Double-station full-automatic winder and working method thereof

A fully automatic, winder technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of low degree of automation, affecting product quality, affecting production progress, etc., to improve the degree of automation, improve Production efficiency and production line safety, improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

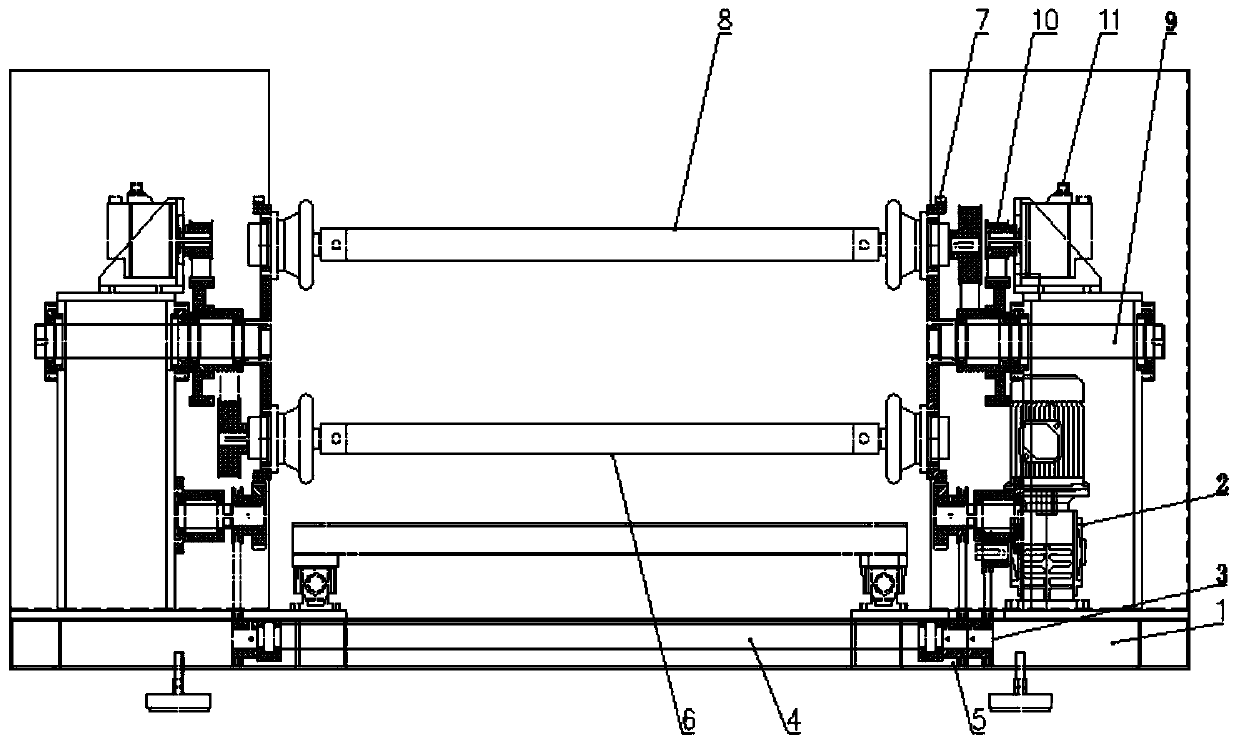

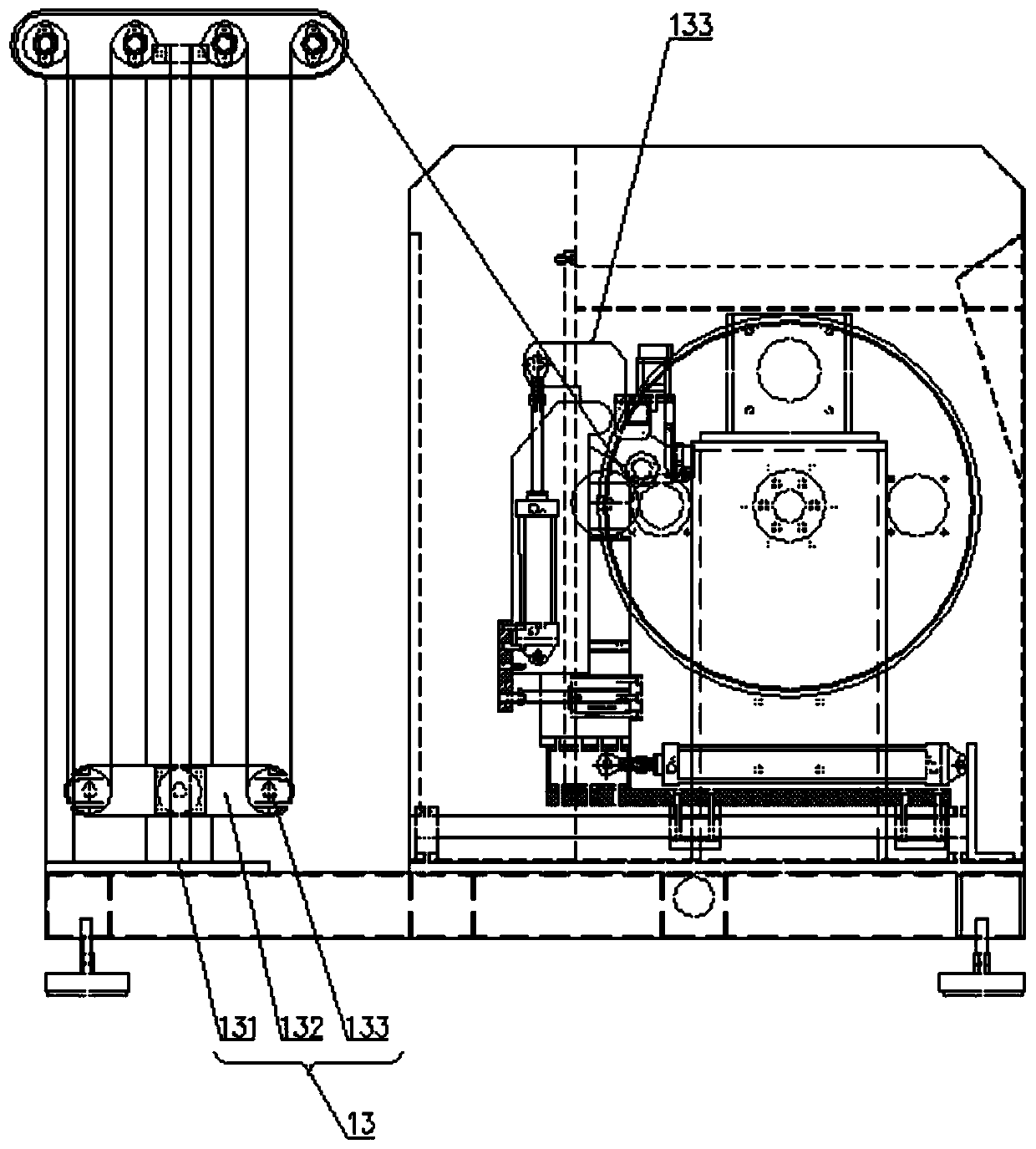

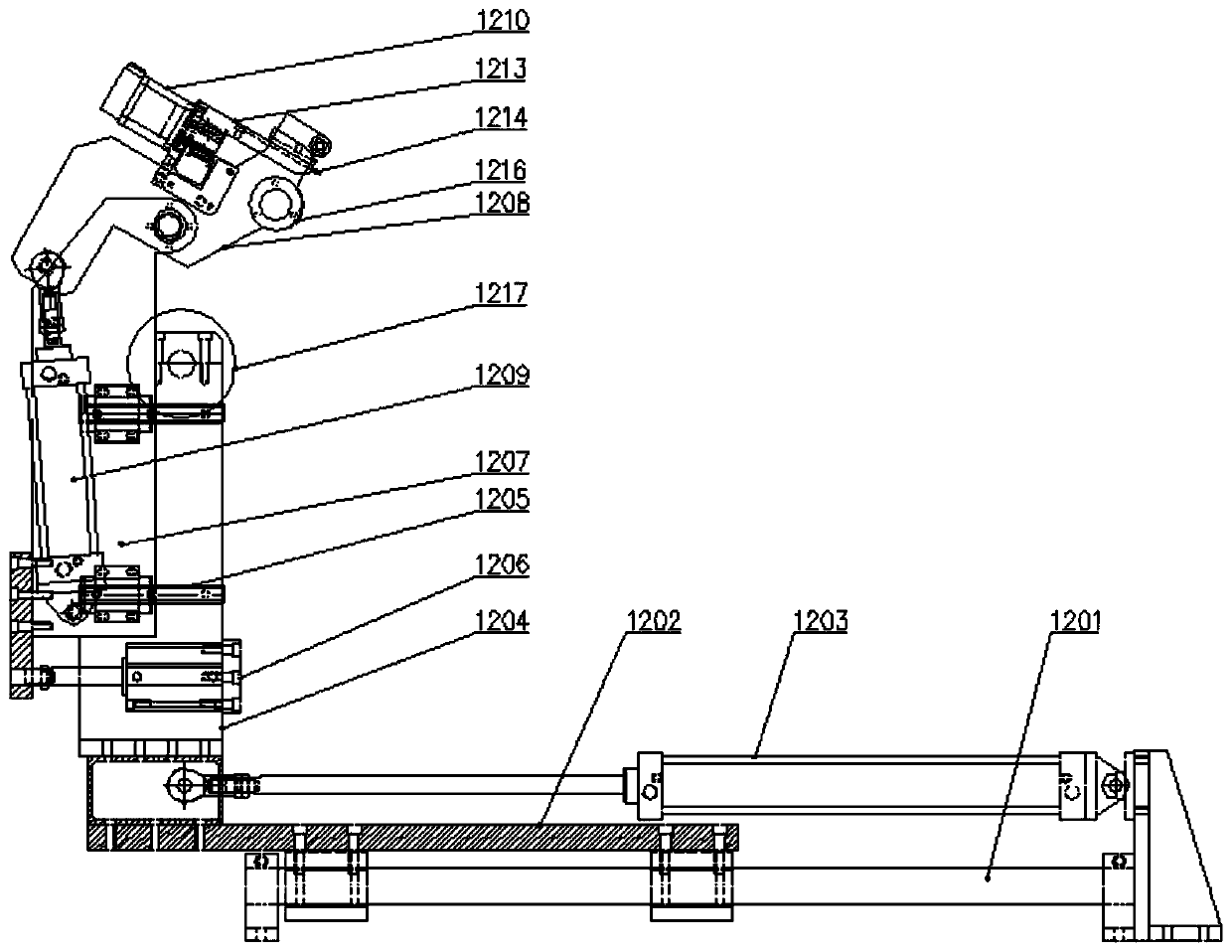

[0048] Such as Figure 1-4 A double-station fully automatic winder is shown, including: base bracket 1, worm gear motor 2, rotating shaft sprocket set 3, rotating central shaft 4, transition sprocket set 5, first winding air inflation Shaft 6, gear turntable 7, second rewinding inflatable shaft 8, turntable center shaft 9, motor synchronous pulley group 10, rewinding servo motor 11 and automatic cutting and smoothing mechanism 12, the base bracket 1 is in the shape of " ", the base bracket 1 is fixed with a worm gear motor 2, one side of the worm gear motor 2 is connected to a rotating shaft sprocket set 3, and the rotating shaft sprocket set 3 is provided with a rotating central shaft 4. The rotating shaft sprocket set 3 is set at one end of the rotating central shaft 4, the rotating central shaft 4 is fixed on the base bracket 1 through a bearing seat, and a transition sprocket set is provided on one side of the rotating shaft sprocket set 3 5. The transition sprocket set 5...

Embodiment 2

[0059] Such as figure 1 A double-station fully automatic winder is shown, including: base bracket 1, worm gear motor 2, rotating shaft sprocket set 3, rotating central shaft 4, transition sprocket set 5, first winding air inflation Shaft 6, gear turntable 7, second rewinding inflatable shaft 8, turntable center shaft 9, motor synchronous pulley group 10, rewinding servo motor 11 and automatic cutting and smoothing mechanism 12, the base bracket 1 is in the shape of " ", the base bracket 1 is fixed with a worm gear motor 2, one side of the worm gear motor 2 is connected to a rotating shaft sprocket set 3, and the rotating shaft sprocket set 3 is provided with a rotating central shaft 4. The rotating shaft sprocket set 3 is set at one end of the rotating central shaft 4, the rotating central shaft 4 is fixed on the base bracket 1 through a bearing seat, and a transition sprocket set is provided on one side of the rotating shaft sprocket set 3 5. The transition sprocket set 5 is...

Embodiment 3

[0061] Such as figure 1 and 2 A double-station fully automatic winder is shown, including: base bracket 1, worm gear motor 2, rotating shaft sprocket set 3, rotating central shaft 4, transition sprocket set 5, first winding air inflation Shaft 6, gear turntable 7, second rewinding inflatable shaft 8, turntable center shaft 9, motor synchronous pulley group 10, rewinding servo motor 11 and automatic cutting and smoothing mechanism 12, the base bracket 1 is in the shape of " ", the base bracket 1 is fixed with a worm gear motor 2, one side of the worm gear motor 2 is connected to a rotating shaft sprocket set 3, and the rotating shaft sprocket set 3 is provided with a rotating central shaft 4. The rotating shaft sprocket set 3 is set at one end of the rotating central shaft 4, the rotating central shaft 4 is fixed on the base bracket 1 through a bearing seat, and a transition sprocket set is provided on one side of the rotating shaft sprocket set 3 5. The transition sprocket s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com