Multi-station polishing and grinding equipment

A polishing and multi-station technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc., can solve problems such as product drop, long time consumption of consumables, and inability to achieve process continuity. Achieve high operating efficiency, realize the continuity of the process, and the effect of ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in the preferred embodiment are only for convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

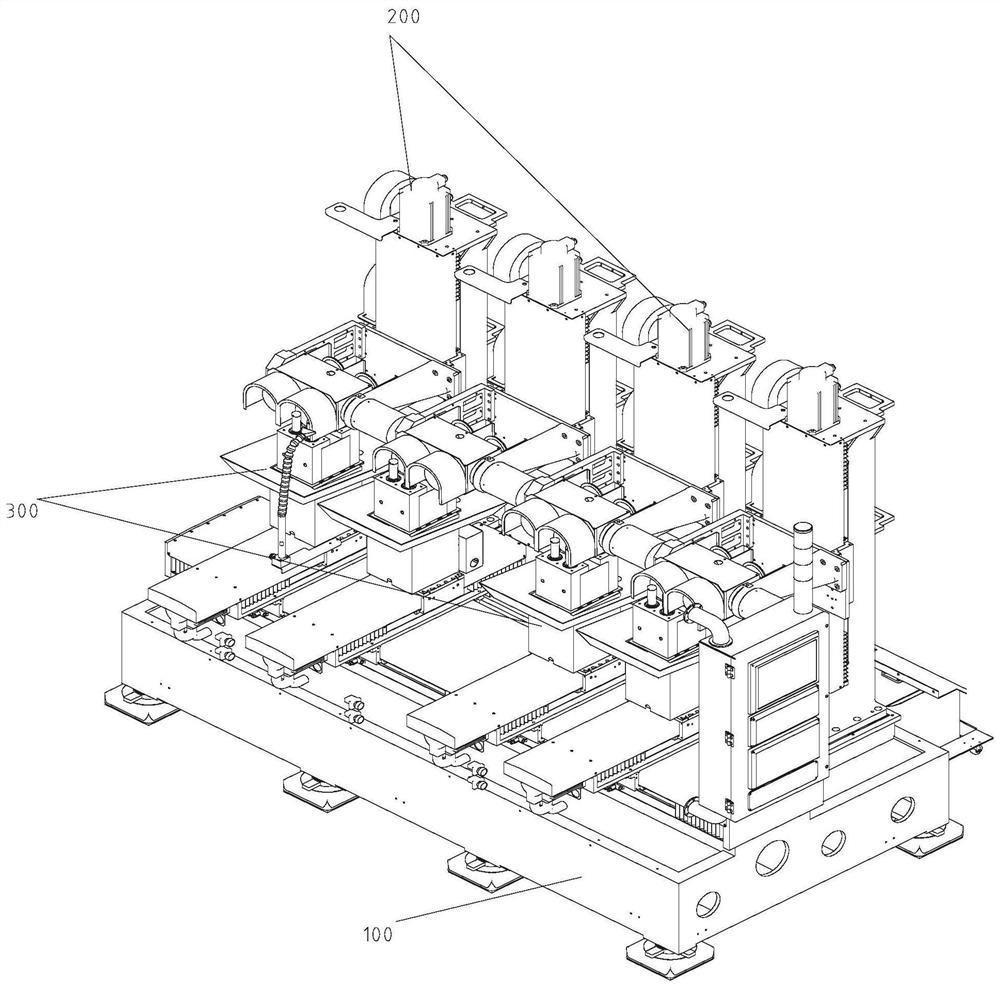

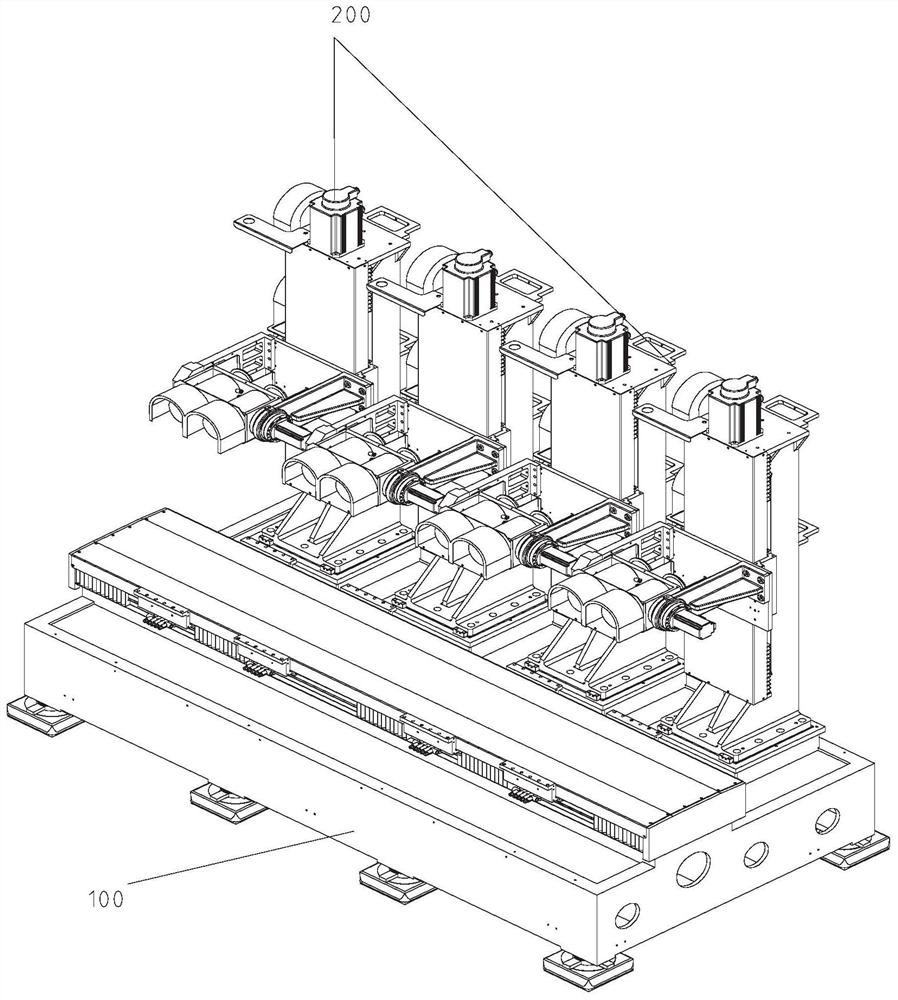

[0053] Such as figure 1 As shown, the present invention provides a multi-station polishing and grinding equipment, including a machine table and a polishing machine and a jig that are arranged on the machine table in one-to-one correspondence.

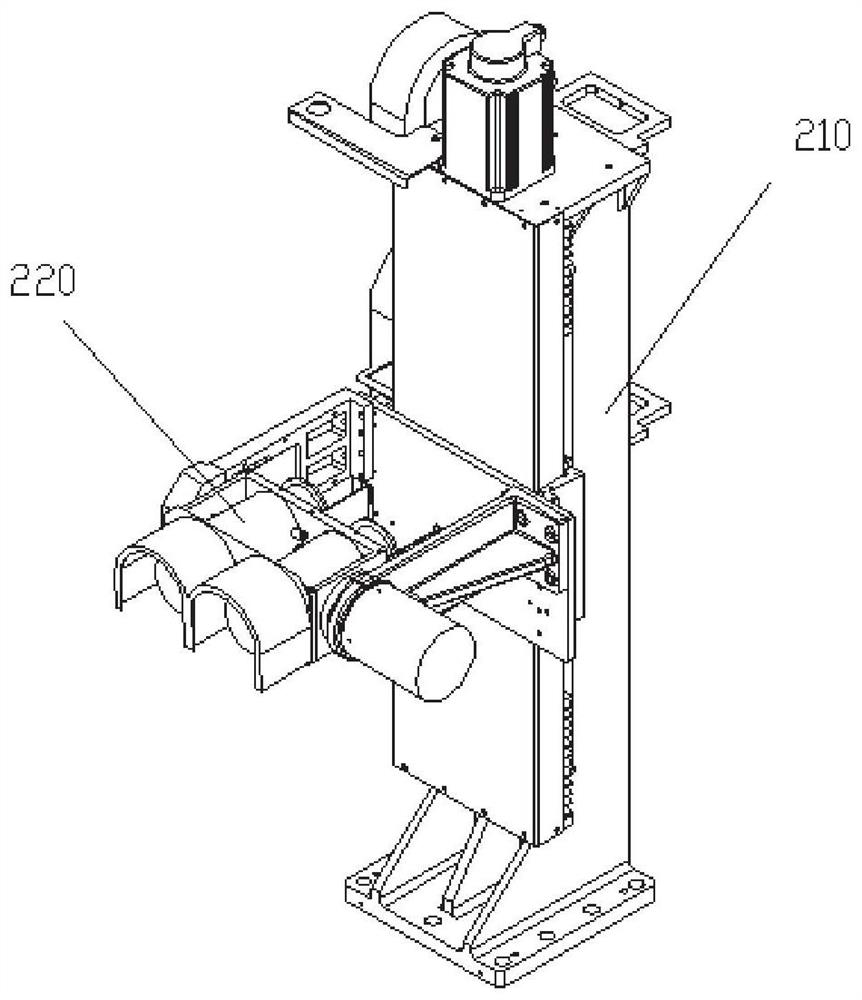

[0054] Such as Figures 2 to 5 As shown, the polishing machine includes a Z-axis linear module 210 arranged on the machine table and a grinding head assembly 220 driven by the Z-axis line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com