Crawler-type pipeline detection robot

A pipeline inspection and robot technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of increased construction costs, large detection blind spots, interference, etc., to achieve convenient transportation and storage, expand applicability, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and embodiments.

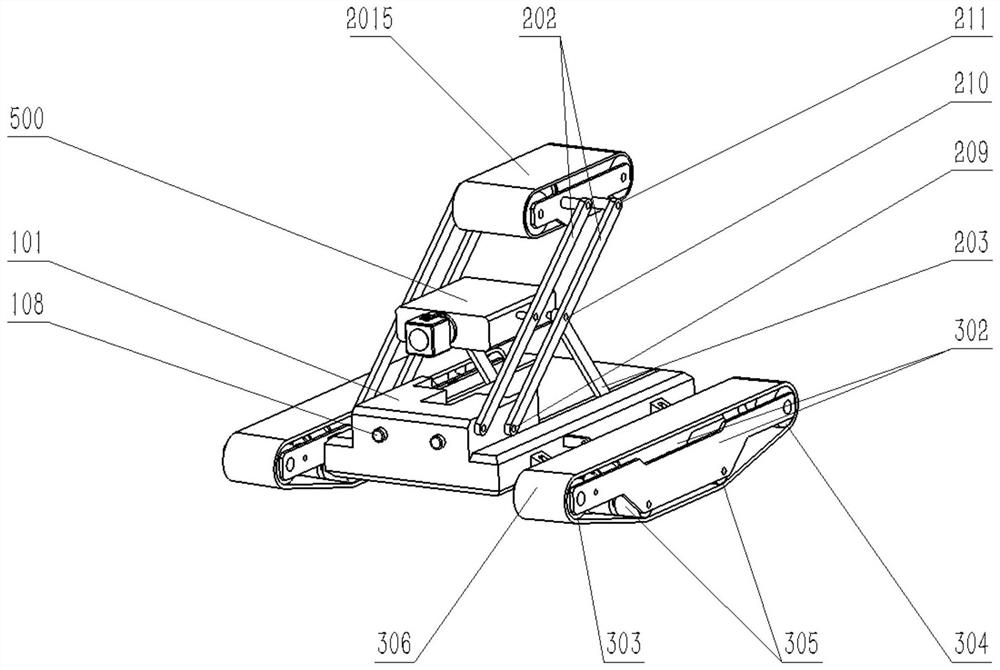

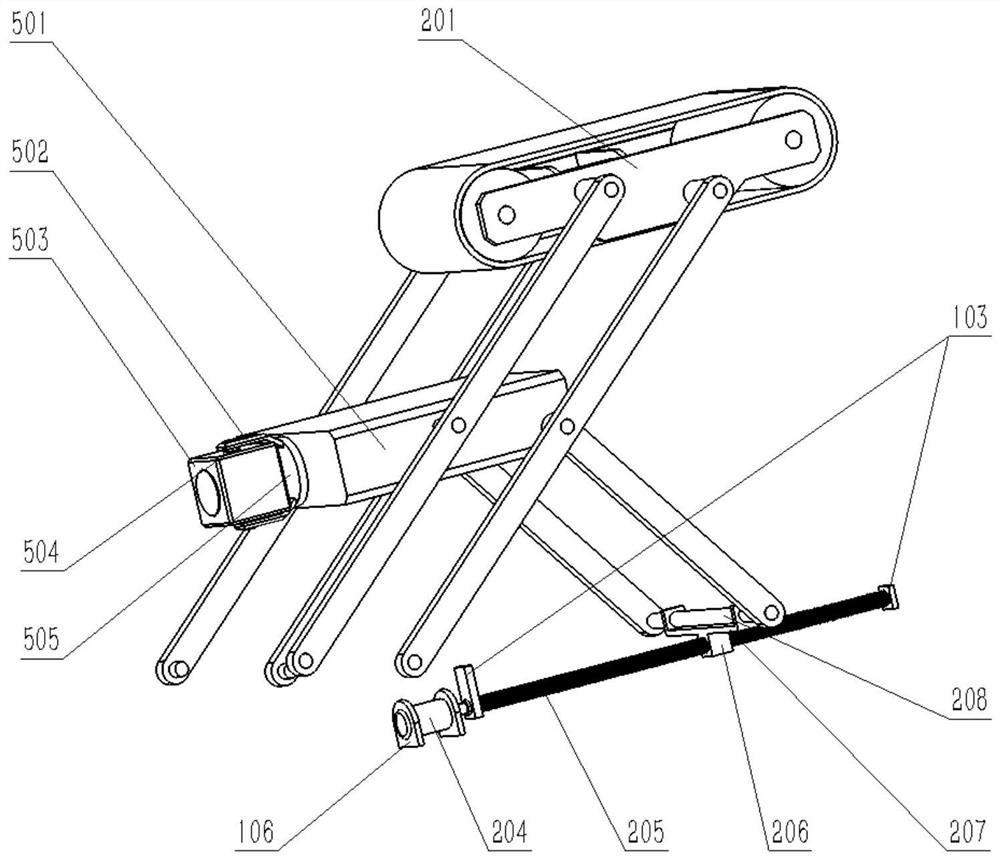

[0042] like figure 1 As shown, the present invention includes a main casing 101, a lifting mechanism, a traveling mechanism, a displacement mechanism and a detection mechanism 500;

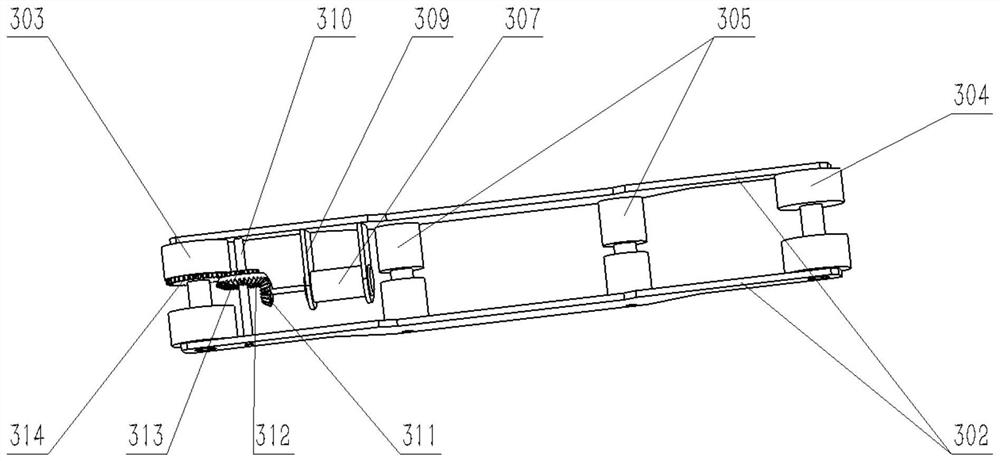

[0043] Corresponding running mechanisms are respectively installed on both sides of the main casing 101 , and two vehicle lights 108 are symmetrically arranged on the front end of the main casing 101 . A displacement mechanism is installed inside the main casing 101, and the walking mechanism is connected with the displacement mechanism. A lifting mechanism and a detection mechanism 500 are installed on the main casing 101. The detection mechanism 500 is installed in the middle of the lifting mechanism; The start of the mechanism drives the walking mechanisms on both sides of the main casing 101 to rotate synchronously around the center line of the robot, so that the bottoms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com