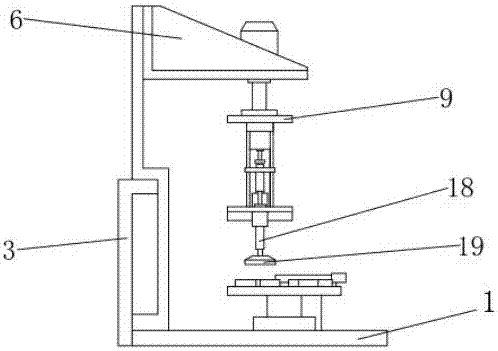

Collimation measuring device

InactiveCN1546945AGuaranteed to be parallelSynchronous rotationUsing optical meansMeasurement deviceOptical axis

The invention refers to a kind of laser collimating device, especially refers to a kind of shift collimating measuring device for two hole axle measuring states. The character of the device lies in: it is made up of transmitter, receiver and measuring bracket. The transmitter and the receiver are set on the L type bottom bracket of itself measuring bracket, and the light axis is parallel to the base of the L type bottom bracket, and they rotates synchronously, the light source of the transmitter, the small hole of the light blocking board and the lens are on the same light axis in order, the two-dimension position optical measuring device of the receiver and the lends are on the same light axis. The two-dimension optical measuring device of the receiver is connected to the computer through a signal wire; the computer has a two-dimension coordinate displaying frame of off-set position of light spot. The invention can measure the relative shift between two holes or two axles, and it also can measure the off-set angle.

Owner:WUHAN UNIV OF TECH

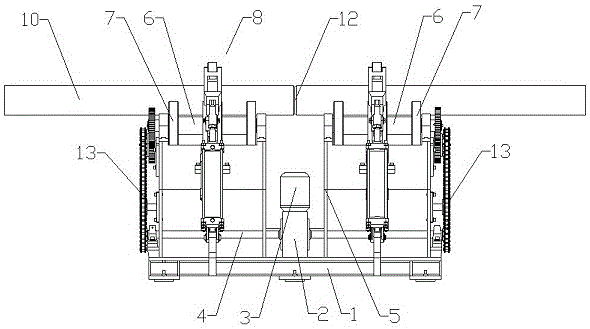

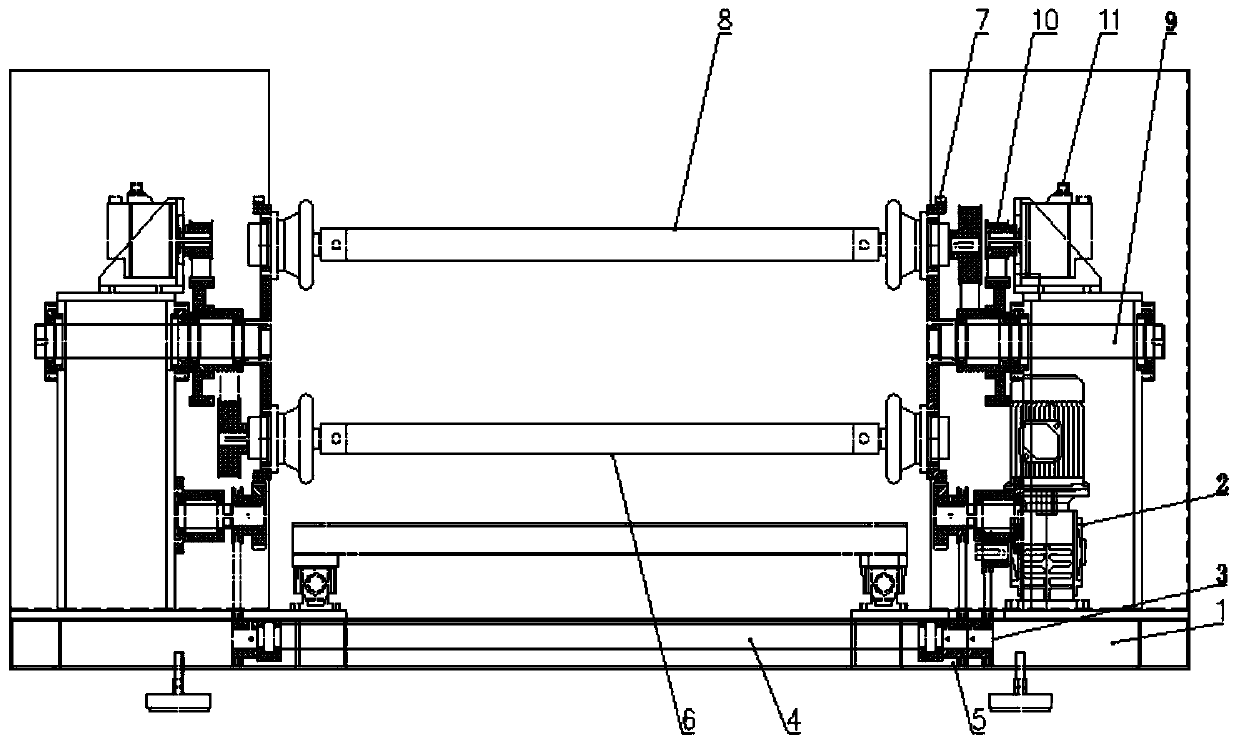

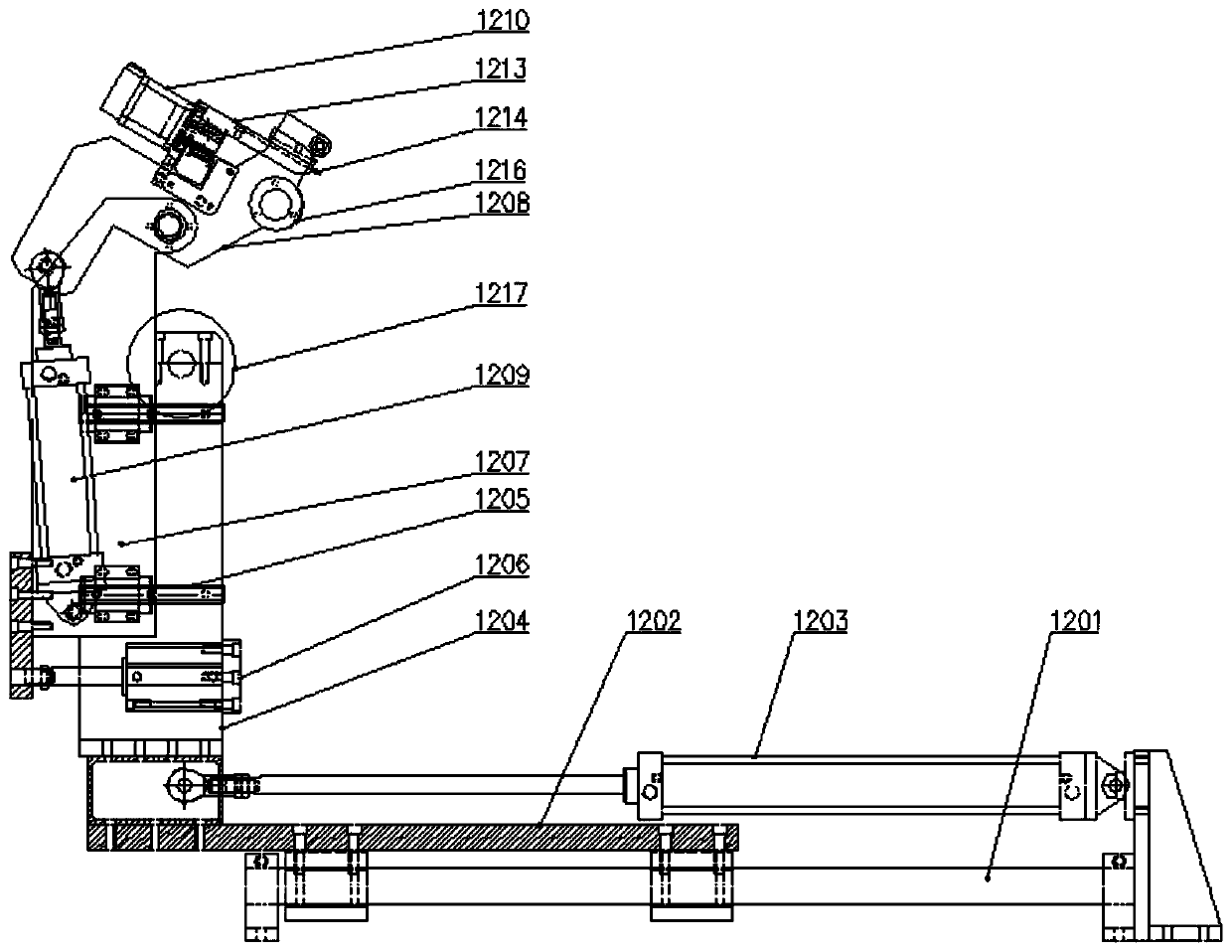

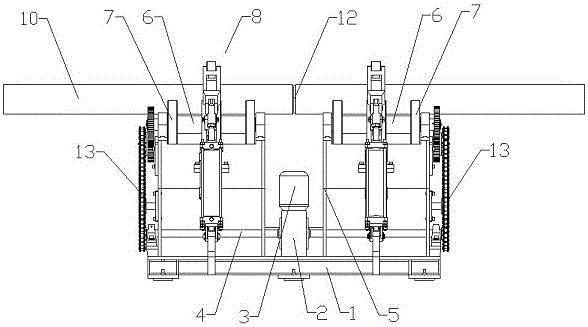

Pipe assembly welding external clamping device

ActiveCN105057967ALower skill requirementsReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesSkill setsEngineering

The invention discloses a pipe assembly welding external clamping device which comprises a base. The base is provided with a supporting device capable of supporting two assembly pipes, and enabling the two assembly pipes to be located on the same axis and to rotate synchronously, so that assembly welding precision of the pipes is guaranteed. The coaxiality of the assembly pipes does not need to be adjusted repeatedly, and adjustment by a level gauge is not needed, either. After the two assembly pipes are placed on a left roller rack and a right roller rack of an assembly device to be compressed, the coaxiality of the two assembly pipes can be guaranteed, the skill requirements for operators are lowered, and the labor intensity of the operators is relieved. Assembly efficiency is high.

Owner:HIMILE MECHANICAL MFG

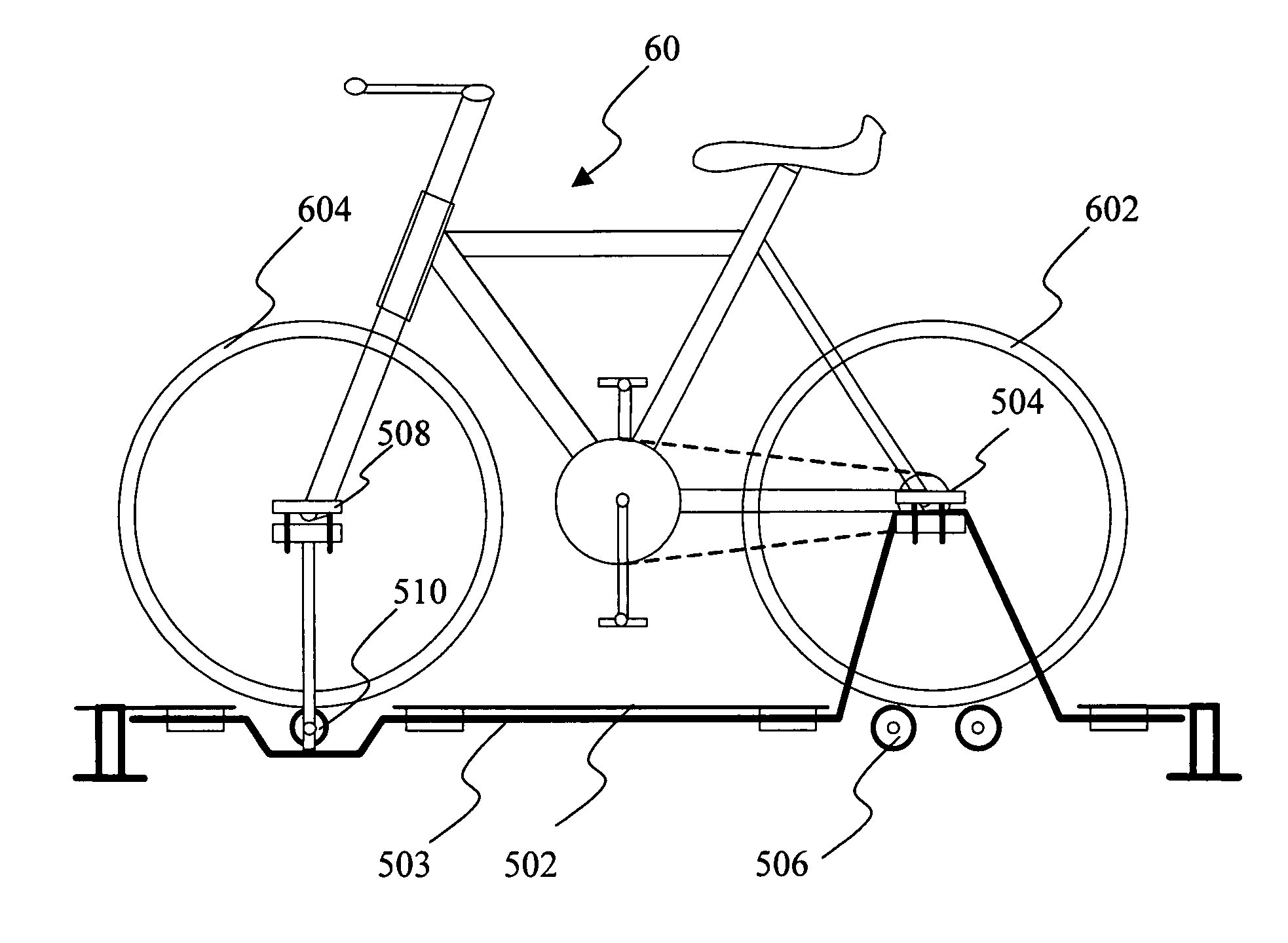

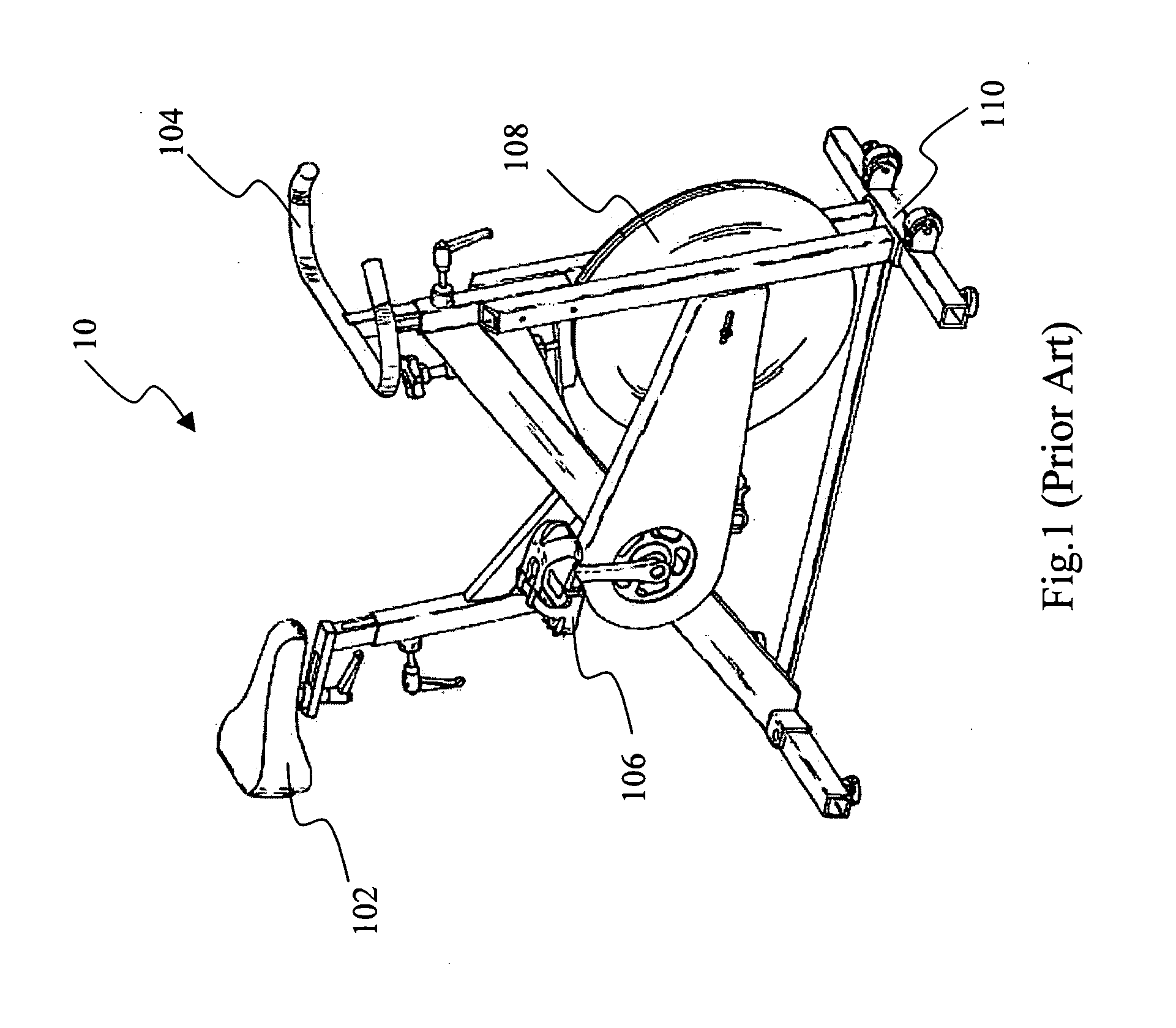

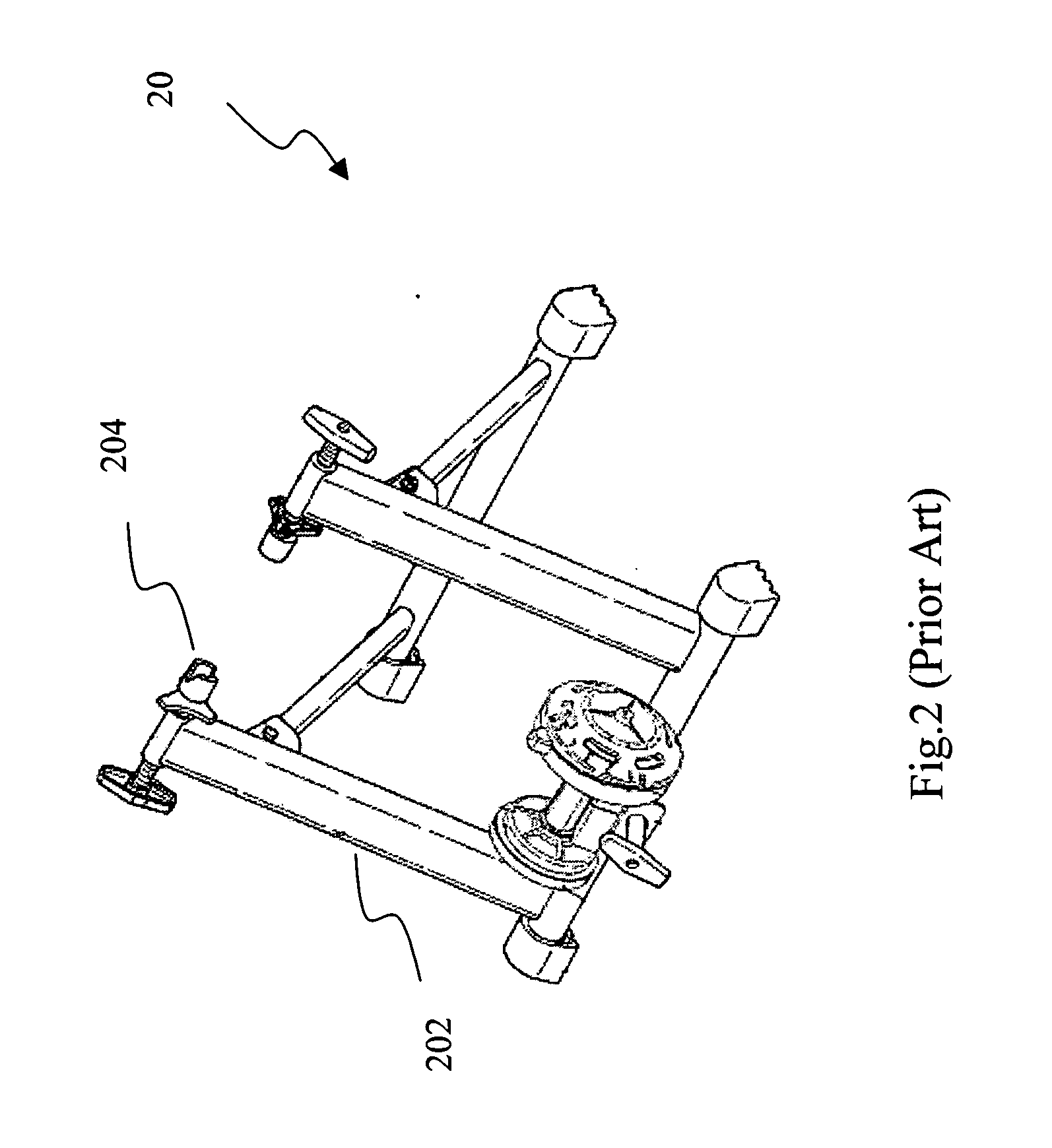

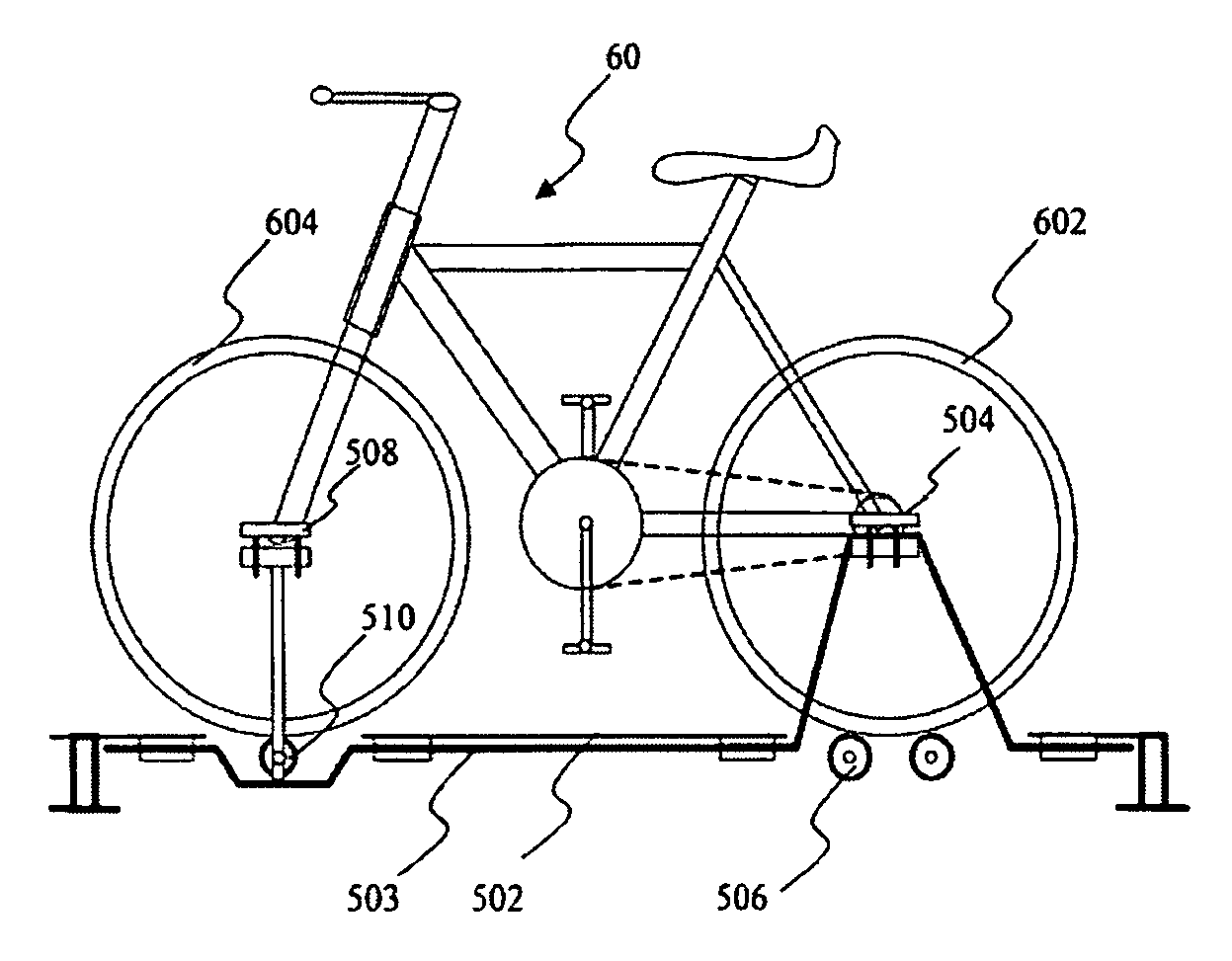

Auxiliary supporting device of a bicycle

InactiveUS20070202998A1Synchronous rotationStiltsMovement coordination devicesEngineeringControllability

An auxiliary supporting device is designed for supporting and fixing a bicycle. When a user rides a bicycle which is set up on this supporting device, the bicycle will neither move forward nor fall down if the user applies the skill of riding bicycle. This device can be used to train a rider for better bicycle controllability or to let user exercise at a fixed location.

Owner:WAN KUO HUI

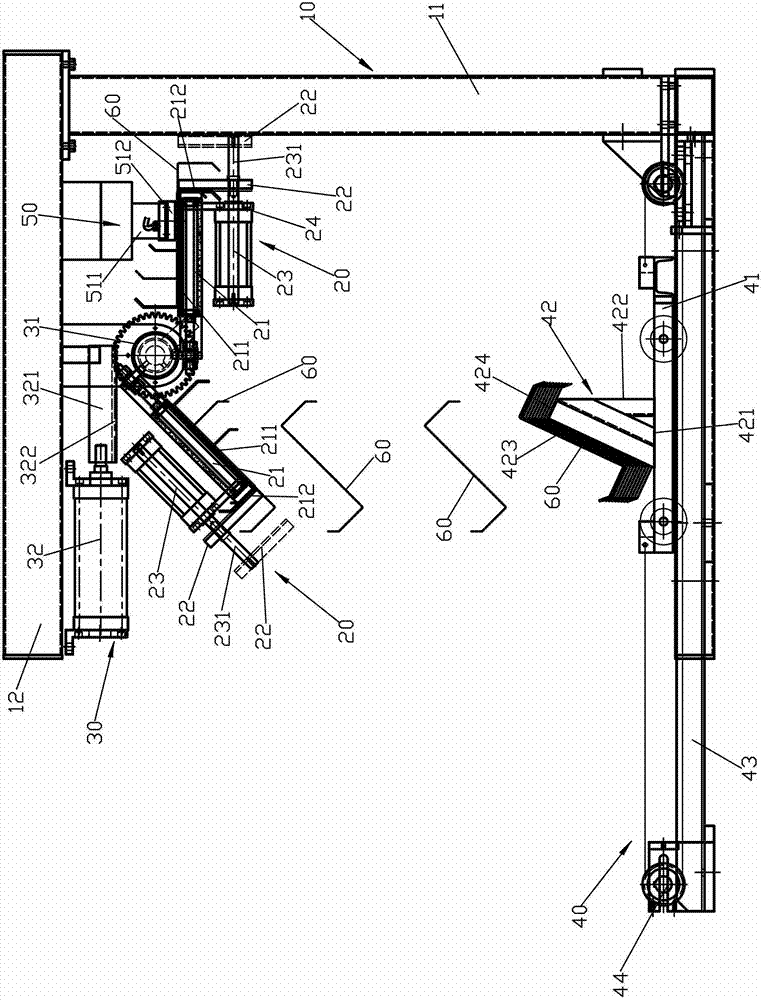

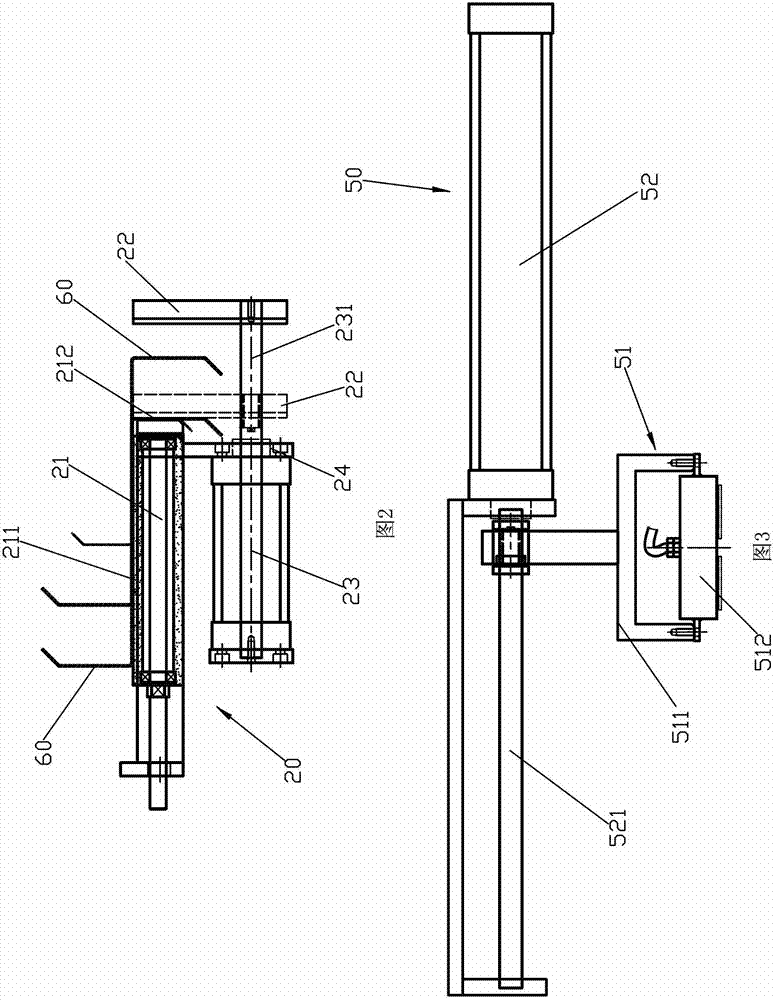

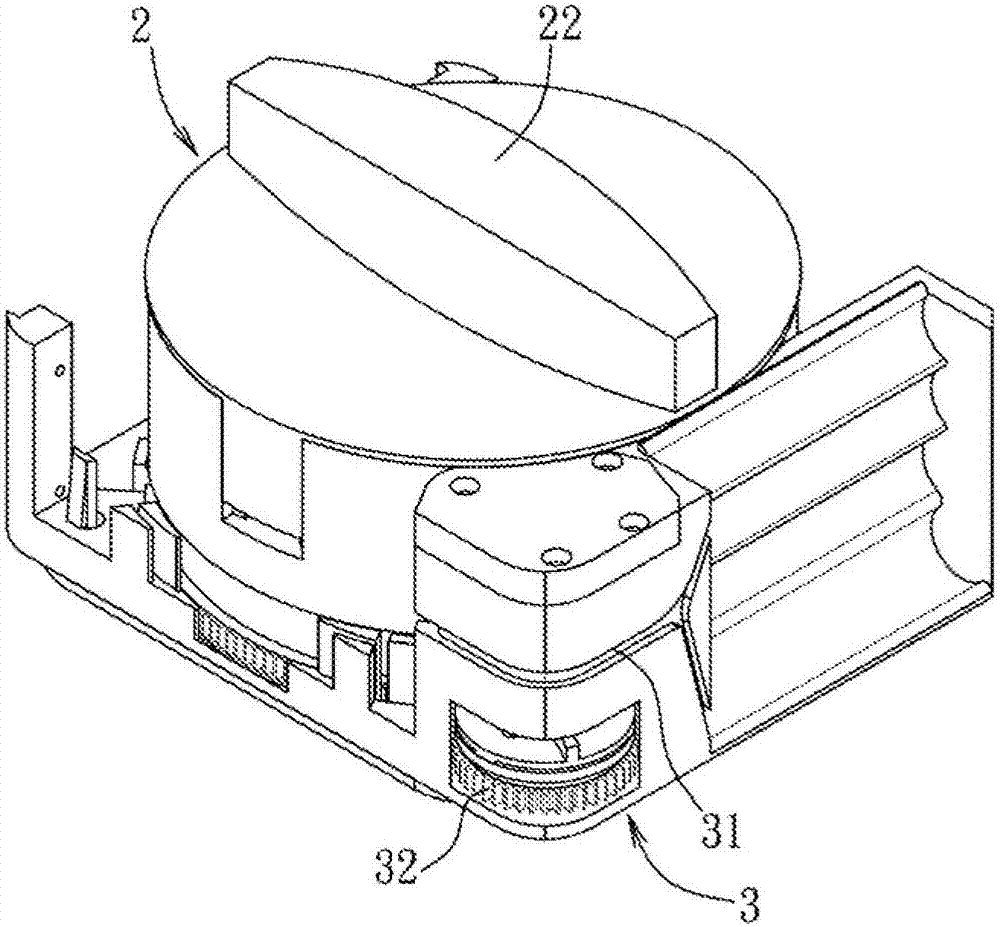

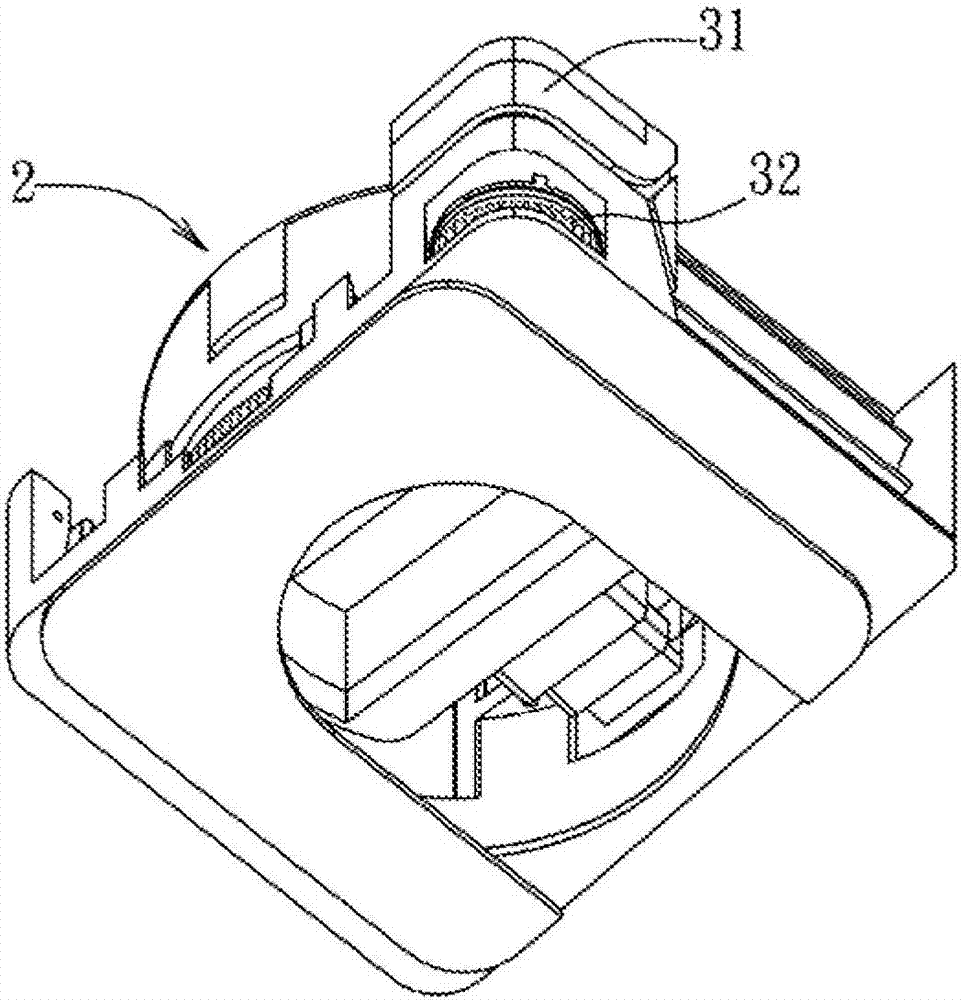

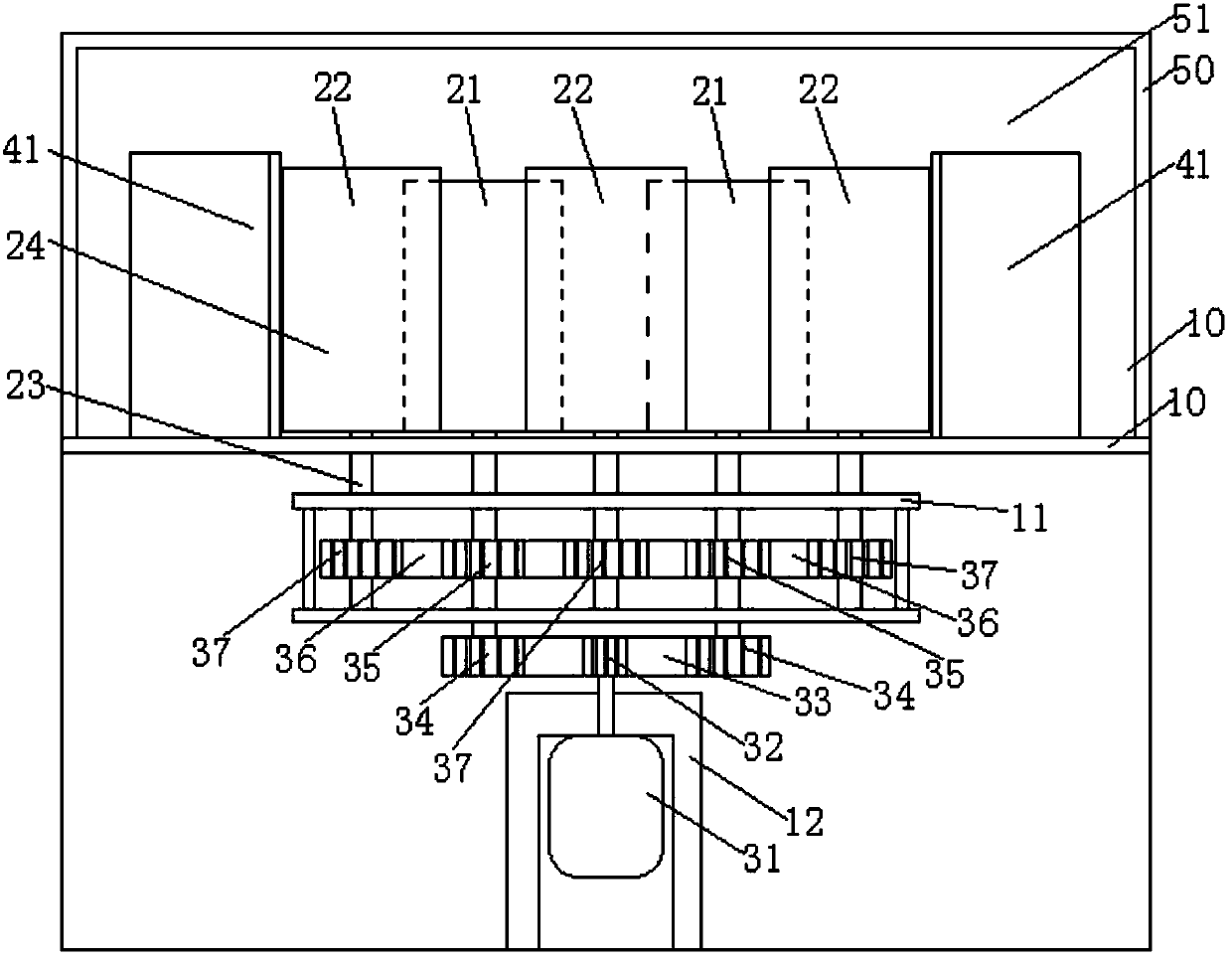

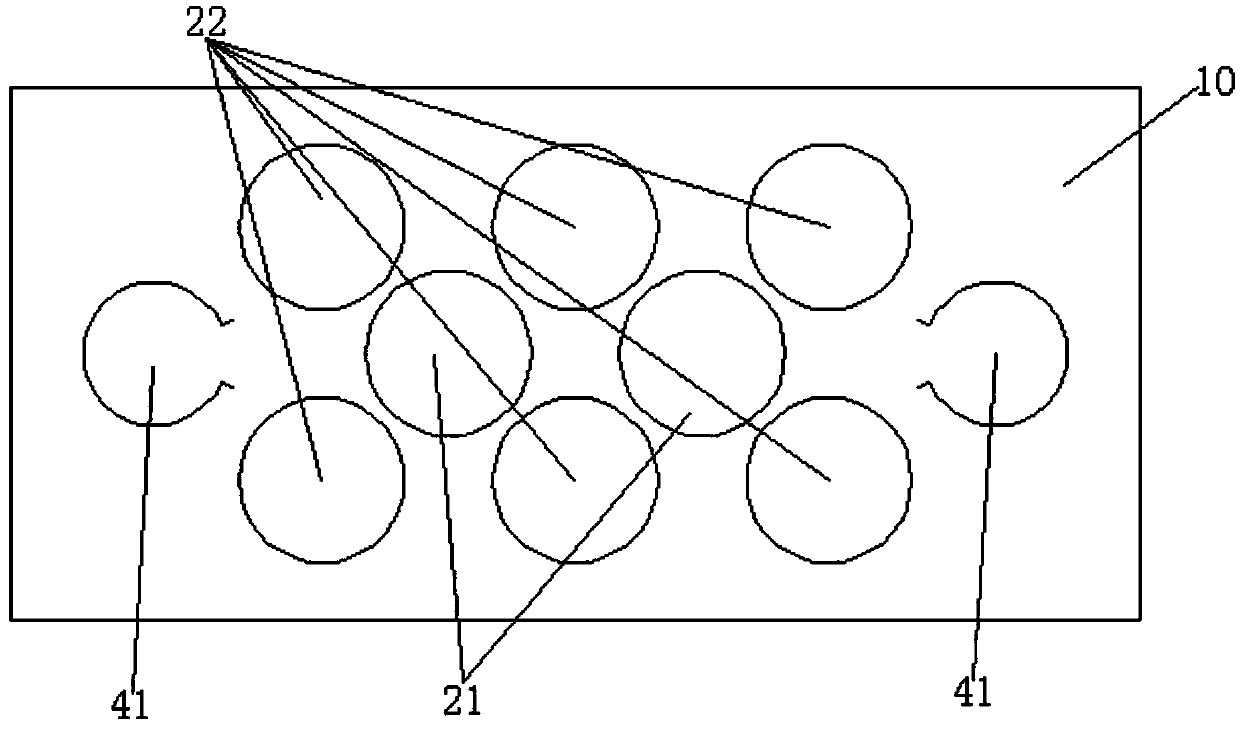

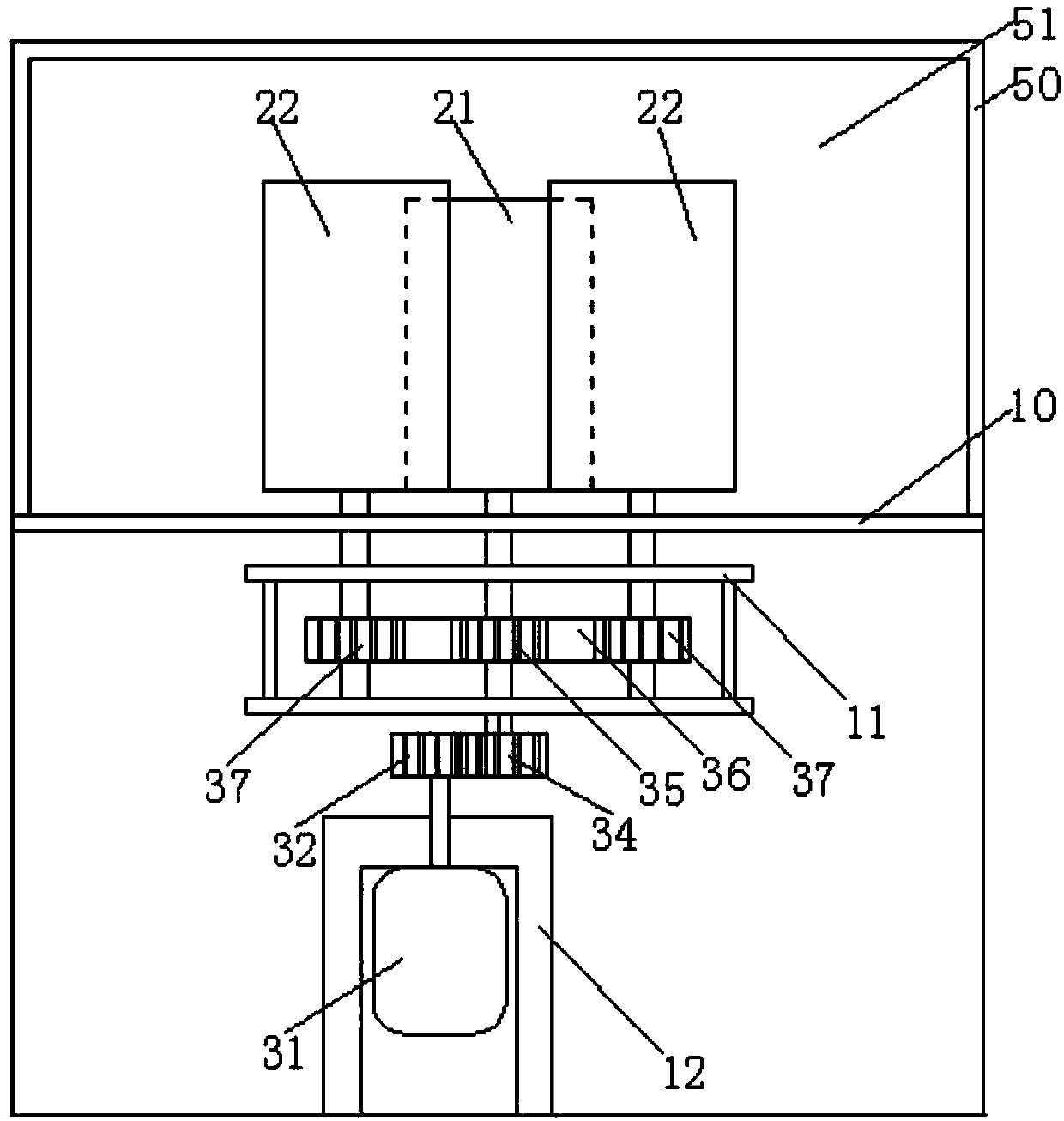

Z-steel stacking equipment

ActiveCN102862824AIncrease productivityEasy to produceStacking articlesEngineeringMechanical engineering

The invention discloses Z-steel stacking equipment, comprising a machine frame 10, a clamping device 20, a rotary device 30 and a stacking platform device 40. The clamping device 20 comprises a workbench 21, a clamping base 22 and a clamping power device 23, wherein the clamping power device 23 is connected with the clamping base 22 in a transmission manner to drive the clamping base 22 to move between a releasing position and a clamping position in a manner relative to the workbench 21. The rotary device 30 comprises a rotary base 31 and a rotary power device 32, the workbench 21 is fixedly connected with the rotary base 31, the rotary power device 32 is connected with the rotary base 31 in a transmission manner to drive the rotary base 31 and the workbench 21 to rotate between a feeding position and a discharge position in a manner relative to the machine frame 10. The stacking platform device 40 comprises a stacking platform 41, and the clamping device 20 arranged at the discharge position is positioned above the stacking platform 41. The Z-steel stacking equipment has the following advantages: automatic stacking is realized, and the production efficiency is high; the production flow is simplified, and the packaging in the next stage is facilitated; the stacking effect is good, and the artificial finishing is not needed; and the equipment structure is simple, and the cost is low.

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

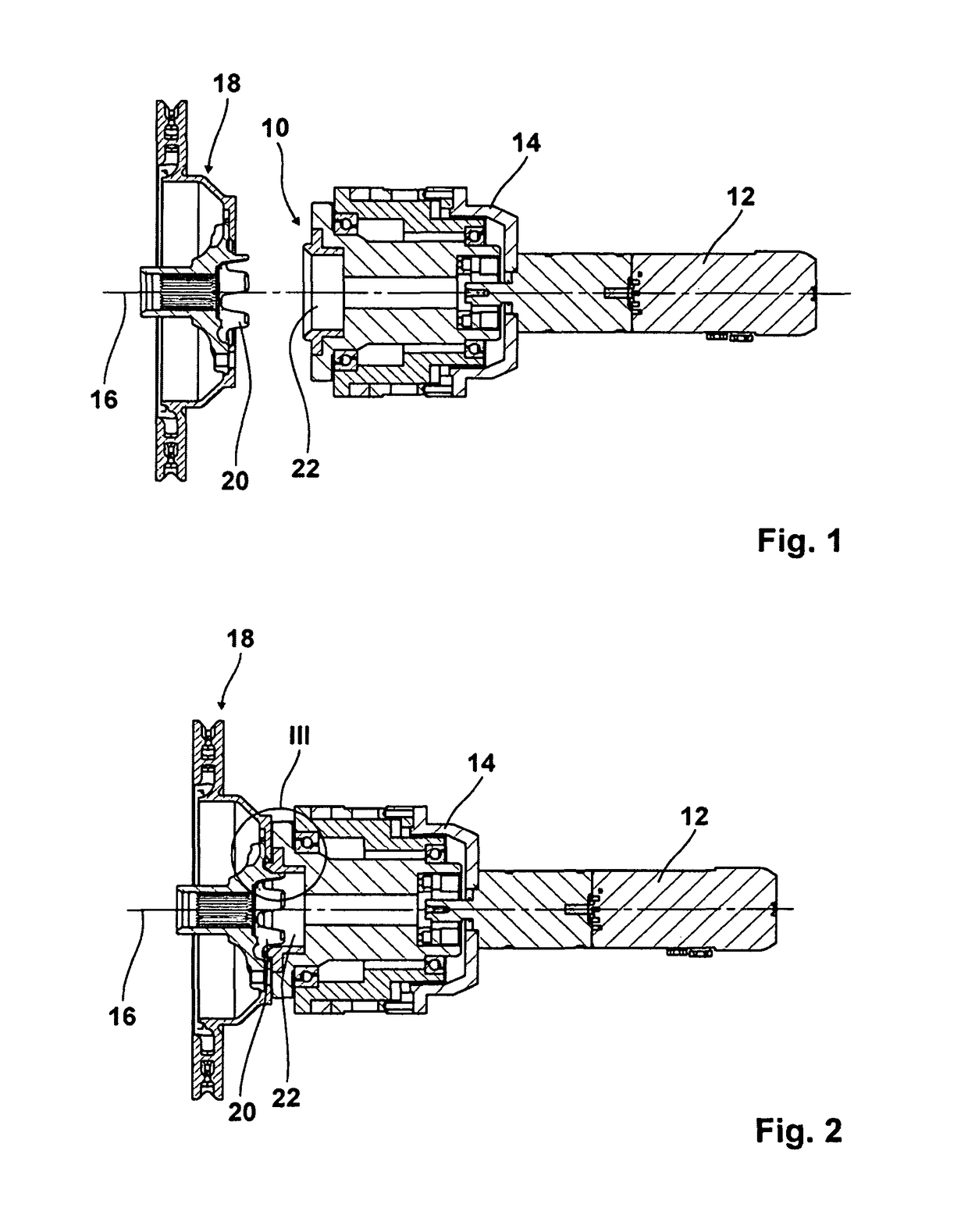

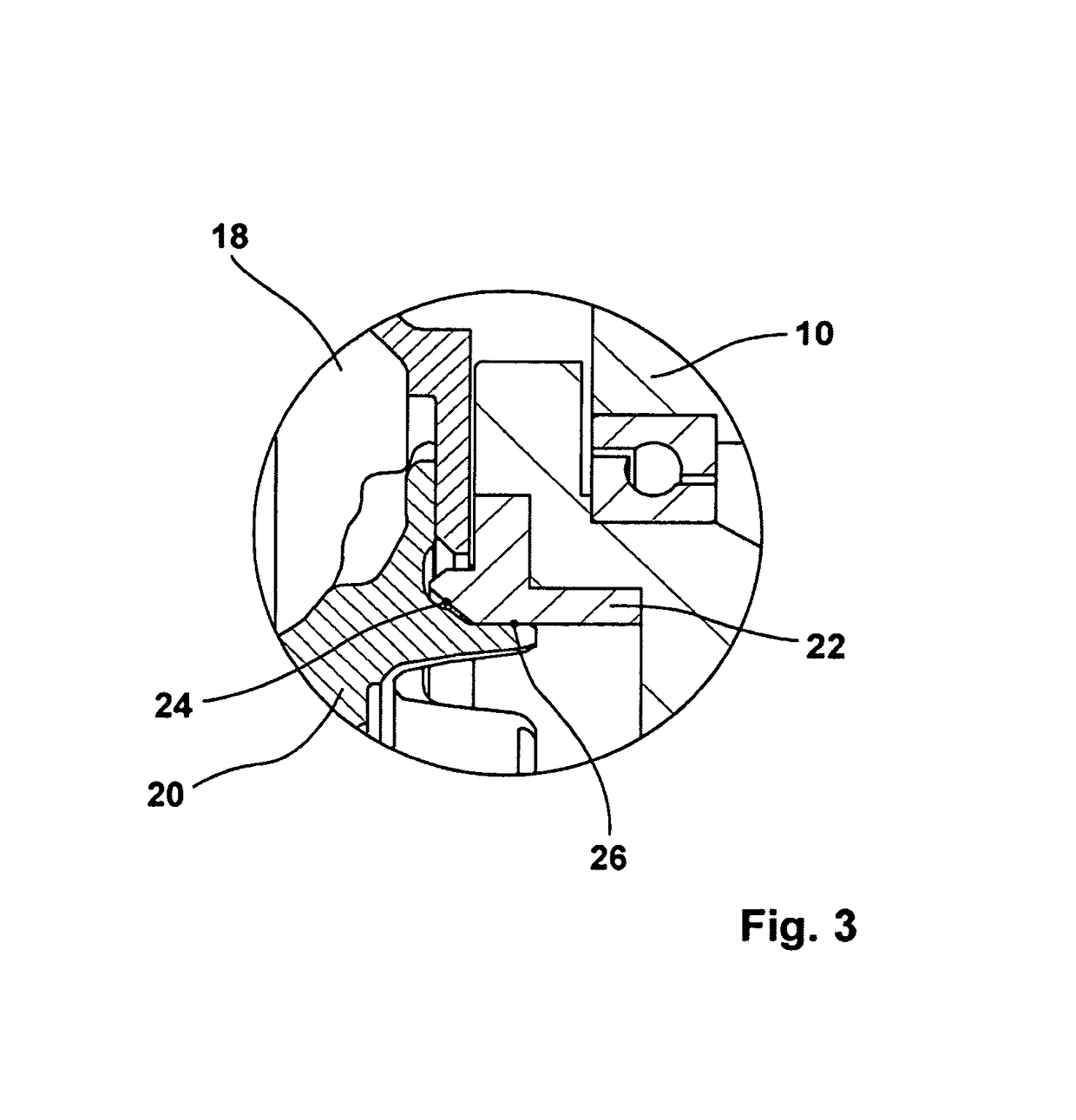

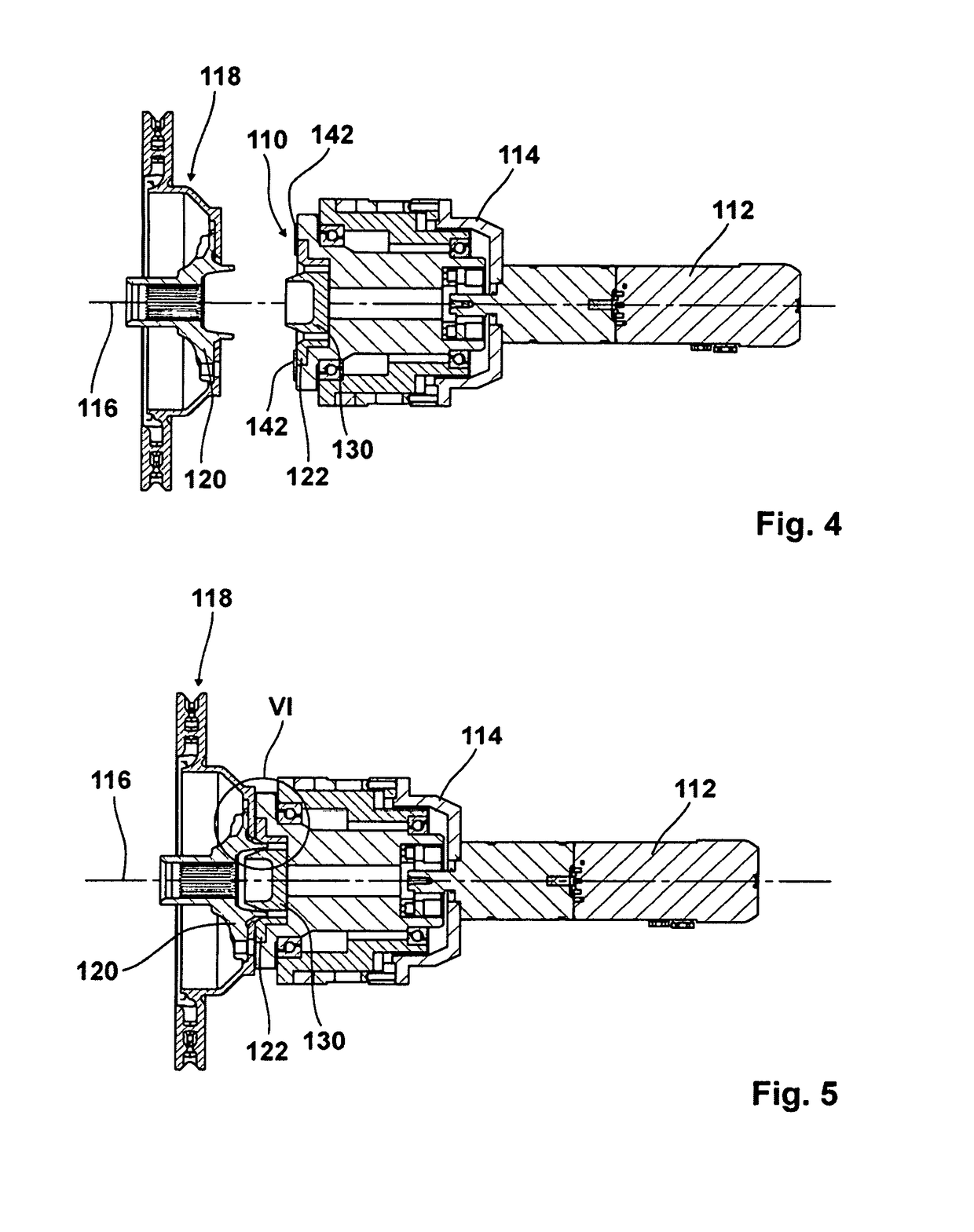

Printer

InactiveCN101780728AWork lessSynchronous rotationRotary pressesPrinting press partsEngineeringPrinting press

The invention relates to a printer, which includes: a roller wherein a temperature processing liquid flows through, roller locks used for the roller and configured to a rapidly replaced device, and a pipeline clutch, using the pipeline of the temperature processing liquid to connect to the roller, wherein, the pipeline clutch has a first clutch half part on the roller and a second clutch half part on the pipeline. Also provided is a positioning device for automatically performing modulation or positioning of at least one of the clutch half parts relative to the other when the roller is inserted in the roller locks.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Battery diaphragm packing and ending device

ActiveCN101707259ASynchronous rotationWinding is not out of shapeFinal product manufacturePrimary cellsReciprocating motionEngineering

The invention relates to a battery diaphragm packing and ending device comprising at least one vertical plate, at least one vertical plate driving mechanism, at least one clip, at least one clip driving mechanism, at least one rotational driving mechanism and an installing plate, wherein the vertical plate driving mechanism enables the vertical plate to do straight reciprocating motion on the installing plate; the clips, the clip driving mechanism and the rotating driving mechanism are installed on the vertical plate; the clips are used for clamping batteries; and the rotational driving mechanism is used for enabling the clips to drive the batteries to rotate for coiling diaphragms. The packing and ending operations of the device are automatically finished completely without personnel, and therefore, the product conformance is enhanced. A left and a right synchronous wheels are driven by a motor by a connecting shaft; and by adopting the synchronous wheels, the left and the right clips rotate synchronously so that the coiling operation is not distorted or deflected.

Owner:SHENZHEN YINGHE TECH

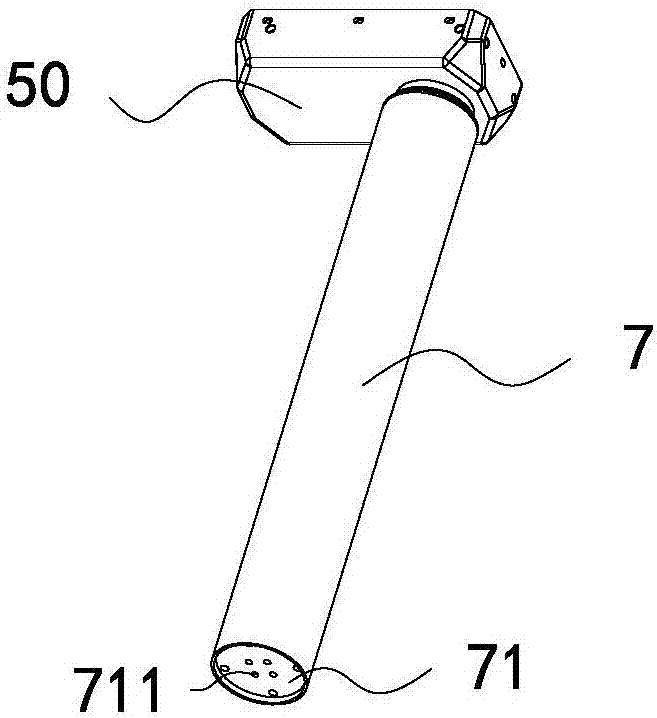

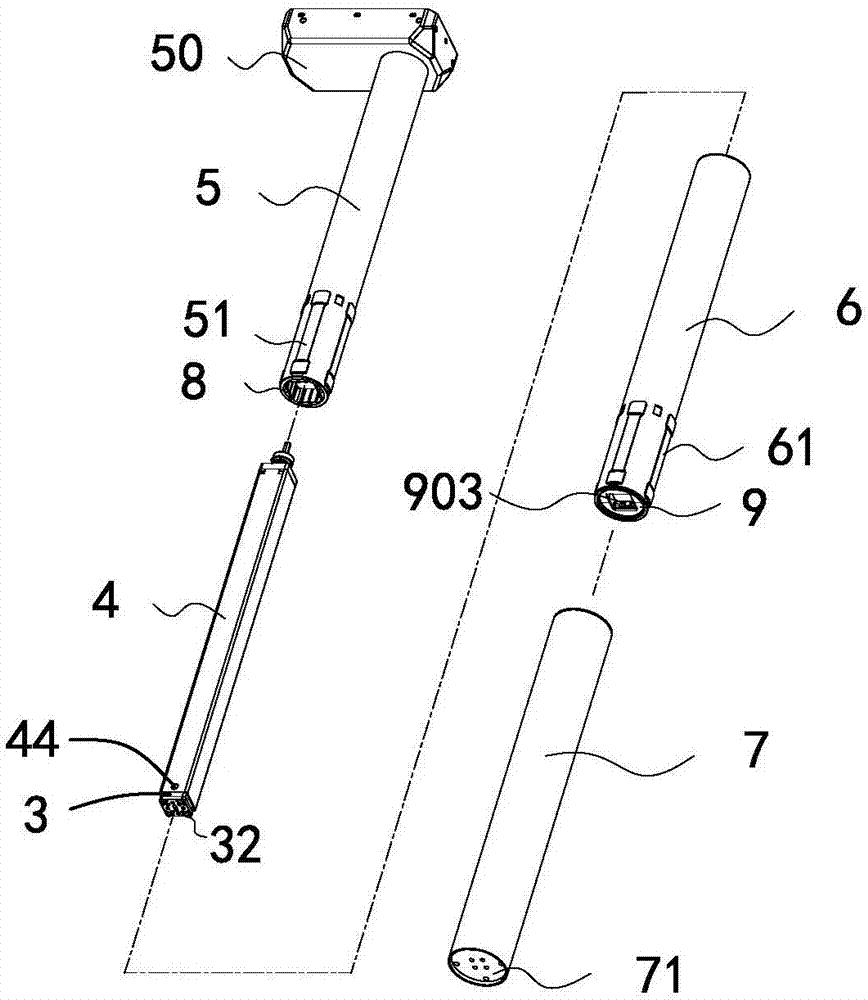

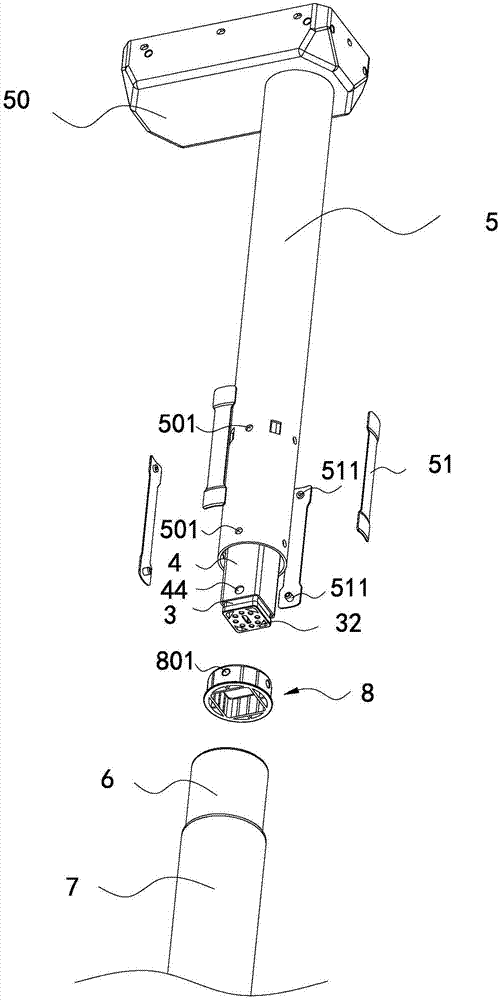

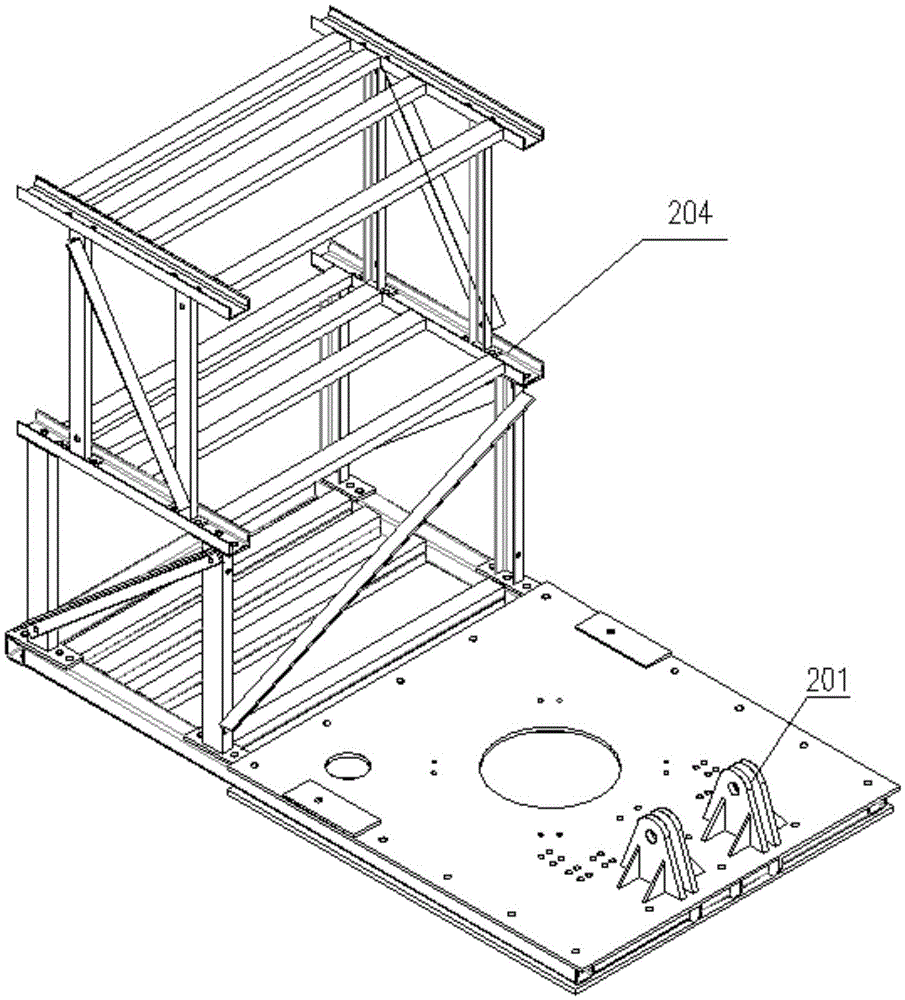

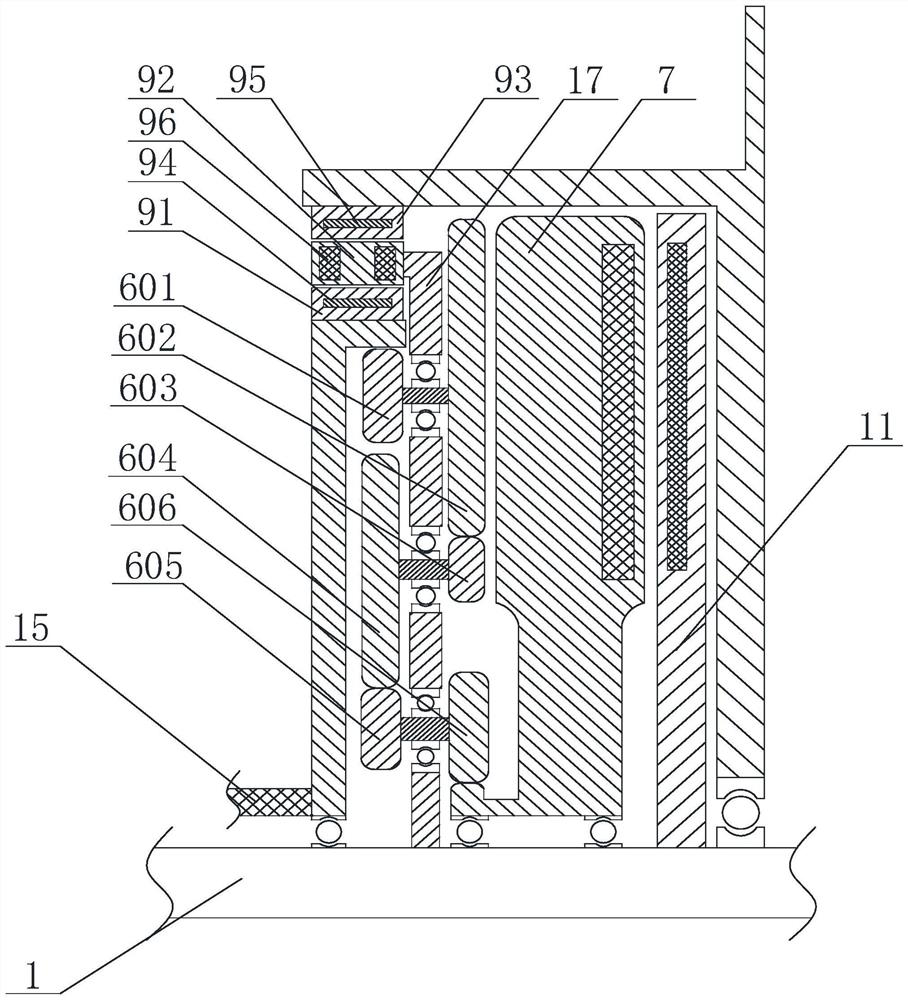

Lifting stand column

PendingCN107420506ALow structural requirementsLow costGearingManufacturing technologyStructural engineering

The invention discloses a lifting stand column and belongs to the technical field of linear driving. The lifting stand column comprises an inner tube, a medium tube and an outer tube which are sequentially sleeved from inside to outside, wherein a bottom shell is fixedly connected at the upper end of the inner tube; a driver is arranged in the bottom shell and connected with a screw rod drive assembly; the inner tube is sleeved outside the screw rod drive assembly; the screw rod drive assembly comprises a first sleeve tube and a second sleeve tube which is sleeved outside the first sleeve tube; the first sleeve tube and the second sleeve tube can be relatively moved in the axial direction and maintain the relative fixation in the circumferential direction; the lower end of the outer tube is fixedly connected with the lower end of the first sleeve tube; a guide sleeve for maintaining the relative fixation of the inner tube and the second sleeve tube in the circumferential direction is arranged between the inner tube and the second sleeve tube; and a connecting component is fixedly connected between the medium tube and the second sleeve tube to maintain the relative fixation of the medium tube and the second sleeve tube in the circumferential direction. The lifting stand column disclosed by the invention has the advantages that the manufacturing process is simpler and the product cost is reduced.

Owner:NINGBO HAISHIKAI DRIVER TECH CO LTD

Auxiliary supporting device of a bicycle

InactiveUS7883449B2Synchronous rotationStiltsMovement coordination devicesEngineeringControllability

Owner:WAN KUO HUI

Gear assembly and a door mount mechanism including the same

A gear assembly includes a planetary gear set and a clutch. The planetary gear set includes a sun gear, at least one planet gear meshing with the sun gear, a carrier supporting the at least one planet gear, and an outer ring gear meshing with the at least one planet gear. The clutch is operable to engage with and disengage from the planetary gear set to enable the planetary gear set to switch between a first mode and a second mode.

Owner:深圳唐果屋智能科技有限公司

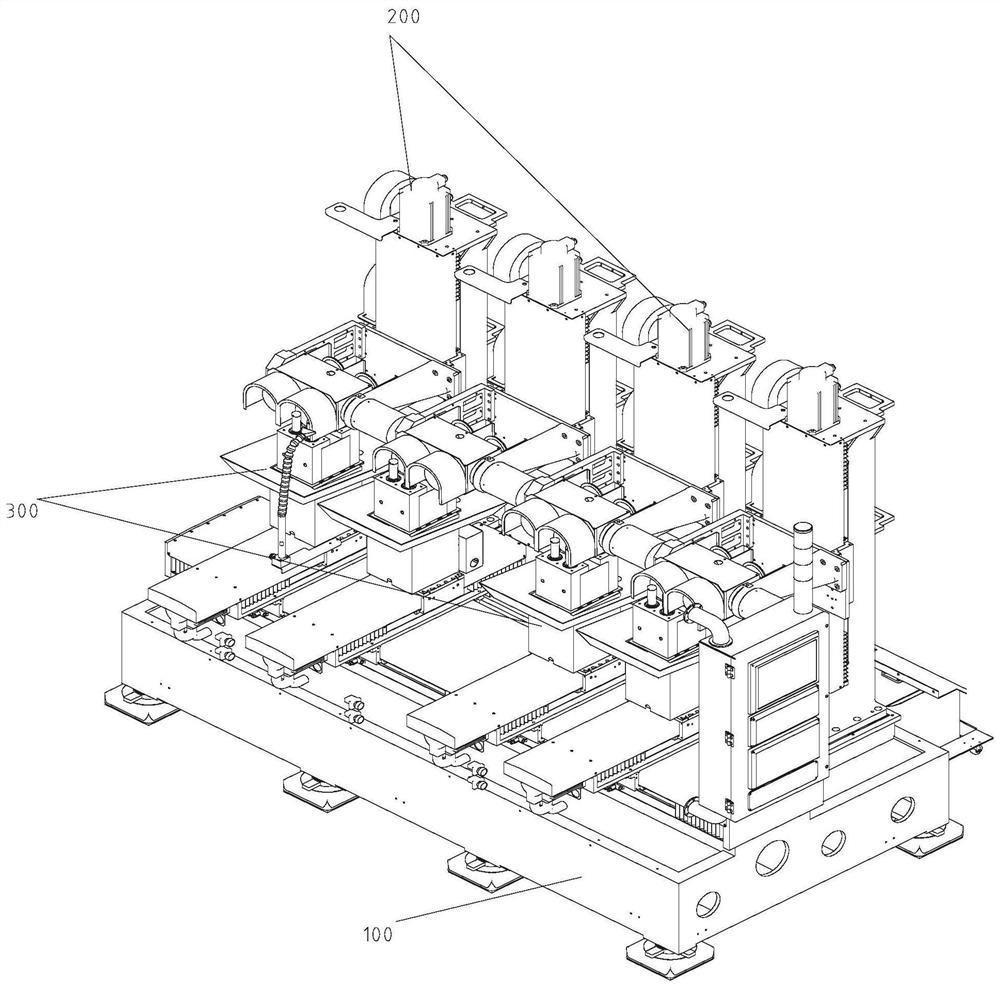

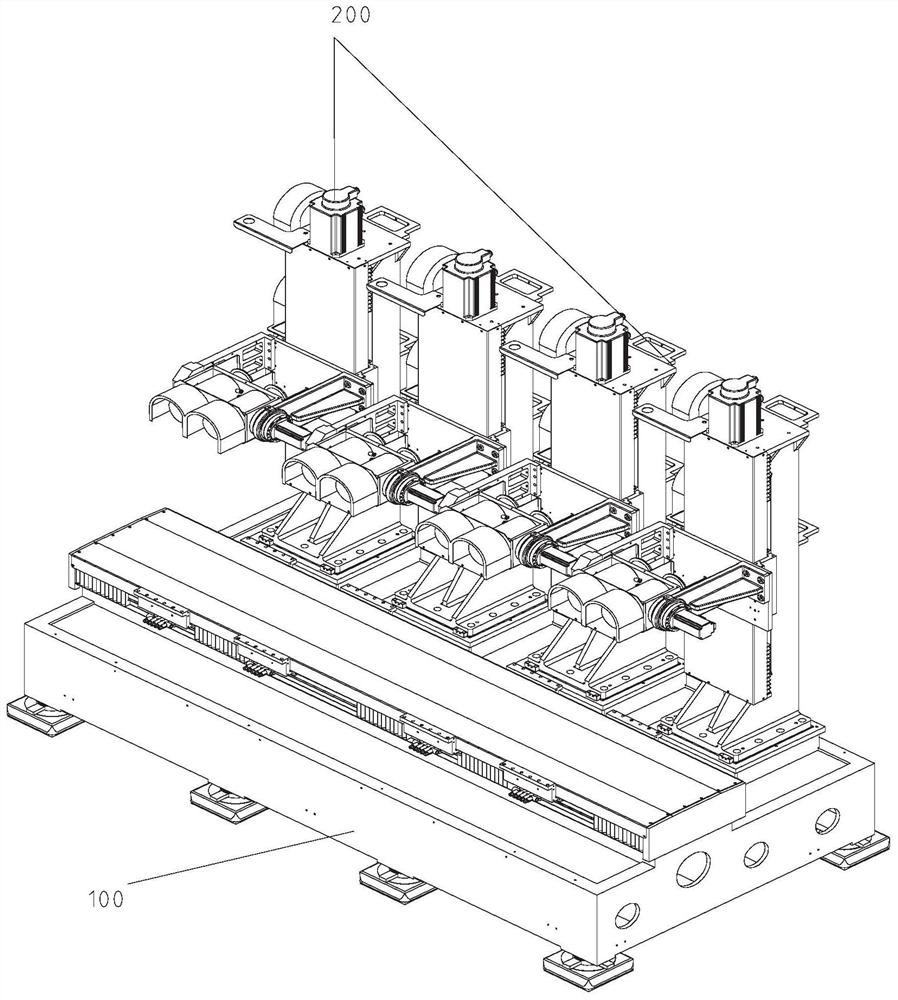

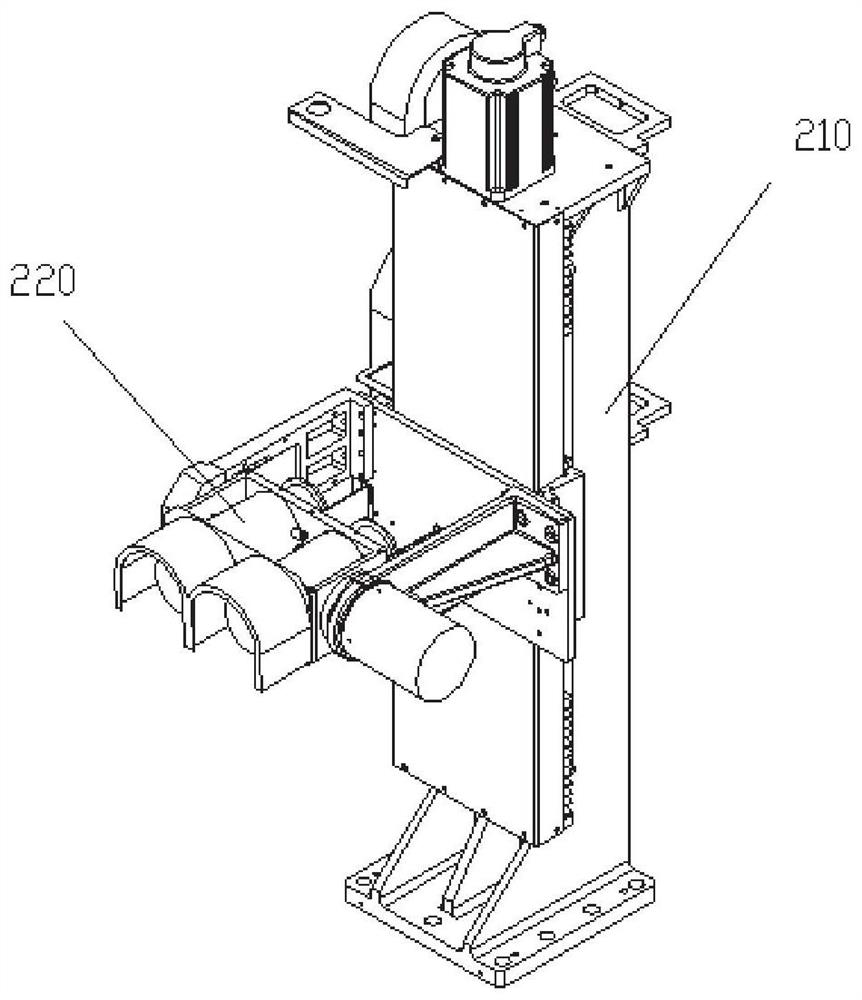

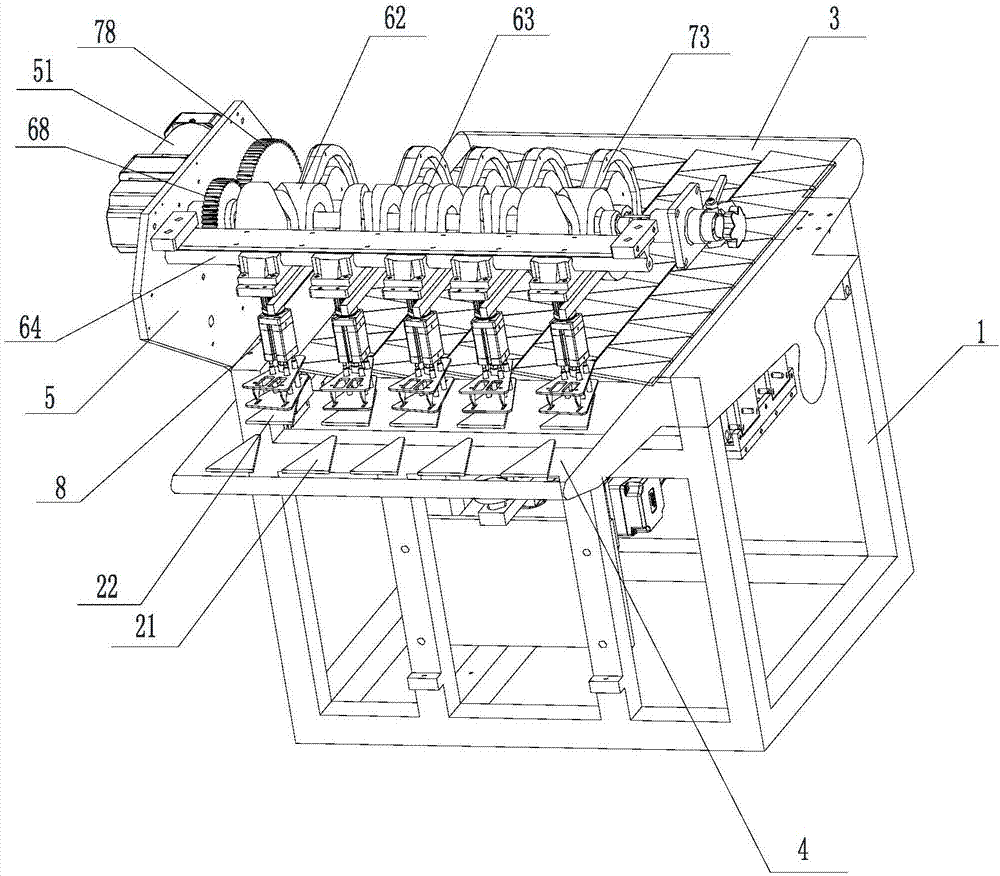

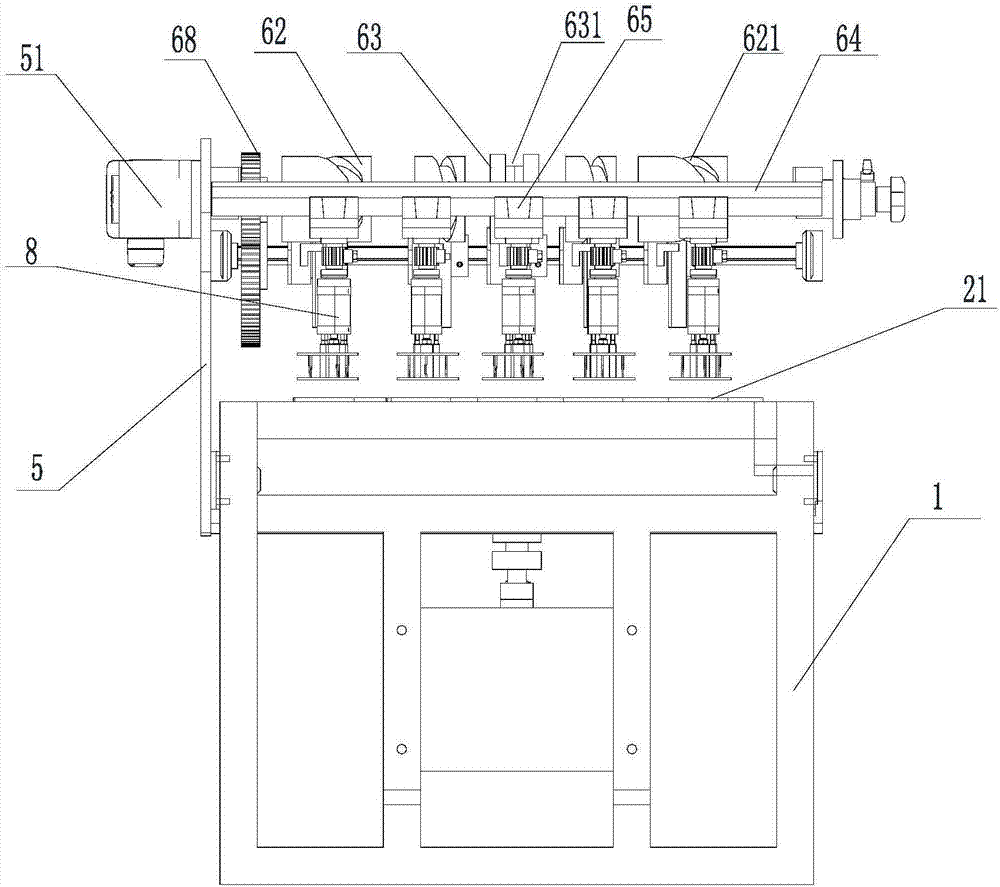

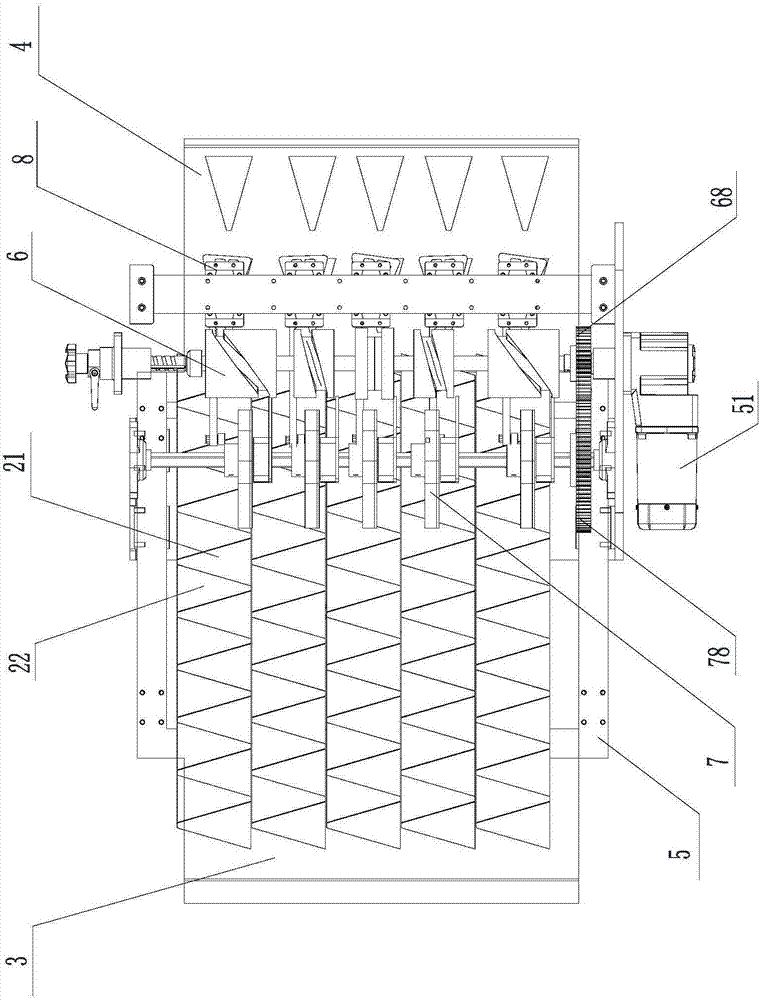

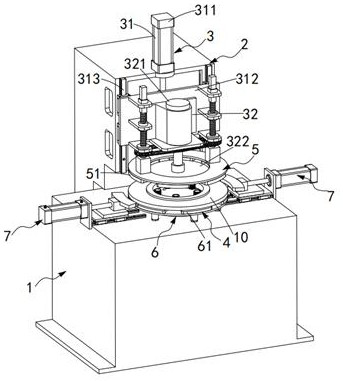

Multi-station polishing and grinding equipment

PendingCN111775012AImprove work efficiencyAchieving Process ContinuityGrinding carriagesGrinding drivesElectric machinerySpring steel

Multi-station polishing and grinding equipment comprises a machine table and polishing and grinding machines and fixtures arranged on the machine table in one-to-one correspondence, wherein the polishing and grinding machines comprise Z-axis linear modules and grinding head assemblies that are arranged on the machine table, the grinding head assemblies comprise grinding head supports, grinding head seats are rotatably arranged on the grinding head supports, and at least one double-head motor is arranged on each grinding head seat; the fixtures comprise XY linear modules and fixture bodies; thetop of the C axis is in transmission connection with a rotating main shaft, the rotating main shaft is provided with a driving wheel, a sleeve is provided with a driven wheel, and the driving wheel is in transmission connection with the driven wheel through a timing belt. When the C axis drives the driving wheel to rotate, the driven wheel is driven to rotate through the timing belt, and the sleeve is driven to rotate on the upper support frame, so that a product clamped in a spring steel sheet is driven to rotate, and the polishing and grinding machines can grind the products on the matchingfixtures through polishing discs. The multiple sets of polishing and grinding machines and multiple fixtures in the invention are matched, synchronous processing can be achieved, the unified regulation of the control system is facilitated, and individual control is also realized. All sets of polishing and grinding machines do not affect each other, thereby realizing multiple technological processes, and having high operating efficiency.

Owner:深圳市永霖科技有限公司

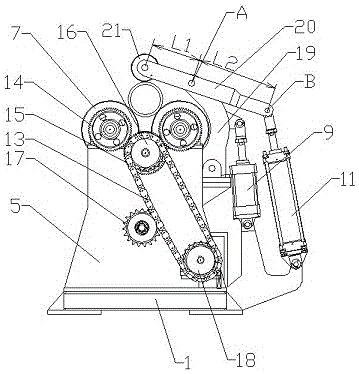

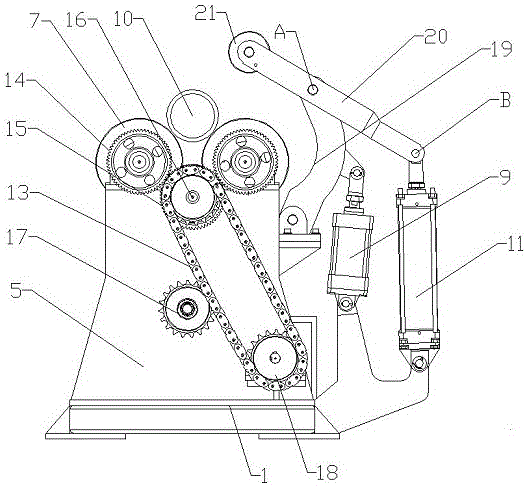

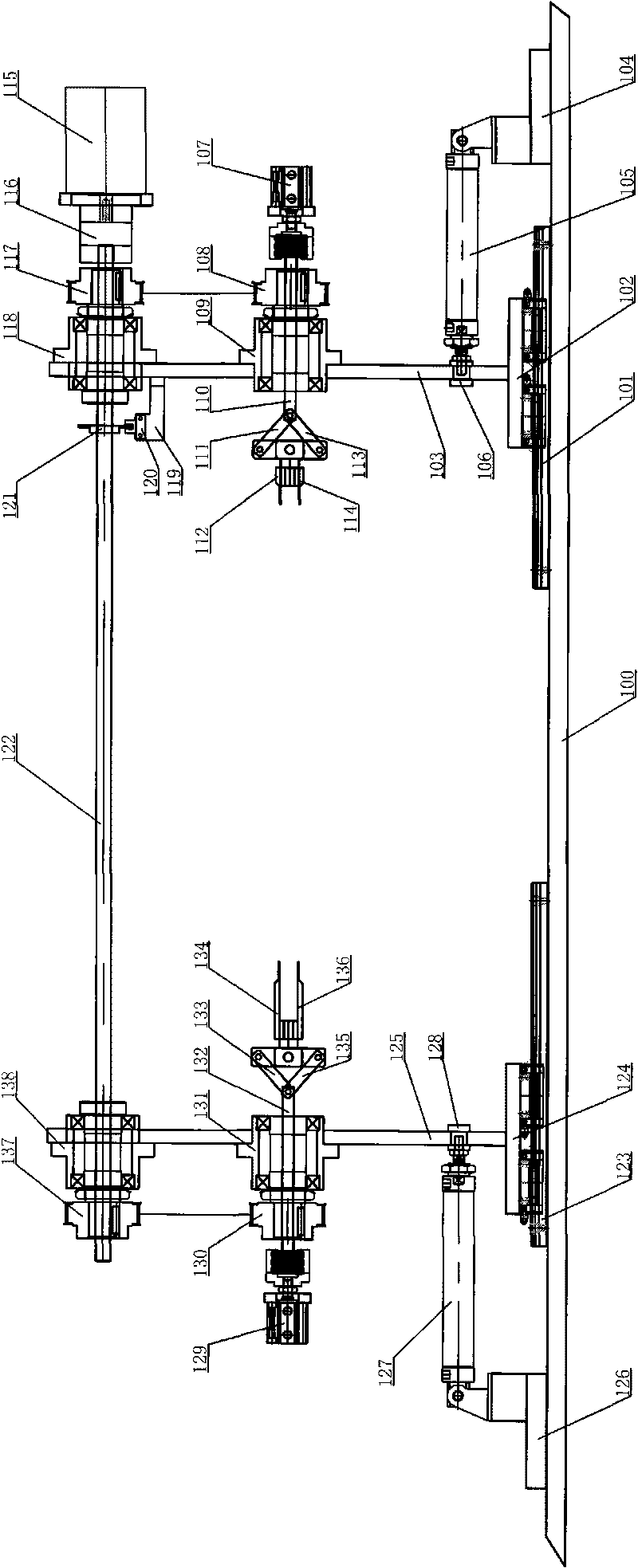

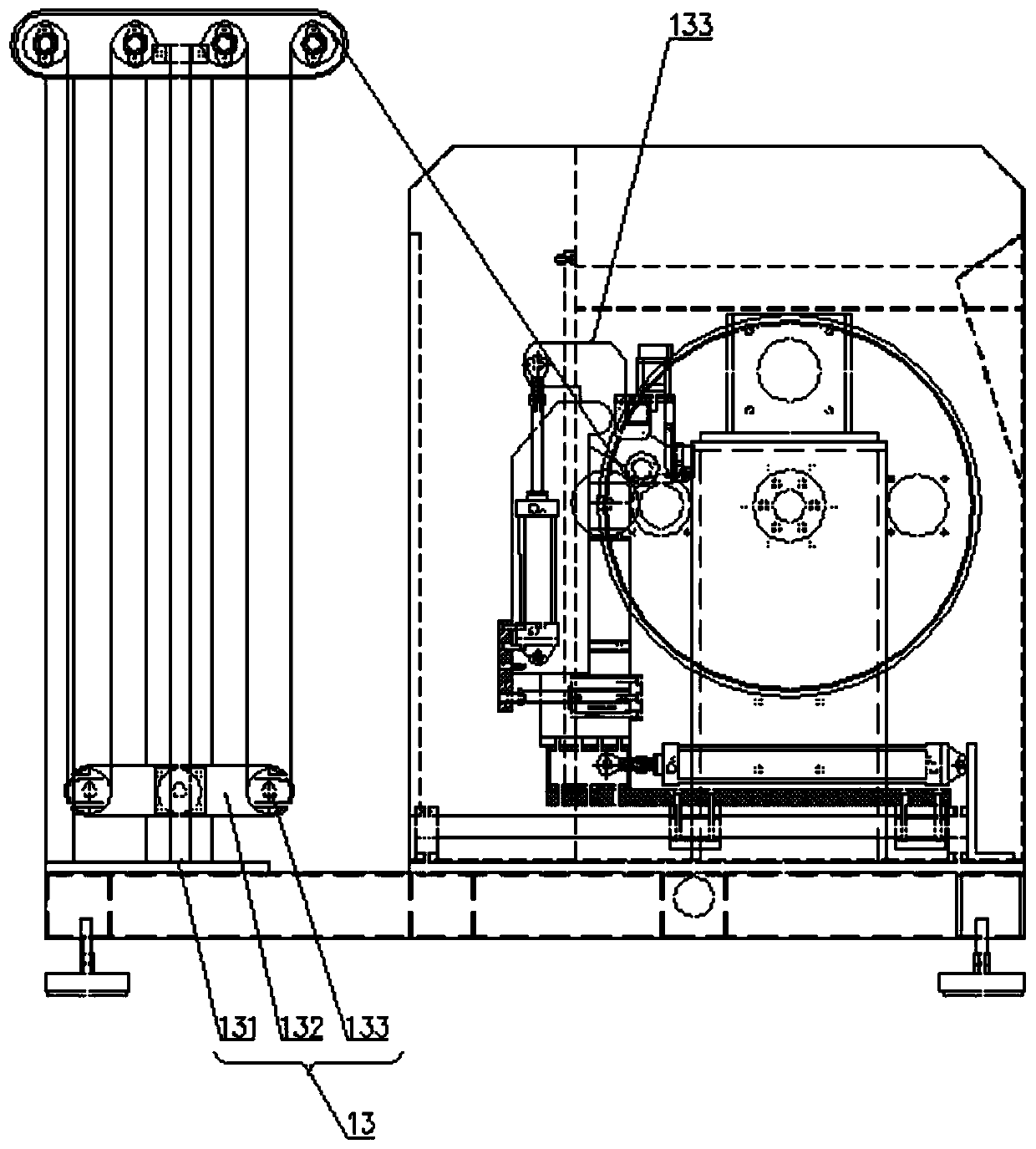

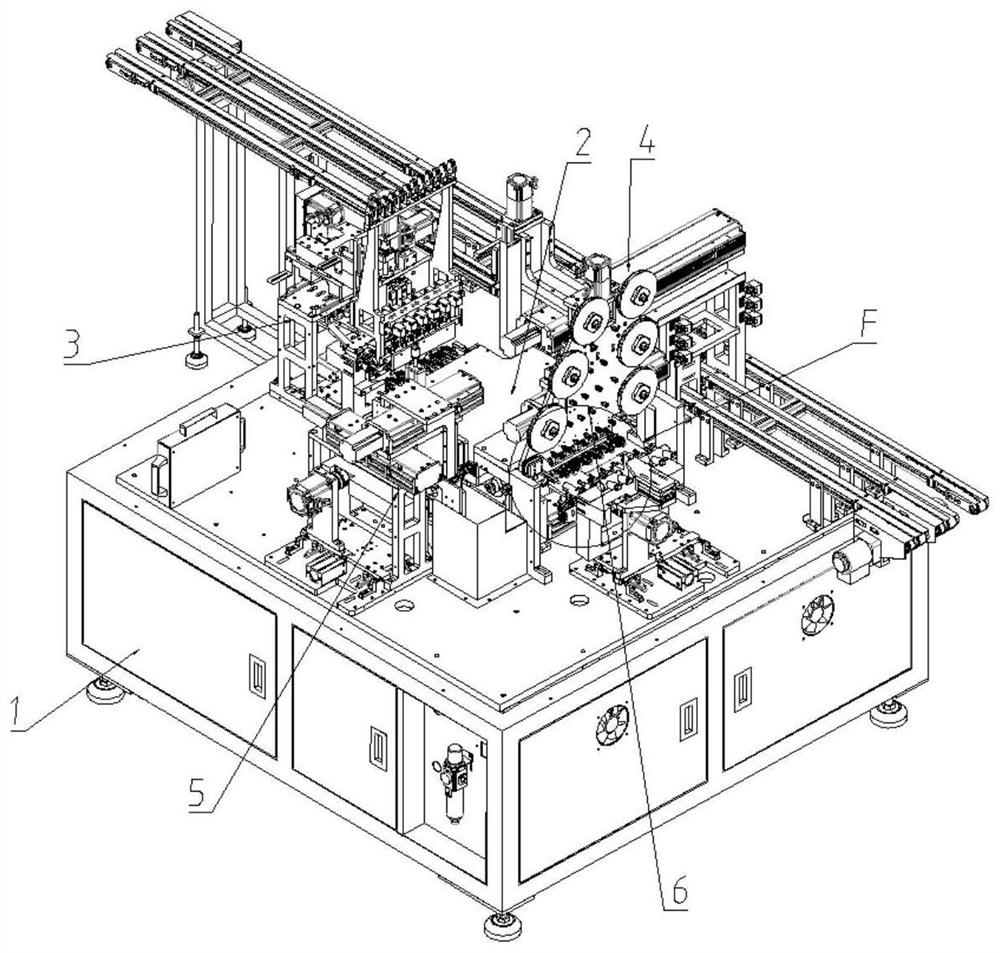

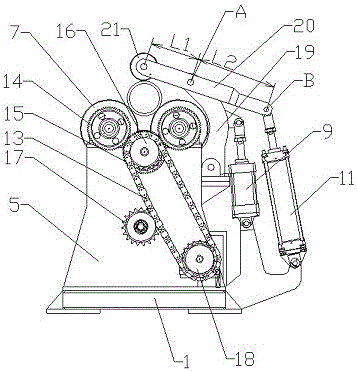

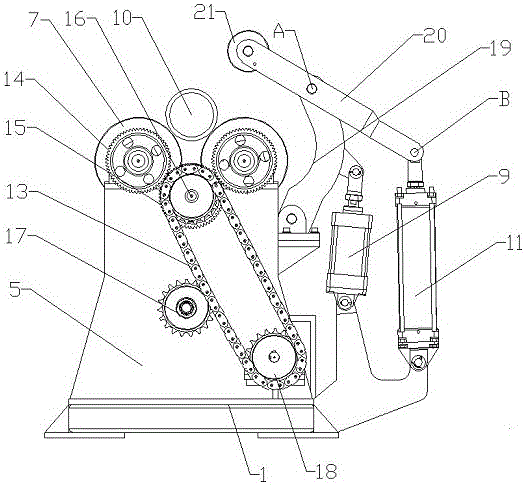

Double-station full-automatic winder and working method thereof

PendingCN110668223AReduce distanceAvoid wastingArticle deliveryWebs handlingRotational axisProduction line

The invention discloses a double-station full-automatic winder. The winder comprises a base bracket, a turbine worm reduction motor, a rotating shaft sprocket group, a rotating central shaft, a transition sprocket group, a first winding air inflation shaft, a gear rotary table, a second winding air inflation shaft, a turntable central shaft, a motor synchronous belt wheel group, a winding servo motor, an automatic material cutting flattening mechanism, an automatic material cutting and leveling mechanism, and a material storage and slow bearing mechanism, wherein the turbine worm reduction motor is connected with the rotating central shaft through the rotating shaft sprocket group, and the rotating central shaft is connected with the first winding air inflation shaft and the second windingair inflation shaft through the rotating shaft sprocket group and the gear turntable. The invention also comprises a working method of the double-station full-automatic winder. According to the double-station full-automatic winder, two winding shafts are fixed on the gear rotary table through the structural mode of borrowing and hiding, the rotating is synchronous, and the positioning is accurate; the distance between the winding shafts is shortened, and material waste is avoided; the non-stop roll-change unloading and automatic material cutting and flattening are realized, and the equipmentproduction efficiency and the production line safety are improved.

Owner:太仓创晟机械有限公司

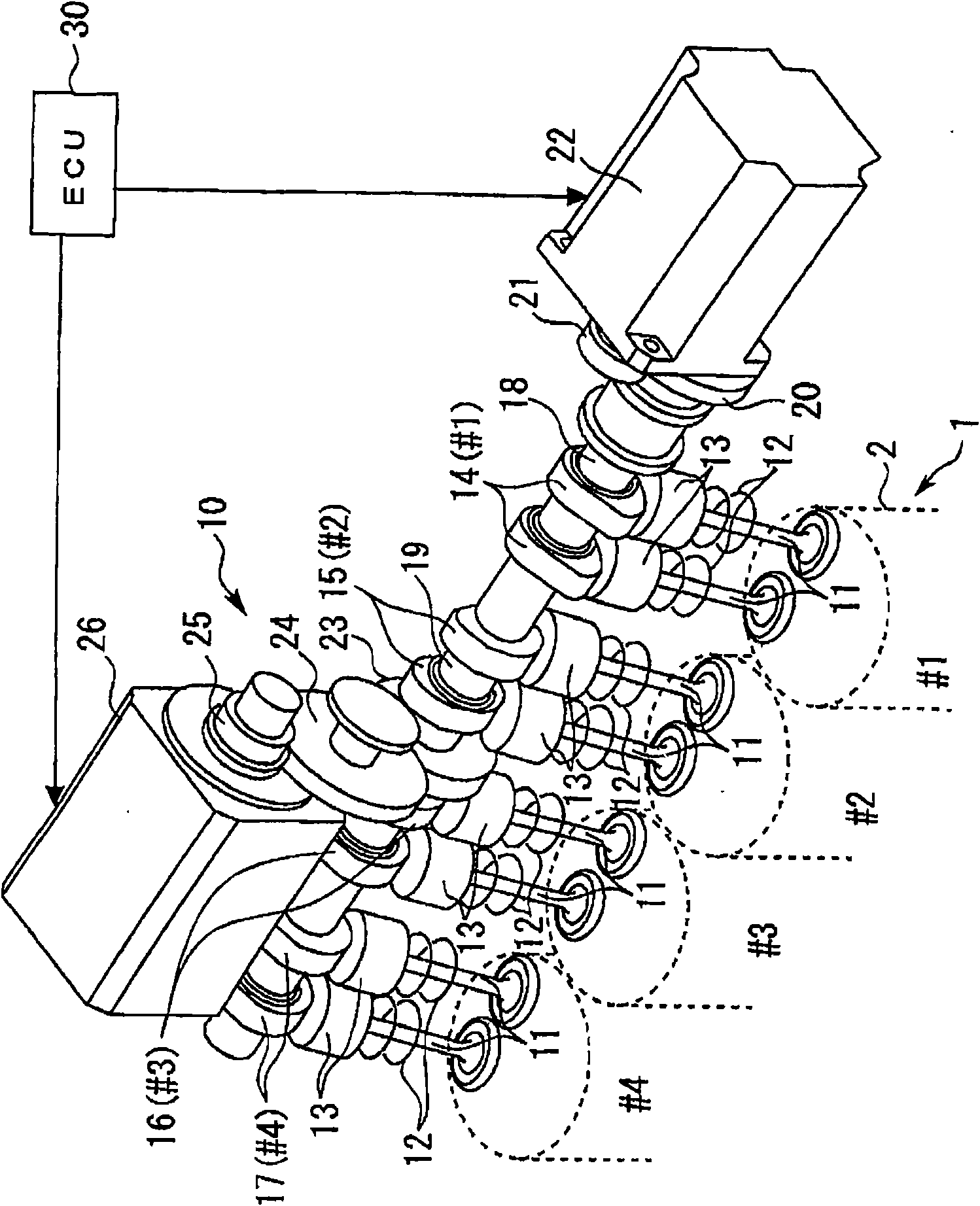

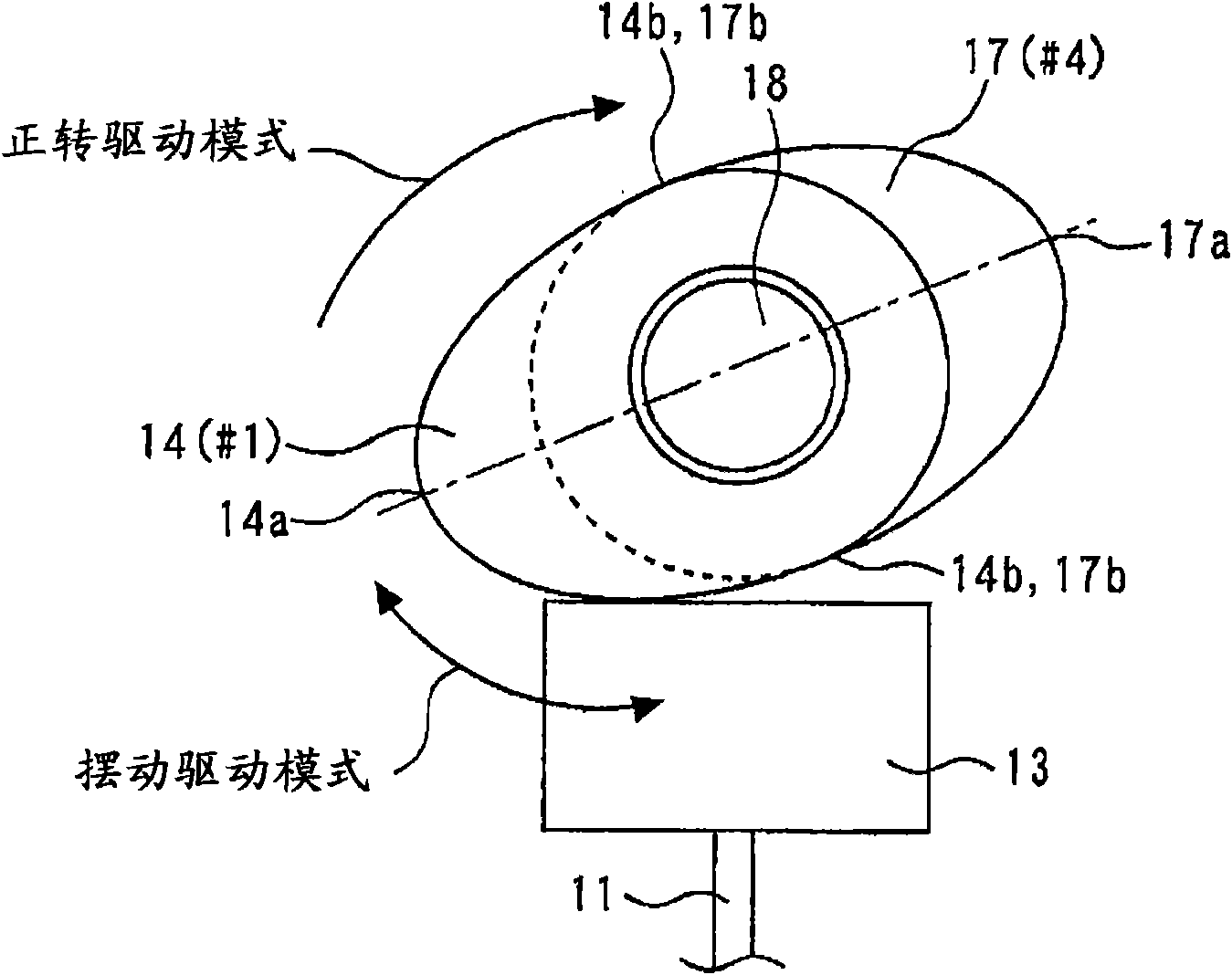

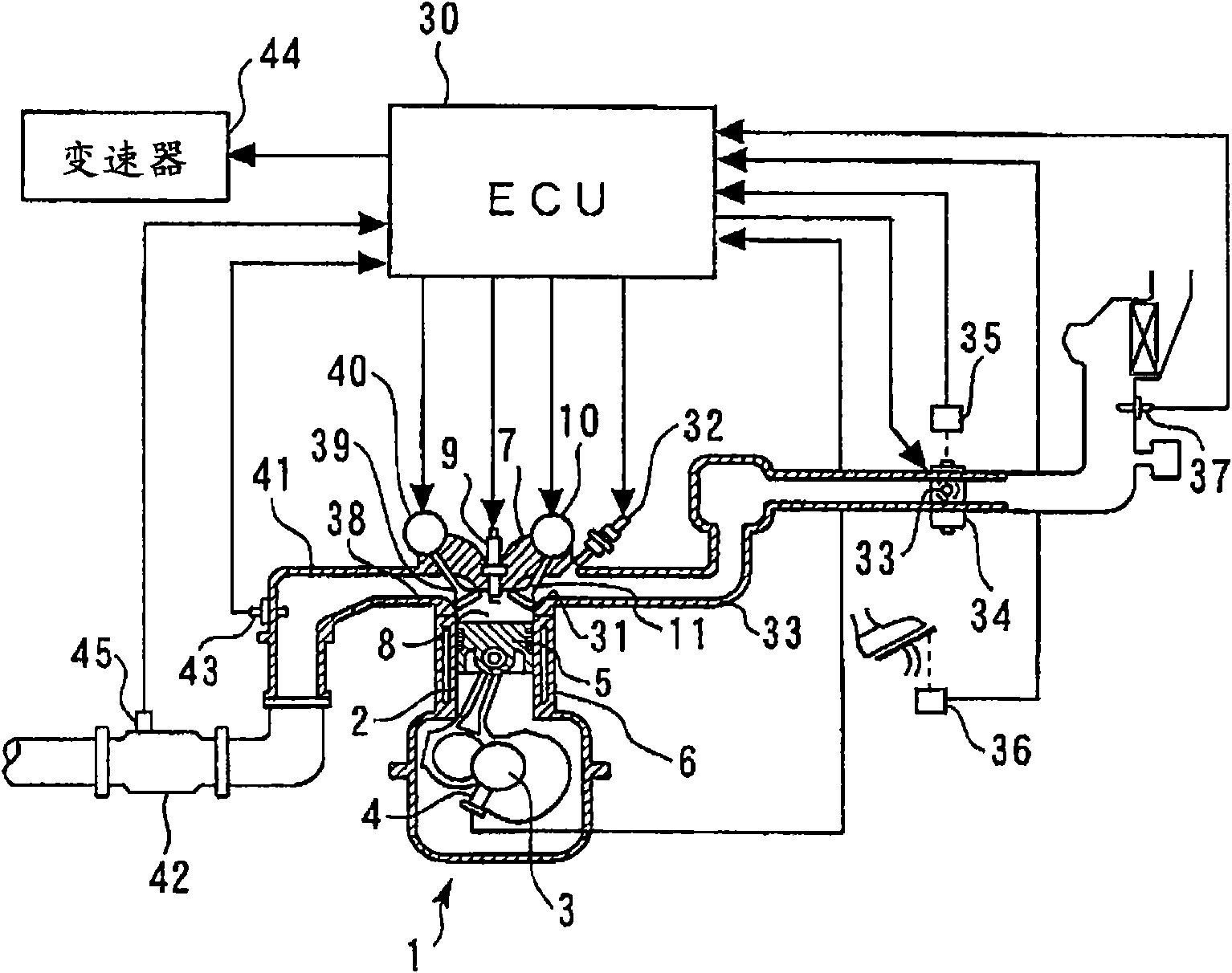

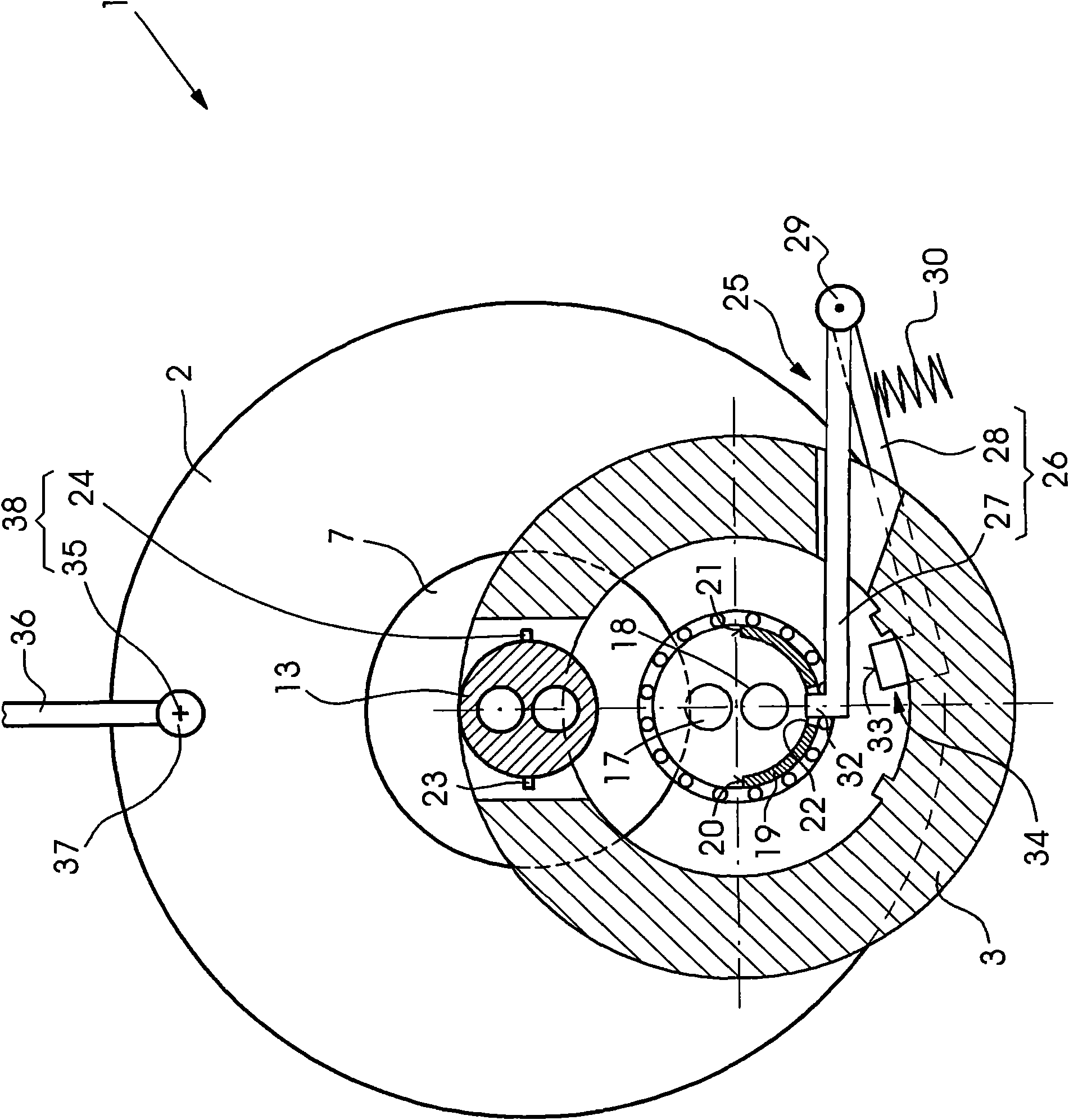

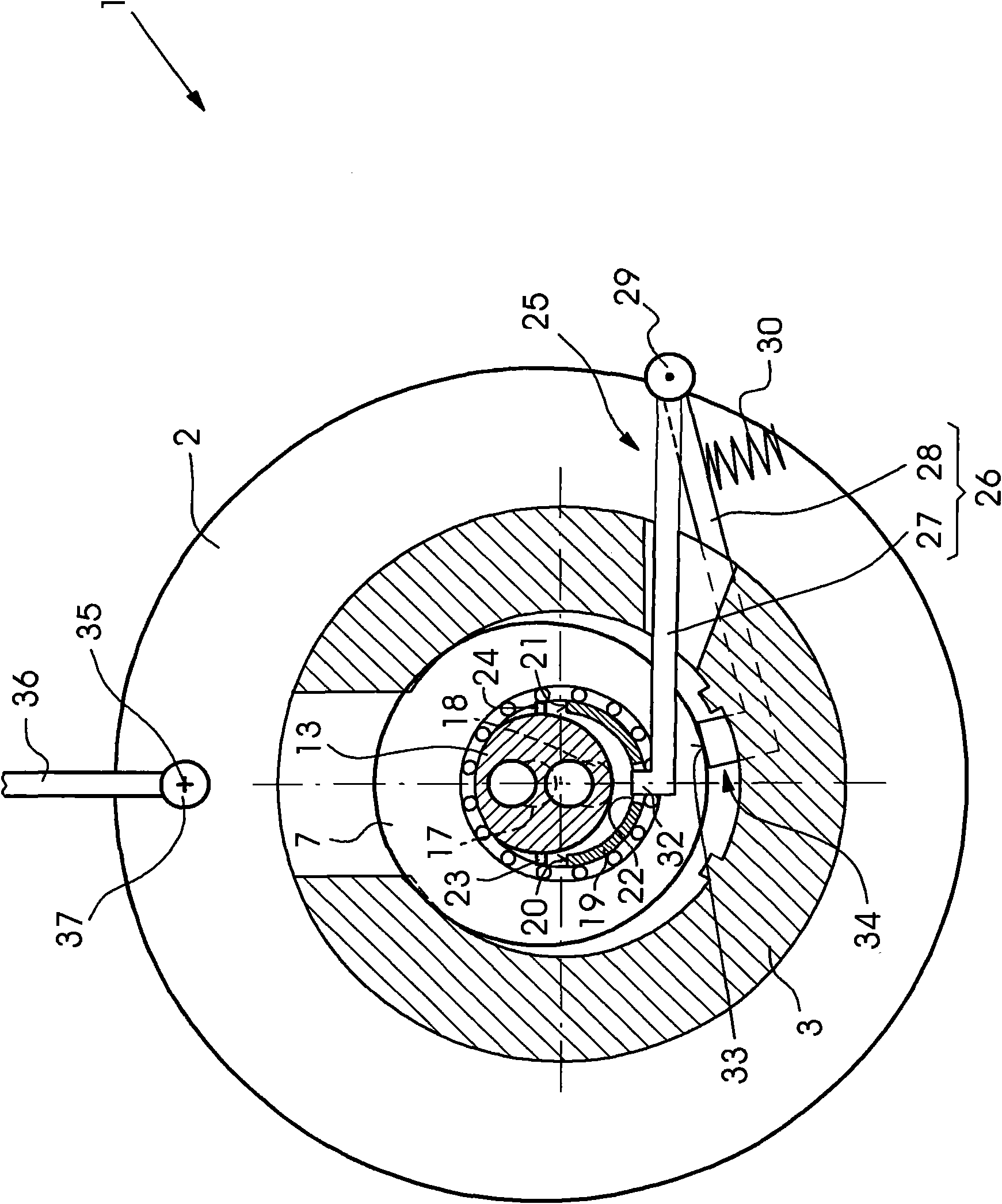

Controller of variable valve actuator

InactiveCN101542079AReduce power consumptionReduced power ratingInternal combustion piston enginesOutput powerCamInertia

A controller of variable valve actuator in which power consumption and rating of a motor can be reduced by reducing spring reaction during valve lift by the rotary inertial torque of a cam shaft. Before starting valve lift, the rotary inertial torque of a cam shaft is set at a predetermined level or above. From start of lift to the maximum lift, spring reaction of a valve spring is used as deceleration torque of the rotary inertial torque of the cam shaft. From the maximum lift to the end of lift, spring reaction is used as the acceleration torque of the rotary inertial torque of the cam shaft. The spring reaction is offset by the rotary inertial torque of the cam shaft, and only the friction resistant torque becomes the motor torque during valve lift.

Owner:TOYOTA JIDOSHA KK

Dough sheet separating machine and dough sheet axial transport equipment

ActiveCN106912517AAchieve separationThe overall structure is simple and reliableDough processingEngineeringCam

The invention discloses a dough sheet separating machine and dough sheet axial transport equipment. The dough sheet separating machine comprises a separating mechanism which comprises a first camshaft arranged on a support and at least two cylinder cams arranged on the first camshaft and capable of being driven by the first camshaft for rotation, a closed first track is arranged on a cylindrical surface of the cylinder cam, the separating mechanism also comprises a separating guide rail which enables parallel arrangement with the first camshaft and at least two separating moveable members capable of moving along the separating guide rail, the separating mechanism also comprises several driving members provided with a first bearing, the first bearing is stretched into a first track of the cylinder cam; several separating units are respectively corresponded and connected with the separating moveable members, the separating unit is fixedly connected with the driving member, so that the separating unit can move along the separating guide rail when the cylinder cam is rotated. The dough sheet separating machine and the dough sheet axial transport equipment solve the disadvantages of complex structure and high cost of the current dough sheet separating machines, and have the advantages of simple structure and reduced cost.

Owner:BEIJING SHENCHEN MECHANICAL EQUIP

Double-face machining process for annular workpiece for automobile motor

ActiveCN113500477ACounteract gravitySynchronous rotationGrinding drivesGrinding feedersMachining processGrinding process

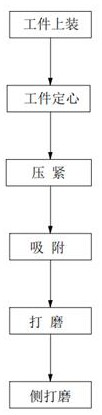

The invention relates to the technical field of machining of annular workpieces for automobile motors, in particular to a double-face machining process for an annular workpiece for an automobile motor. The double-face machining process comprises the following steps of workpiece loading, workpiece centering, pressing, adsorption, grinding and side grinding. A pressing adsorbing assembly is matched with a material cutting mechanism to position an annular workpiece and then rotate the annular workpiece, in the rotating process of the annular workpiece, an upper grinding piece in an upper grinding mechanism and a lower grinding piece in a lower grinding mechanism are utilized to approach the annular workpiece at a constant speed for grinding, and compared with an existing mode that the lower grinding piece is fixedly arranged, the technical problem that in the annular workpiece grinding process, the grinding precision of lower end face grinding is inconsistent with that of the upper end face of the annular workpiece due to the quality factor of the annular workpiece is solved.

Owner:江苏城邦汽车配件制造有限公司

Dual-shaft hinge module and portable electronic device

ActiveUS11142932B2Synchronous rotationDigital data processing detailsWing accessoriesGear wheelElectronic equipment

Owner:COMPAL ELECTRONICS INC

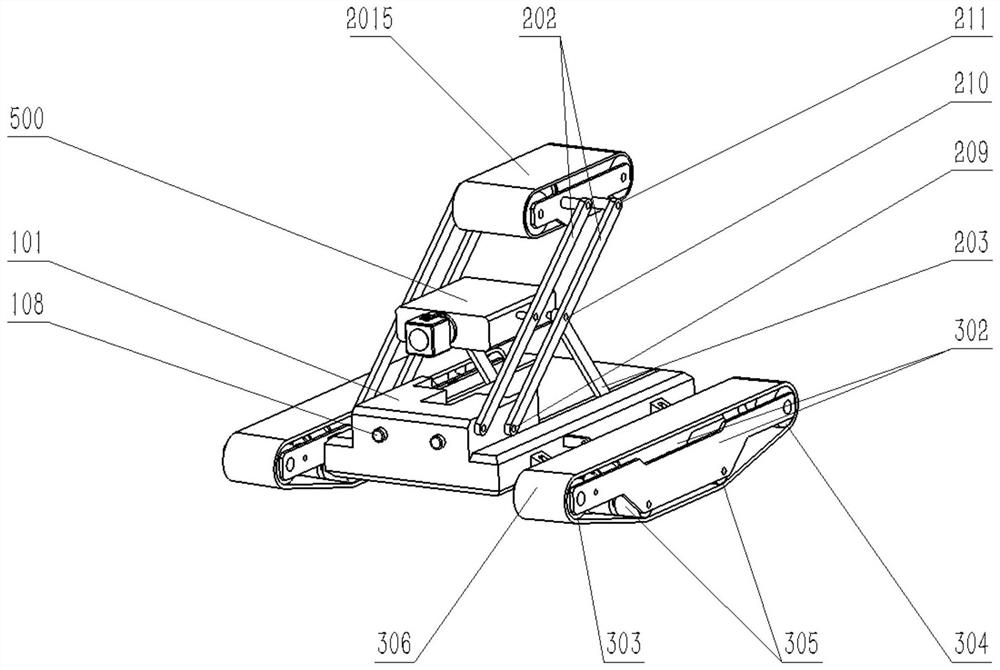

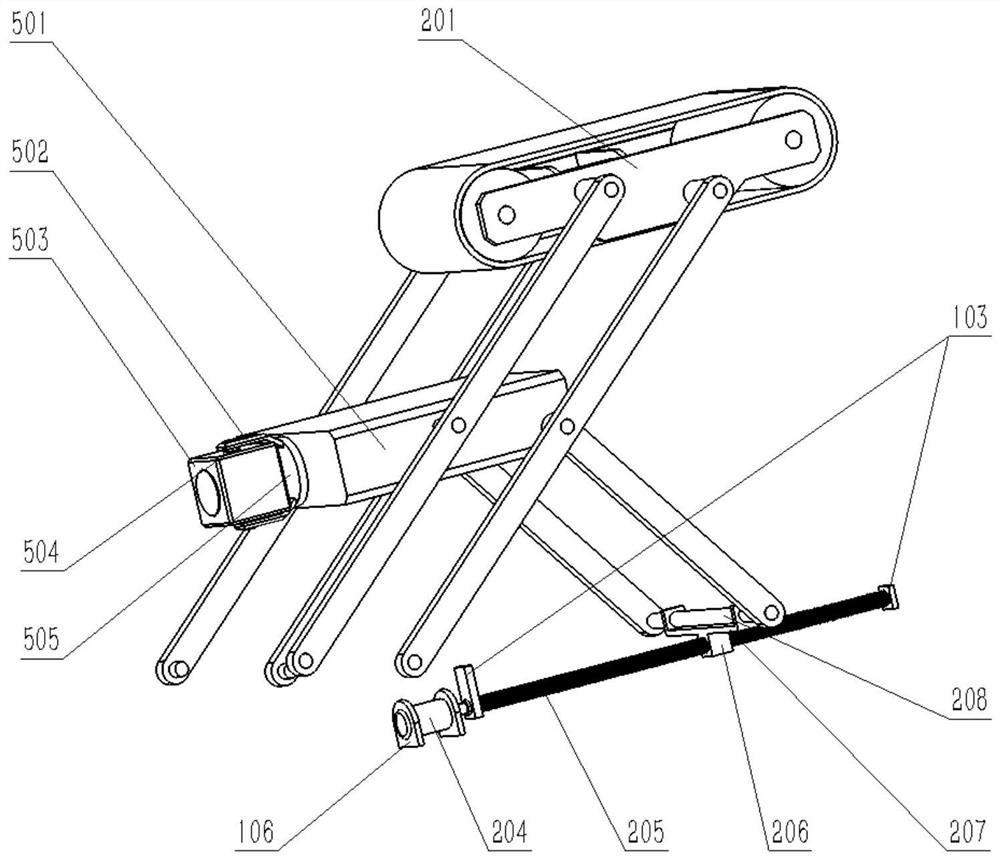

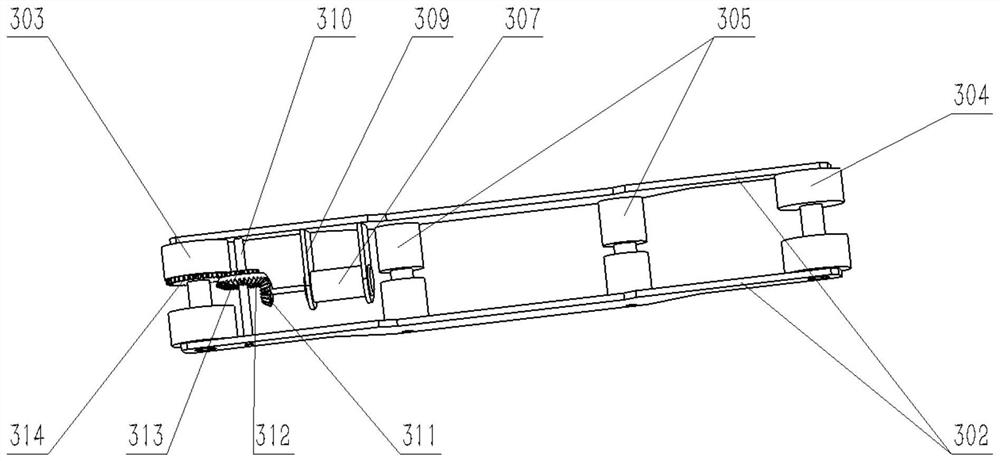

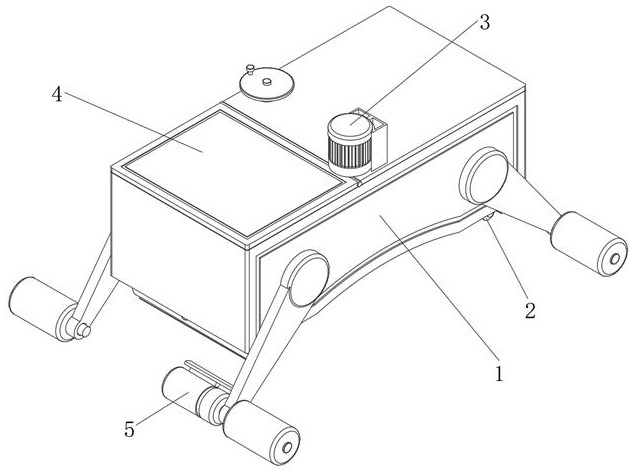

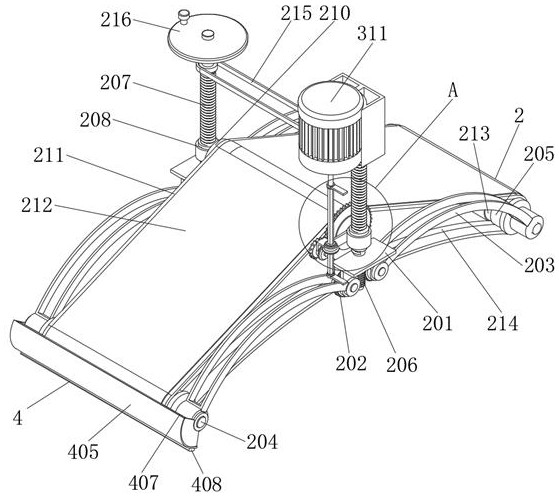

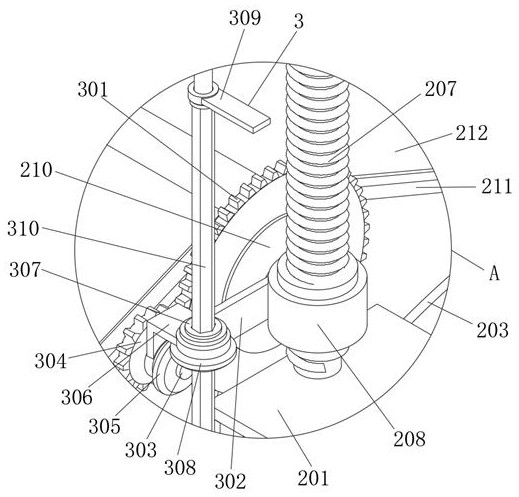

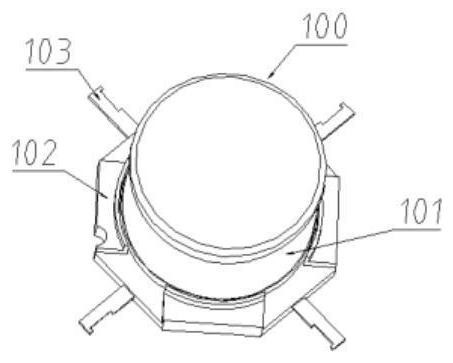

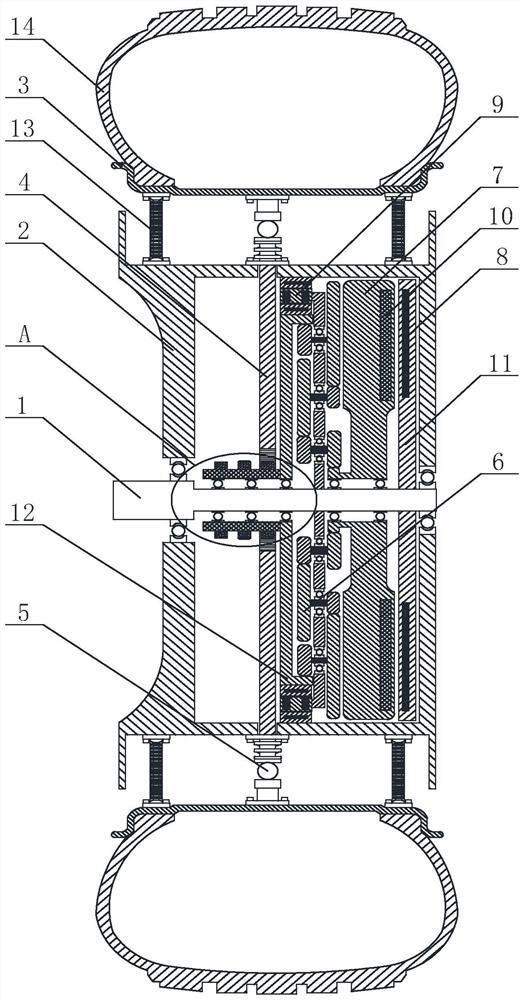

Crawler-type pipeline detection robot

ActiveCN114321566AImprove adaptabilityImprove applicabilityPigs/molesNuclear energy generationStructural engineeringControl theory

The invention discloses a crawler-type pipeline detection robot. Corresponding walking mechanisms are installed on the two sides of the main shell respectively, a displacement mechanism is installed in the main shell, the walking mechanisms are connected with the displacement mechanism, a lifting mechanism and a detection mechanism are installed on the main shell, and the detection mechanism is installed in the middle of the lifting mechanism; the robot is arranged in a pipeline, and the displacement mechanism is started to drive the walking mechanisms on the two sides of the main shell to synchronously and circumferentially rotate around the center line of the robot, so that the bottoms of the walking mechanisms on the two sides of the main shell are attached to the inner walls of different pipelines; and the lifting mechanism is started, so that the upper part of the lifting mechanism is also attached to the inner wall of the pipeline, and the detection mechanism is used for detecting the pipeline. According to the invention, the robot adapts to pipelines with different widths, the ability of the robot to move and cope with a severe and sudden environment is enhanced, and the ability and efficiency of detection of problematic pipelines are improved; the robot containing state design is compact, and space is saved.

Owner:HANGZHOU DIANZI UNIV

Steel container surface arc-shaped welding seam polishing device

ActiveCN113458903AReduce labor intensityImprove polishing efficiencyEdge grinding machinesGrinding wheel securing apparatusTransmission beltWeld seam

The invention discloses a steel container surface arc-shaped welding seam polishing device, and belongs to the technical field of welding seam polishing. A worm is connected between two symmetrical worm wheels in an engaged manner so that the worm can drive the left worm wheel and the right worm wheel to synchronously and oppositely rotate when rotating, and the positions of two first roller columns on the lower portion are adjusted; and by arranging screw rods and screw sleeves which are in threaded connection and fixedly connecting the bottoms of the screw rods and the worm, when the two first roller columns on the lower portion move and are adjusted oppositely to the middle position, second roller columns on the upper portion can move upwards, stable supporting is formed on a transmission belt, lifting formed by pressing of an arc-shaped welding seam is adopted in cooperation, the bottom of the transmission belt can be adjusted to be in an arc shape to be tightly attached to the arc-shaped welding seam, so that when abrasive paper polishes the outer surface of the arc-shaped welding seam, the angle does not need to be repeatedly adjusted during movement, the polishing efficiency and the polishing accuracy are improved, and the labor intensity of workers is conveniently reduced.

Owner:南通金盛不锈钢有限公司

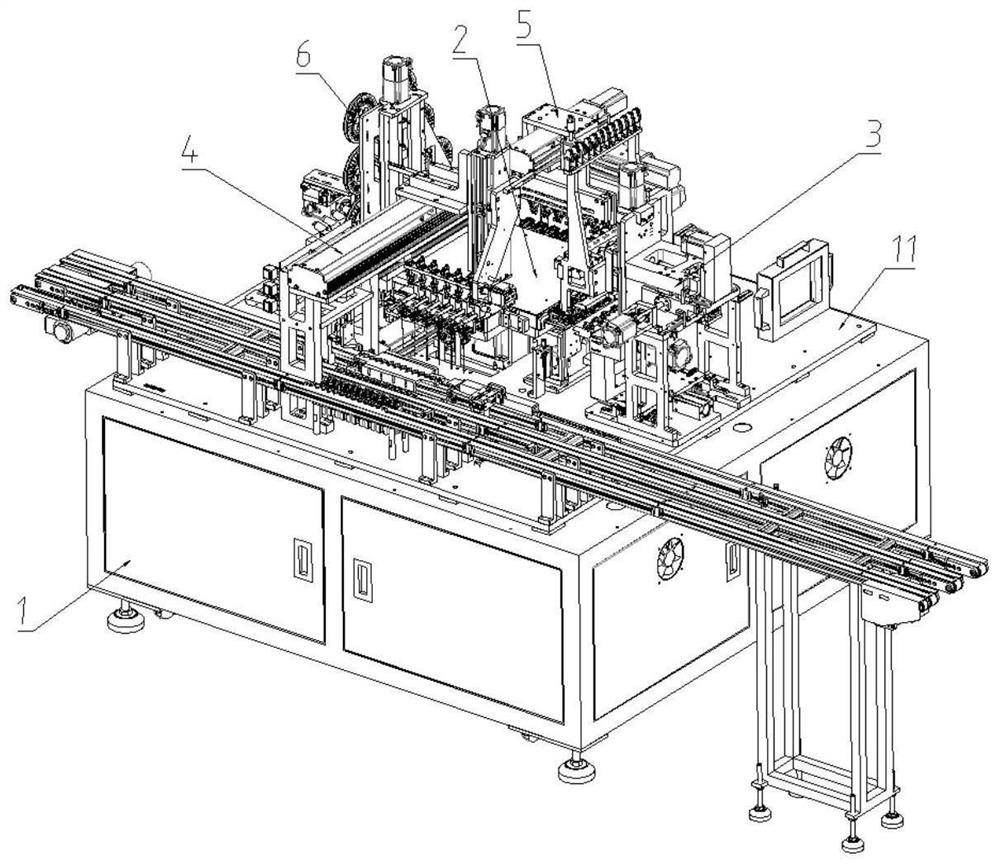

Automatic production equipment for shielding inductor

The invention provides automatic production equipment for a shielding inductor. The automatic production equipment comprises a rack; at least one group of chucks; one first transmission rod which is arranged on one side of each group of chucks, wherein the first transmission rods can rotate along the horizontal axis relative to a mounting plate, and the first transmission rods and the corresponding chucks are arranged in a row; a first rotary driving assembly which comprises a second bracket which is arranged at a winding station on the mounting plate and can move back and forth along a group of chucks close to or far away from the winding station; and a second transmission rod which is rotatably arranged on the second bracket, wherein the rotation axis of the second transmission rod is collinear with the rotation axis of the first transmission rod located on the winding station, and the second transmission rod and the first transmission rod can be selectively connected or disconnected. The equipment can realize automatic processing of the shielding inductor.

Owner:DONGGUAN DONGHONG AUTOMATION TECH CO LTD

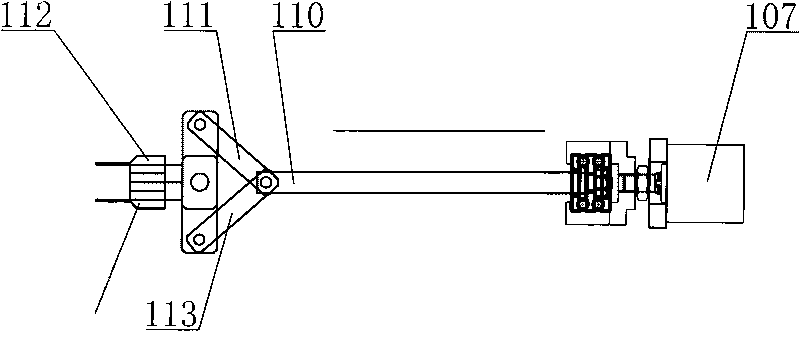

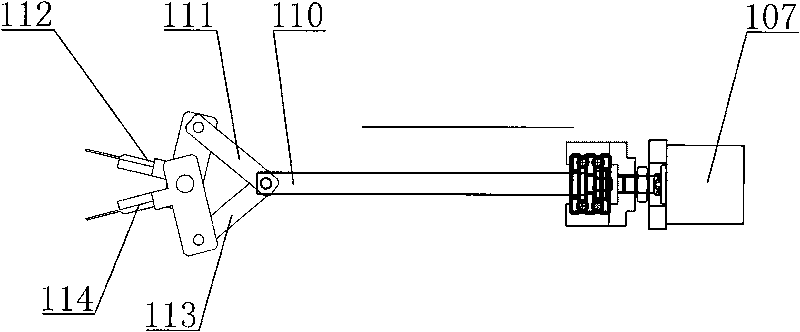

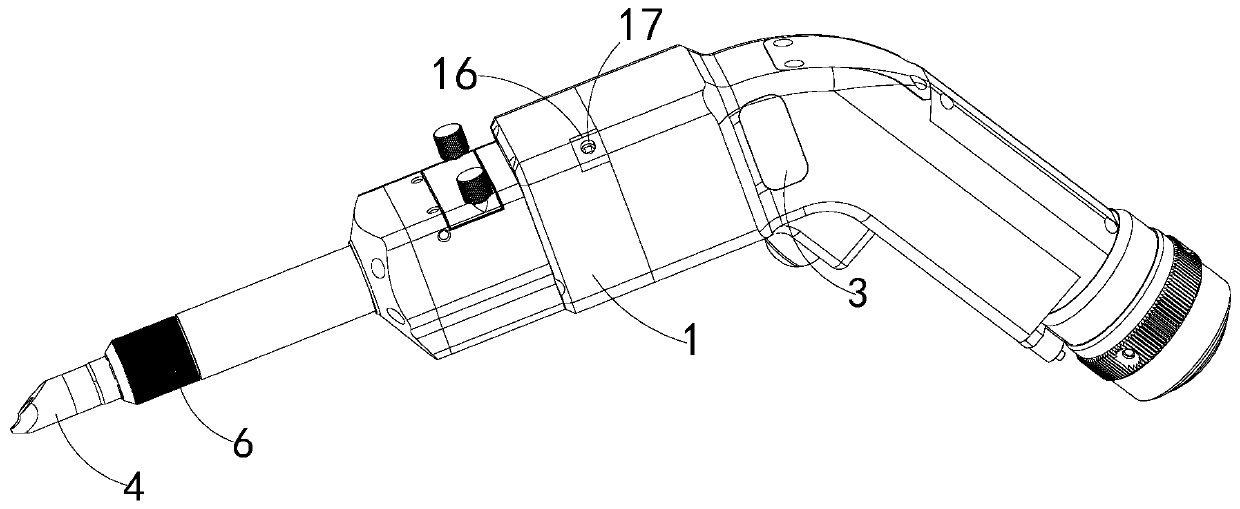

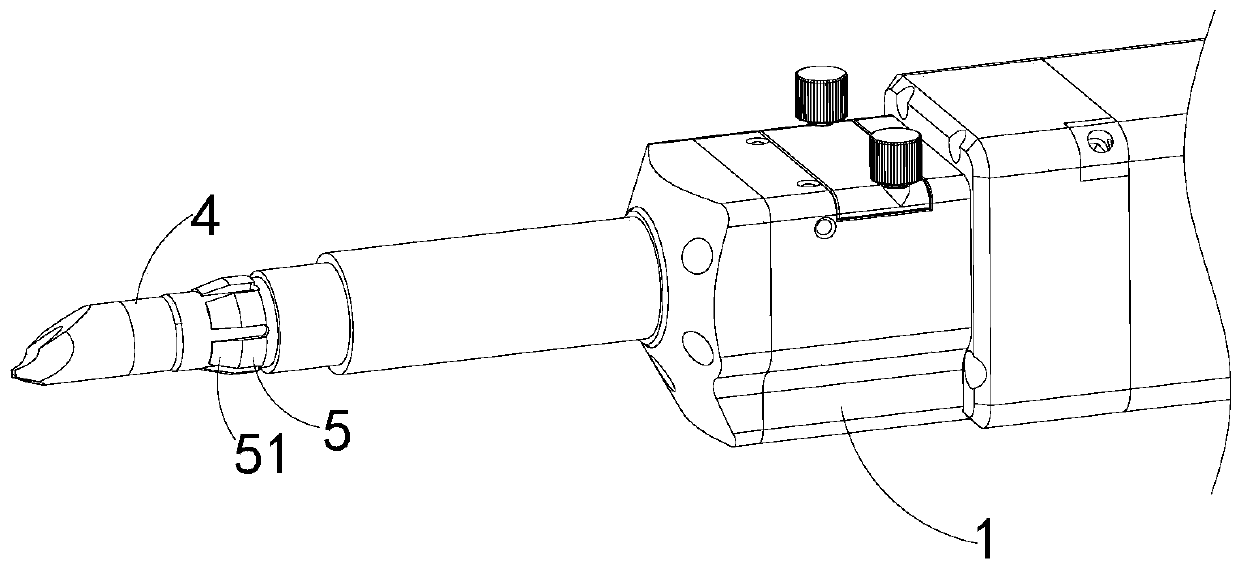

Handheld laser gun head capable of adjusting light spot

The invention provides a handheld laser gun head capable of adjusting a light spot. A collimating lens is mounted on a collimating lens base, the collimating lens base is inserted into a gun head bodythrough a through hole, and therefore, the collimating lens base can be taken out conveniently for replacing the collimating lens. The handheld laser gun head is further provided with a fixed plate and a sleeve, so that a moving spray nozzle can be fixed through the fixed plate and the sleeve in a moving process of the nozzle, and the spray nozzle cannot shake; and according to the handheld lasergun head, a first wedge lens is mounted in an inner rotor, a second wedge lens is mounted in an outer rotor, the outer rotor is adjusted to rotate relative to the inner rotor, the first wedge lens and the second wedge lens are enabled to rotate relatively, different angle differences are produced between the first wedge lens and the second wedge lens, a refraction angle of a light path is changed, movement of the light spot can be realized, then the size of the light spot is changed, and multiple welding technological requirements can be met.

Owner:武汉兴弘光电技术有限公司

Device for machining parts

InactiveCN106925982ASynchronous rotationGuaranteed to workMetal working apparatusDrive motorEngineering

The invention discloses a device for processing parts, which comprises a mounting platform and a supporting base, a supporting plate is arranged on the supporting base, a driving motor is arranged on the supporting plate, a rotating assembly is connected to the driving motor, and a rotating assembly is arranged on the mounting platform. There is a first turntable, the first turntable is provided with a first clamping part, the installation platform is provided with a second turntable, and a second stopper is arranged on the second turntable. The invention can quickly complete the processing of a large number of mechanical parts, automatically add sealing gaskets to the mechanical parts, improve the work efficiency, reduce the cost, be automatic and efficient, and the quality of the processed mechanical parts is high, reducing the mixing of defective products The utility model has the advantages of simple structure, strong practicability, low manufacturing cost and remarkable economic benefit.

Owner:全南县韬寻机械设备开发有限公司

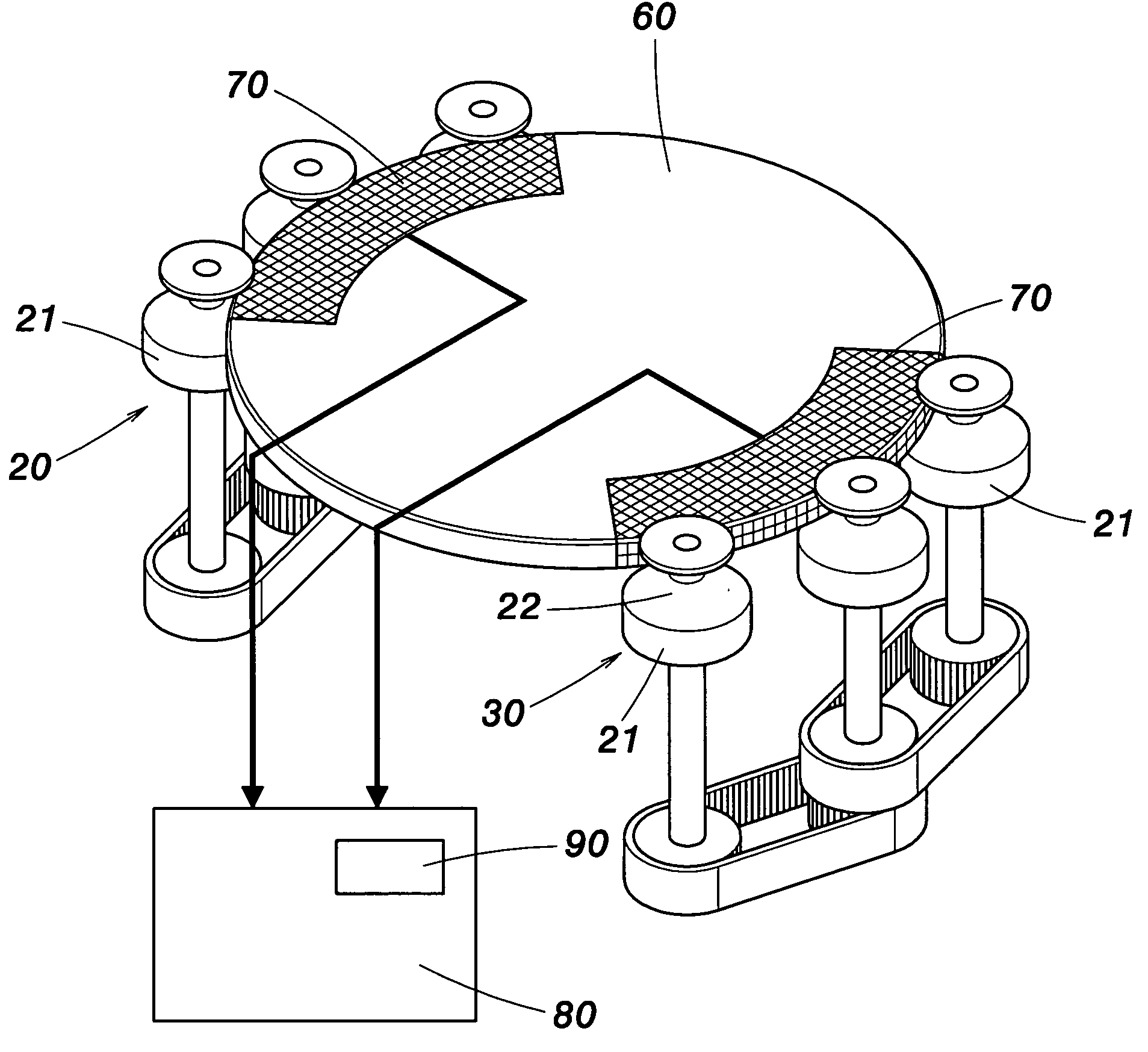

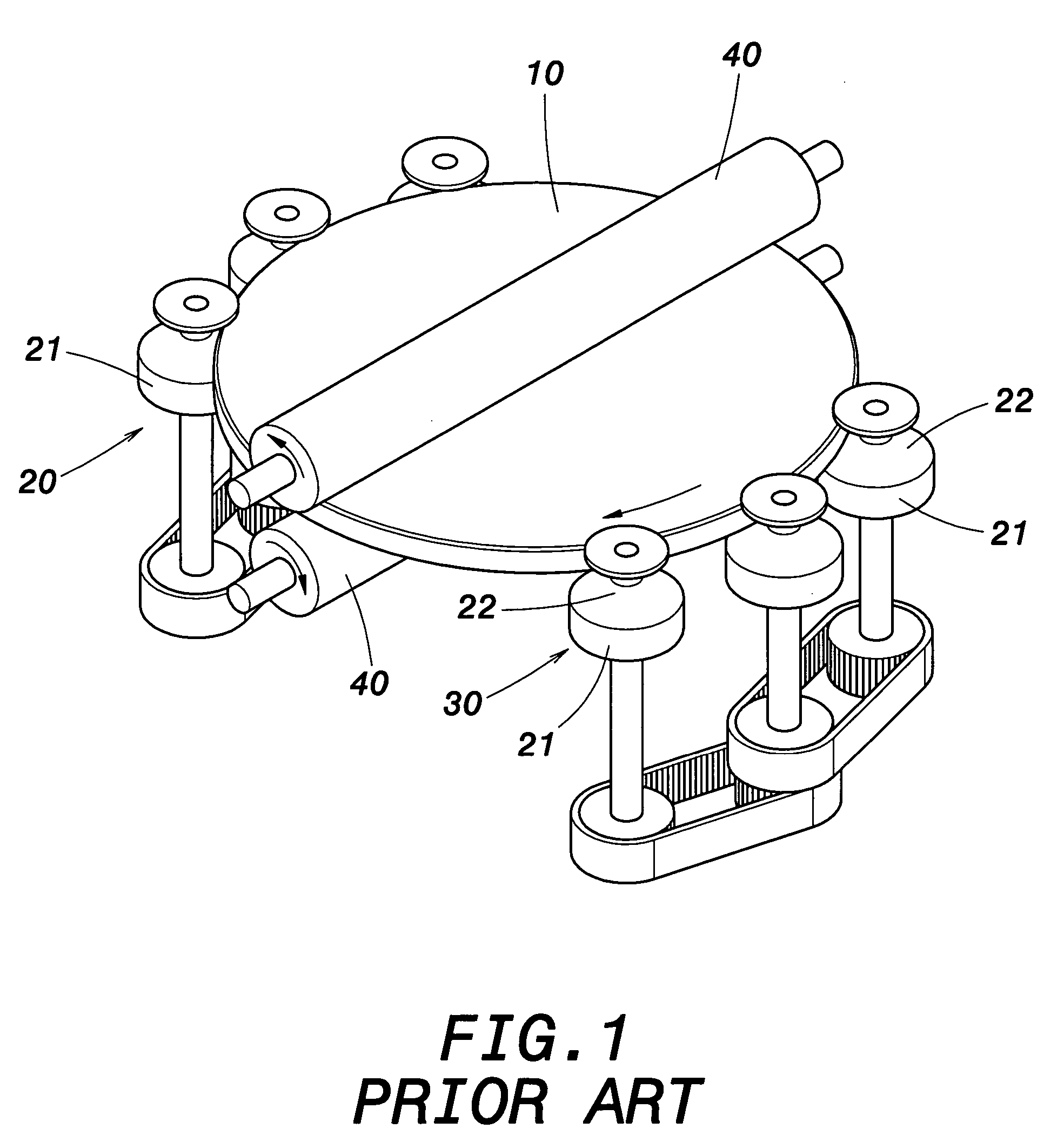

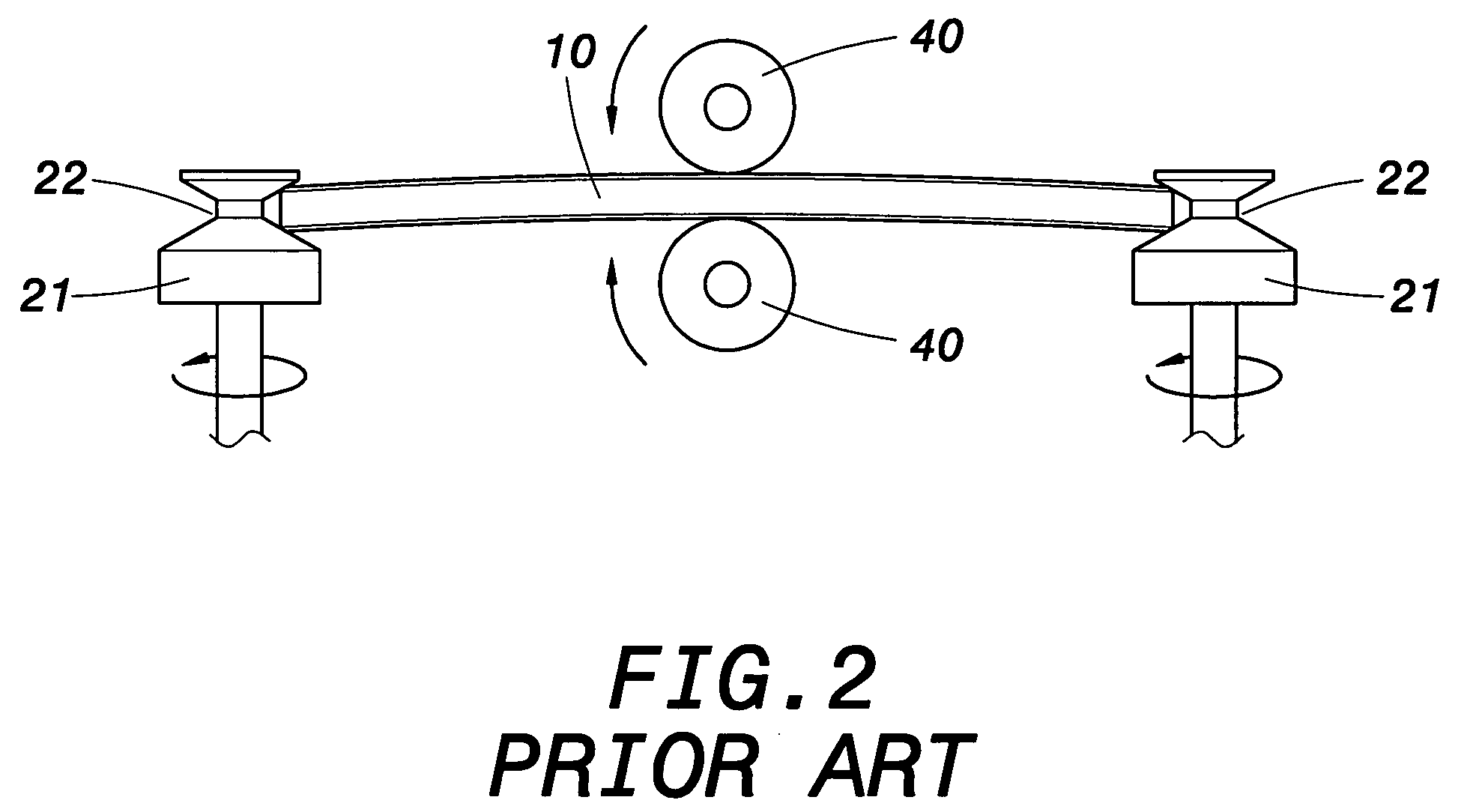

Device used for detecting clamping force of processed object and method thereof

ActiveUS20050103121A1Small clamping forceSynchronous rotationSemiconductor/solid-state device manufacturingApparatus for force/torque/work measurementEngineeringElectric properties

A device used for detecting the clamping force of a processed object and a method thereof are proposed. The device comprises a detection unit, a basis component and a pressure detection component disposed on the basis component. The basis component having the pressure detection component is closely placed between pivotal rods so that the detection unit can detect variation of electric properties of the pressure detection component to adjust the spacing between the pivotal rods, hence facilitating adjustment of the clamping force.

Owner:NAN YA TECH

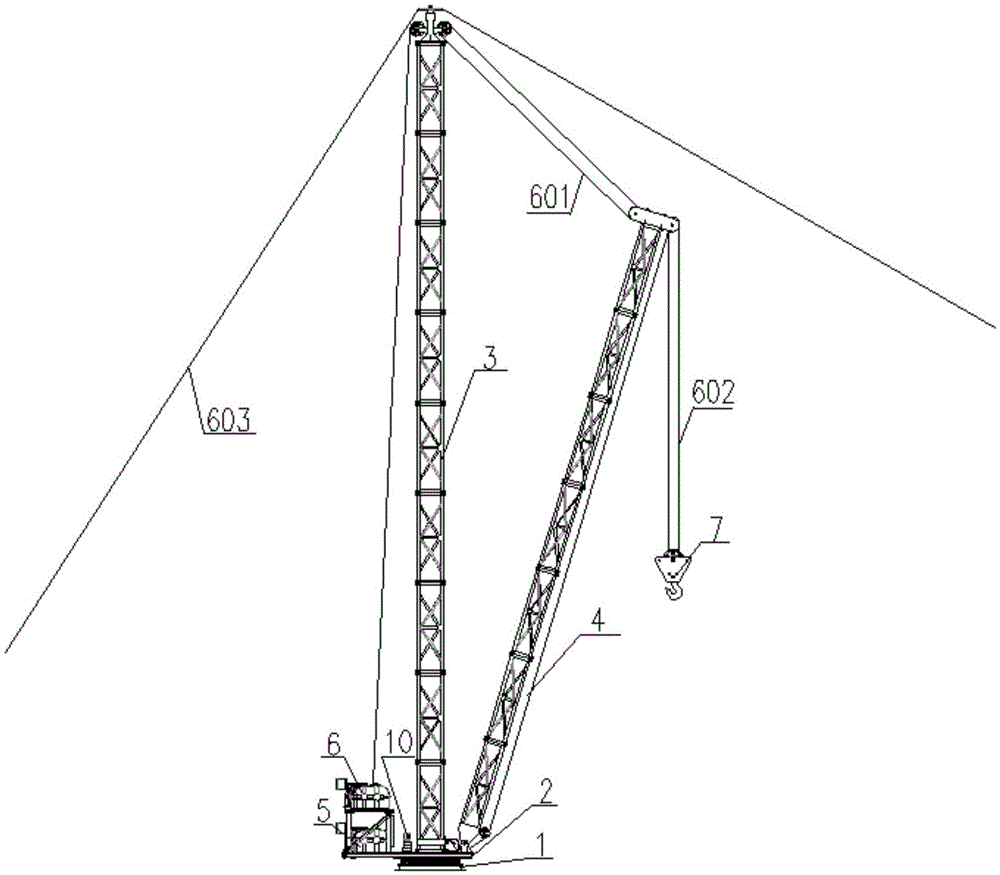

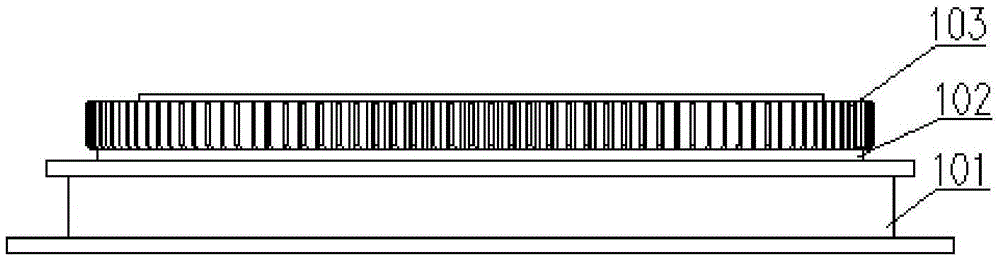

Mast crane applied to river network area

InactiveCN105584938ASynchronous rotationAvoid interferenceCargo handling apparatusPassenger handling apparatusRiver networkEngineering

The invention discloses a mast crane applied to the river network area. The mast crane comprises a body. The body comprises a rotation base, a rotation platform, a main mast and a lifting mast. The rotation base is fixed, and the main mast and the lifting mast can synchronously rotate with the rotation platform through a rotation driving vertical motor. A lifting winch and a variable amplitude winch are arranged in a layering manner, a variable amplitude steel wire rope penetrates the top of the main mast from back to front, a lifting steel wire rope directly penetrates the bottom of the main mast, and the situation that the steel wire ropes interfere with each other can be effectively prevented. In addition, a winch system is arranged at the rear end of the rotation platform, and the balance weight balancing function can be achieved. The main mast and the rotation platform are connected through bolts or pins. When the main mast is integrally assembled, an installing support plays a supporting role, the main mast is pulled and erected through a vertical rod, and therefore the main mast can be rapidly assembled.

Owner:STATE GRID CORP OF CHINA +2

Printer

InactiveCN101780728BWork lessSynchronous rotationRotary pressesPrinting press partsCouplingEngineering

The machine (1) has a roller (2) via which a tempering fluid i.e. water, flows. Roller locks (3) lock the roller and are designed as fast replacement devices. An electric coupler connects a tempering fluid pipeline with the roller. The electric coupler has a coupling half (13) provided at the roller, and another coupling half provided at the pipeline. A positioning device (38) adjusts or aligns a correct angle position of one of the coupling half relative to the other half in an automatic manner during insertion of roller into the locks.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Automatic cup wiping machine

PendingCN108043849AAchieve fixationRealization of automatic cup wipingHollow article cleaningEngineeringFriction force

The invention discloses an automatic cup wiping machine. The automatic cup wiping machine comprises a worktable, a wiping mechanism and a driving mechanism; the wiping mechanism comprises an inner wall wiping rod, and a set of outer wall wiping rods arranged around the periphery of the inner wall wiping rod; and the inner and outer wall wiping rods are respectively contacted with inner walls and outer walls of cup bodies, and are driven by the driving mechanism to respectively rotate in the same clock hand direction. In the automatic cup wiping machine, when the cup bodies are wiped, frictionforce in two opposite directions is applied to the inner walls and the outer walls of the cup bodies; and when the cup bodies are fixed through external force, the external force only needs to overcome a difference value of the two friction force to realize fixation of the cup bodies, so that labors are saved, and automatic cup wiping is finally realized.

Owner:苏州行鼎餐饮设备有限公司

Pipe fitting group butt welding external clamping device

ActiveCN105057967BLower skill requirementsReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses a pipe assembly welding external clamping device which comprises a base. The base is provided with a supporting device capable of supporting two assembly pipes, and enabling the two assembly pipes to be located on the same axis and to rotate synchronously, so that assembly welding precision of the pipes is guaranteed. The coaxiality of the assembly pipes does not need to be adjusted repeatedly, and adjustment by a level gauge is not needed, either. After the two assembly pipes are placed on a left roller rack and a right roller rack of an assembly device to be compressed, the coaxiality of the two assembly pipes can be guaranteed, the skill requirements for operators are lowered, and the labor intensity of the operators is relieved. Assembly efficiency is high.

Owner:HIMILE MECHANICAL MFG

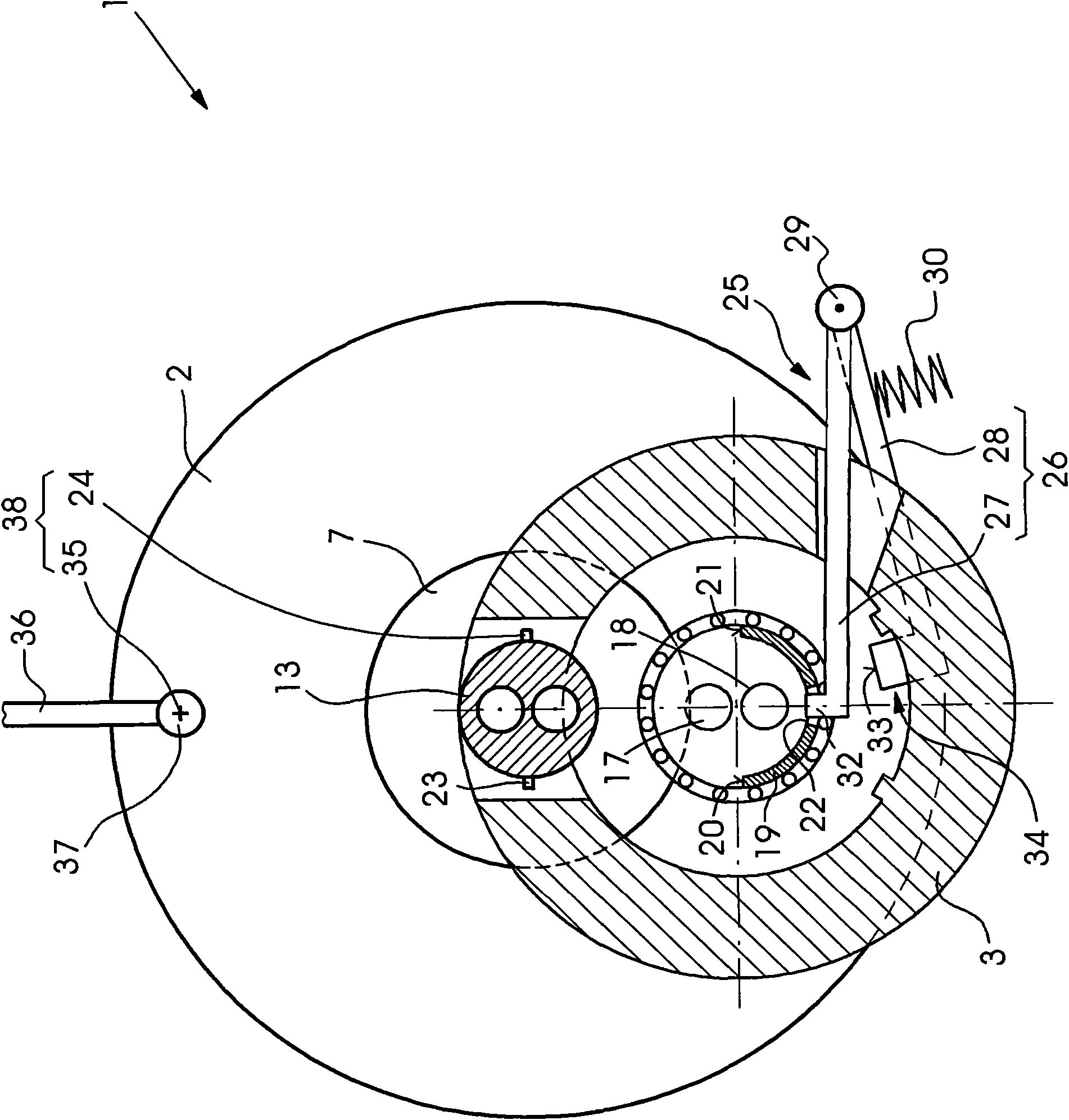

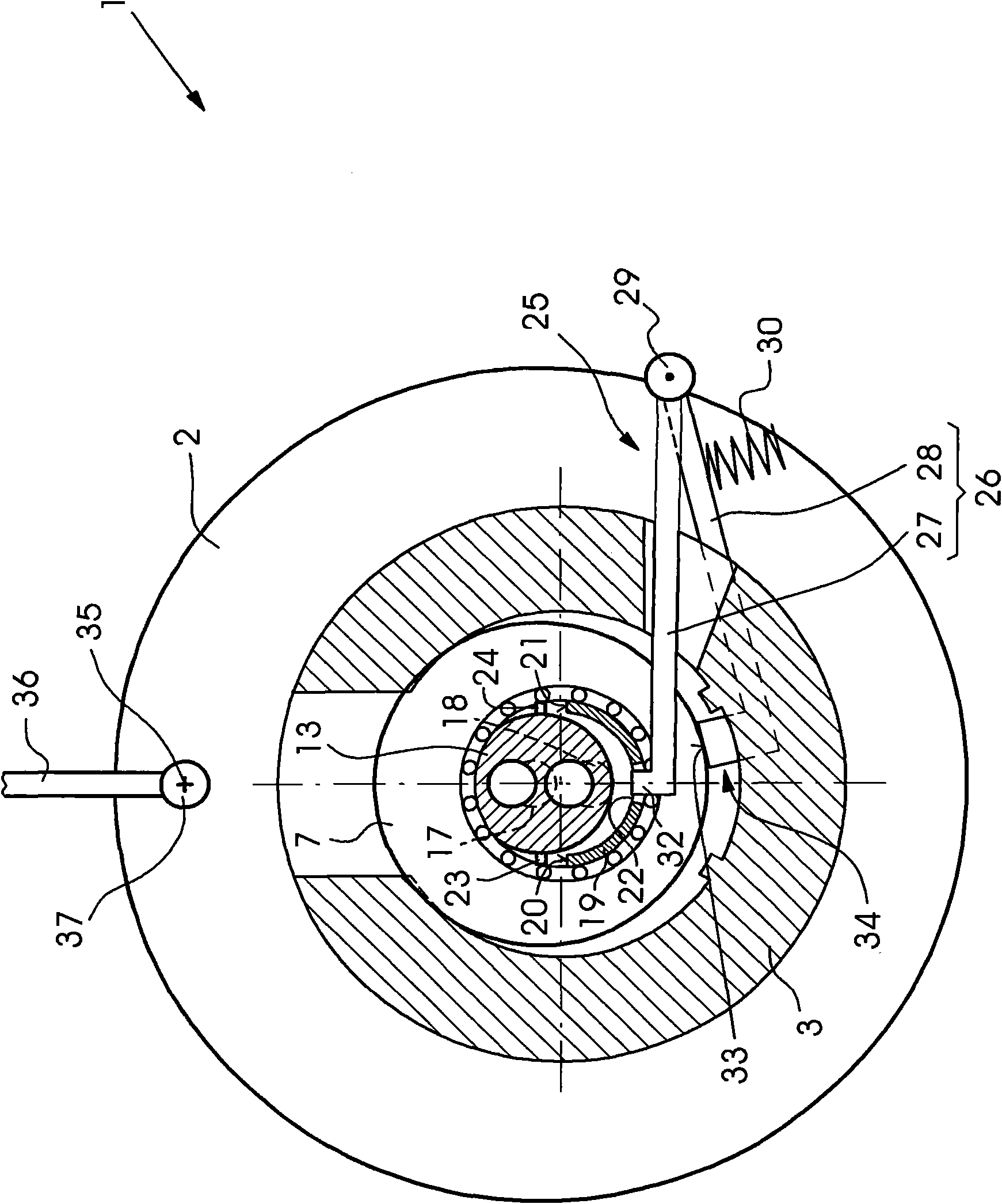

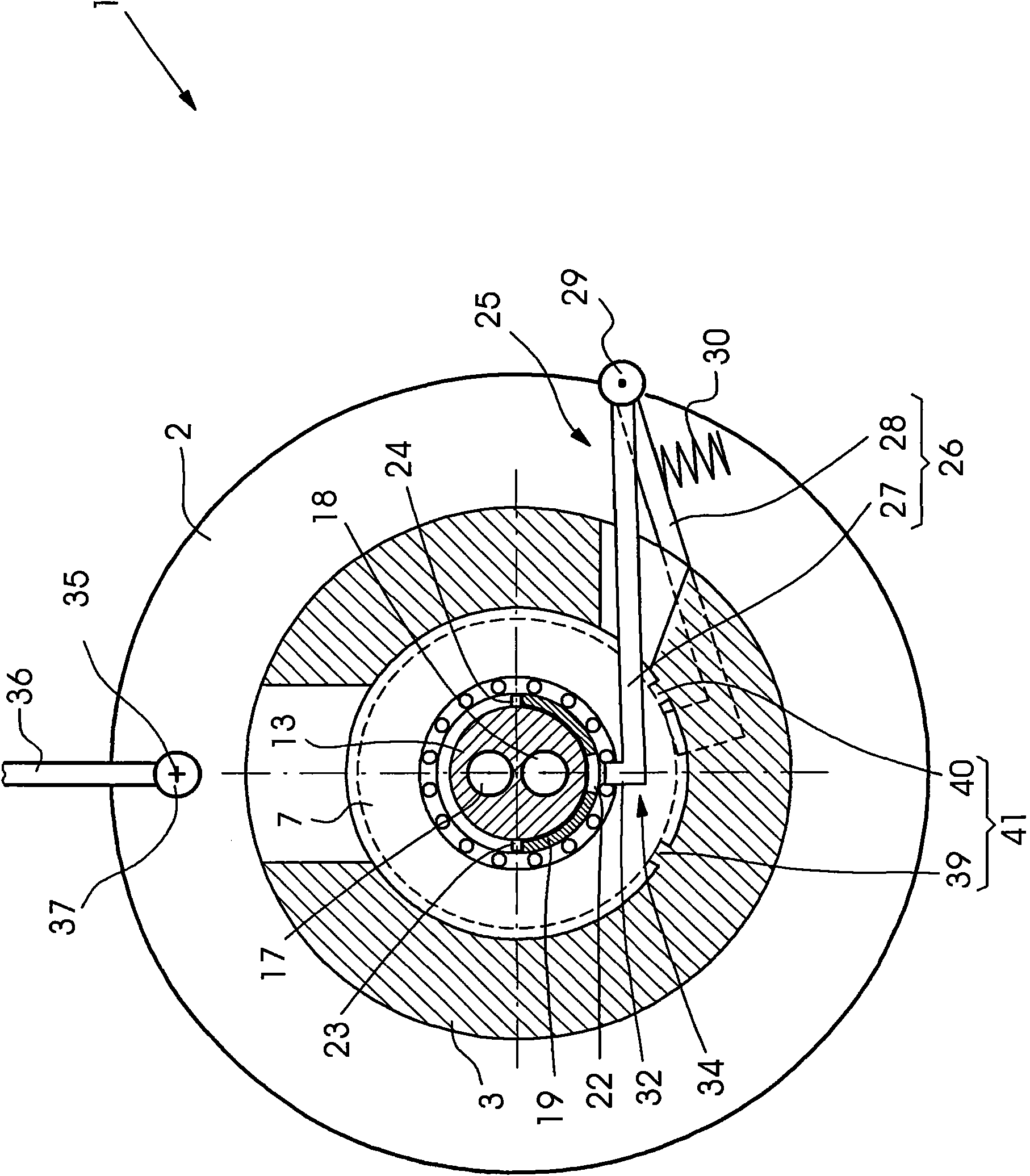

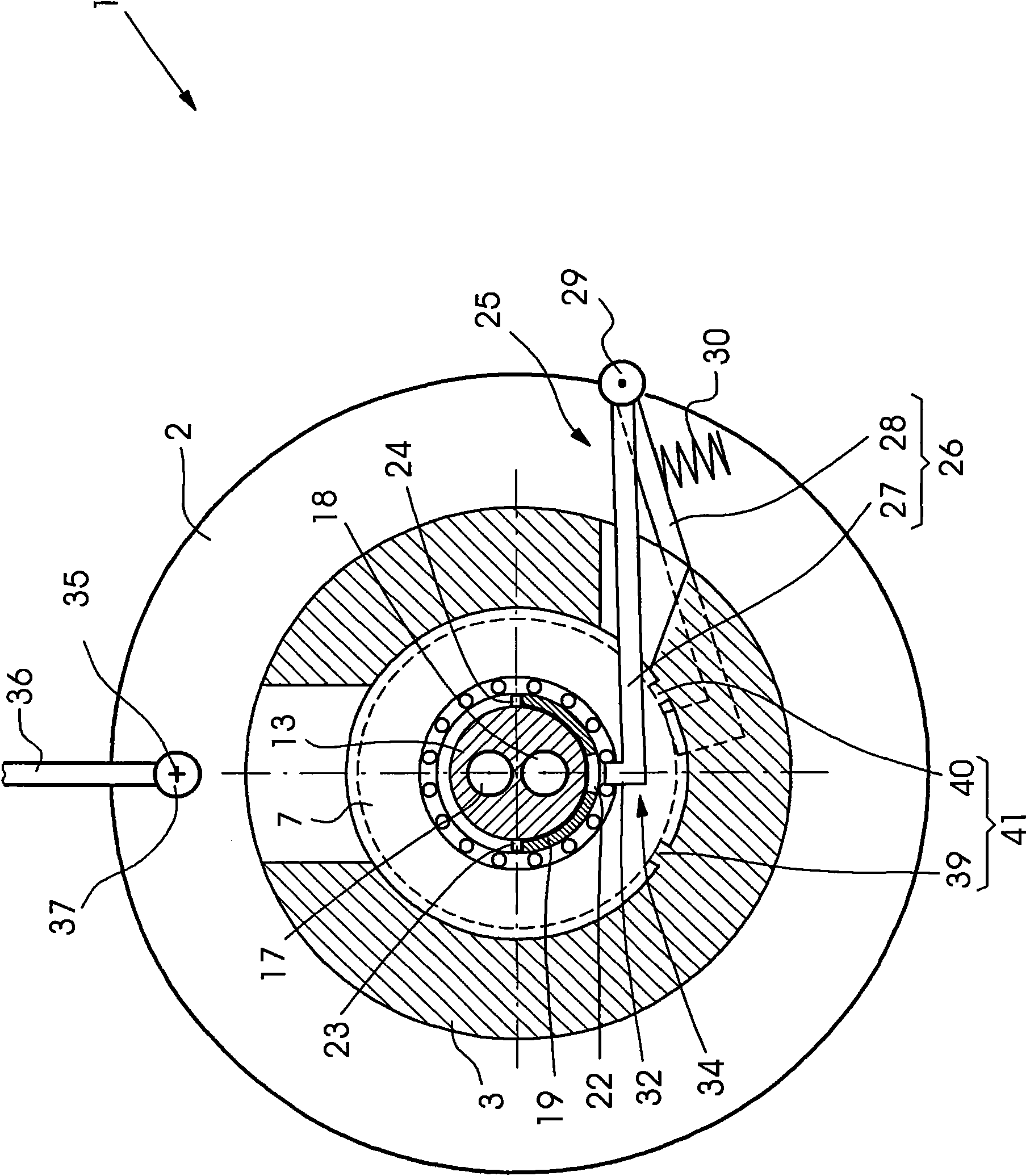

Anti-gravity power generation wheel and operation method thereof

PendingCN114665660AImprove power generation efficiencyImprove battery lifeMechanical energy handlingWheelsRatchetFlywheel

The invention discloses an anti-gravity power generation wheel and an operation method thereof, the wheel comprises a main shaft, a hub, a rim, a stator and a flywheel rotor are coaxially arranged on the main shaft, the flywheel rotor can rotate relative to the stator to generate current, a ratchet shaft sleeve connected to the flywheel rotor sleeves the main shaft, n ratchets are arranged on the ratchet shaft sleeve, n is a positive integer, and n is a positive integer. A gravity converter movably penetrating through the hub is arranged on the rim, and when the wheel rotates till the gravity converter is vertical, the ratchet vertically moves downwards relative to the gravity converter and is driven by the gravity converter to rotate by a certain angle. The gravity of the automobile is larger than the traction force in the running process of the automobile, the distance of several centimeters of the automobile moving downwards due to the gravity is converted into rotation of the flywheel rotor relative to the stator through the suspension type hub, the gravity converter, the ratchet wheel and the ratchet wheel shaft sleeve so as to generate electric energy, and therefore energy conversion in the running process of the automobile is achieved. The power generation efficiency of the wheels is improved, and the cruising ability of the electric automobile is greatly prolonged.

Owner:ZHONGCI POWER EQUIP (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com