Anti-gravity power generation wheel and operation method thereof

An anti-gravity, wheel technology, applied in the direction of wheels, electric components, electromechanical devices, etc., can solve the problems of reducing the power generation capacity of wheels, difficult production and application of wheels, poor power generation capacity, etc., to improve the speed, drive efficiency and power generation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

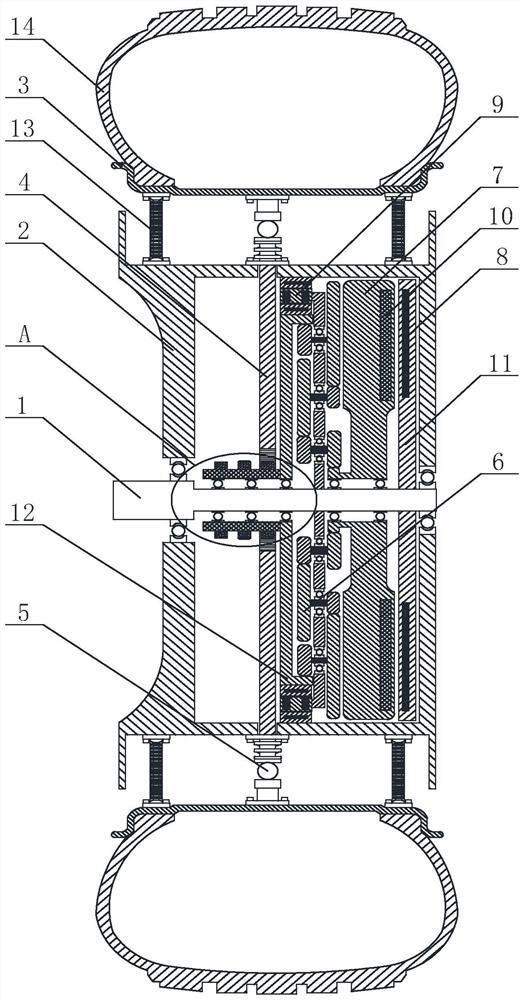

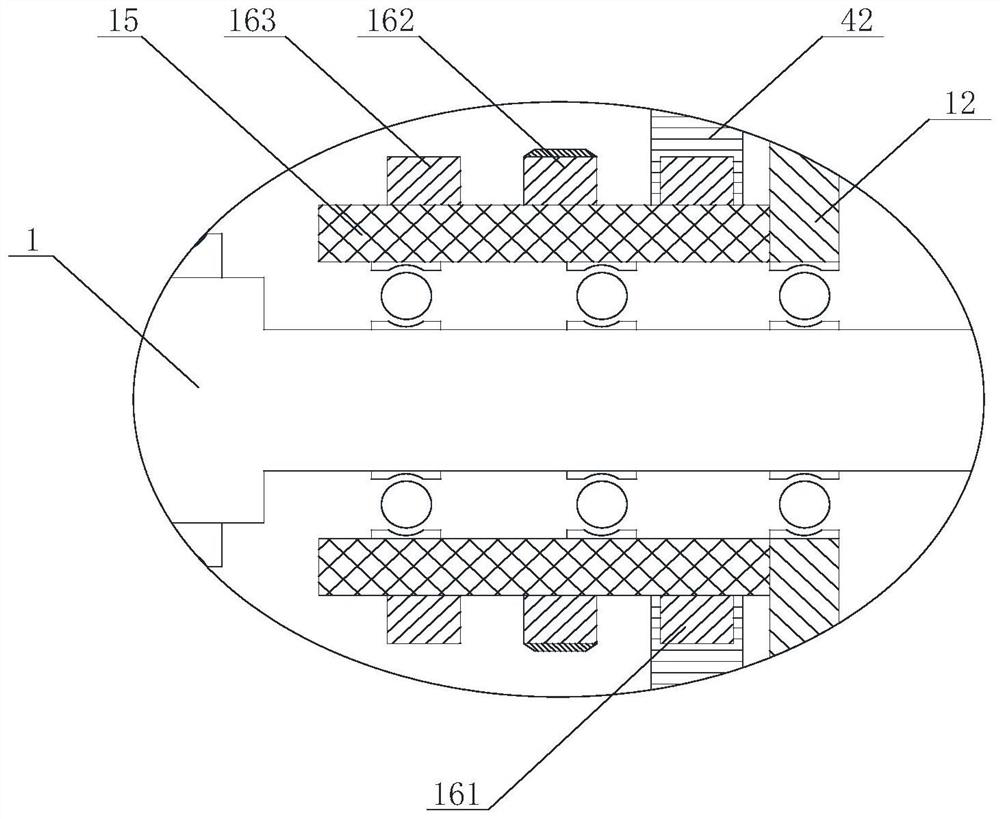

[0050] like Figure 1 to Figure 7The shown anti-gravity power generation wheel includes a main shaft 1 on which a hub 2, a rim 3, a stator and a flywheel rotor 7 are coaxially arranged, and the flywheel rotor 7 can rotate relative to the stator to generate current , the main shaft 1 is sleeved with a ratchet bushing 15 connected to the flywheel rotor 7, the ratchet bushing 15 is provided with n ratchet wheels, wherein n is a positive integer, and the wheel rim 3 is provided with a movable Through the gravity converter 4 of the hub 2, when the wheel rotates until the gravity converter 4 is vertical, the ratchet moves vertically downward relative to the gravity converter 4, and is subject to the gravity converter 4 The drive rotates a certain angle.

[0051] In this technical solution, components such as ratchet bushings and gravity converters are used to push the flywheel rotor to rotate during the running process of the vehicle, thereby realizing power generation during the r...

Embodiment 2

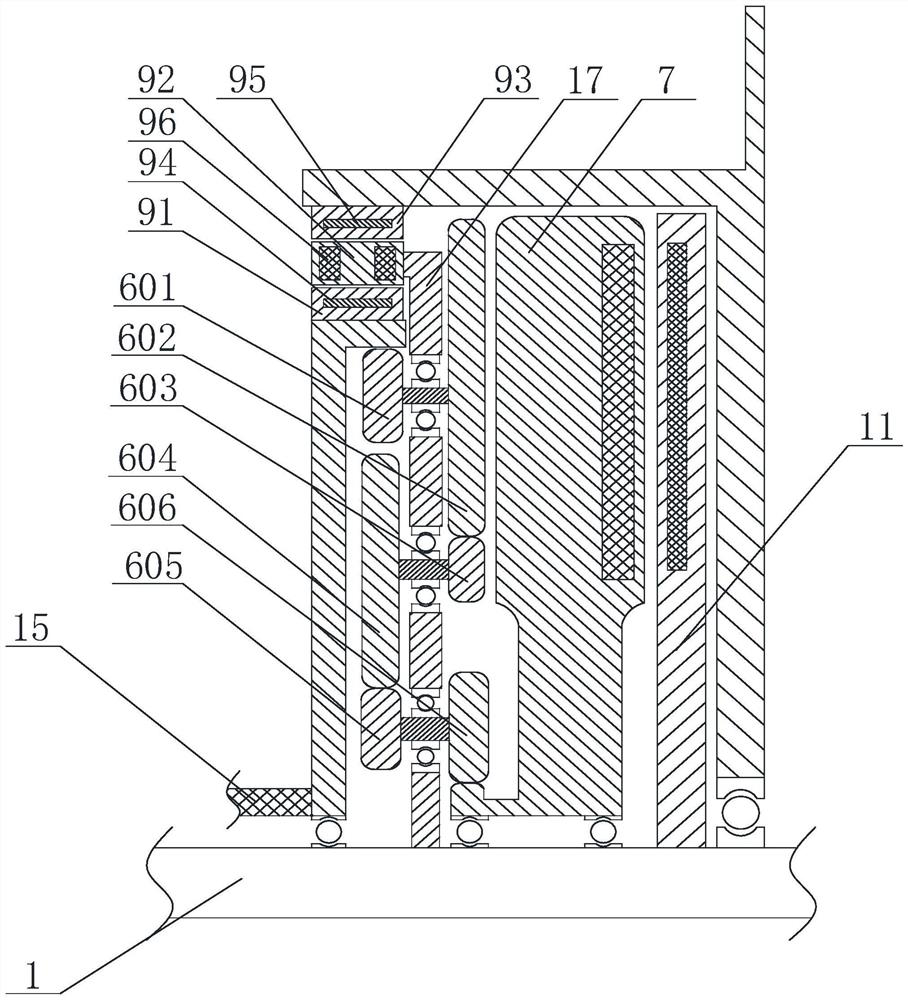

[0060] On the basis of Example 1, as Figure 5 As shown, the adjustment mechanism includes a first sleeve 51 mounted on the inner wall of the rim 3 , the support rod 43 is at least partially located in the first sleeve 51 , and the bottom surface of the first sleeve 51 A first spring 52 is provided on the upper part, and the first spring 52 is connected to the end face of the support rod 43; the side wall of the support rod 43 .

[0061] When the hub moves vertically downward relative to the rim, the adjustment mechanism of the gravity converter in the non-vertical state can allow the support rod to move vertically downward with the hub for a certain distance, or generate a lateral offset during the downward movement. During this process, the position of the support rod in the sleeve changes; after the hub is reset, the support rod returns to the initial position coaxial with the first sleeve again under the action of the first spring and the second spring. In addition, the ...

Embodiment 3

[0063] On the basis of Example 1, as Image 6 and Figure 7 As shown, the adjustment mechanism includes two supports 55 mounted on the inner wall of the rim 3, and a telescopic piece 54 with an adjustable length is hinged on the support 55, and the telescopic piece 54 is connected to the support The end faces of the rods 43 are hingedly connected.

[0064] In one or more embodiments, the telescopic element can be a hydraulic cylinder, the position of the gravity converter can be adjusted by precisely controlling the length of the hydraulic cylinder, one end of the hydraulic cylinder is hinged to the support, and the other end is hinged to the support rod. In one or more embodiments, as Figure 8 As shown, the telescopic element includes a second sleeve 541, and a connecting rod 542 is slidably disposed in the second sleeve. The connecting rod and the second sleeve are connected by a third spring 543 to realize self-adaptive adjustment of the overall length of the telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com