Dough sheet separating machine and dough sheet axial transport equipment

The technology of transportation equipment and separation device is applied in the field of dough sheet separation device and dough sheet turning transportation equipment, which can solve the problems of high cost and complicated structure, and achieve the effect of simple and reliable structure and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

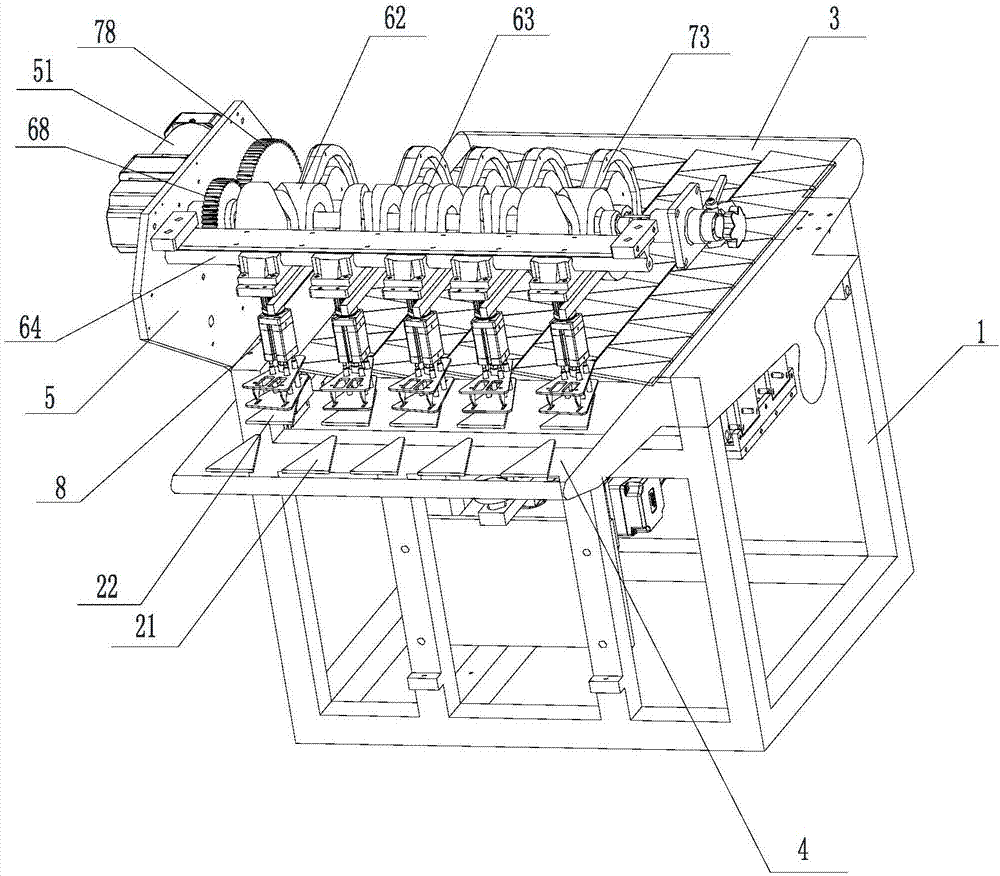

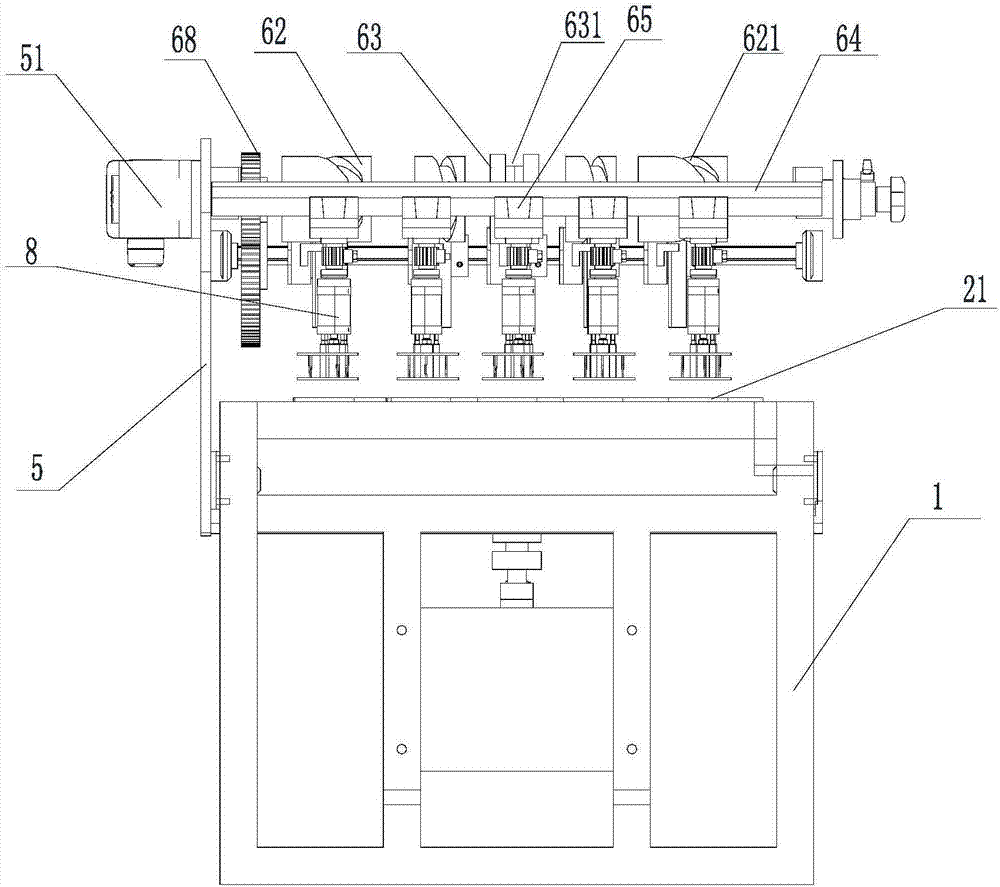

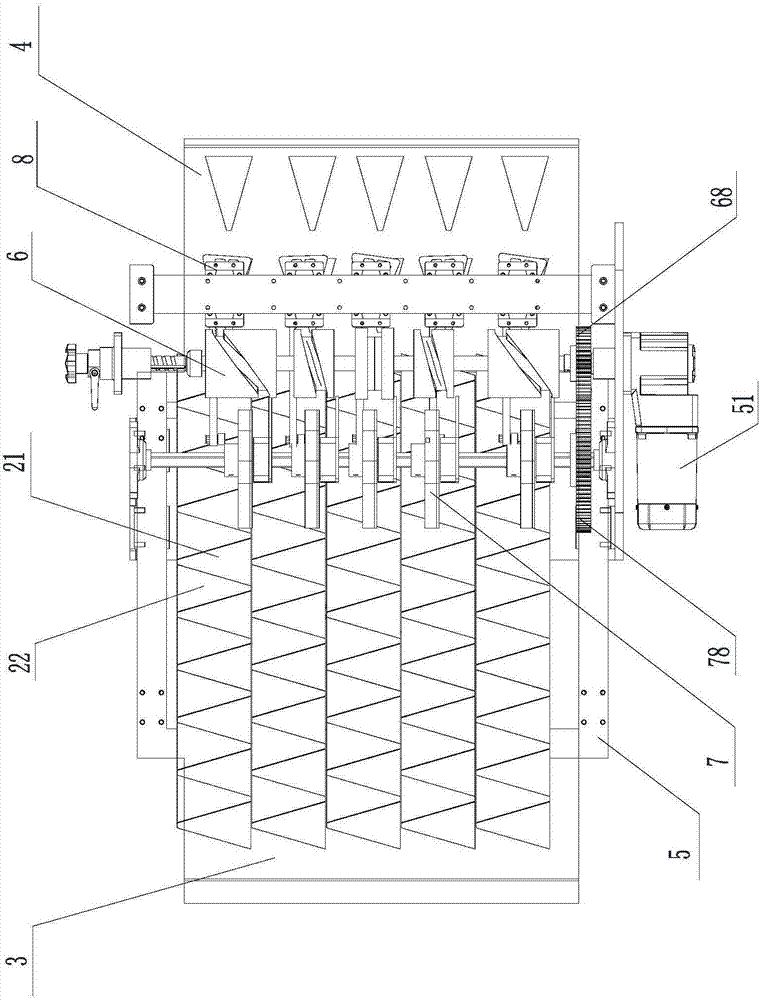

[0048] The dough sheet separating device of the present invention is suitable for separating a plurality of small dough sheets cut from a whole sheet of dough in one direction, wherein the shape of the small dough sheets is not limited. The dough sheet separation device includes a separation mechanism 6 and a plurality of separation units 8 that grab the dough sheets and drive the dough sheets to move. The separation mechanism 6 includes a first camshaft 61 arranged on the bracket and at least two cylindrical cams 62 arranged on the first camshaft 61 and driven by the first camshaft 61 to rotate. The cylindrical surface of the cylindrical cam 62 is provided with a closed first track 621, and the separation mechanism 6 also includes a separation guide rail 64 arranged parallel to the first camshaft 61 and at least two separation guide rails 64 movable along the separation guide rail 64. The moving part 65 , the separation mechanism 6 also includes a plurality of transmission pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com