Z-steel stacking equipment

A stacking material and equipment technology, applied in the field of Z-shaped steel stacking equipment, can solve the problems of poor stacking, poor stacking effect, and rising labor costs, and achieve convenient clamping, good stacking effect, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

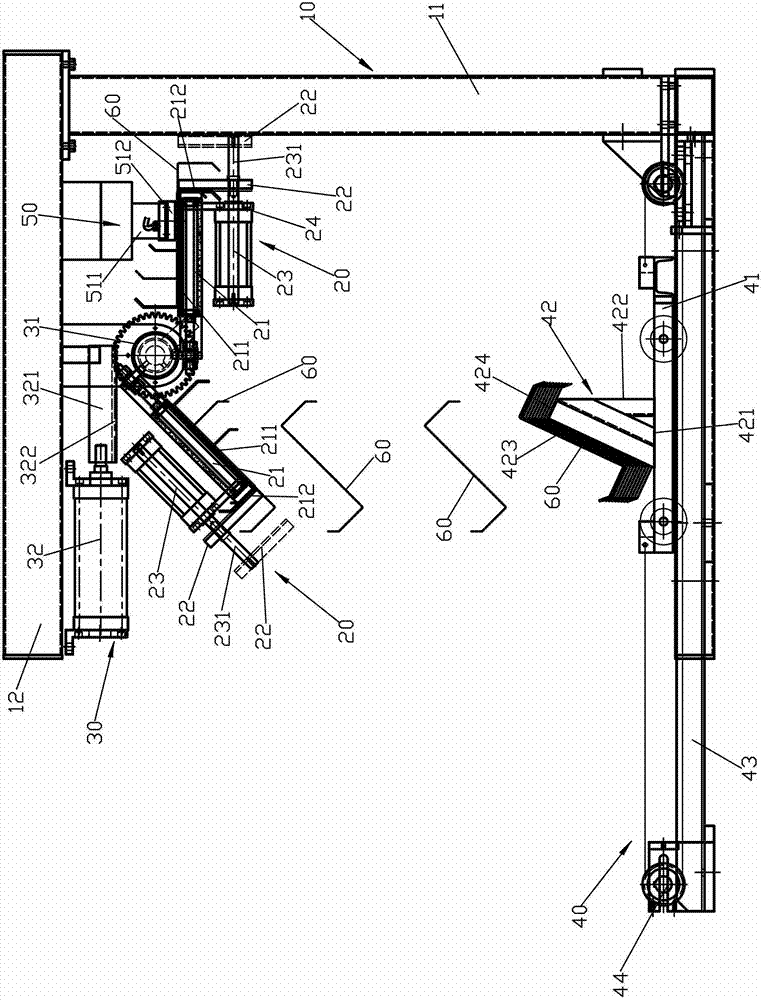

[0033] Z-shaped steel stacking equipment, please refer to figure 1 , including a frame 10, a clamping device 20, a rotating device 30, a stacking platform device 40 and a pulling device 50. This equipment is mainly used in the steel structure industry. It is an automatic process for separating Z-shaped steel from the forming machine to the packaging stage. It is used to stack the Z-shaped steel 60 formed on the forming machine on the stacking table. The Z-shaped steel 60, such as figure 1 and figure 2 As shown, at least one middle side and two small sides are included, and some small sides are provided with inverted edges as required.

[0034] The frame 10 includes a vertical column 11 and a beam 12 fixed on the top of the vertical column 11 .

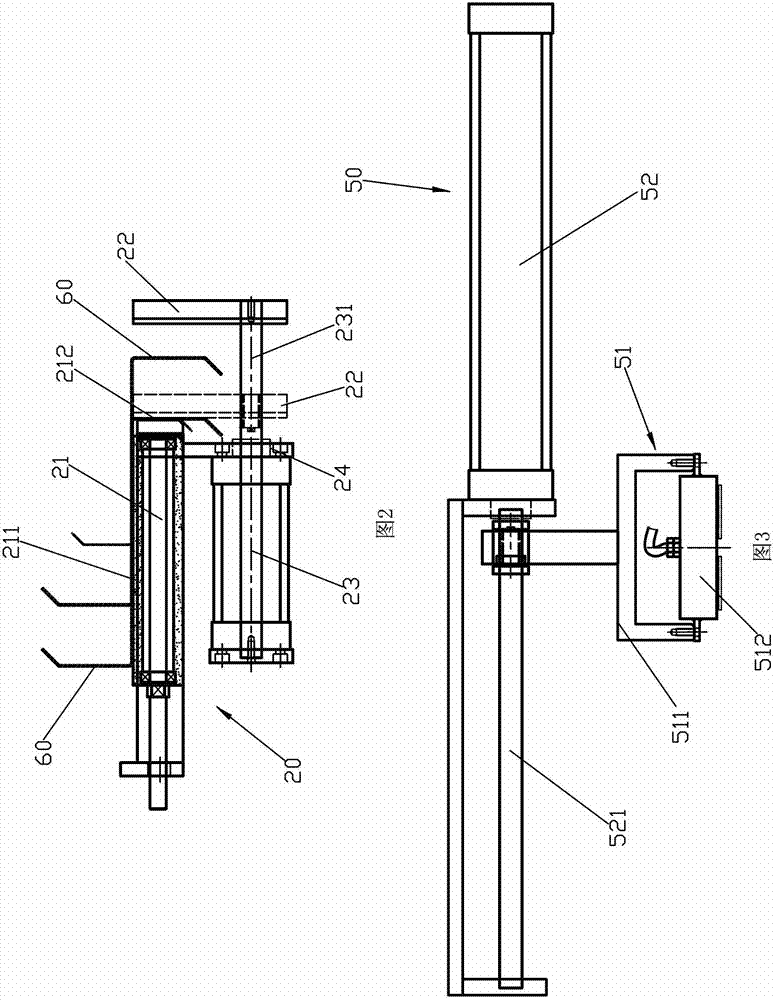

[0035] For the clamping device 20, please refer to the figure 1 and figure 2 , including a workbench 21, a clamping seat 22 that can move relative to the workbench 21, and a clamping power device 23 installed on the workbench 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com